1

TECHNICAL SPECIFICATION

FOREWORD ........................................................ 2

TOOLS LIST 250-300 SE ........................................ 3

TECHNICAL SPECIFICATION ............................. 4

ENGINE ............................................................... 4

CARBURETOR .................................................. 4

CYCLE PART ....................................................... 5

STANDARD ADJUSTMENT ................................. 6

FORK .................................................................. 6

SHOCK ABSORBER ............................................. 7

OPERATIONS REQUIRING DISASSEMBLY OR NOT

ENGINE ............................................................... 8

REMOVING THE ENGINE ................................. 9

REASSEMBLING THE ENGINE IN THE FRAME

........................................................................ 9

DISMANTLING THE ENGINE .......................... 10

❱❘ Gear box drainage ................................................. 10

❱❘ Removing the pinion and selector .......................... 10

❱❘ Removing the cylinder head / the cylinder / the

piston ......................................................................... 11

❱❘ Removing the clutch housing ................................. 12

❱❘ Removing the pressure plate and discs ................. 13

❱❘ Remove the electric starter .................................... 13

❱❘ Removing the primary transmission ....................... 14

❱❘ Removing the primary transmission ....................... 15

❱❘ Removing the torque limiter and the starter drive .. 15

❱❘ Removing the ignition ............................................. 16

❱❘ Intake pipe and valve box ...................................... 16

❱❘ Remove the gear selection .................................... 17

❱❘ Removing the connecting rod assembly ................ 18

❱❘ Connecting rod assembly ....................................... 18

CHECKING ENGINE COMPONENTS ............. 19

❱❘ Balance weight, checking the external dimensions 19

❱❘ Radial play of the connecting rod head .................. 19

❱❘ Checking the crankshaft run out ............................ 19

❱❘ Piston ..................................................................... 20

❱❘ Gap spacing ........................................................... 20

❱❘ Piston pin check ..................................................... 20

❱❘ Checking the wear condition of the cylinder .......... 20

❱❘ Functional check .................................................... 21

❱❘ Valve stop learning after cylinder reassembly ....... 24

❱❘ Valve box intake pipe sleeve .................................. 24

❱❘ Clutch ..................................................................... 25

❱❘ Gearbox .................................................................. 25

❱❘ Valve box and intake pipe ...................................... 33

❱❘ Gearbox output pinion............................................ 33

❱❘ Starter drive assembly ........................................... 33

❱❘ Mounting the ignition and its cover ........................ 34

❱❘ Mounting the electric starter .................................. 34

SYNERJECT) INJECTION SYSTEM

INSTRUCTION MANUAL .................................... 35

INTRODUCTION SYNERJECT SYSTEM ......... 35

1.1- Synerject system .............................................. 35

1.2- Description Exxodiag diagnostic .................. 35

1.3- Diagnostic tool kit contents. ........................... 36

1.4- Installation of the diagnostic tool ................... 36

PRESENTATION OF THE SOFWARE ............. 40

2.1- Connection with Keyless system ................... 40

2.2-

Software settings: configuration menu

2.3- Update menu and synchronization ................ 43

3 - Using

3.1- Identification ..................................................... 45

3.2- Reading the default codes .............................. 46

3.3- Erasing default codes ...................................... 48

3.4- Test the actuators ............................................ 49

3.5- Updating the ECU ............................................. 51

3.6- Screen printing function.................................. 53

TORQUES TABLE ........................................... 54

CARBURETOR ADJUSTEMENT TABLE ........ 55

❱❘ SE 250-Carburetor adjustments table ................... 55

❱❘ SE 300-Carburetor adjustments table ................... 56

CHECKING THE LOAD CIRCUIT .................... 57

❱❘ Static control value ................................................. 57

❱❘ Dynamic control values .......................................... 57

the software

.............................................. 45

.................... 42

T° SENSOR, ENGINE RPM SENSOR, HIGH

VOLTAGE COIL ............................................... 58

WIRING DIAGRAM .......................................... 59

❱❘ Main harness .......................................................... 59

❱❘ Standard lights harness .......................................... 60

❱❘ Racing lights harness .............................................. 61

❱❘ Accessories harness ................................................ 62

REASSEMBLING THE ENGINE ...................... 27

❱❘ Assembling the half crankcases ............................. 27

REASSEMBLING THE ENGINE ...................... 28

❱❘ Gear selection mechanism ..................................... 28

❱❘ Primary transmission and clutch ............................ 29

❱❘ Clutch discs, pressure plate ................................... 30

❱❘ Clutch housing........................................................ 30

❱❘ Piston and cylinder ................................................. 31

❱❘ Squish table ............................................................ 32

❱❘ Cylinder head ......................................................... 32

1

FOREWORD

This manual is primarily intended for qualified mechanics working in a properly equipped

workshop.

A solid knowledge of mechanics and the specific SHERCO tools for the 250 SE-R and

300 SE-R engines are required to perform the various operations.

This workshop manual complements the SHERCO 250 SE-R and 300 SE-R user manual

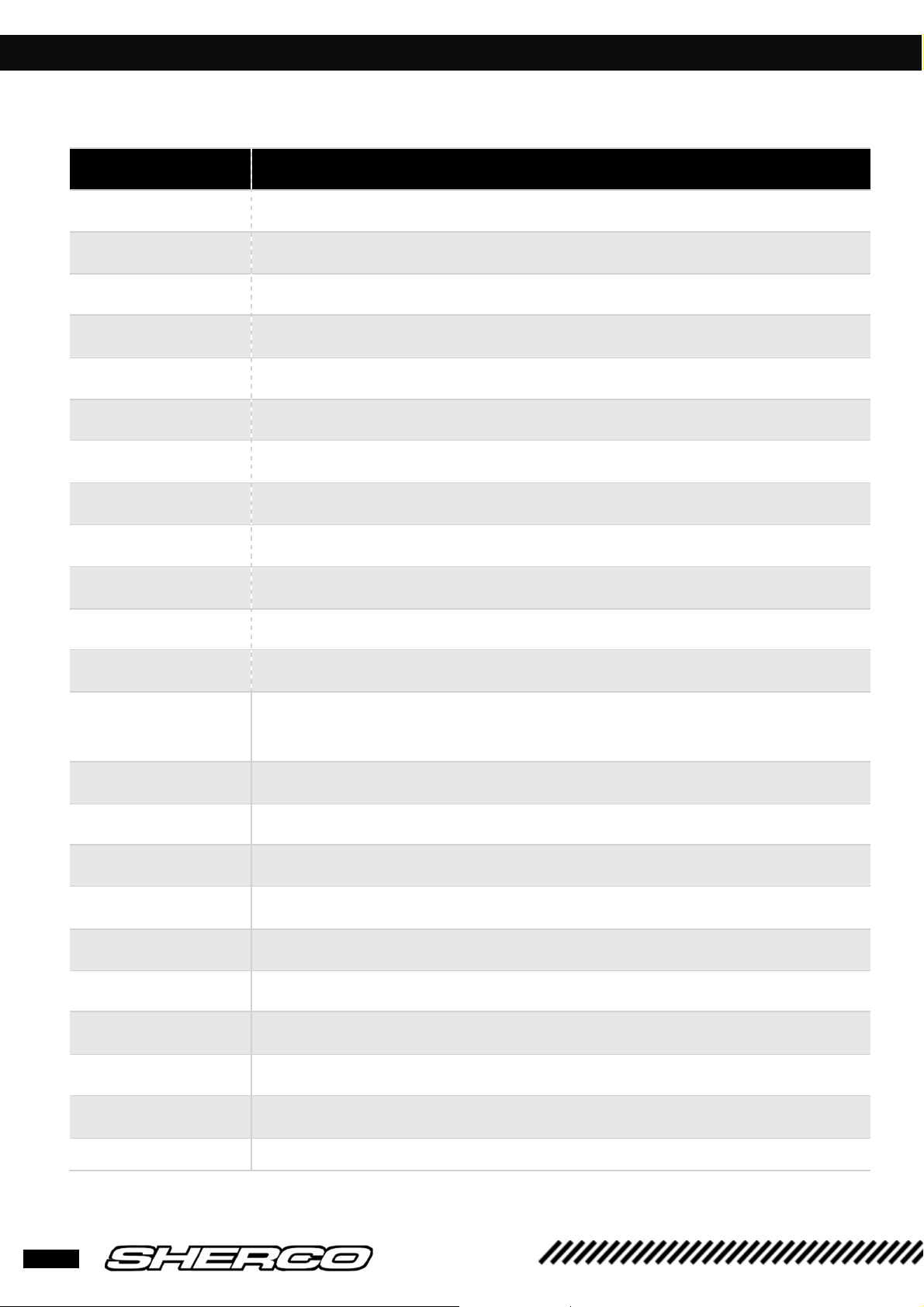

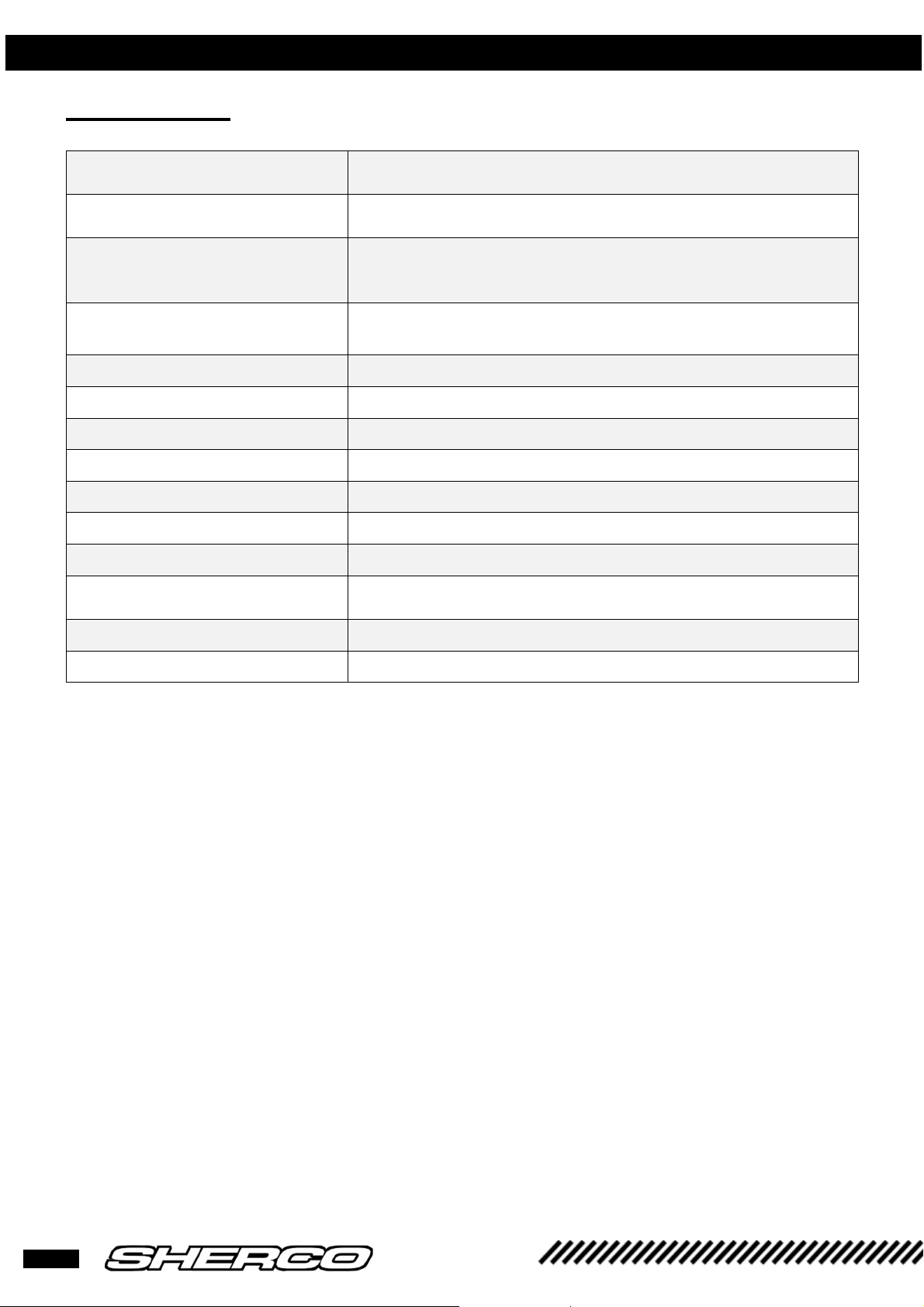

TOOLS LIST 250-300 SE

Tool reference Designation

5749 Clutch block

4753 Ignition block

2067 Swing-arm pin tool

R467 Right crankcase primary shaft bearing tool

R465 Secondary shaft bearing tool

5397 Gearbox output shaft bearing tool

R446 Gearbox output spi tool

5398 Barrel selection bearing tool

5399

R469 Right crankcase crankshaft bearing tool

Left crankcase crankshaft bearing tool

5400

5401

5402

1968

1821

5206

2073

R462

R464

R453

R444

Clutch side crankshaft spi tool

Ignition side crankshaft spi tool

HK0808 needle cage tool

(water pump, starter drive double pinion, starter drive)

