Shimaden SR73A Series, SR74A Series Instruction Manual

- 1 -

"Notice"

Please ensure that this instruction manual is given to the final user

of the instrument.

Preface

This instruction manual is meant for those who will be involved

in the wiring, installation, operation and routine maintenance of

the SR73A and 74A series.

This manual describes the care, installation, wiring, function, and

proper procedures for the operation of SR73A and 74A series.

Keep this manual at the work site during operation of the SR73A

and 74A series. While using this instrument, you should always

follow the guidance provided herein.

For matters regarding safety, potential damage to equipment

and/or facilities, additional instructions are indicated by the

following headings:

Exercise extreme caution as indicated. This heading indicates

hazardous conditions that could cause injury or death of

personnel.

Exercise extreme caution as indicated. This heading indicates

hazardous conditions that could cause damage to equipment

and/or facilities.

NOTE

This heading indicates additional instructions and/or notes.

The mark designates a protective conductor terminal. Make

sure to properly ground it.

The Matters regarding Safety

SR73A and 74A Series

Digital Controller

Instruction Manual

Thank you for purchasing the Shimaden SR73A and 74A Series. Please check that the delivered product is

the correct item you ordered. Please do not begin operating this product until you have read this instruction

manual thoroughly and understand its contents.

SR73A and 74A series controllers are designed for controlling

temperature, humidity and other physical subjects. It must not

be used in any way that may adversely affect the safety, health

or working conditions of those who come into contact with the

effects of its usage. When used, adequate and effective safety

countermeasures must be provided at all times. No warranty,

express or implied, is valid in the case of usage without having

implemented proper safety countermeasures.

To avoid damage to the connected equipment, facilities or the

product itself due to a fault of the product, safety

countermeasure must be taken before usage, such as proper

installation of the fuse and the overheating protection device.

No warranty, express or implied, is valid in the case of usage

without having implemented proper safety countermeasures.

• The mark on the plate affixed to the instrument:

On the terminal nameplate affixed to the case of your

instrument, the mark is printed. This is to warn you of the

risk of electrical shock which may result if the charger is

touched while it is energized.

•A means to allow the power to be turned off, such as a switch

or a breaker, should be installed in the external power circuit

to be connected to the power terminal of the instrument.

Fix the switch or the breaker adjacently to the instrument in a

position which allows it to be operated with ease, and with an

indication that it is a means of turning the power off. The

switch or the breaker should meet the requirements of IEC

947.

• Fuse:

Since the instrument does not have a built-in fuse, do not

forget to install a fuse in the power circuit to be connected to

the power terminal.

The fuse should be positioned between the switch or the

breaker and the instrument and be attached to the L side of

the power terminal.

Fuse Rating: 250V AC 0.5A/medium lagged or lagged type

Use a fuse which meets the requirements of IEC 127.

• Voltage/current of a load to be connected to the output

terminal and the alarm terminal should be within a rated

range. Otherwise, the temperature will rise and reduce the

life of the product and/or result in problems with the product.

For the rated voltage/current, see 8. Specifications on page

15. The output terminal should be connected with a device

which meets the requirements of IEC 1010.

•A voltage/current different from that of the input

specification should not be added on the input terminal. It

may reduce the life of the product and/or result in problems

with the product.

For the rated voltage/current, see 8. Specifications on page

15.

For the rated voltage (mV or V) or current (4~20 mA) input,

the input terminal should be connected with a device which

meets the requirements of IEC1010 as input terminals.

• In the case where the heater break alarm (optional) input is

0~5V DC, the CT input terminal should be connected to an

apparatus which meets IEC 1010 requirements.

• As the CT input terminal for the heater break alarm

(optional), only the attachment CT should be used. Using

anything else may result in problems with the product.

For the CT provided, refer to 1-1 Check before Use on page

2. (Except when 0~5V DC input has been selected.)

• The SR73A and 74A series controllers are provided with a

draft hole for heat discharge. Take care to prevent metal or

other foreign matter from obstructing it. Failure to do so may

result in problems with the product and may even result in

fire.

SR73AFC-1DE Sep. 2000

WARNING

CAUTION

WARNING

CAUTION

CAUTION

- 2 -

• Do not block the draft hole or allow dust or the like to adhere

to it. Any rise in temperature or insulation failure may result

in a shortening of the life of product and/or problems with the

product.

