Sherwood Medical Kangaroo 224, Kangaroo 324 User manual

If

plug

with

cord

completely

CAUTION:

cleaning

and

isopropyl

from

If

cleaning

with

isopropyl

removed.

Avoid

as

of

the

A.C.

receptacle

alcohol.

the

pump

dry.

of

the

exposing

this

can

power

prior

A.C.

alcohol;

lead

cord

is

necessary,

plug

section

If

the

pump

to

cleaning.

receptacle

upon

completion

A.C.

receptacle

to

an

electrical

wipe

of

the

the

power

has a detachable

Do

not

reconnect

is

necessary,

ensure

and

shock

use a cotton

that

power

or

exterior

cord

with a cloth

power

power

all

residue

cord

fire

hazard.

surfaces

cord,

cord

swab

and

to

excess

of

the

wall

dampened

disconnect

to

pump

dampened

liquid

is

moi

‘ire,

the

until

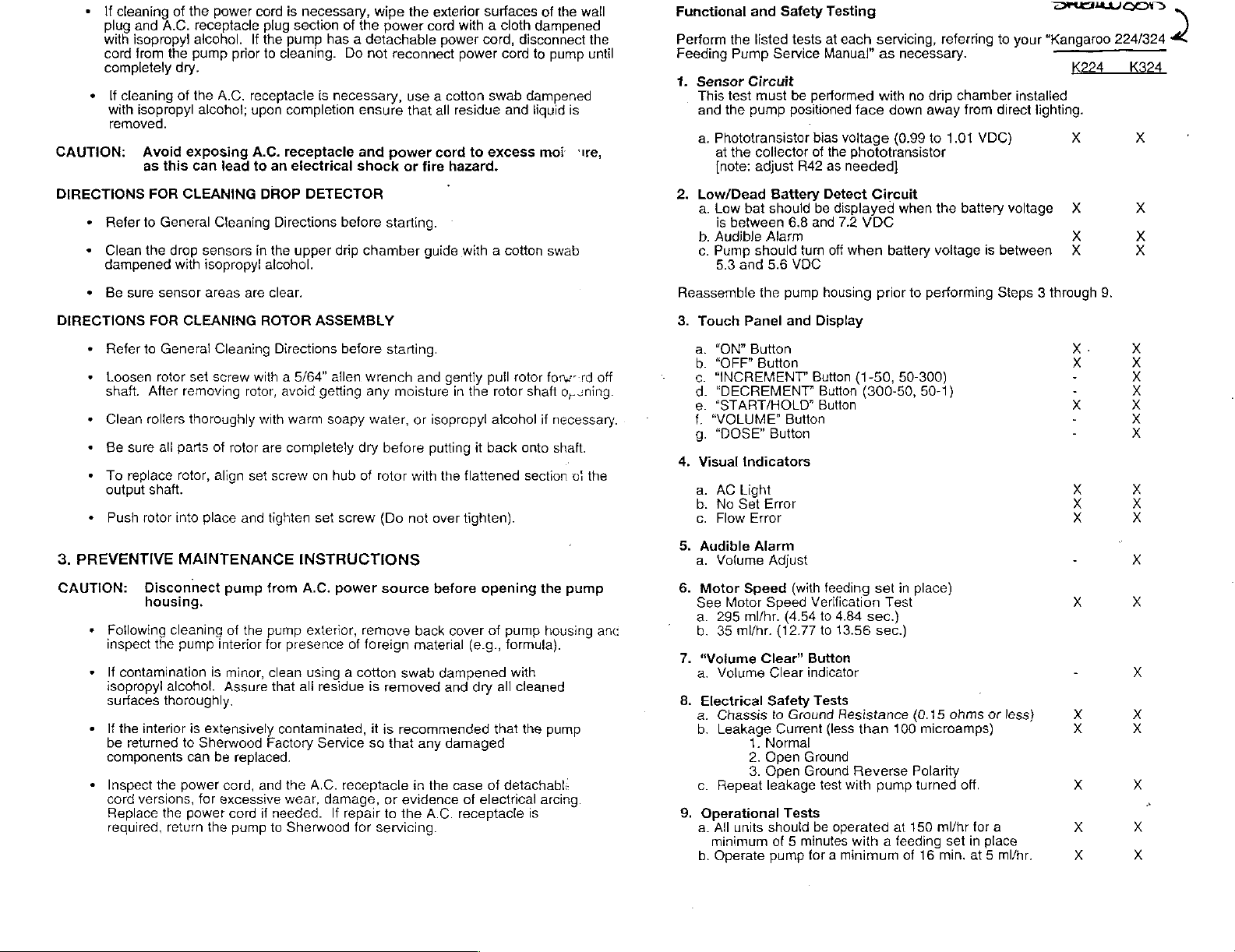

Functional

Perform

Feeding

1.

the

Pump

Sensor

This

test

and

the

a.

