V4.0 2020-06

Shenzhen Yuejiang Technology Co., Ltd | China

ADDRESS: 9-10 Floors, Building No.2, Chongwen Garden, Nanshan i-Park, Nanshan District,

Shenzhen, China

Contents

I. Fast Assembly

1.1. Accessories List ..............................................................

II. Operation Panel

. Home Page ......................................................................

2.1

. 3-Point Leveling Interface ................................................

2.2

. File Directory Interface .....................................................

2.3

. Control Tools Interface .....................................................

2.4

2.5. 3D Print Functional Module Control Interface ..................

2.6. Zero Point Setting Interface .............................................

. X/Y/Z Motion Control Interface ........................................

2.7

2.8

. Other Settings Interface ..................................................

2.9

. Working Process Control Interface ..................................

. Switch Mixing Mode Configuration Interface .................

2.10

2.11

. Gradient Mixing Mode Configuration Interface .............

III. 3D Printing

3.1. 3-Point Leveling ..............................................................

3.2. Set the Zero Point .......................................................... 8

1

4

4

4

4

5

5

5

5

6

6

6

7

3.3. Install/Remove the Filament ............................

3.4. Use the Slicing Software ..................................

3.4.1. Install the Slicing Software .......................1010

3.4.3. Online Printing ...........................................

3.4.4. Configuration of Color Mixing Scheme ......1113

3.5. Power-Loss Resume ........................................ 16

3.6. Printing Control ................................................ 16

IV. Troubleshooting

4.1. 3D Printing Failure ............................................

4.2. Whole Machine Failure .....................................

4.3. 3D Print Functional Module Failure ..................

4.4. Maintenance of 3D Print Functional Module .... 20

Parameters

................................................................

9

103.4.2. Configuration for Initial Use .......................

18

18

19

21

Symbol Description

Description

Basic terms or reference information.

Note: Updated Firmwares, User Manuals, Softwares and Tutorial Videos will be uploaded to our official website www.dobot.cc

constantly, please use them for better experience. Any support, please contact us: mooz@dobot.cc.

Note

Important precaution: ignoring it may cause

malfunction of the machine and the

corresponding risk.

Warning

Important warning: rules must be strictly

observed, otherwise it may cause

machine breakdown and personal injury.

I

Fast Assembly

1.1 Accessories List

Identical Linear Actuators x 3

Printer Head Module x 1

Base + Main Control

Board + Heated Bed x 1set

LCD Touch Pad x 1

L-type Hex Screwdrive x 2

Spare Parts:

Quick Pipe Connector x 1

Nozzle x 2

Nozzle Sealing Gasket x 3

PTFE Pipe x 3

Temperature Sensor x 1

Bourbon Pipe x 1

Cable Clip x 5

1.1.1 Install the Filament Support

Set up the filament support, and place the

filament on it. As shown below

Bourdon Pipe x 3

250g PLA Filament x 3

Extruder x 3

Filament Support x 3

Printer Head Control Board

x 1

12V Power Adapter x 1

Usb 2.0 Cable x 1

(A-Male to B-Male)