For spaces between installed instruments, refer to 2-4

External Dimensions and Panel Cutout on page 3.

• It should be noted that repeated tolerance tests against

voltage, noise, surge, etc., may lead to deterioration of the

instrument.

Contents

1. Introduction...........................................................................2

1-1. Check before use......................................................2

1-2. Caution for use .........................................................2

2. Installation and wiring ..........................................................2

2-1. Installation site (environmental conditions).............2

2-2. Mounting..................................................................3

2-3. How to remove the instrument out of the case.........3

2-4. External dimensions and panel cutout......................3

2-5. Wiring.......................................................................3

2-6. Terminal arrangement ..............................................3

2-7. Terminal arrangement table .....................................4

3. Instruction for front panel.....................................................4

3-1. Drawing and the name of the parts...........................4

3-2. Instruction for front panel ........................................4

4. Screen instruction..................................................................5

4-1. Power on and initial screen display..........................5

4-2. Alarm type code table ..............................................5

4-3. Screen change...........................................................5

4-4. Instruction for screen change and each screen.........6

4-5. Measuring range code table......................................7

4-6. Supplementary explanation of screens ....................8

5. Operation...............................................................................8

5-1. Setting of set value (SV) ..........................................8

5-2. AT (Auto tuning)......................................................8

5-3. Setting of alarm........................................................9

6. Supplement ...........................................................................9

6-1. Auto return function.................................................9

6-2. PID (Screen No.2, 4 and

5 of mode 1 screen group)........................................9

6-3. Control output characteristics

( digit of function selecting

screen of mode 2 screen group)..............................10

6-4. Error message.........................................................10

7. Instructions on Communication..........................................10

7-1. General ...................................................................10

7-2. How to connect SR73A or 74A

with host computer ................................................10

7-2-1. Control signals........................................................10

7-2-2. Connection of RS-422A.........................................10

7-2-3. Connection of RS-485 ...........................................11

7-2-4. Terminal resistance ................................................11

7-2-5. Control of 3-state output ........................................11

7-3. Setting of communication parameters....................11

7-3-1. Communication mode

selecting screen ( ).......................................11

7-3-2. Communication address ( )

setting screen..........................................................11

7-3-3. Communication data format ( )

selecting screen ......................................................11

7-3-4. Communication rate ( ) selecting screen.....11

7-3-5. Delay ( ) setting screen................................11

7-4. Communication protocol .......................................11

7-4-1. Communication procedure.....................................11

7-4-2. Explanation of block .............................................11

7-5. Text ........................................................................12

7-5-1. Text format.............................................................12

7-5-2. Data format.............................................................12

7-5-3. Communication error .............................................13

7-5-4. Non-response process ............................................13

7-5-5. Restrictions by commands, etc. .............................13

7-6. A list of transmitted/received data .........................14

7-6-1. Read command.......................................................14

7-6-2. Write command......................................................14

8. Specifications......................................................................15

4

1. Introduction

1-1.Check before use

This product has been fully checked for quality assurance prior to

shipment. Nevertheless, you are requested to make sure that there

is no error, damage or shortage of delivered items by confirming

the model codes and checking the external view of the product

and the number of accessories.

Confirmation of Model Codes:

Check the model codes stuck to the case of the product to

ascertain if the respective codes designate what was specified

when you ordered the product, referring to the following code

table:

Checking accessories:

Instruction manual 1 set

Unit decal 1 sheet

Current transformer (CT) for heater break alarm:

included with the heater break alarm option (Except when 0~5V

DC input has been selected, though.)

TYPE CTL-6-S for 30A selection

TYPE CTL-12-S36-8 for 50A selection

1-2.Caution for use

(1) Avoid operating keys of the front panel with hard or sharp

objects or motions. Lightly touch the operating keys with

finger tip for operation.

(2) Avoid using solvents such as thinner; wipe gently with a dry

cloth.

2. Installation and wiring

2-1. Installation site (environmental conditions)

(1) Where flammable gas, corrosive gas, oil mist and particles

that can deteriorate electrical insulation are generated or are

abundant.

(2) Where the temperature is below -10 °C or above 50 °C.

(3) Where the relative humidity is 90%RH or below dew point.

(4) Where highly intense vibration or impact is generated or

transferred.

