Shimaden SR90 Series Instruction Manual

SR90 Series

Digital Controller

COMMUNICATION INTERFACE

(RS-232C/RS-485)

INSTRUCTION MANUAL

Thank you for purchasing the Shimaden SR90 series controller. Please check that the delivered

product is the correct item you ordered. Please do not begin operating this product until you have

read this instruction manual thoroughly and you understand its contents.

Notice

Please ensure that this instruction manual is given to the final user of the instrument.

Preface

This instruction manual describes the communication interface (RS-232C/RS-485) which is an optional function of the

SR90 series (SR91, SR92, SR93 and SR94). For details of SR90 product’s overview, performance, parameters, how

to install, wiring, operation, and so on, please refer to the separate document "SR90 Series (SR91, SR92, SR93,

SR94) Digital Controller Instruction Manual".

SR90C-1BE

Feb. 2006

Contents

Notice..........................................................................1

Preface........................................................................1

1. Safety rules ............................................................3

2. Outline ....................................................................4

2-1. Communication interface ...........................................4

2-2. Communication protocol and specifications ...............4

3. Connecting controller with host computer.........6

3-1. RS-232C ....................................................................6

3-2. RS-485.......................................................................6

3-3. 3-state output control .................................................6

4. Setting of parameters ...........................................7

4-1. Setting of communication mode.................................7

4-2. Setting of communication protocol .............................7

4-3. Setting of communication address .............................7 6-7. Examples of messages ............................................18

4-4. Setting of communication data format........................7

4-5. Setting of start character............................................8

4-6. Setting of communication BCC ..................................8

4-7. Setting of communication rate....................................8

4-8. Setting of delay time ..................................................8

4-9. Setting of memory mode............................................8

5. Outline of Shimaden protocol..............................9

5-1. Communication procedure.........................................9

(1) Master/slave relation............................................................9

(2) Communication procedure...................................................9

(3) Time-out ............................................................................... 9

5-2. Communication format...............................................9

(1) Outline of communication format .........................................9

(2) Details of basic format section I ......................................... 10

(3) Details of basic format section II ........................................ 10

(4) Outline of text section ........................................................ 11

5-3. Details of Read command (R)..................................13

(1) Format of Read command (R) ...........................................13

(2) Format of normal response to Read command (R) ...........13

(3) Format of error response to Read command (R) ............... 14

5-4. Details of Write command (W) .................................14

(1) Format of Write command (W)........................................... 15

(2) Format of normal response to Write command (W)........... 15

(3) Format of error response to Write command (W) ..............16

5-5. Details of response codes........................................16

(1) Type of response codes..................................................... 16

(2) Order of priority of response codes.................................... 16

6. Outline of MODBUS protocol ............................ 17

6-1. Outline of transfer mode...........................................17

(1) ASCII mode ........................................................................17

(2) RTU mode.......................................................................... 17

6-2. Configuration of messages ......................................17

(1) ASCII mode ........................................................................17

(2) RTU mode.......................................................................... 17

6-3. Slave address ..........................................................17

6-4. Function codes.........................................................17

6-5. Data .........................................................................18

6-6. Error check...............................................................18

(1) ASCII mode ........................................................................18

(2) RTU mode.......................................................................... 18

(1) ASCII mode ........................................................................18

(2) RTU mode.......................................................................... 19

7. Communication data address ........................... 20

7-1. Details of communication data addresses................20

(1) Data address and read/write.............................................. 20

(2) Data address and the number of data ...............................20

(3) Data ...................................................................................20

(4) Read/Write of <Reserved> data ........................................20

(5) Option-related parameters ................................................. 20

(6) Parameters not displayed on the front panel .....................20

7-2. Communication data address ..................................21

8. Supplementary explanation............................... 23

8-1. Table of measuring range codes ..............................23

8-2. Table of event types .................................................24

8-3. ASCII code list..........................................................24

2

1. Safety rules

For matters regarding safety, potential damage to equipment and/or facilities, additional instructions and notes are

indicated by the following headings.

