SHERCO 2015 450 SEF-R Workshop Manual

MANUEL D’ATELIER I WORKSHOP MANUAL I MANUAL DE TALLER

450 SEf-R

FOREWORD .................................................................................................................................................................................................... 4

ENGINE TOOLS LIST 450 SEF-R.....................................................................................................................................................................5

TECHNICAL SPECIFICATIONS ........................................................................................................................................................................ 6

• ENGINE ......................................................................................................................................................................................................................... 6

• CHASSIS ....................................................................................................................................................................................................................... 7

FACTORY SETTINGS ......................................................................................................................................................................................8

• FORK ............................................................................................................................................................................................................................ 8

• SHOCK ABSORBER ........................................................................................................................................................................................................ 9

OPERATIONS REQUIRING THE REMOVAL, OR NOT, OF THE ENGINE ............................................................................................................ 10

REMOVING/INSTALLING THE ENGINE ..........................................................................................................................................................11

• REMOVING THE ENGINE .............................................................................................................................................................................................. 11

• INSTALLING THE ENGINE IN THE FRAME ..................................................................................................................................................................... 12

REMOVING THE ENGINE .............................................................................................................................................................................. 13

• PREPARATION ............................................................................................................................................................................................................. 13

• REMOVING THE CYLINDER HEAD COVER ..................................................................................................................................................................... 13

• POSITIONING THE ENGINE AT TOP DEAD CENTER ........................................................................................................................................................ 13

• REMOVING THE CAMSHAFT ........................................................................................................................................................................................14

• REMOVING THE DISTRIBUTION TENSIONER ................................................................................................................................................................ 14

• REMOVING THE DRIVE CHAIN ...................................................................................................................................................................................... 14

• REMOVING THE CYLINDER HEAD ................................................................................................................................................................................. 15

• REMOVING THE CYLINDER ..........................................................................................................................................................................................15

• REMOVING THE PISTON ..............................................................................................................................................................................................15

• REMOVING THE IGNITION COVER .................................................................................................................................................................................15

• REPLACING THE STATOR AND THE ENGINE SPEED SENSOR......................................................................................................................................... 16

• REMOVING THE ROTOR ............................................................................................................................................................................................... 16

• REMOVING THE DRIVE CHAIN ...................................................................................................................................................................................... 16

• REMOVING THE ELECTRIC STARTER ............................................................................................................................................................................ 16

• REMOVING THE CLUTCH .............................................................................................................................................................................................17

• REMOVING THE WATER PUMP HOUSING ...................................................................................................................................................................... 17

• REMOVING THE CLUTCH HOUSING .............................................................................................................................................................................. 17

• REMOVINGTHE WATER PUMP OILSEAL AND THE BEARING SEAL ..................................................................................................................................18

• REMOVING THE CLUTCH BELLHOUSING ......................................................................................................................................................................18

• REMOVNG THE FREEWHEEL SPROCKET ...................................................................................................................................................................... 19

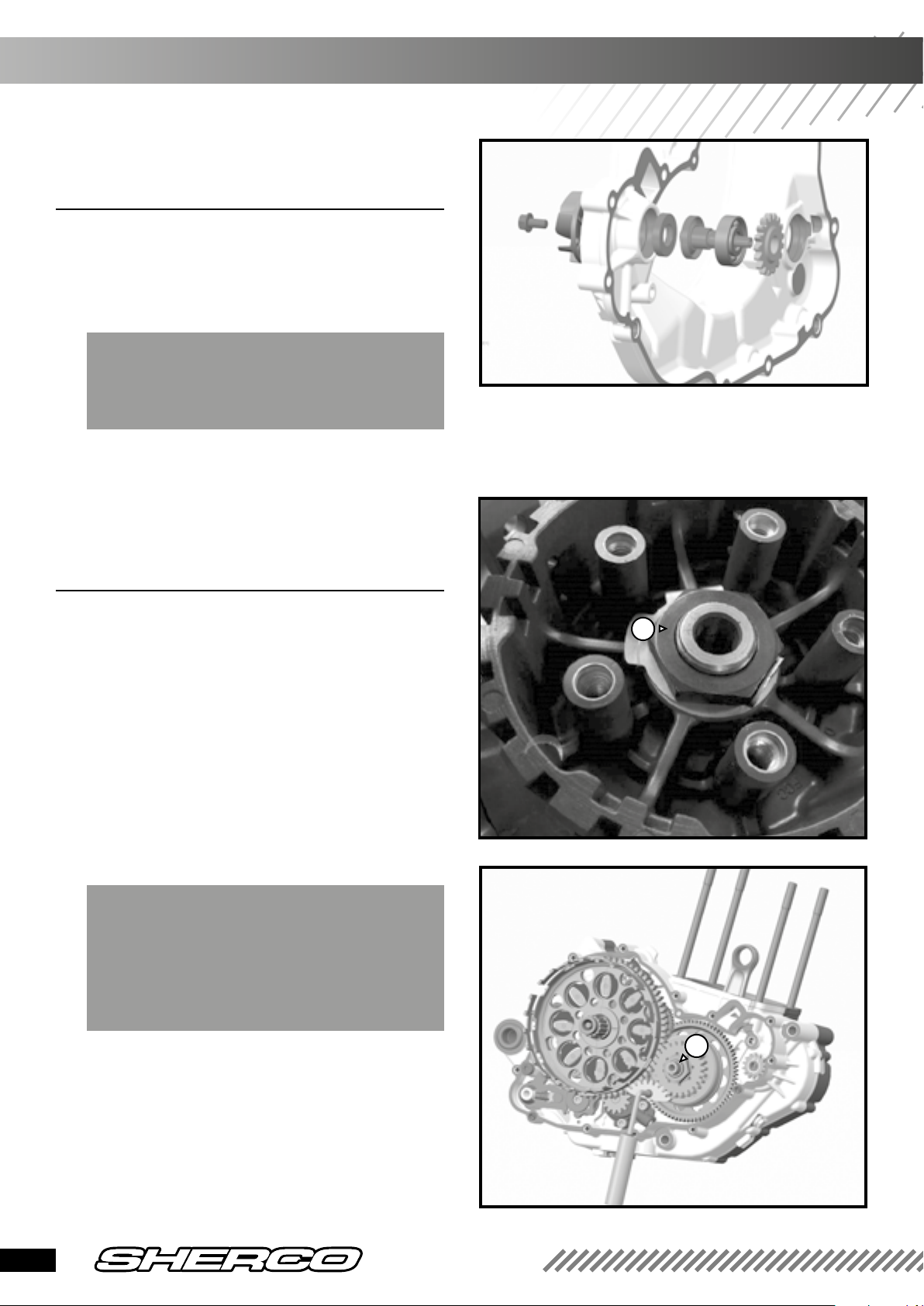

• REMOVING THE OIL PUMP ........................................................................................................................................................................................... 19

• CHANGING THE OIL PUMP ........................................................................................................................................................................................... 19

• REMOVING THE INDEX SHIM .......................................................................................................................................................................................19

• SEPARATING THE CENTRAL CRANKCASES .................................................................................................................................................................. 20

• REMOVING THEGEARBOX ............................................................................................................................................................................................ 20

• REMOVING THE CRANKSHAFT ..................................................................................................................................................................................... 20

2

450 SEF-R

SUMMARY

CHECKING INDIVIDUAL PARTS ................................................................................................................................................................... 21

• CHECKING THE CENTRAL CRANKCASES ..................................................................................................................................................................... 21

• CHECKING THE LEFT CRANKCASE ............................................................................................................................................................................... 21

• CHECKING THE RIGHT CRANKCASE ............................................................................................................................................................................. 21

• CHECKING THE FREEWHEEL BEARING ......................................................................................................................................................................... 22

• CHANGING THE CRANKSHAFT BEARINGS .................................................................................................................................................................... 22

• CHECKING THE CRANKSHAFT .....................................................................................................................................................................................23

• CHECKING THE GEARBOX ............................................................................................................................................................................................ 24

• CHECKING THE CLUTCH .............................................................................................................................................................................................. 24

• CHECKING THE TOP ENGINE ........................................................................................................................................................................................ 25

• CHECKING THE CYLINDER HEAD .................................................................................................................................................................................28

• CHECKING THE DISTRIBUTION..................................................................................................................................................................................... 28

ENGINE ASSEMBLY ...................................................................................................................................................................................... 29

• INSTALLING THE CENTRAL CRANKCASES ...................................................................................................................................................................29

• INSTALLING THE CLUTCH HOUSING .............................................................................................................................................................................31

• INSTALLING THE WATER PUMP HOUSING .................................................................................................................................................................... 31

• INSTALLING THE CLUTCH ............................................................................................................................................................................................32

• INSTALLING THE ELECTRIC STARTER .......................................................................................................................................................................... 32

• SETTING THE PISTON RINGS ....................................................................................................................................................................................... 33

• INSTALLING THE PISTON .............................................................................................................................................................................................33

• INSTALLING THE CYLINDER .........................................................................................................................................................................................34

• INSTALLING THE CYLINDER HEAD ............................................................................................................................................................................... 34

• INSTALLING THE DRIVE CHAIN ....................................................................................................................................................................................35

• INSTALLING THE ROTOR ............................................................................................................................................................................................. 35

• INSTALLING THE CAMSHAFT AND SETTING THE VALVE TIMING .................................................................................................................................... 36

• CHECKING VALVE CLEARANCE ..................................................................................................................................................................................... 36

• COMPLETING THE ENGINE ASSEMBLY ......................................................................................................................................................................... 37

• INSTALLING THE IGNITION COVER ............................................................................................................................................................................... 37

ENGLISH

TIGHTENING TORQUE CHART ......................................................................................................................................................................38

CLEANING THE THROTTLE BODY ................................................................................................................................................................. 40

• EQUIPMENT ................................................................................................................................................................................................................ 40

• REMOVING THE THROTTLE BODY ................................................................................................................................................................................ 40

• CLEANING THE THROTTLE BODY ................................................................................................................................................................................. 42

• INSTALLING THE THROTTLE BODY...............................................................................................................................................................................42

CHANGING THE TPS (THROTTLE POSITION SENSOR) .................................................................................................................................43

INJECTION DIAGNOSTIC TOOL SYNERJECT ................................................................................................................................................ 44

• 1- PRESENTATION OF THE SYNERJECT INJECTION SYSTEM ........................................................................................................................................ 44

• 2- SOFTWARE OVERVIEW ............................................................................................................................................................................................50

• 3- USING THE SOFTWARE ........................................................................................................................................................................................... 54

CHECKING THE CHARGING CIRCUIT ............................................................................................................................................................ 67

WIRING DIAGRAM ....................................................................................................................................................................................... 69

3

This manual is intended for qualified mechanics working in a properly equipped workshop. Performing

the different operations requires sound knowledge of mechanics and SHERCO tools specific to 450 SEF-R

engines.