SR73A and 74A

8: Multi-input Thermocouple, R.T.D., Voltage (mV)

4: Current (mA) 6: Voltage (V)

Y1: Contact I1: Current P1: SSR-drive voltage V1: Voltage

0: None 1: Alarm 2: Alarm + Heater break alarm (30, 0A)

3: Alarm + Heater break alarm (50, 0A) 4: Set value bias

5: Alarm + Set value bias

6: Alarm + Heater break alarm (30, 0A) + Set value bias

7: Alarm + Heater break alarm (50, 0A) + Set value bias

A: Alarm + Heater break alarm (0~5V input, corresponding

to 0~500A)

B: Alarm + Heater break alarm (0~5V input) + set value bias

5 : RS-485 6 : RS-422A

C: Without 9: With

SR73A-8 Y1- 1 5 0

Item Code and Description

1. Series

2. Input

3. Output

4. Optional

function

5. Communication

function

6. Remarks

Note: Contact our representative concerning any problems with

the product, accessories or related items.

In the case where there is an intention to operate this product at

one of the following sites, be aware that the occurrence of fire

and/or other dangerous situations is considerable.

Exercise caution and avoid these places when selecting an

operational site.

CAUTION

- 3 -

(5) Near high voltage power lines or where inductive

interference can affect the operation of the product.

(6) Dew drops or direct exposure to sun light.

(7) Where the elevation is in excess of 2,000 m.

2-2.Mounting

(1) Machine the mounting hole by referring to panel cutout in

section 2-4.

(2) Applicable thickness of the mounting panel is from 1.0 to 3.5

mm.

(3) As this product provides mounting fixture, insert the product

from the front panel for installation.

2-3.How to remove the instrument out of the case

There is no need to remove your

SR73A and 74A series controllers out

of the case. Nevertheless, should the

need arise, for example, for

replacement, follow the steps

described below:

Insert a minus screwdriver of 6mm ~

9mm into the opening (where

packing is exposed) of the front case

and rotate the screwdriver while

pushing up the lock lever behind the

packing. Once the instrument comes

out by a few millimeters, you can

remove it by hand.