Phototransistor

at

the

[note:

and

Safety

listed

Service

Circuit

must

pump

positioned

collector

adjust

tests

be

performed

bias

of

R42

Testing

at

each

Manual”

servicing,

as

with

face

voltage

the

phototransistor

as

needed]

referring

necessary.

no

drip

down away

(0.99

to

chamber

from

1.01

to

direct

VDC)

NUS.

your

“Kangaroo

installed

lighting.

K224

X

Com

224/324

K324

DIRECTIONS

Refer

Clean

dampened

Be

DIRECTIONS

Refer

Loosen

shaft.

Clean

Be

To

output

Push

3.

PREVENTIVE

CAUTION:

ㆍ

Following

inspect

If

contamination

isopropyl

surfaces

If

the

be

components

Inspect

cord

Replace

required,

FOR

to

General

the

drop

with

sure

sensor

FOR

to

General

rotor

After

rollers

sure

all

parts

replace

rotor,

shaft.

rotor

into

Disconnect

housing.

cleaning

the

alcohol.

thoroughly.

interior

returned

the

versions,

the

return

CLEANING

Cleaning

sensors

in

isopropy!

areas

are

CLEANING

Cleaning

set

screw

of

rotor

align

and

with a 5/64”

rotor,

with

set

removing

thoroughly

place

MAINTENANCE

pump

of

pump

is

to

can

power

power

the

interior

is

minor,

Assure

extensively

Sherwood

be

replaced.

cord,

for

the

and

excessive

cord

pump

DROP

DETECTOR

Directions before

the

upper

drip

chamber

alcohol.

clear.

ROTOR

are

tighten

ASSEMBLY

Directions

allen

avoid

getting

warm

soapy

completely

screw

on

set

before

dry

hub

of

screw

wrench

any

water,

rotor

INSTRUCTIONS

from

A.C.

power

pump

exterior,

for

presence

clean using a cotton

that

ali

contaminated,

Factory

the

A.C.

wear,

if

needed.

to

Sherwood

of

residue

Service

receptacle

damage,

If

repair

for

remove

foreign

is

it

so

servicing.

starting.

guide

starting.

and

moisture

or

isopropyl

before

putting

with

(Do

not

over

source

before

back

material

swab

removed

is

recommended

that

any

in

the

or

evidence

to

the

A.C.

with a cotton

gently

puil

in

the

rotor

alcohol

it

back

the

flattened

tighten).

opening

cover

of

(e.g.,

dampened

and

dry

that

damaged

case

of

of

electrical

receptacle

swab

rotor

fons--rd

shaft

if

onto

section o the

the

pump

housing

formula).

with

all

cleaned

the

pump

detachabl:

arcing.

is

off

o,

ning.

necessary.

shaft.

pump

and

Low/Dead

a.

Low

is

between

b.

Audible

c.

Pump

5.3

and

Reassemble

3.

Touch

.

“ON”

“OFF”

.

INCREMENT”

.

“DECREMENT”

.

“START/HOLD”

“VOLUME”

.

“DOSE”

oonocu

.

Visual

a.

AC

Light

b.

No

Set

c.

Flow

.

Audible

a.

Volume

.

Motor

See

Motor

a.

295

b.

35

mi/hr.

.

“Volume

a.

Volume

.

Electrical

a.

Chassis

b.

Leakage

c.

Repeat

.

Operational

a.

All

units

minimum

b.

Operate

Battery

bat

should

6.8

Alarm

should

5.6

VDC

the

pump

Panel

and

Button

Button

Button

Button

Indicators

Error

Error

Alarm

Adjust

Speed

(with

Speed

ml/hr.

(4.54

(12.77

Clear”

Clear

Safety

to

Ground

Current

1.

Normal

2.

Open

3.

Open

leakage

Tests

should

of 5 minutes

pump

Detect

be

displayed

and

7.2

VDC

turn

off

when

housing

Display

Button

(1-50,

Button

(300-50,

Button

feeding

Verification

to

4.84

to

Button

indicator

Tests

sec.)

13.56

Resistance

(less

than

Ground

Ground

test

be

operated

Reverse

with

with a feeding

for a minimum

Circuit

when

battery

prior

50-300)

set

in

Test

sec.)

