Page 1

kangaroo

Det

、

Feeding

Service

Enteral

Pump

Manual

Page 2

woo

Page 3

table

of

contents

section

1.

general

—product

2.

maintenance

一

routine

ーcleanind

—housing

—drop

—rotorassembiy

—calibration

—additional

人

—recommended

—charger

—ambulatory

3.

circuit

—charger

—ambulatory

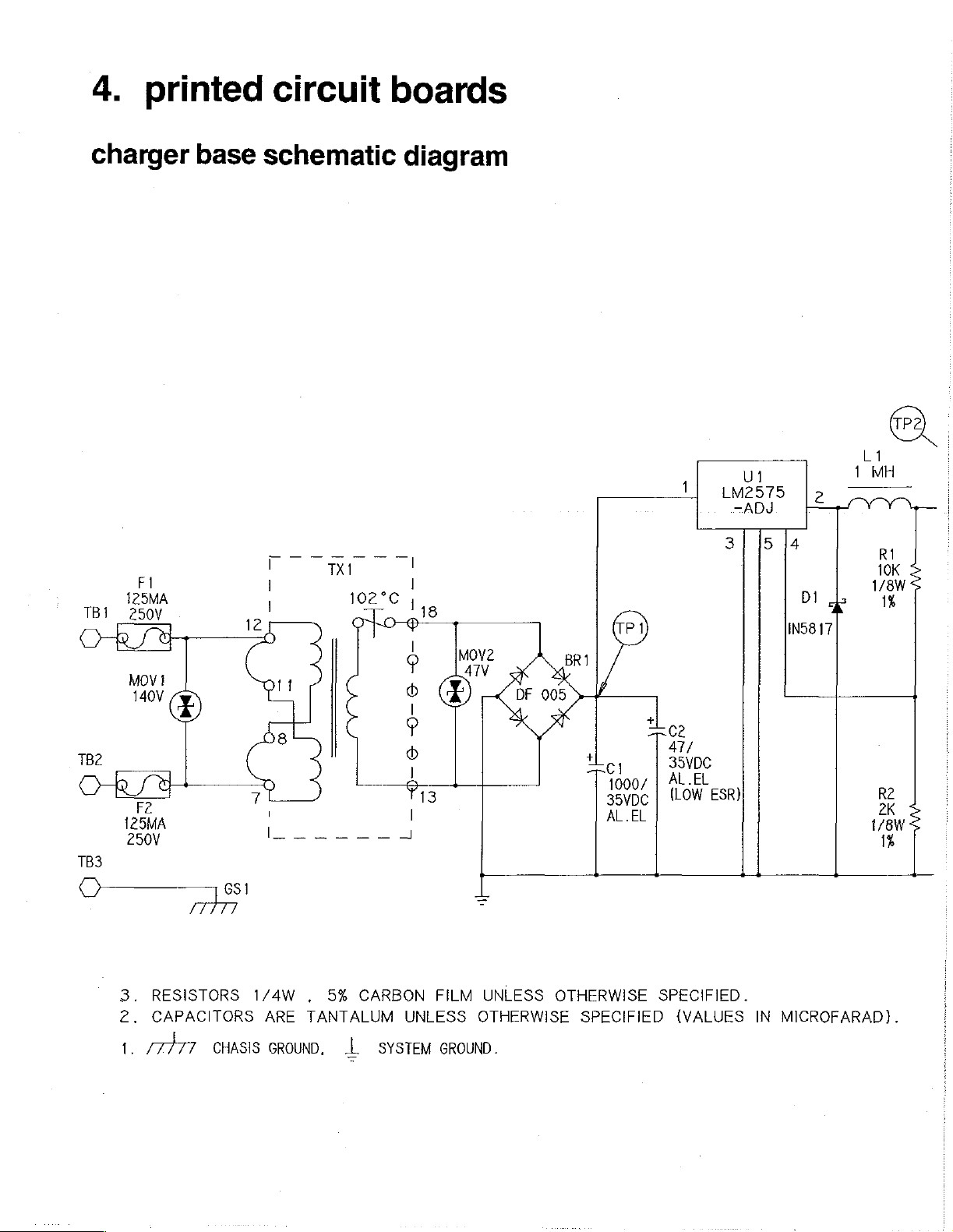

4.

printed

—charger

—ambulatory

detector

description

—AC

—Supply

—charge

一 quick

—Microprocessor

—power

—power-on

—reset

一

battery

一

touch

—LED

ーdrop

一

motor

—fail-safe

一

rotor

—frame

—pump

—audio

—

language

—schematic

—assembly

一

parts

—schematic

—assembly

information

description

maintenance

し に に ーー に ーー に トト

.............................,....,........2.

...........

tests . eernenennnes

base

pump

base

to

DC

voltage

current

charge

pump

supply

circuit

monitoring

panel

display

detector

detection

detection

set

alarm

circuit

base

list

pump

.....................................

:.................

ーー

トド に に

トト に トート

.......................,,........,........

...........................

1.1.1.

スト

トレ

トレ

2...

ーー トー

rea

performance

assembly

assembly

.

conversion

output

outpul

control . «νεο

test

......................,....

........................,.........

...............................

eee

................................

...............................

..................

εν

ενω

νεο

0...

νε ω νε

ων

..... ーー 10-13

....................................

........................

circuit

................................,..

1.10...

.

............................,....

. .

ντ

..

..

τν νε ω νε

ων

ενω

ενω

ων

νεο

ον

νοκ

εννοω

가

아게 기가 에 세세 우게

44.

eee,

εκ εκ ο νε

νεο ν ον

sneen

...............................,....

detection

.................................

......................,...............

selection

.................,..........,....

boards

..........................................

diagram

diagram

.

ee

diagram

Чадгат

.................................

...............,...........,.....

krrenkekre

.................................

........

еее

es

A

ニー

ューーー

0.1.1...

e

rr

ενω κ νεος

erekkee

eee

ων ον

마이

아아

enkes

νε κ νο ον

eee

page

1,2

3

3

3

3

3

4

4

4,5

6,7

8

8

9

9

9

9.

9

10

10

10,11

1

11

11

1

12

12

12

19

12

12

12

13

14,

15

14

15

15

16-18

16,

17

18

5.

final

assembly

—chargerbase

—parts

—partS

—

атьщаюгу

—parts

一

Parts

6.

specifications

7.

troubleshooting

8.

factory

service/ordering

......................

breakdown

HS...

ec

ритр

diagram

......... ο νεο

............................

ον

κενο

0...

εν

εννοω

cee

ων

εν ων

teens

χε

breakdowndiağram............................

SE

κ

........................................

guide

................................

information

..................

νο

ον ον

19,

20

19

20

21,

22

21

22

23,

24

25

26

Page 4

1.

general

information

product

The

Sherwood

to

regulate

Portable

Intelligent

Small and

Carrying

Touch

Pumping

—Feeding

—Feeding

—Drop

—

—

—Pump

—Self

—Preset

—Pump

Periodic

the

panel

sensors

Battery

Unit

is

diagnosed

description

Medical

flow

operation—built

battery

lightweight

case

operation.

shut

container

tube

low

(alarms

left

on

“HOLD”

set

is

improperly

dose

has

motor

malfunction

systems

Kangaroo

rate

of

charging

and

frame

off

and

is

empty

becomes

blocked

15

problem

been

check

enteral

for

activation

occluded

minutes

longer

loaded

which

delivered

after

Pet

Feeding

feedings.

in

battery.

for

longer

easy

transport.

for

ambulatory

of

before

than

2V2

requires

pump

Pump

Some

operating

or

tabletop

audible and

pump

shut

off)

minutes

technical

has

servicing,

been

is a rotary

of

the

features

times and

use.

visible

including

turned

alarms

on.

peristaltic

provided

extended

pump

by

lifetime.

when:

battery

defective

designed

this

pump

are:

Large

Detachable

Low

approximately

Integral

Use

misloading

Pump

Volume

Programmable

Programmable

WARNING—This

The

the

LED

display.

occlusion

pole

of

safety

running

delivered

pump

pump.

will

charger

pressure.

12

psi

clamp

on

interlock

of

pump

indicator

totalizer.

dose

dose

Kangaroo

not

operate

base.

Pump

(82.7

kPa)

charger

pump

set

to

repetition

sets

onto

pump.

LEDs.

be

delivered.

Pet

if

sets

timer.

will

not

overcome

nominal,

base.

to

safeguard

Pump

other

requires

than

15

PSI

against

the

Kangaroo

back

peak

use

pressure

(103

kPa).

the

risk

of

of a Kangaroo

Pump

Sets

greater

over-infusion

are

than

Pump

loaded

due

Set.

onto

to

Page 5

"

10

9

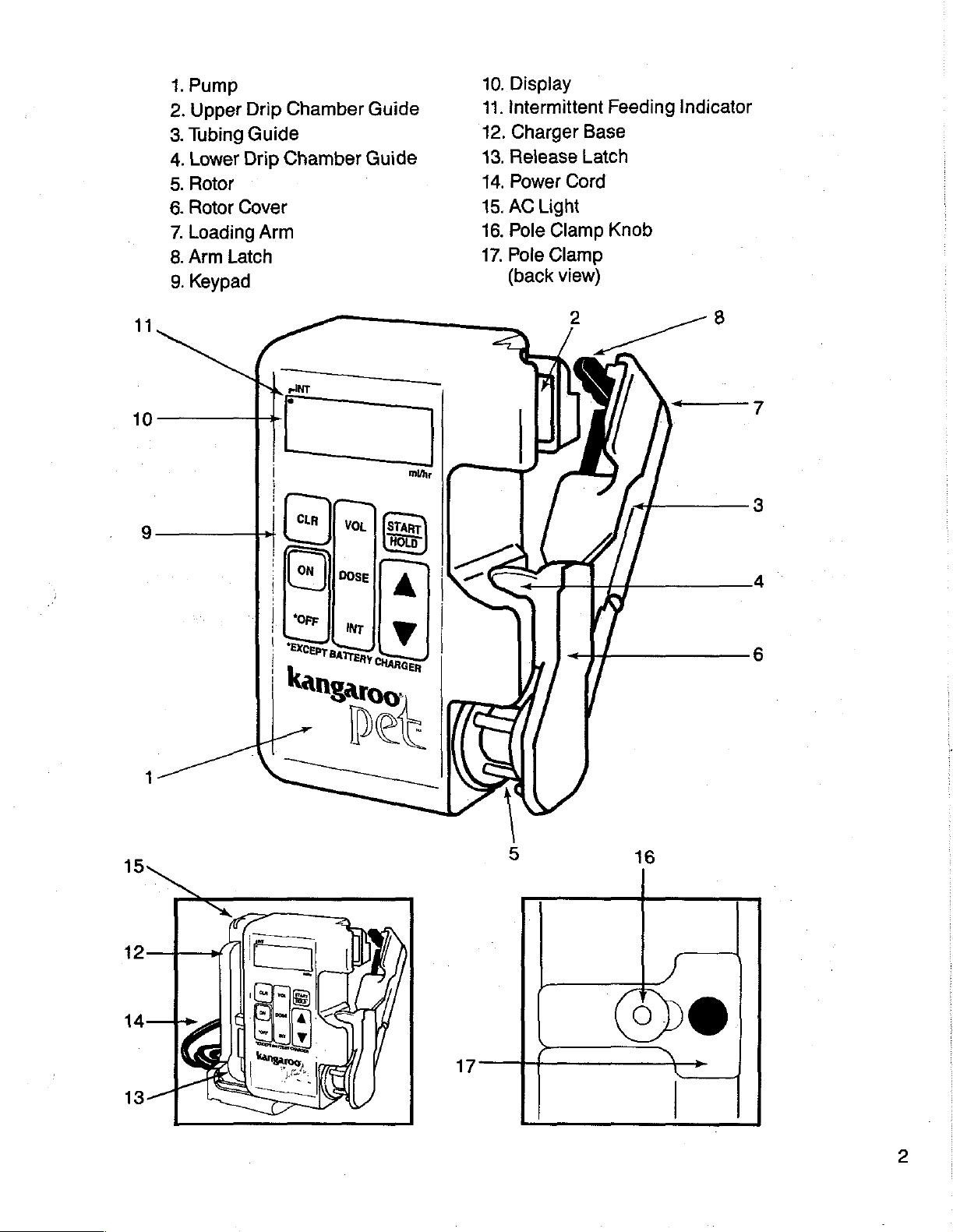

1.