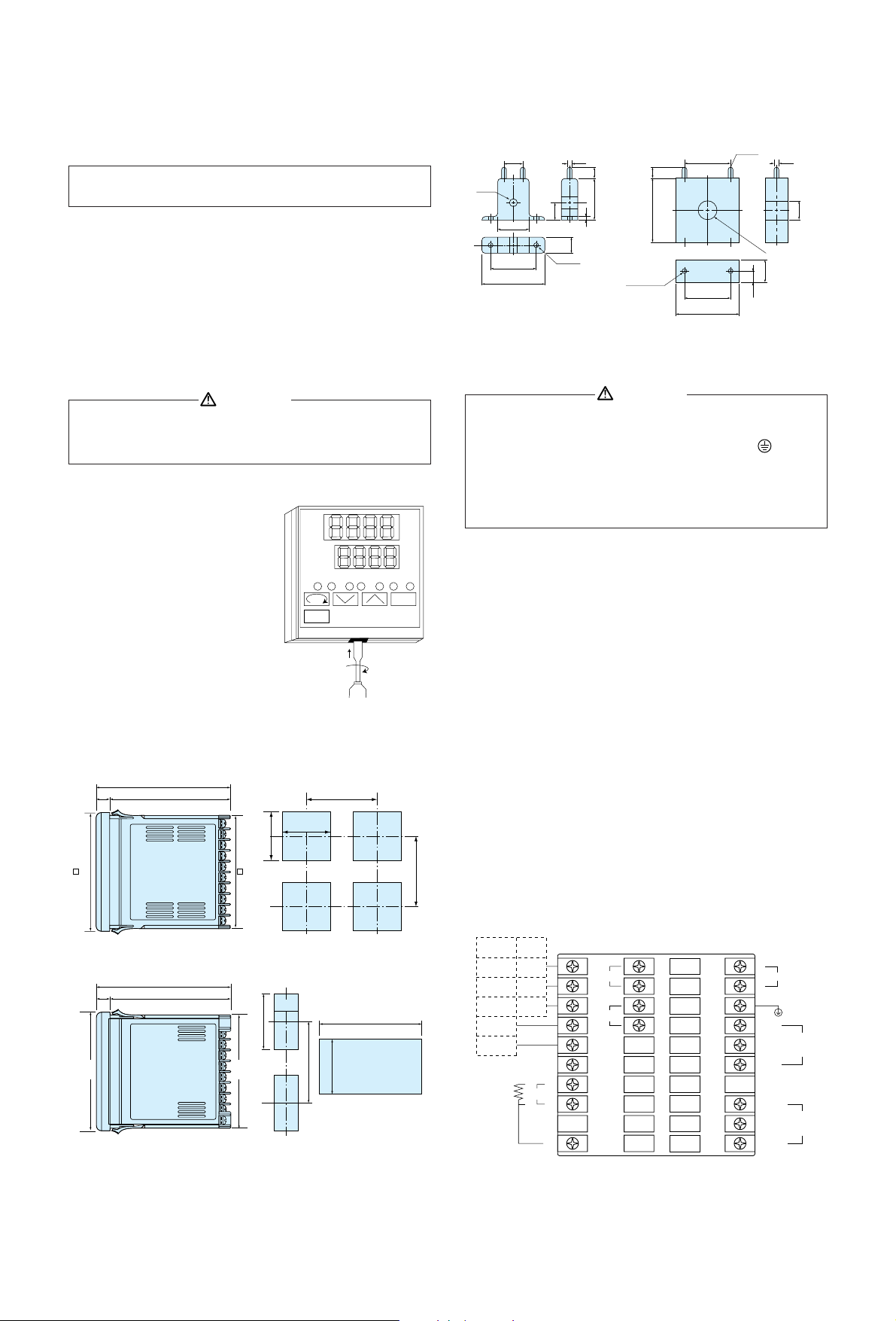

2-4.External dimensions and panel cutout

SR73A External dimensions SR73A Panel cutout

SR74A External dimensions SR74A Panel cutout

(unit : mm)

Note: The environmental conditions belong to the installation

category II of IEC 664 and the degree of pollution is 2.

When the instrument is removed/replaced in the case, make sure

the power is off. If it is done while the power is on, it may lead

to problems with the product and/or other problems.

ENT

MAN

PV

SV

˚C

OUT AT AH AH/HB MAN STBY COM

SHIMADEN

110

96 91.6

10010

130 min.

130 min.

92

+0.8

0

92

+0.8

0

110

10010

45

+0.6

0

(48 x N-3)

+1.0

0

92

+0.8

0

92

+0.8

0

130 min.

When N pieces are

installed laterally.

N= number

height 96

×

width 48

height 91.6

×

width 44.6

Dimension of current transformer (CT) for heater break

alarm

• For 0-30A (CTL-6-S)...................................For 0-50A (CTL-12-S36-8)

(unit : mm)

2-5.Wiring

(1) Wiring operation should be done according to the instruction

for the terminal arrangement in section 2-6. Exercise care

that no wrong connection is made.

(2) Crimp terminal should accommodate the M3.5 screw and

should have a width of less than 7mm.

(3) For thermocouple input, select the compensation wire

suitable to the thermocouple type.

(4) For R. T. D. input, leads should be less than 5Ω in resistance

and three leads should have the same resistance.

(5) Input signal line should be conducted safely apart from the

high voltage power line.

(6) Shield wiring (single point grounding) is effective for static

induction noise.

(7) Short interval twisted pair wire for input signal is effective

for electromagnetic induction noise.

(8) For power line, use wire or cable which is 1mm

2

or more in

sectional area and of which the performance is equal to or

higher than that of 600V vinyl insulated wire.

(9) Earth grounding should be performed with earth resistance

less than 100Ω and with wire thicker than 2mm

2

.

