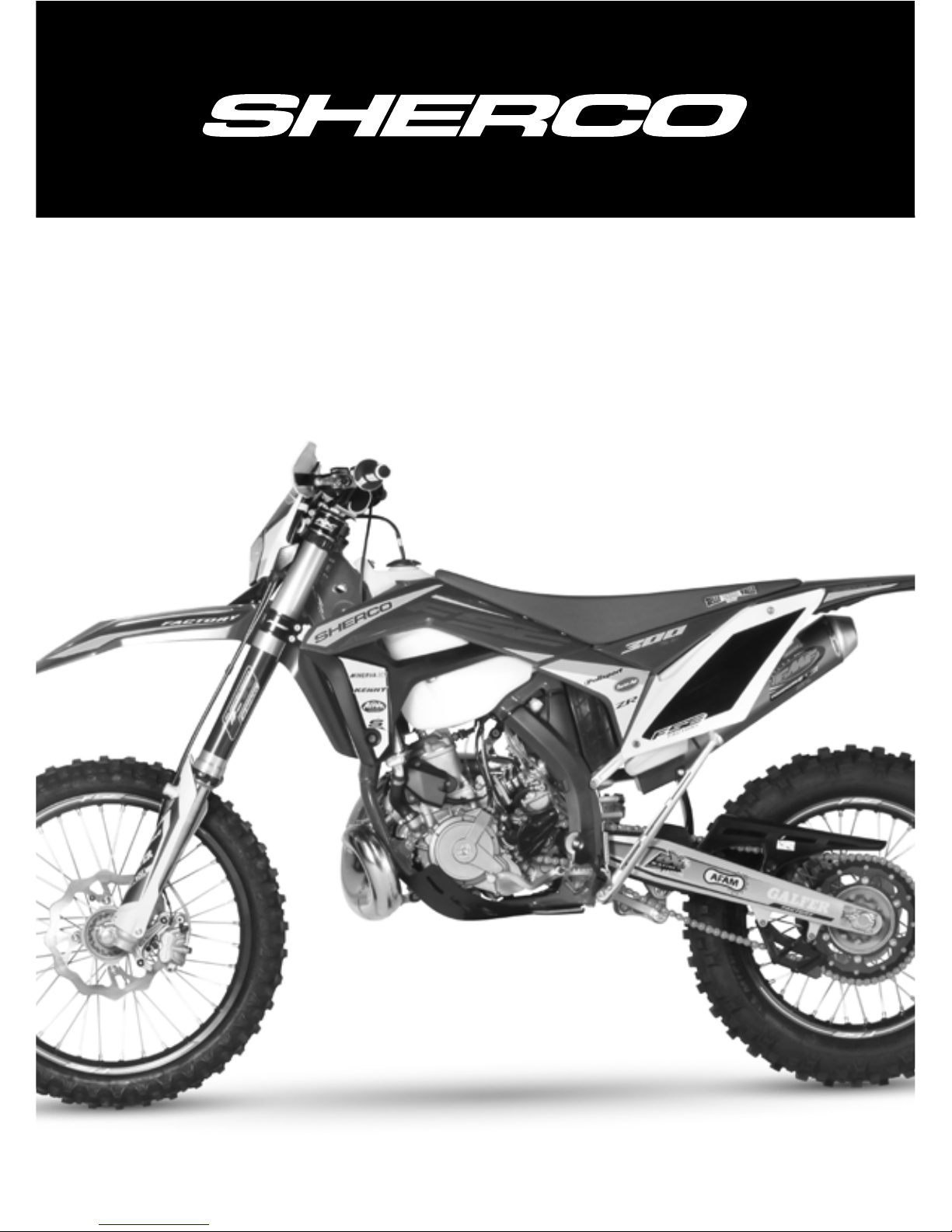

SHERCO 250 SE/R, 300 SE/R Workshop Manual

WORKSHOP MANUAL

250 SE/R

300 SE/R

2

250-300 SE-R

ENGLISH

CONTENTS

FOREWORD ................................................................4

ENGINE TOOL LIST .....................................................5

250 SE-R and 300 SE-R ....................................................5

TECHNICAL SPECIFICATIONS .....................................6

Engine ...............................................................................6

Carburettor ........................................................................7

Cycle part ..........................................................................7

FACTORY SETTINGS ...................................................8

Fork ..................................................................................8

Shock absorber .................................................................9

OPERATIONS REQUIRING REMOVAL OF THE ENGINE OR

NOT ...........................................................................9

ENGINE REMOVAL/ASSEMBLY .................................10

Removing the engine .......................................................10

Reassembling the engine in the frame ..............................11

DISMANTLING THE ENGINE ......................................12

Draining the gearbox ........................................................12

Removing the pinion and selector .....................................12

Removing the cylinder head, cylinder and piston ................13

Removing the clutch housing ............................................14

Removing the pressure plate and discs .............................15

Removing the electric starter ............................................16

Removing the primary transmission ..................................16

Removing the locking mechanism .....................................17

Removing the ignition housing ..........................................18

Removing the torque limiter and the starter drive...............18

Removing the ignition .......................................................19

Intake pipe and valve box .................................................19

Separating the half crankcases .........................................20

Removing the gear selection.............................................20

Removing the connecting rod assembly ............................21

CHECKING ENGINE COMPONENTS ............................22

Connecting rod assembly .................................................22

Balance weights, checking the external dimensions ...........22

Radial play of the connecting rod head .............................22

Lateral play of the connecting rod head ............................23

Checking the crankshaft's run out ....................................23

Piston..............................................................................23

Gap spacing ....................................................................24

Piston pin check ..............................................................24

Checking the wear condition of the cylinder ......................24

Standard cylinder replacement .........................................24

Disassembling the exhaust valve system ...........................25

Functional check ..............................................................26

Valve stop learning after cylinder reassembly ....................30

Valve box, intake pipe sleeve ............................................30

Clutch .............................................................................31

Connecting rod assembly .................................................31

REASSEMBLING THE ENGINE ...................................32

Gearbox ..........................................................................32

Assembling the half crankcases........................................33

Gear selection mechanism ...............................................34

Primary transmission and clutch .......................................35

Clutch discs, pressure plate..............................................36

Clutch housing .................................................................37

Piston and cylinder ..........................................................38

Cylinder head ..................................................................39

Valve box and intake pipe .................................................40

Gearbox output pinion ......................................................40

Mounting the ignition and its cover ...................................41

Mounting the electric starter .............................................41

DIAGNOSTIC TOOL ...................................................42

Presentation of the ignition management system and exhaust

valve opening management system ..................................42

Description of Exxodiag diagnostic tool reference 4967 .....43

Composition of the diagnostic tool ....................................43

Installing the diagnostic tool .............................................43

Connection with Keyless system .......................................47

Software setup : setup menu ............................................48

Update and synchronisation menu ....................................49

Using the software ...........................................................51

TIGHTENING TORQUES TABLE ..................................61

CARBURETTOR ADJUSTMENT TABLE .......................62

SE-R 250 carburettor adjustment table .............................62

CARBURETTOR ADJUSTMENT TABLE .......................63

SE-R 300 carburettor adjustment table .............................63

CHECKING THE LOAD CIRCUIT..................................64

Static control values (engine off) 250 SE-R/300 SE-R ........64

Dynamic control values ....................................................64

T° SENSOR, ENGINE RPM SENSOR, HV COIL CHECK . 65

Main harness...................................................................66

Standard lights harness ....................................................67

Racing lights harness .......................................................68

Accessories harness ........................................................69

3

This manual is primarily intended for qualified mechanics working in a properly

equipped workshop.

A solid knowledge of mechanics and the specific SHERCO tools for the 250

SE-R and 300 SE-R engines are required to perform the various operations.

This workshop manual complements the SHERCO 250 SE-R and 300 SE-R user

manual.