Water pump spi seal tool

Engine support

Primary pinion block tool

Spring block (pin selection)

Magnetic flywheel puller

Crankshaft ring extractor

Selector axis bearing assembly tool

Selector spi seal tool

6267

4967

3

Diagnostic Key less tool

Diagnostic briefcase

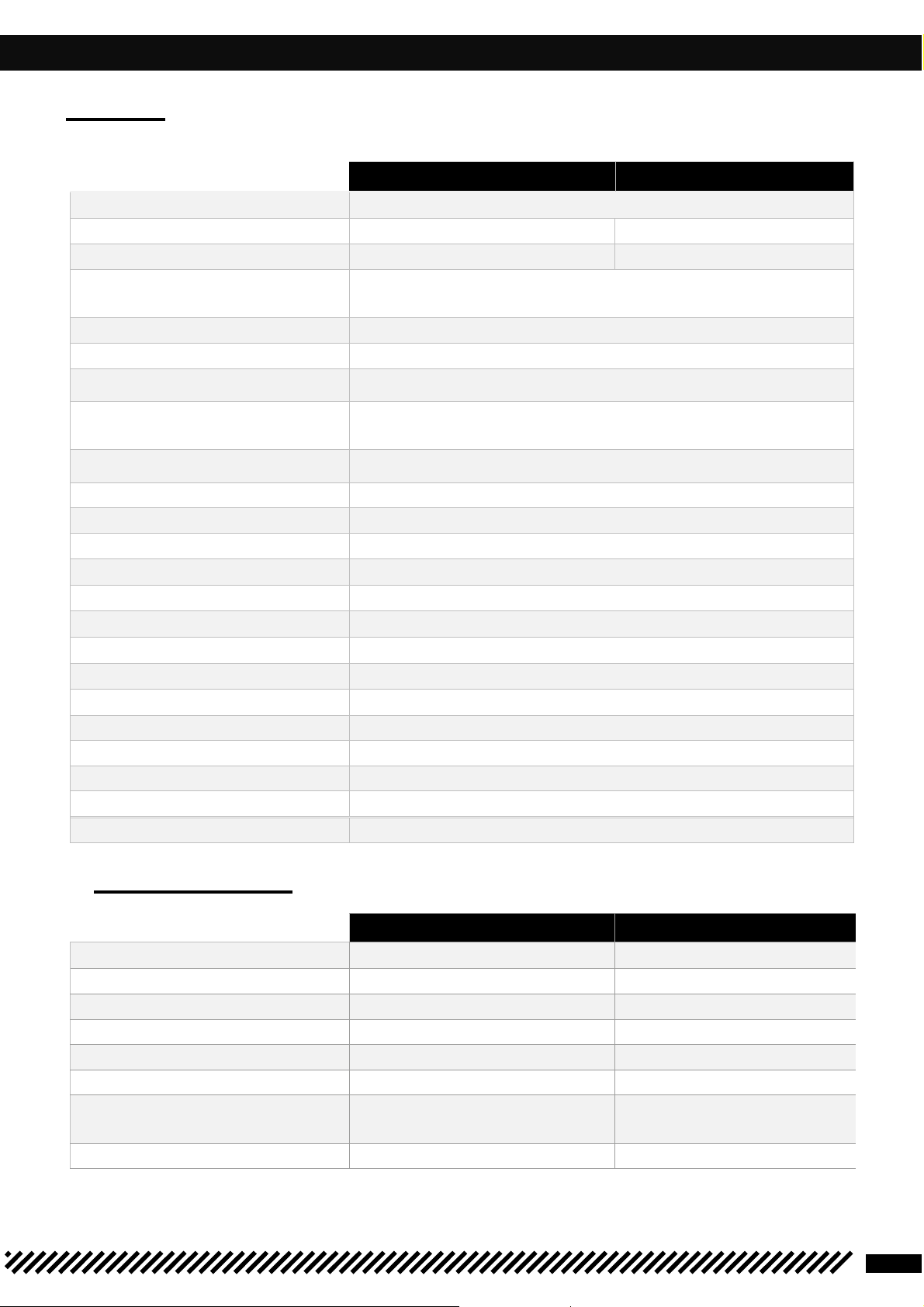

250/300 SE

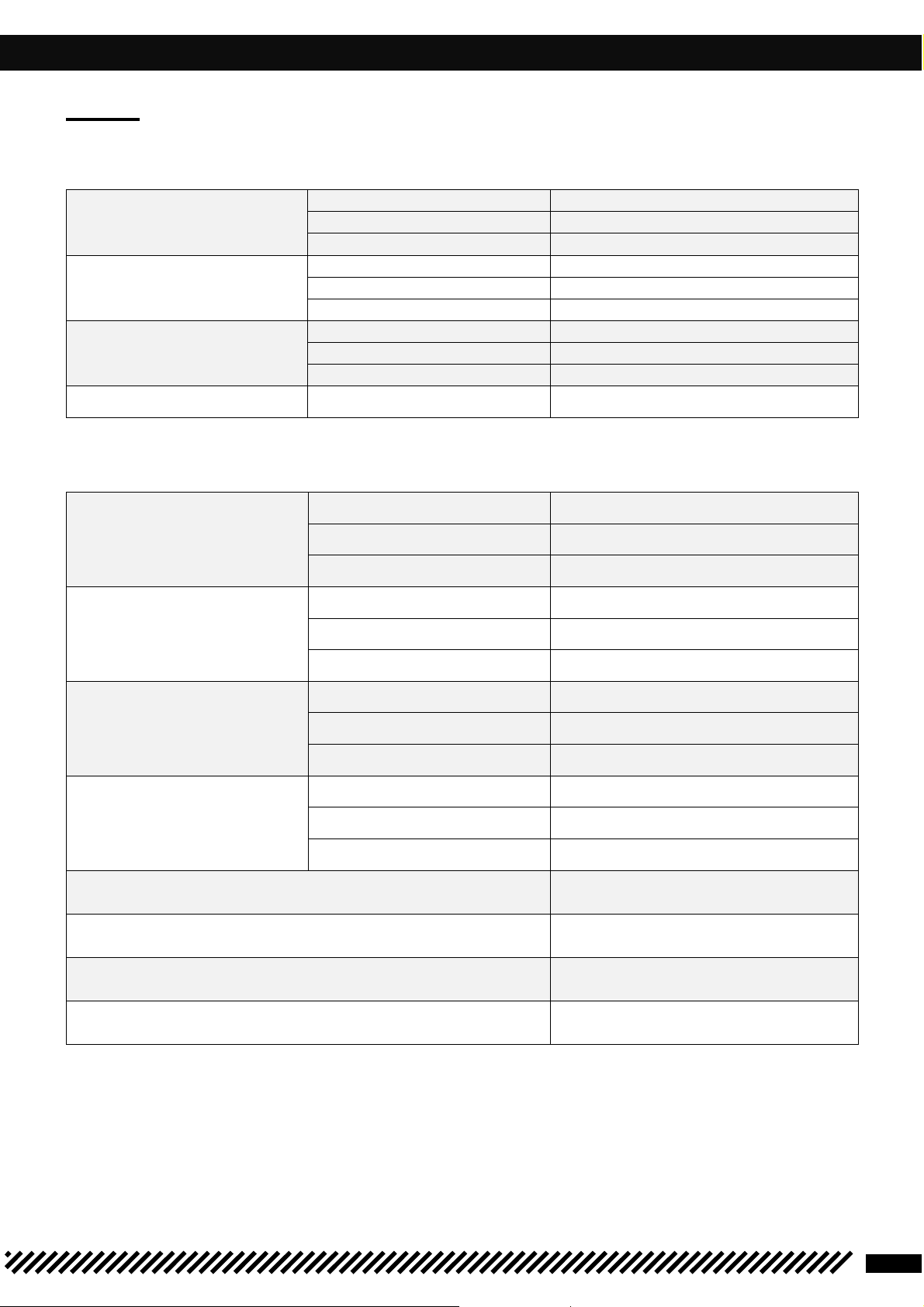

TECHNICAL SPECIFICATION

ENGINE

Type

Capacity

Bore/Stroke

Petrol

Cooling

Ignition system

Spark plug

Distance between spark

plug electrodes

Piston

Engine oil

Primary transmission

Gearbox : 6 speeds

1st 14 : 32

2nd 15 : 26

3rd 29 : 27

4th 21 : 24

5th 23 : 22

6th 25 : 21

Final transmission

Clutch

Starter

Battery

249.32 CC

66.4/72 mm

Cast aluminum

750 ml SAE 10W40

27 : 75

Oil bathed multi disks, hydraulic control

Electric starter

12V 4Ah

Unleaded with an octane rating of at least 98 mixed with 2-

250 300

Single cylinder 2 stroke liquid cooling

stroke oil (2 %)

Liquid with forced circulation

Synerject electronic ignition

NGK BR7ES/DENSO W22ESRU

0.7 mm

14 X 49

293.14 CC

72/72 mm

Alternator

220W

CARBURETOR

Carburetor type

Needle position

Jet needle

Main jet

Idle jet

Choke jet

Air regulating screw

opening

Valve spacing

KEA 162 (KEA 115) KEA 172 (KEA 115)

KEP 40 (KEA38) KEP 42 (KEA 38)

85 (50) 85 (50)

3rd position from the top

N°7 N°7

KEIHIN PWK 36S AG KEIHIN PWK 36S AG

250 300

3rd position from the top

N1EG (N84K) N8RE (N84K)

1T 1/4 1T 1/2

4

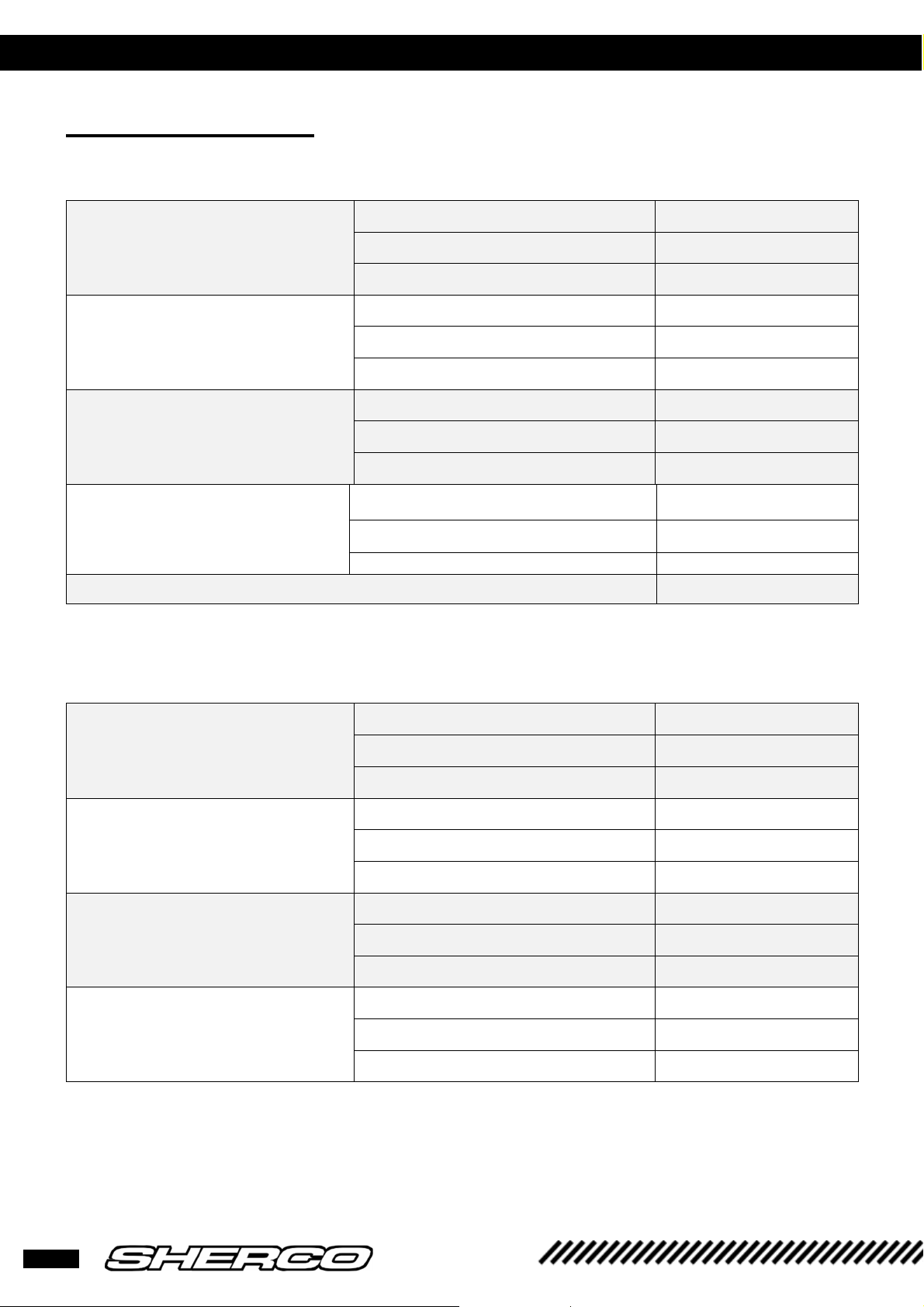

TECHNICAL SPECIFICATION

Frame

Semi

-

perimeter CrMo

steel with aluminum sub frame

Angle of the steering column

CYCLE PART

Fork

Rear suspension

Travel Front/Rear FACTORY 330/330mm

Front brake rotor Ø 260mm

Rear brake rotor Ø 220mm

Brake disc Limit : 2.7mm front et 3.6mm rear

Front tire 90/90-21’’

