Page 1

Technical Service Instructions SI-1F30D

Front chainwheel

FC-7800

General Safety Information

WARNING

• Be careful not to let the cuffs of your clothes get caught in the chain

while riding, otherwise you may fall off the bicycle.

• Check that the tension of the chain is correct and that the chain is not

damaged. If the tension is too weak or the chain is damaged, the

chain should be replaced. If this is not done, the chain may break and

you may fall off the bicycle.

• Check that there are no cracks in the crank arms before riding the

bicycle. If there are any cracks, the crank arm may break and you

may fall off the bicycle.

• Obtain and read the service instructions carefully prior to installing the

parts. Loose, worn, or damaged parts may cause injury to the rider.

We strongly recommend only using genuine Shimano replacement

parts.

• Read these Technical Service Instructions carefully, and keep them in

a safe place for later reference.

Note

• Make sure that the chainring combination matches the front chainwheel

tooth configuration in the Product specifications table. If other

combinations are used, the distance between the chainrings will be

incorrect and the chain might slip off and get caught in between them.

• When the chain is in the position shown in

the illustration, the chain may contact the

front chainrings or front derailleur and

generate noise. If the noise is a problem,

shift the chain onto the next-larger rear

sprocket or the one after.

• Check that there is no looseness in any

joints or connections before riding the

bicycle. (BB-FC, FC-PD)

• If you feel any looseness in the bottom bracket axle, the bottom

bracket should be replaced.

• In addition, if pedaling performance does not feel normal, check this

once more.

• Do not wash the bottom bracket with high-pressure jets of water.

• Apply grease to the bottom bracket before installing it.

• To ensure the best performance, be sure to use only the specified

type of chain. The wide type of chain cannot be used.

• If the chain keeps coming off the chainrings during use, replace the

chainrings and the chain.

• You should periodically wash the chainrings in a neutral detergent

and then lubricate them again. In addition, cleaning the chain with

neutral detergent and lubricating it can be an effective way of

extending the useful life of the chainrings and the chain.

• Parts are not guaranteed against natural wear or deterioration

resulting from normal use.

• For maximum performance we highly recommend Shimano lubricants

and maintenance products.

• For any questions regarding methods of installation, adjustment,

maintenance or operation, please contact a professional bicycle

dealer.

Front

chainrings

Rear

sprockets

t

Page 2

Specifications

130 mm

A-53 / 42T, B-53 / 39T, B-52 / 39T, B50 / 39T,

54 / 42T, 55 / 42T, 56 / 44T

CN-7800

43.5 mm

B.C. 9/16" x 20T.P.I. (English thread)

165, 167.5, 170, 172.5, 175, 177.5, 180 mmCrank arm length

Pedal threads

Applicable chain

Chain line

Chainwheel tooth combination

Bolt circle diameter

68 mm (1.37 X 24 T.P.I.)

70 mm (M36 X 24 T.P.I.)

Shell width

(Thread dimensions)