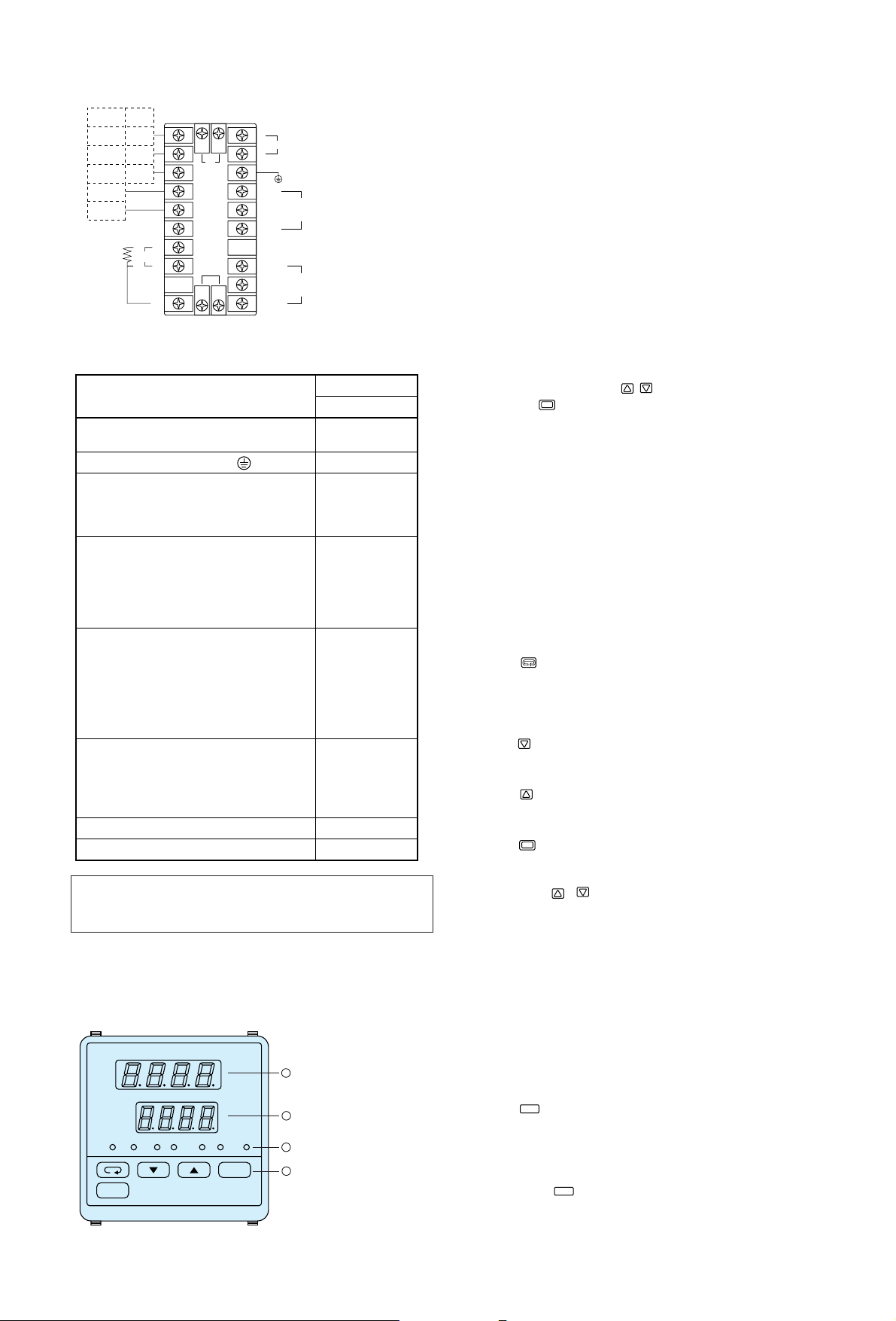

2-6.Terminal arrangement

SR73A

15

21

30

40

2.8

3

10.5

7.525

10

φ 5.8

2- φ 3.5

φ 12

φ 2.36

φ 12

940

15

7.5

2.3630

30

40

2-M3 depth 4

• Always disconnect this product from any power source

during wiring operation to prevent electrical shock.

• Be certain that the protective conductor terminal ( ) is

properly grounded. Otherwise, a serious electric shock may

result.

• Avoid touching the wired terminal and charged devices while

supplying power.