Rear tyre 140/80-18’’

Pressure front / Rear 0.9 bar

Fuel tank capacity 10.4Ll with1 liter of reserve

Wheel base 1480mm

KAYABA USD Ø48mm Closed cartridge(FACTORY)

WP XPLOR USD Ø48mm (RACING)

KAYABA suspension with separate cylinder (FACTORY)

WP suspension with separate cylinder (RACING)

Aluminum swing arm

RACING 300/330mm

27.3°

Weight (without fuel) 119 kg

5

250/300 SE

STANDARD ADJUSTMENT

Compression

Rebound

Spring

Fork oil

Compression

Rebound

Preload

Spring stiffness

Type of oil

Spring length with preload spacer

Quantity of oil

FORK

Factory settings

Racing settings

– Fork KAYABA USD Ø48 mm

Comfort 20 clicks back

Standard 13 clicks back

Sport 8 clicks back

Comfort 18 clicks back

Standard 13 clicks back

Sport 10 clicks back

Rider weight

Rider weight

Rider weight

01M 345 CC

– Fork WP XPLOR suspension USD Ø48mm

Comfort 18 clicks back

Standard 15 clicks back

Sport 12 clicks back

Comfort 18 clicks back

: 65-75 kg 4.0N/mm (Original)

: 75-85 kg 4.2N/m

: 85-95 4.4N/m

Standard 15 clicks back

Sport 12 clicks back

Comfort +0 tours

Standard +0 tours

Sport +6 tours

Rider weight

Rider weight

Rider weight

Oil level measurement (fork compressed and spring

removed) from the top of the fork tube

: 65 - 75 kg 4.2N/mm

: 75 - 85 kg 4.4N/mm (Original)

: 85 - 95 kg 4.6N/mm

SAE 4

474 mm

606ml

100mm (min30-max 120 mm)

6

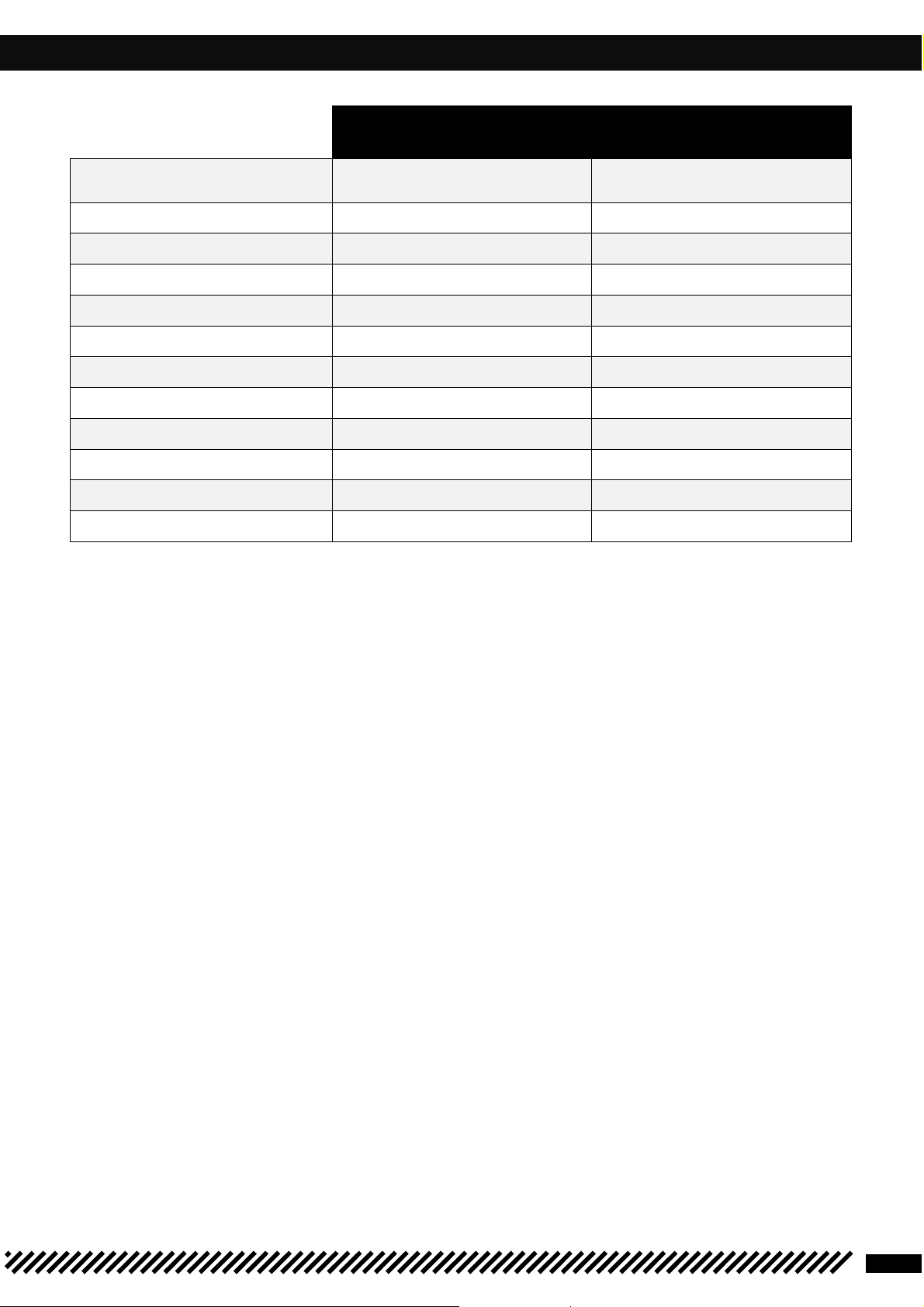

Low

-

speed compression

High

-

speed compression

Rebound

Spring stiffness

Low

-

speed compression

High

-

speed compression

Rebound

Spring stiffness

STANDARD ADJUSTMENT

SHOCK ABSORBER

Factory Settings

– KAYABA shock absorber

Comfort 20 clicks back

Standard 14 clicks back

Sport 12 clicks back

Comfort 2,5 turns back

Standard 1.5 turns back

Sport 1 turn back

Comfort 15 clicks back

Standard 13 clicks back

Sport 11 clicks back

Type of oil

Racing Settings

Rider weight : 65-75 kg

Rider weight : 75-85 kg

Rider weight : 85-95 kg

K2C

– WP suspension shock absorber

Comfort 17 clicks back

Standard 12 clicks back

Sport 9 clicks back

Comfort 2 turns back

Standard 1.5 turns back

Sport 1 turn back

Comfort 16 clicks back

Standard 14 clicks back

50N/mm

46N/mm

48N/mm (original)

7

Sport 12 clicks back

Rider weight : 65-75 kg

Rider weight : 75-85 kg

Rider weight : 85-95 kg

250/300 SE

51N/mm

54N/mm (original)

57N/mm

OPERATIONS REQUIRING DISASSEMBLY OR NOT ENGINE

Operation requiring engine

Operation not requiring engine

Crankshaft

(including

the crank

Complete gearbox

Crankshaft bearing

Gearbox bearing

Piston

Cylinder

Cylinder head

Ignition

Starter gear set

Complete clutch

Water pump

Speed selection assembly

kit)

removal

•

•

•

•

removal

•

•

•

•

•

•

•

•

8

REMOVING / REISTALLING THE ENGINE

WARNING

WARNING

REMOVING THE ENGINE

To remove the engine, you must remove the swing arm's pivot bolt to detach the rear

wheel/swing arm assembly. Secure the chassis with a jack to prevent the motorcycle

from overturning.

• Drain (refer to the owner’s manual)

- the engine oil

- the engine coolant

• Remove the seat.

• Disconnect the battery.

• Remove the fuel tank and its covers.

• Disconnect all the electrical wiring connectors from the engine.

(Starter, TPS sensor, water temperature sensor, coil, fuel injector)

• Remove the exhaust.

• Remove the ignition coil.

• Remove the carburetor.

• Remove the chain.

• Remove the chain guard.

• Remove the clutch slave cylinder.

When the clutch slave cylinder is removed, the piston is no longer held in place. Secure

the piston with a plastic collar.

• Remove all of the water hoses connected to the engine.

• Remove the left radiator.

• Loosen all of the engine bolts.

• Loosen the swing arm bolt.

• Remove the brackets that attach the cylinder head to the chassis.

• Remove the engine mounting bolts.

• Remove the swing arm bolt.

• Remove the motor.

REASSEMBLING THE ENGINE IN THE FRAME

The motor should be reinstalled in the frame in the reverse order of how it was removed. The following

torque values should be utilized.

Tightening torques:

Engine mounting bolts: 60Nm

Swing arm axle nut: 100 Nm

Clutch receiver screws: 10 Nm

Cylinder head bracket bolts: 23Nm

Exhaust mounting bolts: 10Nm

9

250/300 SE

DISMANTLING THE ENGINE

1

2

3

4

5

1

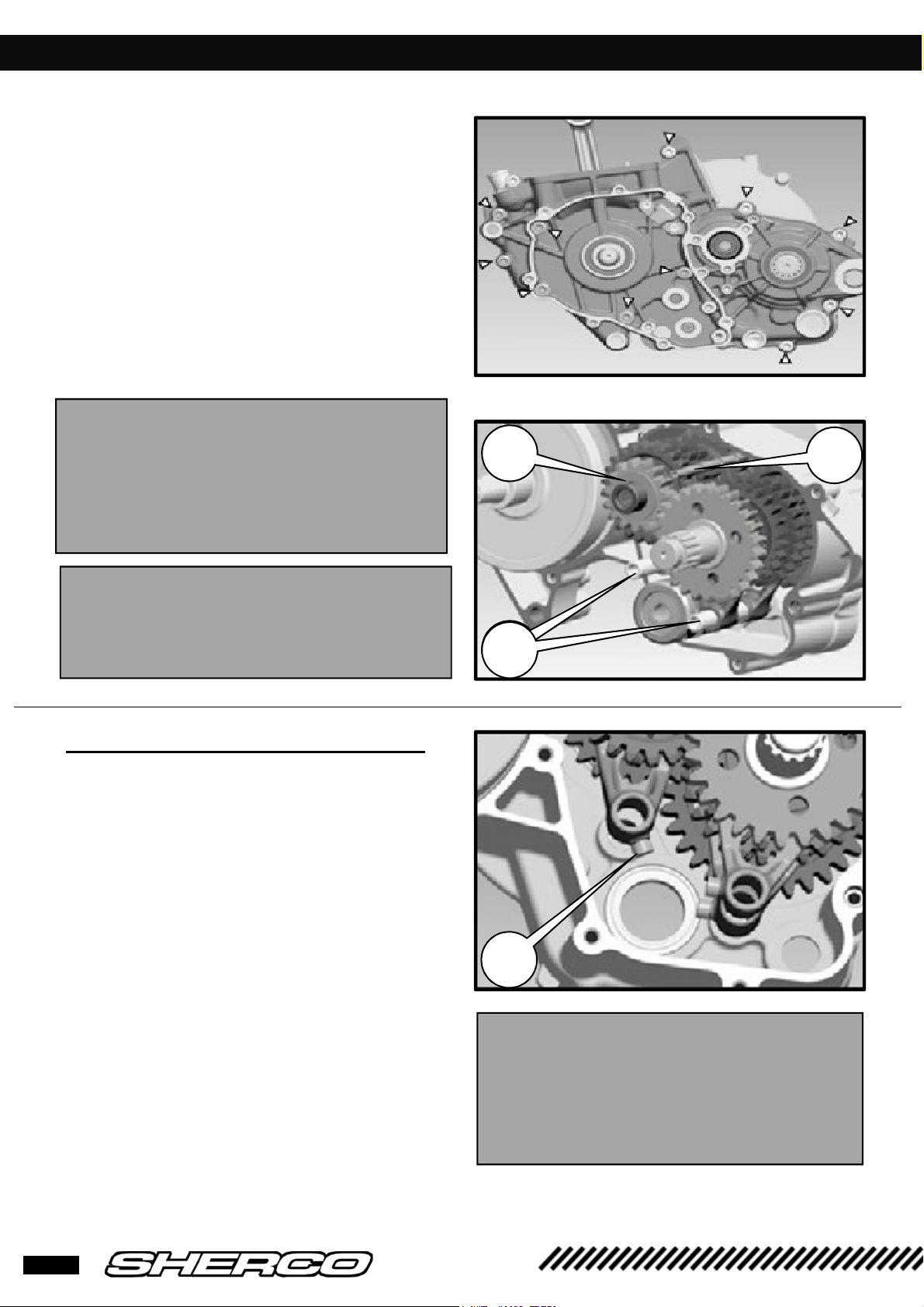

❱❘ Gear box drainage

• Remove drainage plugs

oil

flow out.