4

450 SEF-R

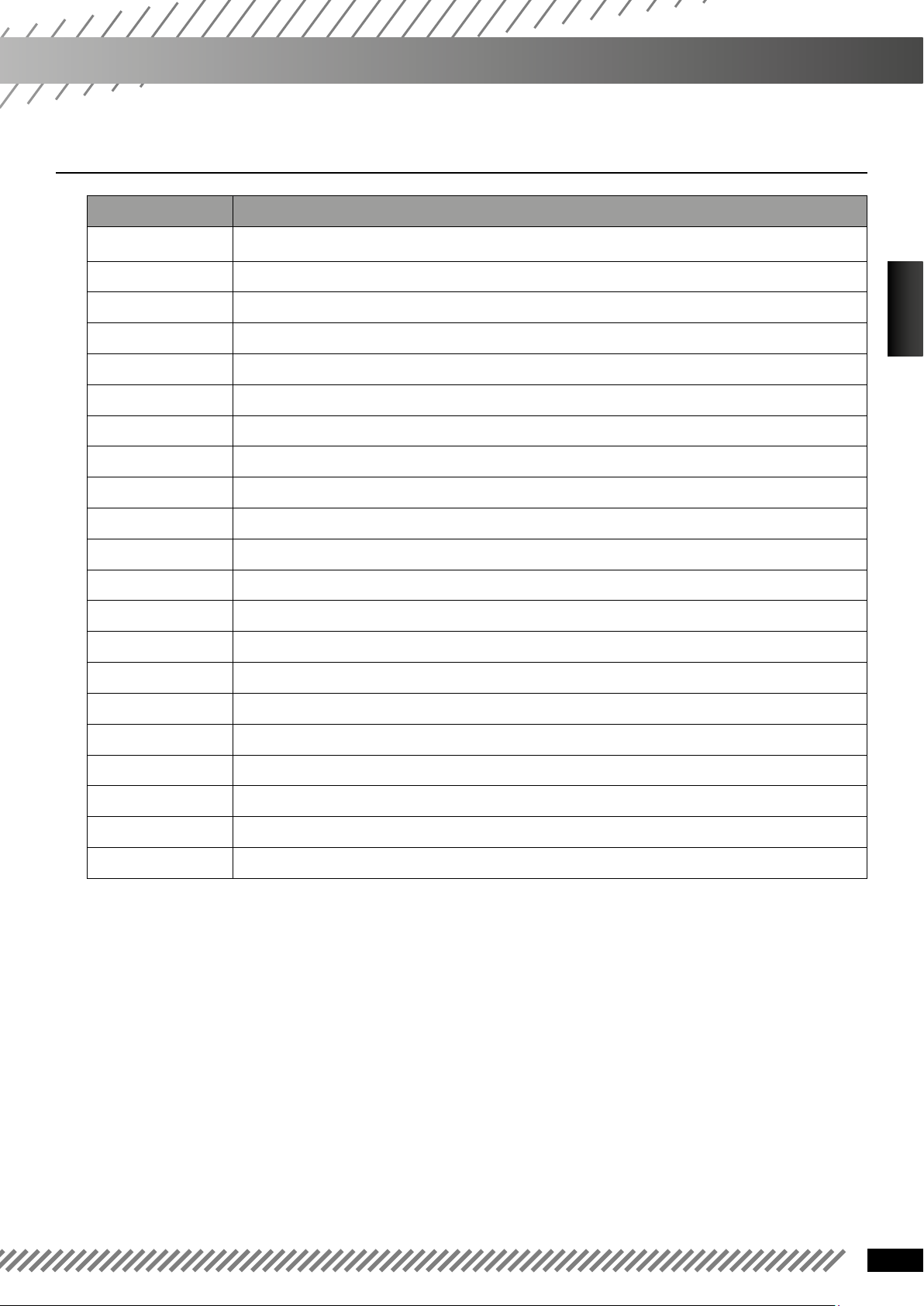

Tools List for 450 SEF-R Engine

❱❘ 450 SEF-R

Tool reference Description

1819 Top dead center timing screw

5749 Clutch removal tool ADLER

4753 Fret-type ignition unit

1822 Water pump bearing axis tool

1968 Water pump oil seal tool

R455 Engine support

5593 Primary drive locking tool

5774 Piston support

R462 Flywheel puller

R464 Crankshaft ring extractor

R450 Oil seal selector

R472 Applying tool for oil seal selector

5773 Special 450 spark plug wrench

5028 PUSH-IN TOOL WP Ø48

4967 Synerject injection diagnostic tool

FRANÇAIS

ENGLISH

5132 Adjustable hook spanner wrench WP Ø48

5029 Joint guide tool WP Ø48

5030 Bottle-type leveling tool WP

5031 Pipe vise clamp WP 48/60

R453 Selector shaft bearing assembly tool

R444 Oil seal selector

5

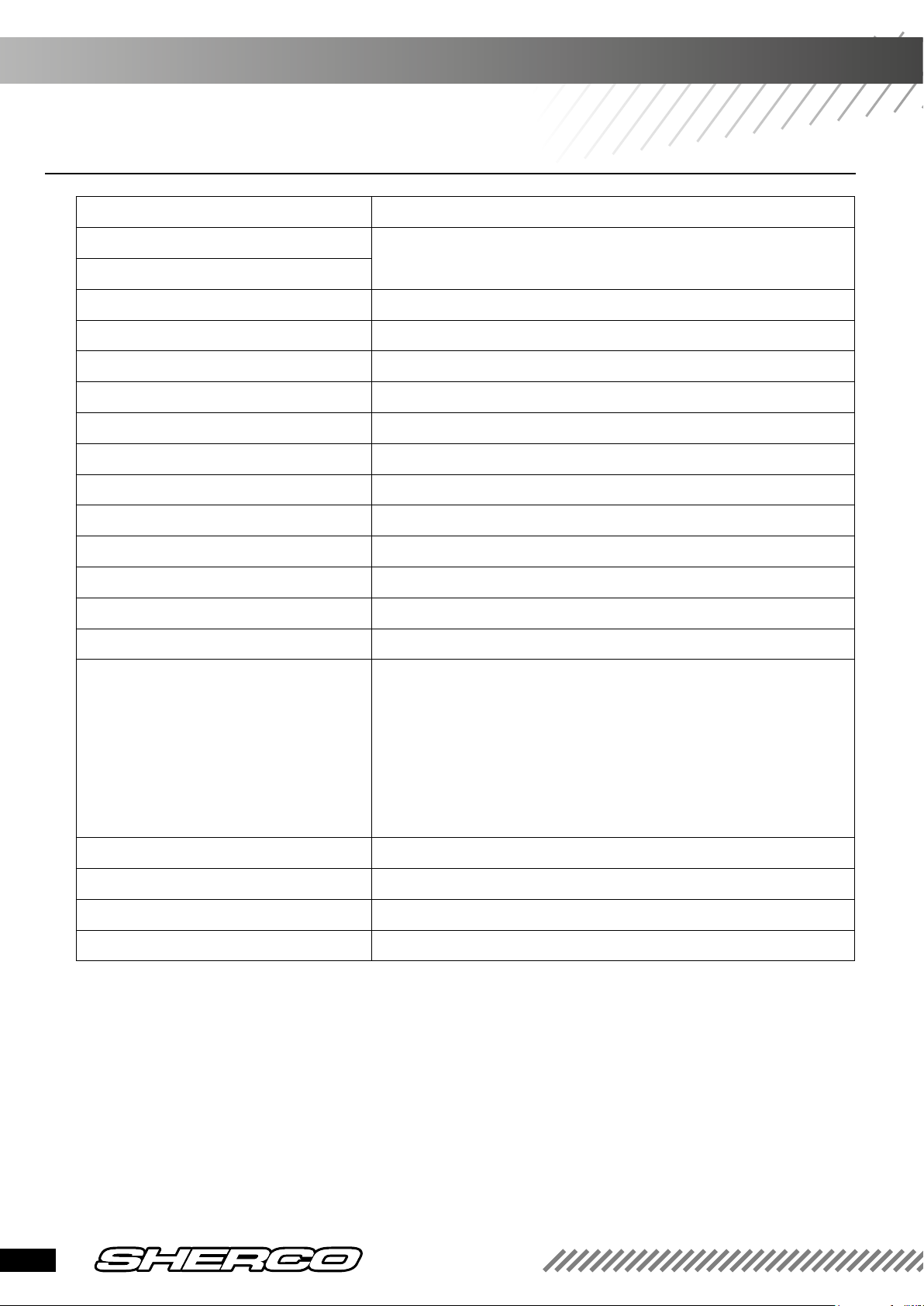

❱❘ ENGINE

Type Single cylinder 4 stroke liquid cooled

Displacement 449.4 cc

Bore / Stroke

Compression ratio 11.84: 1

Unleaded gasoline with an octane rating of at least 95

Distribution 4-valve, double overhead camshaft, chain drive

Intake valve diameter 38 mm

Exhaust valve diameter 30.5

Intake valve cold clearance 0.15-0.2 mm

Exhaust valve cold clearance 0.2-0.25 mm

Crankshaft bearings 2 roller bearings

Piston forged aluminum

Lubrication full pressure lubrication with 2 trochoid pumps

95/63.4 mm

Motor oil 1 liter SAE 10W40

Primary drive 25 : 75

Gearbox

First gear

Second gear

Third gear

Fourth gear

Fifth gear

Sixth gear

Final drive 14 X 49

Clutch multi disc clutch in oil bath, hydraulically operated

Start-up/battery Electric 12V 4Ah

Electronic injection Synerject

6 speed

13 : 32

16 : 29

19 : 27

21 : 24

23 : 22

25 : 21

6

450 SEF-R

TechnicalSpecications

❱❘ Chassis

Frame Semi-perimeter Cr Mo steel with aluminum subframe

Fork SACHS USD Gold Series Ø 48mm (standard) & WP USD Ø 48mm

Semi-perimeter Cr Mo steel with aluminum subframe

(racing)

