Shimaden GAT10-DN Instruction Manual

GAT10-DNT-1BE

May. 2016

GAT10-DN

RS-485/DeviceNet Converter

Instruction Manual

Basic Part

Thank you for purchasing our product. Please check that the delivered product is

the item exactly as ordered by you. Please read this manual thoroughly to

understand the contents before you start operating the product.

Please ensure that this instruction manual is given to the end user.

For details of the operation and parameters of Shimaden instruments to be connected to the

GAT10-DN, please refer to the instruction manual and communication interface instruction

manual of the instrument.

This instruction manual is meant for persons involved in wiring, installation, operation and

routine maintenance for the GAT10-DN. It describes matters to be attended to in handling

it, how to install it, wiring for it, its functions and operating procedure. It is requested that

for ready reference, this manual is kept at the work site where the GAT10-DN is used.

In operating it, please follow the instructions contained herein.

This instruction manual describes matters to be attended to concerning safety, potential damage

to equipment and/or facilities, additional explanations and notes under the following headings:

" Warning" ◎This heading indicates that failure to follow instructions could cause injury or

even death.

" Caution" ◎This heading indicates that failure to follow instructions could cause damage

to equipment and/or facilities.

"Note" ◎This heading indicates additional explanations or notes.

The safety rules apply only to this product. For those as a PLC system, please refer to the User's

Manual of PLC Unit.

The GAT10-DN is designed for general industrial use. Therefore, it should not be used in any

way that might result in injury or fatality, or must be used only after adequate safety measures

are taken. No responsibility will be taken for any accident resulting from the usage of this

product without appropriate safety measures being in place.

● The GAT10-DN must be housed in a control box or the like to prevent the terminal board

from coming into accidental physical contact with personnel.

● The GAT10-DN should not be taken out of the case. If your hand or an electric conductor is

put inside it, an electric shock may result in serious injury or even death.

● Make sure that the protective conductor terminal is grounded.

If there is any possibility of doing harm or damage to peripheral devices, equipment or

products, you must take appropriate safety measures such as installing the proper fuse or an

overheating prevention device before you start using the GAT10-DN. No responsibility will be

taken for any accident resulting from the usage of this product without appropriate safety

measures being in place.

● As means to turn the power off, a switch or a breaker should be installed in the external

power circuit to be connected to the power supply terminal of the GAT10-DN. The switch

or the breaker should be installed adjacently to the GAT10-DN and in a position which

allows it to be operated easily, with an indication that it is a means of disconnecting the

GAT10-DN from its power source. The switch or the breaker should meet the GAT10-DN

requirements of IEC60947.

● Fuse:

The instrument has no built-in fuse. Ensure to install a fuse in the power circuit to be

connected to the power supply terminal. The fuse should be placed between the GAT10-DN

and the switch or the breaker.

Fuse Rating/Characteristic: 250VAC 0.5A/ In the case of a medium time-lagged or timelagged type switch, one which meets the requirements of IEC60127 should be used.

● Make sure that a draft hole should not be blocked and that it should be protected from dust

and dirt. Failure to do so might cause fire or faulty operations.

● Do not repeat endurance tests for voltage, noise, surging and the like. Doing so might cause

fire or faulty operation.

● Do not attempt to disassemble, repair, or modify the GAT10-DN. Doing so might cause fire

or faulty operation.

1. Safety Rules

Caution

● Control lines and communication cables should not be bundled with the main power circuit

or the power line, or installed adjacently. They should be spaced apart by more than 100 mm

as a guideline. Failure to do so might cause faulty operation.

This instruction manual: 1 Connector : 1

Mounting base :

1

Note: If you find a problem with the product or some of the attached items missing, please

contact our sales agent.

■ Checking Attached Items

Avoid installing the GAT10-DN in the following locations. Failure to do so might cause fire or

faulty operations.

● Where flaming gas, corrosive gas, soot, or particles that can deteriorate electrical insulation

is generated or is abundant.

● Where ambient temperature lowers below -10℃ or exceeds 50℃.

● Where relative humidity exceeds 90%RH or falls below dew point.

