SHERCO 2013 SE 250i-R, 2013 SE 300i-R, 2011 SE 2.5i-F, 2011 SE 3.0i-F Shop Manual

Shop manual

2013

SE 250i-

R

SE 300i-

R

1/54

CONTENTS

Forward ................................................................................................................................................... 2

Motor tools SE25i-F ............................................................................................................................... 3

Technical specification - Motor ............................................................................................................. 4

Technical specification - Frame ............................................................................................................ 5

Standard adjustement – Fork ............................................................................................................... 6

Standard adjustment - Fork Sachs USD Gold Series Ø48MM.......................................................... 6

Standard adjustment - Fork WP USD Gold Series Ø48MM .............................................................. 6

Standard adjustement – Shock absorber ............................................................................................ 7

Standard adjustment - WP Shock absorber ........................................................................................ 7

Operations requiring demounting or not engine ................................................................................. 8

Removing the motor .............................................................................................................................. 9

Removing the motor: ............................................................................................................................ 9

Motor top end ....................................................................................................................................... 11

Disassembling the right side ............................................................................................................... 23

Disassembling the left side ................................................................................................................. 26

Crankcase / Transmission / Central crankcases .............................................................................. 29

Tightening torques ............................................................................................................................... 36

Clean injector body .............................................................................................................................. 38

SHERCO diagnostic tools ................................................................................................................... 41

Software installation ........................................................................................................................... 42

Software presentation (the various interfaces) : ................................................................................... 42

Connecting the diagnostic kit wiring ................................................................................................... 43

Performing diagnostic ......................................................................................................................... 43

Synchronizing the ECU / with the butterfly openning sensor (TPS) .................................................... 45

Electrical installation checking ........................................................................................................... 47

Regulator ............................................................................................................................................ 47

Cable diagram (Injection / light) .......................................................................................................... 48

Injection beam .................................................................................................................................... 48

Light beam ......................................................................................................................................... 50

Racing lighting cable diagram : ........................................................................................................... 52

Flasher installation cable diagram : ..................................................................................................... 53

Fan cable diagram : ............................................................................................................................. 54

2/54

Forward

This manual is designed primarily for skilled mechanics working in a properly equipped

workshop. The execution of the operations in this manual requires a strong mechanical

knowledge and specific SHERCO tools designed for the SE 250i-R and SE 300i-R engine.

This workshop manual is a supplement to the SHERCO SE 250i-R and SE 300i-R owner’s

manual.