Rear suspension WP Suspension with separate cylinder

Travel front/rear 300/300 mm

Front brake Disc Ø 270 mm (standard), Ø 256 mm (racing)

Rear brake Disc Ø 220 mm

Disc brakes Wear limit: 2.7 mm front and 3.6 mm rear

Front tire 90/90-21’’

Rear tire 140/80-18’’

Pressure off-road front/rear 0.9 bar

Fuel tank capacity 8.5 l with 1 l reserve

Steering angle 27.3°

Wheelbase 1480mm

Weight 120 kg

ENGLISH

7

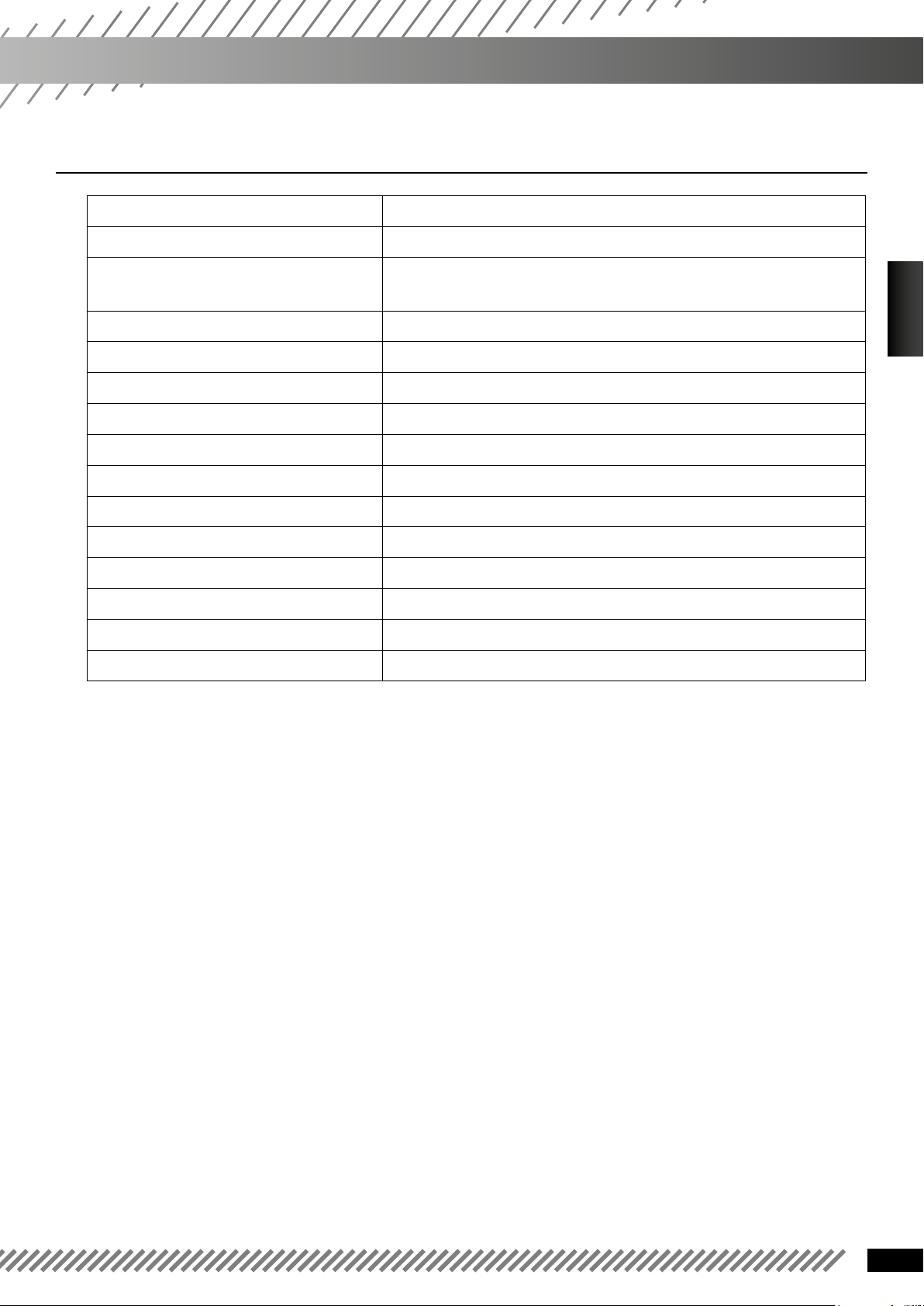

❱❘ FoRK

Original settings - Fork SACHS USD Gold Series Ø48 mm

Compression 12 clicks back

Rebound 12 clicks back

Spring stiffness 4.5 N/mm

Type of oil SAE 5

Quantity of oil per fork leg 600 cm

3

Oil level measurement (fork compressed and spring removed) from the top of the fork tube

Original settings - Fork WP Suspension USD Ø48mm

Compression Comfort 21 clicks back

Standard 14 clicks back

Sport 9 clicks back

Rebound Comfort 19 clicks back

Standard 14 clicks back

Sport 11 clicks back

Preload Comfort 0 turn

Standard 2 turns

Sport 4 turns

Spring stiffness Rider weight: 65-75 kg 4.2N/mm

Rider weight: 75-85kg 4.4 N/mm (original)

Rider weight: 85-95kg 4.6N/mm

130mm

Type of oil SAE 4

Oil level measurement (fork compressed

and spring removed) from the top of the

fork tube

8

450 SEF-R

110mm

FACTORY SETTINGS

❱❘ Shock absorber

Factory Settings - WP suspension shock absorber

Low-speed compression Comfort 17 clicks back

Standard 12 clicks back

Sport 9 clicks back

High-speed compression Comfort 2 turns back

Standard 1.5 turns back

Sport 1 turn back

Rebound Comfort 16 clicks back

Standard 14 clicks back

Sport 12 clicks back

Spring stiffness Rider weight: 65-75 kg 51N/mm

Rider weight: 75-85 kg 54N/mm (original)

Rider weight: 85-95 kg 57N/mm

ENGLISH

9

Operations requiring

the removal of the engine

Operations not requiring

the removal of the engine

Crankshaft (including crankshaft

repair kit)

Complete transmission •

Crankshaft bearing •

Gearbox bearing •

Piston •

Cylinder •

Cylinder head •

Distribution •

Ignition •

Starter gears •

Freewheel •

Complete clutch •

Water pump •

Oil pump •

•

Gear selector set •

10

450 SEF-R

removing/installing the engine

❱❘ Removing the engine

WARNING

To remove the engine, remove the swing arm pivot axis, which allows you to remove the whole rear wheel / swing arm set. In

order to prevent the bike from tipping over, hold the frame using a jack.

• Empty (see the User Manual)

- The engine oil

- The coolant.

• Place the motorcycle on a stool.

• Remove the saddle.

• Disconnect the battery (see user manual).

• Remove the tank along with its vents (refer to the user manual).

• Disconnect the entire harness connected to the engine

(starter case, TPS, water temperature sensor, pencil coil and injector).

• Remove the springs of the exhaust pipe in order to remove it.

• Remove the pencil coil

• Remove the throttle body.

• Remove the chain guard.

• Remove the secondary transmission line (quick release).

• Remove the clutch receiver.

ENGLISH

WARNING

When the clutch receiver is removed, the piston is no longer supported. Hold the piston with a plastic clamp.

• Remove the water radiator hoses connected to the engine.

• Remove the left radiator.

• Remove the cylinder head frame mounting brackets.

• Remove the frame guards on both the right and left sides of the bike.

• Unscrew the swing arm pivot.

• Loosen the other two engine axes

• Unscrew the swing arm pivot and pull the swing arm slightly backward.

• Remove the engine axes.

• Remove the engine through the left side by pivoting it.

NOTE :

You should need some help to perform this operation, as the weight is considerable. Make sure you do not

damage the engine mounting brackets on the frame.

11

❱❘ INSTALLING THE ENGINE IN THE FRAME

• Position the motor within the frame.

• Position the swing arm.

• Set the engine axes.

• Tighten the motor axes to 40 Nm.

• Tighten the swing arm pivot to 100 Nm.

• Set the frame guards and secure them with clamps.

• Put the right and left cylinder head supports. Put red thread lock and tighten to 25 Nm.

• Fit the left radiator and tighten to 10 Nm.

• Place the cooling hoses

• Make sure the engine is clean and place back the clutch receiver. Tighten to 10 Nm.

• Place the secondary chain and adjust the tension (see procedure on the user manual).

• Put the chain guard.

• Put the throttle body.

• Put the pencil coil.

• Put the exhaust pipe and secure it to the cylinder with its two springs.

• Reconnect the entire harness connected to the engine

(starter case, TPS, water temperature sensor, pencil coil and injector).