WARNING: This heading indicates hazardous conditions that could cause injury or death of personnel unless

extreme caution is exercised.

CAUTION: This heading indicates hazardous conditions that could cause damage to equipment and/or facilities

unless extreme caution is exercised.

WARNING

The SR90 Series Digital Controller is designed for controlling

temperature, humidity and other physical quantities in general industrial

facilities. It must not be used in any way that may adversely affect the

safety, health or working conditions of those who come into contact with

the effects of its use. When used, adequate and effective safety

countermeasures must be provided at all times by the user. No warranty,

express or implied, is valid when this device is used without the proper

safety countermeasures.

When using this instrument, house it in a control box or the like to

prevent terminals from coming into contact with personnel.

● Do not open this device’s case, or touch the boards or the inside of the

case with your hands or a conductor.

The user should never repair or modify this device.

Doing so might cause an accident that may result in death or serious

bodily injury from electric shock.

CAUTION

To avoid damage to connected peripheral devices, facilities or the product

itself due to malfunction of this device, safety countermeasures such as

proper installation of the fuse or installation of overheating protection

must be taken before use. No warranty, express or implied, is valid if

usage results in an accident when the user has not taken the proper

safety countermeasures

.

Please operate this product safely after referring to and understanding

the safety rules described in the separate Instruction Manual.

3

2. Outline

2-1. Communication interface

There are two types of communication systems, RS-232C and RS-485, employable in the SR90 series communication

interface (however, only RS-485 applies to SR91). Each of them is capable of setting various data for the SR90 and

reading through a personal computer or the like, using signals that comply with EIA standards.

RS-232C and RS-485 are data communication standards established by the Electronic Industries Association of the

U.S. (EIA). The standards cover electrical and mechanical aspects, namely, matters related to applicable hardware

but not the data transmission procedure for the software. Therefore, it is not possible to communicate unconditionally

with an apparatus that has the same interface.

Hence, users need to have sufficient knowledge of product specifications and transmission procedures.

When RS-485 is used, two or more SR90 controllers can be connected to each other. There seems only a few

computers, etc., that support this interface. Use a separately-purchased off-the-shelf line converter for RS-232C <--->

RS-485 to support that interface.