[1]

and

[2],

let the

❱❘ Removing the pinion and

selector

•

Unfold the safety washer tab

device.

•

Remove the gearbox output pinion

•

Remove the screw first

the selector.

•

Release the clutch control rod.

[3]

using a punch

[5]

first and then

[4].

10

DISMANTLING THE ENGINE

1

2

3

4

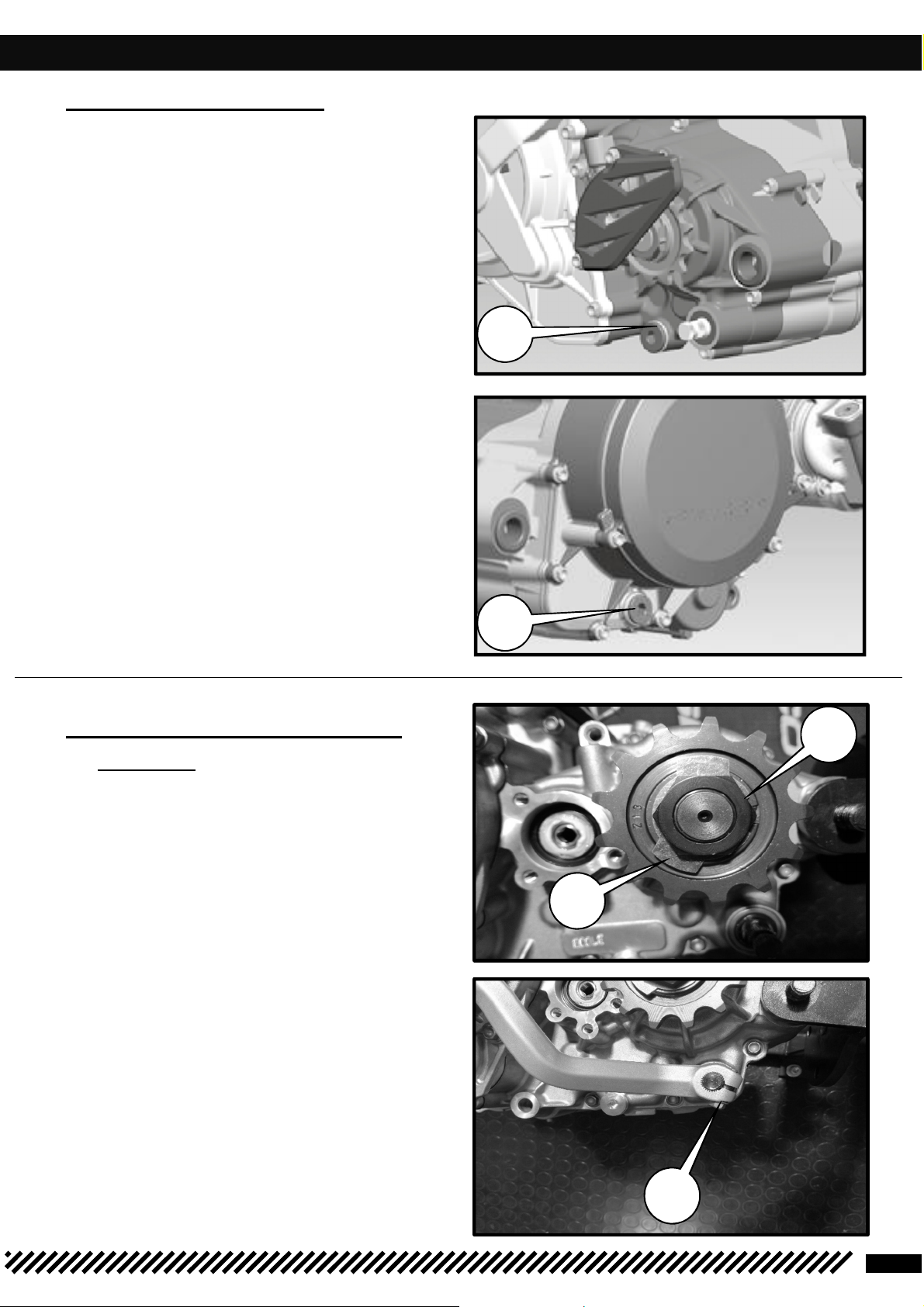

❱❘ Removing the cylinder head / the cylinder / the piston

•

Remove the shoulder screws

cashers, remove

two O-rings

the cylinder head and the

[1]

the copper

•

Remove the exhaust valve actuator

• Remove the exhaust chamber cover.

• Remove the 4 screws

• The cylinder and remove it.

• Mask the cover.

[4]

on the base of

[2]

11

250/300 SE

DISMANTLING THE ENGINE

• Remove the piston pin clips.

• Remove the piston pin.

• Remove the piston and extract the needle

bearing from the connecting rod.

•

Remove the gasket

❱❘ Removing the clutch housing

•

Remove the screws and the water pump

cover.

•

Remove the gasket

• Remove the screws and extract the clutch

housing.

• Remove the gasket

.

12

DISMANTLNG THE ENGINE

3 2

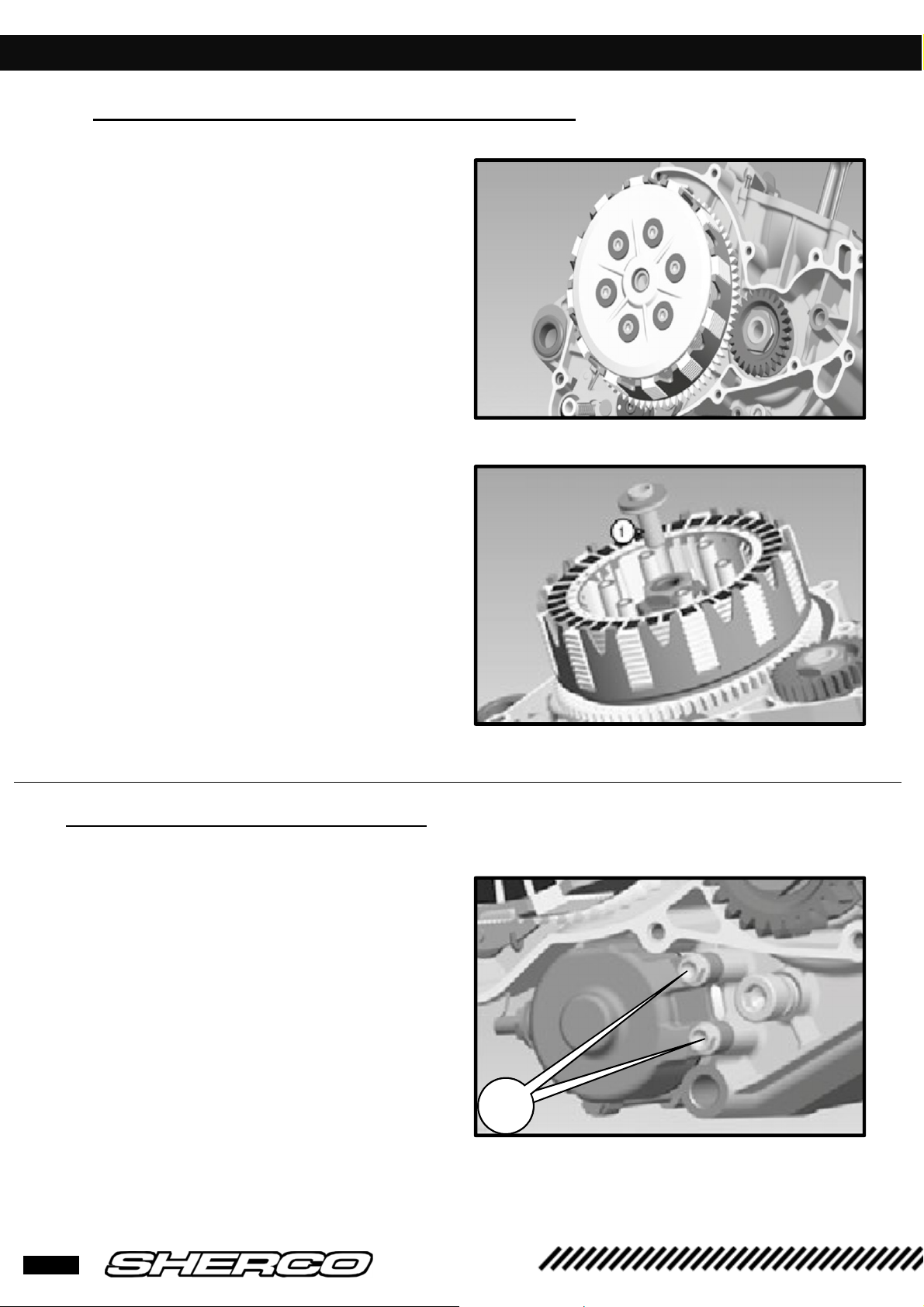

❱❘ Removing the pressure plate and discs

• Loosen the pressure plate screws

• Remove the screws, springs and springs

cups.

• Remove the pressure plate and discs from

housing.

• Remove the support part

shaft

[1]

on the primary

❱❘ Remove the electric starter

• Remove the 2 screws

[2]