100

pump

at

of

the

battery

voltage

to

performing

50-1)

place)

(0.15

ohms

microamps)

Polarity

turned

off.

150

mil/hr

set

16

min.

voltage

is

between

Steps 3 through

or

less)

fora

in

place

at 5 ml/hr.

X

X

x

"MMX

xxx

хх

9.

KOK

OX

D>

KOK

xxx

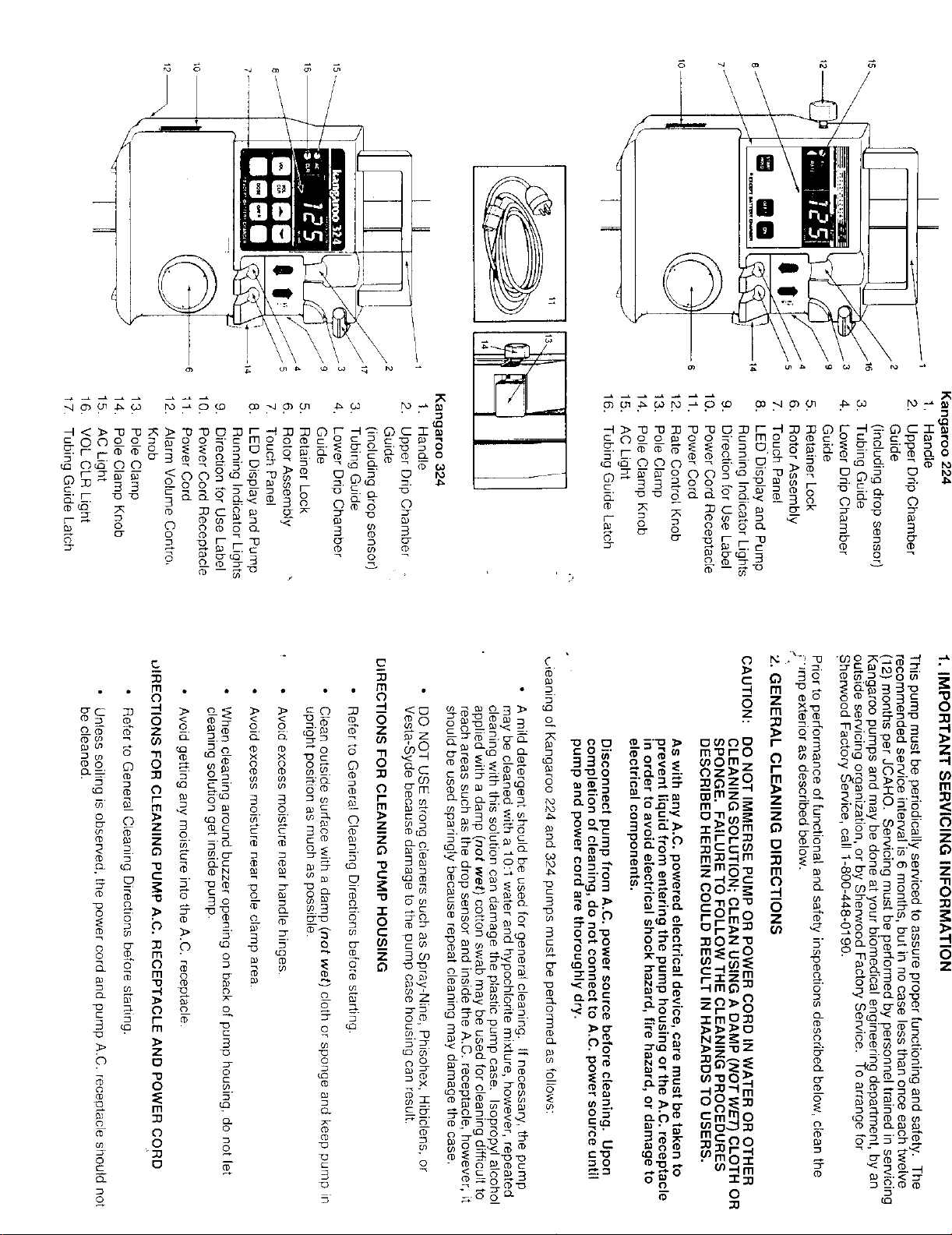

15.

13.

14.

16.

17.

Tubing

AC

VOL

Light

CLR

Guide

Light

Latch

Pole

Pole

Clamp

Clamp

Knob

Alarm

Knob

Volume

Contro.