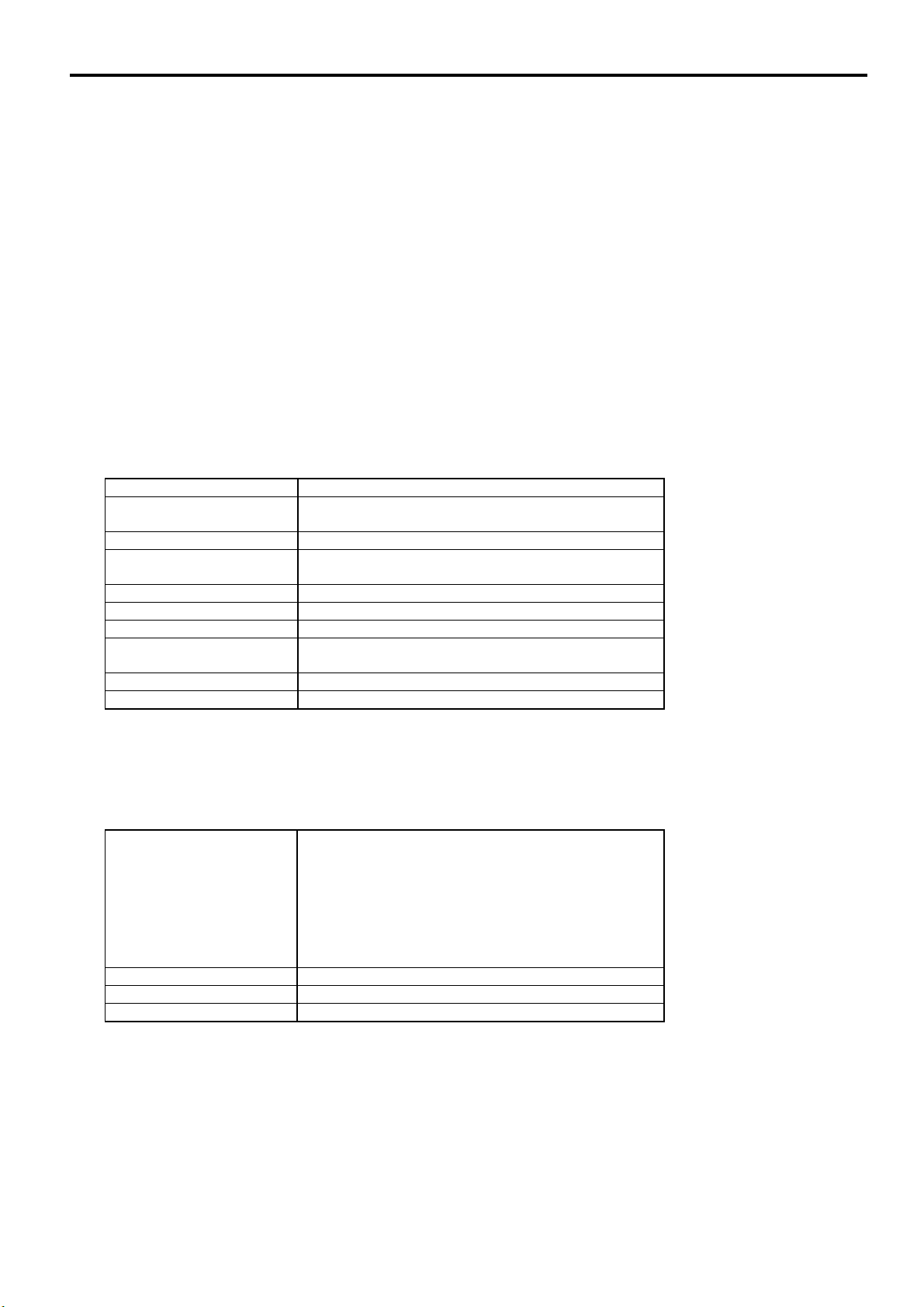

2-2. Communication protocol and specifications

The SR90 Series supports the SHIMADEN standard protocol and MODBUS communication protocol.

Common to each protocol

Signal level EIA RS-232C, RS-485 compliant

Communication system RS-232C 3-line half-duplex system

RS-485 2-line half-duplex multi-drop (bus) system

Synchronization system Start-stop synchronization

Communication distance RS-232C max. 15m

RS-485 max. 500 m (depending on connection conditions)

Communication speed 1200, 2400, 4800, 9600, 19200 bps

Transmission procedure Non-procedural

Communication delay time 1 to 100 x 0.512 msec

Number of connectable devices RS-232C 1

RS-485 max. 31 (depending on connection conditions)

Communication address 1 to 255

Communication memory mode EEP, RAM, R_E

Shimaden protocol

This is a SHIMADEN proprietary communication protocol. The table below lists the specifications of this protocol.

Data format Data length: 7 bits, Parity: Even, Stop bit: 1 bit

Data length Data length: 7 bits, Parity: Even, Stop bit: 2 bits

Parity Data length: 7 bits, Parity: None, Stop bit: 1 bit

Stop bit Data length: 7 bits, Parity: None, Stop bit: 2 bits

Data length: 8 bits, Parity: Even, Stop bit: 1 bit

Data length: 8 bits, Parity: Even, Stop bit: 2 bits

Data length: 8 bits, Parity: None, Stop bit: 1 bit

Data length: 8 bits, Parity: None, Stop bit: 2 bits

Communication code ASCII code

Control code STX_ETX_CR, @_:_CR

Communication BCC ADD, ADD_two’s cmp, XOR, None

4

MODBUS protocol

This is a communication protocol developed for PLCs by Modicon Inc. (AEG Schneider Automation International

S.A.S.)