• Reinstall the tank along with its vents (refer to the user manual).

• Reconnect the battery (refer to the user manual).

WARNING

Before reconnecting, check that the ignition key (SEF 450 standard) or the switch (450 SEF / R racing) is in the «OFF» position.

• Place back the saddle.

• Fill coolant and engine oil (refer to the user manual).

12

450 SEF-R

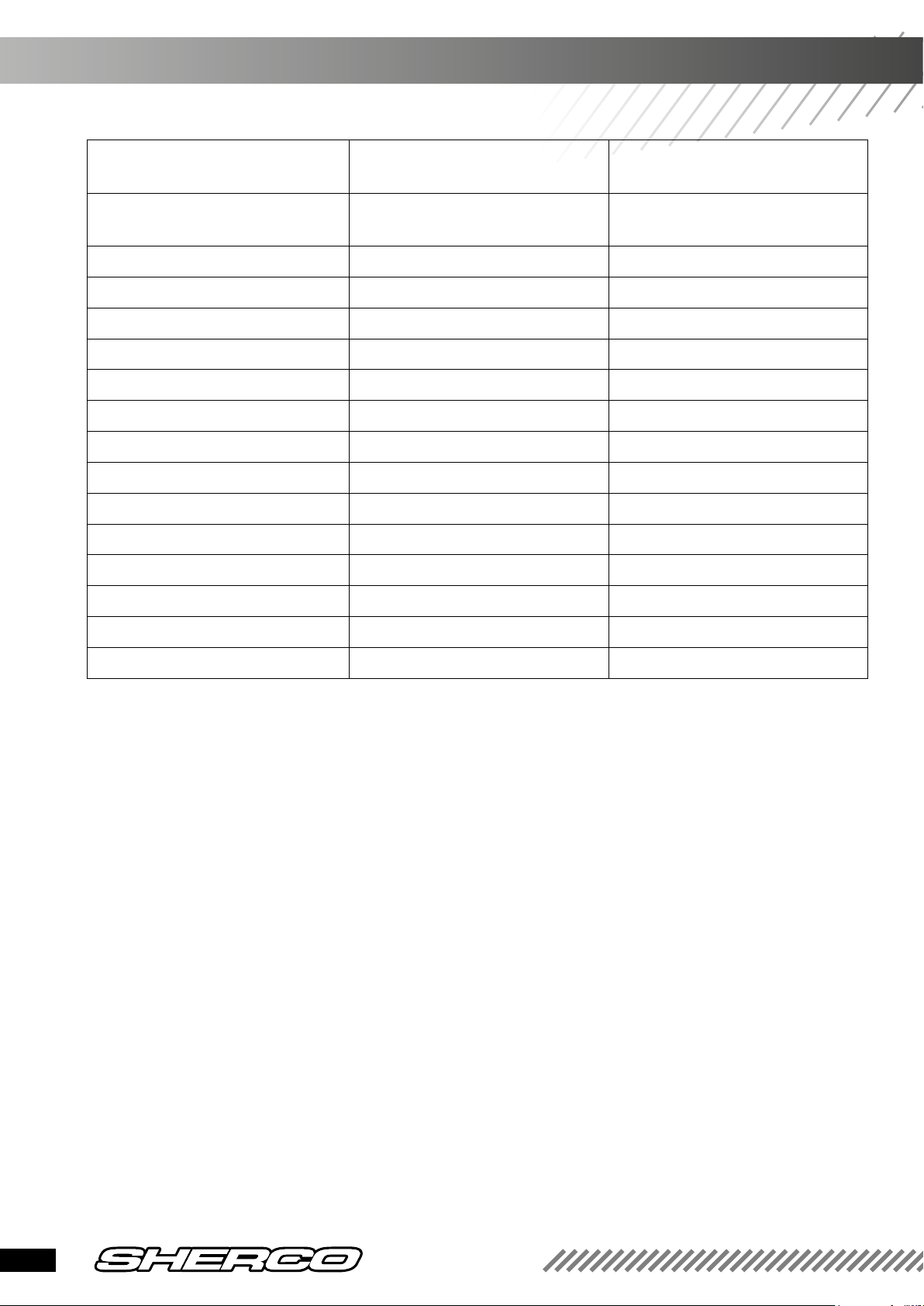

REMOVING THE ENGINE

❱❘ PrEparation

• Place the engine on the R455 engine support tool.

• Drain the engine oil (see user manual).

• Make sure to be in a clean environment before

starting the dismantling of the engine.

• Remove the output shaft pinion.

ENGLISH

❱❘ Removing the cylinder head cover

• Remove the spark plug with the special spark plug tool 5773.

• Unscrew the 3 screws (1) and remove the cylinder head

cover.

WARNING

The screws have an O-ring.

• Remove the cylinder head cover gasket.

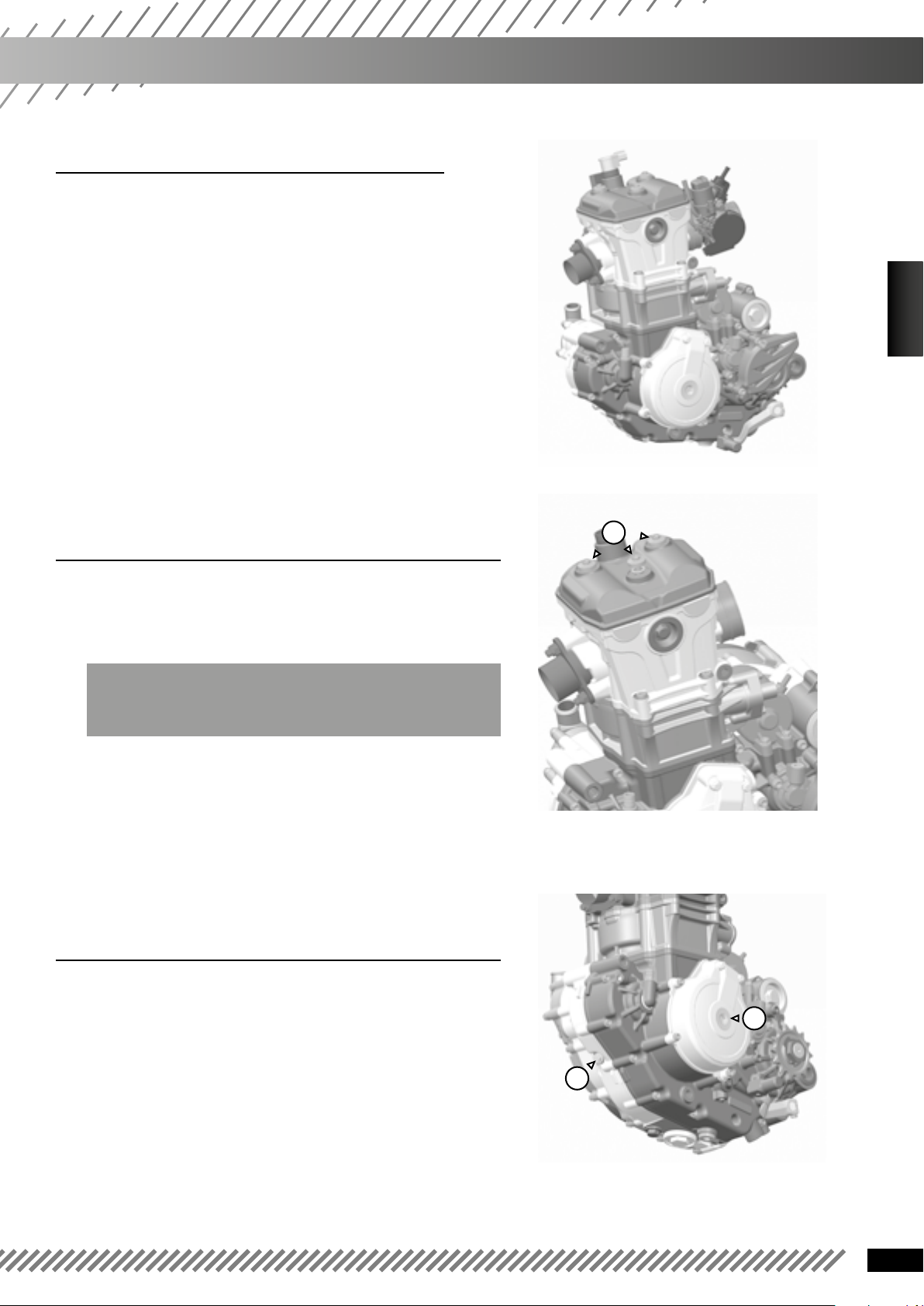

❱❘ Set the engine at top dead center

1

• Remove the ignition cover plug (1).

• Remove the timing control plug (2).

• Rotate the motor counterclockwise in order to align

the center of the hole of the crankshaft with that of the

crankshaft timing control, set the top dead center timing

tool on (2) (Ref. 1819).