2.

3.

4.

5.

6.

7.

8.

9.

tS

Pump

Upper

Tubing

Lower

Rotor

Rotor

Loading

Arm

Keypad

Drip

Guide

Drip

Cover

Latch

Chamber

Chamber

Arm

Guide

Guide

10.

Display

intermittent

11.

Charger

12.

Release

13,

Power

14.

Light

AC

15.

Clamp

Pole

16.

Clamp

Pole

17.

(back

view)

Base

Latch

Cord

Feeding

Knob

Indicator

15

12

14

13-7

Page 6

2.

maintenance

routine

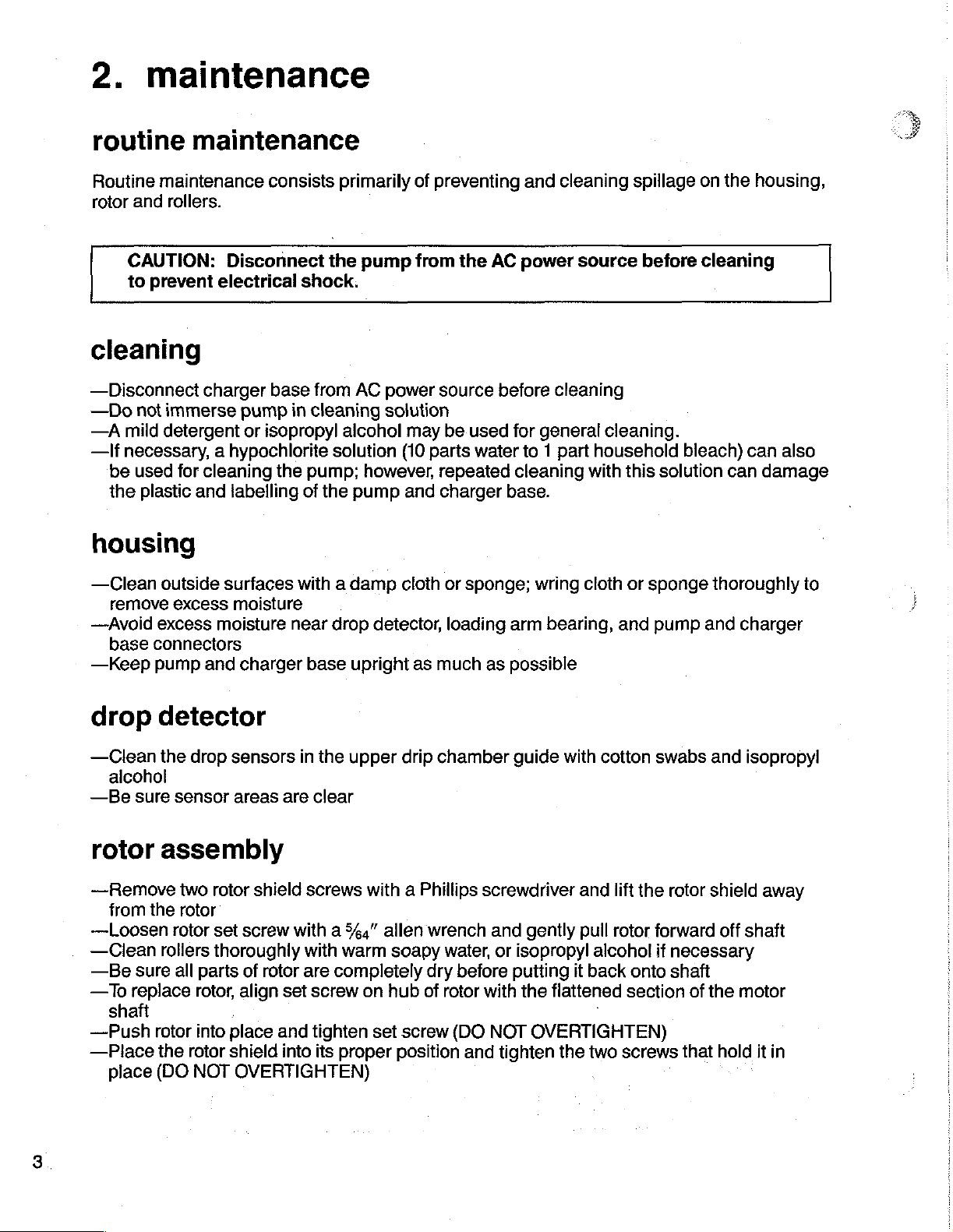

Routine

rotor

and

CAUTION:

to

maintenance

maintenance

rollers.

Disconnect

prevent

electrical

consists

cleaning

—Disconnect

—Do

not

—A

mild

—lf

necessary, a hypochlorite

be

used

the

plastic

charger

immerse

pump

detergent

for

cleaning

and

tabelling

or

isopropyl

housing

—Clean

remove

—Avoid

base

—Keep

outside

excess

excess

surfaces

moisture

moisture

connectors

pump

and

charger

shock.

base

from

in

cleaning

the

pump;

of

the

with a damp

near

base

primarily

the

pump

AC

power

solution

alcohol

solution

however,

pump

drop

detector,

upright

of

preventing

from

the

source

may

be

(10

parts

repeated

and

charger

cloth

or

loading

as

much

AC

before

used

for

water

cleaning

base.

sponge;

arm

as

possible

and

cleaning

power

source

cleaning

general

to 1 part

with

wring

cloth

bearing,

spillage

before

cleaning.

household

this

solution

or

sponge

and

pump

on

the

cleaning

bleach)

can

thoroughly

and

charger

housing,

can

also

damage

to

drop

—Clean

alcohol

—Be

sure

rotor

—

Remove

from

the

-—Loosen

—Clean

—Be

sure

—To

replace

shaft

ーPush

—

Place

place

detector

the

drop

sensors

sensor

areas

assembly

two

rotor

shield

rotor

rotor

set

screw

rollers

rotor

the

(DO

thoroughly

all

parts

rotor,

into

rotor

NOT

of

align

. ]

place

shield

OVERTIGHTEN)

in

are

screws

with a 54”

with

rotor

are

set

and

into

the

upper

clear

with a Phillips

warm

completely

screw

tighten

its

proper

on

set

drip

chamber

allen

wrench

soapy

dry

hub

of

screw

position

screwdriver

and

water,

or

before

rotor

with

(DO

NOT

and

tighten

guide

with

cotton

and

gently

isopropyl

putting

the

pull

alcohol

it

back

flattened

OVERTIGHTEN)

the

two

swabs

lift

the

rotor

forward

if

onto

section

screws

and

isopropyl

rotor

shield

off

shaft

necessary

shaft

of

the

motor

that

hold

away

it

in

Page 7

2.

maintenance

(cont.)

CARE

TO

ALCOHOL

PUMP

SHOULD

ELECTRICAL

OR

HOUSING.

OTHER

calibration

There

is

no

calibration

additional

Motor

turning,

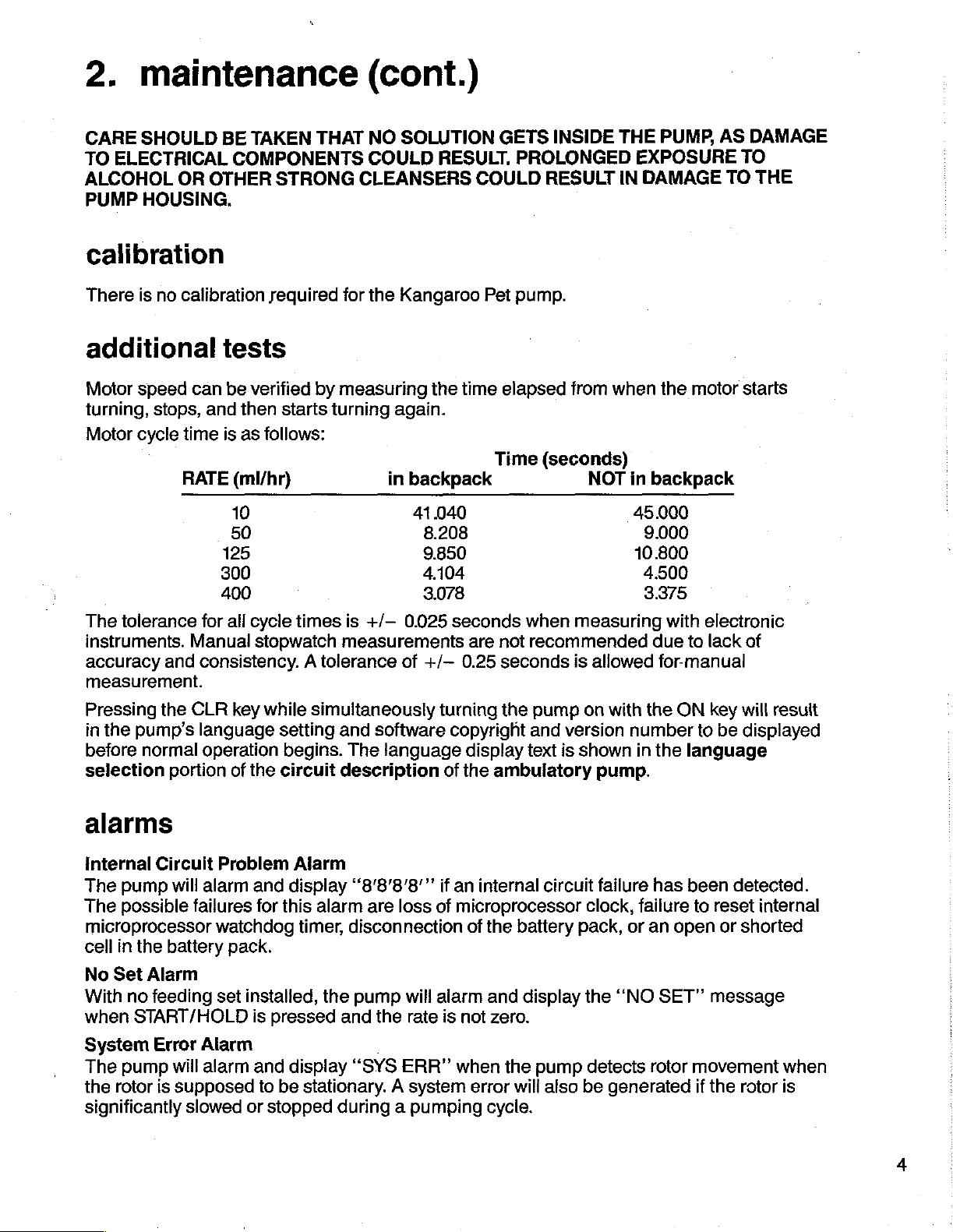

Motor

speed

stops,

cycle

can

and

time

RATE

300

400

BE

TAKEN

COMPONENTS

STRONG

required

tests

be

verified

then

starts

is

as

follows:

(ml/hr)

10

50

125

THAT

NO

COULD

CLEANSERS

for

the

by

measuring

turning

SOLUTION

RESULT.