Extruder Motor Power

Cable x 3

8-Core Cable x 2

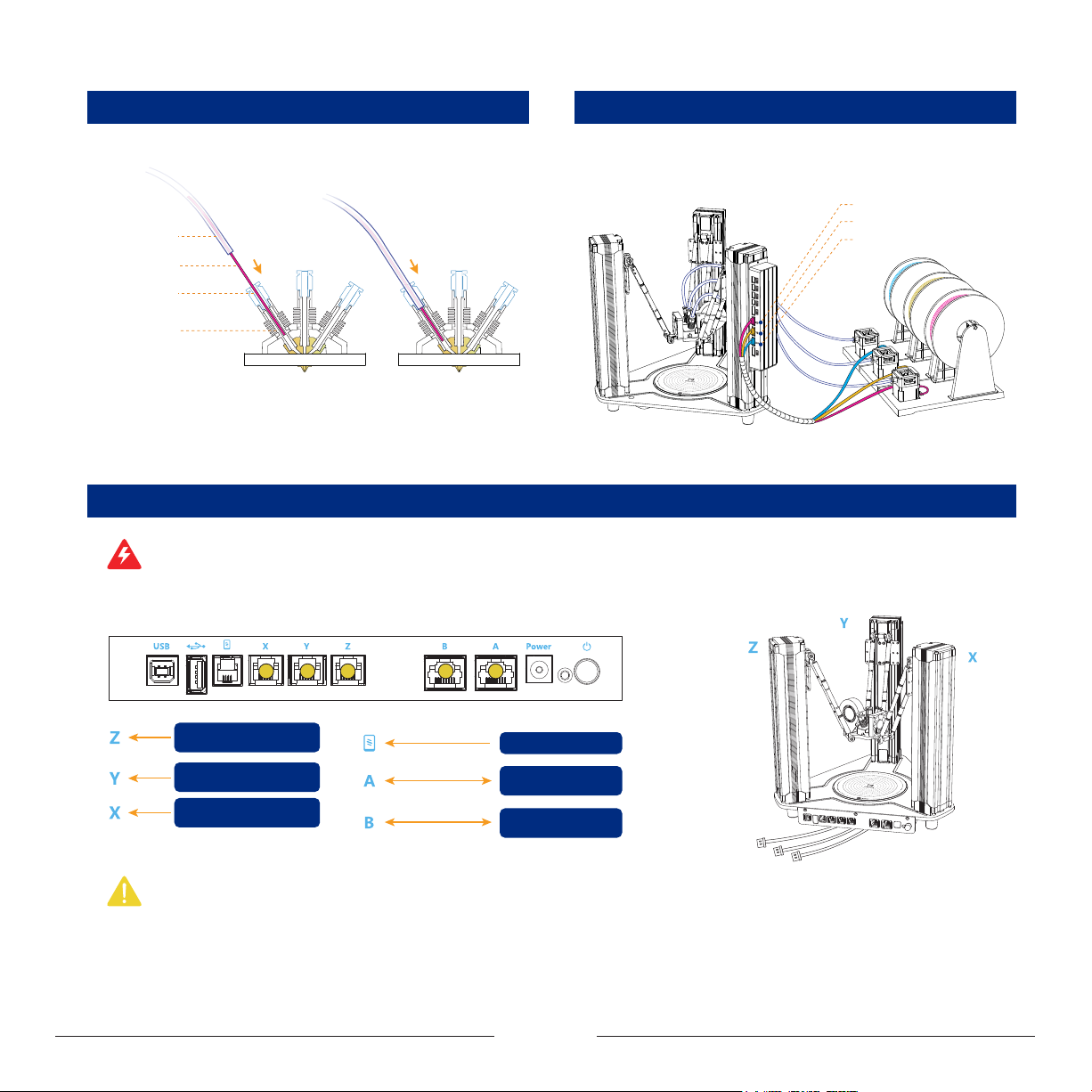

1.1.2 Connect the Bourdon Pipe and Extruder

Run the filament through the extruder and insert one end of the bourdon pipe into pipe connector. Keep

feeding the filament until it extends out of the other end of the pipe for about 20~30mm.Place the

extruder on the filament support orderly after proper connecting.

Bourdon pipe

bourdon

Note:

In case the bourdon pipe and pipe connector need to be detached: Press down the plastic part of the connector and pull the

pipe out quickly (see the illustration above).

1

1.1.3 Connect the Bourdon Pipe to the Print Head

1.1.4 Install Extruder Motor Power Cables

Straighten out the filament, insert it into the print head. In the meanwhile,

feed the bourdon pipe into the pipe connector to clamp it.

Bourdon pipe

Filament

Quick pipe

connector

PTFE pipe

Connect the extruders to the corresponding ports of the printer head control

board with cables. As shown below:

Extruder port (For RED filament)

Extruder port (For YELLOW filament)

Extruder port (For BLUE filament)