FOREWORD

4

250-300 SE-R

ENGLISH

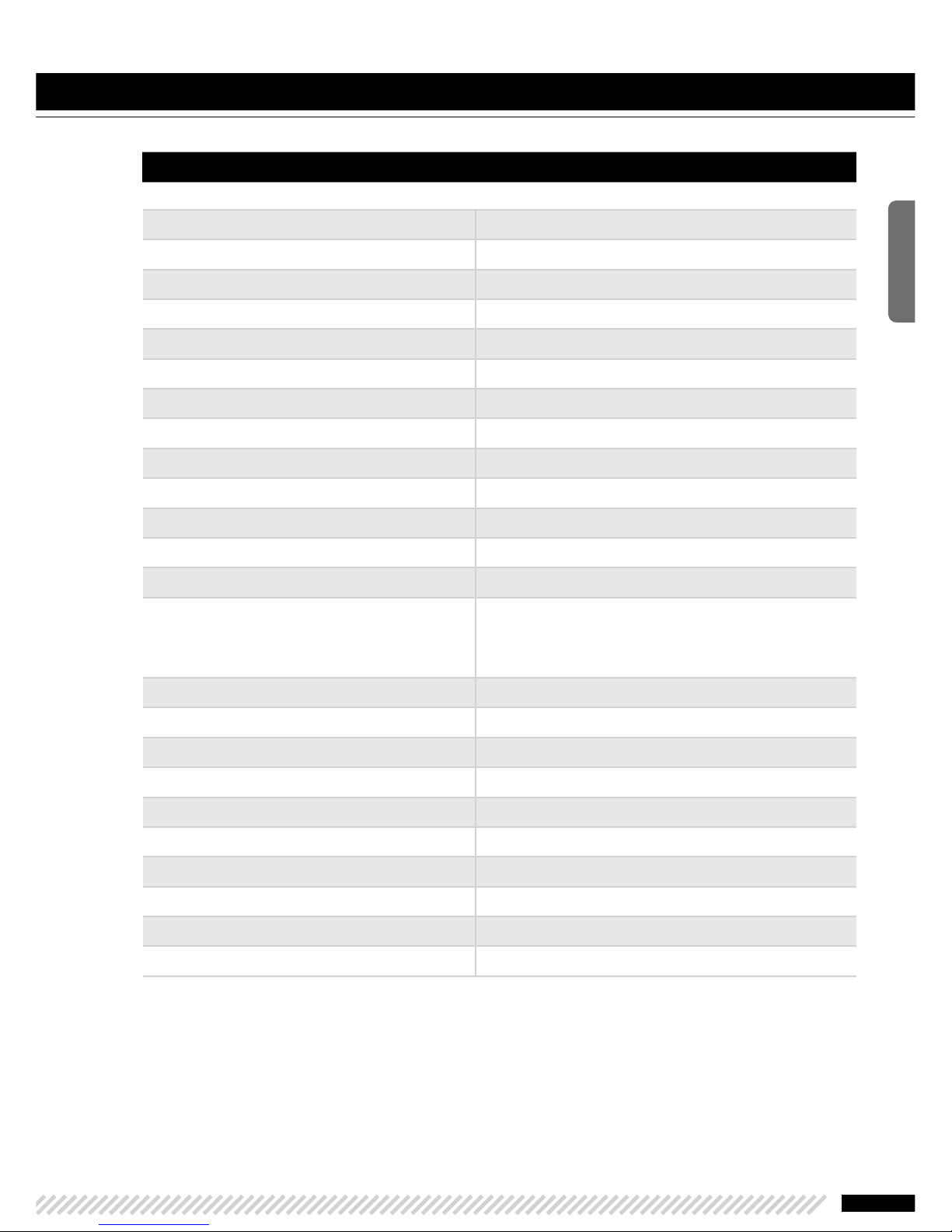

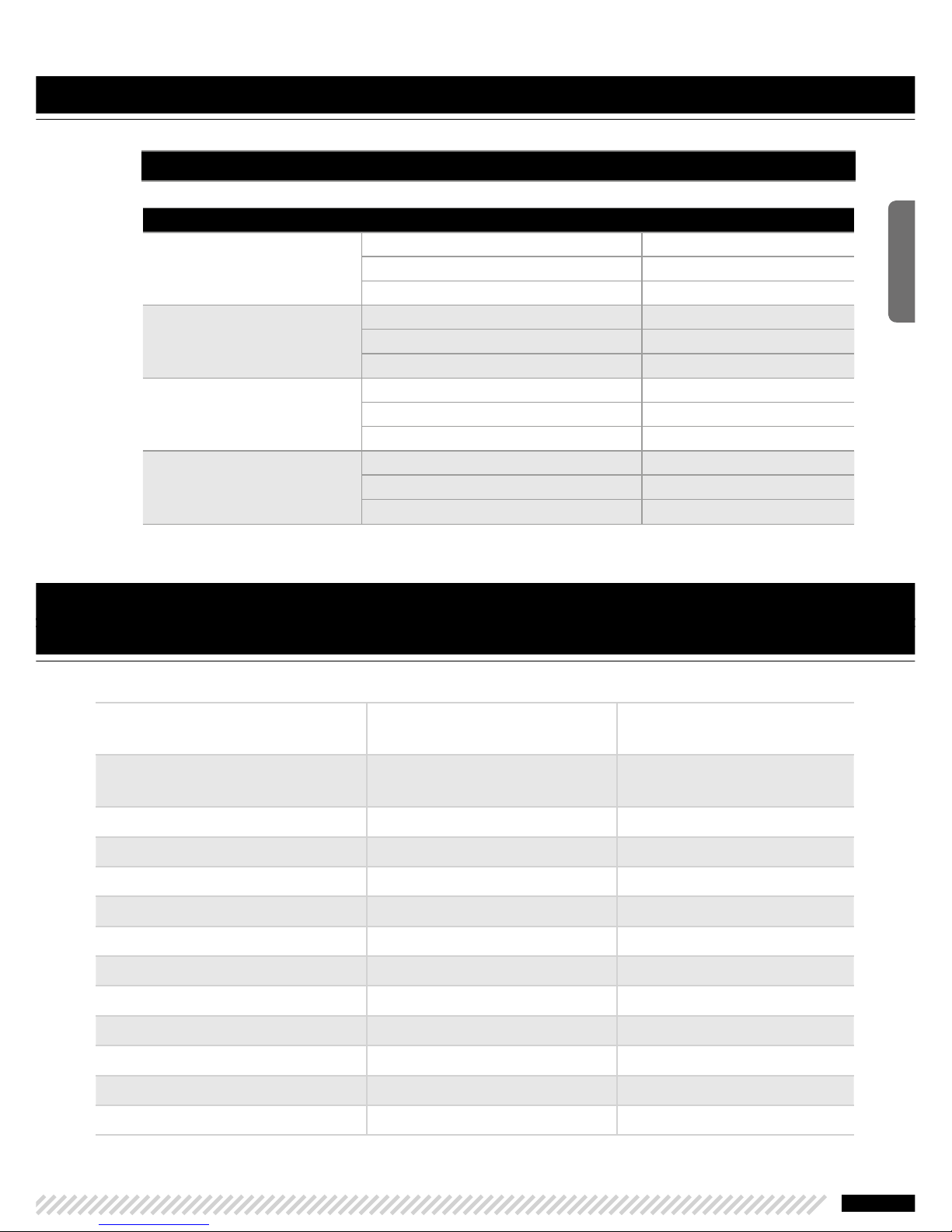

ENGINE TOOL LIST

250 SE-R and 300 SE-R

Tool reference Designation

5749 Clutch block

4753 Ignition block

2067 Swing-arm pin tool

R467 Right crankcase primary shaft bearing tool

R465 Secondary shaft bearing tool

5397 Gearbox output shaft bearing tool

R446 Gearbox output spi tool

5398 Barrel selection bearing tool

5399 Left crankcase crankshaft bearing tool

R469 Right crankcase crankshaft bearing tool

5400 Clutch side crankshaft spi tool

5401 Ignition side crankshaft spi tool

5402 HK0808 needle cage tool

(water pump, starter drive double pinion,

starter drive)