Direction

Power

Power

Cord

Cord

tor

Receptacle

Use

Label

Touch

Rotor

LED

Running

Display

Assembly

Panel

Indicator

and

Pump

Lights

+

Guide

Retainer

Lock

{including

Tubing

Lower

Drip

Guide

drop

Chamber

sensor)

Guide

Upper

Drip

Chamber

-

Kangaroo

Handle

324

14

|

|

・

o

-

Kangaroo

2.

Tubing

AC

Pole

Light

Clamp

Guide

Knob

Latch

Pole

Rate

Clamp

Control

Knob

Direction

Power

Power

Cord

Cord

for

Receptacle

Use

Label

onou

Touch

LED

Running

Indicator

Lights

Rotor

Display

Assembly

Panel

and

Pump

BB

Lower

Guide

Retainer

Drip

Lock

Chamber

Tubing

(including

Guide

drop

sensor)

Guide

Upper

Drip

Chamber

1.

Handle

224

DIRECTIONS

・

*

be

Refer

Unless

cleaned.

to

soiling

General

is

observed,

Cleaning

Directions

the

power

before

cord

and

starting.

pump

A.C.

receptacle

should

not

FOR

CLEANING

PUMP

A.C.

RECEPTACLE

AND

POWER

CORD

«

*

When

cleaning

Avoid

getting

cleaning

solution

any

around

get

moisture

inside

buzzer

into

pump.

opening

the

A.C.

on

receptacle.

back

of

pump

housing,

do not

let

!

・

+

Avoid

Avoid

excess

excess

moisture

moisture

near

near

handle

pole

clamp

hinges.

area.

*

+

Clean

upright

Refer

to

outside

position

General

surface

as

Cleaning

much

with

as

Directions

a

possible.

damp

(not

before

wet)

starting.

cloth

or

sponge

and

keep

pump

in

DIRECTIONS

*

Vesta-Syde

DO

NOT

FOR

USE

because

CLEANING

strong

damage

cleaners

PUMP

to

such

HOUSING

the

as

pump

Spray-Nine,

case

housing

Phisohex,

can

result.

Hibiciens,

or

cleaning

applied

should

reach

areas

be

with

with

used

a

such

this

damp

sparingly

solution

as

(not

the

drop

because

wet}

can

sensor

damage

cotton

repeat

and

swab

the

inside

cleaning

plastic

may

the

be

pump

may

used

A.C.

damage

case.

receptacle,

for

cleaning

Isopropyl

the

case.

however,

difficult

alcohol

to

it

vieaning

+

A

may

of

mild

Kangaroo

be

detergent

cleaned

224

with

should

and

a

10:1

324

be

used

pumps

water

for

and

must

general

hypochlorite

be

performed

cleaning.

mixture,

if

as

necessary,

follows:

however,

the

repeated

pump

electrical

completion

pump

Disconnect

and

power

cord

are

thoroughly

dry.

components.

of

pump

cleaning,

from

A.C.

do

not

power

connect

source

to

A.C.

before

power

cleaning.

source

Upon

until

DESCRIBED

As

in

prevent

order

with

any

liquid

to

avoid

A.C.

HEREIN

from

electrical

powered

entering

COULD

electrical

shock

the

RESULT

pump

hazard,

device,

IN

housing

fire

hazard,

or

damage

to

HAZARDS

care

or

must

the

TO

A.C.

be

USERS.

taken

receptacle

to

2.

CAUTION:

GENERAL

DO

CLEANING

SPONGE.

FAILURE

CLEANING

NOT

IMMERSE

SOLUTION;

DIRECTIONS

PUMP

TO

CLEAN

FOLLOW

OR

POWER

USING

THE

CORD

CLEANING

A

DAMP

IN

WATER

(NOT

PROCEDURES

WET)

OR

CLOTH

OTHER

OR

了

Sherwood

ramp

Prior

to

exterior

performance

Factory

as

described

Service,

of

functional

call

below.

1-800-448-0190.

and

safety

inspections

described

below,

clean

the

This

recommended

(12)

outside

Kangaroo

months

pump

servicing

pumps

must

per

service

JCAHO.

organization,

or

by

Sherwood

Factory

Service.

To

arrange

for

be

and

periodically

may

interval

Servicing

be

is

done

serviced

6

months,

at

must

your

to

be

assure

but

biomedical

performed

in

no

proper

case

engineering

by

functioning

less

personnel

than

department,

once

trained

and

each

safety.

in

twelve

servicing

by

The

an

1,

IMPORTANT

SERVICING

INFORMATION

Loading...

Loading...