3/54

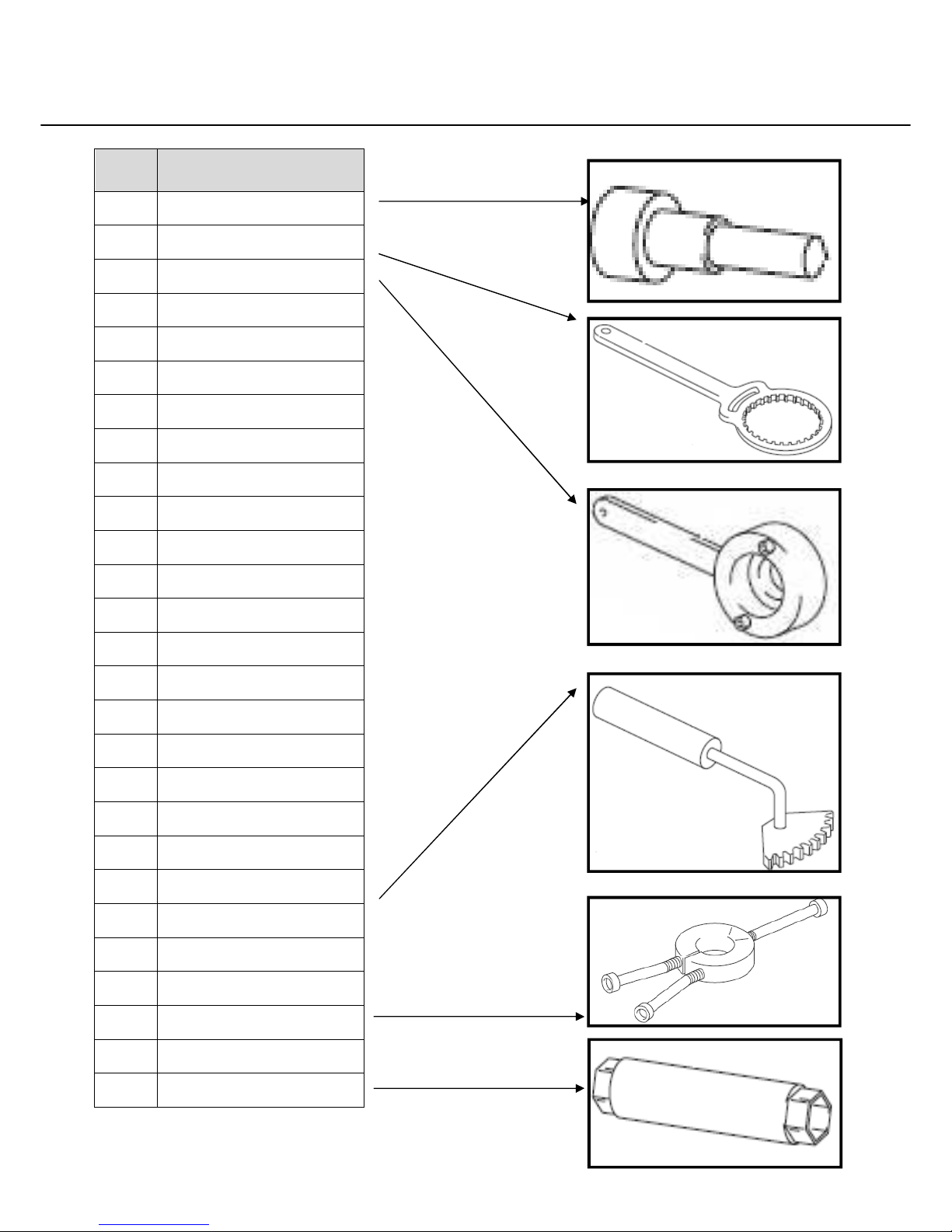

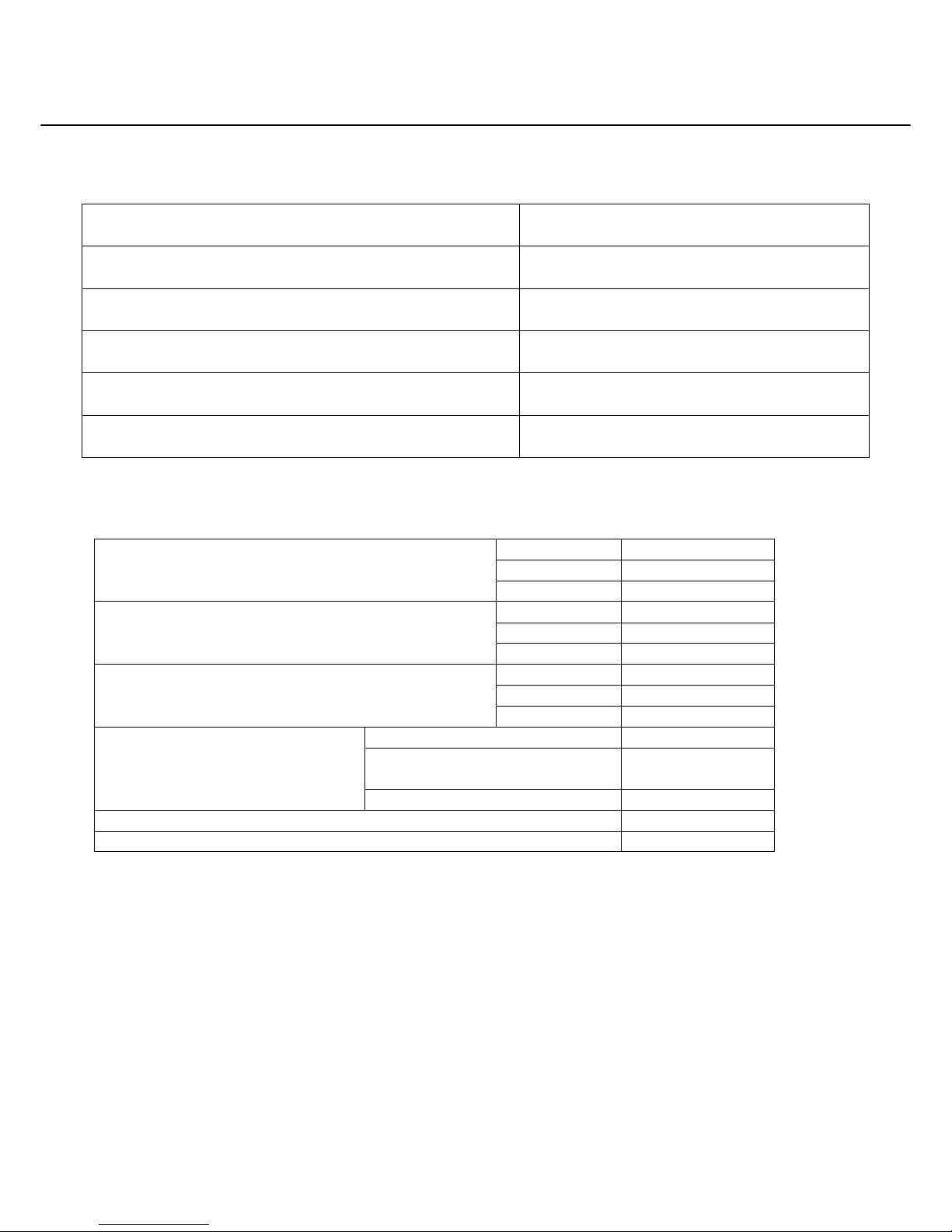

Motor tools SE25i-F

Tool

ref

Designation

1819

Dead point

1814

Clutch holder tool

1815

Ignition tool

2067

Swingarm tool

2068

Freewheel tool

2069

Oil seal tool (Gear box exit)

2070

Oil level gauge tool

2071

Bearing tool 6905 (Gear selector

drum)

2072

Bearing tool 6222 (Clutch shaft)

2079

Bearing tool 6203 left ( Balancer)

2080

Oil seal tool 8x18x5

1822

Bearing tool (Water pump shaft)

2078

Oil seal 36x57x7,5 Right

(Crankshaft)

2077

Bearing tool 4905 Right (Balancer)

2074

Bearing tool 6003 (Gear shaft)

1968

Oil seal tool (Water pump)

2075

Piston tool

2076

Bearing tool (Crankshaft)