1968 Water pump spi seal tool

1821 Engine support

5206 Primary pinion block tool

2073 Spring block (pin selection)

R462 Magnetic flywheel puller

R464 Crankshaft ring extractor

R453 Selector axis bearing assembly tool

R444 Selector spi seal tool

6267 Diagnostic Key less tool

4967 Diagnostic briefcase

5

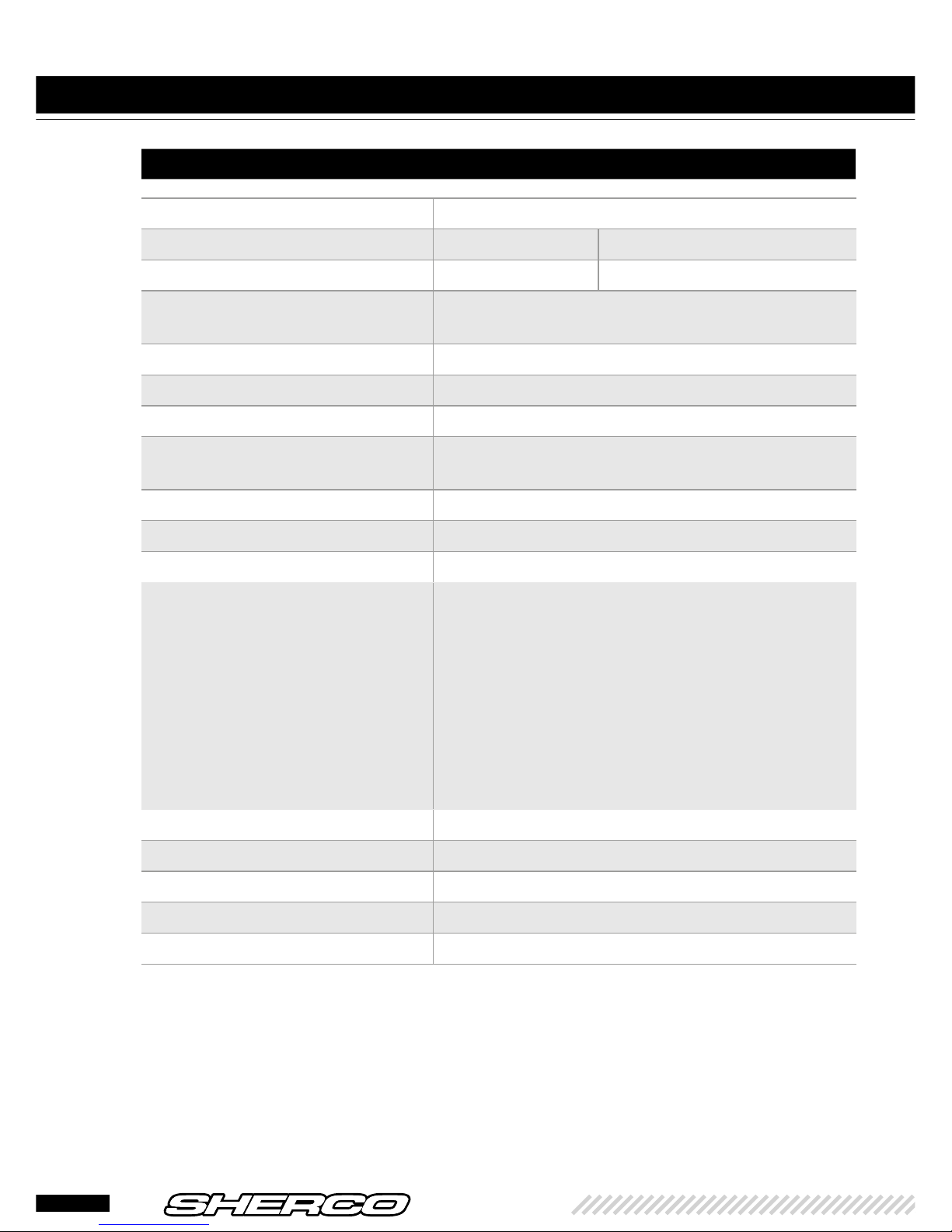

TECHNICAL SPECIFICATIONS

Type

Single cylinder 2 stroke liquid cooling

Capacity 249.32 CC

293.14 CC

Bore/Stroke 66.4/72 mm

72/72 mm

Petrol

Unleaded with an octane rating of at least 98

mixed with 2-stroke oil (2 %)

Cooling

Liquid with forced circulation

Ignition system

Synerject electronic ignition

Spark plug

NGK BR7ES/DENSO W22ESRU

Distance between spark plug

electrodes

0.7 mm

Piston Cast aluminium

Engine oil 750 ml SAE 10W40

Primary transmission 27 : 75

Gearbox :

1st

2nd

3rd

4th

5th

66 speeds

14 : 32

15 : 26

19 : 27

21 : 24

23 : 22

25 : 21

Final transmission 14 X 49

Clutch Oil bathed multi disks, hydraulic control

Starter Electric starter

Battery 12V 4Ah

Alternator 220W

ENGINE

6

250-300 SE-R

ENGLISH

250 300

Carburettor type

KEIHIN PWK 36S AG KEIHIN PWK 36S AG

Needle position 3rd position from the top

3rd position from the top

Jet needle

N1EG (N84K) N8RE (N84K)

Main jet KEA 165 (KEA 115) KEA 172 (KEA 115)

Idle jet KEP 42 (KEA38) KEP 42 (KEA 38)

Choke jet 85 (50) 85 (50)

Air regulating screw

opening

1T 1/4 1T 1/2

Valve spacing N°5.5 N°7

CARBURETTOR

Rahmen

Halbperimetrisch aus CrMo-Stahl mit hinterem

Bügel aus Aluminium

Fork

(Racing) WP suspension USD Ø48 mm

(Factory) WP suspension Xplor

Rear suspension

WP suspension with separate cylinder, aluminium

swing arm

Front/rear stroke 300/330 mm

Front brake Ø 260 mm disc

Rear brake Ø 220 mm disc

Disc brakes Wear limit : 2.7 mm front and 3.6 mm rear

Front tyre 90/90-21’’

Rear tyre 140/80-18’’