Kangaroo

the

again.

in

backpack

41.040

8.208

9.850

4.104

3.078

COULD

Pet

time

Time

GETS

INSIDE

PROLONGED

RESULT

pump.

elapsed

(seconds)

from

NOT

THE

EXPOSURE

IN

DAMAGE

when

in

backpack

45.000

9.000

10.800

4.500

3.375

PUMP,

the

motor

AS

TO

TO

starts

DAMAGE

THE

The

tolerance

instruments.

accuracy

for

Manual

and

consistency. A tolerance

measurement.

Pressing

in

the

before

selection

the

pump’s

normal

portion

CLR

language

operation

alarms

Internal

The

The

microprocessor

cell

No

With

when

System

The

the

significantly

Circuit

pump

will

possible

in

the

battery

Set

Alarm

no

feeding

START/HOLD

Error

pump

rotor

will

is

supposed

alarm

failures

Alarm

alarm

slowed

all

cycle

stopwatch

key

while

setting

begins.

of

the

circuit

Problem

and

for

this

watchdog

pack.

set

installed,

is

pressed

and

to

be

or

stopped

times

is

+/—

0.025

measurements

of

-/—

simultaneously

and

software

The

language

description

Alarm

display

timer,

'8'8'8'8"”

alarm

are

loss

disconnection

the

pump

and

the

will

rate

.

display

stationary. A system

“SYS

during a pumping

ERR”

seconds

are

0.25

turning

copyright

display

of

the

if

an

of

microprocessor

of

alarm

is

not

when

error

when measuring

not

recommended

seconds

the

pump

and

text

ambulatory

internal

the

battery

and

display

zero.

the

pump

will

cycle.

is

allowed

on

version

is

shown

pump.

circuit

failure

clock,

pack,

the

detects

also

be

with

due

for-manual

with

the

ON

number

in

the

has

failure

or

an

open

“NO

SET”

rotor

generated

electronic

to

lack

of

key

will

to

be

displayed

language

been

detected.

to

reset

internal

or

shorted

message

movement

if

the

rotor

result

when

is

Page 8

2.

Low

The

threshold.

pressing

state

final

Flow

The

maintenance

Battery

pump

without being

20-second

Error

pump

Alarm

will

The

the

START/HOLD

Alarm

will

approximately

alarm

alarm

placed

long

alarm

two

motor

and

may

LO

and

display

be

on

BATT

display

cycles

“LO

acknowiedged

key

twice.

the

alarm

“FLO

(i.e.,

(cont.)

BATT”

The

charger

before

set

when

by

pump

base

disabling

ERR”

is

empty

placing

before

when

the

battery

the

will

run

turning

itself.

no

drops

or-flow

voltage

pump

for

:

is

restricted).

15

minutes

itself

have

on

off.

been

drops

the

charger

in

The

detected

below a preset

base

the

low

battery

pump

will

within

or

by

give

we

a

Dose

The

Delivered

pump

will

programmed

not

occur

Hold

The

2.5

minutes.

Alarm

The

following

1.

Turn

2.

Remove

3.

The

when

Error

pump

will

Test

audible

steps:

the

pump

alarm

dose;

the

Alarm

alarm

Any

alarm

pump

the

pump

should

Alarm

and

i.e.,

pump

and

press

and

on

and

generate

display

when

display

of

any

the

set

set

from

is

in

pump

any

“DOSE

the

volume

the

intermittent

“HLD

key

(except

set

safety

non-zero

the

pump

the

audible

DEL”

counter

ERR”

the

interlock

rate.

(if

loaded)

alarm

when

equals

feeding

when

ON

key)

and

the

pump

the

mode.

the

pump

restarts

may

be

and

push

display

has

dose

setting.

is

left

the

2.5

tested

the

START/HOLD

‘‘no

SEt.”

delivered

This

in

the

HOLD

minute

by

performing

the

alarm

state

timer.

the

key.

does

for

Page 9

2.

maintenance

(cont.)

recommended

SERIAL

EQUIPMENT

CONTROLNO:

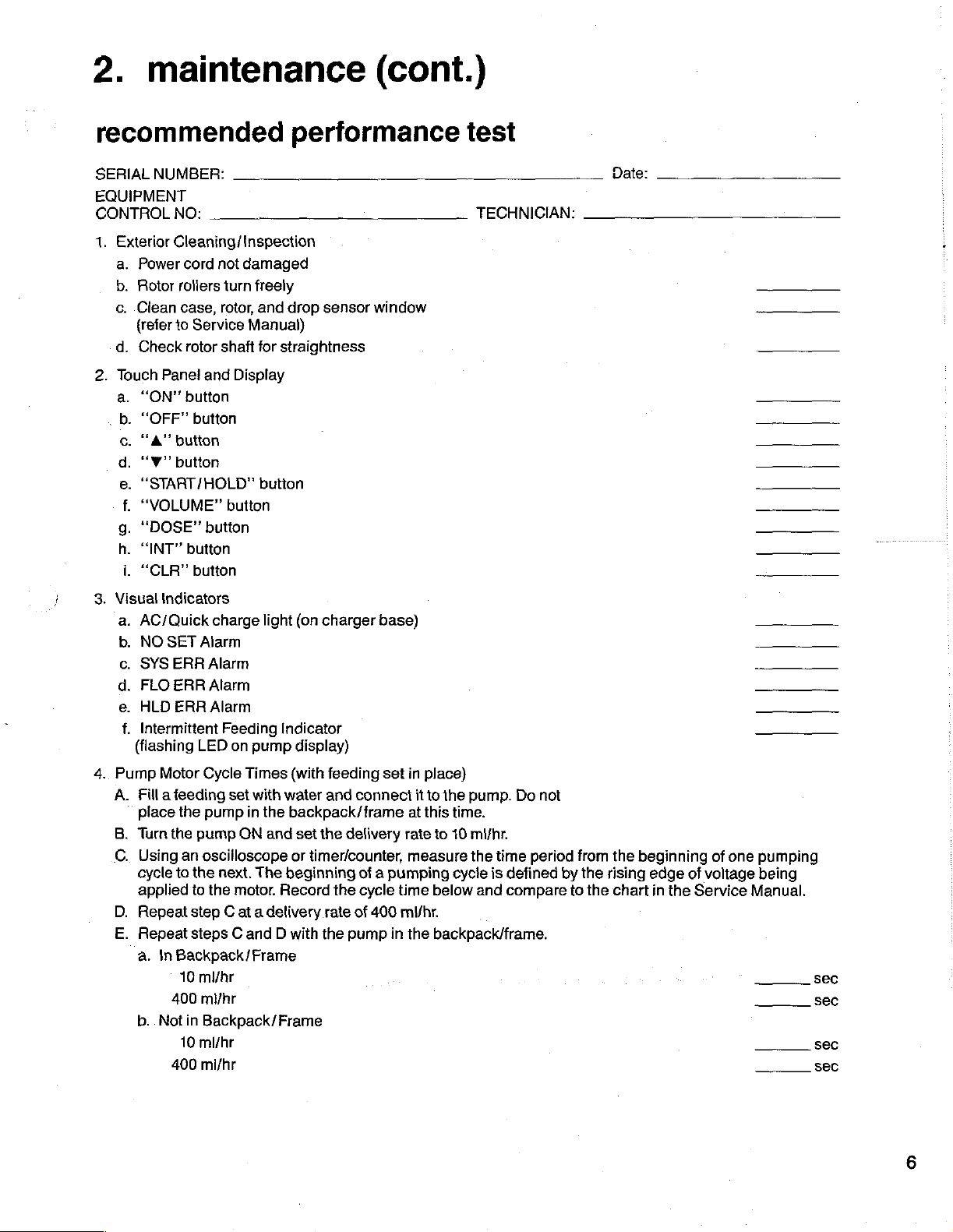

1.

2.

NUMBER:

Exterior

a.

Power

b.

Rotor

c.

Clean

(refer

d.

Check

Touch

Panel

a.

“ON”

.

b.

“OFF”

c.

“A”

d.

“Y”

e.

“START/HOLD"

f.

“VOLUME”

g.

“DOSE”

h.

“INT”

i.

“CLR”

Cleaning/Inspection

cord

not

damaged

rollers

turn

case,

rotor,

to

Service

rotor

button

shaft

and

Manual)

Display

button

button

button

button

button

button

button

performance

freely

and

drop

sensor

for

straightness

button

test

Date:

TECHNICIAN:

window

3.

Visual

4..

A.

B

C.

D.

E.

Pump

.

Indicators

AC/Quick

NO

SET

SYS

ERR

FLO

ERR

appa

HLD

ERR

.

Intermittent

-0

(flashing

Motor

Filla

feeding

place

the

Turn

the

Using

an

cycle

to

the

applied

Repeat

Repeat

a. In

b..

to

step C at a delivery

steps C and D with

Backpack/Frame

10

400

Not

in

10

400

charge

light

Alarm

Alarm

Alarm

Alarm

Feeding

LED

on

Cycle

set

pump

pump

oscilloscope

next.

the

ml/hr

mi/hr

Backpack/Frame

ml/hr

mi/hr

pump

Times

with

in

the

ON

and

The

motor.