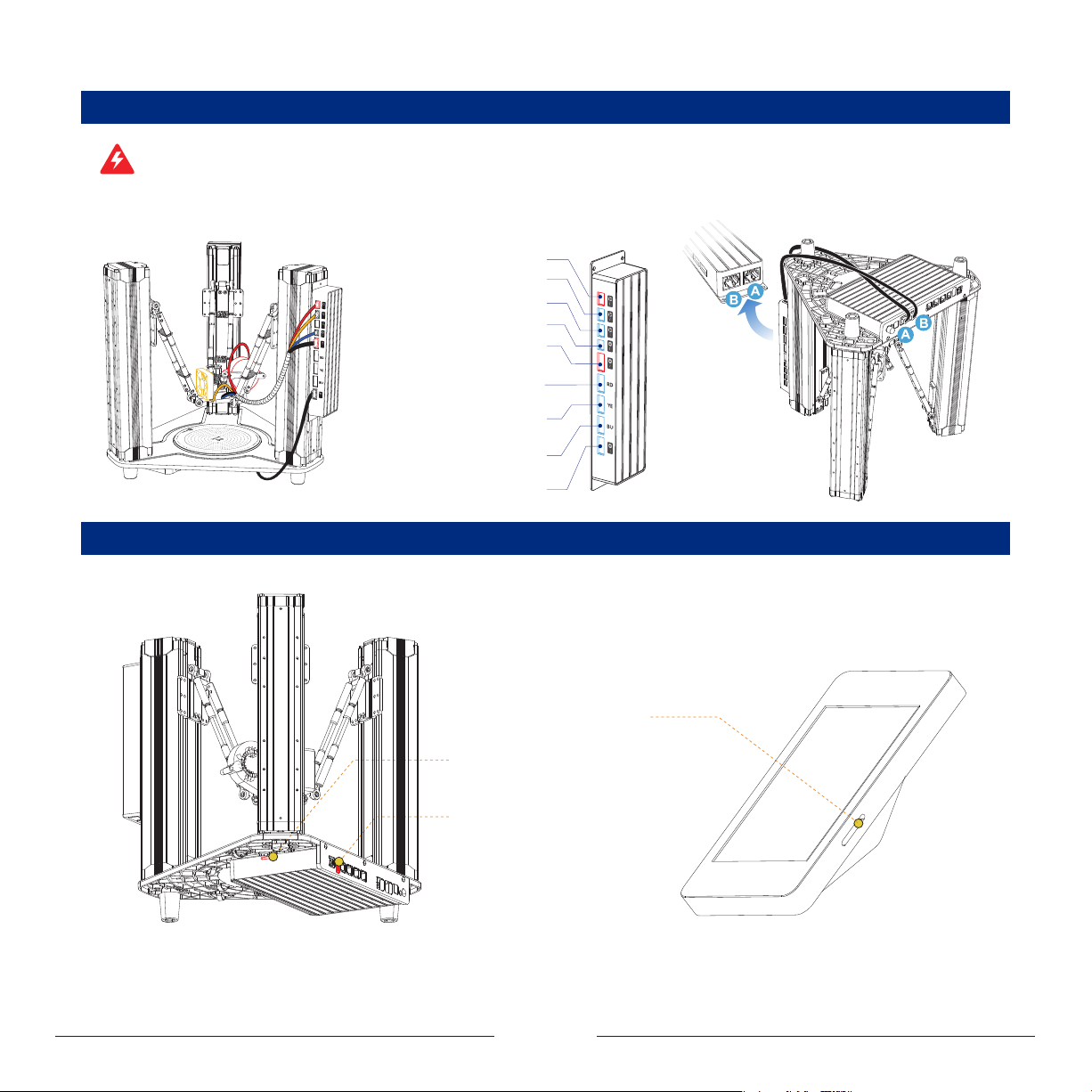

1.1.5 Connect Cables to Main Control Board

Warning: Wrong connection of cables may cause burnout of control board! Hot-plug is strictly prohibited! Always make sure that all cables are plugged in place before power-on!

Plugging of cables during power-on status will cause malfunction!

Before power on the machine, please follow the chart below and connect all cables to the main control board correctly.

Linear actuator on left side

of main control board

Linear actuator on oppsite

side of main control board

Linear actuator on right side

of main control board

Note: The linear actuators are labeled with X, Y, Z based on mounting positions in the above drawing, which should be connected to the corresponding port on main control

board correctly!

8-core cable

8-core cable

LCD touch pad

Port A on printer

head control board

Port B on printer

head control board

2

1.1.6 Connect Cables to Printer Head Control Board

Warning: Wrong connection of cables may cause burnout of control board! Hot-plug is strictly prohibited! Always make sure that all cables are plugged in place before power-on!