1

2

13

❱❘ Removing the camshafts

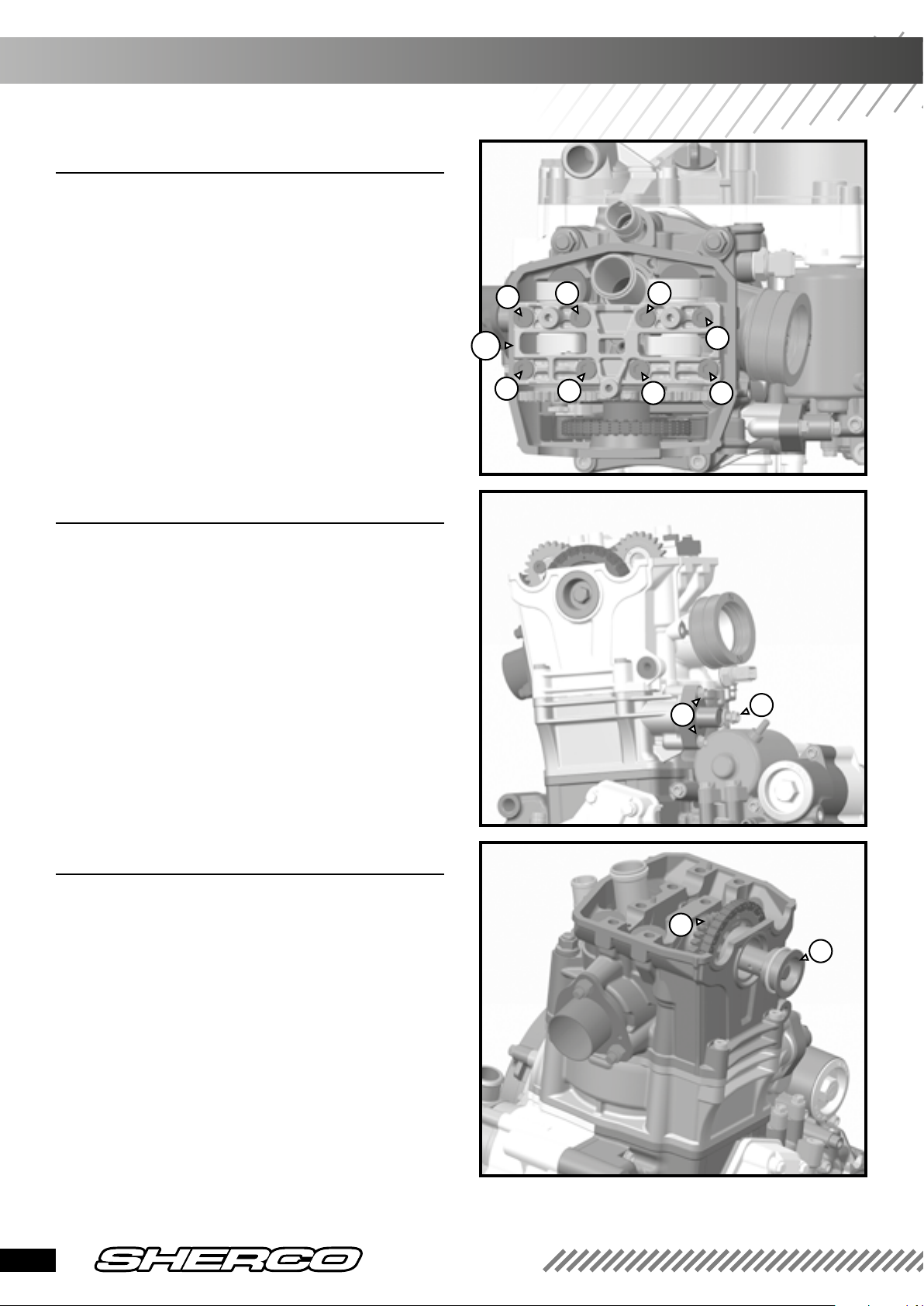

• Unscrew the eight screws from the shaft

bearing cap cam following the order shown in the

picture.

• Remove the bearing cap (A).

• Remove the camshafts.

4

68

❱❘ Removing the distribution tensioner

• Unscrew the screw (1) and remove the spring.

• Unscrew the two screws (2).

• Remove the tensioner along with its gasket.

A

3

7

5

2

1

2

1

❱❘ Removing the drive chain

• Remove the shaft (1).

• Hold the pinion (2) and disengage the chain.

• Remove the pinion (2).

• Remove the timing tool from the top dead cen-

ter position 1819.

14

2

1

450 SEF-R

REMOVING THE ENGINE

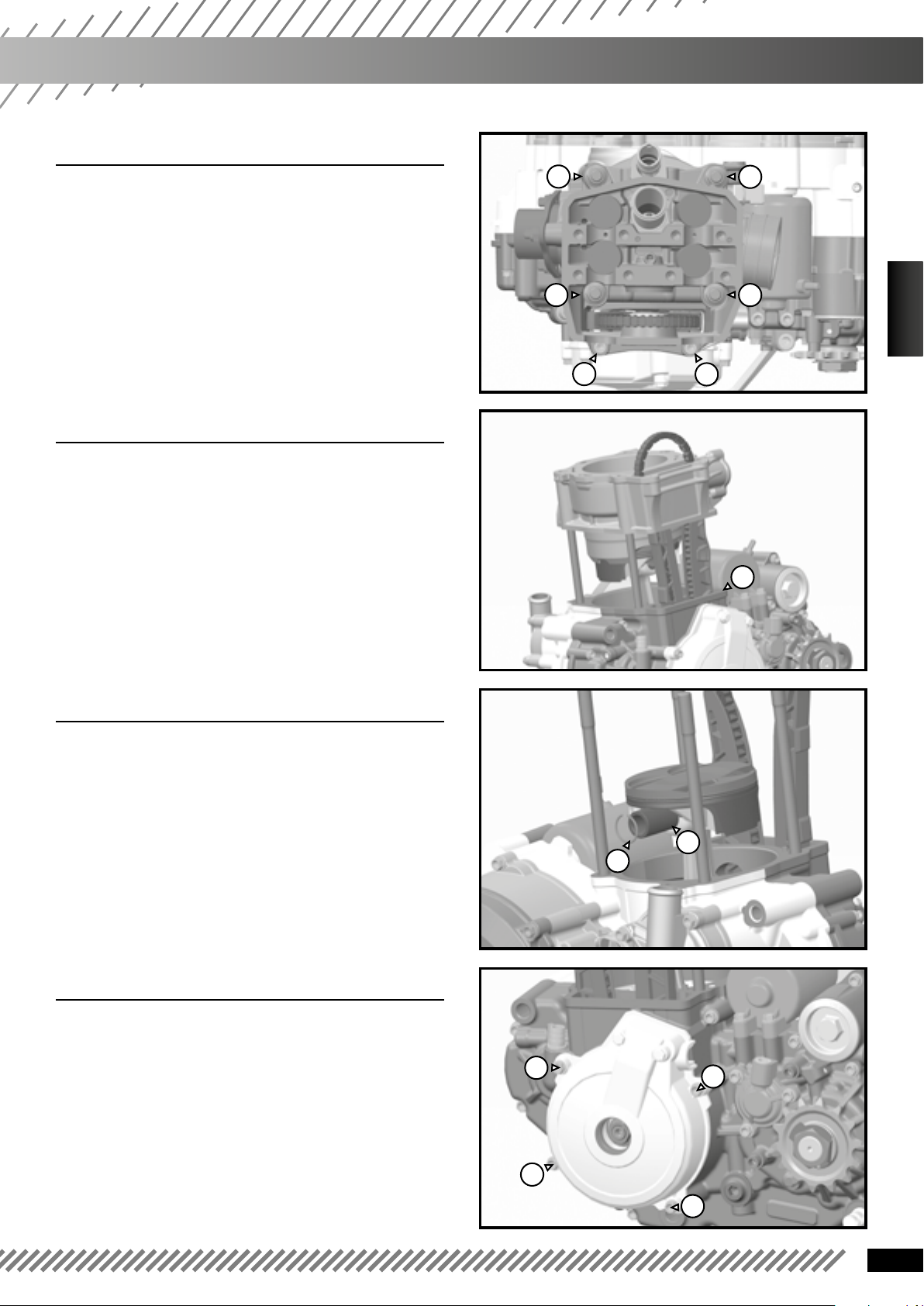

❱❘ Removing the cylinder head

• Unscrew the cylinder head bolts following the

orderindicated in the picture.

• Remove the cylinder head by pulling it vertically.

• Remove the cylinder head gasket with caution.

6

3

❱❘ Removing the cylinder

• Remove the cylinder by it pulling vertically.

• Remove the cylinder gasket (1) carefully.

❱❘ Removing the piston

4

5

ENGLISH

2

1

1

• Remove the securing clip (1) from the piston pin

and remove the piston pin (2).

• Remove the piston.