1816

Ring tool

1821

Engine support tool 250

1817

Pinion tool

1818

Piston support

2073

Resort tool

R462

Flywheel puller

R464

Ring extractor

R450

Gear selector oil seal tool

3785

Spark key

4/54

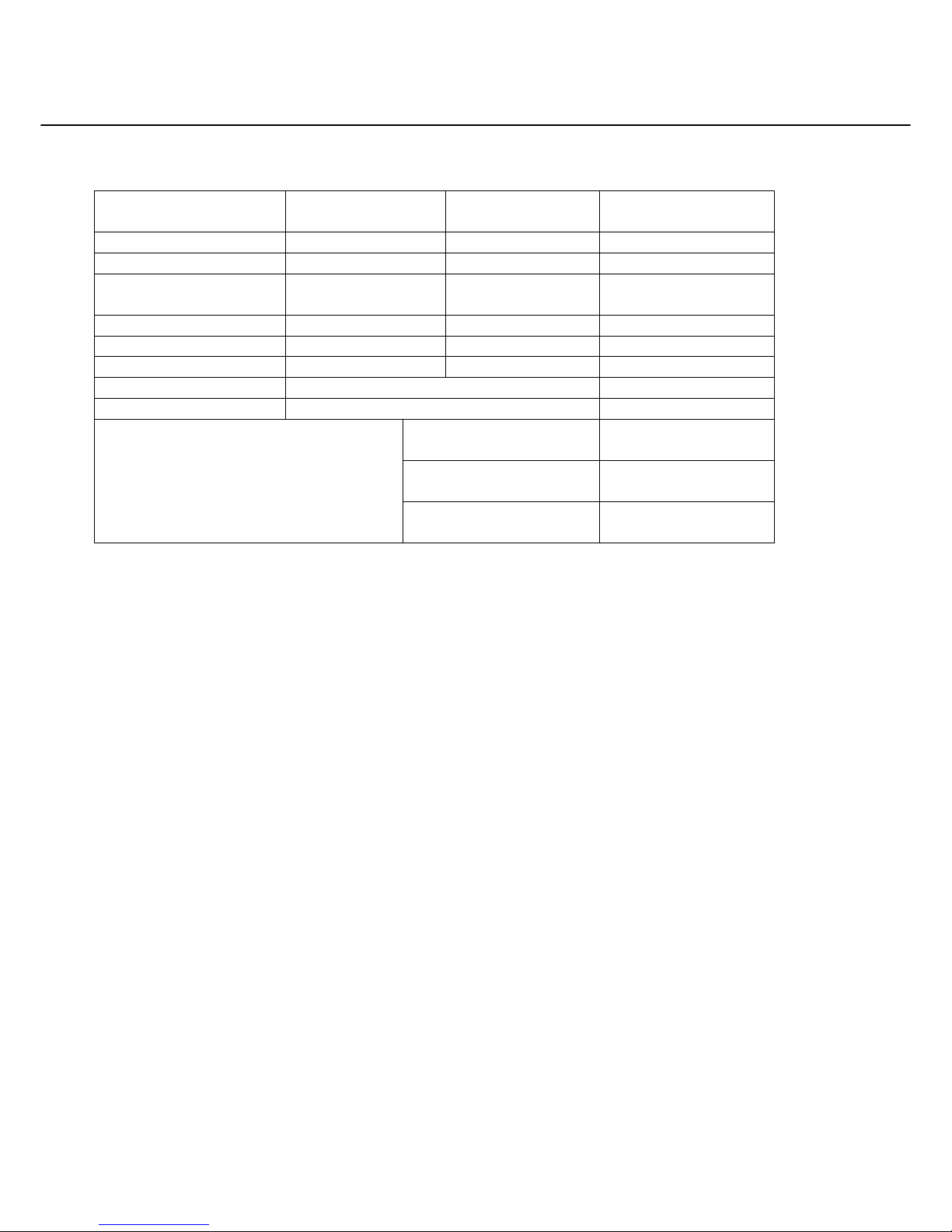

Technical specification - Motor

Type Liquid cooled single cylinder 4 strokes engine

Displacement 249.4 CC 303.7 CC

Bore/Stroke 78/52mm 84/54.8mm

Compression ratio 12.6 :1 12.8:1

Fuel Without lead 95 or 98

Valve timing 4 valves, DOHC driven by tooth type chain

Admission valve diameter 29mm

Exhaust admission valve 25mm

Thickness admission valve 0.15-0.2mm

Thickness exhaust valve 0.2-0.25mm

Crankshat bearing 2 roller bearing

Piston Aluminium forge

Lubrification Lubrication under pressure with 2 trochoidal pumps

Motor oil 1 L SAE 10W60

Primary reduction ratio 21 :70

Gear box :

1ère

2ème

3ème

4ème

5 ème

6 ème

6 speed

14 : 33

17 : 30

19 : 28

21 : 26

23 : 24

25 : 22

Final transmission 13 X48 13 X 48

Clutch Multi-disk in oil bath. Hydraulic command

Ignition system / Batterie Electric start/12V 6.5Ah

Electronic injection Magneti Marelli

5/54

Technical specification - Frame

Frame

Semi-perimeter CrMo steel with aluminum subframe

Fork

SACHS USD Gold Series 48mm dia. (standard) & WP USD 48mm dia.

(racing)

Rear suspension

WP Suspension with separate cylinder

Travel Front/rear 300/300mm

Front brake

270mm (standard), 256mm (racing)

Rear brake

220mm

Brake disc

2.7mm front and 3.6mm rear

Front tire

90/90-21”

Rear tire

140/80-18”

