Shenzhen Mindray Bio-medical Electronics Co BC-6800 Service Manual

BC-6800

Auto Hematology Analyzer

Service Manual

II

Copyright

© 2011-2012 Shenzhen Mindray Bio-medical Electronics Co., Ltd. All rights Reserved.

For this Service Manual, the issued Date is 2012-03 (Version: 2.0).

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray)

owns the intellectual property rights to this Mindray product and this manual. This manual may

refer to information protected by copyright or patents and does not convey any license under

the patent rights or copyright of Mindray, or of others.

Mindray intends to maintain the contents of this manual as confidential information. Disclosure

of the information in this manual in any manner whatsoever without the written permission of

Mindray is strictly forbidden.

Release, amendment, reproduction, distribution, rental, adaptation, translation or any other

derivative work of this manual in any manner whatsoever without the written permission of

Mindray is strictly forbidden.

. , are the trademarks, registered or otherwise, of Mindray in

China and other countries. All other trademarks that appear in this manual are used only for

informational or editorial purposes. They are the property of their respective owners.

Responsibility on the Manufacturer Party

Contents of this manual are subject to changes without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not be liable for

errors contained herein nor for incidental or consequential damages in connection with the

furnishing, performance, or use of this manual.

Mindray is responsible for safety, reliability and performance of this product only in the

condition that:

I

all installation operations, expansions, changes, modifications and repairs of this

product are conducted by Mindray authorized personnel;

the electrical installation of the relevant room complies with the applicable national

and local requirements;

the product is used in accordance with the instructions for use.

zThis equipment must be operated by skilled/trained medical professionals.

zIt is important for the hospital or organization that employs this equipment to

carry out a reasonable service/maintenance plan. Neglect of this may result

in machine breakdown or injury of human health.

zBe sure to operate the analyzer under the situation specified in this manual;

otherwise, the analyzer will not work normally and the analysis results will

be unreliable, which would damage the analyzer components and cause

personal injury.

II

Warranty

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

Exemptions

Mindray's obligation or liability under this warranty does not include any transportation or other

charges or liability for direct, indirect or consequential damages or delay resulting from the

improper use or application of the product or the use of parts or accessories not approved by

Mindray or repairs by people other than Mindray authorized personnel.

This warranty shall not extend to:

¾Malfunction or damage caused by improper use or man-made failure.

¾Malfunction or damage caused by unstable or out-of-range power input.

¾Malfunction or damage caused by force majeure such as fire and earthquake.

¾Malfunction or damage caused by improper operation or repair by unqualified or

unauthorized service people.

¾Malfunction of the instrument or part whose serial number is not legible enough.

¾Others not caused by instrument or part itself.

III

Customer Service Department

Manufacturer:

Address:

Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Mindray Building,Keji 12th Road South,High-tech industrial

park,Nanshan,Shenzhen 518057,P.R.China

Website:

E-mail Address:

Tel:

Fax:

www.mindray.com

service@mindray.com

+86 755 81888998

+86 755 26582680

EC-Representative: Shanghai International Holding Corp. GmbH(Europe)

Address:

Fax:

Eiffestraβe 80, 20537 Hamburg, Germany

0049-40-2513175

Tel:

0049-40-255726

IV

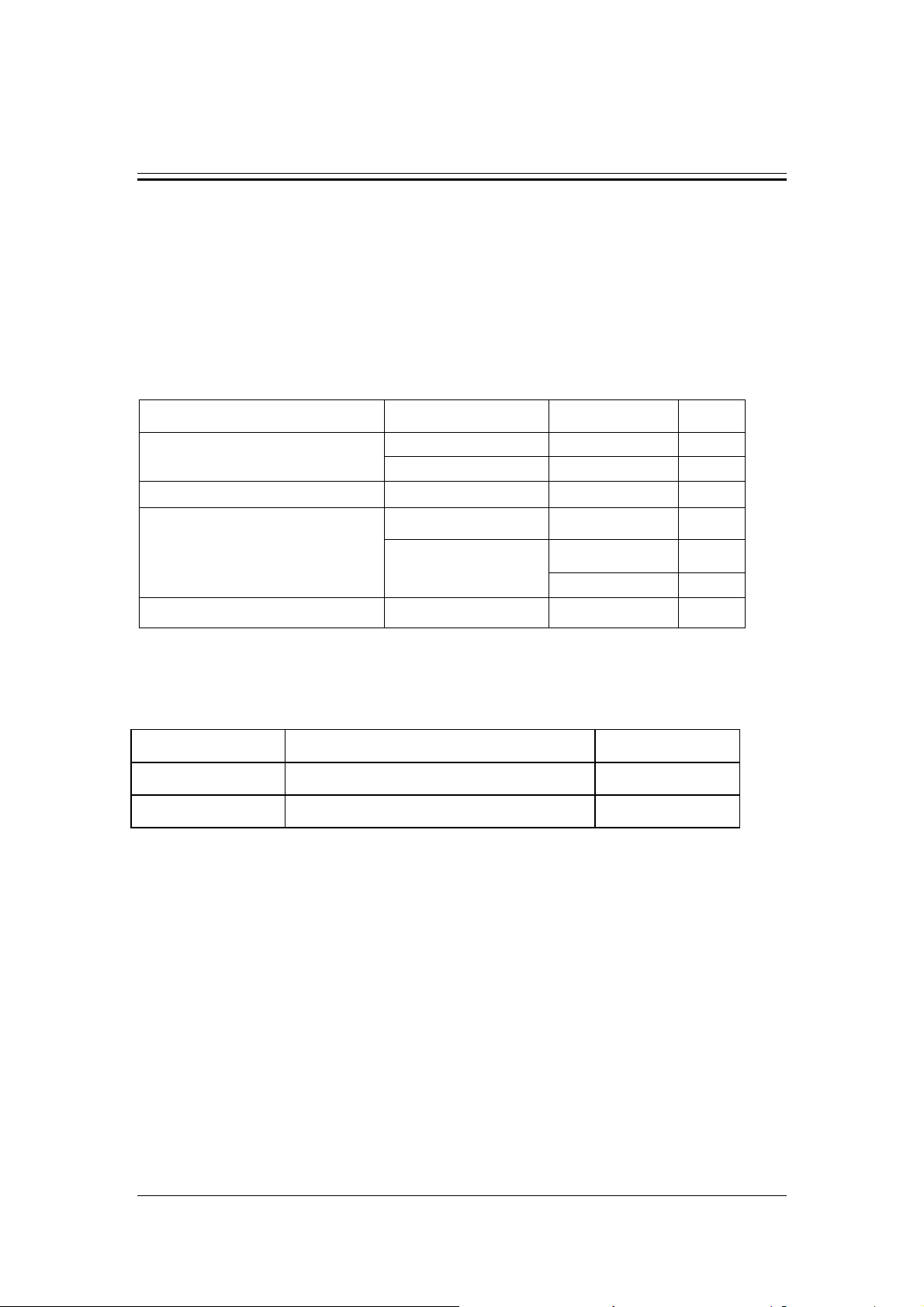

Version Record

Version Updated Contents Related T/N & S/N Updated Date

1.0 First version Released N/A

2.0

1:Update Error Code;

2:Added Preventive Maintenance

Chapter;

3:Updated FRU List;

4:Updated PC software name to DMU;

5:DMU IP connection screen changed

6:RUO parameters updated from12 items

to 14 items;

7 : Add ASTM protocol option in DMU

setup;

8:Correct some unclear pictures in

hardware;

9:Update partly materials name and part

number(like WC2 Waste Bath),Deleted

some wrong items;

10:Add part numbers of some cables in

FRU List;

TXQ-12009-BC-6800

TXQ-12013-BC-6800

TXQ-12022-BC-6800

SXQ-12001-BC-6800

TXQ-12027-BC-6800

2012.9

11:Vacuum Relieve Valve(Regulator)

updated the life time from 3-years to

4-years;