S

G

-

X

5

3

-

B

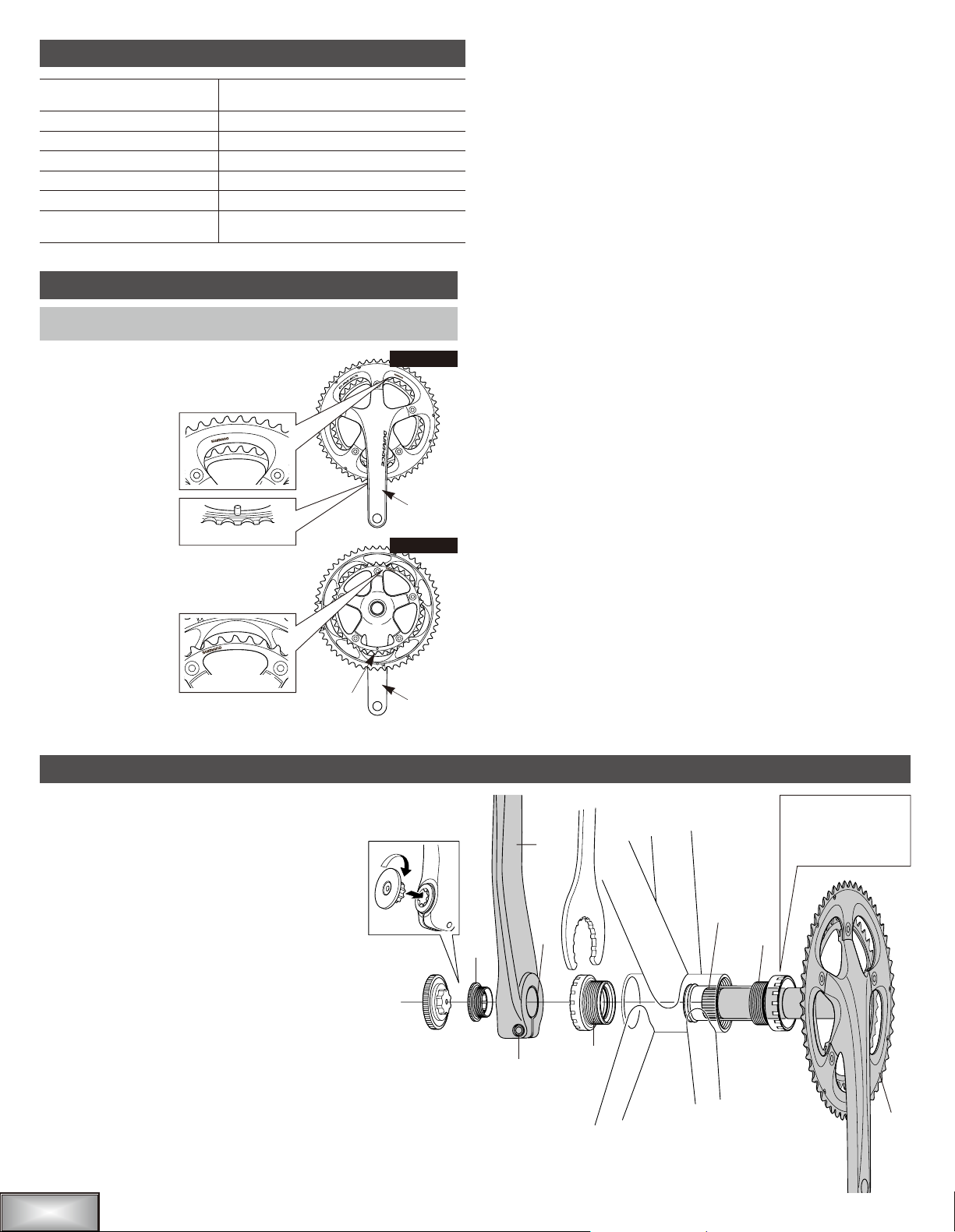

With the marked surface of the larger

chainring facing out, set the larger chainring

so that the chain drop prevention pin is lined

up with the crank arm position.

Chain drop prevention pin

Installation of the chainrings

Smooth shifting will not be possible if the chainrings are incorrectly

installed, so be sure to install the chainrings in the correct positions.

With the marked surface of the smaller

chainring facing away from the crank arm,

set the chainring so that the o mark is

lined up with the crank

arm position.

S

G

-

X

5

3

-

B

Crank arm

S

G

-

X

1

0

S

3

9

-

B

B

D

Crank arm

o mark

Outer side

Inner side

S

G

-

X

1

0

S

3

9

-

B

B

D

Mark

Installation of the front chainwheel

Follow the procedure in the figure.

1, 2 Use the special tool TL-FC32 to install the right

adapter (counterclockwise thread) and the left

adapter (clockwise thread).

Tightening torque: 35 - 50 N·m {305 - 435 in. lbs.}

3 Insert the right crank unit.

4 Set section A of the left crank into the axle of the

right crank unit where the groove is wide.

5 Use the TL-FC16 to tighten the cap.

Tightening torque: 0.7 - 1.5 N·m {6 - 13 in. lbs.}

6 Tighten the bolt of the left crank.

Note : Each of the bolts should be

evenly and equally tightened to

12 - 15 N·m {106 - 132 in. lbs.}.

5

2

4

(A)

1

Wide groove area

TL-FC16

TL-FC32

6

clockwise for 70 mm

[M36] bottom

brackets

t

Loading...

Loading...