Pressure TT

0.9 bar

Fuel tank capacity

8.51 with 1l of reserve

Angle of the steering column 27.3°

Wheel base 1470mm

Weight (with fuel) 102 kg

6/54

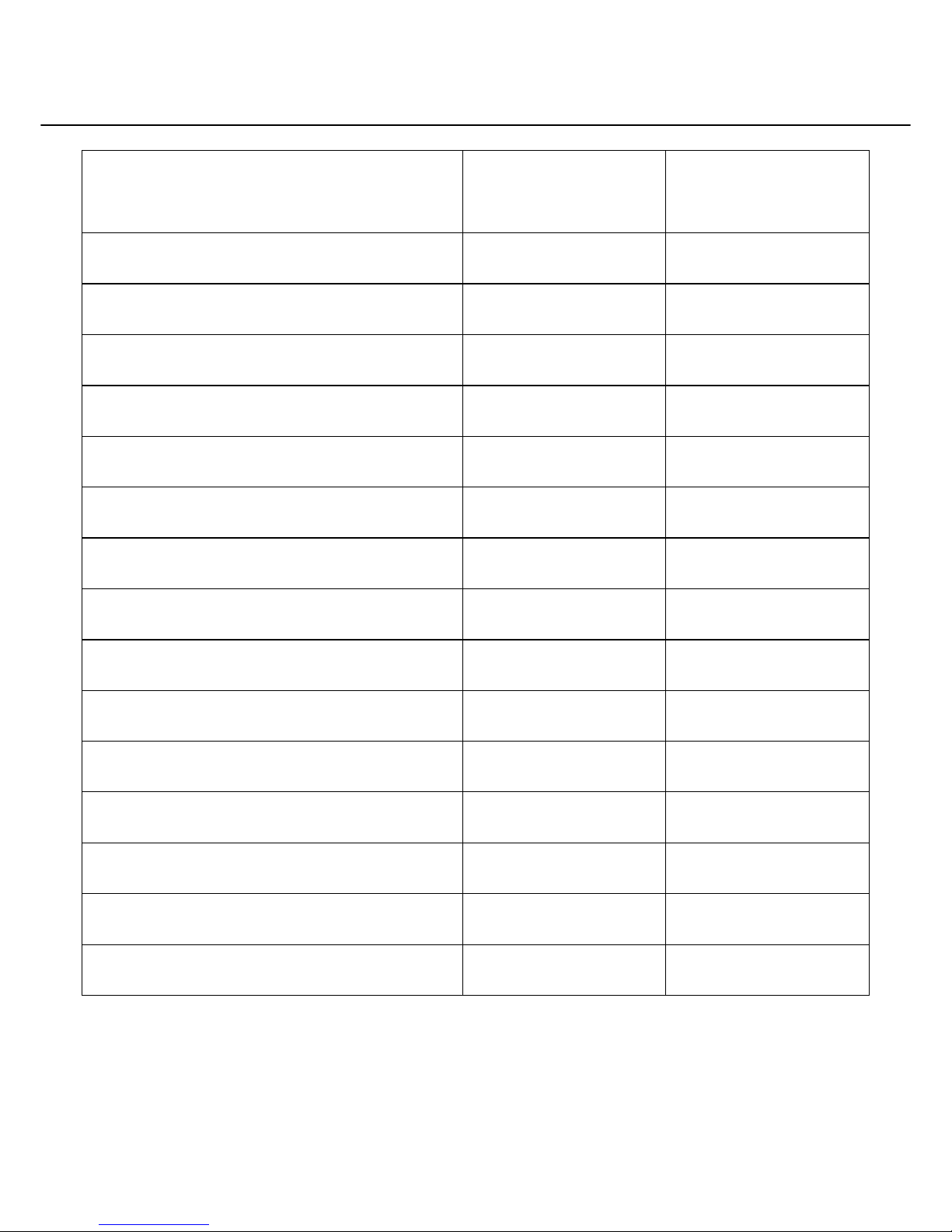

Standard adjustement – Fork

Standard adjustment - Fork Sachs USD Gold Series Ø48MM

Compression

Turn clockwise to the stop, then back of 12

clicks

Rebound

Turn clockwise to the stop, then back off

12 clicks

Spring

4.5N/mm

Fork oil

SAE 5

Oil capacity

600cm3

Oil level

130mm

Standard adjustment - Fork WP USD Gold Series Ø48MM

Compression Comfort 20 clicks back

Standard 13 clicks back

Sport 8 clicks back

Rebound Comfort 18 clicks back

Standard 13 clicks back

Sport 10 clicks back

Preload Comfort 2 turns

Standard 4 turns

Sport 6 turns

Spring stiffness Rider weight: 143 -165 lbs 4.0N/mm

Rider weight: 165- 187 lbs 4.2 N/mm

(original)

Rider weight: 187- 210 lbs 4.4N/mm

Type of oil SAE 4

Oil level 110mm

7/54

Standard adjustement – Shock absorber

Standard adjustment - WP Shock absorber

Low-speed

compression

Comfort 20 clicks back

Standard 15 clicks back

Sport 12 clicks back

High-speed

compression

Comfort 2.5 clicks back

Standard 2 clicks back

Sport 1.5 clicks back

Rebound Comfort 15 clicks back

Standard 13 clics en arrière

Sport 11 clics en arrière

Spring stiffness Rider weight: 143 -165

lbs

48N/mm

Rider weight: 165- 187

lbs

51N/mm (origine)

Rider weight: 187- 210

lbs

54N/mm

8/54

Operations requiring demounting or not engine

Removing engine Not demounting engine

Crankshaft •

Gear box •

Crankshaft bearing •

Gear Box bearing •

Piston •

Cylinder •

Cylinder head •

Valve timing •

Ignition •

Pinion of ignition system •

Freewheel •

Clutch •

Water pump •

Oil pump •

Gear selection •

9/54

Removing the motor

Removing the motor:

To remove the engine, you must remove

the swing arm axle, the swing arm and the rear

wheel. To keep the bike from falling, remember

to support the chassis with an appropriate jack.

• Drain (refer to the owners manual)

- the engine oil

- the engine coolant

• Remove the seat.

• Disconnect the battery.

• Remove the fuel tank and its covers.

• Disconnect all the electrical wiring

connectors from the engine. (Starter, TPS

sensor, water temperature sensor, coil, fuel

injector).

• Remove the exhaust.

• Remove the ignition coil.

• Remove the fuel injector body.

• Remove the chain.

• Remove the chain guard.

• Remove the clutch actuating cylinder.

When the clutch actuating cylinder is

removed the piston is loose. Hold the piston it

in place using a plastic strap.

• Remove all of the water hoses

connected to the motor.

• Remove the left radiator.

• Loosen all of the engine bolts [A].

• Loosen the swing arm bolt.

• Remove the brackets that attach the

cylinder head to the chassis.

• Remove the motor mounting bolts.

• Remove the swing arm bolt.

• Remove the motor.

10/54

Reinstalling the motor:

• The motor should be reinstalled in the

frame in the reverse order of how it was

removed. The following torque values should

be utilized.

Tightening torques :