Though the specifications of this protocol are open, only the communication protocol is defined in this protocol, and

physical layers, such as the communication medium, are not stipulated.

The table below shows the specifications of this protocol.

- ASCII mode

Data format

Data length

Parity

Stop bit

Communication code ASCII code

Control code :_CRLF

Error check LRC

Data length: 7 bits, Parity: Even, Stop bit: 1 bit

Data length: 7 bits, Parity: Even, Stop bit: 2 bits

Data length: 7 bits, Parity: None, Stop bit: 1 bit

Data length: 7 bits, Parity: None, Stop bit: 2 bits

- RTU mode

Data format

Data length

Parity

Stop bit

Communication code Binary data

Control code None

Error check CRC

Data length: 8 bits, Parity: Even, Stop bit: 1 bit

Data length: 8 bits, Parity: Even, Stop bit: 2 bits

Data length: 8 bits, Parity: None, Stop bit: 1 bit

Data length: 8 bits, Parity: None, Stop bit: 2 bits

5

3. Connecting controller with host computer

The SR90 series controller is only provided with 3 lines for input and output, i.e., for data transmission, data reception

and grounding for signals, and not with any other signal lines.

In these instructions, the drawings give an example of control signal processing methods. Please refer to the

documents that came with your host computer for further details.

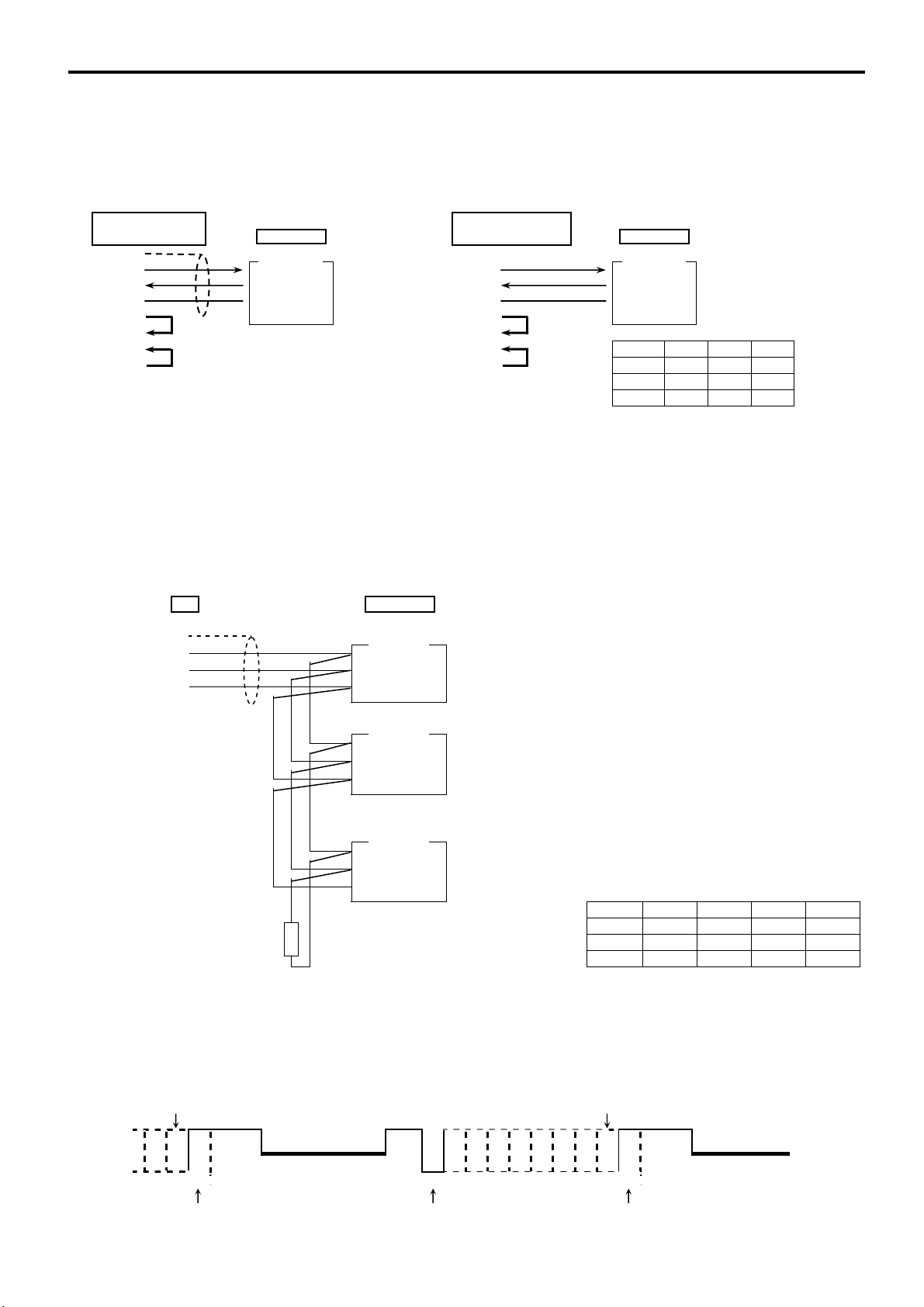

3-1. RS-232C

Host (25 pins) Host (9 pins)

SR90 series [PC/AT

FG ( 1) Controller Controller

SD ( 2) RD Å data reception SD (3) RD Å data reception

RD ( 3) SD Å

SG ( 7) SG Å

data transmission

grounding for signals

RD (2) SD Å

SG (5) SG Å

RS ( 4) RS (7)

CS ( 5) CS (8) SR90 series terminal no.

DR ( 6) DR (6) SR92 SR93 SR94

ER (20) ER (4) SG [ 1] [ 1] [ 1]

SD [ 2] [ 2] [ 2]

*1: Figures in ( ) represent pin numbers of connector. RD [ 3] [ 3] [ 3]

3-2. RS-485

The input/output logical level of the SR90 controller is basically as follows:

In the mark state - terminal < + terminal

In the space state - terminal > + terminal

Until immediately before transmission, however, plus terminals and minus terminals of the controller have high

impedance and outputs at the above levels are produced immediately before starting transmission. (See 3-3. 3-state

output control.)

Host

FG

+

-

SG

Controller 2

SR90 series

Controller 1

+

-

SG

+

-

SG

:

:

Controller N

SR91 SR92 SR93 SR94

SG [ 1] [ 1] [ 1] [ 1]

Terminal resistor + [11] [ 2] [ 2] [ 2]

(120) - [12] [ 3] [ 3] [ 3]

+

-

SG

3-3. 3-state output control

Since RS-485 is of the multi-drop system, transmission output has high impedance always while communication is not carried out or

signals are being received in order to avoid collision between transmission signals. It changes from high impedance to the normal

output condition immediately before transmission and returns to high impedance control simultaneously when transmission

terminates. As the 3-state control is delayed by about 1 msec (maximum) from the completion of transmission of an end character

end bit, however, a few milliseconds' delay should be provided if the host side starts transmission immediately upon reception.

END CHARACTER END CHARACTER

1 Transmitted signal

High impedance High impedance

0

end bit start bit end bit

compatible

] SR90 series

data transmission

grounding for signals

In the case of RS-485, provide it with the attached

Note1:

terminal resistor of 1/2W, 120 across terminals +

and if necessary.

Nevertheless, it should be provided to only the last

controller.

If two or more controllers are provided with terminal

resistors, correct operation cannot be guaranteed.

SR90 series terminal no.

6

4. Setting of parameters

There are the following 9 communication-related parameters for the SR90 series controller. These parameters are

unable to be set or changed by communication; use front key for setting and changing.