Off-road pressure front/rear 0.9 bar

Fuel tank capacity 10.4 l including 1 litre reserve

Steering column angle 27.3°

Wheelbase 1480 mm

Weight 105 kg

Gewicht 105 kg

CYCLE PART

7

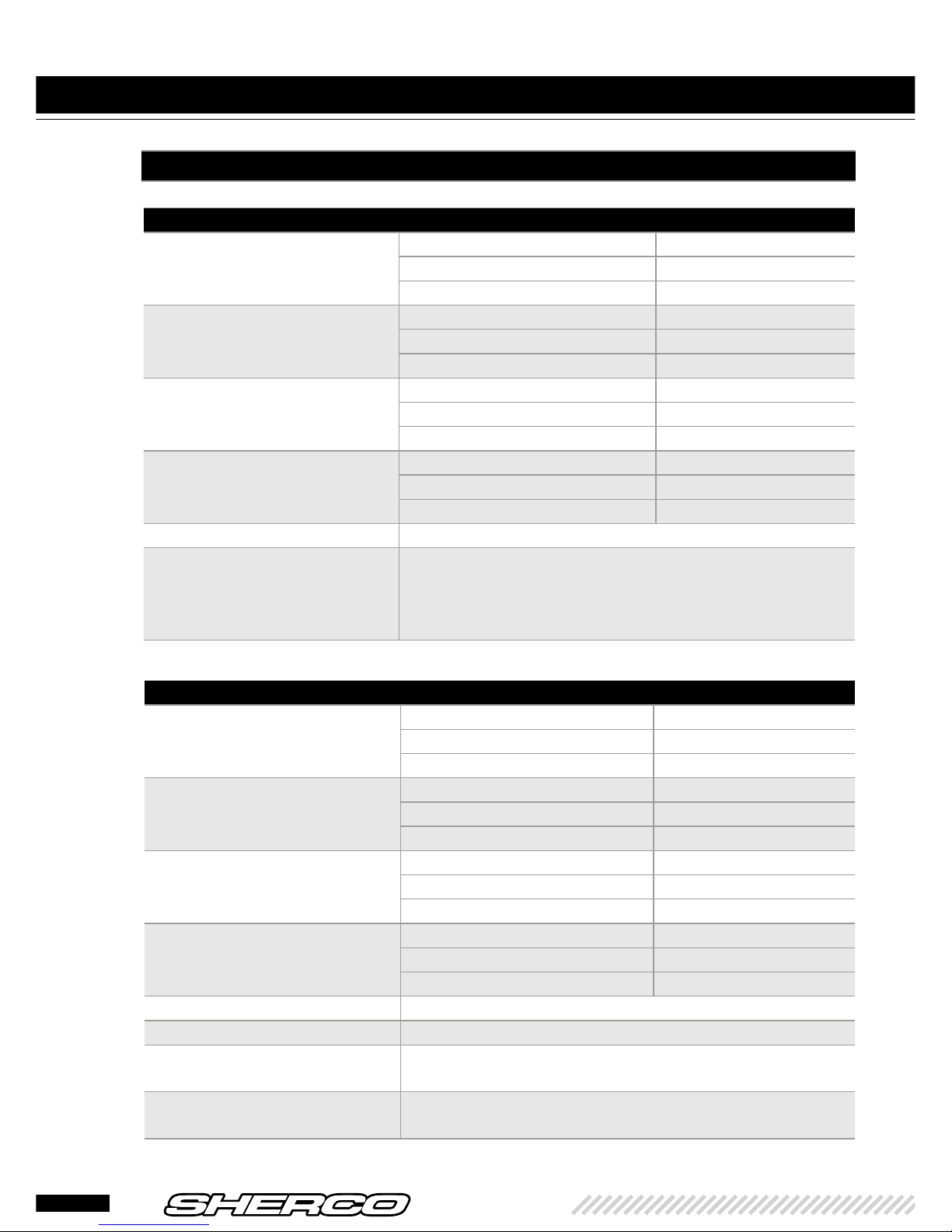

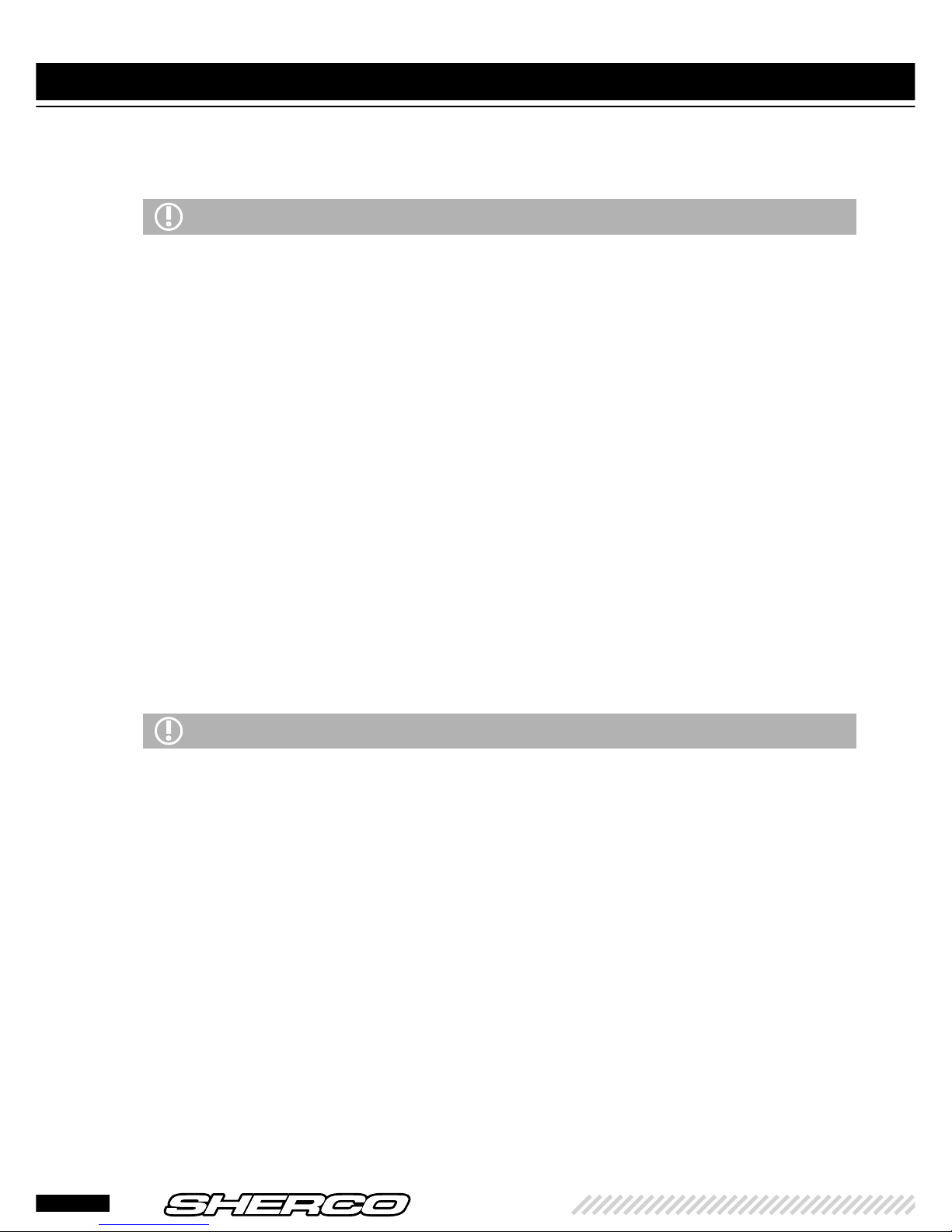

FACTORY SETTINGS - WP FORK USD SUSPENSION Ø48 MM

Compression

Comfort 20 clicks back

Standard 13 clicks back

Sport

8 clicks back

Expansion

Comfort 18 clicks back

Standard 13 clicks back

Sport 10 clicks back

Pre-tension

Comfort 4 turns

Standard

6 turns

Sport 8 turns

Spring stiffness

Driver weight : 65-75 kg 4.0N/mm

Driver weight : 75-85 kg 4.2N/mm (factory)

Driver weight : 85-95 kg 4.4N/mm

Oil type SAE 4

Measured oil level

(compressed and spring-less

fork) from the top of the

upper tube

110 mm

FACTORY SETTINGS

FORK

FACTORY SETTINGS - WP FORK XPLOR SUSPENSION

Compression

Comfort 18 clicks back

Standard 15 clicks back

Sport

12 clicks back

Expansion

Comfort 18 clicks back

Standard 15 clicks back

Sport 12 clicks back

Pre-tension

Comfort + 0

Standard

+ 0

Sport + 6

Spring stiffness

Driver weight : 65-75 kg 4.2 N/mm

Driver weight : 75-85 kg 4.4 N/mm (factory)

Driver weight : 85-95 kg 4.6 N/mm

Oil type SAE 4

Quantity of oil 606 ml

Oil level height from the top

of the tube

100 mm (Min. 90 – Max. 120 mm)

Spring length with pretension spacer

474 mm

8

250-300 SE-R

ENGLISH

FACTORY SETTINGS - WP SUSPENSION SHOCK ABSORBER

Low speed compression

Comfort 20 clicks back

Standard 15 clicks back

Sport 12 clicks back

High speed compression

Comfort 2.5 turns back

Standard 2 turns back

Sport 1.5 turns back

Expansion

Comfort 15 clicks back

Standard 13 clicks back

Sport 11 clicks back

Spring stiffness

Driver weight : 65-75 kg 48N/mm

Driver weight : 75-85 kg 51N/mm (factory)

Driver weight : 85-95 kg

54N/mm

SHOCK ABSORBER

OPERATIONS REQUIRING REMOVAL

OF THE ENGINE OR NOT

Operation requiring removal

of the engine

Operation not requiring the

removal of the engine

Crankshaft (including

connecting rod kit)

•

Complete gearbox •

Crankshaft bearing •

Gearbox bearing •

Piston •

Cylinder •

Cylinder head •

Ignition •

Starter pinions •

Complete clutch •

Water pump •

Gear selection assembly •

9

ENGINE REMOVAL/ASSEMBLY

REMOVING THE ENGINE

• Drain (see user manual).

• Engine oil.

• Coolant.

• Remove the seat.

• Disconnect the battery.

• Remove the tank with its inlets.

• Disconnect the complete wiring harness connected to the engine (starter

terminal, interference suppressor, actuator).

• Remove the exhaust (see user manual).

• Remove the carburettor.

• Remove the secondary transmission chain (quick coupler).

• Remove the chain guard.

• Remove the clutch slave cylinder.

WARNING

To remove the engine, you must remove the swing arm's pivot bolt to detach the rear wheel/swing

arm assembly. Secure the chassis with a jack to prevent the motorcycle from overturning.

• Remove the water hoses connected to the engine.

• Remove the left radiator.

• Loosen all the engine screws.

• Loosen the swing-arm pin.

• Remove the cylinder head-frame lugs and its electric motor.

• Remove the engine pins.

• Remove the swing-arm pin.

• Disconnect the valve cables from the pulley.

• Remove the engine.

WARNING

When the clutch slave cylinder is removed, the piston is no longer held in place. Secure the piston

with a plastic collar.

10

250-300 SE-R

ENGLISH

REASSEMBLING THE ENGINE IN THE FRAME

To reassemble, follow the disassembly procedure in reverse while respecting the tightening torques of screws and nuts :

Engine screw : 60Nm.

Swivel-arm screw : 100 Nm.

Clutch slave cylinder screw : 10 Nm.

Head-frame screw : 23 Nm.

11

DISMANTLING THE ENGINE

Refer to the 250 SE-R/300 SE-R spare parts catalogue for exploded views.