Plugging of cables during power-on status will cause malfunction!

Before power on the machine, please follow the chart below and connect all cables to the printer head control board correctly.

Blower fan (Red terminal) port

Filament barrel cooling fan port

Reserved fan port

Temperature sensor (White cable) port

Heating rod (Red terminal) port

Extruder port

(For RED filament)

Extruder port

(For YELLOW filament)

Extruder port

(For BLUE filament)

Heated bed port

1.1.7 External Interface Description

Touch pad SD interface: It is used

for updating the firmware of touch pad.

Main board SD interface: It is used

for updating the firmware of main

board and printing in offline mode.

U disk interface: It is used for

updating the firmware of main

board and printing in offline mode.

3

II Operation Panel

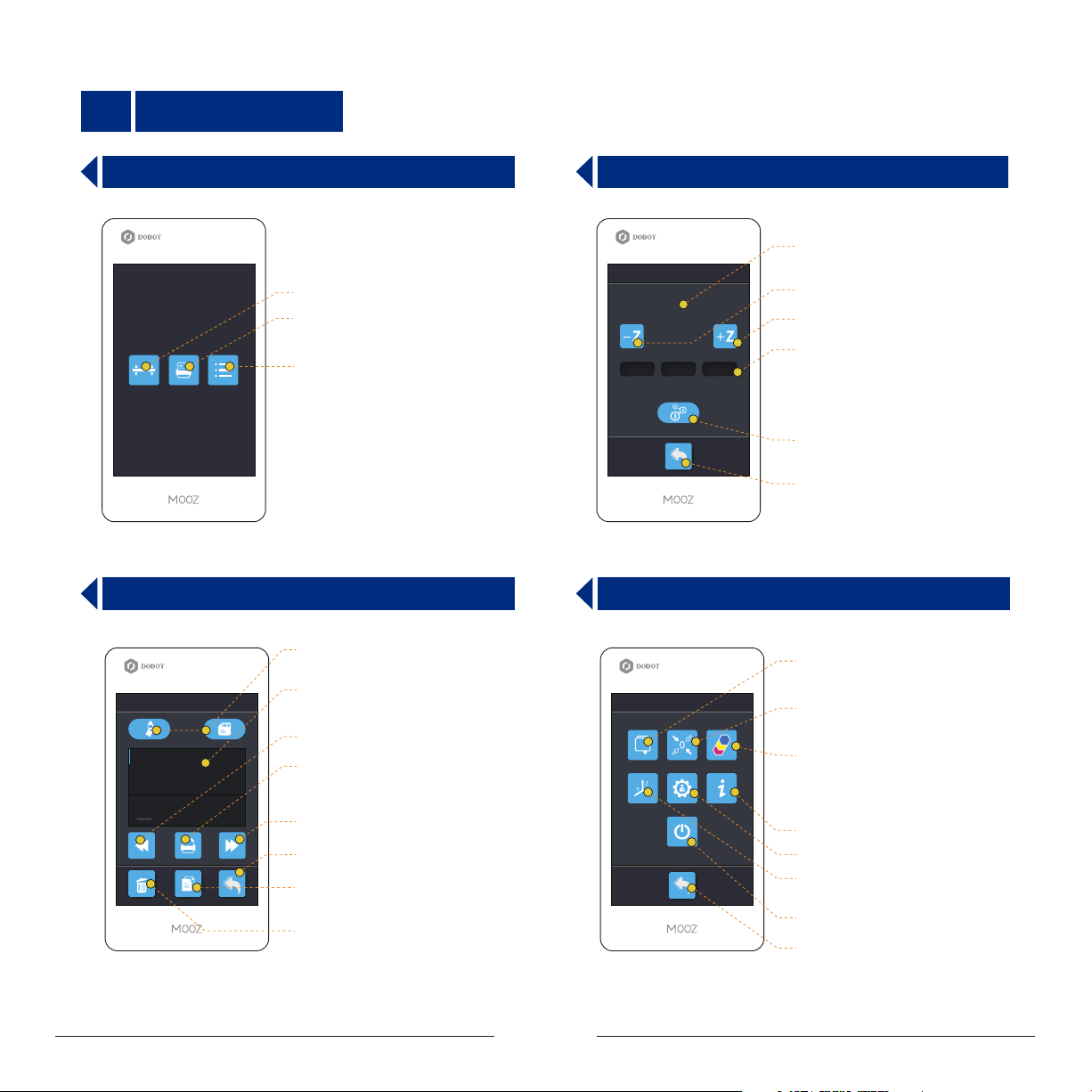

2.1 Home Page

Entrance to 3-point leveling interface

Entrance to le directory interface

Entrance to control tools interface

2.3 File Directory Interface

MicroSD card and U disk switching

buttons

Files

Model.gcode

........ .gcode

.........

.........

.........

Display supported Gcode les

in the current disk (microSD / U disk)

Page backward

File execution button: After selecting

the file, press the button to start printing

Page forward

Return

File copy: Copy the selected file to

the other disk

File delete: Delete the selected file

2.2 3-Point Leveling Interface

Display current coordinates

Leveling

Adjust nozzle downward

Z: 20

Y: 20X: 20

Adjust nozzle upward

Step distance switching buttons:

1 mm0.06 mm 10 mm

It should be used along with “-Z” and

“+Z” buttons, indicating the moving

distance of Z axis when the button

is pressed (0.06mm/1mm/10mm)