Motor mounting bolts: 60Nm

Swing arm axle nut: 100 Nm

Clutch receiver screws: 10 Nm

Cylinder head bracket bolts: 23Nm

Exhaust mounting bolts: 10Nm

11/54

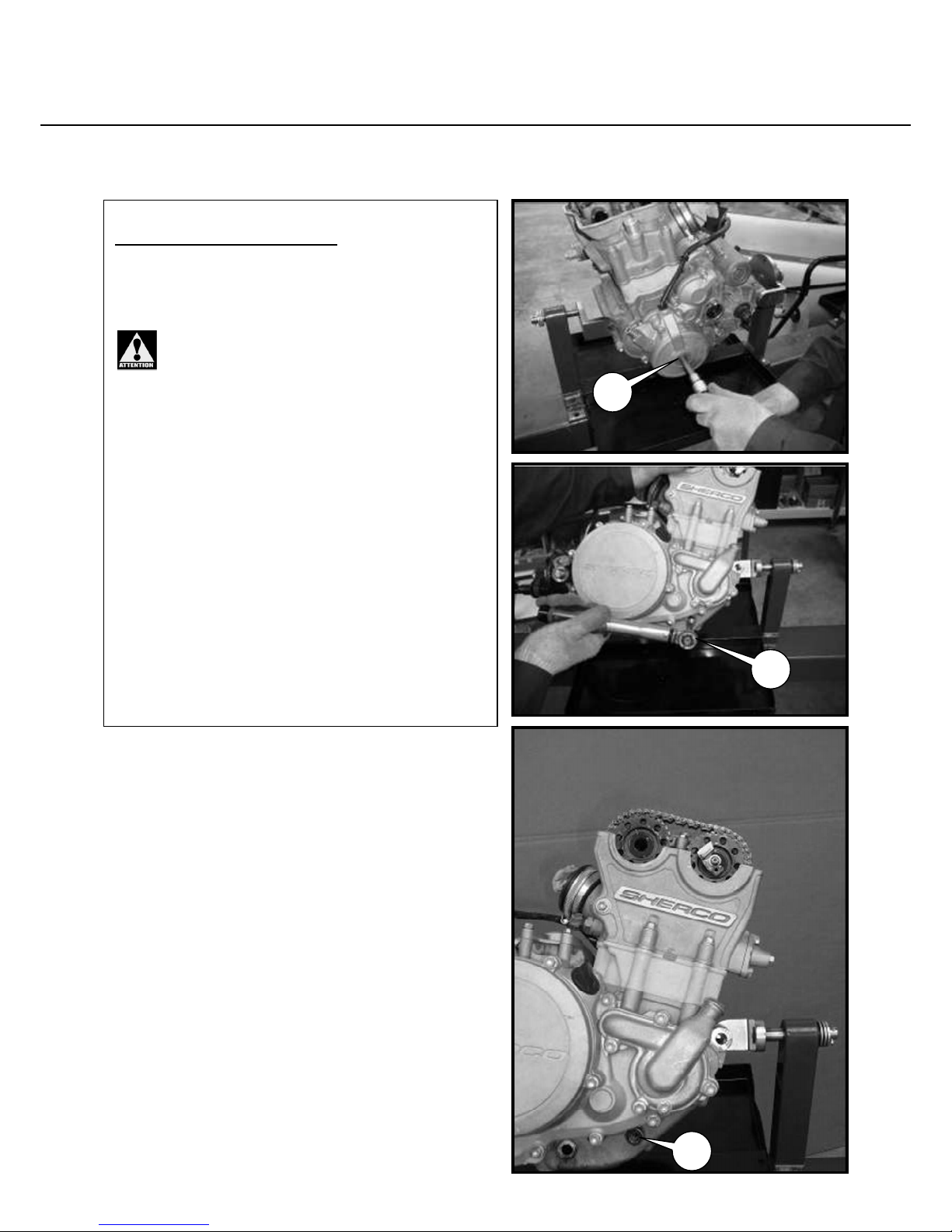

Motor top end

For additional details refer to the parts catalog SE 250i_SE 300i..

Removing the cylinder head:

• Remove the spark plug.

• Remove the valve cover.

• Remove the three valve cover screws.

These three screws are equipped with orings ref: 0900.

• Remove the cap from the ignition cover.

[A].

• Remove the timing control plug [A]

• Turn the engine counterclockwise in

order to align the timing marks on the

crankshaft with the marks on the timing gear.

Install the special tool that locks the engine at

Top Dead Center [A] (ref 1819)

A

A

A

12/54

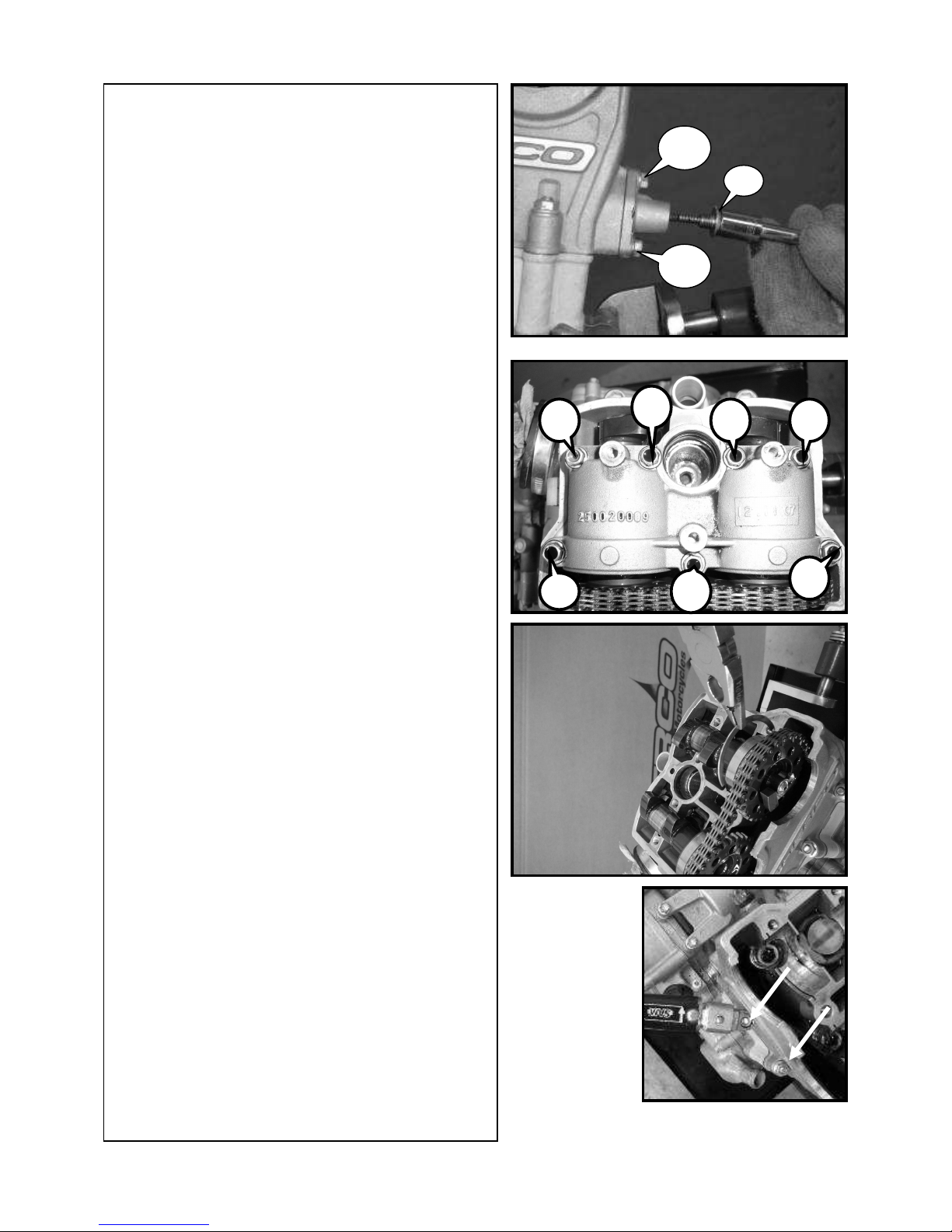

• Remove the screws from the cam chain

tensioner as shown in the photo.

• Remove the cam chain tensioner.

• Remove the spark plug well.

• Remove the camshaft bearing journal.

Starting on the inside, remove the screws

In a criss cross manner (see the numbers on

the photo).

• Remove the exhaust camshaft retaining

clip.

• Remove the exhaust camshaft.

• Remove the intake camshaft retaining

clip.

• Remove the intake camshaft.

• Remove the two nuts M6 and the

washer.