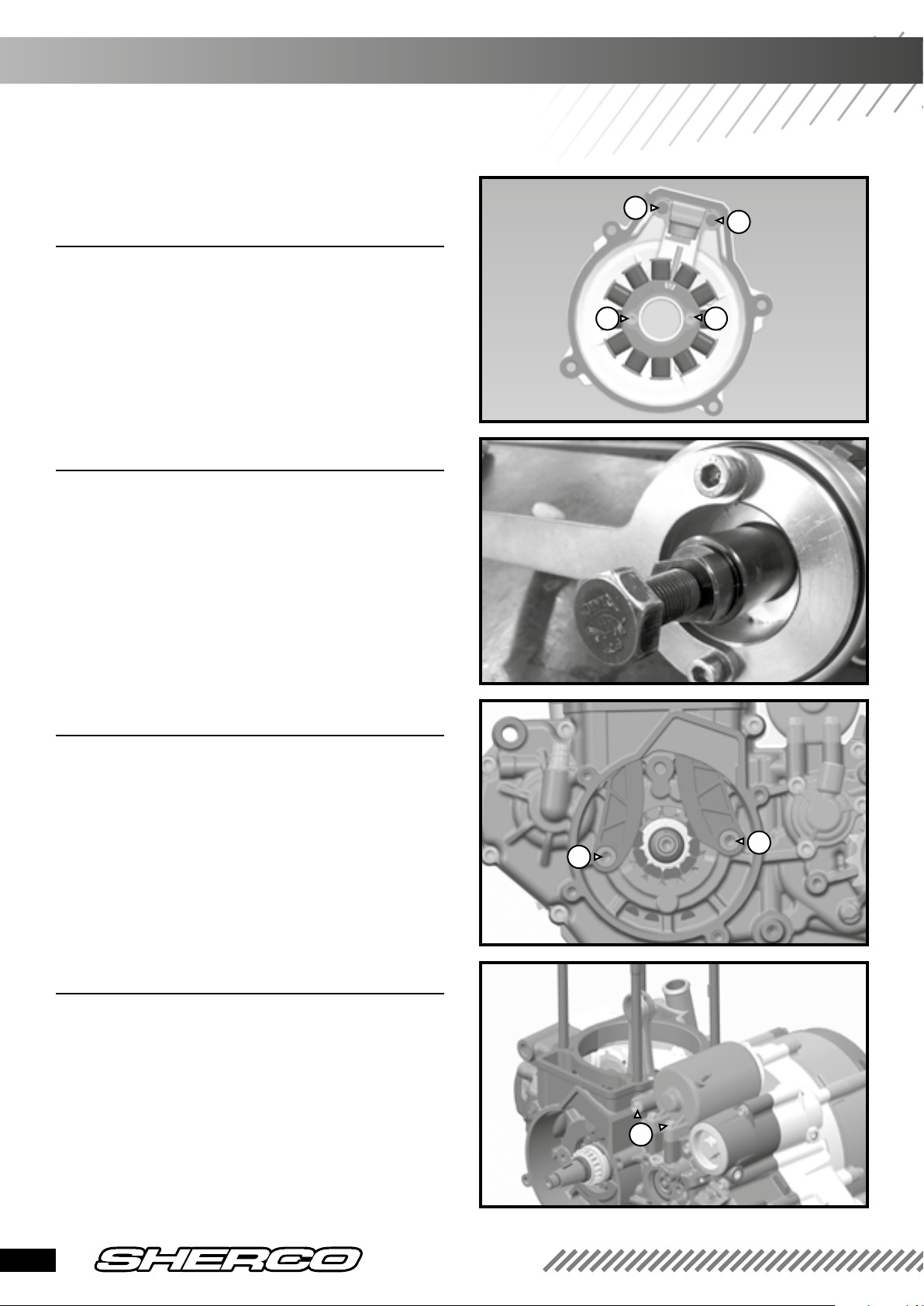

❱❘ Removing the ignition cover

• Remove the 4 screws (1) and remove

the ignition cover.

• Remove the ignition cover gasket with caution.

2

1

1

1

1

1

15

❱❘ Changing the stator and the engine

speed sensor

• Remove the 2 screws from the sensor (2) and

the two screws from the stator (1).

• Set up the new parts.

• Reinstall the screws with red thread lock

and tighten to 7 Nm,

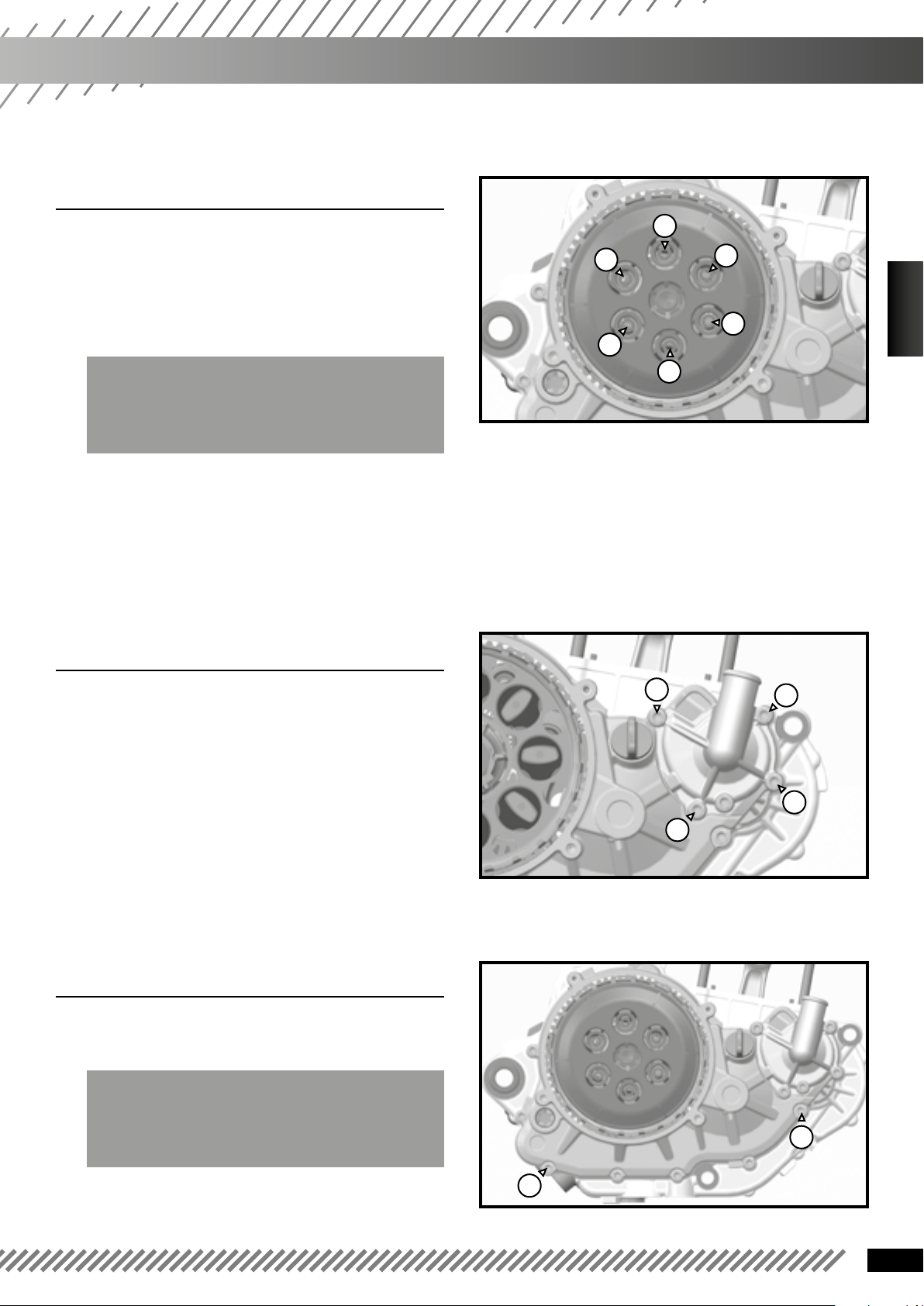

❱❘ Removing the rotor

• Use the rotor maintenance tool 4753.

• Unblock the central nut.

• Extract the flywheel with the flywheel

extractor R462.

2

2

1 1

❱❘ Removing the drive chain

• Unscrew the drive chain guide plates (1) and (2).

• Remove the drive chain.

❱❘ Removing the electric starter

• Unscrew the two screws (1) and pull

horizontally to the left.

Remove the oil filter, if not done yet.

1

2

1

16

450 SEF-R

REMOVING THE ENGINE

❱❘ Removing the clutch

• Remove the clutch housing cover by unscrewing

the 4 screws. Beware of the O-ring located on the

rim of the cover.

• Set the TDC 1819 tool.

WARNING

Do not use this tool for tightening or loosening

with a torque value higher than 10 Nm.

• Remove the 6 screws from the pressure plate.

• Remove the friction and metal plates.

• Make sure the inner clutch hub can freely

rotate.

❱❘ removing the water pump housing

4

2

5

3

6

1

ENGLISH

• Remove the screws (1) of the water pump

housing.

Beware of the O-ring located on the rim.

❱❘ Removing the clutch housing

• Dismount the 8 screws of the clutch housing.

WARNING

You need to identify the screws,

6 are 25 mm long, 2 are 30mm long (screw (1)).

1

1

1

1

1

• Remove the clutch housing and remove

the seal carefully.

1

17

❱❘ DRemoving the water pump oil seal

and the bearing

• Remove the water pump turbine with a 10 soc-

ket by unscrewing it while holding the drive pinion.

• Remove the water pump shaft. Both oil seals

have been made accessible.

WARNING

The 2 seals are not identical

nor are they interchangeable.

• Disconnect the shaft from the water pump

drive pinion.

• Remove the water pump bearing.

❱❘ Removing the clutch bellhousing

• Remove the finger follower from the clutch hub

• Flatten the safety tab.

• Block the clutch hub using the 5749 and uns-

crew the nut.

• Remove the hub, the notched washer and the

bellhousing.

• Remove the drive pinion of the oil pump if it

does has not remained stuck to the bellhousing.

• Check the needle bearings and change them if

necessary

• Visually check the clutch bellhousing.

WARNING

If you want to dismount the freewheel or the balancer

shaft further on, block the primary drive with the

tool 5593. Unlock the nut off the mass of the balancer

shaft (2).

1

2

18

450 SEF-R

REMOVING THE ENGINE

❱❘ Removing the freewheel sprocket

WARNING

See previous paragraph for the unlocking of the

balancer shaft nut.

• Remove the securing clip (1) and their washers.

• Remove the torque limiter (2).

• Remove the oil pump intermediate pinion (3).

• Unscrew the nut and remove the freewheel

bellhousing (4) with a 2-arm puller.

WARNING

Do not damage the end of the crankshaft: oil passage,

pin lubrication and lip sealing.

2

1

1

3

4

FRANÇAIS

ENGLISH

• Remove the freewheel sprocket.

❱❘ Removing the oil pump

• Remove the oil pump intermediate pinion.

• Remove the 3 screws (1).

❱❘ Changing the oil pump

• Remove the securing clip in pin end condition

and remove it.

WARNING

The pump to the left of the wall is 8 mm thick and the

one to the right is 12 mm thick.

❱❘ Removing the index shim

1

1

1

• Keep the selection locking latch blocked (1)

• Pull on the scorpion and remove the selector

shaft.

• Unblock the index shim and the locking latch

with an Allen key (2)

2

A

1

2

B

19

❱❘ Separating the central crankcases

• Remove the screw (A - p. 19) with an Allen key.

• Remove the water pump drive pinion (B - p.19)

by removing the securing clip. Beware of the needle

that may fall.