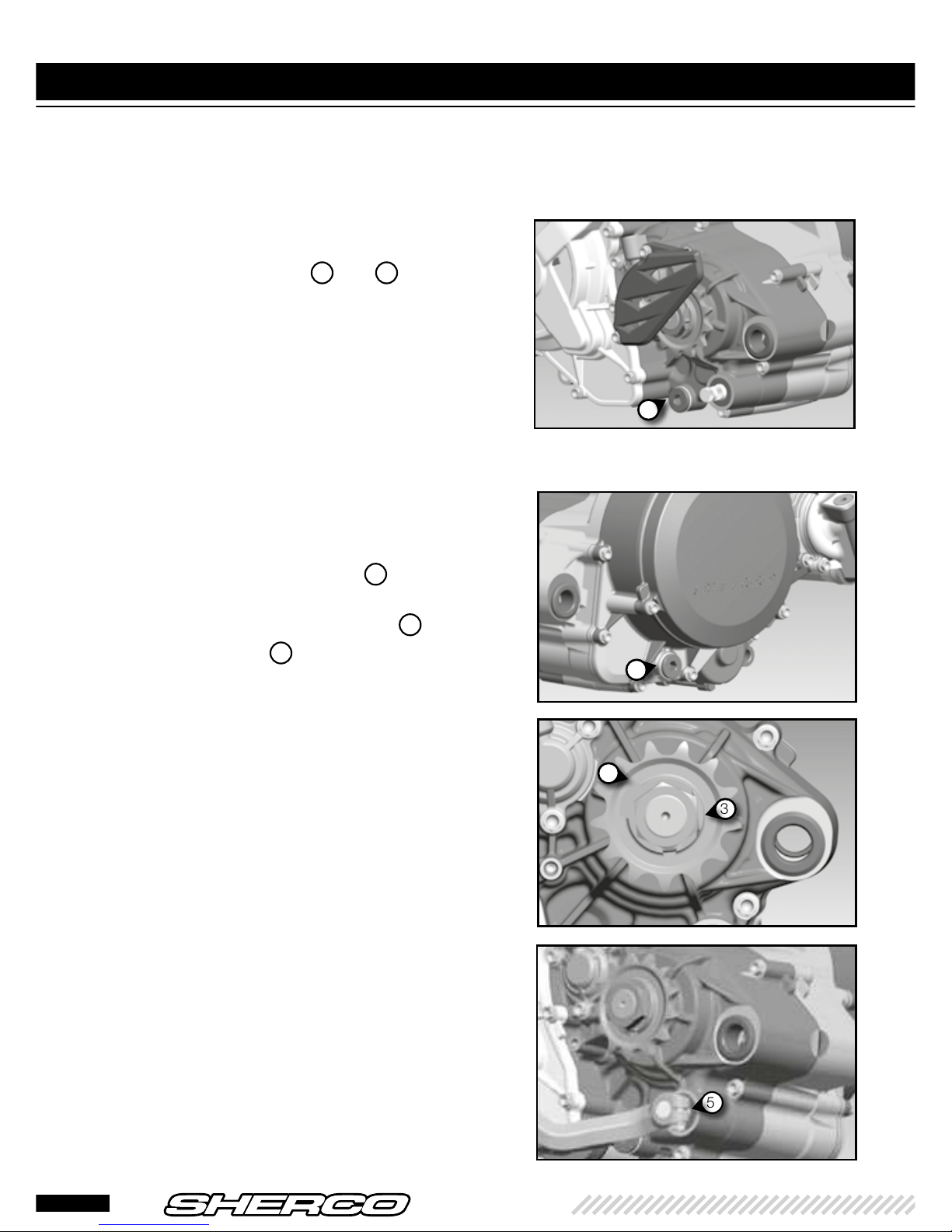

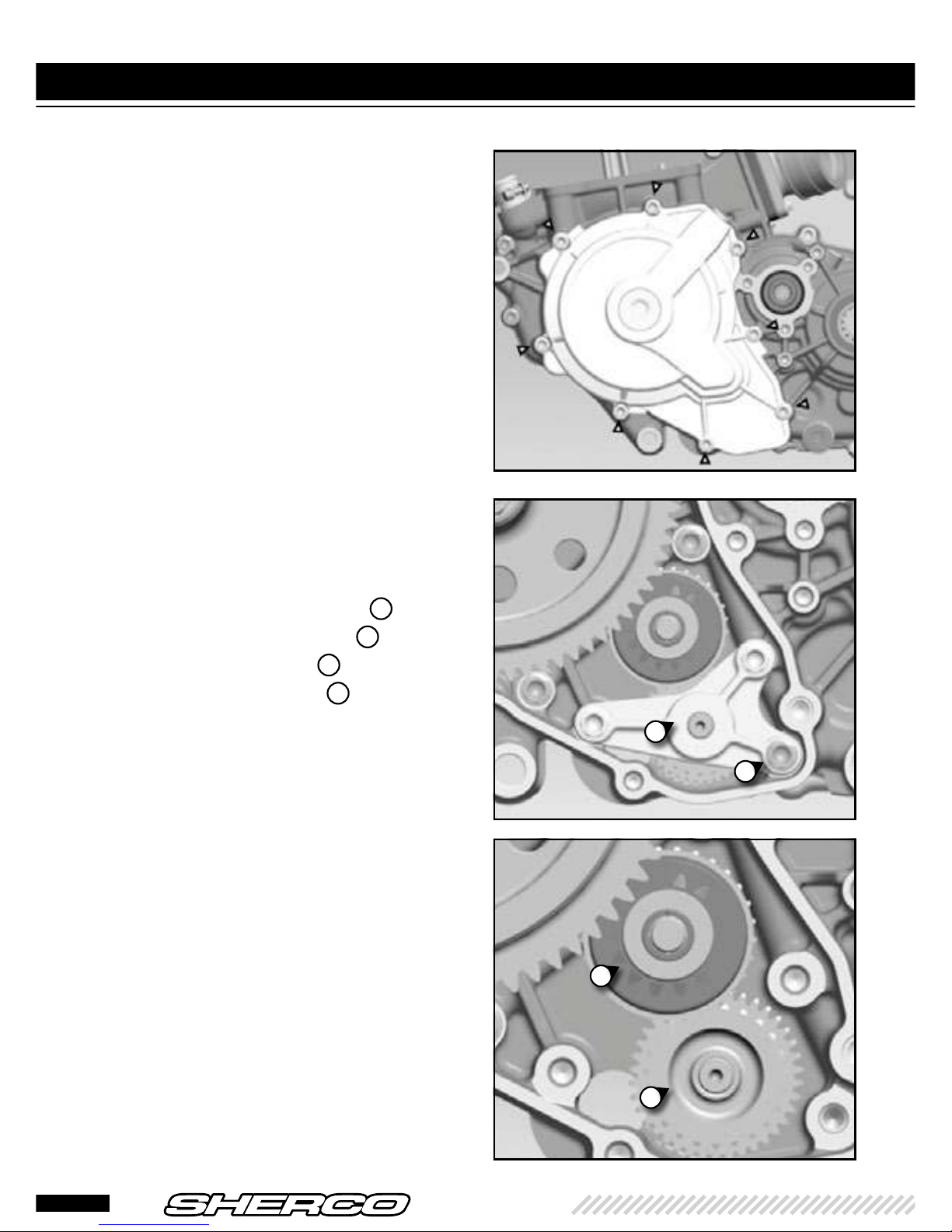

DRAINING THE GEARBOX

• Remove the drain plugs 1 and 2, let the

oil drain.

REMOVING THE PINION AND

SELECTOR

• Unfold the safety washer's tab 3 using a

punch.

• Remove the gearbox output pinion

4

.

• Remove the screw

5

and extract the

selector.

• Remove the clutch control rod.

1

2

4

3

5

12

250-300 SE-R

ENGLISH

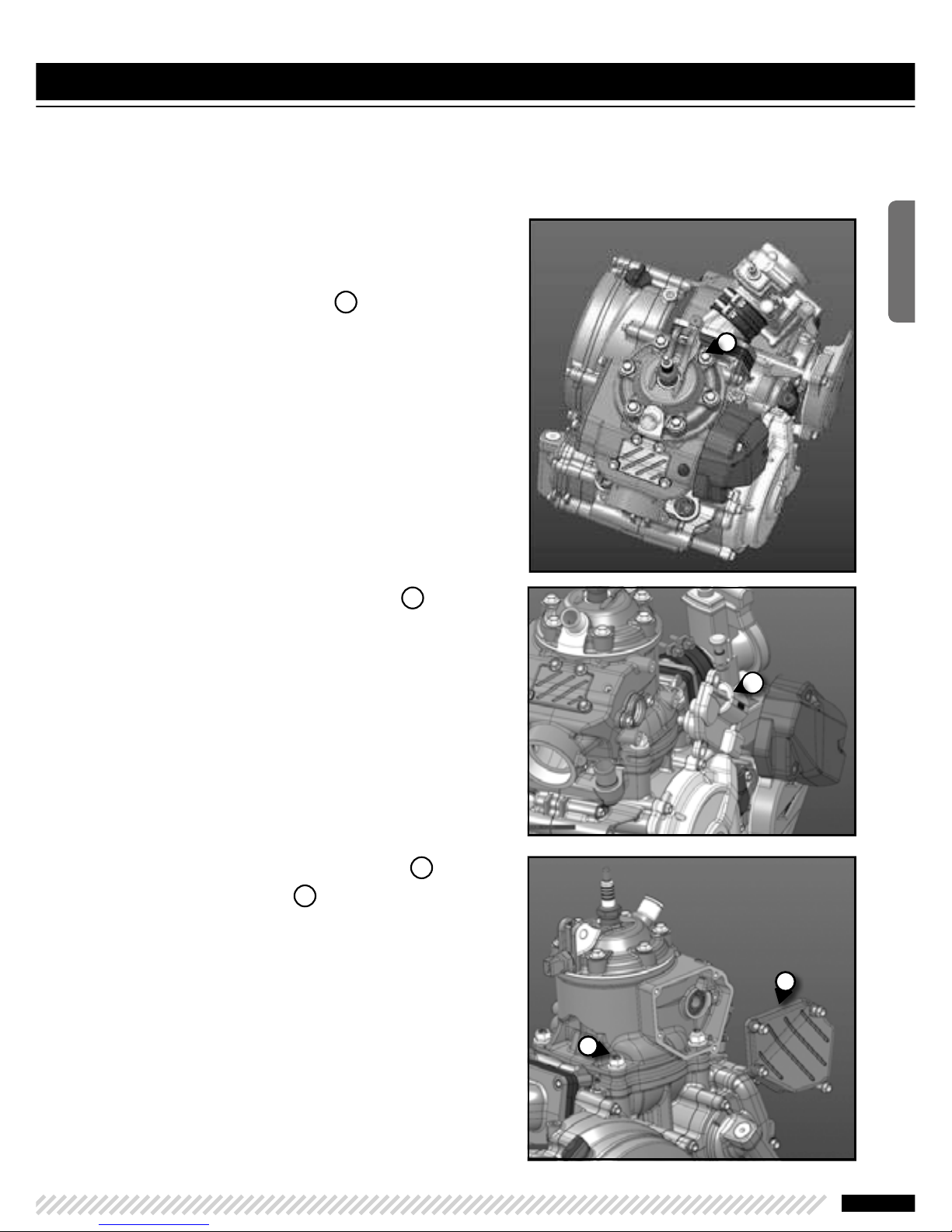

• Remove the exhaust valve actuator 2.