12:Add’801-3100-00208-00/Pneumatic

connecter kit into FRU List’;

130:Add‘801-3110-00114-00/reagents

connecter kit (6 colors) (FRU)’;

14:Correct DMU light status;

15: Add Scanner Rotation Function in

auxiliary Setup and update Rotation

scanner Debug screen in SPU;

16:Add floater setup option;

17:Add USB protection Open/close

function;

V

Table of Contents

Copyright................................................................................................................................... I

Version Record ........................................................................................................................ V

Table of Contents..................................................................................................................... 1

1 Using This Manual.............................................................................................................1-1

1.1 Scope ....................................................................................................................... 1-1

1.2 Introduction............................................................................................................... 1-1

1.3 General Operations.................................................................................................. 1-1

1.4 Symbol ..................................................................................................................... 1-2

2 Product Specification........................................................................................................ 2-1

2.1 Equipment Name ..................................................................................................... 2-1

2.2 Power Supply Requirement ..................................................................................... 2-1

2.3 Dimension and Weight ............................................................................................. 2-1

2.4 Measurement Mode ................................................................................................. 2-1

2.5 Sample Types........................................................................................................... 2-1

2.6 Minimum Sample Volume ........................................................................................ 2-2

2.7 Throughput............................................................................................................... 2-2

2.8 Capacity of the Autoloader....................................................................................... 2-2

2.9 Performance Specifications...................................................................................... 2-3

2.10 Conditions of Use ................................................................................................... 2-13

2.11 Sound ..................................................................................................................... 2-14

2.12 Functions of the Analyzer....................................................................................... 2-14

3 Software System................................................................................................................ 3-1

3.1 Overview .................................................................................................................. 3-1

3.2 Introduction of Startup and Shutdown...................................................................... 3-1

3.3 Menu Structure......................................................................................................... 3-1

3.4 Password.................................................................................................................. 3-6

3.5 Analyzer Software Update ..................................................................................... 3-20

3.6 DMU Software Installation...................................................................................... 3-26

3.7 DMU Software Update ........................................................................................... 3-33

1

Table of Contents

3.8 Backup and Restoration......................................................................................... 3-37

3.9 Connection device between the DMU and analyzer.............................................. 3-40

3.10 LIS Communication Setup ..................................................................................... 3-45

3.11 Uni-directional LIS Communication........................................................................ 3-48

3.12 Bi-Directional LIS Communication ......................................................................... 3-54

4 Operation Principles ......................................................................................................... 4-1

4.1 Measurement of the Optical Channel ...................................................................... 4-1

4.2 HGB Measurement .................................................................................................. 4-4

4.3 RBC/PLT Measurement ........................................................................................... 4-4

5 Fluidics ............................................................................................................................... 5-1

5.1 Parameter Measurement ......................................................................................... 5-2

5.2 Reagent System....................................................................................................... 5-3

5.3 Measurement Flow................................................................................................... 5-5

5.4 Sample Volume........................................................................................................ 5-6

5.5 Time of Preparation and Measurement.................................................................... 5-6

5.6 Temperature of Fluidics ............................................................................................ 5-6

5.7 Reagent Consumption Volume ................................................................................ 5-7

5.8 Sample Dilution Flow ............................................................................................... 5-8

5.9 Introduction to Fluidic Parts...................................................................................... 5-9

5.10 Pneumatic System ................................................................................................. 5-20

5.11 Detailed Introduction to Fluidic Channels .............................................................. 5-26

5.12 Introduction to Sequences ..................................................................................... 5-34

6 Optical System................................................................................................................... 6-1

6.1 Introduction of Optical Theories ............................................................................... 6-1

6.2 Optical System Structure.......................................................................................... 6-3

6.3 Troubleshooting of the Optical System .................................................................... 6-4

7 Hardware System...............................................................................................................7-1

7.1 Overview .................................................................................................................. 7-1

7.2 Data and COME Carrier Board ................................................................................ 7-1

7.3 Drive Control Board................................................................................................ 7-16

7.4 Motherboard........................................................................................................... 7-26