13

250/300 SE

DISMANTLING THE ENGINE

WARNING

housing ring

4

3

6

6

1

3

2

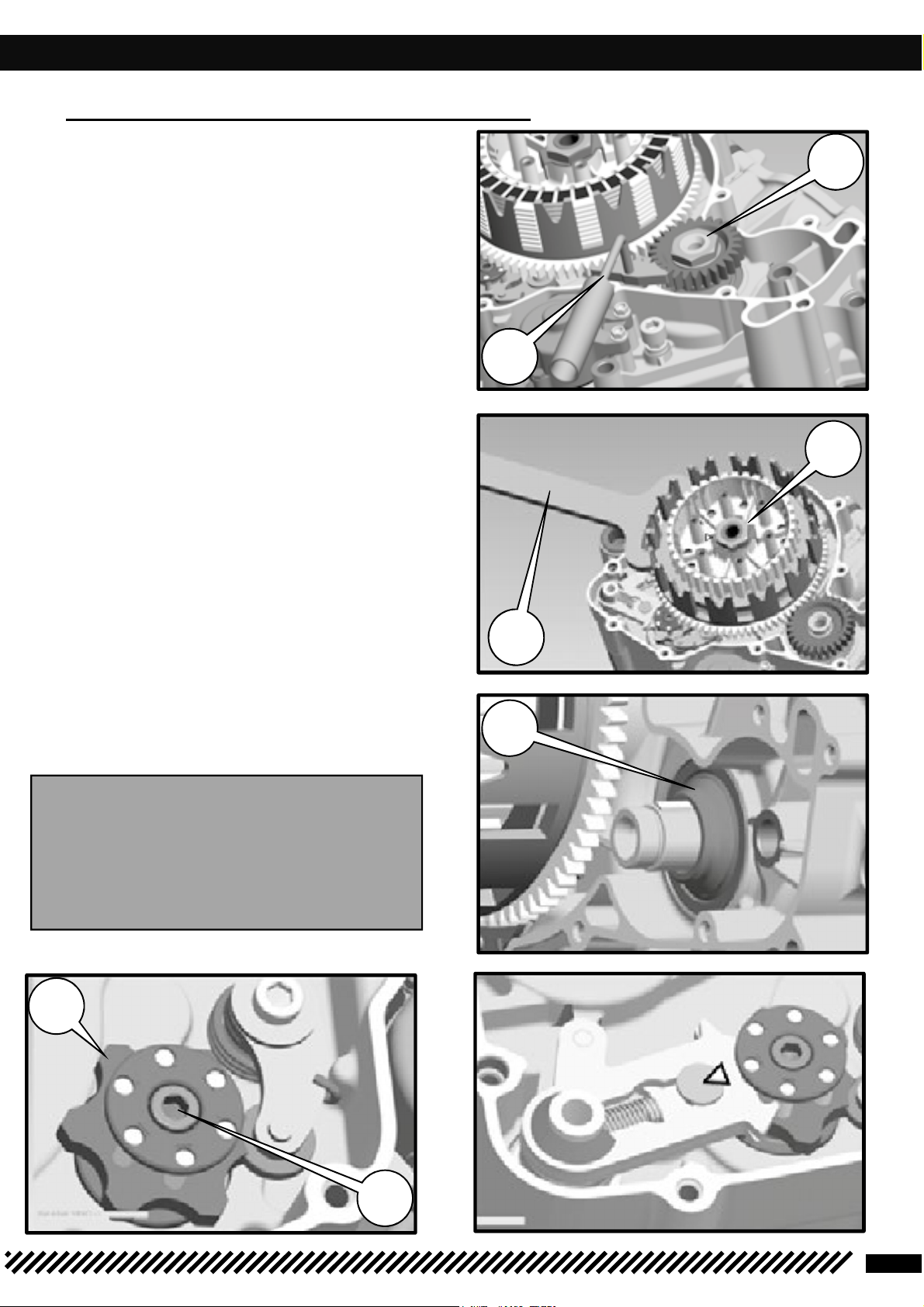

❱❘ Removing the primary transmission

• Lock the pinion at the end of the crankshaft

with the 5206 tool

[3]

• Unscrew the primary transmission nut

and then remove it with its conical washer

• Open the clutch boss lock washer

• Apply the 5749 tool

hold the boss, then loosen the nut.

• Remove the tool.

• Remove the boss the crenellated washer,

the housing with 2 needle cages

[6]

which is designed to

[5]

[4]

• Removing the primary transmission pinion

and the spacer

crankshaft

To the pin and the o-ring.The primary

transmission pinion and the clutch

are paired, which is why they can not be

changed separately. Always replace them

..

[1]

together.

at the end of the

14

DISMANTLING THE ENGINE

2

1

2

2

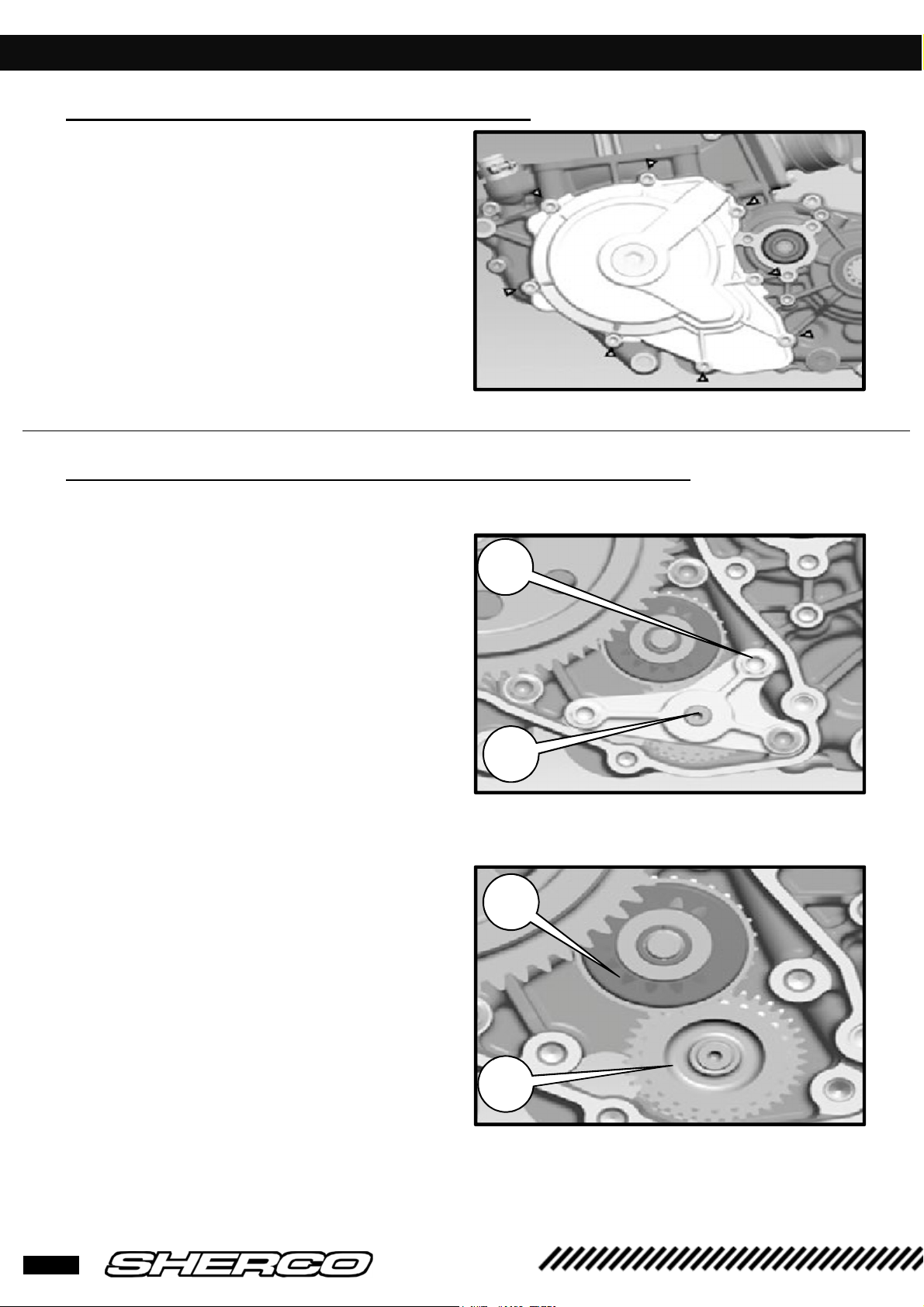

❱❘ Removing the primary transmission

• Remove the screws and extract the ignition

housing with its gasket

❱❘ Removing the torque limiter and the starter drive

• Remove the 3 shoulder screws [1]

• Remove the torque limiter lug [2]

• Remove the starter drive [3]

• Remove the torque limiter [4]

15

250/300 SE

DISMANTLING THE ENGINE

2 1

3

2

4

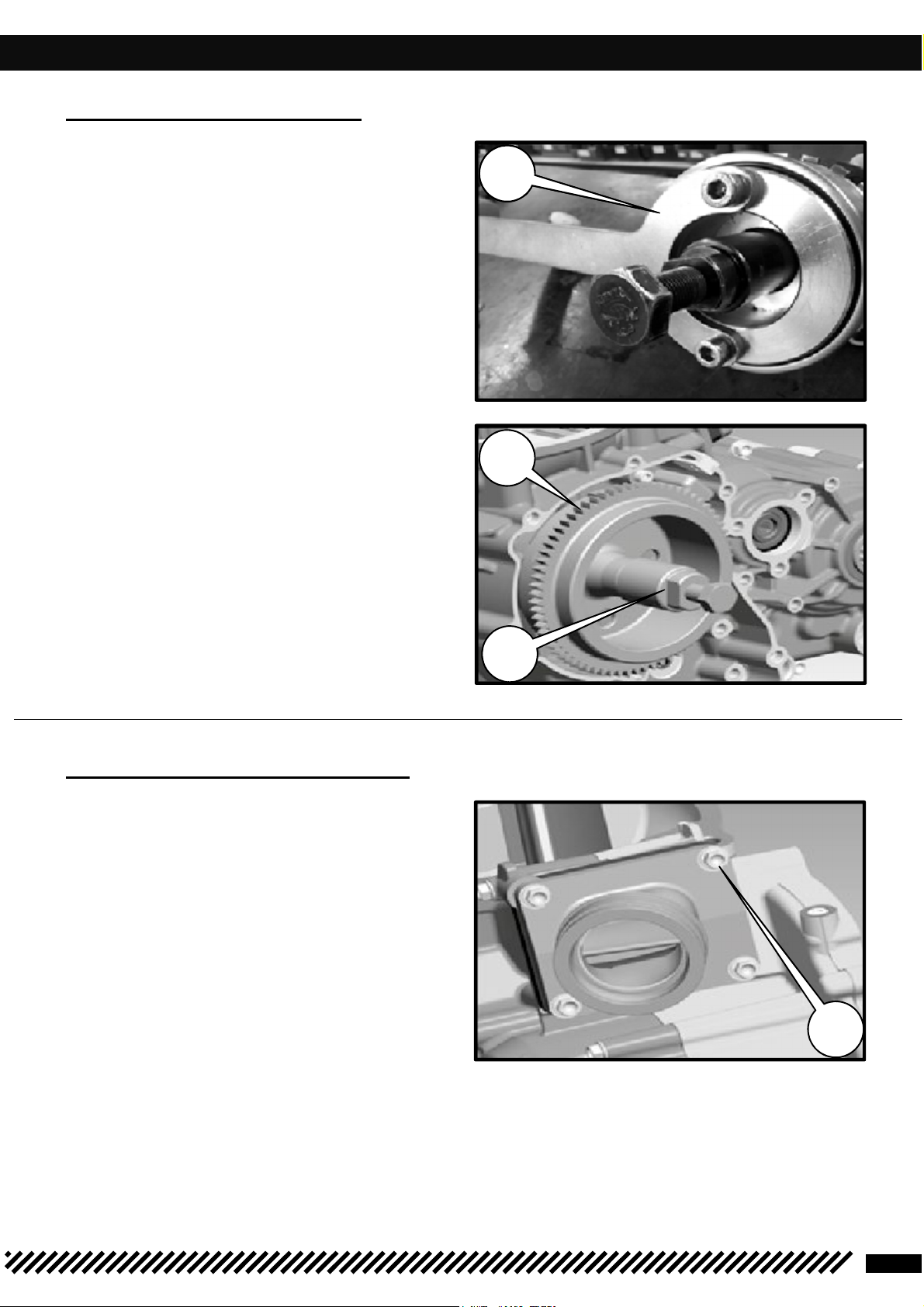

❱❘ Removing the ignition

•

Hold the flywheel with the 4753 tool

unscrew the shoulder nut.

•

Position the R462 puller

magnetic wheel

[3]

[2]

and extract the

[1]

and

❱❘ Intake pipe and valve box

• Remove the 4 THEP screws

• Remove the pipe, the valve box, and their

respective gasket.

[4]

16

DISMANTLING THE ENGINE

WARNING

WARNING

1 2

3

4

WARNING

•

Separate the half crankcases.

•

Tilt the engine so that the ignition side is

facing you.

•

Remove all the fixing screws.

•

Remove the seal ring and its o-ring from the

gearbox output shaft.

•

Lift the left half crankcase by lightly tapping

the gearbox output shaft with a plastic

mallet to separate it from the other half.

•

Remove the half crankcase and the central

gasket

between the half housings to separate

them should be avoided as much as

possible. You may damage the gasket

Prizing a screwdriver or other tool

surfaces.

Pay attention to the gearbox shafts' set

rings. They can remain stuck inside the

housing

❱❘ Remove the gear selection

• Remove the gearbox lubrication tube ,

• Remove the set ring from the primary shaft

[2]

• Remove the two pin from the shift forks [3]

and push the shift forks to the side to

release tem from the cylinder

• Remove the selection cylinder from its

bearing

• Remove the shift forks

• Remove the primary and secondary shaft

from their bearing together.

When dismantling, take care not to lose

the small rollers

identify which is the corresponding fork

for each roller to facilitate reassembly

[4]

on the fork studs

17

250/300 SE

DISMANTLING THE ENGINE

WARNING

❱❘ Removing the connecting rod assembly

• Remove the connecting rod assembly from its bearing (if necessary by tapping lightly with a plastic mallet

on the end of the crankshaft).