CAUTION

WARNING

422A 485

SG SG

SD+ +

SD– –

RD+

RD–

TC•mV

RTD

V•mA

IN PUT

1

2

3

4

5

6

7

+A

–B

8

9

B

10 20

21

SB

22

23

CT

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

L

11

12

13

14

15

16

17

18

19

N

COM+

NO –

NC

COM

AH

AL/HB

~

Power

CONTROL

OUTPUT

ALARM

OUTPUT

- 4 -

SR74A

2-7.Terminal arrangement table

3. Instruction for front panel

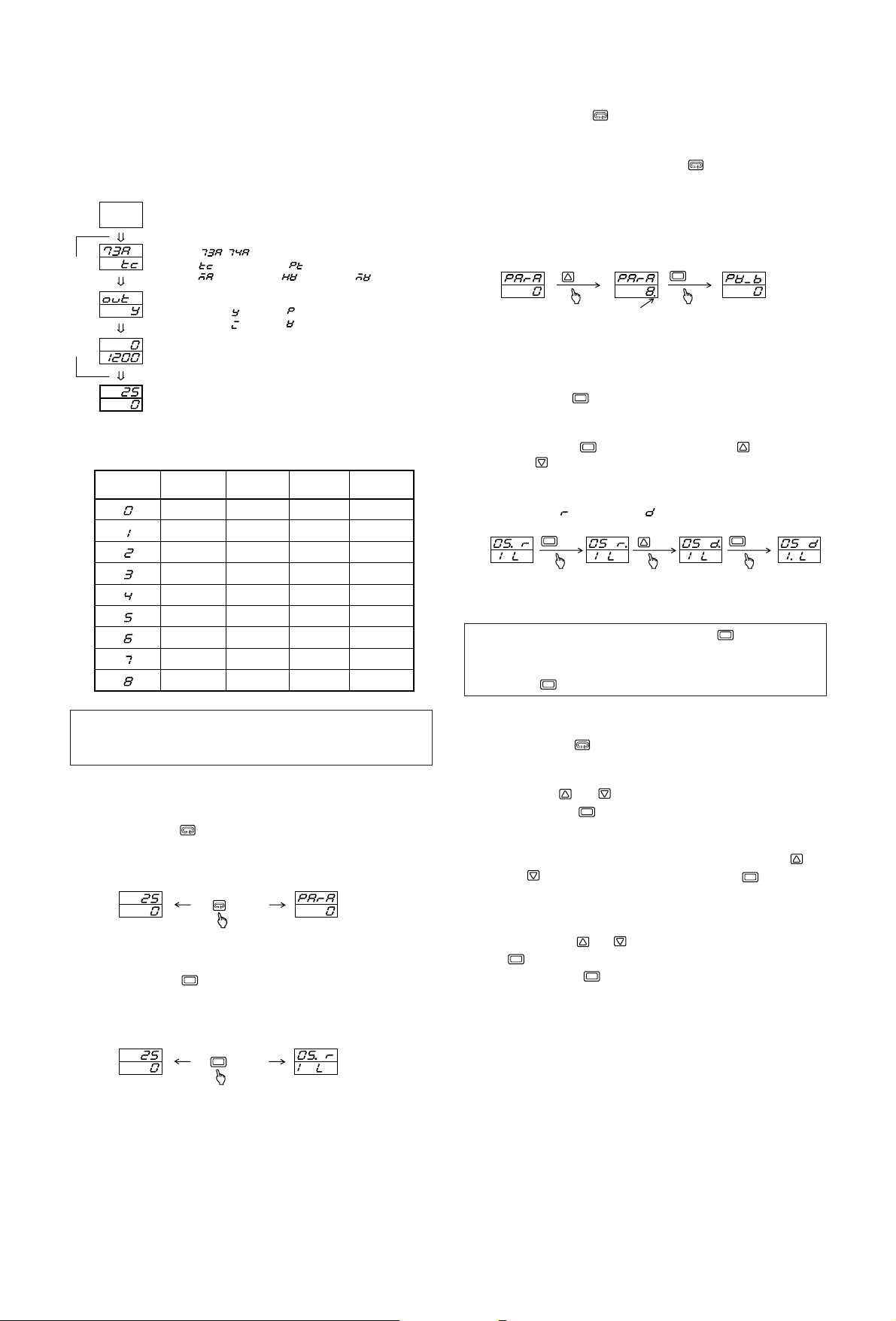

3-1. Drawing and the name of the parts

This is an example of the front panel of SR73A.