2

3

1

2

3

4 5

7

6

13/54

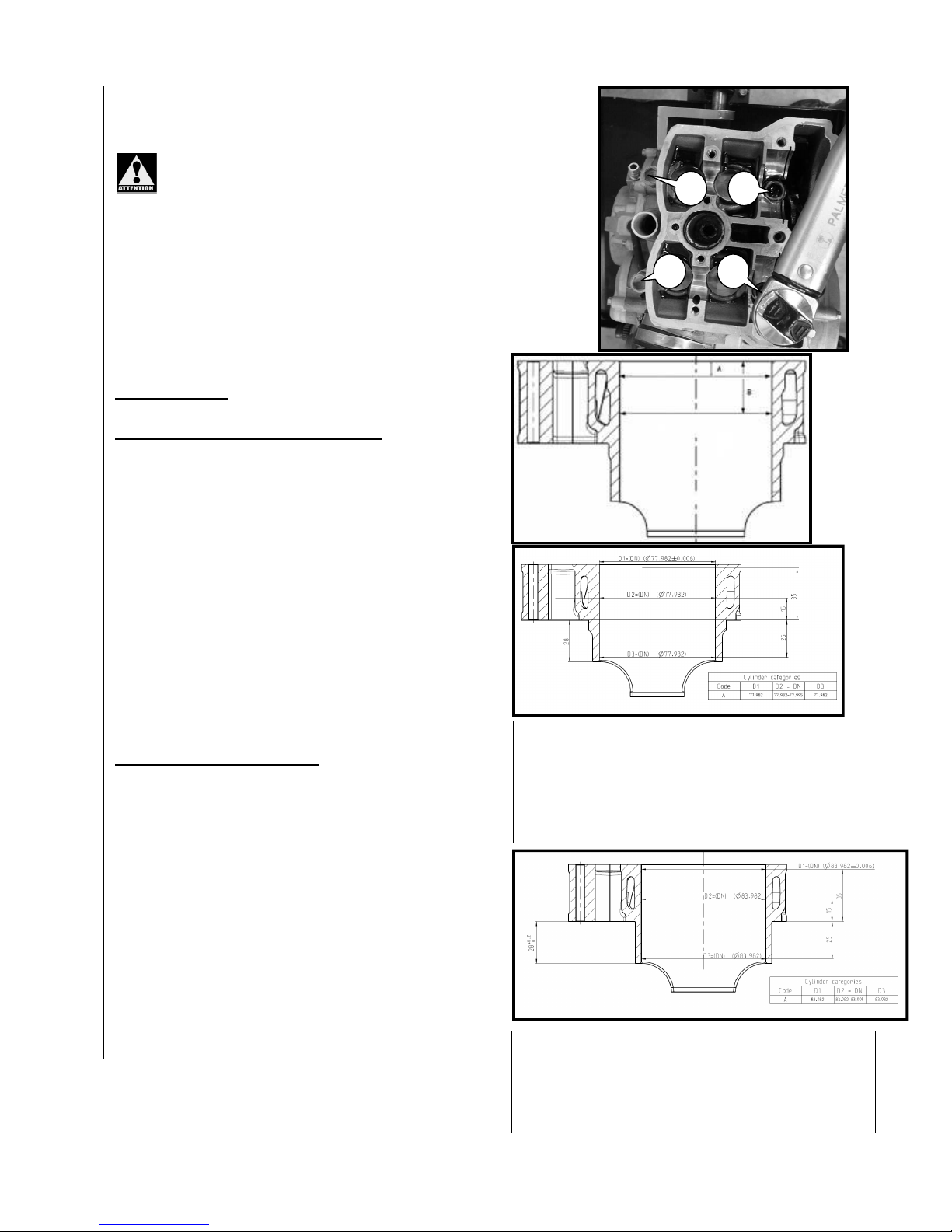

Standard

SE 250i

-R:

Cylinder diameter (A) = 77.982±0.01 mm

Cylinder diameter (B) = 77.982~77.995 mm

Taper limit 0.05 mm

Out of round limit 0.05 mm

Standard

SE 300i

-R:

Cylinder diameter (A) = 83.982±0.01 mm

Cylinder diameter (B) = 83.982~83.995 mm

Taper limit 0.05 mm

Out of round limit 0.05 mm

• Remove the cylinder head bolts (Be sure

to loosen them in the correct direction).

Black bolt N°1 on the picture is longer , 3

bolts are identical .

• Remove the cylinder head.

• Remove the head gasket and the

cylinder.

Motor top end:

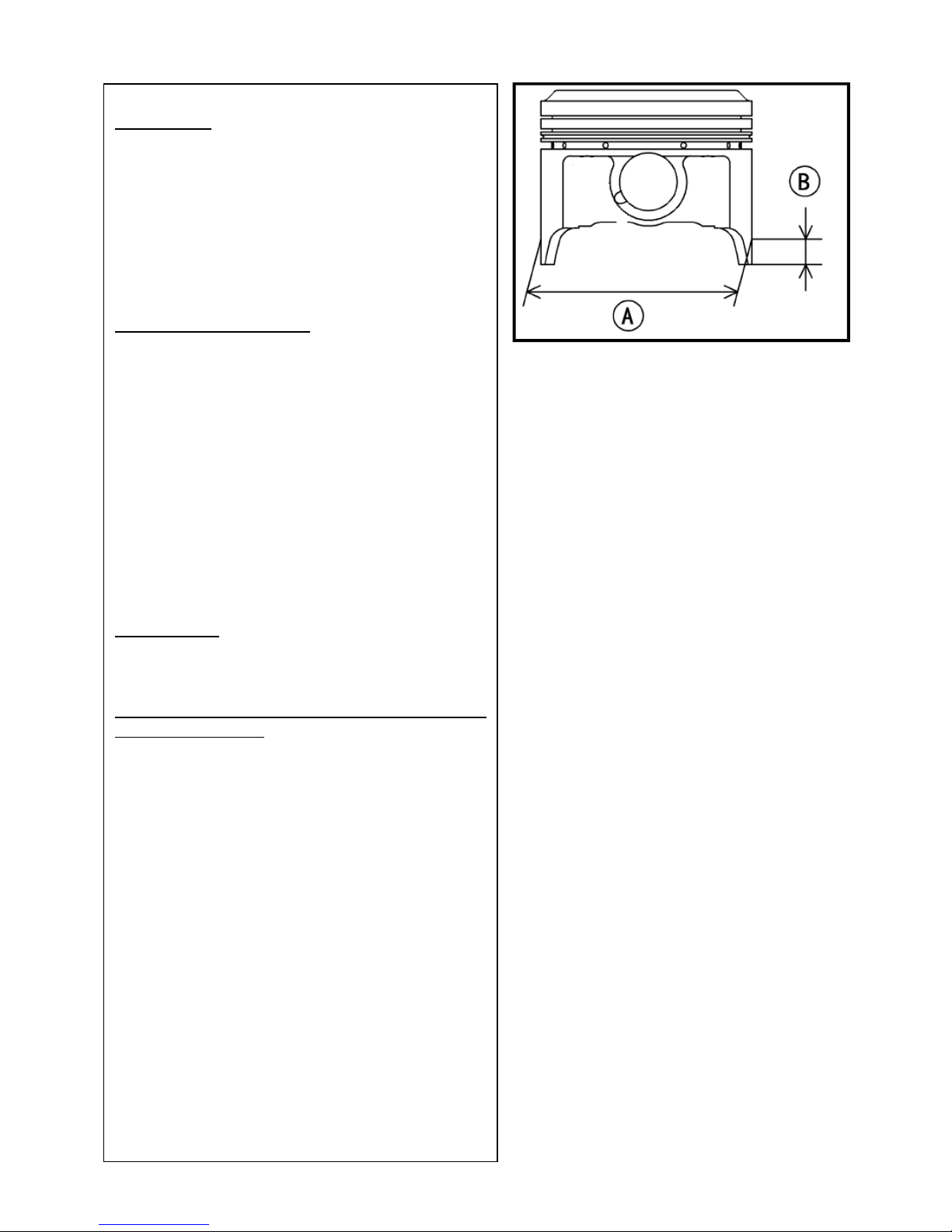

Inspection of the cylinder for wear:

Measure the inside diameter of the cylinder

when it is cold.

• Inspect the inside of the cylinder for any

scratches or other evidence of abnormal wear.

If the cylinder is badly damaged or worn it

should be replaced.

• Since the cylinder does not wear in a

uniform manner measure in from side to side

and up and down as shown.

If the inside measurement of the cylinder

exceeds the tolerance limit it must be replaced.

(A)=10 mm

(B)=25 mm

Piston / cylinder clearance

To determine the piston / cylinder clearance as

accurately as possible it is sufficient to measure

the piston and the cylinder, and then calculate

the difference between the two values.

Measure the diameters as shown.

Piston / cylinder clearances

Standard 0.03 – 0.05 mm

Limit 0.10 mm

1 4

14/54

Piston wear:

• Using a micrometer measure the outside

diameter of the piston [A] 10mm [B] above the

bottom of the piston and at right angles to the

axis of the piston.

If the outer diameter of the piston is below the

tolerance it must be replaced.

Piston 250i-R= 77.950±0.005 mm

Piston 300i-R= 83.950±0.005 mm

Ring groove / piston ring:

• Using a feeler gauge measure the

clearance between the piston ring and the ring

groove.

• Check in several places to determine the

actual clearance if the clearance is greater than

the maximum, replace the piston ring and if

necessary the piston.

Ring groove / piston ring

Standard

Compression ring: 0.030-0.065 mm

Limit 0.13 mm

Oil control ring: 0.020-0.055 mm

Limit 0.13 mm

Ring end gap

Compression ring: 0.3-0.4 Limit 0.7 mm

Oil control ring: 0.3-0.5 mm

Inspect the connecting rod, the piston pin and

the piston for wear:

• Visually inspect the circlips in place.

If they appear worn or distorted replace them. If

the hole for the circlips appears worn replace

the piston.

• Measure the piston pin with a

micrometer.

If at any place on the pin the diameter is below

the limit replace the piston pin.

• Measure the diameter of the piston pin

holes in the piston and the hole in the

connecting rod. If the one or more holes in the

piston are incorrect replace the piston.

If the diameter of the hole in the connecting rod

is incorrect, replace the connecting rod.

Piston pin diameter

15.997-16.000 mm

Piston pin hole diameter in the piston

16.004-16.009 mm

Connecting rod hole diameter

16.000-16.011 mm

15/54

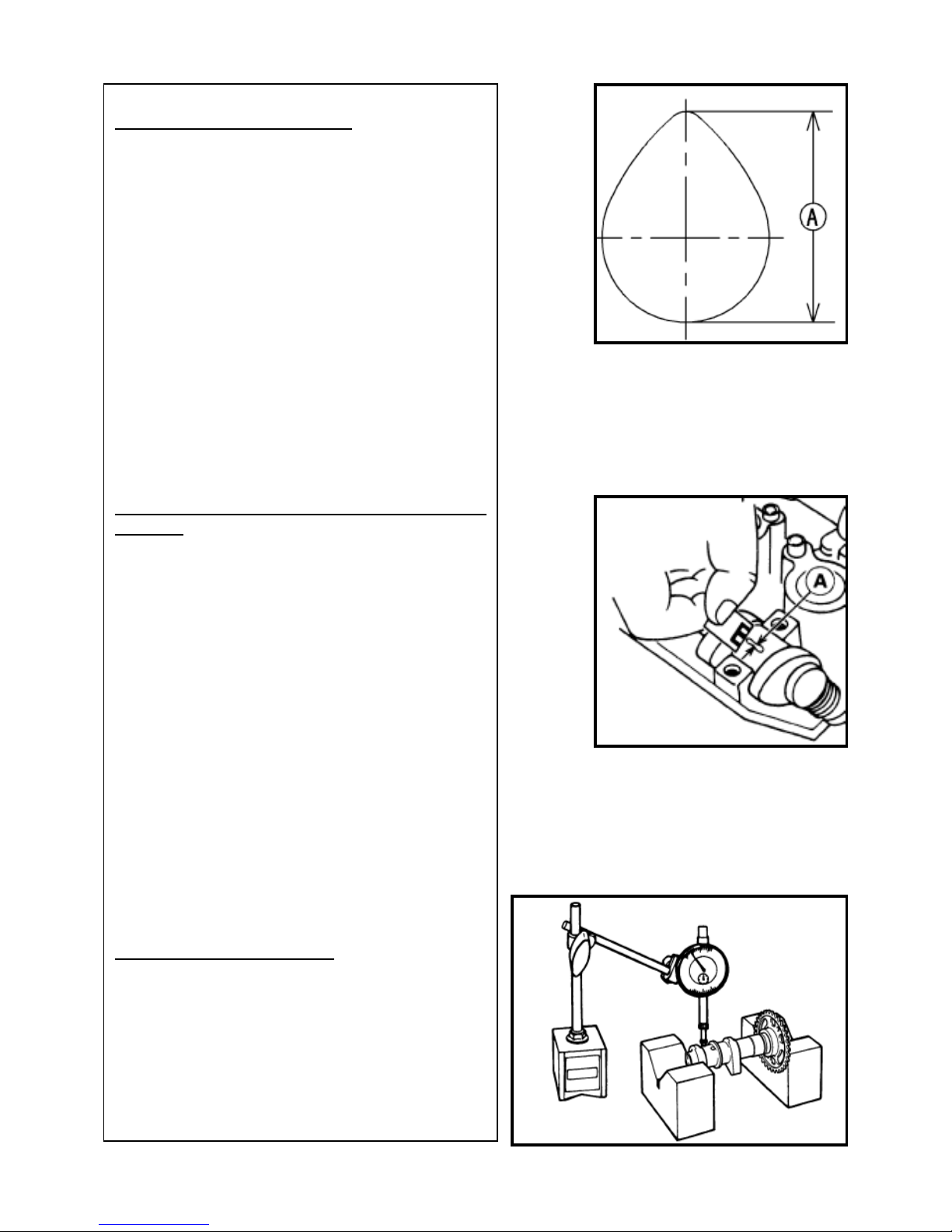

Check the camshafts for wear:

• Remove the camshafts.