7.5 Network Board ....................................................................................................... 7-30

7.6 Power Board........................................................................................................... 7-32

2

Table of Contents

7.7 Power Patching Board ........................................................................................... 7-36

7.8 Laser Drive Board .................................................................................................. 7-38

7.9 Scatter Pre-amplification Boards ........................................................................... 7-43

7.10 Fluorescence Pre-amplification Board ................................................................... 7-49

7.11 Pneumatic Pressure Detection Board.................................................................... 7-54

7.12 Heating Control Board............................................................................................ 7-56

7.13 Diluent Heating Board ............................................................................................ 7-60

7.14 Valve Drive Board................................................................................................... 7-64

7.15 Indicator Board ....................................................................................................... 7-74

7.16 Touchscreen Control Board.................................................................................... 7-75

7.17 Prefix List of Board Interfaces ................................................................................ 7-76

7.18 Motors, Photocouplers and Micro-switches ........................................................... 7-77

8 Mechanical System ........................................................................................................... 8-1

8.1 Analyzer Structure.................................................................................................... 8-1

8.2 Appearance.............................................................................................................. 8-1

8.3 Layout Introduction................................................................................................... 8-3

9 Replacing the FRU.............................................................................................................9-1

9.1 Overview .................................................................................................................. 9-1

9.2 Removal and Installation of the Board ..................................................................... 9-1

9.3 Sheath Fluid Impedance Bath................................................................................ 9-11

9.4 Aperture.................................................................................................................. 9-12

9.5 HGB Bath Assembly............................................................................................... 9-16

9.6 RBC Bath Assembly............................................................................................... 9-17

9.7 SRV Assembly........................................................................................................ 9-17

9.8 Sample Probe ........................................................................................................ 9-23

9.9 Pneumatic Unit....................................................................................................... 9-24

9.10 Barcode Scanner Assembly................................................................................... 9-26

9.11 Radiator Fan........................................................................................................... 9-27

9.12 Power Supply Assembly......................................................................................... 9-28

9.13 Diaphragm pump.................................................................................................... 9-30

9.14 WBC Mixing Assembly........................................................................................... 9-33

9.15 WBC Bath Assembly .............................................................................................. 9-35

9.16 Reagent Pre-Heating Bath Assembly .................................................................... 9-36

9.17 Sheath Fluid Pre-heating Bath Assembly .............................................................. 9-38

3

Table of Contents

9.18 Diluent Heating Bath Assembly.............................................................................. 9-39

9.19 Sheath Fluid Filter .................................................................................................. 9-40

9.20 Waste Filter ............................................................................................................ 9-40

9.21 START Switch Assembly........................................................................................ 9-41

9.22 Pressure Regulator ................................................................................................ 9-42

9.23 Vacuum Overflow Valve ......................................................................................... 9-43

9.24 Screen Assembly ................................................................................................... 9-45

9.25 Tube Clamp for Mixing ........................................................................................... 9-46

9.26 Autoloading Assembly............................................................................................ 9-47

9.27 Piercing Unit ........................................................................................................... 9-48

9.28 Autoloader .............................................................................................................. 9-50

9.29 Tube Sensor Assembly .......................................................................................... 9-52

9.30 Cistern and Waste Bath ......................................................................................... 9-53

9.31 Syringe Assembly................................................................................................... 9-56

9.32 Filter and Drying Assembly .................................................................................... 9-60

9.33 Replacing the Backwater Bath Assembly .............................................................. 9-61

9.34 USB Assembly ....................................................................................................... 9-62

9.35 Mindray Valve......................................................................................................... 9-63

9.36 Burkert Valve.......................................................................................................... 9-66

9.37 Waste Valve............................................................................................................ 9-67

9.38 Gas Valve............................................................................................................... 9-68

9.39 SMC 2-way Fluidic Valves...................................................................................... 9-69

9.40 Probe Wipe of the Open-Vial Module .................................................................... 9-70

9.41 Optical System ....................................................................................................... 9-71

9.42 Units in the Autoloader........................................................................................... 9-79