When parameters are set, see "6. Explanation of Screen Group and Setting" of the separate instruction manual for the

controller and follow the described steps.

4-1. Setting of communication mode

1-36

Initial value: Loc

Setting range: Loc, Com

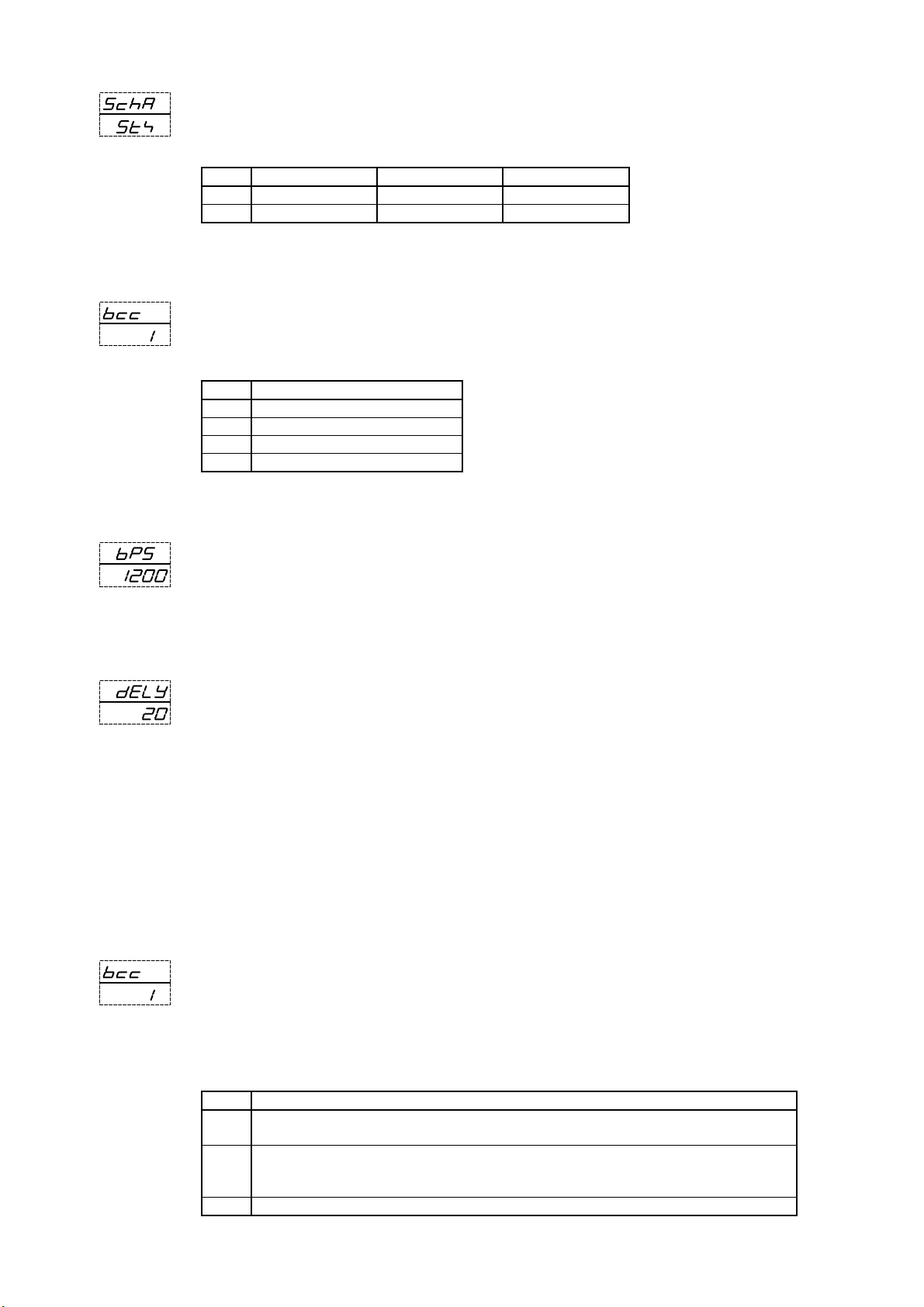

4-2. Setting of communication protocol

1-37

4-3. Setting of communication address

1-38

Note 1: Although 1 to 255 addresses are available for setting, the number of connectable controllers is

4-4. Setting of communication data format

1-39

Select communication mode. Front key operation allows only change from Com to Loc, though.