● Where highly intense vibration or impact is generated.

● Near high voltage power lines or where inductive interference can affect the operation of

the product.

● Where the product is exposed to direct sunlight, wind or rain.

● Where the elevation exceeds 2,000 m.

● Where the product is directly exposed to the flow of emitted air.

■ Installation Site

Caution

In wiring, close attention should be paid to the following.

● Always disconnect the GAT10-DN from any power source during wiring operation to

prevent an electric shock.

● Make sure that the protective conductor terminal is grounded properly. Failure to do so

might cause electric shock.

● Don't touch the wired terminals and charged devices while the instrument is energized.

Doing so might cause electric shock.

■ Wiring

Caution

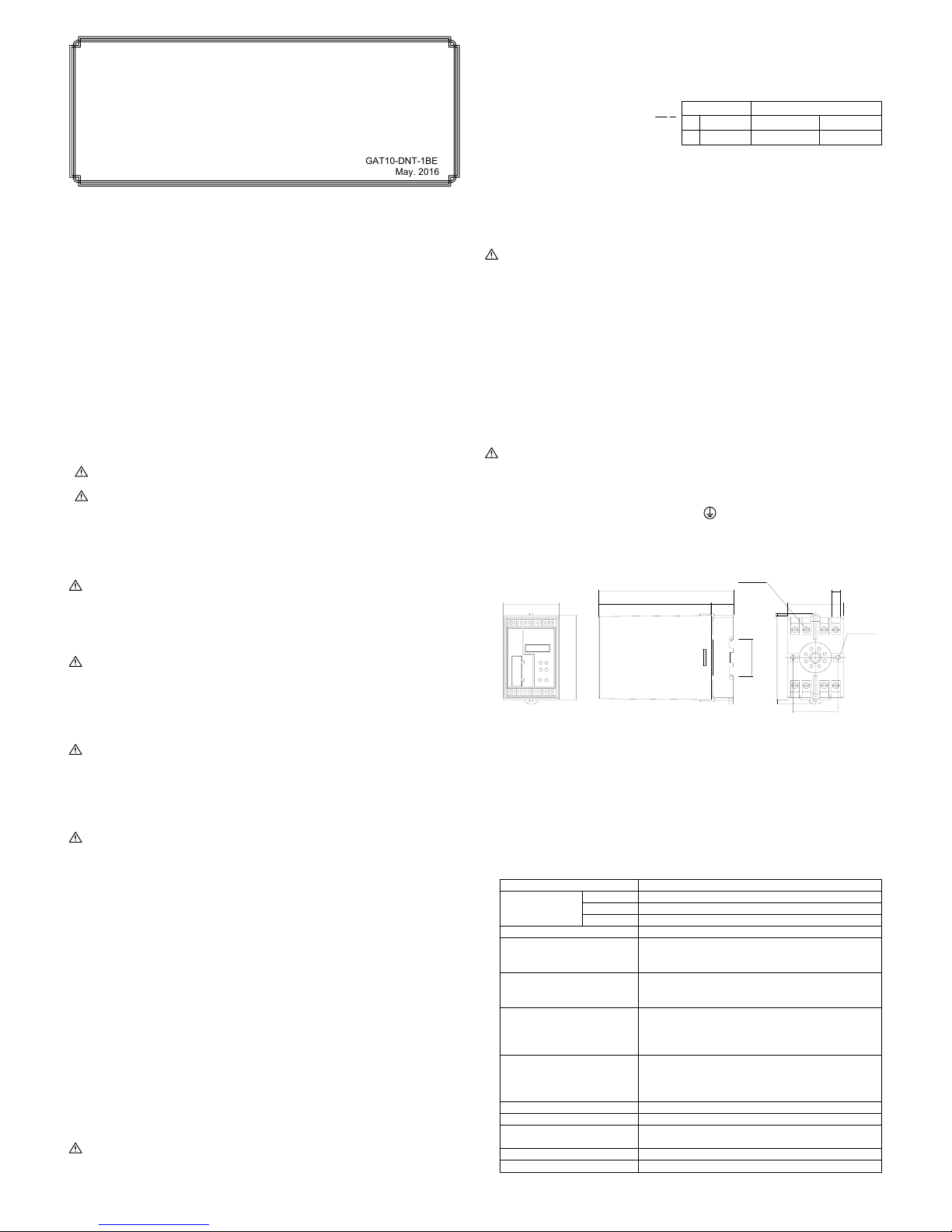

■ External Dimensions

This is the "Basic" Part of the instruction manual. Please also read the "Design" Part, which

you can download from our website. (URL http://www.shimaden.co.jp)