9.43 Power Board and Power Conversion Board .......................................................... 9-85

9.44 Pressure Detection Board ...................................................................................... 9-87

9.45 Indicator Board ....................................................................................................... 9-88

9.46 Valve Control Board ............................................................................................... 9-89

9.47 Heating Control Board............................................................................................ 9-91

9.48 Data Board and Power Drive Board....................................................................... 9-92

9.49 Mother Board ......................................................................................................... 9-93

9.50 Liquid Level Detection Board ................................................................................. 9-95

9.51 Network Port Patching Board................................................................................. 9-96

4

Table of Contents

9.52 Diluent Heating Control Board ............................................................................... 9-97

9.53 Touchscreen Control Board.................................................................................... 9-98

9.54 Pneumatic Unit Control Board................................................................................ 9-99

9.55 Boards inside the Optical System ........................................................................ 9-100

9.56 Cap Assembly ...................................................................................................... 9-101

9.57 Transformer.......................................................................................................... 9-102

9.58 Replacing the Wires ............................................................................................. 9-103

9.59 Replacing the Connectors.................................................................................... 9-104

9.60 Components inside the Assemblies ..................................................................... 9-106

9.61 Replacing the Photocoupler (PHC/Sensor) ..........................................................9-111

10 Error Code ...................................................................................................................... 10-1

10.1 Overview ................................................................................................................ 10-1

10.2 Message Area Error ............................................................................................... 10-3

10.3 Error Area Error ...................................................................................................... 10-6

11 Preventive Maintenance................................................................................................ 11-1

11.1 Tools and Consumables......................................................................................... 11-1

11.2 Service Plan ........................................................................................................... 11-2

11.3 Status Check ........................................................................................................ 11-23

11.4 Regular Replacement .......................................................................................... 11-26

12 FRU LIST......................................................................................................................... 12-1

12.1 Board list ................................................................................................................ 12-1

12.2 Valve list ................................................................................................................. 12-2

12.3 Tube and Connector list ......................................................................................... 12-2

12.4 Part list ................................................................................................................... 12-4

12.5 Cable list................................................................................................................. 12-9

12.6 Wearing parts list.................................................................................................. 12-10

A.1 Rubber Tubing Information ................................................................................... 12-13

A2. Connector Information .......................................................................................... 12-14

A3. Connecting Tubing Information ............................................................................. 12-16

A4. Other Material Information .................................................................................... 12-16

A5. Valve Information .................................................................................................. 12-17

A6. Table of All Tubes.................................................................................................. 12-21

5

Table of Contents

6

1 Using This Manual

zBe sure to operate and service the analyzer strictly as instructed in this manual

and the operator's manuals.

1.1 Scope

To use this manual effectively, you need the following capabilities:

Comprehensive knowledge of circuit and fluidics;

Comprehensive knowledge of reagents;

Comprehensive knowledge of controls;

Comprehensive knowledge of troubleshooting;

Mastering the way to operate this analyzer;

Using basic mechanical tools and understand related terminology;

Using a digital voltmeter (DVM) and an oscilloscope;

Reading pneumatic/hydraulic schematics and understand related terminology.

1.2 Introduction

This manual comprises 13 chapters and the fluidic diagrams in appendices.

1.3 General Operations

Name Operation

Click

Enter

press the desired item lightly with your finger; or to left-CLICK it

with the mouse.

to CLICK the desired edit box and use the external keyboard or

the pop-up keyboard to enter the desired characters or digits; or

to scan the number by using the bar-code scanner.

Delete

to move the cursor to the character or digit that you want to

delete by clicking the left button of the mouse or using

[←][→][Home][End], and then delete the character after the

cursor by pressing [Del], or delete the character before the cursor

by pressing [BackSpace] ([←] on the upper right part of the soft

keyboard).