Indicator

water

Record

(on

charger

display)

(with

feeding

and

base)

set

connect

backpack/frame

set

the

delivery

or

timer/counter,

beginning

of a pumping

the

cycle

rate

of

the

pump

400

in

place)

it

to

the

at

this

rate

to

measure

time

below

mi/hr.

in

the

backpack/frame.

pump.

time.

10

mi/hr.

the

cycle

and

Do

time

is

defined

compare

not

period

by

from

the

to

the

the

beginning

rising

chart

edge

in

the

of

one

of

voltage

Service

pumping

being

Manual.

sec

sec

sec

sec

Page 10

2.

maintenance

(cont.)

recommended

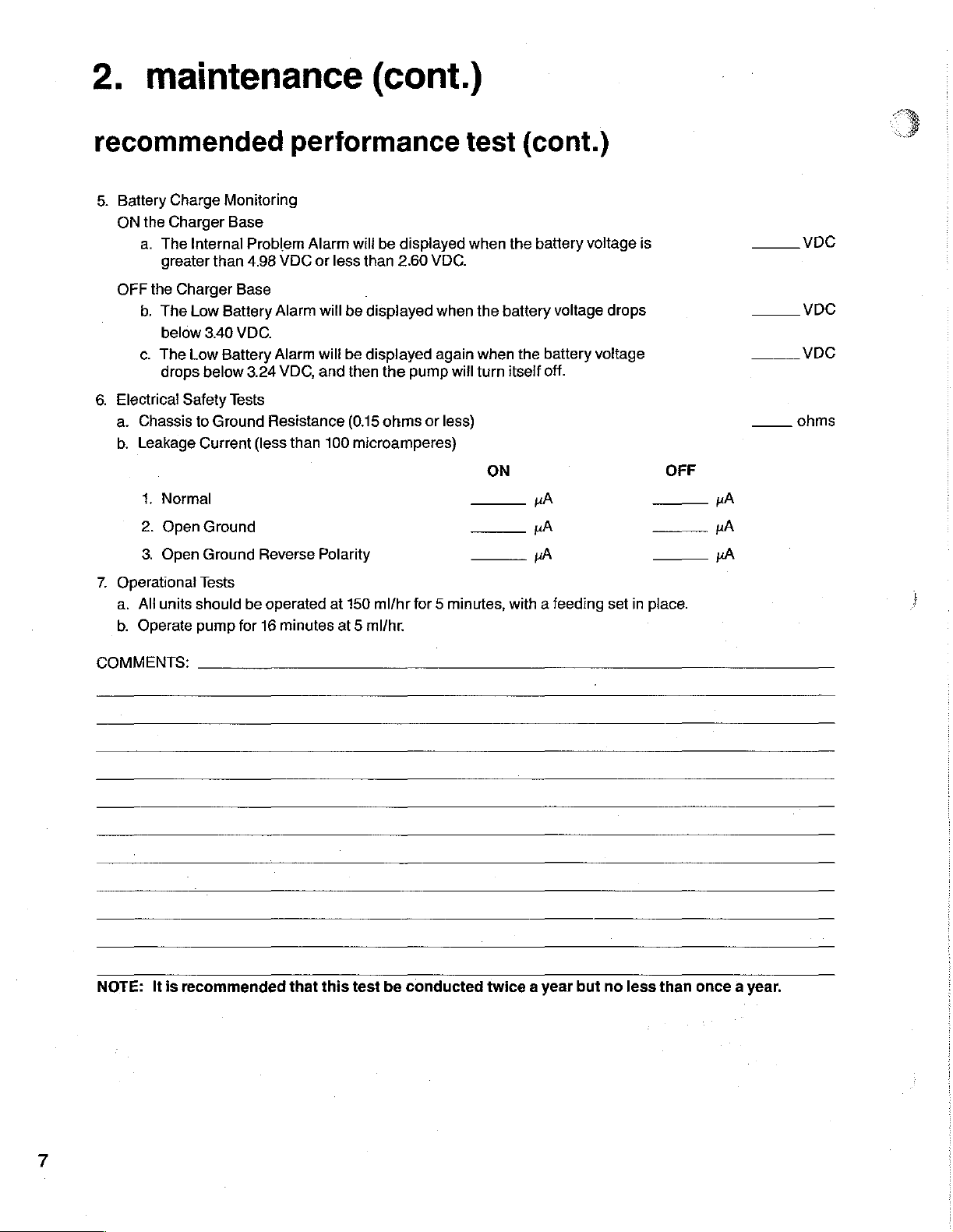

5.

Battery

ON

OFF

6.

Electrical

a.

b.

7.

Operational

a.

b.

Charge

the

Charger

a.

The

Internal

greater

the

Charger

b.

The

Low

below

c.

The

Low

drops

Safety

Chassis

Leakage

1.

2.

3.

All

Operate

to

Normal

Open Ground

Open Ground

units

should

Monitoring

Base

than

Base

Battery

3.40

VDC.

Battery

below

Tests

Ground

Current

Tests

pump

for

Problem

4.98

3.24

be

performance

Alarm

will

VDC

or

less

than

Alarm

will

be

displayed

Alarm

wili

be

displayed

VDC,

and

then

Resistance

(less

than

Reverse

operated

16

minutes

(0.15

100

microamperes)

Polarity

at

150

at 5 ml/hr.

be

displayed

2.60

the

pump

ohms

ml/hr

for 5 minutes,

VDC.

when

again

or

less)

test

when

the

when

will

turn

ON

—

(cont.)

the

battery

battery

the

itself

нА pA

pA

HA

with a feeding

voltage

voltage

battery

off.

is

drops

voltage

set

in

—

—

place.

OFF

HA

A

—

vDC

VvDC

vDC

ohms

COMMENTS:

NOTE:

It

is

recommended

that

this test

be

conducted

twice a year

but

no

less

than

once a year.

Page 11

2.

maintenance

(cont.)

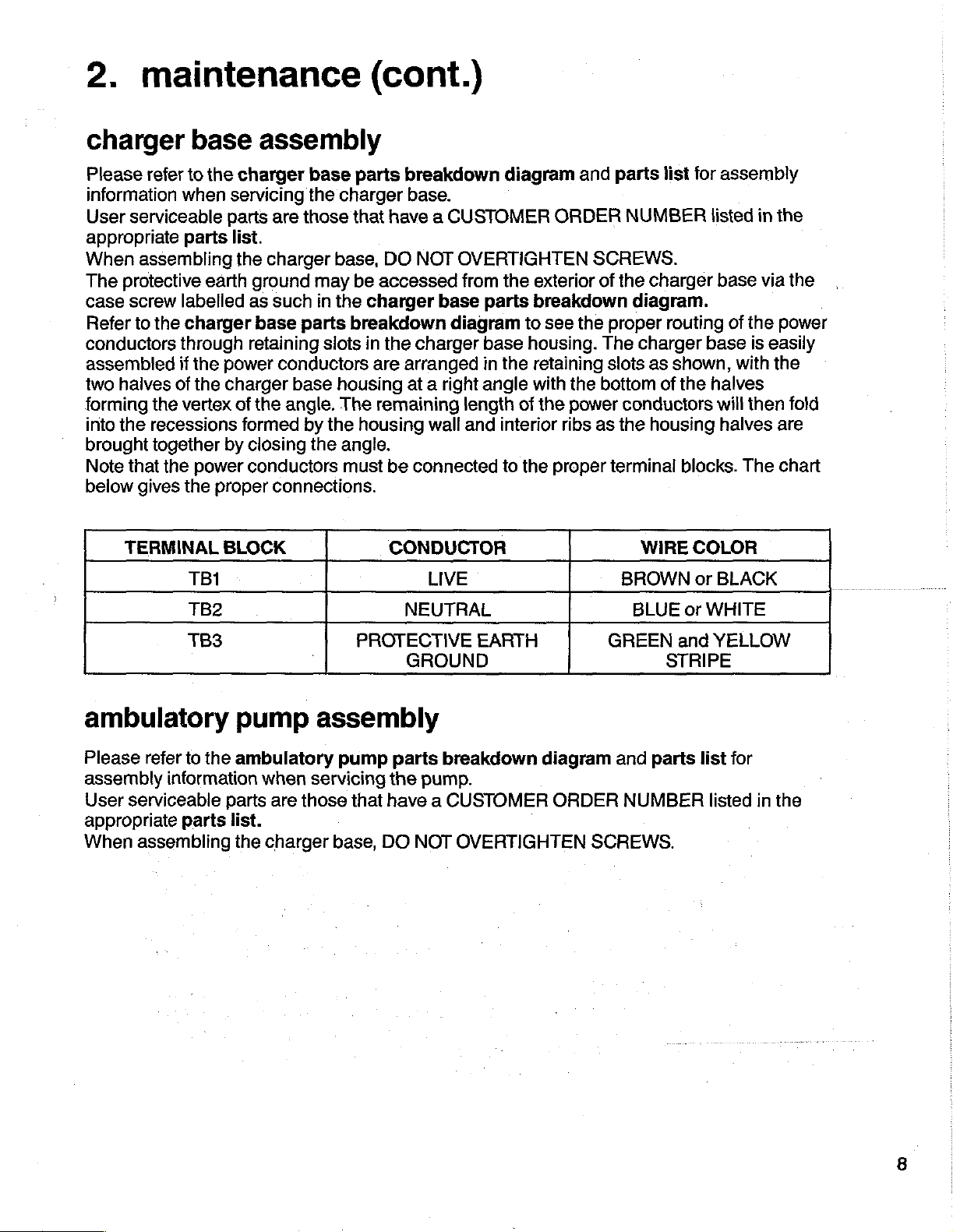

charger

Please

information

User

serviceable

appropriate

When

The

case

Refer

conductors

assembled

two

forming

into

brought

Note

below

assembling

protective

screw

to

haives

the

that

gives

TERMINAL

base

refer

to

the

when

parts

labelled

the

charger

through

if

of

the

vertex

recessions

together

the

the

earth

the

the

power

proper

TB1

TB2

TB3

power

charger

by

BLOCK

servicing

parts

list.

the

of

assembly

charger

ground

as

base

retaining

the

formed

closing

conductors

base

the

are

those

charger

may

such

in

parts

conductors

base

angle.

by

the

connections.

charger

base,

the

breakdown

slots

housing

The

the

angle.

must

parts

that

be

PROTECTIVE

breakdown

base.

have a CUSTOMER

DO

NOT

accessed

charger

in

the

are

remaining

housing

be

CONDUCTOR

base

charger

arranged

at a right

wall

connected

LIVE

NEUTRAL

GROUND

diagram

OVERTIGHTEN

from

the

exterior

parts

diagram

base

in

angle

length

and

EARTH

breakdown

to

housing.

the

retaining

with

of

the

interior

to

the

and

ORDER

see

the

the

power

ribs

proper

parts

NUMBER

SCREWS.

of

the

charger

diagram.

proper

The

charger

slots

as

bottom

conductors

as

the

housing

terminal

WIRE

BROWN

BLUE

GREEN

list

for

listed

routing

base

shown,

of

the

halves

will

blocks.

