Shimaden EM51 series Instruction Manual

EM51 Series

Plug-in Type Servo Controller

Instruction Manual

Thank you for purchasing our product.

Check that the delivered product is the correct item you ordered.

Do not begin operating this product until you have read and

thoroughly understood the contents of this Instruction Manual.

EM51F2CE

Dec. 2010

Notice: Make sure that this Instruction Manual is given to the final user of the device.

Preface: This Instruction Manual is meant for persons involved in wiring, installation, operation and routine maintenance

of the EM51 Series. It describes matters to be attended to in handling the EM51 Series, how to install it and its wiring.

It is requested that for ready reference, this manual is kept at the work site during operation of the EM51 Series.

In operating it, please follow the instructions contained herein.

This Instruction Manual describes matters to be attended to concerning safety, potential damage to equipment

and/or facilities, additional explanations and notes under the following headings.

WARNING: This heading indicates that failure to follow instructions could cause injury or even death.

CAUTION: This heading indicates that failure to follow instructions could cause damage to equipment and/or facilities.

The EM51 Series Servo Controller is designed for controlling

temperature, humidity and other physical quantities in general

industrial facilities. Therefore, it should not be used in any way

that might result in injury or fatality, or must be used only after

adequate safety measures are taken. No responsibility will be

taken for any accident resulting from the usage of this device

without appropriate safety measures being in place.

•

This device must be housed, for example, in a control box to

prevent the terminal board from coming into accidental physical contact with personnel.

•

To prevent electric shock, always turn off and disconnect this

device from the power supply before starting wiring.

•

Do not touch wired terminals or charged parts with your hands

while the power is supplied.

To avoid damage to connected peripheral devices, facilities or

the product itself due to malfunction of this device, safety countermeasures such as proper installation of the fuse or installation

of overheating protection must be taken before use. No responsibility will be taken for any accident resulting from the usage

of this device without appropriate safety measures being in

place.

•

The Alert Symbol Mark on the plate affixed to this device:

The Alert Symbol Mark indicated on the nameplate affixed

on the casing of this device warns you not to touch charged

parts while this device is powered ON. Doing so might cause

an electric shock.

•

A means for turning the power OFF such as a switch or a

breaker must be installed on the external power circuit connected to the power supply terminal on this device.

Fasten the switch or breaker at a position where it can be easily operated by the operator, and indicate that it is a means

for powering this device OFF.

•

Use this device by ensuring the wire connection part is firmly tightened.

•

Fuse: This device has no built-in fuse. Ensure to install a fuse

in the power circuit to be connected to the power supply terminal.

Fuse rating/characteristic: 250V AC 0.5A

•

Use the device with the power voltage, frequency, load current

and voltage within their rated ranges.

•

Use the device with the relay contact current only within its

rated range. When using with any motor, use only within

approx. 1/5 of the rated range since inrush current or surge

voltage may occur.

•

Users are prohibited from remodeling this device or using it

in a prohibited or unauthorized manner.

WARNING

CAUTION

1. Specification

Input ............................................See ordering information.

Feedback Resistance ...................100Ω ~ 2kΩ randam/3-wire

Output .........................................Relay contact or Triac (SSR)

Output Rating/Contact Protection

Relay contact..........................240V AC, 1A (inductive load)/

CR Absorber

Triac (SSR) ............................

20 ~ 120V AC, 1A (inductive load)/

CR Absorber + varistor

Hysteresis...................................

Approx. 0.5% fixed of input signal range

Deadband (DB) ...........................

1 ~ 10% variable of input signal range

Dead Time...................................Approx. 0.2 sec.

(Chattering prevention)

Zero & Span Adjustment ............0% (ZERO): 0 ~ 20% variable

100% (SPAN): 70 ~ 100% variable

Output Action Display ................M2-M1/LED green lighting

M2-M3/LED red lighting

Operating Ambient Temperature

.....-10 ~ +50°C

Operating Ambient Humidity ....

.

90% RH max. (no dew condensation)

Storage Temperature...................-20 ~ 65°C

Power Supply..............................See ordering information.

Power Consumptio

n....................Approx. 4 VA

Insulation Resistance

Between the input and power supply terminals: 500V DC, 100MΩ min.

Between the output and power supply terminals:

500V DC, 100MΩ

min.