1-1

Click the arrow buttons by the ends of the scroll bar, or move the

Drag Scroll Bar

SELECT from ××

pull-down list

(for pull-down list)

cursor to the slide bar and press the left key of the mouse; or

press the slide bar with your finger.

to CLICK the down arrow button of the desired box to display the

pull-down list, (and DRAG SCROLL BAR) to browse and then

CLICK the desired item; or to press the keys

([↑][↓][PageUp][PageDown]) to browse the current list and press

[ENTER] to select the desired item.

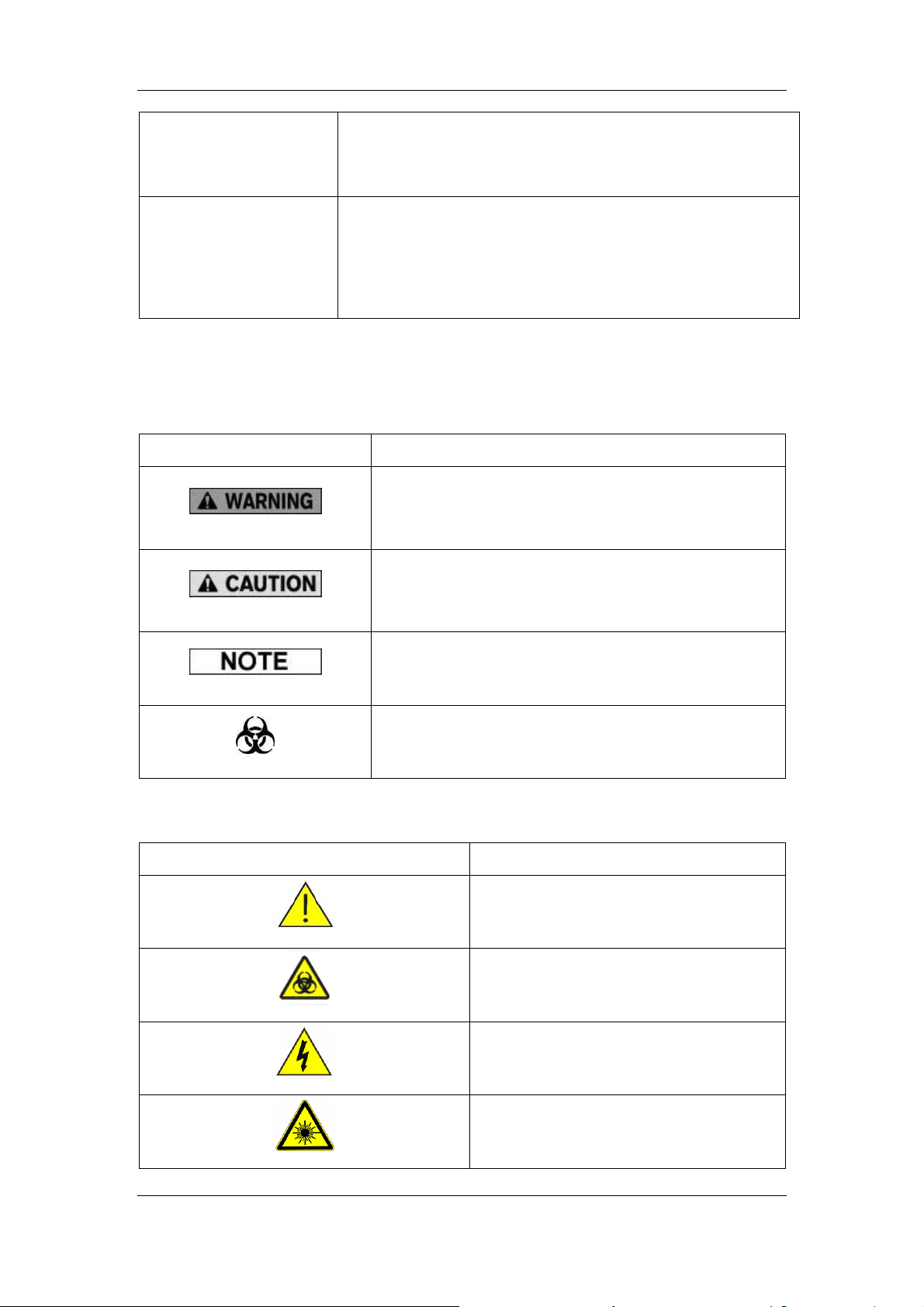

1.4 Symbol

You will find the following symbols in this manual.