• Clean all parts and check for wear. Replace if necessary.

When completely dismantling the engine, it is best to replace all gaskets, spi seals, o-

rings and even bearings

❱❘ Connecting rod assembly

• If the roller bearing has been changed, the

inner ring which sits against the balance

weight must also be changed.

• Heat the R464 tool to approximately 150°C,

immediately thread it onto the inner ring.

Place the tool correctly on the ring to

encourage heat transfer, then extract the

ring.

• To mount the new ring, heat the tool to

approximately 150°C. Insert the new ring and

thread it immediately onto the connecting rod assembly.

18

CHECKING ENGINE COMPONENTS

A

❱❘ Balance weight, checking the external dimensions

• Use a caliper to measure the external

distance of the balance weights:

External value : 64.3mm +0 / -0.2

❱❘ Radial play of the connecting rod head

• Position the crankshaft on the V and place a

dial gauge [A] against the connecting rod

64.3

head.

• Push B the connecting rod head towards the

gauge, then in the opposite direction.

• The difference between these two

measurements corresponds to the radial

play.

Radial play of the connecting rod head :

Standard : 0.015 mm – 0.025 mm

Tolerable limit : 0.06 mm

If the radial play is greater than the tolerated limit, the crankshaft must be replaced

❱❘ Checking the crankshaft run out

• Measure the lateral play of the connecting

rod head

[A]

;

B

Lateral play of the connecting rod head :

Standard : 0.8 mm - 1 mm

Tolerable limit : 1.25 mm

If the play is greater than the tolerated limit, the

crankshaft must be replaced

19

250/300 SE

CHECKING ENGINE COMPONENTS

WARNING

❱❘ Piston

• If you want to install a used piston, check the following points :

• Skirt : look for any marks (tightening). Light marks can be removed with a soft stone.

• Segment grooves : Segments must not get stuck in their groove. These can be cleaned with an

old segment or emery cloth (400 grit).

• Segment retainers must be tightly held and must not be worn.

• Segments : Check the condition and gap spacing.

❱❘ Gap spacing

• Thread the segment into the cylinder and position it with the piston (about 10 mm from the

top edge of the cylinder).

• Using a spacer, the gap spacing is measured.

Gap spacing :

Standard 0.35-0.45mm ,

Max 0.65mm.

If the gap is greater than indicated, check the condition of the cylinder and the piston. If their

dimensions are within the tolerance range, replace the segment

❱❘ Piston pin check

Piston pin diameter

Standard 17,995-17,998 mm

Tolerable limit 17,962

piston pin hole diameter

Standard : 18.006-18.010mm

Tolerable limit : 18.08

❱❘ Checking the wear condition of the cylinder

• To detect cylinder wear, the bore is measured with a bore comparator at about 10 mm

from the top edge of the cylinder. Measure from both direction to identify any potential

ovality.

Cylinder Cylinder bore Piston

250 66.410-66.420

A

300 72.10-72.020

66.421-66.430

72.021-72.030

B

A

B

20

CHECKING ENGINE COMPONENTS

•

Remove the valve cover

•

Remove the actuator support

•

Remove the stop screw

copper sealing washer

•

Remove the bore circlip with circlip pliers

[29].

•

Remove the valve mechanism assembly

[6].

[10]

[9].

[12].

with the

❱❘ Functional check

•

Clean and descale all the dismantled parts.

•

Check with your fingernail that there are no notches on the exhaust barrels [32] and [35],

visually check their seating in the cylinder.

•

Inspect the axis of rotation of the exhaust valve [33], replace it if there are notches that you can

feel with your fingernail.

•

Test the play in the exhaust barrel bearings [31] and check that there is no hard point over

360°.

•

Systematically change all the gaskets on the top of the engine [28, 7, 26, 4, 5, 11, 15, 9]

before reassembling.

•

To reassemble, follow the disassembly procedure in reverse, paying attention to the following

points.

21

250/300 SE

CHECKING ENGINE COMPONENTS

WARNING

When reassembling the actuator support

[12]

, be careful that the 2 screws are not

the same lengt

•

After reassembly, check the lateral play of

the central valve minimum 0.1 mm

•

Check that the pin stops against the valve

(kidney-shaped contact) when it is 100 %

open

.

•

Check that the pin stops against the valve

(kidney-shaped contact) when it is 100 %

closed

22

CHECKING ENGINE COMPONENTS

WARNING

In the following cases the valve must not reach the stopper during opening and

closing

•

Check the lateral play of all the mechanics

minimum 0.1 mm

23

250/300 SE

CHECKING ENGINE COMPONENTS

WARNING

4X M5X16

4X M5X16

4Nm

M6X20

❱❘ Valve stop learning after cylinder reassembly

After any maintenance operation on the internal parts of the cylinder and/or

after changing the cylinder, the Sherco diagnostic tool's machine learning

application must be run (see p63 diagnostic tool chapter).

❱❘ Valve box intake pipe sleeve

•

Over time the carbon tabs gradually lose

their elasticity, which results in a loss of

power.

•

Replace the worn or damaged box.

•

Check the condition of the intake sleeve,

especially if it is not cracked

24

CHECKING ENGINE COMPONENTS

4

❱❘ Clutch

• Stopper

•

Rod [8] check for wear. Minimum length : 194.7 mm.

•

Springs

[3]

check wear.

[17]

Check their length. Minimum spring length 45 mm. Replace the 6 springs if

necessary.

•

8 clutch plates [14] Minimum thickness 2.68 mm.

•

The 7 smooth disks must be in good condition with a maximum deformation limit of 0.05 mm.

Refer to the 250 SE-R/300 SE-R spare parts catalogue for exploded views

❱❘ Gearbox

•

Apply grease to the shift fork studs and

thread the rings

•

Fix the securing washers

and secondary shaft.

•

Position both the primary and secondary

shafts and push them into their respective

bearings until they stop.

[1]

over them.

[2]

on the primary

•

Identify the direction and location of the

forks on the picture. Fork

[3]

corresponds

to the primary shaft.

25

250/300 SE

CHECKING ENGINE COMPONENTS

WARNING

1

WARNING

WARNING

gearbox shafts must now turn without any

1

A used fork must have its original pinion and its

rollers

•

Attach the forks in the grooves of the sliding

gears and push the barrel into its ball bearing.

•

Oil the fork shafts and thread them into the

forks. Push the forks into their housing in the

housing until they stop

When the forks are attached in the barrel, it is

important to be careful that the rollers do not

fall off the studs

.

The

hard points.

26

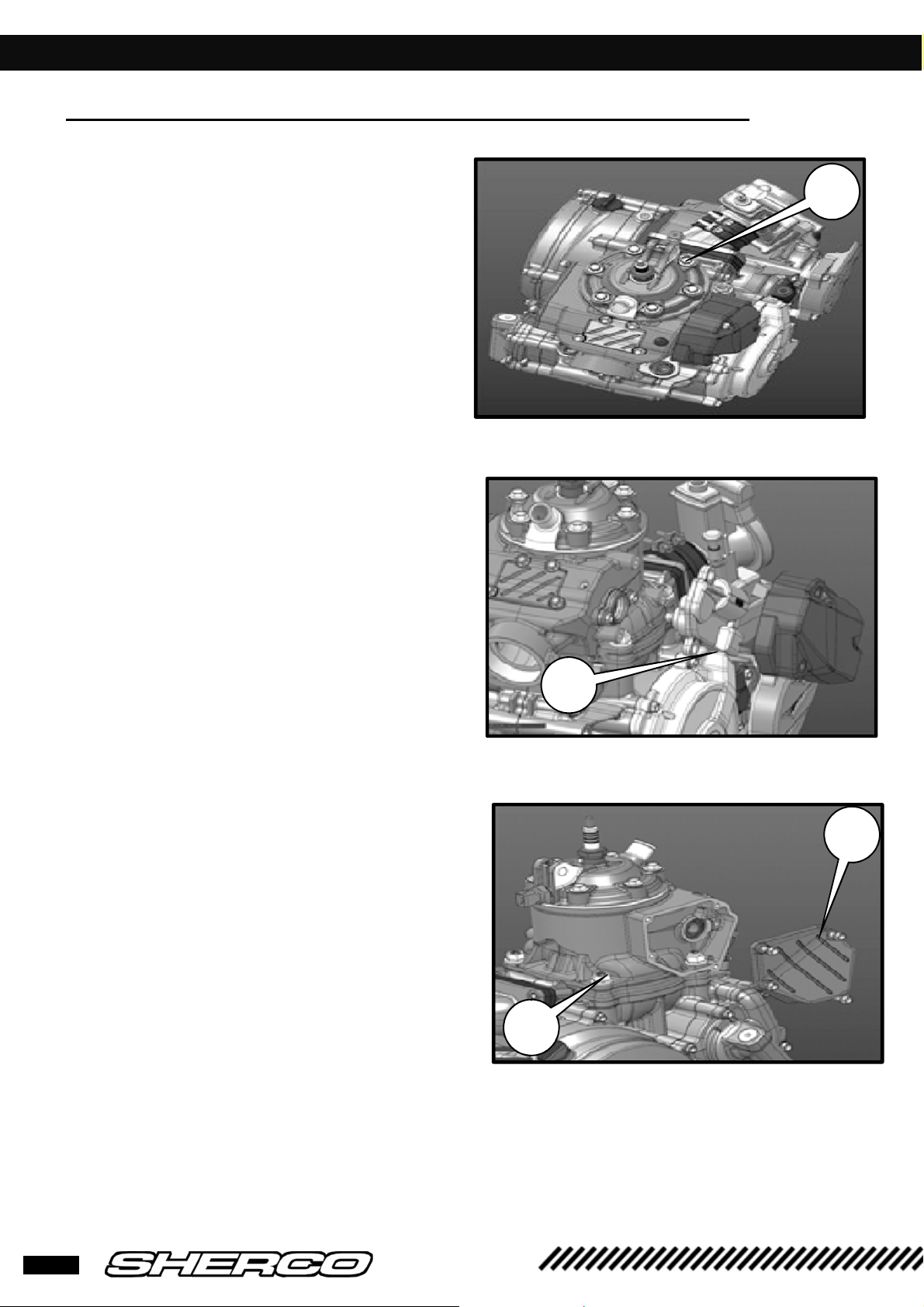

REASSEMBLING THE ENGINE

WARNING

Pay attention to the tube indexing, flat section

❱❘ Assembling the half crankcases

•

Assemble the gearbox lubrication tube on the right half crankcase

near oil cap rivet.

• Fit the o-ring onto the gearbox lubrication tube.

• Make sure that the centering rings are in place

on the right half crankcase and that the gearbox

shaft washers are also assembled.

• Lubricate the seals of the left half housing and

put in position.

• Fix the screws and tighten to 10 Nm.

•

Next, lightly tap the crankshaft with a plastic

mallet and check that the shafts turn without

hard points

any

27

250/300 SE

REASSEMBLING THE ENGINE

❱❘ Gear selection mechanism

•

Put the spring in the crankcase with the

strand bent upwards.

•

Thread the spacer, the locking pin the

washer, coat the CHC M6X20 screw with

blue threadlock and assemble all parts.

•

Attach the spring to the lever. The other end

of the spring must be pressed against the

housing.

•

Fit the star selector's indexing pin onto the

drum.

•

Pull the lock lever back to position the star

selector.

•

Coat the screw with blue threadlock and

assemble the star selector on the drum

•

Grease the already assembled selection pin

and thread it into the needle bearings

without forgetting the lock washer.

•

When the prong stops against the star

selector push it back so that the shaft can

be lowered completely

•

Check that the return spring strands are

against the pin on each side of the housing.

•

Position the selector and try changing all

the gears. You will have to turn the gearbox

output shaft to change the different gears.

Remove the selector again

28

REASSEMBLING THE ENGINE

2 1

3

❱❘ Primary transmission and clutch

•

Grease the connecting rod assembly seal.

•

Thread the previously oiled o-ring onto the

connecting rod assembly, then fit the steel

spacer with the groove on the same side as

the balance weight.

•

Install the half-moon pin in its housing.

•

Thread the pinion onto the rear of the

crankshaft with the shoulder facing down.

•

Thread the washer

needle cages

[1]

and the two oiled

[2]

onto the primary shaft

•

Fit the clutch housing and its crenellated

washer [3]

•

Coat the threads of the primary shaft with

blue threadlock.

•

Mount the clutch boss on the primary

shaft, coat its nut with red threadlock and a

new safety washer.

•

Employ the 5749 tool and tighten the nut to

100Nm.

•

Remove the tool and brake the nut by

folding the edge of the lock washer.

•

Put blue threadlock on the crankshaft

thread.

•

Assemble the conical washer and nut.