Dielectric Strength

Between the output and power supply terminals: 1 min. at 1000V AC

Material.......................................ABS resin molding

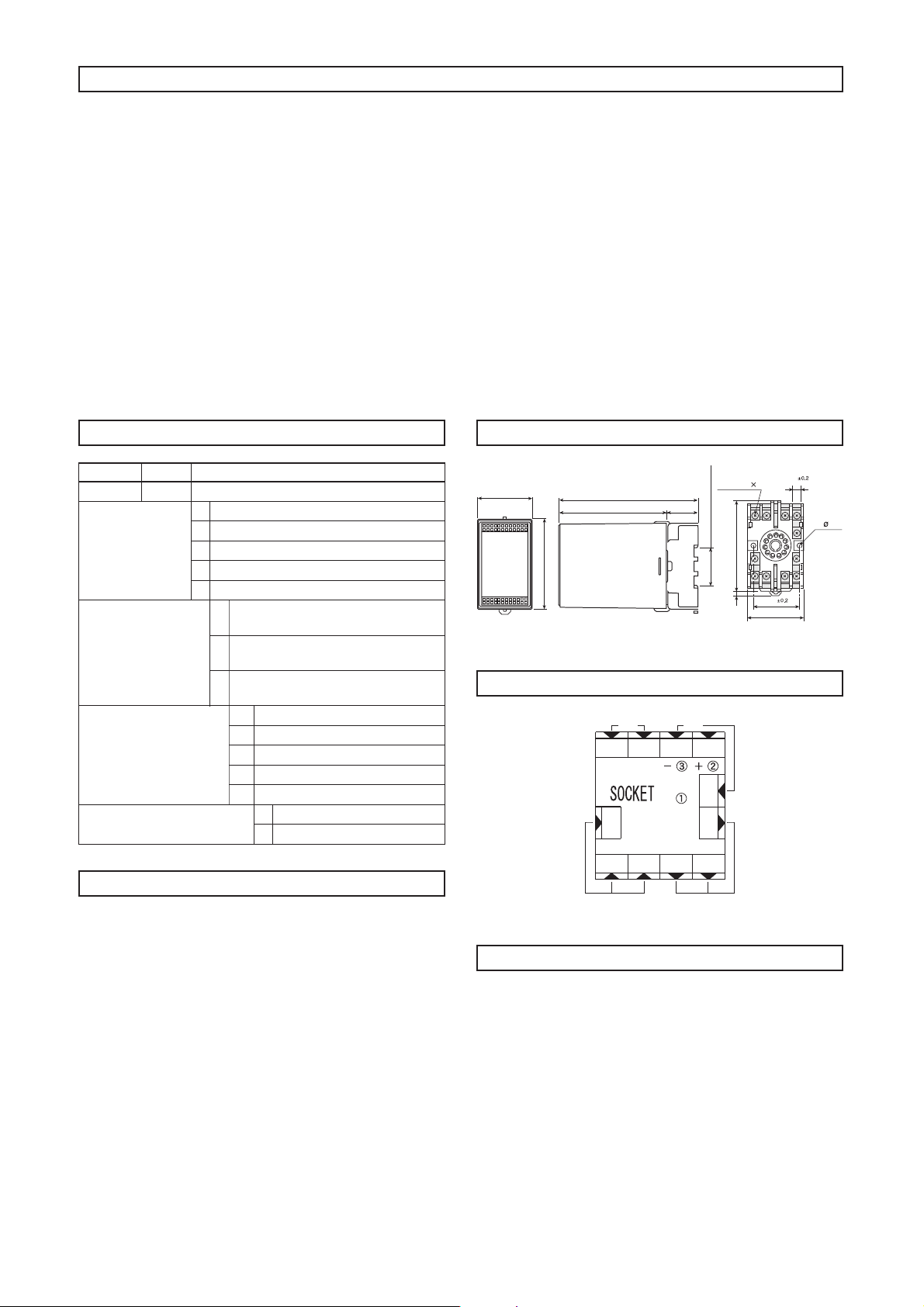

External Dimension

s...................80 (H)

x

50 (W) x130 (D) mm

Installatio

n ..................................11P Plug-in

Weigh

t.........................................Approx. 350g

(Exclusively used for AC load)

2. Ordering Information

ITEMS CODE SPECIFICATIONS

1. SERIES

EM51- Plug-in type servo controller

1

1 ~ 5mA DC, Receiving Impedance

: 250Ω

2

4 ~ 20mA DC, Receiving Impedance

: 62Ω

2. INPUT 3 0 ~ 10V DC, Input Resistance:200kΩ

5 Potentiometer 100Ω ~ 2kΩ, 3-wire type

9 Others (Please consult before ordering.)

Y

Contact 240V AC, 1A (inductive load)/

with CR Absorber

3. OUTPUT

R

Contact

240V AC, 1A (inductive load)/

without CR Absorber

S

Triac 20 ~ 120V AC, 1A (inductive load)

(Motor Supply Voltage: 20 ~ 120V AC)

13-

100 ~ 110V AC ±10%, 50/60Hz

14-

110 ~ 120V AC ±10%, 50/60Hz

4. POWER SUPPLY 15-

200 ~ 220V AC ±10%, 50/60Hz

16-

220 ~ 240V AC ±10%, 50/60Hz

99-

Others (Please consult before ordering.)

5. REMARKS

0 Without

9

With (Please consult before ordering.)

5. Terminal Arrangement

3. Installations

Do not use this device in the following sites to avoid any trouble since

us

e in such circumstances may generate severe harmful influence on

its performa

nce or its useful life, or lead to other shortcomings:

1. Locations that are filled with or generate corrosive gas or inflammable gas

2. Locations where high temperature/humidity is present

3. Locations where direct sunlight or radiant heat such as that from

an electric furnace is present

4. Locations where any vibration or shock may be experienced

4. External Dimensions & Panel Cutout

6. Wiring

1. Wiring should be routed according to the indications located on

the terminal face plates.

Do

not apply too much force when tightening the terminal screw.

2. Keep wiring away from strong electrolyte circuits, or use shielding

wire to protect the feedback resistance wire from the input

signal/control motor.

3. If you inadvertently connect the motor power supply to the feedback

resistance circuit of the control motor, the potentiometer will

burn.

4. Connection terminal symbols found on control motors may vary

depending

on their manufacturer. Refer to the instruction man-

ual supplied by the manufacturer in question for clarification.

50

08

4.53

.xam 18

7.8

51 max.

130

10

0 30

11-M3.5 7

d

et

n

uom e

b

ot

l

i

ar

eh

t tif oT

Unit: mm

40

2- 4.5

8 7 6 5

4

3

10911 1 2

V U

R2

R1

R3 M1 M2

M3

Feed-Back

Potentiometer

MOTOR

POWER INPUT

Potentiomerer

4

Loading...

Loading...