COLOR

or

BLACK

or

WHITE

and

YELLOW

STRIPE

assembly

in

the

base

via

of

the

power

is

easily

with

the

then

halves

The

are

chart

the

fold

ambulatory

Please

assembly

User

appropriate

When

refer

to

the

information

serviceable

parts

assembling

pump

ambulatory

when

paris

are

those

list.

the

charger

assembly

pump

servicing

base,

parts

the

that

have a CUSTOMER

DO

breakdown

pump.

NOT

OVERTIGHTEN

diagram

ORDER

SCREWS.

and

parts

NUMBER

list

for

listed

in

the

Page 12

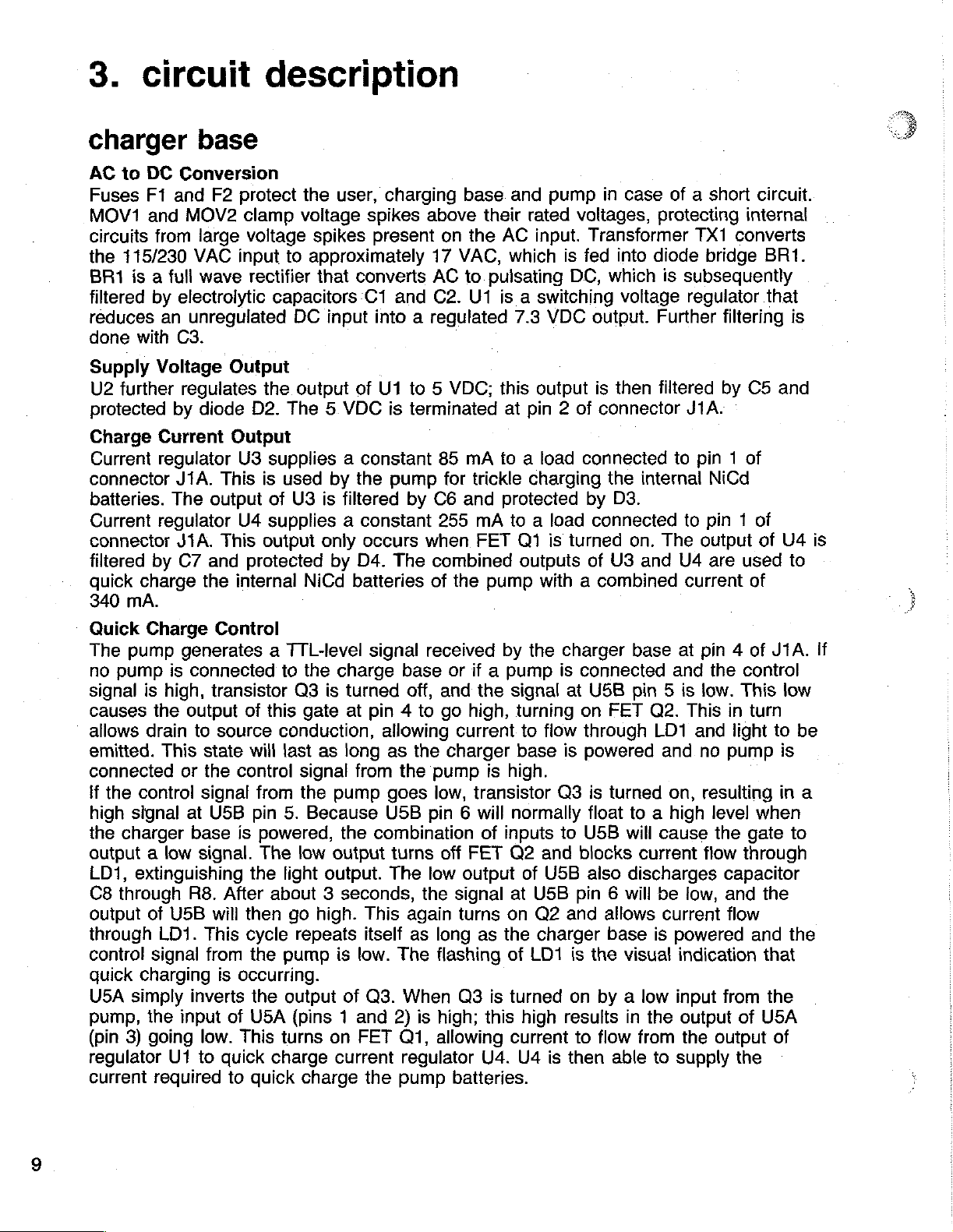

3.

circuit

description

charger

AC

to

DC

Conversion

Fuses

MOV1

circuits

the

BR1

filtered

reduces

done

Supply

U2

protected

Charge

Current

connector

batteries.

Current

connector

filtered

quick

340

F1

and

and

from

115/230

is a full

by

electrolytic

an

with

C3.

Voltage

further

by

Current

regulator

J1A.

The

regulator

J1A.

by

charge

mA.

regulates

C7 and

base

F2

protect

MOV2

VAC

unregulated

large

input

wave

Output

diode

Output

U3

This

output

U4

This

the

internal

clamp

voltage

rectifier

capacitors

the

D2.

supplies a constant

is

of

supplies a constant

output

protected

the

user,

voltage

spikes

to

approximately

that

converts

:C1

DC

input

output

The

used

U3

NiCd

of

5.

VDC

by

the

is

filtered by

only

occurs

by

D4.

batteries

charging

spikes

present

and

base.

above

on

the

17

VAC,

AC

to

C2.

U1

their

pulsating

into a regulated

U1

to 5 VDC;

is

terminated

85

mA

pump

The

for

trickle

C6

and

255

mA

when

FET

combined

of

the

pump

and

rated

AC

which

pump

input.

in

voltages,

Transformer

is

fed

into

DC,

which

is a switching

7.3

VDC

output.

this

output

at

pin 2 of

fo a load

charging

protected

to a load

Q1

outputs

with a combined

is

connector

connected

by

connected

is

turned

of

then

the

D3.

U3

case

of a short

protecting

diode

is

voltage

Further

filtered

to

internal

on.

The

and U4

circuit.

internal

TX1

converts

bridge

BR1.

subsequently

regulator

that

filtering

by

C5

is

and

J1A.

pin 1 of

NiCd

to

pin 1 of

output

are

current

of

used

of

U4

to

is

%

Quick

The

no

signal

causes

allows

emitted.

connected

if

high

the

output a low signal.

LD1,

C8

output

through

control

quick

USA

pump,

(pin

regulator

current

Charge

pump

pump

generates a TTL-level

is

connected

is

high,

the

output

drain

This

or

the

control

signal

charger

at

base

extinguishing

through

of

R8.

U5B

LD1.

signal

charging

simply

3)

inverts

the

input

going

U1

required

Control

transistor

of

to

source

state

will

the

control

signal

USB

from

pin

is

powered,

The

the

After

will

then

This

cycle

from

the

is

occurring.

the

of

USA

low.

This

to

quick

to

quick

signal

to

the

charge

Q3

is

turned

this

gate

at

conduction,

last

as

long

signal

the

pump

5.

Because

the

low

output

light

output.

base

pin 4 to

allowing

as

from

the

goes

USB

combination

turns

The

about 3 seconds,

go high.

repeats

pump

output

(pins 1 and

turns

charge

charge

This

itself

is

low.

of

G3.

on

FET

current

the

The

When

2)

G1,

regulator

pump

received

or

off,

and

go high,

current

the

charger

pump

low,

pin 6 will

off

low

output

the

signal

again

as

turns

long

flashing

O3

is

high;

allowing

batteries.

by

the

if a pump

the

signal

turning

to

flow

base

is

high.

transistor

normally

of

inputs

FET

Q2

and

of

at

U5B

on

Q2

as

the

charger

of

LD1

is

turned

this

high

current

U4.

U4

charger

is

connected

at

U5B

on

through

is

powered

Q3

is

float

to

U5B

blocks

U5B

also

pin 6 will

and

is

the

on

results

to

is

then

base

pin 5 is

FET

Q2.

LD1 and

and

turned

to a high

will

cause

current

discharges

be

allows

base

current

is

visual

by a low

in

the

flow

from

able

to

at

pin 4 of

and

the

control

low.

This

This

in

turn

light

no

pump

on,

resulting

level

the

gate

flow

through

capacitor

low,

and

flow

powered

indication

input

from

output

the

supply

of

output

the

J1A.

to

in

when

the

and

that

the

U5A

of

If

low

be

is

a

to

the

Page 13

3.

circuit

description

(cont.)

ambulatory

pump

Microprocessor

Microprocessor

Motorola

groups

digit

outputs.

driven

in a 1

here)

Power

The

base.

battery

operate

and

Power

levels

MC68HC705C8

of

eight.

driver.

Ports C and D are

by

a 4

us

minimum

has

approximately 8 Kbytes

Supply

pump

The

pack

from

battery

from

are

boosted

significantly

produces a regulated 5 VDC.

connected

U13,

or

U6.

source

U13

outputs

of

power.

regulates

of

U4

Port A drives

FETs

and

MHz

can

receive

pump

contains

connects

the 5 VDC

are

prevented

the

acceptable

less

than 5 VDC.

to

J2.

The

The 5 VDC

the

U7

and

controls

8-bit

the

keypad

crystal

oscillator

instruction

power

three

to

the

output

from

here

because

output

output

output

U6

of

power

all

operations

processor

the

LED

rows,

used

for

execution

of

from

sub-C

pump

of

the

backdriving

sources

the

The

output

The

output

of

U7

of

U7

U7

down

the

drop

of

the

with

32

display

and

segments;

also

miscellaneous

that

clocks

time.

ROM

its

internal

NiCd

circuit

The

and

NiCd

cells

board

charging

each

is

fed

to

switching

input

drives

to

U2

of

U2

of

U2

the

remaining

is

also

fed

to 4 VDC.

detection

pump

I/O

and

lines

available,

charging

Port B drives

reads

the

keypad

non-bussed

the

internal

circuit

processor

144

bytes

batteries,

of

RAM

with a capacity

via

connector

base.

The

other

charging

by

diodes

voltage

is

unregulated

in

turn

drives.

is

also

used

to

pump

to

FET

Q7

to

This

voltage

circuit.

columns

1/0.

base.

divided

The

This

into

the

LED

and

processor

at 2 MHz,

(in

the

configuration

internally.

or

from

the

charger

of

J6.

1800

The

mAh.

pump

currents, 5 VDC,

D1,

D10,

and

booster

and

regulator

drive

circuit

create a switched

feeds voltage

U2.

Voltage

sometimes

U7

which

the

pump

not

driven

inverter

is

a

four

display

SW1

is

resulting

used

The

may

also

D16.

motor

by

U2,

U6;

Power-On

The

pump

Activating

from 5 VDC)

the

microprocessor

the

processor

U9

and

controls

power

because

latch

be

the

pump

The

circuit

generated

microprocessor,

microprocessor

been

the

latch

latch

will

is

turn

Circuit

circuit

this

normally

that

turns

Q4

and

FET

Q18.

from

all

U9

is a CMOS

and

by

circuit.

pressed,

because

is

disabled.

disabled, a RESET

on.