● The GAT10-DN enables writing and reading, from the DeviceNet, of Measured values,

Target set values and parameters for up to 8 Shimaden instruments with RS-485

communication.

● The GAT10-DN is connectable to the following Shimaden products:

Digital controllers : SR80 series, SR90 series, SR253

Program controller: FP93

Digital indicator : SD16

Servo controller : EM70

3. Specifications

Item

Supply voltage

■ General Specifications

Power consumption

Insulation resistance

Dielectric strength

Mounting

Mass

Temperature

Humidity

Storage temperature

Approx. 250g(Including base)

DIN rail or screw

Specifications

100~240V AC±10% 50/60Hz

24V AC±10% 50/60Hz

24V DC±10%

-10~50℃

90%RH or less(no dew condensation)

2. Preliminary Steps

Please confirm that the delivered product is exactly as you specified by comparing the

model codes pasted on the case of the GAT10-DN with the following codes.

Example of model code

:

GAT10-DN-90-0

■ Confirmation of Specification Codes

①②

Ambient conditions

for operation

-20~65℃

5VA(100~240V AC)

4VA(24V AC)

3W (24V DC)

Between input/output terminals and power terminal 2300V AC 1

minute (induction current: 3mA)

Between power terminal and protective conductor terminal

1500V AC 1 minute (induction current: 3mA)

Between input/output terminals and power terminal 500V DC

20MΩ min.

Between input/output terminals and protective conductor

terminal 500V DC 20MΩ min.

Material of case

Color of case

External dimensions

PPO resin molding

H80xW50xD120 mm(Including base, but excluding front

connector)

Black

Altitude 2000 m from the sea level or lower

Caution

Caution

Warning

Warning

Code and DescriptionItem

①②Power supply

Special note

90: 100-240V AC

0: Without

08: 24V AC/DC

9: With

100

120

50

80

8-M3.5×7

20

(2)

7.8

±0.2

51 min.

(4)

35.4

81 min.

2-φ4.5

(Unit mm)

40

±0.2

No. 2

CableColor and Signal Connector

GAT10-DN

■ DeviceNet Specifications

Transmission rate

125k bps

250k bps

500k bps

Setting not allowed

● DeviceNet transmission rate setup

■ RS-485 (Shimaden standard protocol) Specifications

Specifications

EIA RS-485 compliant

2-line half duplex multidrop

Start-stop synchronization

Max. 500 m

19200 bps

7 bit/even parity/1 stop bit

Max. 8

SR80 series, SR90 series, SR253, SD16, EM70, FP93

Approx. 1.5 sec

(when 8 Shimaden units are connected and without SV

value updating, and parameter reading/writing)

Terminal arrangement

● Use the special cable for DeviceNet.

● Use the attached connector.

● The connector is equivalent to the MTB2, 5/5-ST-5. 08 ABGYAU made by PHOE NIX CONTACT.

● For grounding and terminating resistor for DeviceNet, refer to the DeviceNet Specification s published by

ODVA.

4. Wiring

■ Connecting DeviceNet communications

Item

Signal level

Communication method

Synchronization method

Communication distance

Communication rate

Data format

Number of connectable

Shimaden instrument

Connectable products

Scan time

■ Connecting RS-485 communications

RS-485

Power supply

Terminating resistor

(attached to the instrument)

Shimaden instruments

No particular maintenance is required for the GAT10-DN. Check the inspection items listed in Master

PLC User's Manual so that your system can always be used in optimal conditions.