Code Effective command COM lamp

Loc Read

Com Read, write

Unlighted

Lighted

Initial value: shim

Setting range: shim, asc, rtu

Select communication protocol.

Code Protocol

shim Shimaden protocol

asc

rtu

MODBUS ASCII mode

MODBUS RTU mode

Initial value: 1

Setting range: 1 to 255

Select communication protocol.

While one host and one SR90 controller can be connected in the case of RS-232C, one host and 31 SR90

controllers (max.) can be connected in case of RS-485 by the multi-drop system.

Therefore, each instrument is assigned an address (machine No.) so that only the instrument with the

designated address can answer.

31 maximum.

Initial value: 7E1

Setting range: 8 types shown in the following table.

Select either one of the communication data formats shown below

Data length Parity Stop bit Shimaden ASCII RTU

Code

7 bits Even 1 bit

7 bits Even 2 bits

7 bits None 1 bit7 bits

7 bits None 2 bits

8 bits Even 1 bit

8 bits Even 2 bits

None 1 bit8 bits

8 bits None 2 bits

Support

Not Support

7

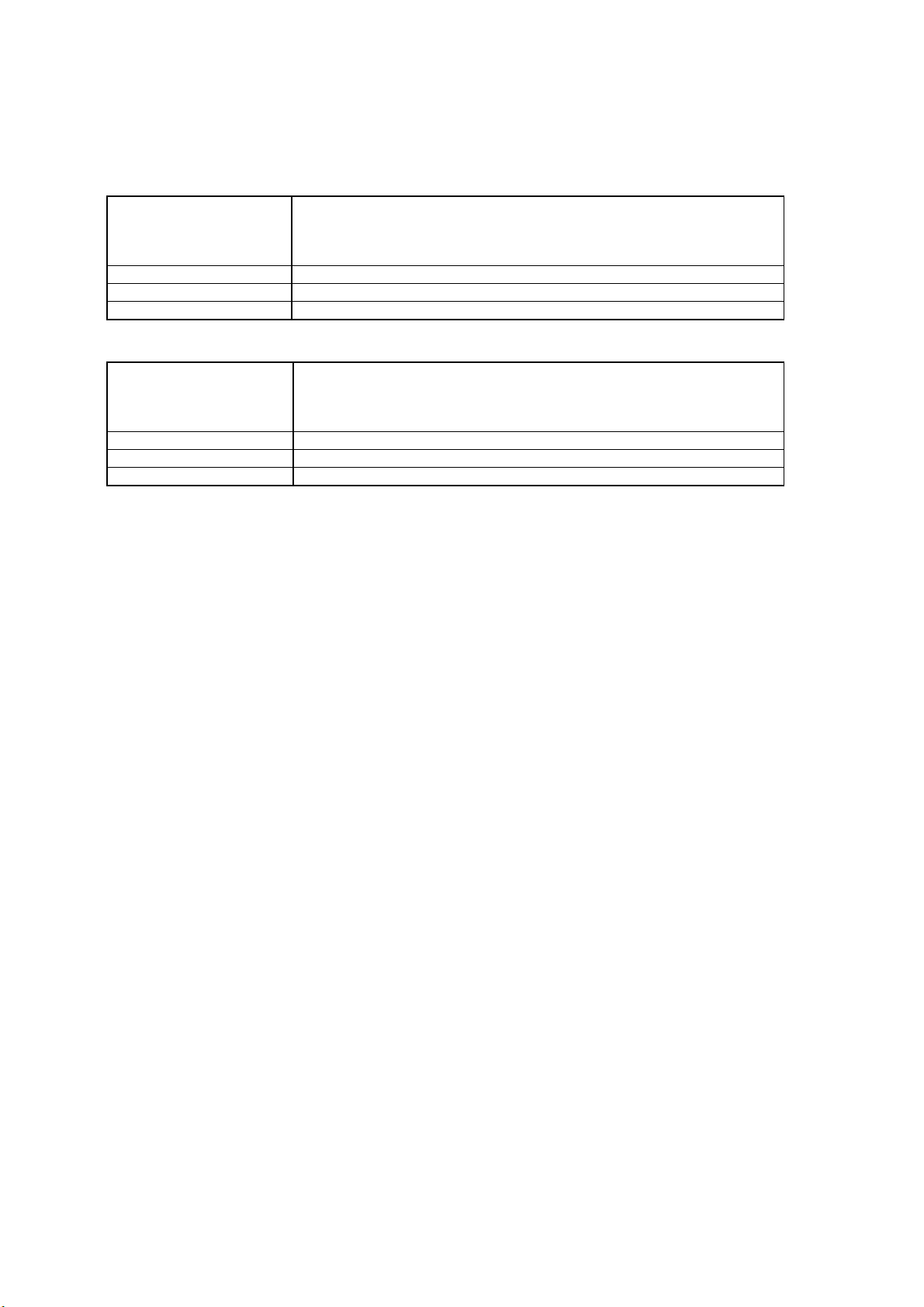

4-5. Setting of start character

1-40

Initial value: STX

Setting range: STX, ATT

Select a control code to be used. This is used for Shimaden protocol only.

Code Start character Text end character End character

STX STX (02H) ETX (03H) CR (0DH)

ATT "@" (40H) ":" (3AH) CR (0DH)

4-6. Setting of communication BCC

1-41

Initial value: 1

Setting range: 1, 2, 3, 4

Select a BCC operation method to be used in BCC checking. This is used for Shimaden protocol only.

Code BCC operation method

1

Addition

2 Addition + 2's complement

3

XOR

4 None

4-7. Setting of communication rate

1-42

Initial value: 1200 bps

Setting range: 1200, 2400, 4800, 9600, 19200 bps

Select a rate at which data are transmitted to host computer.