The

microprocessor

purpose

of

this

may

be

activated

open

is

connected

is

already

on

the

rest

the

resistors

Q18

lies

in

pump.

circuits

IC. A negative

©18

if

not

already

the

regulators

turning

also

it

monitors

constant

If

the

pump

pulse

microprocessor

will

turn

on

and

arrangement

in

switch

powered

and

the

except

creates a negative

to

the

IRQ

of

the

capacitors

main

for

turned

and a pulse

on.

The

/O

current

is

connected

will

be

will

not

only

activate

is

to

enable

two

ways.

line

when

pump

The

of

the

this

occurs,

circuit

if

connected

ground

the

going

latch,

pulse

on.

If

will

path,

which

from

the

latch

be

generated

microprocessor

line

PC1.

regulator

generated

see a low

the

PC1

Q10

to

an

as

on

timing

processes

microprocessor

first

is

by

pressing

going

pulse

(dropping

microprocessor

an

interrupt

not

already

to

them

and

is

draws

the

and

will

then

will

only be low

keeps

active

charger

above,

PC1

however,

turned

form a latch

used

to

negligible

ON

key

Q18

turn

to

the

turn

C45

charged

base

and

the

in

the

to

start.

the

ON

to

and

to

U9

pin

is

generated

on.

that

completely

power

will

turn

on,

RESET

on

the

if

the

on

power

input

rest

ON

key

remove

of

even

while

the

microprocessor

so

the

software.

quick

The

charging

key.

ground

2.

If

and

the

will

of

the

has

when

the

10

Page 14

3.

pump

was

Removal

circuit

battery

not

activated

of

power

accomplished

power

to

all

circuits

description

as

soon

and

to

by

asserting

as

the

the

ON

the

microprocessor

port

except

for

pump

switch

PCO.

Q10

is

plugged

was

This

and

(cont.)

into

the

not

pushed.

and

the

rest

turns

U9.

off

the

charger

of

the

latch

base,

pump

and

even

circuits

FET

Q18,

if

the

is

killing

latch

ED

v

Reset

The

as

result

U12

pulse

constantly

U12

will

isolate

Battery

Resistors

Circuit

microprocessor

seen

earlier,

in a pulse

is a watchdog

every

250

reset,

also

monitors

generate a reset

U12

power

Monitoring

R5

and

A/D converter

bits

are

read

serially

milliseconds

Software

quick

U11)

Touch

The

charging

to

deliver

Panel

touch

arranged

PB3.

Microprocessor

microprocessor

represent

not

part

this

switch

displayed

lines

from

(or

in

the

panel

in a 3x3

each

of

the

is

driven

on

the

each

may

is

the

generated

timer

milliseconds.

U12

its

from

R6

into

an

every

receive a low

activation

by

and

power

will

generate a pulse

supply

pulse

divide

eight

by

other

voltage.

to

the

the 5 VDC

the

bit

the

microprocessor

resetting

microprocessor

is

necessary,

quick

charge

is

connected

matrix,

ports

decodes

switch

matrix.

Microprocessor

by

LEDs.

other.

Switch

in

PBO.

port

current.

with

PB4,

the

row/column

the

matrix.

Switch

Diodes

input

of

the

latch

circuit.

R12

and

C11.

monitor.

This

pulse

train

at

If

its

supply

microprocessor.

buss.

battery

voltage

representation

using

of

the

watchdog

determines

PC5

to

the

pump

the

rows

PB5

and

It

should

SW1

D4A,

D4B,

debouncing

when

signals

circuit

being

PB6

information

ports

is

used

PB4,

D18A, D18B,

is

on

the

RESET

Power

The

microprocessor

resets a timer

its

output

drops

Diode

by

2;

of

one

ports

the

the

charger

board

driven

read

the

be

noted

PB5

to

select

applied

which

below

D9 and

this

voltage

half

of

PC7,

timer

battery

with

by

microprocessor

column

and

that

and

the

D12,

accomplished

line

for

three

to

the

reasons.

pump

generates a negative

in

U12.

If

this

timer

will

reset

the

microprocessor.

approximately

capacitor

is

then

the

battery

PC6,

U12).

needs

base

(isolated

connector

voltage.

and

to

be

4.5

C43

converted

PDO

every

quick

by

optoisolator

J5.

The

ports

information.

generates a unique

the

ON

key

PB6

also

read

language

D13A

in

and

software.

Software

is

independent

switch

for

messages

D13B

isolate

The

circuit

is

not

VDC,

somewhat

by

The

eight

500

charged.

panel

PB1,

PB2

byte

to

SW1

parallel

first,

will

going

U12

the

If

is

and

in

the

and

when

.

Så

11

LED

Display

LEDs

messages.

Q13

DP4,

DP3,

Microprocessor

respectively.

connections

by

port A of

drive

the

the

display

DP2

and

DP1

The

FETs

than

possible

with

microprocessor.

segments.

are

used

to

ports

PB3,

PB2,

allow a greater

the

microprocessor

These

I/O

display

PB1

current

lines

feeding

and

flow

are

profile

PBO

drive

to

the

I/O

ports.

capable

information

FETs

LED

segment

Segment

of

sinking

and

Q16,

Q15,

Q14

common

information

enough

current

error

and

is

driven

to

Page 15

3.

Drop

The

Two

through

photodiode

drip

through a sixth

to

surrounding

then

circuit

Detector

pump

IR

chamber

the

monitors

LEDs

are

J3

pins 3 and

is

protected

yoke.

order

microprocessor.

passive

input

to

the

Motor

The

pump

is

controlled

on

simultaneously,

motor

by

microprocessor

surrounding

before

applying

removed

RC

before

Fail-Safe

In

the

unlikely

circuit

Q3

the

Q2

O1

F1.

will

gets

voltage

turns

turns

The

its

fail-safe

event

crowbar

power

at

the

on,

raising

on

and

description

fluid

flow

by

optically

driven

microprocessor.

is

FET

controls

networks.

power

applying

from

anode

allows

circuit

by

constant

4. A photodiode

from

the

The

signal

low-pass

The

networks.

connected

Q6.

The

and

are

the

through

from

filter,

signal

The

to

motor

time

motor

The

RC

Q6;

dynamic

that

the

motor

the

power

the

the

current

takes

supply

motor

of

Q2

exceeds

voltage

from

approximately

effects

from

the

delayed

circuit;

at

the

(cont.)

detecting

current

the

amplified,

output

pump

is

also

from

networks cause

conversely,

brake

should

to

gate

the

source

is

likewise

of

visible

photodiode

chopped

the

photodiode

of

this

circuit

braked

so

that

they

port

TCMP.

power

Q5.

continuously

ground

as

the

battery

and

the

motor

voltage

of

Q1.

to

13

seconds

connected

processing

When

drops

Q11

failing

and

connected

to

light

by a polysulfone

is

amplified,

and

finally

is

processed

is

board

by

pass

FET

never

This

the

dynamic

to

run

blow

runs,

on

the

directly

to

by

connector

Q5.

Q6

transition

signal

the

motor

and

fuse

Fi.

Q3

gate

the

gate

trip.

through

J3

pins 1 and

differentiated,

then

and

the

to

the

filter

squared

by

U5

and

buffered

J2.

Power

Q5

are

integral

for

simultaneously.

is

buffered

brake

through

not

turn

Constant

charges

(set

by

of

Q1

through

by

O5

to

Q6

off, a fail-safe

current

capacitor

divider

rises

above

it

to

ground,

drip

chamber.

circuit

2.

board

The

to

passed

the

presentation

the

by U1

never

and

to

the

turned

motor

The

U1

and

the

be

released

is

always

regulator

C3.

When

R1

and

R2),

ground,

blowing

Rotor

The

the

Detection

microprocessor

interaction

of 3 magnets

microprocessor

in

software.

Frame

The

effect

pocket

Pump

The

switch

the

arm

Audio

Audible

board

port

Detection

microprocessor

switch

Set

microprocessor

S2. A magnet

in

the

frame.

Detection

connected

pump

set

and

the

Alarm

alarms

through

PC3

is

activates

loading

connector

boosted

monitors

receives

detects

detects

to

the

the

arm

are

generated

by

U14

the

in

pump

switch

is

then

J4.

and U15

the

rotation

on

the

signal

the

presence

the

frame

the

presence

circuit

when

pump

from

of

rotor

S1

of

will

of a pump

board

the

the

with

on

port

the

close S2

through

pump

closed.

using a piezoelectric

The

TTL-level

to a

oscillation

20

VDC

.

DC

motor

Hall-effect

PD5.

Debouncing

backpack

when

set

on

J1

pins

set

is

properly

element

generated

level.

by

counting

switch

frame

the

pump

port

on

PD7,

4, 5 and

inserted

connected

by

pulses

S1.

of

port

is

fully

using a Hall-effect

6.

The

to

the

microprocessor

The

this

switch

PD3,

inserted

SIPS

into

the

the

pump

generated

occurs

using

Hall-

into

magnet

loading

circuit

by

its

on

at

12

Page 16

3.

circuit

language

description

selection

(cont.)

Sage”

E

Selection

the

rotary

by

placing

the

battery

the

CLR

the

the

language

key

top

inside

and

the

numbers

at

of

the

language

switch

the

compartment.

battery

increase

of

mounted

tip

of a small

compartment.

display

while

the

simultaneously

as

switch.