Name of parts

: Measured value

(PV) display

: Set value (SV)

display

: Monitor LED

: Key switches

10 20

23 24

19

18

17

16

15

14

13

12

2221

11

9

8

7

6

5

4

3

2

1

422A 485

RD–

RD+

SD– –

SD+ +

SG SG

L

N

COM+

NC

COM

AL/HR

AH

NO –

Power

CONTROL

OUTPUT

ALARM

OUTPUT

CT

SB

IN PUT

RTD

TC•mV

V•mA

+A

–B

B

~

Heater break alarm (option) CT input terminal

Name of terminal and description

Terminal number

SR73A and 74A

Power terminal

100-260V AC±10% 50/60Hz 12VA

Protective conductor terminal ( )

Input terminal

R. T. D. A, Thermocouple, Voltage, Current +

R. T. D. B, Thermocouple, Voltage, Current –

R. T. D. B

Output terminal

Contact: COM, SSR Drive voltage, Voltage,

Current +

Contact: NO, SSR Drive voltage, Voltage,

Current –

Contact: NC

Communication terminal

For RS-422A For RS-485

SG SG

SD+ +

SD– –

RD+

RD–

Alarm output (option) terminal

COM Contact rating 240V AC 1.5A

(resistive load)

AH Higher limit alarm

AL/HB Lower limit alarm or heater break alarm

Set value bias (option) input terminal

11-12

13

21-22

23-24

7

8

10

18

19

20

1

2

3

4

5

14

15

16

Note: For Thermocouple, Voltage, and Current input,

measurement error results by connection between B and

B terminal.

3-2. Instruction for front panel

: Measured value (PV) display (green)

(1) Displays current measured value on the mode 0 basic

screen.

(2) Displays parameter type on each parameter screen.

: Set value (SV) display (orange)

(1) Displays set value on the mode 0 basic screen.

(2) Displays selected item and set value on each parameter

screen.

: Monitor LED

(1) OUT (output) monitor LED (green)

• For contact or SSR drive voltage output, a light turns

on for output ON and turns off for output OFF.

• For current or voltage output, the light intensity

changes proportionally to the output altitude.

(2) AT (auto tuning) monitor LED (green)

• On selection by , ON turns on AT waiting

( key), flashes on AT execution.

(3) AH alarm output monitor LED (red)

• Turns on for higher limit alarm output ON.

(4) AL/HB alarm output monitor LED (red)

• Turns on for lower alarm output ON or heater break

alarm ON.

(5) MAN (manual control output) monitor LED (green)

• Flashes when control output is in manual operation.

(6) STBY (control output stop) monitor LED (green)

• Turns on when the control output stop mode is

selected.

(7) COM (communication) monitor LED (green)

• Turns on when the remote communication mode is

selected.

: Key switches

(1) (parameter) key

• Press on set screen to move to next set screen.

• Keep pressing three (3) seconds for function of move

key between basic screen of the mode 0 screen group

and direct call screen of mode 1 screen group.

(2) (down) key

• Press on the set screen to flash the point of the least

digit and to reduce data or back increment data.

(3) (up) key

• Press on the set screen to flash the point of the least

digit and to increase data of increment data.

(4) (entry/registration) key

• Press on the set screen of the mode 0 screen group

and mode 1 screen group to fix the data changed by

the , keys and to extinguish flash of the point.

• The function selecting screen, of the mode 2 screen

group, registers data of the point flashing digit and

simultaneously shifts a data changeable digit (the

point flashing digit).

• The input scaling screen, of the mode 2 screen group,

registers data and shifts a parameter capable of being

set (in the row in which the rightmost point is

flashing).

• Press the key for five seconds and it functions to

change the basic screen of the mode 0 screen group to

the function selecting screen of the mode 2 screen

group and vice versa.

(5) (manual) key

• Pressing this key on the control output screen changes

automatic control output to manual control output and

vice versa. During manual control output, the MAN

monitor LED flashes.

• The key does not function in the control output

stop mode.

ENT

MAN

ENT

MAN

PV

SV

OUT AT AH MAN STBY COMAH/HB

SHIMADEN

ENT

MAN

˚C

4

3

2

1

- 5 -

4. Screen instruction

4-1. Power on and initial screen display

After turning on power, the display shows each power on initial

screen for approx. 1.5 seconds, then moves into the basic screen

of the mode 0 screen group.

4-2.Alarm type code table

4-3.Screen change

(1) Screen change from mode 0 group to mode 1 group

• Pressing the key for three seconds on the basic screen

of the mode 0 screen group changes it to the direct call

screen of the mode 1 screen group and vice versa.