•

Lock the primary gear with the 5206 tool

and tighten the crankshaft pinion nut to

150 Nm using red threadlock.

•

Remove the 5206 tool and check there are

hard points in the primary transmission by

rotating the connecting rod

29

250/300 SE

WARNING

REASSEMBLING THE ENGINE

❱❘ Clutch discs, pressure plate

• Oil the push pin [1] and thread it onto the

primary shaft.

• Before assembly oil the clutch plates.

• Start with clutch plate. The 8 clutch discs

and the 7 smooth discs are alternated.

• Place the pressure plate, springs, cups and

CHC screws.

• Tighten the screws crosswise to 10 Nm

❱❘ Clutch housing

•

Check that the two centering bushing are in

place in the clutch housing.

•

Fit the housing gasket and hold it in place

with a Little grease.

•

Glue the water pump set ring [2] with a little

grease.

•

Position the clutch housing making sure that

the water pump assembly is in place. The

connecting rod assembly must be rotated so

that the water pump pinion can engage the

end of the crankshaft.

•

Fix the THEP M6 screws and tighten to

10Nm except for the M6X12 to 6Nm

Put a new seal on the M6x50 screw, cooling liquid drain screw, and the M6x12 screw.

•

Check that the shafts turn without any hard

points

30

WARNING

REASSEMBLING THE ENGINE

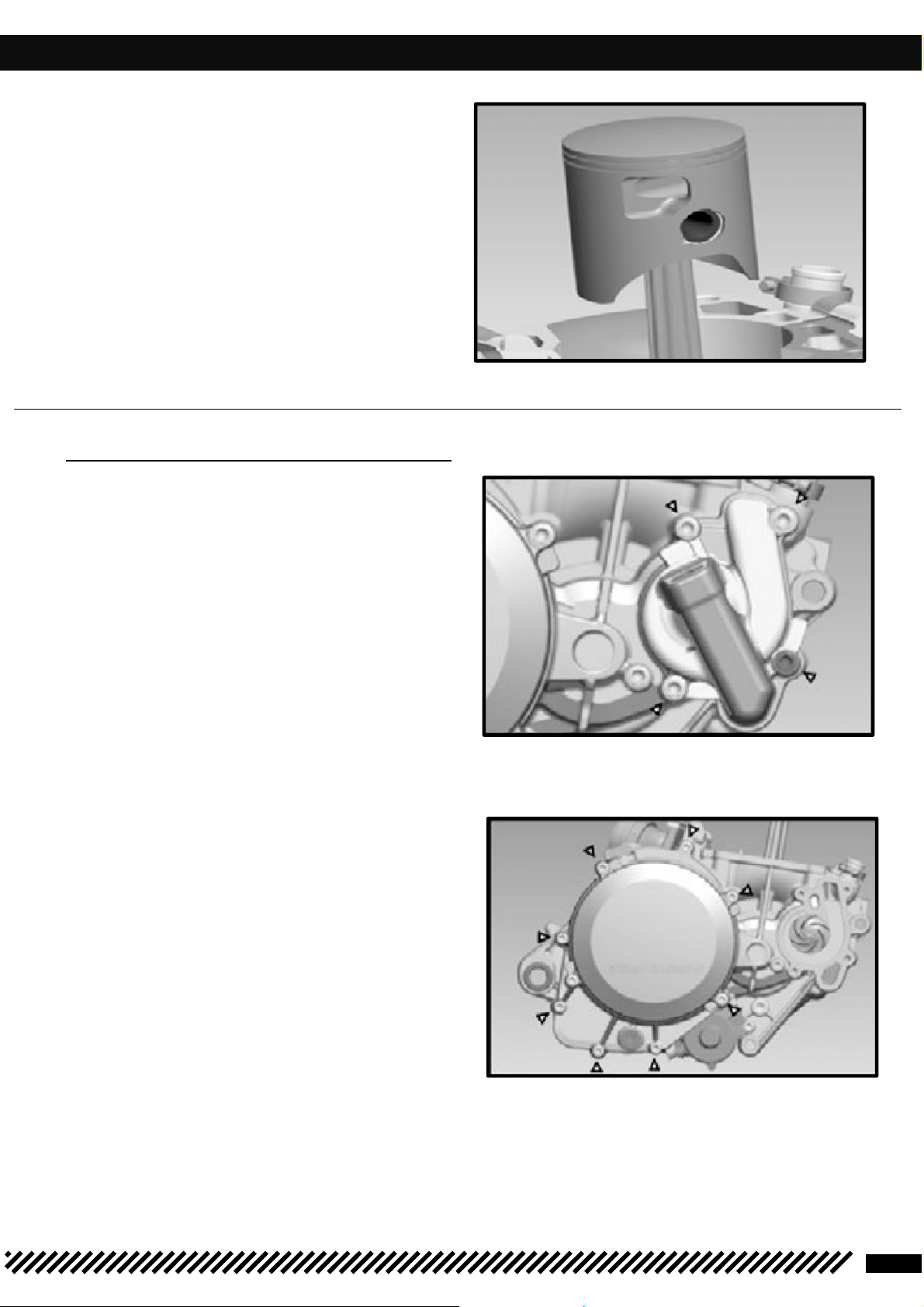

❱❘ Piston and cylinder

•

Oil the parts thoroughly before reassembling.

•

Thread the needle bearing into the small

end, position the piston (the arrow on the top

of the piston in the direction of the exhaust).

•

Position the shaft and the clips with the open

side down.

•

Place the 0.5 mm header gasket.

•

Correctly position the segments, reference

marks facing up.

•

Install the cylinder.

•

Tighten the flange nuts in 2 passes.

•

The 1st to 20 Nm and the 2nd to 35 Nm.

•

Check the squish by measuring the distance

between the piston surface at top dead

center and the cylinder head surface

firstly measure after having

placed a 0.5 mm header

gasket), depending on the

value obtained from the

following squish adjustment

table, adjust with one or more

header gaskets

31

250/300 SE

REASSEMBLING THE ENGINE

❱❘ Squish table

Squish, Standard = 1.7±0.1 mm (Set back of piston = -0.05mm)

Measurement of piston's overrun

or set back (-) (X mm)

Made with a 0.5 mm gasket

X ≤ - 0,25 1,9 mm 0,3 mm 4942

-0,25 < X ≤ - 0,15 1,8 mm 0,4 mm 7238

-0,15 < X ≤ - 0,05 1,7 mm 0,5 mm 3840

-0,05 < X ≤ 0,05 1,6 mm 0,6 mm 4932 + 4942

0,05 < X ≤ 0,15 1,5 mm 0,7 mm 7238 + 4942

0,15 < X ≤ 0,2 1,45 mm 0,75 mm 4943

Squish 1st

measurement

0.5 mm gasket

Thickness of

gasket to have

a 1.7 mm

Squish

Sherco

reference

gasket(s) to be

mounted for

1.7 mm Squish

❱❘ Cylinder head

•

Clean the cylinder gasket and cylinder head surfaces.

•

Put the 2 centering pins on the cylinder.

•

Position the cylinder head.

•

Fit the M8 shouldered screws with new copper washers.

•

Tighten three times crosswise to 25Nm

32

REASSEMBLING THE ENGINE

❱❘ Valve box and intake pipe

•

Place a new valve box gasket.

•

Put the complete valve box in the intake

duct.

•

Install a new intake pipe gasket.

•

Assemble the intake pipe with the 4M6

screws.

•

Install the intake sleeve with its metal collar

❱❘ Gearbox output pinion

•

Oil the o-ring and thread it onto the output

shaft.

•

Thread over the spacer so that the gasket

sits in place.

•

Place the gearbox output pinion, the safety

washer.

•

Put blue threadlock on the thread.

•

Thread the safety washer.

•

Fix the nut to tighten to 150Nm.

•

Unfold the safety washer's tab onto the nut.

❱❘ Starter drive assembly

•

Put the double pinion in the needle cage.

•

Put the starter drive in place.

•

Position the retaining triangle and fix the 3

THEP screws.

•

Lubricate the pinions with grease spray

33

250/300 SE

REASSEMBLING THE ENGINE

WARNING

❱❘ Mounting the ignition and its cover

•

Put the half moon pin in its housing on the crankshaft.

•

Thread the rotor onto the crankshaft.

•

Put blue threadlock on the thread.

•

Using the 5207 tool, put on the nut and tighten to 60Nm.

•

Put the 2 centering sleeves in position.

•

Fit a new gasket and secure the ignition cover

❱❘ Mounting the electric starter

•

Replace the starter's o-ring with a new gasket.

•

Lightly grease the o-ring.

•

Install the starter into the right crankcase.

•

Fix the starter with the 2 THEP screws.

•

Finish by oiling and threading the clutch control rod into the primary shaft.

•

Fit the speed selector with its screw and washer

•

Fit the two drain plugs with a new seal.

The gear box must be filled when the engine is back on its frame ; if not, a

certain amount of oil will escape out the primary shaft.

34

1

2

4

3

SYNERJECT) INJECTION SYSTEM INSTRUCTION MANUAL

INTRODUCTION SYNERJECT SYSTEM

1.1- Synerject system

[1]

Synerject M3C controller : 3459

[3]

High voltage coil : 8308

[2]

Engine actuator : 6933

[4]

Water temperature sensor : 0380

1.2- Description Exxodiag diagnostic Tools référence 4967

Your Sherco 250 SE-R and 300 SE-R is equipped with a Synerject electronic management

system consisting of an M3C controller, an ignition, an engine actuator, a high voltage coil, a

water temperature sensor and a specific electrical harness

35

250/300 SE

SYNERJECT

mail to courrierxxotest.com.

1.3- Diagnostic tool kit contents.

The case consists of a USB to MUX output cable, a MUX peripheral device, a MUX to

motorcycle diagnostic connector cable, an installation CD (or the link below), a user manual

1.4- Installation of the diagnostic tool

In case of problem during the installation please contact EXWOTEST at +33 (0)4 50 02 34 34 or by

A- Installing the software and drivers

• Open the installation CD on your computer

• Run “ sherco_setup”

•

Select the language.

)

INJECTION SYSTEM INSTRUCTION MANUAL

• Click on « Next ».

• Choose the installation folder.

36

SYNERJECT

)

INJECTION SYSTEM INSTRUCTION MANUAL

• Click on « Next ».

• Click on « Install ».

• Installation in progress.

37

250/300 SE

SYNERJECT

•

Check the box « Start the driver installation

• The following window will open. Read the

« I accept the terms of the license agreement »

)

INJECTION SYSTEM INSTRUCTION MANUAL

»

and click on « Finish ».

terms of the license agreement. Check the box

and click on « Install ».

• Installation in progress.

38

SYNERJECT

)

INJECTION SYSTEM INSTRUCTION MANUAL

• The following window will open. Click on

« Finish ».

The installation is complete

.

B- Connect the « MUXDIAG II » cable and its interface to a USB port on your computer

Connect the cable to the diagnostic connector of the motorcycle.

Make sure the « MUXDIAG II » unit is properly powered by checking the LED:

• Solid blue

• Flashing blue

• Blue off

• Solid green:

• Flashing green (slow):

• Flashing green (fast):

• Green off:

• Solid red

• All LEDs OFF:

: PC connection properly established.

: communication with PC in progress.

: no connection to the PC, or device in standby; it can also indicate a problem with the USB connector.

firmware issue.

no firmware.

: correct power supply to the card.

the outlet is not powered on, or is off or USB in on standby mode.

firmware correctly run.

communication with PC in progress.

39

250/300 SE

SYNERJECT

PRESENTATION OF THE SOFWARE

2.1- Connection with Keyless system

Sherco had a Keyless system on its motorcycles which allows the bike to switch on without

any key and switch off automatically after 30secondes of non-use.

This last point blocks the diagnostic, this is why it is necessary to follow the steps down

below before doing it.

1.

Remove the plug

part of the bike).

2

)

INJECTION SYSTEM INSTRUCTION MANUAL

(1)

from the connector

1

(2)

(located on the rear sub frame – on the right

2

1

2.

Take the shunt (3) (reference 6267) and connect the plug (1) into it.

3

3.

You can now do the diagnostic by following the next explanations.

40

SYNERJECT

Update and

)

INJECTION SYSTEM INSTRUCTION MANUAL

Information:

To set up the connection with the motorcycle, the motorcycle must be switched on (On). To

navigate through the different menus, the USB cable with the «MUXDIAG II» device only may be

connected to the computer.

Run the software using the icon

The following menu will come up

:

update, proxy

Diagnostics menu

(diagnostic, map

updates,etc.)

Setup menu

(language selection, units,

etc.)