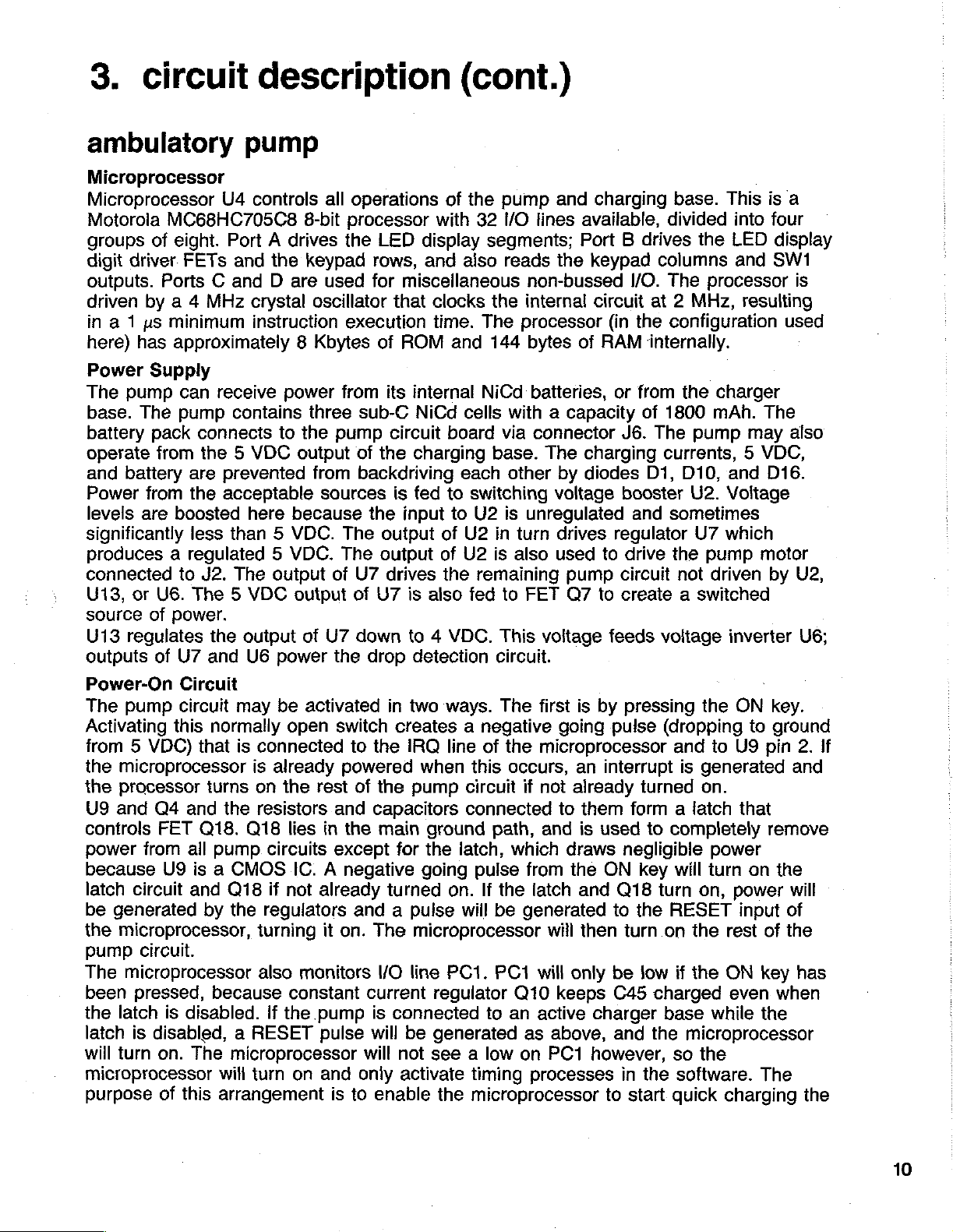

SWITCH

POSITION

the

0

1

2

3

4

5

6

7

8

9

used

for

the

pump

on

the

pump

flat-bladed

This

access

The

text.

The

switch

is

#

English

English

screwdriver

hole

chart

language

turning

rotated

LANGUAGE

(U.S./Canada)

English

(UK/Australia)

German

French

Halian

Swedish

Spanish

(U.S./Canada)

English

(UK/Australia)

display

circuit

or

Dutch

or

board.

is

located

below

the

in a clockwise

Japanese

Japanese

shows

display

pump

is

determined

This

into

the

next

to

the

text

may

on.

Note

direction.

rotary

DISPLAY

switch

switch

the

right-hand

switch

be

accessed

that

the

TEXT

CUS

EnA

GEr

nEth

FrA

itA

Sdn

ESP

CUS

EnA

by

the

position

may

access

settings

Switch

hole

switch

position 0 is

be

rotated

inside

screw

by

country

by

pressing

setting

of

hole

Page 17

4.

printed

circuit

boards

charger

125MA

ТВТ

OR

250v

Fİ

base

schematic

diagram

fP

1

|

U1

LM2575

—ADJ

3|

Isla

IN5817

2

D1

L1

1

MH

一 一 一

^

Ri

10K

1/8W

M

i

MOV!

Мо

182

125MA

250V

TB3

THE

3.

2.

1.

р)

RESISTORS

CAPACITORS

77777

CHASIS

1/4W

ARE

GROUND,

,

5%

CARBON

TANTALUM

Å

UNLESS

SYSTEM

=

FILM

UNLESS

OTHERWISE

GROUND.

BRI

Le

АЕ.

OTHERWISE

SPECIFIED

ce

47/

35VDC

ЕЕ

SPECIFIED.

{VALUES

IN

MICROFARAD).

ew

=

1%

Page 18

Page 19

uz

RS

1/8W

1%

[66100

μη

77907

000

U3

=>)

N

[171086

iL)

一

——

TFT

|

(H3)

一

—

1086]

IN

|!

OUT A vis

|

十

一

十

out

oyn

OUT

Jl

3

L

L

=

22/

10006

»

Co

ee

10VDC

2N3906

1

CER

R4

izin

1/8W

1%

ce

03

((P9)

RE

бо | INS817

RT

ato

了

R10

49.9K

VEN

Da

(РЭ

οἱ

|

i

|

Œ

;

i

|

!

1

i

i

τῷ

|

1000/

|

16006

AL.EL

if

|

(LOW

| 1

LD1

HLMP

1520

R3

1202

ESR)

LE

]

Lio

9123

+

|

3

À

2

A,

|

uz

|

CS

100/

10vDc

D3

时

4

{

1N5817

R9

12K

|

RU

WW

2.2K

ei

ペーー

JIA

STANDARD/QUICK

CHARGE

REGULATED

GROUND

STANDARD

ト

CHAR6E

/QUICK

CONTROL]

|

7

5

5)

バジ

Page 20

Page 21

charger

base

PCB

assembly

TP4

ar

р

LI

E

Cg

diagram

Fa

i

Ú3(

OLD1

U4

UUU

MEDICAL

CHARGING

BASE

UNIT

ce(

GS1

|)

ВВ!

一

7p3

C7

C1

一

α΄

SECONDARY

一

©

=

©

|

ra

2

Μον2

TP7

LU

|

D4

|P

C3

ma

a3<

|

Ra

92

R11

4

UNU

Ro]

J

4

1

b2

[70

—

ППП

Lol?

1A

©

pee

レー

N_

C5

$

115

1181

C

220

- =

PRIMARY

PA

-

115

Cemi

TX1

LO

dk

00593

00595

REV

Γ

Fe

===

TB3

TB2

El

ノ

Page 22

Page 23

parts

list

REORDER

7774101682

7774-101955

7774102003

-

7714102029

7774102060

7774102078

7774-200427

7774-202563

7774-202571

7774-300441

7774-300466

7774-300730

7774-030089

7774-030865

7774-030006

7714-030014

7774-400753

7774-040104

7774-401611

7774-402684

7774-402866

7774-404144

7774-040427

7774-406248

7774-406586

7774-406594

7774-406602

7774-500818

7774-050186

7774-501717

7774-501733

7774-501741

7774-501766

7774-501899

7774-600618

7774-802669

7774-802776

7774-400613

7774-302785

7774-310457

NOT

AVAILABLE

7774-802974

7774-501725

NO.

FUSE

CLIP

18

AMP

1MH

INDUCTOR

HEAT

SINK

HEAT

SINK

TRANSFORMER

QUAD

1.5A

LOW

STEP-DOWN

MOSFET

PNP

TRANSISTOR

SCHOTTKY

HEXFET

140

VOLT

BRIDGE

47

VOLT

49.9K

OHMS

120

OHMS

12K

OHMS

2K

OHMS

2.2K

OHMS

10K

OHMS

330

OHMS

383

OHMS

121

OHMS

15

OHMS

4.7

OHMS

10

UF

SOLID

100

UF

47

UF

AL.

100

UF

22

UF

SOLID

1000

UF

0.1

UF

GREEN

4

PIN

FRICTION

TERMINAL

NO.

4-40

NO.

4-40 x %

CHARGER

| THERMAL

TEST

PIN

1000

UF

DESCRIPTION

FAST

ACTING

NAND

CERAMIC

4093

DROPOUT

VOLTAGE

TRANSISTOR

DIODE

TRANSISTOR

VARISTOR

RECTIFIER

VARISTOR

4W

%W

5%

%4W

5%

WW

1%

Ya W 5%

74W

1%

WW

5%

14W

1%

14W

1%

%4W

5%

%4W

5%

TANTALUM

SOLID

AL.

TANTALUM

ELECTROLYTIC

ELCTROLYTIC

TANTALUM

ELECTROLYTIC

CAPACITOR

LED

T-1

UNTINTED

LOCK

BLOCK

KEP

NUT

PAN

GROUND

JOINT

AL.

ELECTROLYTIC

FUSE

115/230

1%

RESISTOR

RESISTOR

COMPOUND

VAC

POS.

REGULATOR

REGULATOR

IRFD9123

2N3906

1N5817

123

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

CAPACITOR

CAPACITOR

CAPACITOR

CAPACITOR

CAPACITOR

CAPACITOR

HEADER

HEAD. X REC.

STRAP

CAPACITOR

QTY

4

__|

2 | Fi,

1

2 | USEDWITMU3,U4

1

1

1

3 | U2,

1

1

1

4 | Di,

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

i

1

1

2 | С6,

1

1

1

1 | JIA

3 | TB1,TB2,

3_ | USED

3. | USED

1

AR | USED

1

DESIGNATION

USED

F2

11

USED

(TX

US

U3,

ui

οἱ

|Q3

D2,

02

MOVI

BRI

MOV2

Rio

АЗ

Rg

R2

ATİ

RI

R8

RS

R4

R6

R7

C8

C5

C2

C4

С7

C1

C9

LDI

GS1

TP1

C3

WITH

WITH

U4

D3,

TB3

WITH

WITH

WITH

F1,

U2

D4

U2,

U2,

U2,

F2

U3,

U3,

U3,

U4

U4

U4

}

15

Page 24

Page 25

4.

printed

circuit

boards

(cont.)

pump

schematic

τι

R56

1000

R26

100K

diagram

>

1/8W

1

LI

47

U2

LT1110CS8

6]

8]

475

|

|

T6

UH

D2

1N58

18

T2

R27

as

2|

T10

SPT

от

yi

11

sel

T11

O

?

—

|!

|

|

ヒーーー

—

PAD

©

©

PICK-UP

7

Ll

|

|

FOR

TERMINAL

a

WIRE

SOLDERING

OUT

8

1

049

4.7UF

16VDC

TANT

U15

CD40

|

|

で

—

14

106BM

7

]

3

ン

i

o

IN

R39

10K

LT

>

U14

1026C%

3

Ll

LE

T-

046

Е

4

16VDC

TANT

M

|

MODULAR

SCHEMATIC

Page 26

Page 27

97

TP0602N3

D

G

s

73

4.7UF

16VDC

TANT

+)

+

4.

16VDC

TANT

C47

¢

C

(

6

048

7UF

14

3}

шв

PS2505-1

051

10UF

10VDC

TANT

I

TI

>

©

Г

|4

16

Page 28

Page 29

4.

printed

circuit

boards

(cont.)

pump

в

A

MALE

AND

HOUSING

시

a!