• Remove the exhaust chamber cover

3

.

• Remove the 4 screws

4

on the base of

the cylinder and remove it.

• Mask the cover.

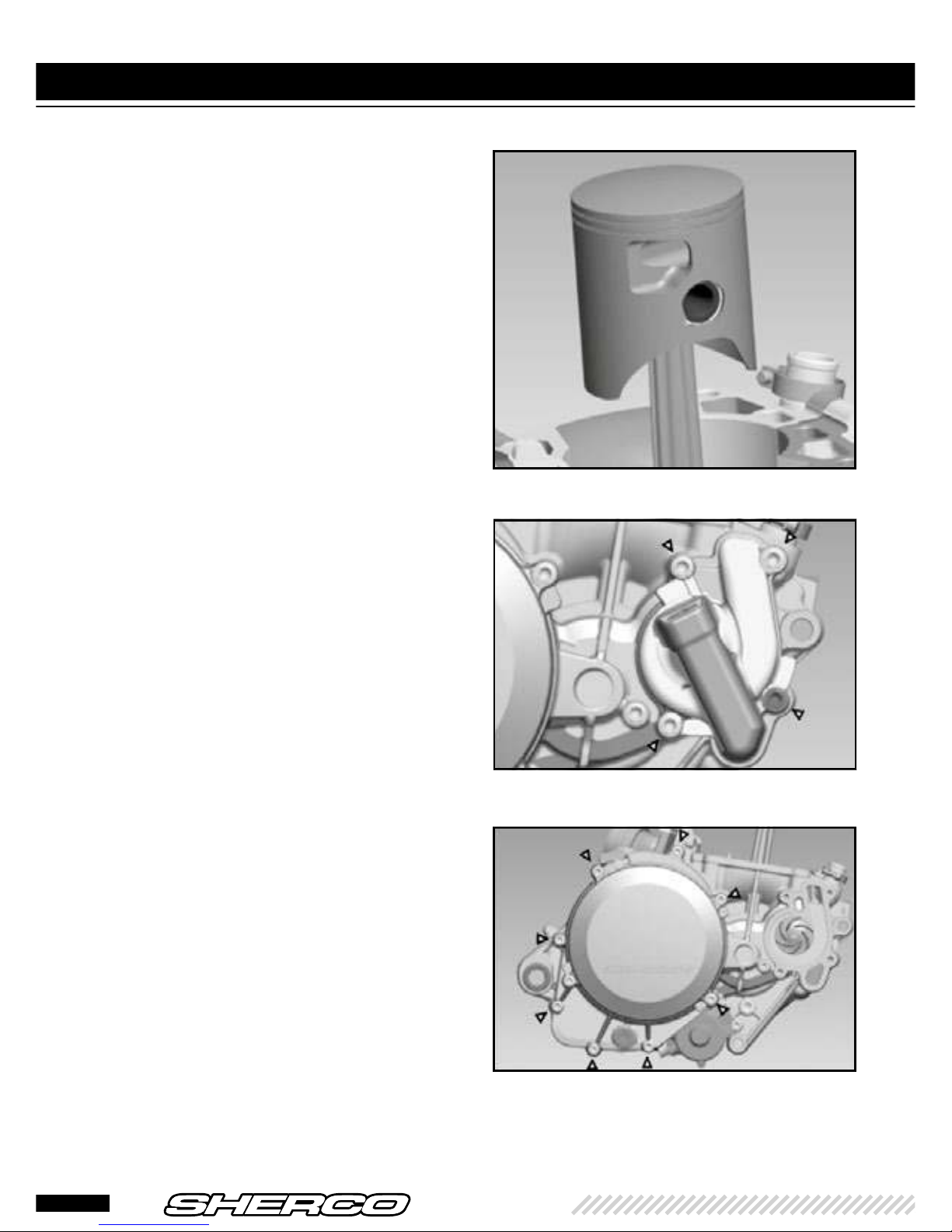

REMOVING THE CYLINDER

HEAD, CYLINDER, AND PISTON

• Remove the shoulder bolts 1, the copper

washers, remove the cylinder head and the two

o-rings.

1

2

3

4

13

DISMANTLING THE ENGINE (next)

• Remove the screws and extract the

clutch housing. Remove the gasket.

REMOVING THE CLUTCH

HOUSING

• Remove the screws and the water pump

cover. Remove the gasket.

• Remove the piston pin clips.

• Remove the piston pin.

• Remove the piston and extract the needle

bearing from the connecting rod eye.

• Remove the header gasket.

14

250-300 SE-R

ENGLISH

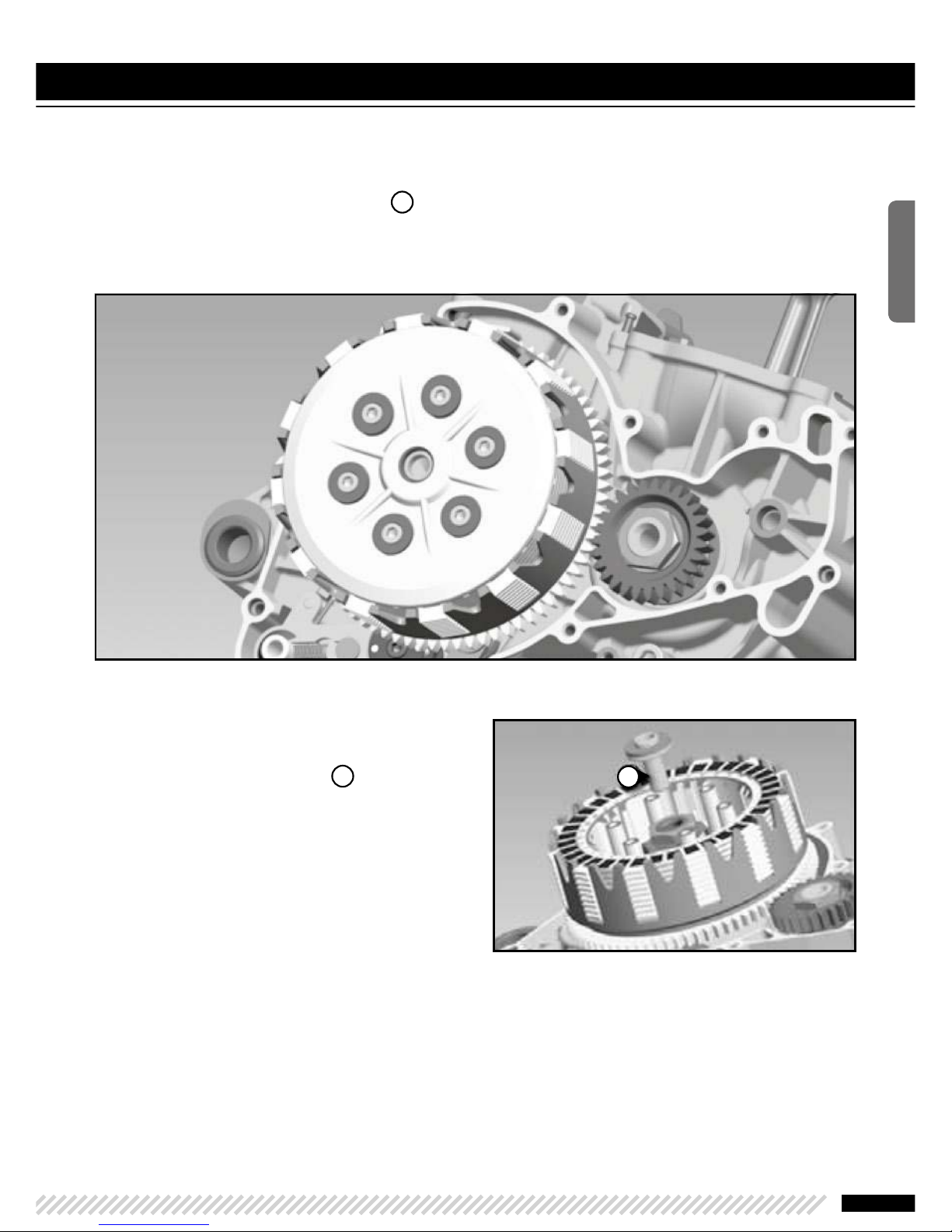

REMOVING THE PRESSURE PLATE AND DISCS

• Loosen the pressure plate screws 1.

• Remove the screws, springs and spring cups.

• Remove the pressure plate and discs from

the housing.

• Remove the support piece

1

on the

primary shaft.