(2) Screen change from mode 0 group to mode 2 screen group

• Pressing the key for five seconds on the basic screen

of the mode 0 screen group changes it to the function

selecting screen of the mode 2 screen group and vice versa.

Measured value (PV)

Set value (SV)

Turning

on power

Series type ( )

,

Input type ( : Thermocouple, : R. T. D.,

Control output type : Contact : SSR drive voltage

: Current : Voltage

Lower limit of the selected measuring range

Higher limit of the selected measuring range

Power on initial screen

: Voltage (mV), : Voltage (V), : Current (mA))

Displays output screen

Mode 0 screen group basic screen

(3) Screen change within mode 0 screen group

• By pressing the key, the screen changes.

(4) Screen change within mode 1 screen group

• Two methods are used for screen change within mode 1

screen group. One is to press the key as shown on

above mode 0 screen group. The other is to mode the

screen directly by indicating screen No. on the top direct

call screen.

Example: Direct calling the screen No.8 PV bias value set

screen

(5) Selecting and setting digit to change of function selecting

screen of mode 2 screen group

• When the function selecting screen is displayed, the point

of selectable digit flashes.

• By pressing key, the selectable digit (digit whose

point is flashing) moves.

• In case of changing the set value, flash the point to be

changed with key, select data with the keys and

press key again to register the set value and move

selectable digit.

Example: changing the control output characteristics from

(heating) to (cooling)

* “.” on the screen shows the selectable digit (digit whose

point is flashing).

(6) Shifting setting items on input scaling screen of mode 2

screen group and setting method

• Pressing the key on the function selecting screen calls

the input scaling screen onto the display. The decimal

point in the rightmost position on the top row flashes.

Press the or key to change the lower limit value

and press the key to register the data.

• Upon registering the lower limit value data, the decimal

point in the rightmost digit in the bottom row begins to

flash. Change the higher limit value by pressing the

or key and register it by means of the key.

• Upon registering the higher limit value data, the decimal

points in the rightmost digits of the bottom and top rows

flash. Change the positions of the decimal points by

pressing the or key and register it by means of the

key.

• Each time the key is pressed, the flashing decimal

point in the rightmost digit moves from the top row→

bottom row→top and bottom rows→top row→.

• In case the lower limit value and the higher limit value are

set to produce a difference which is less than 100 counts or

more than 5000 counts, the higher limit value is forced to

change to +100 or +5000 counts. The higher limit cannot

be set to be less than a lower limit value +100 counts or

more than a lower limit value +5000 counts.

Alarm code

0 ( )

1 ( )

2 ( )

3 ( )

4 ( )

5 ( )

6 ( )

7 ( )

8 ( )

AH

assignment

Not assigned

Higher limit

deviation value

Higher limit

absolute value

Not assigned

Lower limit

deviation value

Lower limit

absolute value

Lower limit

deviation value

Lower limit

absolute value

Higher limit

deviation value

Higher limit

absolute value

Higher limit

deviation value

Higher limit

absolute value

Higher limit

deviation value

Higher limit

absolute value

With/Without

inhibit action

Without

inhibit action

Without

inhibit action

With

inhibit action

With

inhibit action

Without

inhibit action

Without

inhibit action

With

inhibit action

With

inhibit action

Without

inhibit action

Without

inhibit action

With

inhibit action

With

inhibit action

– – – – –

With/Without

inhibit action

– – – – –

– – – – –

– – – – –

– – – – –

– – – – –

AL/HB

assignment

Heater break

Heater break

Heater break

Heater break

Note: In the above table, the alarm codes 5 through 8 are

selectable when the apparatus has the optional function

of heater break alarm.

Note: In case of changing data and pressing key longer

than 5 seconds, the screen moves to mode 0 basic screen

without a data registration. It requires a data verification

with key and screen change.

1-0 direct call screen 1-0 direct call screen 1-8 PV bias value set screen

key

ENT

key

0-0 Basic Screen 1-0 direct call screen

key

3 seconds

ENT

0-0 Basic Screen 2-0 Function selecting screen

ENT

key

5 seconds

several times

point flashes

ENT

ENT

ENT

key

key

ENT

ENT

ENT

ENT

ENT

ENT

key

ENT

Loading...

Loading...