3-point leveling mode initiate/Point

recording button

Return

2.4 Control Tools Interface

Entrance to functional module

control interfaces

Control Tools

Entrance to zero point setting

interface

Entrance to color mixing

configuration interface

Machine information

Entrance to other settings interface

Entrance to X/Y/Z motion control

interface

Auto power-off

Return

4

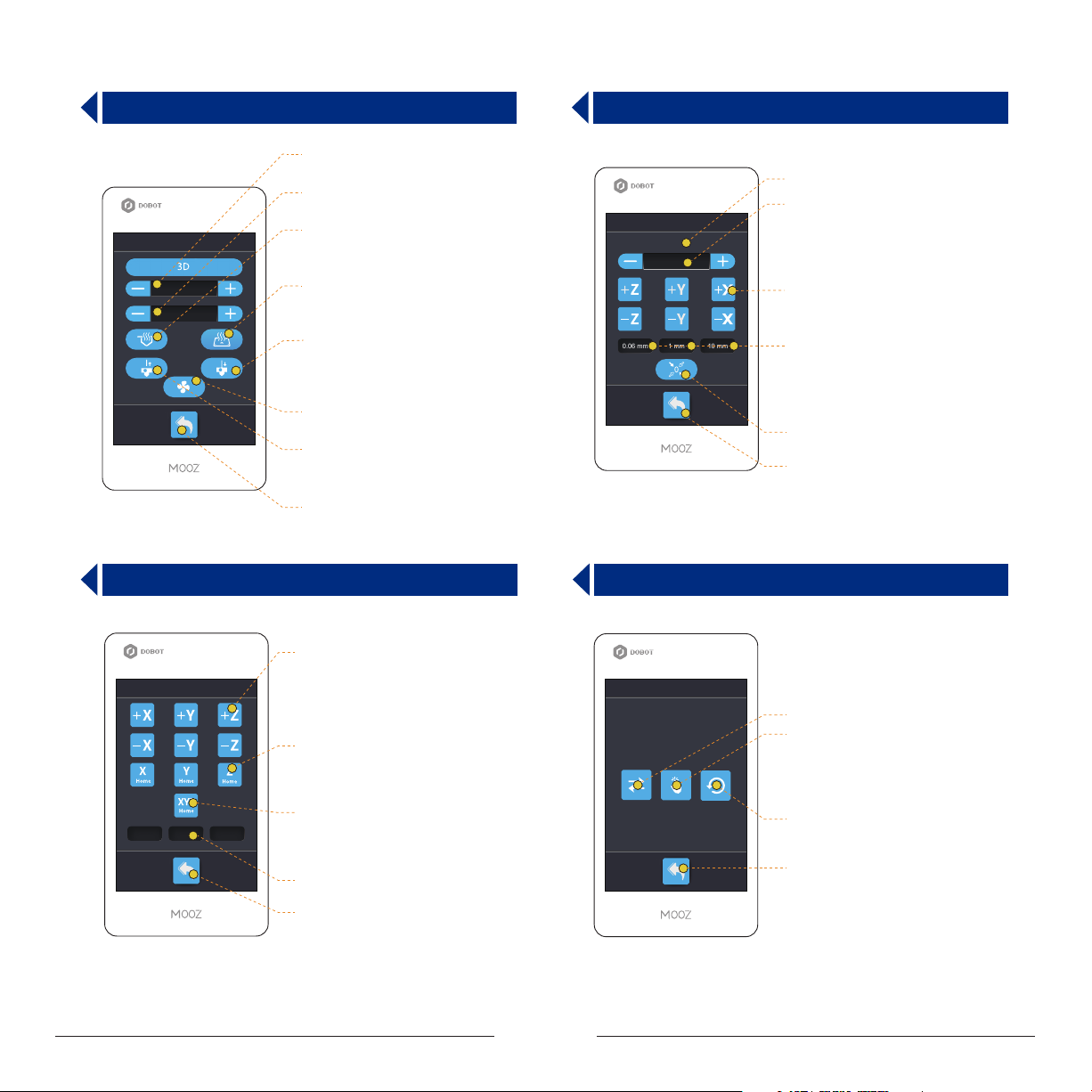

2.5 3D Print Functional Module Control Interface

Set nozzle preheat

target temperature

Set heated bed preheat

target temperature

Function

T:25℃/ 200℃

B:25℃/ 60℃

Preheat nozzle: For testing whether

the nozzle heating is normal, press

again to stop heating

Preheat heated bed: For testing

whether the bed heating is normal,

press again to stop heating

Filament feed button: For installing

filament and testing extrusion

performance, provided that the nozzle

is preheated to about 200ºC

Cooling fan switch: For detecting

whether the cooling fan is normal

Filament retraction button: For

removing filament, provided that the

nozzle is preheated to about 200ºC

Return

2.6 Zero Point Setting Interface

Display current coordinates

Fine tuning value for Z-axis zero point,

Zeroing

X: 20 Y: 20 Z: 20

0 mm

1 mm0.06 mm 10 mm

That is, when the zero point is higher,

it is set to a negative value, and when

the zero point is lower, it is set to a

positive value.

X/Y/Z motion control buttons

Step distance switching buttons:

It should be used along with motion

control buttons, indicating the moving

distance of linear actuators when the

button is pressed (0.06mm/1mm/10mm)

Zero point updating

Return

2.7 X/Y/Z Motion Control Interface

Control motion of X/Y/Z, the

corresponding operations will not

Move

1 mm0.06 mm 10 mm

change any settings

Reset X/Y/Z axis linear actuators

(Not available for MOOZ-3)

Reset all linear actuators, the

corresponding operations will not

change any settings

Step distance switching buttons

Return

2.8 Other Settings Interface

Settings

Switch languages

Calibrate the LCD touch screen

Restore factory settings

Return

5

2.9 Working Process Control Interface

Display execution progress of

current le

X: 20

60℃/60℃

00:00:20

Printing...