■ Maintenance

● The external line should not be bundled with or installed adjacently to a load line except tho se from

the main power circuit line, a high voltage line and the PLC. Otherwise it will easily be affected by

noise, surge or induction.

● For a shielding wire or a shielded cable, one-point grounding on the PLC side is required . Depending

on the condition of external noise, however, it may be better to ground on the externa l side.

1 to 8Local address

Connector

Network current consumption

Special cable for DeviceNet

125k bps 500k bps250k bps

500 m 100 m250 m

Specifications

Master/slave system

CAN Protocol

Trunk line, Drop line

125k/250k/500k bps

Fixed to 24 words each for input and output

0~63

Communication adaptor

Accessories

40mA max.

Item

Communication system

Protocol

Type of transmission line

Type of device

Occupied word count

Node address

Maximum transmission

distance

Connecting cable

Transmission rate

SW6

OFF

ON

OFF

ON

SW7

OFF

OFF

ON

ON

● DeviceNet Node Address Setup

NA0Address

0

1

・・・

62

63

NA5NA4NA3NA2NA1

OFF OFF OFF OFFOFFOFF

ON OFF OFF OFFOFFOFF

OFF ON ON ONONON

・・ ・・ ・・ ・・・・・・

ON ON ON ONONON

2 ON ON OFF OFFOFFOFF

■ External Wiring

As one of the requirements for enabling the GAT10-DN to function thoroughly and to establish a

highly reliable system, external wiring that is not easily affected by noise is necessary. The following

are matters to be attended to for external wiring.

Signal

V

-

CAN_L

Drain

CAN_H

V +

Color

Black

Blue

----

White

Red

The GAT10-DN has a built-in RS-485 terminating resistor. To the Shimaden instrument as the final

station, attach the terminating resistor supplied as an accessory to it. However, please attach the

terminating resistor to only one instrument (final station). If attached to two or more i nstruments,

correct operation cannot be guaranteed.

Note: No devices except Shimaden instruments should be connected to the RS-485 line. Otherwis e,

correct operation cannot be guaranteed.

Note: Make sure to use GAT10-DN as a terminal station of RS-485 communications.

■ Terminating resistor

● DeviceNet

● RS-485

Install the DeviceNet terminating resistor according to the Master PLC Instruction Manual and the

DeviceNet Specifications issued by ODVA.

Transmission rate

Total length

GAT10-DN

SHIMADEN

POWERRESET

MS NS

RX TX

LED indicating operating status of DeviceNet

LED indicating operating status of RS-485

communication

Reset switch

Switch for transmission rate setup

( SW6, SW7 )

Note: Set values become effective upon applying power or resetting.

DeviceNet

connector

V-

CAN_L

CAN_H

Drain

V+

Switch for node address setup

( NA0~NA5 )

Lights "green" when GAT10-DN

operates normally. In other displays,

setting error/device error has occurred.

Name Color Function Remarks

MS

Green/

Red

Module status

(DeviceNet)

Lights "green" when GAT10-DN is online. In other displays, communication

failure/connection error has occurred.

NS

Green/

Red

Network status

(Device Net)

Lights during reception of data

TX Green

RS-485

Data transmission

Lights during transmission of data

RX Green

RS-485

Data receipt

● LED indicating operating status

V -

CAN_L

Drain

CAN_H

V +

V -

CAN_L

Drain

CAN_H

V +

Name of SignalNo.

①

②

③

④

⑤

⑥

⑦

⑧

RS-485 :

-

RS-485 : +

NC

Power supply: N

Power supply: L

Power supply: FG

RS-485 : SG

NC

L

N

⑤

⑥

⑦⑧

④

③

②

①

・

・

・

No. 1

+

-

SG

+

-

SG

No. N

(the final station)

+

-

SG

The contents of this manual are subject to change without notice.

Temperature and Humidity Control Specialists

Head Office: 2-30-10 Kitamachi, Nerima-Ku, Tokyo 179-0081 Japan

Phone: +81-3-3931-7891 Fax: +81-3-3931-3089

E-MAIL: exp-dept@shimaden.co.jp URL: http://www.shimaden.co.jp

PRINTED IN JAPAN

Loading...

Loading...