Symbol It means...

read the statement below the symbol. The statement is

alerting you to an operating hazard that can cause

personnel injury.

read the statement below the symbol. The statement is

You may find the following symbols on the analyzer, reagents, controls or calibrators.

Symbol It means...

alerting you to a possibility of analyzer damage or

unreliable analysis results.

read the statement below the symbol. The statement is

alerting you to information that requires your attention.

read the statement below the symbol . The statement is

alerting you to a potentially biohazardous condition.

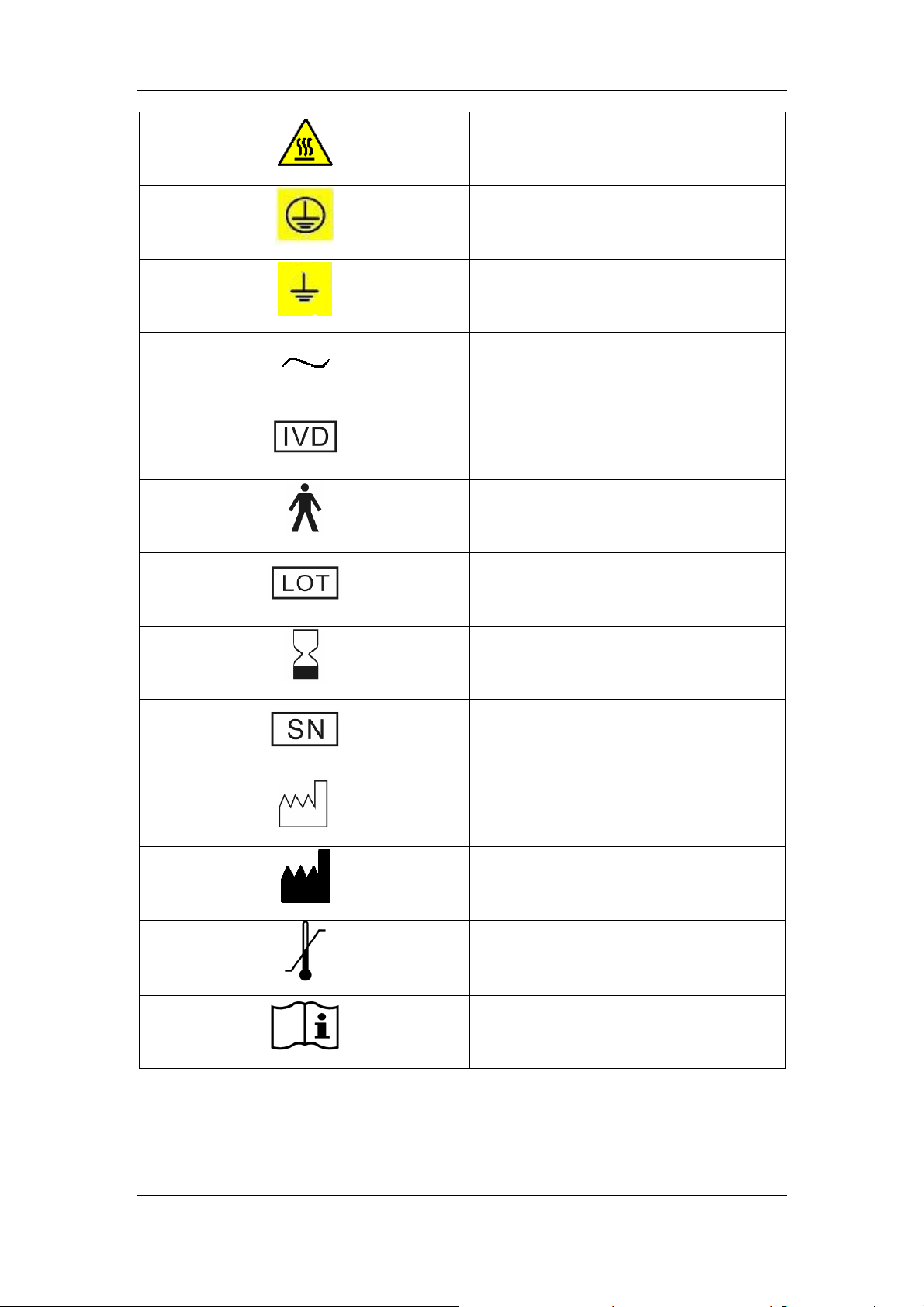

CAUTION, CONSULT ACCOMPANYING

DOCUMENTS.

BIOLOGICAL RISK

HIGH VOLTAGE

WARNING, LASER BEAM

1-2

WARNING, HOT SURFACE

PROTECTIVE EARTH (GROUND)

EARTH (GROUND)

ALTERNATING CURRENT

FOR IN VITRO DIAGNOSTIC USE

TYPE B DEVICE

BATCH CODE

USE BY

SERIAL NUMBER

DATE OF MANUFACTURE

Manufacturer

TEMPERATURE LIMITATION

CONSULT INSTRUCTIONS FOR USE

Be sure to observe the following precautions when you are servicing the analyzer for the safety

of patients and operators.

1-3

zIt is important for the hospital or organization that employs this equipment to

carry out a reasonable installation plan. Neglect of this may result in

machine breakdown or injury of human health.

zNever use combustible gas (e.g. anesthetic) or combustible liquid (e.g. ethanol)

around the analyzer. Otherwise, the risk of explosion may exist.

zContacting exposed electronic components while the equipment is attached to

power can cause personal injury from electric shock or damage to electronic

components. Power down before removing covers to access electronic

components.

zConnect the analyzer to a socket having sole fuse and protective switch. Do

not use the same fuse and protective switch with other equipment (e.g. life

supporting equipment). Otherwise, the equipment failure, over current or

impulse current that occurs at the startup moment may lead to tripping.

zTo prevent personal injury during the maintenance, keep your clothes, hairs

and hands from the moving parts, such as sample probe, pincher and