• Measure the heights [A] of the camshaft

lobes with a micrometer.

If the cams are worn beyond the limits, replace

the cams.

Camshaft height limit 250

Exhaust: 31.245 mm

Intake: 32.145 mm

Camshaft height limit 300

Exhaust: 31.977 mm

Intake: 32.145 mm

Checking the camshafts and camshaft journals

for wear:

• Measure the clearance between the

camshaft and the camshaft journals using

plastigage [A].

Lubricate the fixing bolts with engine oil and

tighten to the proper torque.

Tightening torque

Camshaft journal mounting bolts: 10 Nm

If any of the measurements are over the limit,

then measure the diameter of each journal.

Camshaft / journal clearance

Standard: 0.020 – 0.062 mm

Limit: 0.15 mm

If the diameter of the journal is below the limit

replace the camshaft and measure again.

Camshaft journal diameter

Standard: 23.05 – 23.25 mm

Limit 23.02 mm

If the clearance is outside of the tolerance

limits, replace the entire cylinder head.

Eccentricity of the camshaft:

Measure the camshaft runout.

If it is out of tolerance, replace the camshaft.

Runout: Less than 0.03 mm

16/54

fezf

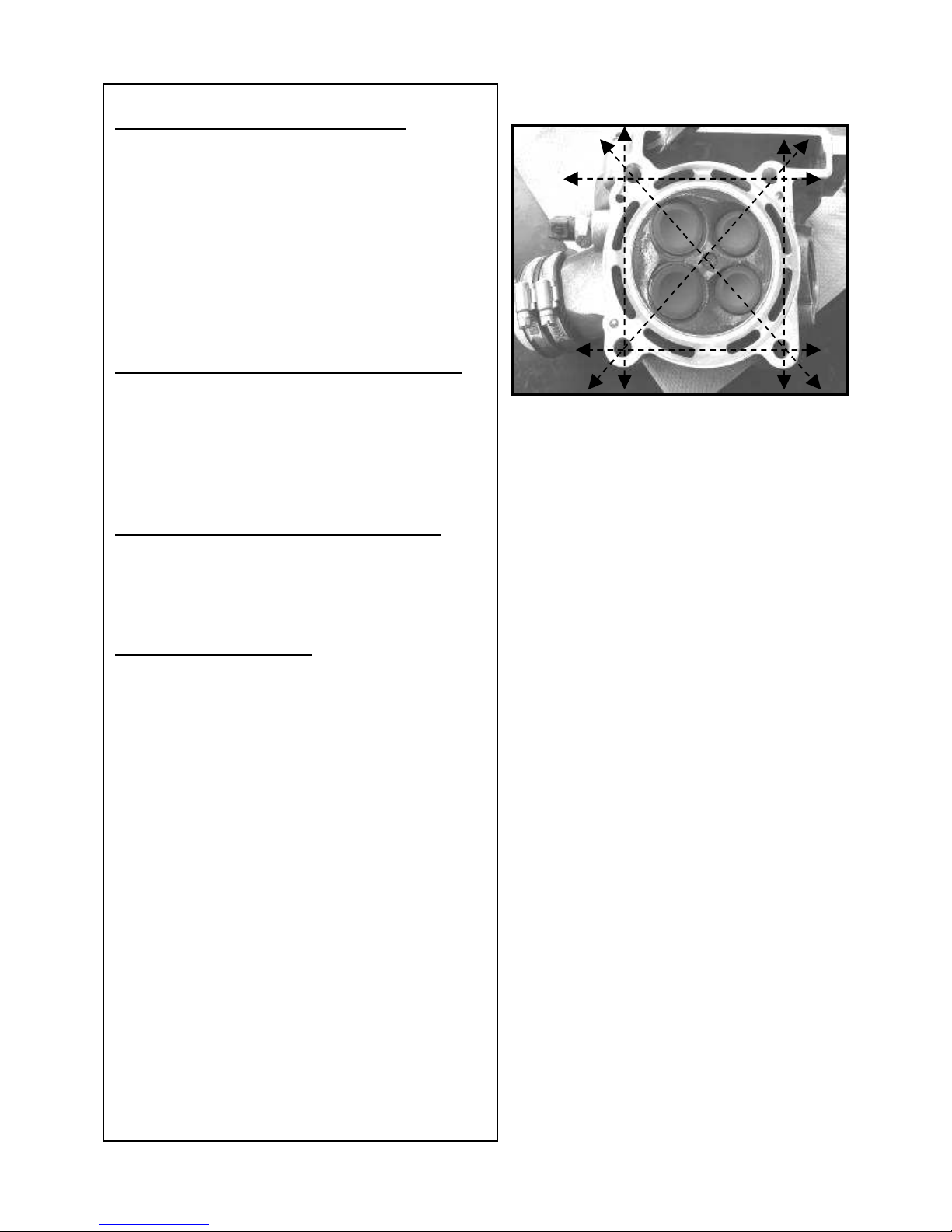

Inspect the cylinder head for flatness:

• Place the cylinder head on the

workbench

• Using a precision straight edge [A] and a

feeler gauge check the head for warpage;

check in several places as shown in the photo.

If the warpage is above the limit, repair if

possible. If the damage is severe replace the

head.

Cylinder head warpage:

Limit = 0.05 mm

Visually inspect the timing chain for damage:

Inspect the timing chain by flexing it to

determine if there are any tight spots. If tight

spots are found it should be replaced.

Check the automatic chain adjuster and make

sure that it is not in the last ratchet notch.

Visually inspect the cam tensioner guides:

Visually inspect all of the cam chain tensioner

channel guides and pads including the ones on

the cylinder head cover.

Change as necessary.

Valve - Guide clearance :

Intake :

Mini clearance : 0.02 mm

Maxi clearance : 0.045 mm

Escape:

Mini clearance : 0.04 mm

Maxi clearance : 0.065 mm

Loading...

Loading...