1

15

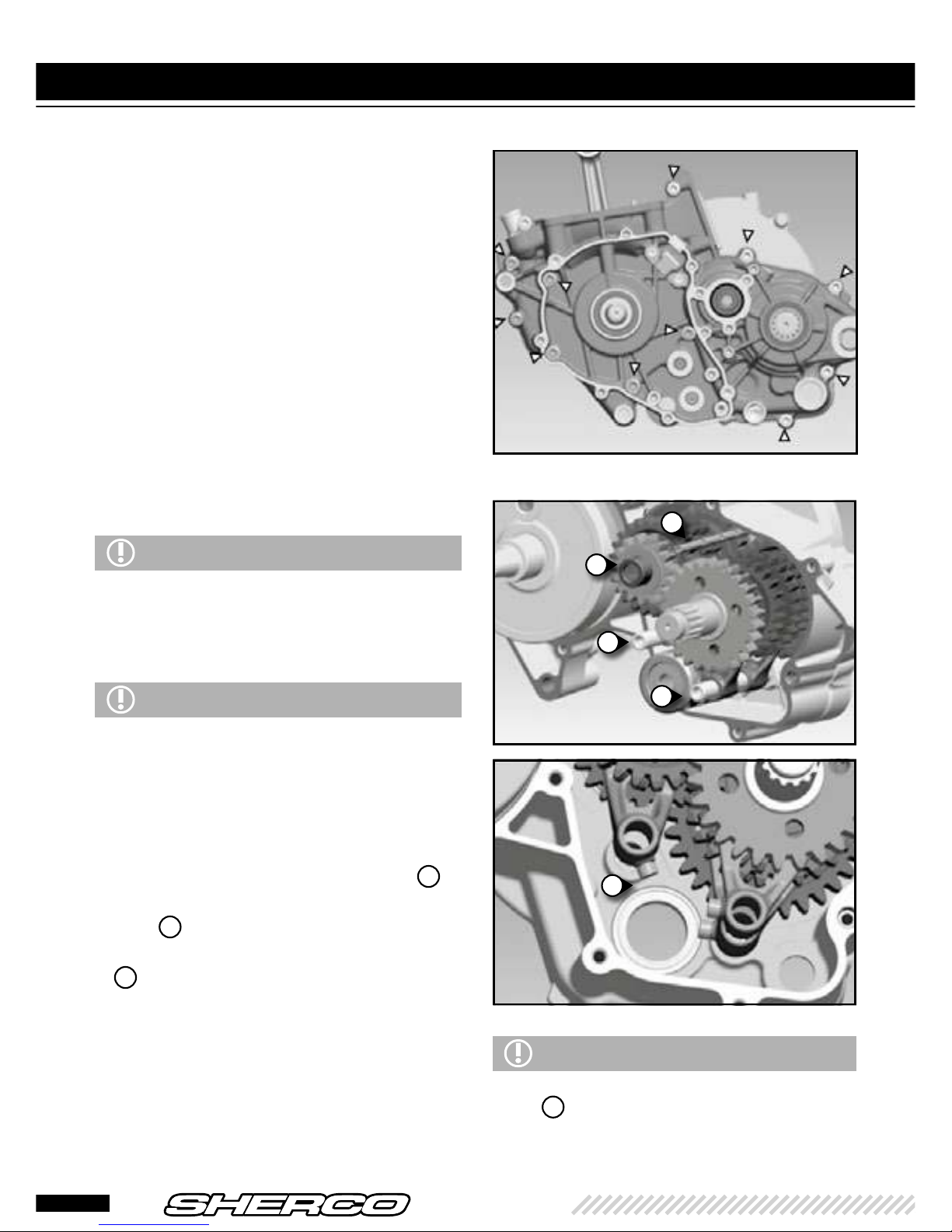

REMOVE THE ELECTRIC

STARTER

• Remove the 2 screws 2.

• Open the clutch boss lock washer

5

.

• Apply the 5749 tool

6

which is designed

to hold the boss, then loosen the nut.

• Remove the tool.

• Remove the boss, the crenellated washer,

the housing with the 2 needle cages.

REMOVING THE PRIMARY

TRANSMISSION

• Lock the pinion at the end of the

crankshaft with the 5206 tool 3.

• Unscrew the primary transmission nut

4

and then remove it with its conical washer.

2

3

4

6

5

DISMANTLING THE ENGINE (next)

16

250-300 SE-R

ENGLISH

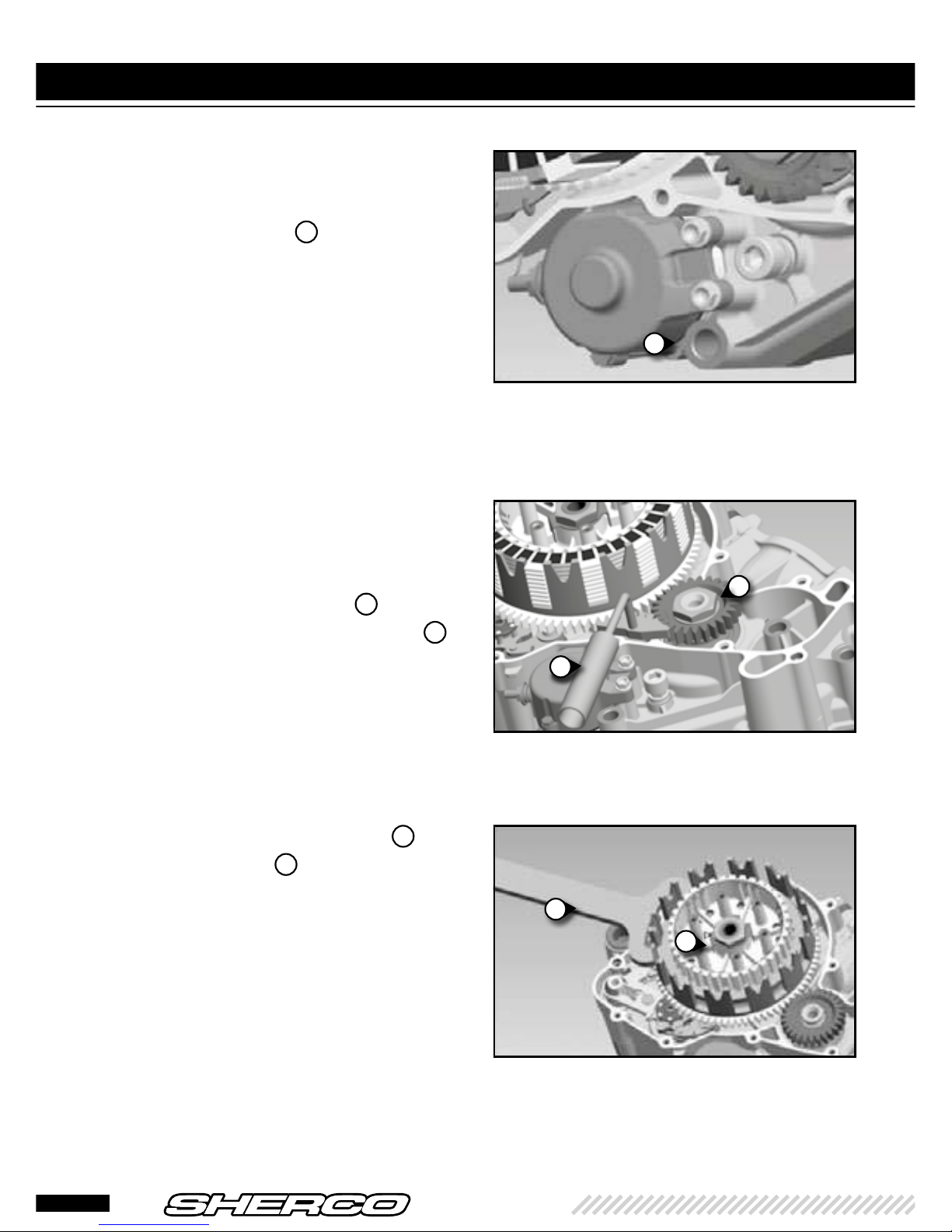

• Removing the primary transmission pinion

and the spacer 1 at the end of the

crankshaft.

PAY ATTENTION

To the pin and the o-ring.

The primary transmission pinion and the clutch

housing ring are paired, which is why they can not

be changed separately. Always replace them

together.

WARNING

Pay attention to the washer which remains at the

bottom of the housing.

PAY ATTENTION

To the star selector's indexing pin. the locking

lever should only be extracted if the housing is

changed.

• Loosen the Allen screw

2

and remove the

star selector 3.

REMOVING THE LOCKING

MECHANISM

• Push back the scorpion with a screwdriver

so that it is no longer in contact with the

star selector, then remove the selection

shaft.

• Then loosen the screw

4

and remove the

lever with its spring and spacer.

1

3

2

17

REMOVING THE IGNITION

HOUSING

• Remove the screws and extract the

ignition housing with its gasket.

REMOVING THE TORQUE

LIMITER AND THE STARTER

DRIVE

• Remove the 3 shoulder screws 1.

• Remove the torque limiter lug

2

.

• Remove the starter drive

3

.

• Remove the torque limiter

4

.