• Turn the housing over and remove the 14 screws

of the central crankcase: (1) length 45 mm x 10; (2)

length 55 mm x 1; (3) length 75 x 3.

• Separate the central crankcases.

1

1

1

3

3

3

1

1

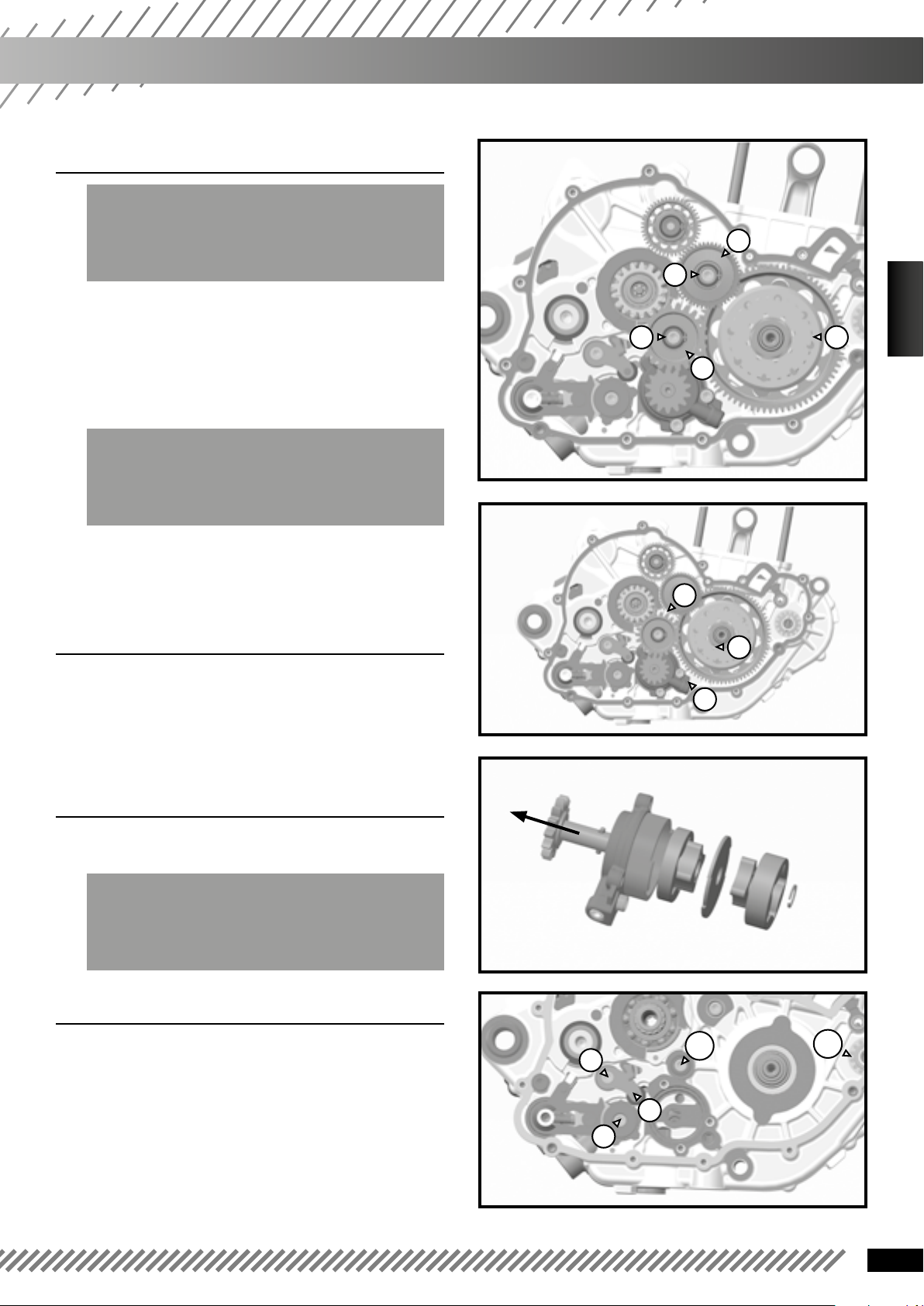

❱❘ Removing the gearbox

• Remove the two fork spindles (1).

• Remove the selection drum.

BEWARE

of the small fork sockets.

• Remove the forks C, L and R.

• Remove the two gearbox shafts.

1

1

2

1

1

❱❘ Removing the crankshaft

• Remove the balancer shaft.

• Remove the crankshaft.

20

R

C

L

450 SEF-R

Checking individual parts

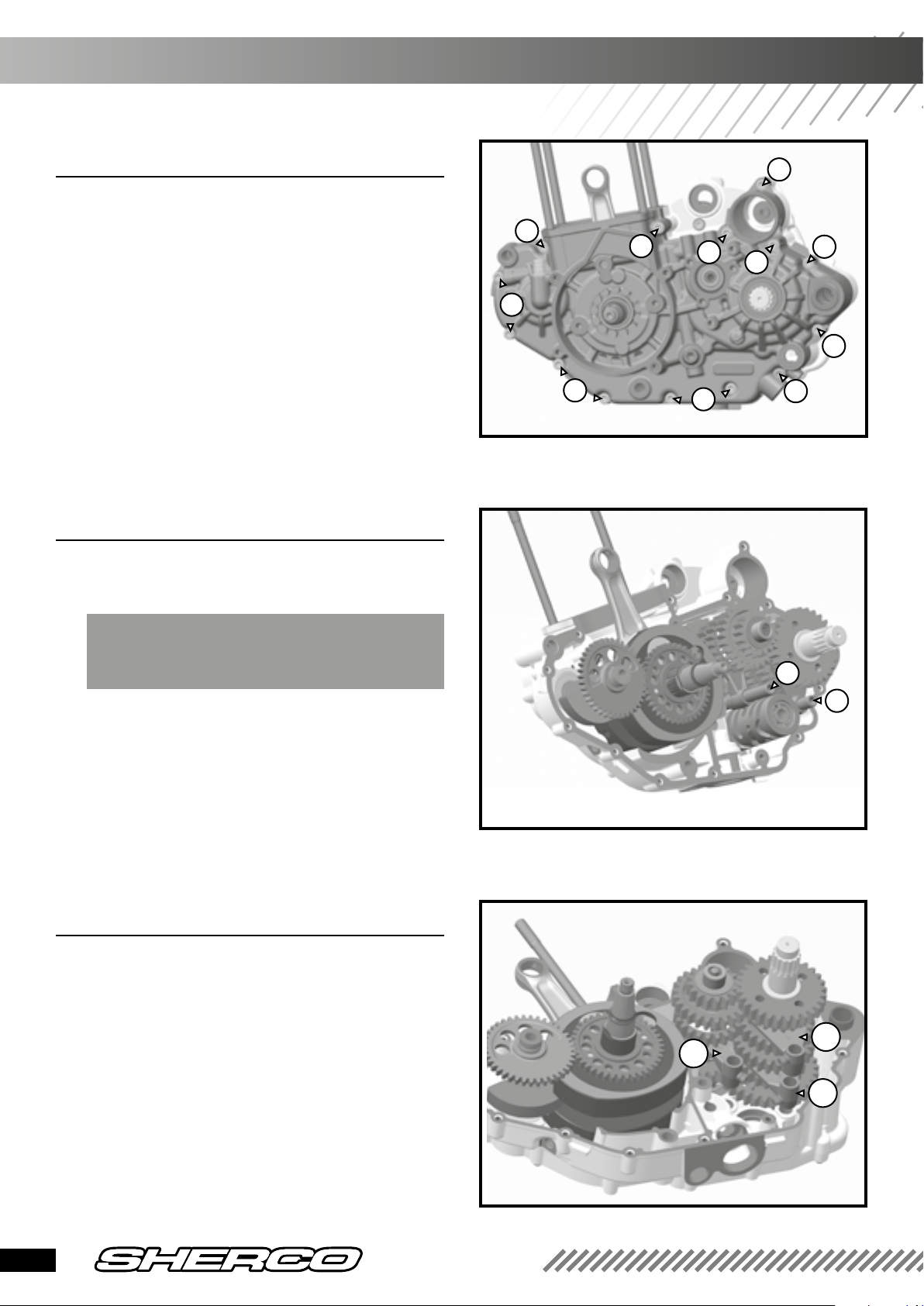

❱❘ Controlling the central crankcases

• Check the general condition of the central cran-

kcases for any possible damage or crack.

Change the defective or worn crankcase set if

necessary.

• Check the condition of the bearings. Change

them if necessary.

❱❘ Left crankcase

ENGLISH

• The crankshaft bearings (1), primary shaft (2)

and secondary shaft (3) of the gearbox are held by

some screws and/or plates.

• Balancer shaft bearing (4).

• Check the bearings, replace them if necessary.

• Remove the bearings.

• Check that their housing is clean and install the

new bearings, hot crankcase at about 70 °C.

• Apply blue thread lock on the bearings of the

retaining screws and tighten them to 5 Nm.

• Check that the top engine oil nozzle (5) and BV

(6) is not clogged or damaged.

WARNING

the piston nozzles (7) are indexed and cannot be

replaced. If damaged, replace the carters.