Model1.gcode

Y: 20

100%

Z: 20

62%

200/200℃

Display time elapsed

Display current coordinates

Display current/target nozzle

temperature

Display current/target heated

bed temperature

Real-time working speed control

buttons

Auto power-off

Abort the process

Pause/Continue the process

2.11 Gradient Mixing Mode Configuration Interface

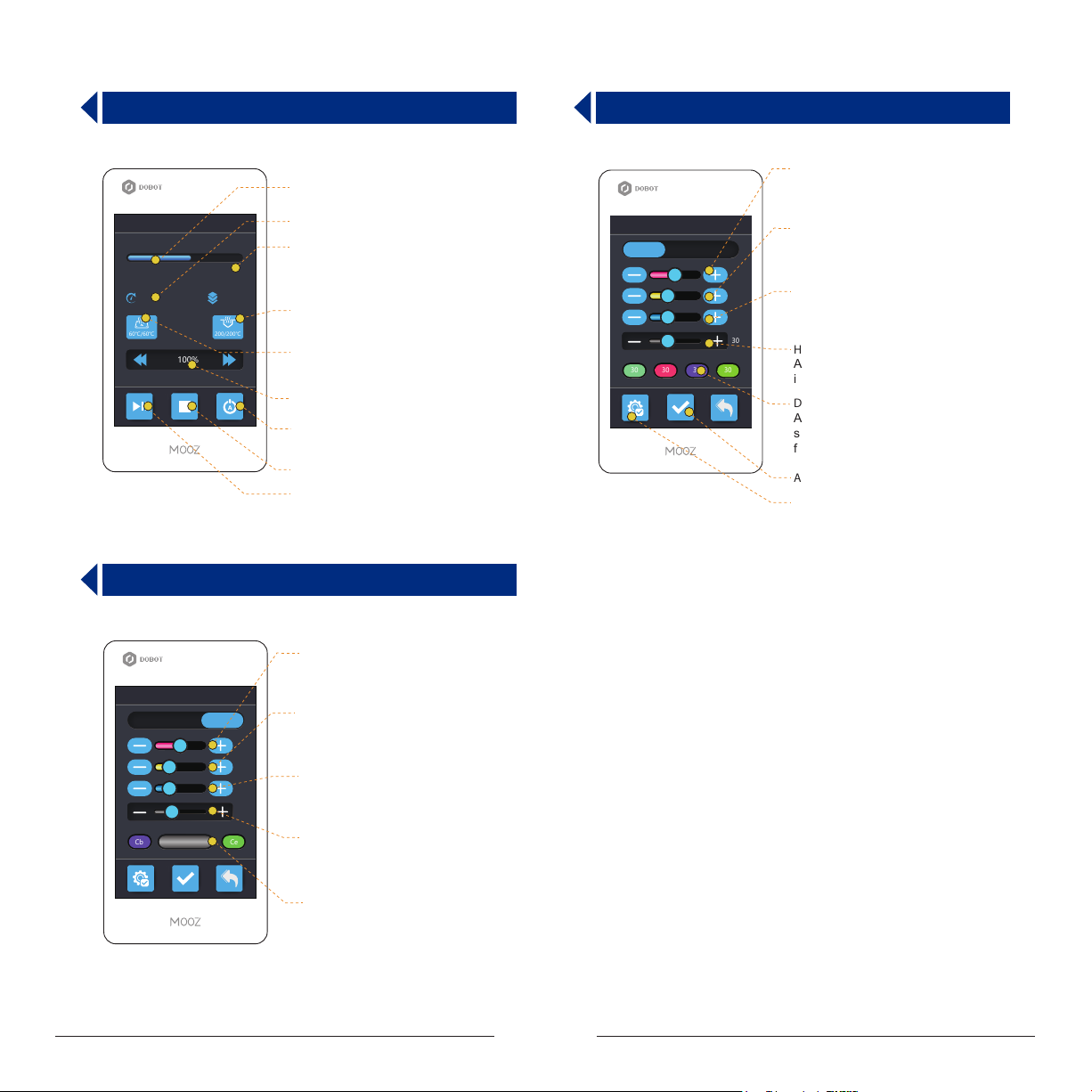

2.10 Switch Mixing Mode Configuration Interface

Red lament percentage:

Adjustment range: 0~100, 0 means

red filament will not be used to mix

Switch

Mixing

Gradient

50

25

25

30

3030 30 30

Yellow lament percentage:

Adjustment range: 0~100, 0 means

yellow filament will not be used to mix

Blue lament percentage:

Adjustment range: 0~100, 0 means

blue filament will not be used to mix

Height adjustment:

Adjustment range: 1~100, default

is 30mm

Display current switching scheme:

A maximum of 4-color switching is

supported, you can set different height

for each color

Applied congured mixing scheme

Default color mixing scheme

Mixing

Switch

Cb Ce

Gradient

30

Red lament percentage:

Adjustment range: 0~100, 0 means

red filament will not be used to mix

Yellow lament percentage:

50

25

25

30

Adjustment range: 0~100, 0 means

yellow filament will not be used to mix

Blue lament percentage:

Adjustment range: 0~100, 0 means

blue filament will not be used to mix

Gradient cycle:

Adjustment range: 1~100, default

is 30mm

Display current mixing scheme:

Cb is cycle begin color, and Ce is

cycle end color

6

Loading...

Loading...