[

it

ita: t +

ELT

P

BLACK

PES

Ear

уж. | (©)

so.

ge

Sana.

1. 7 SEGMENT

2.

UNLESS

ALL

ALL

ELECTROLITIC

CAPACITOR

3,

GROUND

4...

„A

MIRE

7

BAM

TP

5 3

\

Y

ou

O

\

asa

Jr

|(G

Apa

cer

Tie

СЫ

i

1

|

!

A-

©

©

©

©

OTHERWISE

RESISTORS

CAPACITORS

SYMBOLS:

REQUIRES

schematic

TERMINALS

(21

때

BAT

q

(+)

o

pte

MBRS

k

de

MIER

Bi

MORS

7

tox | Barra M T

“o

DC

δι

TO

04

>

ΤΡΙ

ΞΒΙΤΕΝ

TP3 = OLIVE

PS = BACK-PACK

TP7 = v

TP9 = DIG

TEN = MOT Y TPII

Ta =v

TP15 = WATCH

TP17

=

FILTER

TP

19 = LO_BAT

‘Tat = -av

TP23

=

CHRG CONT

TP25 = (.R

LED

DIGITS

SPECIFIED:

1/10W 5 PCT

MONOLITHIC

CAPACITORS

VALUES

IN

SHORTEST

7

-75A

je

+

À

os

.-.

fn

TEST

PAD

REG

GND

TP13

DOG

OUT

TPIT

TP19

CUR

TO

BE

CERAMIC

ALUMINUM

MICROFARADS.

W

ANALOG:

AND

VBAT

=

NL

SHOWN

TPI

me

Tea

TPS

구오

TI

0:

189

00-

TPIS

ZE

=ю

TP21

00

ТРЗ

Ol

TP25

Qi

INSTALLED

METAL

THICKEST POSSIBLE

diagram

RI

ag

в

οι

Re

JA

MCR る 178K

ти

KİNE

si,

ROTATED

90“

VS

ーー

poste

FILM

Y

PCB

tê

TP4

Te

Te

TPIO

ТЫ

TPM

¡O

TP16

TPI

Po

TPzz

1824

1026 TP26 = DEAD

WITH

DECIMAL

DIGITAL: 1 SWITCHED

tray

6.

이

DWG.

TRACE.

4

|

1

R3

šk

so

кот

i

i

vB

POINTS

os

LM334M

30-8

a

2N6028

Ra

İK

w

ri

:

|

:

L

ma

38716V

1

è

BAT

AT

TOP

LEFT

SYSTEM

RIT

™

1.5K

1/8

CORNER.

GROUND.

ML

si

トー

R38

OHM

W.

D5

BATIA,

|

Artes

Ê

1%

г

이

이언

elio;

101

TACT

(50-14)

이 나 el

cz

47

52

R52

2.2K

주

:

=

5%

D7

MMBDS

14 E

ot

=

Rzs

13)

14D

14

η

05

$35

이

R24

took

yz

la

l+

1007

*

==

al

3

4fpsz505-1/2

4

I Е Y

ps

站

65-

ую

io

-本 一 一

A

가

rae

100/10V

05

IRFD123

s

5

G

De

entro

1

1

HH

wz.

TANT

@

TANT

o-

2

2

BE)

Е

ca7/+

1007

(5)

©

Ge

TPOB02N3

ce

wl

1

>

ro

る

200K

s 4

U7

fLri1z0

주 | ons

(m

TRI

1.9

Me

3%

RO

SK

© ©

[8]

Geek

ÍTANT

жена

POWER

Ton

pes

Aso.

000.

MES

5

VT

=

aa.

Riz

VBAT

DI

RB400D

6.swvpc し ヨ

Ls

LE

ασ

A

ue

MAX

1232

8

6

7 F

20K

Z

πο

4.77100

+4V

o!

el

2p

T

100/10

TANT

3

ON

LATCH

costo.

BATI,

HOOK-UP

EE

7

'

Re

100K

08

|prettan

2

|

f

>

É

ь:

2

<

pd

Page 30

Page 31

]

l

og

:

E

|

RU

|

+

Ld

4

1

2

£

é

4

1|38|36

Poo

Po7

ecs

RESET

pee

Poo

pps

бы

poz

MV

トー

Y

jas

ВЕН

Е

>

ΜΟΡΘΗΟΤΟΡΟΘΕΝ

44

5

っ a

5

8

2

2

[22

43

RIS

2.2MEG

166

pa

MMBDS

cs

107

tov

TANT

it

ルー]

1

016

R43

100K

i

vy

Ja

Po er

E

>

va

LEAD PLCC

은

은

41

|

=!

4

14)

Y

vu

NZC

ci?

|

2.

-

1

у

la

à

BE

38

à

3

E

9

us

LMF60CWM

-100

tso-14)

e

Jı

İs

5

AAA

|16|15

14119

ава

a

aaa

P86L20

685|

P84[

mes

Lao

Paol12p

PAI

paz

[ιδιο

도모

paola

РАЗ

pns 上 y

ra

РАТЬ

30

pci

PD3

PDI

33

RS232

|

Why

usa

Ма

В.

ROS

9.1K

4

19 _ 4

4

17

+25)

Rs | do

주니

=

91

E

RAS

it

pe

pu

13

№

мл

Lia

2001-

48169700

OHM

750

—

17

ГВ

14

la

に

1-751

18)

NE

τρ

1

di

GRATE

bras

|

||

цу

Ом

8

6

-1

İz

pk

の

5

ЕВЕ

13

a

T3

cas

TANT

piz|

LA

15%

[4

1

b

2

5

5

5

4

3

2

i

o

i

14|3

P|

D13

|

+4V

8

06

TOS962CPA

m

CAN

f

N

V

saimos

1

+

sz

ЗАРЕ

-

3

013

—,

deb

я

Fi

on

ol

的

v

7.54

DIGIT

5

AH)

625

리너

3

Us

|

7

6

4

а

1

Jia

wolf

5

100/10v

TANT

say

915.16

zf

5

es

ñ

η

5

{ops

一

|

一

|

GS3

Xq

3

о

|

T

614 T gl

2

s)

|

|

|

ihh

в

pp4

一 | 一

ГИГИЕНЕ!

一

一

PS4

SD

N

C44

Aloe

TANT

eo

A

016

al,

5

T

」

|

D

,

y

TPOBOENS

joe

fort

一 | 一

一

|

一

—

|

一

CS1

DSz

0050}

i

ci

l

[cis

Tezer

У

RS232

17

Page 32

Page 33

4.

printed

circuit

boards

(cont.)

pump

PCB

assembly

diagram

BLACK

{-}

COMPONENT

SIDE

Page 34

Page 35

İPİN

1

COMPONENT

SIDE

DETAIL

一

655

이그

Я

oe"

R41

日

Π

R40

61000

00

a

R47

R34

SOLDER

ロロ

035

RIS

只

Does

cio

652

SIDE

=

5

τα

026

o

o

o

ο

o

a

ο

o

o

8

o

o

£

Page 36

Page 37

5.

final

assembly

charger

base

parts

breakdown

diagram

Page 38

Page 39

a

El

т

©)

\

WIRE

ROUTING

DETAIL

a

EARTH

ACCESS

GROUND

19

Page 40

Page 41

5.

final

assembly

(cont.)

pump

parts

breakdown

diagram

Page 42

Page 43

5.

final

assembly

charger

ITEM

1

4

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

34B

34C

34D

ЗАЕ

34G

36

37

34F

38

*PART

OF

ITEM

base

REORDER

7774-005933

7774-905934

7774-903889

7774-809516

7774-808625

7774-303213

7774-304849

7774-304864

7774-304948

7774-305002

7774-305010

7774-402429

7774-500131

NOT

7774-807528

7774-807932

7774-309996

7774-310028

7774-310036

7774-310044

7774-310051

7774406327

7774-310499

7774-311034

7774-310788

7774157924

7774-090026

34

(7774-311034)

parts

NO.

7774-154111

AVAILABLE

7774-181007

7774-310010

7774-310127

*

*

*

3

*

*

list

CHARGER

CHARGER

POWER

FUSE

GROUNDING

MYLAR

NO.

NO.

NO.

NO.

STRAIN

NO.

POLE

PERMANENT

DOW

WRITE-ON

SERIAL

FUSE

COUNTERSUNK

POLE

POLE

SLIDELATCH

POLE

BACK

CHARGER

POLE

FRONT

EXTERNAL

ANESTHETICS

DIRECTION

RELEASE

CHARGE

CAUTION

CABLEWRAP

GROUND

WARNING

Ys”

CORD

WARNING

OVERLABEL

4-10 x 4"

6-32 x 1”

4-10 x 46”

2-56 x 2"

RELIEF

4-40 x 4%"

CLAMP

CORNING

NUMBER

REPLACEMENT

CLAMP

CLAMP

CLAMP

SHELL

CLAMP

SHELL

DIA,

PCB

ASSEMBLY

PCB

ASSEMBLY

LABEL

LABEL

SELF-TAPPING

MACHINE

FLAT

HEAD

ELAT

HEAD

FLAT

HEAD

BUMPER

EASTENER

738

ELECTRICAL

LABEL

LABEL

LABEL

WASHER

SCREW

KNOB

CONNECTOR/WIRE

SPRING

ASSEMBLY

CHARGER

LABEL

FOR

USE

LABEL

LATCH

LABEL

ACTIVE

SHOCK

LABEL

SHRINK TUBING

LABEL

HAZARD

LABEL

SCREW

LABELS

DESCRIPTION

(BOARD

SCREW

SCREW,

SCREW

CAP

SCREW

SEALANT

ASSEMBLY

LABEL

EXCHANGE)

QTY

1

1

1

1

1

2

5

2

2

1

1

1

1

AR

1

1

1

1

1

1

1

1

1

1

1

1

1

*

*

*

*

È

1

1

1

AR

20

Page 44

LE

제

Page 45

21

Page 46

Page 47

5.

final

assembly

(cont.)

pump

ITEM

29

30

31

32

33

34

35

36

37

38

39

42

43

44

45

46

47

48

49

51

52

53

54

55

56

57

58

59

parts

1

2

3

4

7

8

list

REORDER

7774-005925

7774-905926

7774405691

7774-106350

7774-106335

7774-701085

777440634

7774-809516

7774-808120

7774-178003

7774-303213

7774-304849

7774-304898

7774-304906

7774-304914

7774-304948

7774-402460

7774-500016

NOT

AVAILABLE

NOT

AVAILABLE

7774-809987

7774-807528

7774-807536

7774-807551

7774-807890

7774-106368

7774-309798

7774-309806

7774-106376

7774-309830

7774-309848

7774-309863

7774-309871

7774-310135

7774-310465

NO.

PUMP

PCB

ASSEMBLY

PUMP

PCB

ASSEMBLY

BATTERY

SWITCH

MOTOR