4-8. Setting of delay time

1-43

Initial value: 20

Setting range: 1 to 100

Set the length of delay time from receipt of a communication command to transmission.

Delay time (msec) = Set value (count) × 0.512 (msec)

Note 1: When RS-485 is used, some converters take longer time for 3-state control than others and it

may lead to signal collision. This can be avoided by increasing delay time. Care should be taken

particularly when the communication rate is slow (1200bps or 2400bps).

Note 2: Actual delay time from receipt of a communication command to transmission is a total of the

above-mentioned delay time and command processing time by software. Particularly for writing

commands, about 400 msecs maybe taken for processing.

4-9. Setting of memory mode

1-44

Initial value: EEP

Setting range: EEP, Ram, r_E

Since the volatile memory EEPROM used in SR90 series has its limits in number of writing cycles, the life of

EEPROM is shortened if SV data or the like are rewritten frequently by communication. To prevent this, in case

data are to be rewritten frequently by communication, set the RAM mode in which only RAM data are rewritten

without rewriting EEPROM, thereby maintaining the life of EEPROM as long as possible.

Code Description

EEP In this mode EEPROM data are also rewritten every time data are changed by communication.

Accordingly, data are maintained when power is turned off.

Ram In this mode only RAM data are rewritten but EEPROM data are not when data are changed by

communication. Therefore, RAM data are deleted when power is turned off. Upon applying power

again, operation starts with data stored in EEPROM.

r_E SV and OUT data are written in RAM. All other data are written in EEPROM.

8

Loading...

Loading...