2

3

4

1

DISMANTLING THE ENGINE (next)

18

250-300 SE-R

ENGLISH

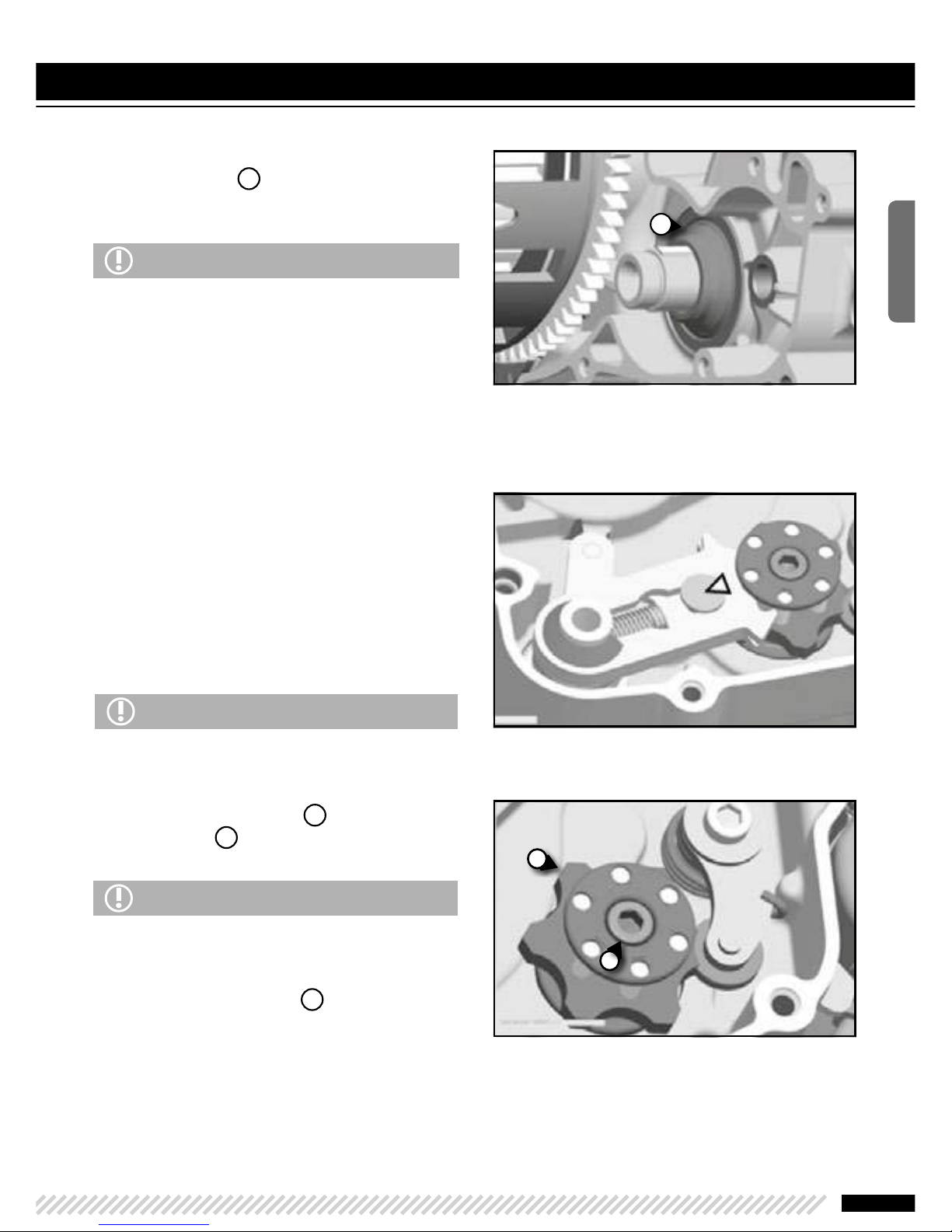

REMOVING THE IGNITION

• Hold the flywheel with the 4753 tool 1

and unscrew the shoulder nut.

• Position the R462 puller

2

and extract

the magnetic flywheel 3.

INTAKE PIPE AND VALVE BOX

• Remove the 4 THEP screws 4.

• Remove the pipe, the valve box, and their

respective gasket.

1

3

2

4

19

• Separate the half crankcases.

• Tilt the engine so that the ignition side is

facing you.

• Remove all the fixing screws.

• Remove the seal ring and its o-ring from

the gearbox output shaft.

• Lift the left half crankcase by lightly tapping

the gearbox output shaft with a plastic

mallet to separate it from the other half.

• Remove the half crankcase and the central

gasket.

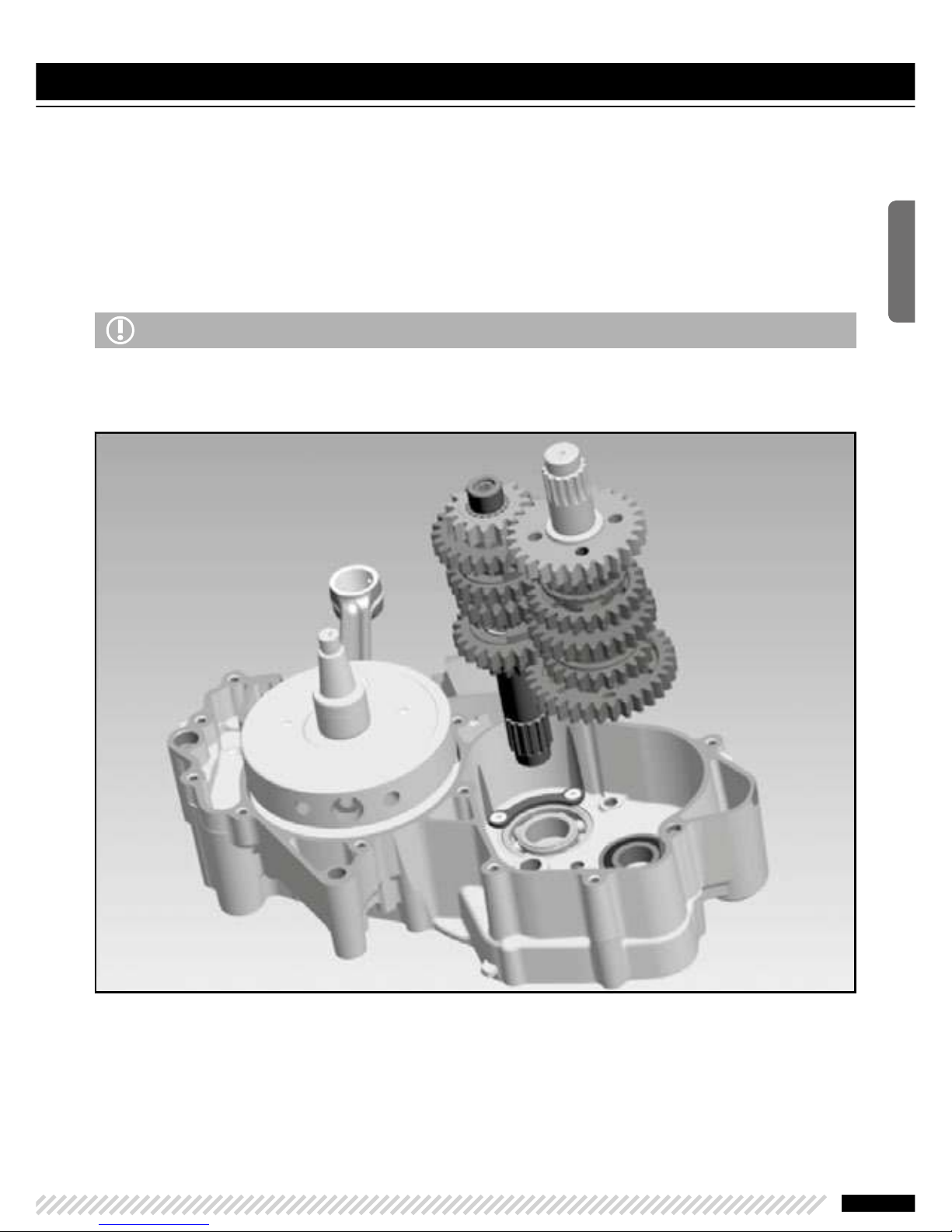

REMOVING THE GEAR

SELECTION

• Remove the gearbox lubrication tube 1.

• Remove the set ring from the primary

shaft

2

.

• Remove the two pins from the shift forks

3

and push the shift forks to the side to

release them from the cylinder.

• Remove the selection cylinder from its

bearing.

• Remove the shift forks.

• Remove the primary and secondary shaft

from their bearing together.

WARNING

Prising a screwdriver or other tool between the

half housings to separate them should be avoided

as much as possible. You may damage the gasket

surfaces.

WARNING

Pay attention to the gearbox shafts' set rings. They

can remain stuck inside the housing.

WARNING

When dismantling, take care not to lose the small

rollers 4 on the fork studs. identify which is the

corresponding fork for each roller to facilitate

reassembly.

1

2

3

3

4

DISMANTLING THE ENGINE (next)

20

250-300 SE-R

ENGLISH

REMOVING THE CONNECTING ROD ASSEMBLY

• Remove the connecting rod assembly from its bearing (if necessary by tapping lightly with a

plastic mallet on the end of the crankshaft).

• Clean all parts and check for wear. Replace them if necessary.

WARNING

When completely dismantling the engine, it is best to replace all gaskets, spi seals, o-rings and even

bearings.

21

Loading...

Loading...