41

250/300 SE

SYNERJECT) INJECTION SYSTEM INSTRUCTION MANUAL

2.2-

Software settings: configuration menu

In this menu, you can modify:

• The diagnostic plug. You can refresh the list by hitting the button.

The number must match the number of the « MUXDIAG II »

device.

• The languages available in the software: English, French, Spanish, Portuguese, German, Italian (the

installation CD provided may not include all languages). Update the software-> page 53).

• Set the unit system.

• Click to return to the home screen.

• Click to save the changes.

42

SYNERJECT

2.3- Update menu and synchronization

)

INJECTION SYSTEM INSTRUCTION MANUAL

A- In this menu, you can update the diagnostic software tool

• To determine whether an update is available,

check that you have an Internet connection,

and then click on the following icon

• If an update is available, the following

window will come up:

• If no update is available, the following

message will come up :

43

250/300 SE

SYNERJECT

•

Click on to start downloading the

update.

•

The following message will come up

•

Click on to start installation

•

Resume the installation process -> page 41. It is not necessary to restart the installation of the drivers

)

INJECTION SYSTEM INSTRUCTION MANUAL

B- Configuration of Internet access parameters

It may be necessary to set up a proxy server to access the Internet

• Click on

• Fill in the following settings if necessary.

• Click on to save your changes.

.

44

SYNERJECT

)

INJECTION SYSTEM INSTRUCTION MANUAL

3 Using

Diagnostic menu and injection mapping update

General

• Click on « Sherco ».

• Click on « M3C ».

the software

• You get the following menu

:

3.1 Identification

You can check the identification of the following (serial number, hours of operation,

calibration number)

45

250/300 SE

SYNERJECT

A. Parameter measurements

)

INJECTION SYSTEM INSTRUCTION MANUAL

General parameters

B. Engine information

Displayed below are the main system values

:

3.2 Reading the default codes

When you click on "read default codes” the system starts checking.

• If no default appears exit the menu by clicking on this icon:

46

SYNERJECT

•

If a default appears:

)

INJECTION SYSTEM INSTRUCTION MANUAL

• You can get the details of the default by clicking on the default display :

• Record the defaults and exit the menu by clicking on this icon

Note:

1-

Transient default/permanent default: a transient default becomes permanent after a

certain number of engine cycles of the following components (injector, fuel pump, etc). For a

permanent default to disappear it takes 40 cycles without the engine default reappearing.

2-

Fan Default : If there is no fan installed on the bike, there will always be a rise in the fan

default code (P0485)

47

250/300 SE

SYNERJECT

3.3 Erasing default codes

1-

If a default appears: go to the menu « Erasing default codes »

Click this icon in order to erase all of the default codes

)

INJECTION SYSTEM INSTRUCTION MANUAL

The following screen will appear:

Confirm by clicking on this icon

48

SYNERJECT

Return to the menu « reading default codes »

Check and make sure that the defaults are the same as before. Check/replace the

defective parts. Check all of the connections.

3.4 Test the actuators

)

INJECTION SYSTEM INSTRUCTION MANUAL

In addition to reading default codes you can also check some of the system components

1-

Ignition coil

When you launch the ignition coil test, the following message will appear

:

:

49

250/300 SE

SYNERJECT) INJECTION SYSTEM INSTRUCTION MANUAL

The system is not able to detect an ignition coil failure with the engine stopped. The test results will be

the same if the coil is faulty or not. Therefore, when testing the ignition coil make sure that the

engine makes the correct sound for a properly functioning ignition coil.

2-

Fan

For the fan perform a standard test. If there is a default it twill appear as a classic default

3-

Exhaust valve learning

.

50

SYNERJECT

3.5 Updating the ECU

By using the diagnostic tool it is possible to make updates to the injection mapping (calibration).

An example would be the fitting of a racing silencer or there is an update from the factory.

These files will be freely available on sherconetwork:

)

INJECTION SYSTEM INSTRUCTION MANUAL

You must pay attention to the model, the displacement, the type of silencer, etc

In case of doubt, contact technical support.

1. Download the desired update (file.mot)

ShercoNetworkInformationTechnical informationInjection Map

.

51

2-

Power up the motorcycle

3-

Click on the computer update

250/300 SE

SYNERJECT

Confirm by clicking on this icon

Select the calibration file (.mot) that was previously downloaded and click open.

4. The file is being downloaded

)

INJECTION SYSTEM INSTRUCTION MANUAL

WARNING

DO NOT TURN OFF THE MOTORCYCLE DURING THE DOWNLOAD OPERATION (FLASH)

DO NOT ABRUPTLY STOP THE FLASH DOWNLOAD PROCESS THERE IS A RISK

OF IRREPAIRABLE DAMAGE TO THE COMPUTER

5. At the end of the download the fuel pump will start and the following message will appear :

INFORMATION : Download was successful

Confirm by clicking on this icon

6. Check to make sure that the correct calibration file was allocated by clicking on

« Identification »

Check to make sure that the file name matches the file that was download

52

SYNERJECT) INJECTION SYSTEM INSTRUCTION MANUAL

Information:

update.

7.

8.

9.

10.

3.6 Screen printing function

If you are communicating with technical support and need help identifying potential

problems you can perform a screen print operation by pressing F10 on your keyboard.

This will allow you to attach these files to your inquiry.

The "identification" screen contains all of the important information about the motorcycle

(serial number of the bike, number of hours of operation, calibration, etc)

the information on serial number and operating hours are not reset during a calibration

Put back the “shunt” on the connector in the air filter box to switch back on “keyless”

mode.

-The ECU power latch will proceed during 20 s.

-Wait 30 s until the ECU stop before starting the bike.

Start the bike, stop it and wait 30 s before to restart the bike11-Switch on the bike and

verify that the parameters of the motor are normal

53

250/300 SE

TORQUES TABLE

Standard tightening torque

Threadlock

M5 7 Nm

M6 10 Nm

M8 25 Nm

Chassis tightening torque

Threadlock

Rear wheel nut 100 Nm

Rear cradle fixing screw 24 Nm

Front wheel nut 40 Nm

Fork end pinch screw 15 Nm

Brake pad pin screw 8 Nm

Pinch screw for lower fork tees WP 12 Nm KYB15

Nm

Pinch screw for upper fork tees WP 17 Nm KYB 17

Nm

Engine screw 60 Nm

Swivel-arm screw 100 Nm

•

•

Head-frame screw 24 Nm

Engine torque

Threadlock

RPM sensor screw 8 Nm

Coolant drain screw 10 Nm

Oil level screw 6 Nm

Clutch slave cylinder screw 9 Nm

Cylinder head crosswise tightening torque

25 Nm

Crankshaft handhold plug 8 Nm

Clutch pressure screw 10 Nm

Water pump housing screw 10 Nm

Ignition flywheel nut 60 Nm

Clutch boss nut 100 Nm

Primary transmission pinion nut 150 Nm

Ignition housing screw 10 Nm

Central crankcase screws 10 Nm

Barrel screw 10 Nm

•

•

•

•

•

Starter triangle screw 10 Nm

Starter screw 10 Nm

Cylinder nut Pass No. 1 20 Nm

Pass No. 2 35 Nm

Gearbox output pinion nut 150 Nm

•

54

CARBURETOR ADJUSTEMENT TABLE

to

45 42 42 40 38 35

1 501 m

N1EG

N1EG

N1EG

N1EH

N1EH

N1EI

3 3 2 2 2 2

165 165 162 160 160 158

to

45 45 42 42 40 38

751 m

N1EF

N1EG

N1EG

N1EG

N1EH

N1EH

3 3 3 2 2 2

168 165 165 162 160 158

to

48 45 45 42 42 40

301 m

N1EF

N1EF

N1EG

N1EG

N1EG

N1EH

4 3 3 3 2 2

170 168 165 162 162 160

to

50 48 45 45 42 42

0 m

N1EE

N1EF

N1EF

N1EG

N1EG

N1EG

4 4 3 3 3 2

172 170 168 165 165 162

❱❘ SE 250-Carburetor adjustments table

Sea level Temperature -20°C

-7°C

3.000 m Air screw 1T1/4 1T3/4 1T3/4 2T1/4 2T1/4

to

2.301 m

2 300 m Air screw 1T1/4 1T1/4 1T3/4 1T3/4 2T1/4 2T1/4

1 500 m Air screw 1T 1T1/4 1T1/4 1T3/4 1T3/4 2T1/4

adjustment

Idle jet

Needle

Needle position

Main jet

adjustment

Idle jet

Needle

Needle position

Main jet

42 42 40 38 35

N1EG N1EG N1EH N1EH N1EI

3

165 162 160 160 158

-6°C

5°C

2

6°C

15°C

2

16°C

24°C

2

25°C

36°C

2

37°C

49°C

adjustment

Idle jet

750 m Air screw 1T 1T 1T1/4 1T1/4 1T3/4 1T3/4

300 m Air screw 1T 1T 1T 1T/4 1T1/4 1T3/4

Needle

Needle position

Main jet

adjustment

Idle jet

Needle

Needle position

Main jet

adjustment

Idle jet

Needle

55

Needle position

Main jet

250/300 SE

CABURETOR ADJUSTEMENT TABLE

❱❘ SE 300-Carburetor adjustments table

Sea level Temperature -20°C

…

-7°C

3.000 m Air screw

to

2.301 m

2 300 m Air screw

to

1 501 m

adjustment

Idle jet

Needle

Needle position

Main jet

adjustment

Idle jet

Needle

Needle position

Main jet

1T1/2 1T/1/2 2T 2T 2T1/2 3T

42

42 42 42 42 42

N8RE

3 2 2 1 1 1

172 172 170 168 165 165

1T 1T1/2 1T 1/2 2T 2T 2T1/2

42

N8RD

3 3 3 2 2 1

175 172 172 170 168 165

-6°C

… 5°C

N8RE

42 42 42 42 42

N8RE

6°C …

15°C

N8RF

N8RE

16°C

…

24°C

N8RF

N8RF

25°C

…

36°C

N8RG

N8RF

37°C

…

49°C

N8RH

N8RG

1 500 m Air screw

to

751 m

750 m Air screw

to

301 m

300 m Air screw

to

0 m

adjustment

Idle jet

Needle

Needle position

Main jet

adjustment

Idle jet

Needle

Needle position

Main jet

adjustment

Idle jet

Needle

Needle position

1T 1T 1T1/2 1T1/2 2T 2T

45 42 42 42 42 42

N8RC

N8RC

N8RB

N8RD

3 3 3 3 2 1

178 175 172 172 170 168

1T 1T 1T 1T1/2 1T/12 2T

48

45 42 42 42 42

N8RC

4 3 3 3 3 2

180 178 175 172 172 170

1/2T 1T 1T 1T 1T1/2 1T 1/2

48 45 45 42 42 42

N8RC

4 4 3 3 3 3

N8RE

N8RD

N8RC

N8RE

N8RE

N8RD

N8RF

N8RE

N8RE

N8RF

N8RF

N8RE

Main jet

182 180 178 175 172 172

56

CHECKING THE LOAD CIRCUIT

❱❘ Static control value

For this control please make sure the bike is off

•

Battery voltage > 12.5V.

•

Resistance values of stator windings : Measurement of the resistance between each winding.

Y1-Y2 0.44Ω±20

Y2-Y3

Y1-Y3

% (at

20°C)

❱❘ Dynamic control values

•

Voltage regulator :

AC (calibrated 200V AC) When idling

22V ±2V

At 6000 rpm min : 77V±3V DC

On regulator output (Calibrated 20V DC) At 4000 rpm

: 14.6V + Red/White, - Green

•

Alternator :

57

250/300 SE

T° SENSOR, ENGINE RPM SENSOR, HIGH VOLTAGE COIL

•

Water temperature sensor resistance (on cylinder head)

TEMP (°C) RESIST (K Ω)

-40

100.950

-30

53.100

-20

29.121

-10

16.599

0

9.750

+10 5.970

+20 3.747

+25 3.000

+30 2.547

+40 1.598

+50 1.150

+60 0.746

+70 0.565

+80 0.377

+90 0.275

+100 0.204

+110 0.153

+125 0.102

•

Pick UP sensor resistance (RPM sensor) : Red ~

Green 100 Ω±20 % (at 20°C).

•

High voltage coil

•

Primary coil 0.75 Ω±10 % (at 25 ± 2.5°C)

58

WIRING DIAGRAM

❱❘ Main harness

59

250/300 SE

WIRING DIAGRAM

❱❘ Standard lights harness

60

WIRING DIAGRAM

❱❘ Racing lights harness

61

250/300 SE

WIRING DIAGRAM

❱❘ Accessories harness

62

Loading...

Loading...