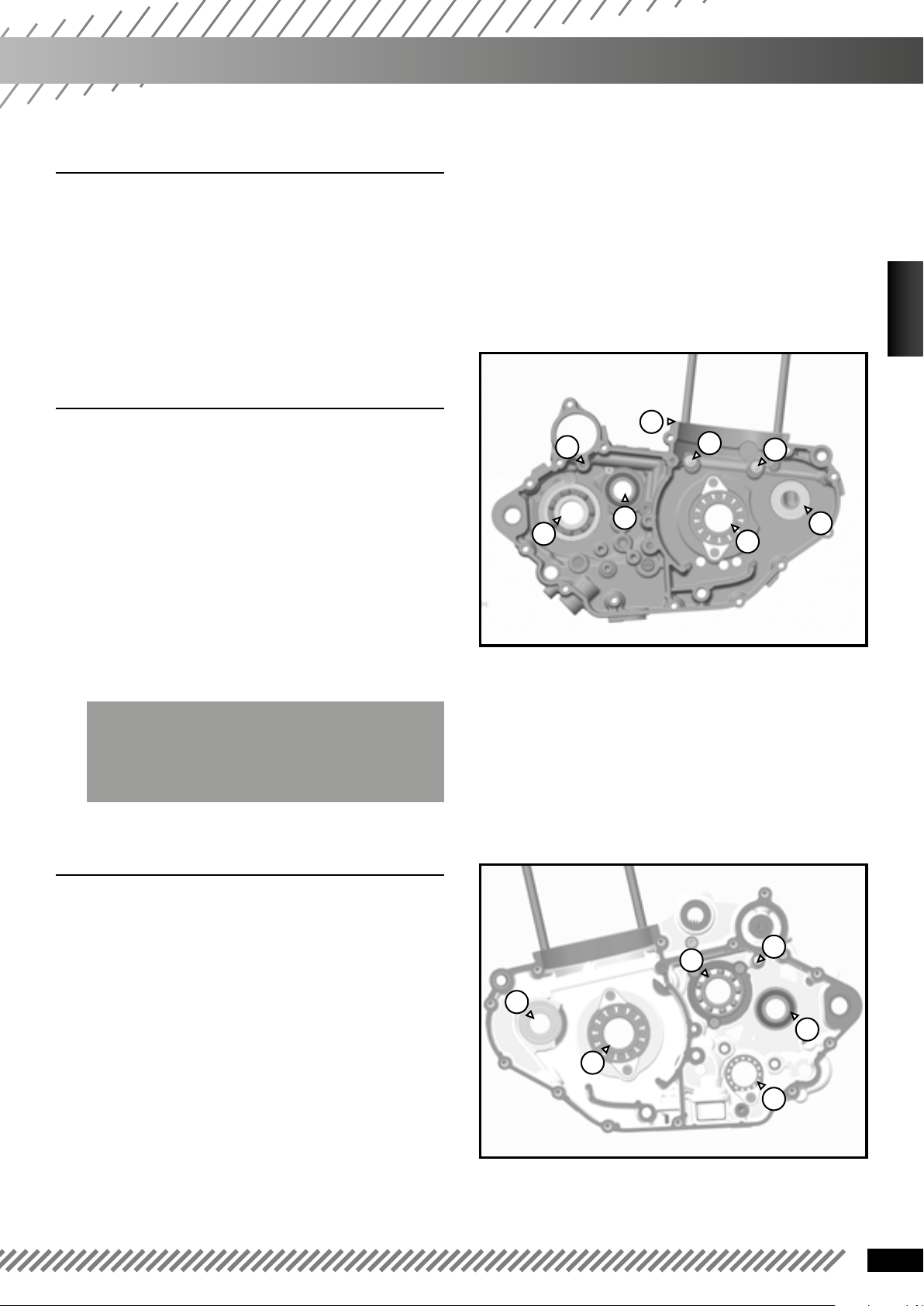

❱❘ Right crankcase

5

6

2

3

7

7

4

1

• The crankshaft bearings (1), primary shaft (2)

and secondary shaft (3) and selection drum (4) are

secured by screws and/or plates.

• Balancer shaft bearing (5).

• Check the bearings, replace them if necessary.

• Remove the bearings.

• Check that their housing is clean and reinstall

the new bearings, hot crankcase at about 70 °C.

• Apply blue thread lock on the bearings of the

retaining screws and tighten them to 5 Nm.

• Check that the oil nozzle (6) and (7) (external

side) is not clogged.

2

6

5

3

1

4

21

❱❘ Checking the freewheel sprocket

bearinge

• Visually check the needle bearing of the

freewheel sprocket.

• Change it if necessary.

• Check the visual aspect of the rolling raceway

of the freewheel sprocket (1).

• Change the pinion if necessary.

• Check the visual aspect of the freewheel, its

clearance with your hand, as well as its capacity to

freely rotate.

• Replace it if necessary; remove the outer

securing clip (2) and remove the freewheel.

WARNING

Replacing the freewheel systematically involves

replacing the freewheel sprocket and vice versa.

1

2

❱❘ Changing the crankshaft bearings

• Change the corresponding bearings (outer rings)

on the central crankcases.

• Pull out the distribution drive pinions with a

2-arm puller.

• Retrieve the inner rings of the crankshaft

bearings by heating the R464 tool and the ring.

WARNING

The radial clearance of the bearings must be

practically zero.

• To remove the drive pinion of the balancer shaft,

tighten 2 screws 8 x 125 in the holes provided for

this purpose.

22

450 SEF-R

Checking individual parts

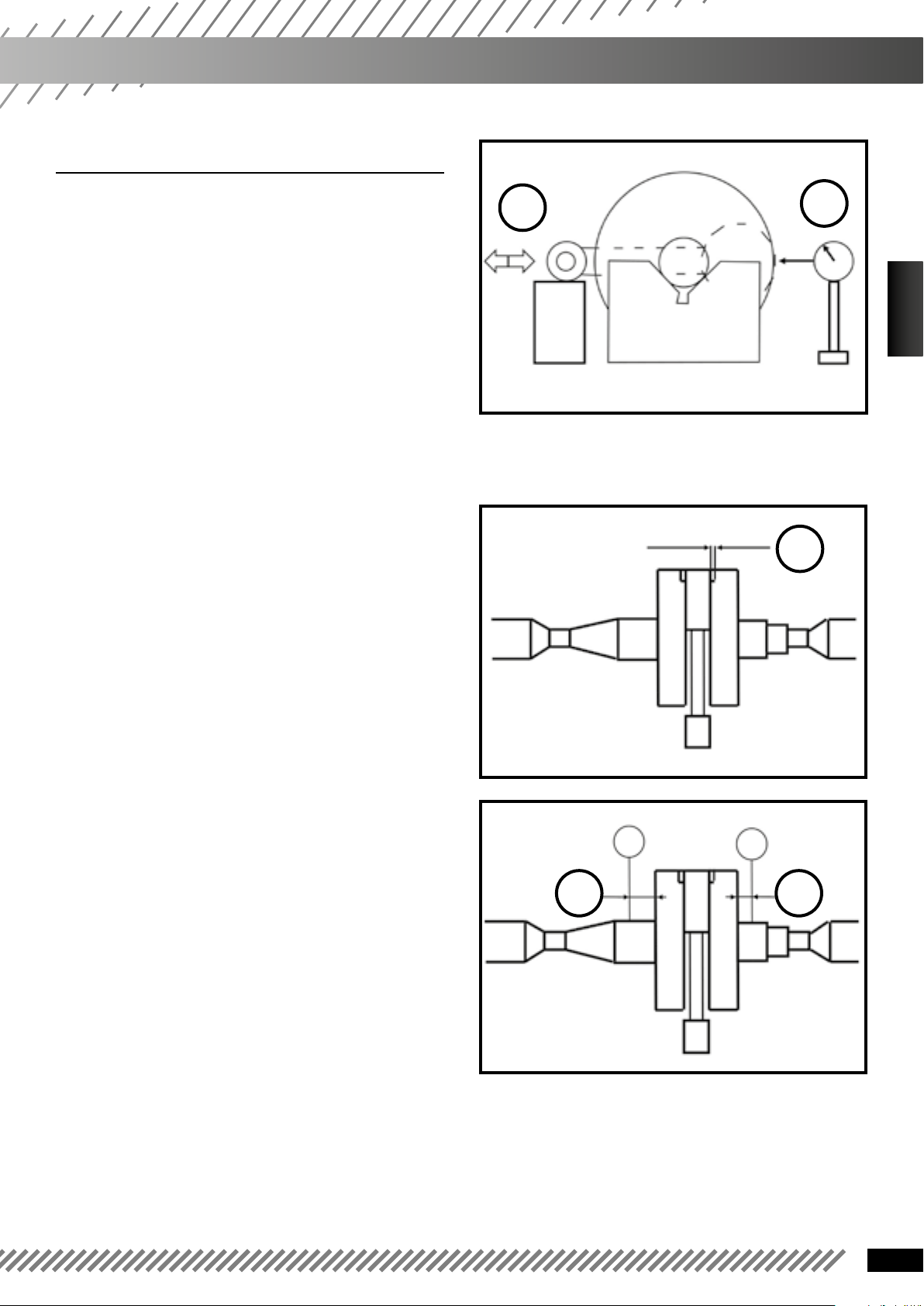

❱❘ Checking the crankshaft

Radial clearance of the connecting rod:

• Place the crankshaft on V-blocks and place a

dial gauge [A] against the connecting rod.

• Push [B] the connecting rod to the gauge and

then in the opposite direction. The difference

between those two measurements is the radial

clearance.

Radial clearance of the connecting rod:

Standard: 0.008 mm - 0.012 mm

Tolerated limit: 0.05 mm

If the radial clearance exceeds the limit, the crankshaft must be replaced.

Lateral clearance of the connecting rod:

• Measure lateral clearance of the connecting rod [A].

Lateral clearance of the connecting rod:

Standard: 0.6 mm - 0.85 mm

Tolerated limit: 1.1 mm

B

A

ENGLISH

A

If the radial clearance exceeds the tolerated limit,

replace the crankshaft.

Checking the runout:

• Place the crankshaft on alignment devices or V-

blocks, and place a gauge as shown in the image.

• Then slowly turn the crankshaft. The maximum

difference between the measurements corresponds

with the offset of the crankshaft.

Runout:

Standard: 0.02 mm maximum

Tolerated limit: 0.08 mm

If the offset is not correct, replace the crankshaft

and align it so to be within tolerated limits.

AA

23

Loading...

Loading...