piercer.

zPossible mechanical movement of the warned position may lead to personal

injury during normal operation, removal and maintenance.

zBe sure to dispose of reagents, waste, samples, consumables, etc. according

to government regulations.

zThe reagents are irritating to eyes, skin and diaphragm. Wear proper personal

protective equipment (e.g. gloves, lab coat, etc.) and follow safe laboratory

procedures when handling them in the laboratory.

zIf the reagents accidentally spill on your skin, wash them off with plenty of

water and if necessary, go see a doctor; if the reagents accidentally spill into

your eyes, wash them off with plenty of water and immediately go see a

doctor.

zImproper servicing may damage the analyzer. Improper maintenance may

damage the analyzer. Maintain the analyzer strictly as instructed by the

service manual and inspect the analyzer carefully after the maintenance.

zFor problems not mentioned in the service manual, contact Mindray customer

service department for maintenance advice.

zTo prevent personal injury or damage to equipment components, remove metal

1-4

jewelry before maintaining or servicing electronic components of the

equipment.

zElectrostatic discharge may damage electronic components. Electrostatic

discharge may damage electronic components. If there is a possibility of

ESD damage with a procedure, then do that procedure at an ESD

workstation, or wear an antistatic wrist strap.

zThis equipment must be operated by skilled/trained medical professionals.

zSamples, controls, calibrators and waste are potentially infectious. Wear

proper personal protective equipment (e.g. gloves, lab coat, etc.) and follow

safe laboratory procedures when handling them in the laboratory.

zAll the analyzer components and surfaces are potentially infectious, so take

proper protective measures for operation and maintenance.

zThe sample probe tip is sharp and may contain biohazardous materials.

Exercise caution to avoid contact with the probe when working around it.

1-5

2 Product Specification

2.1 Equipment Name

Auto Hematology Analyzer

Model: BC-6800/BC-6600

2.2 Power Supply Requirement

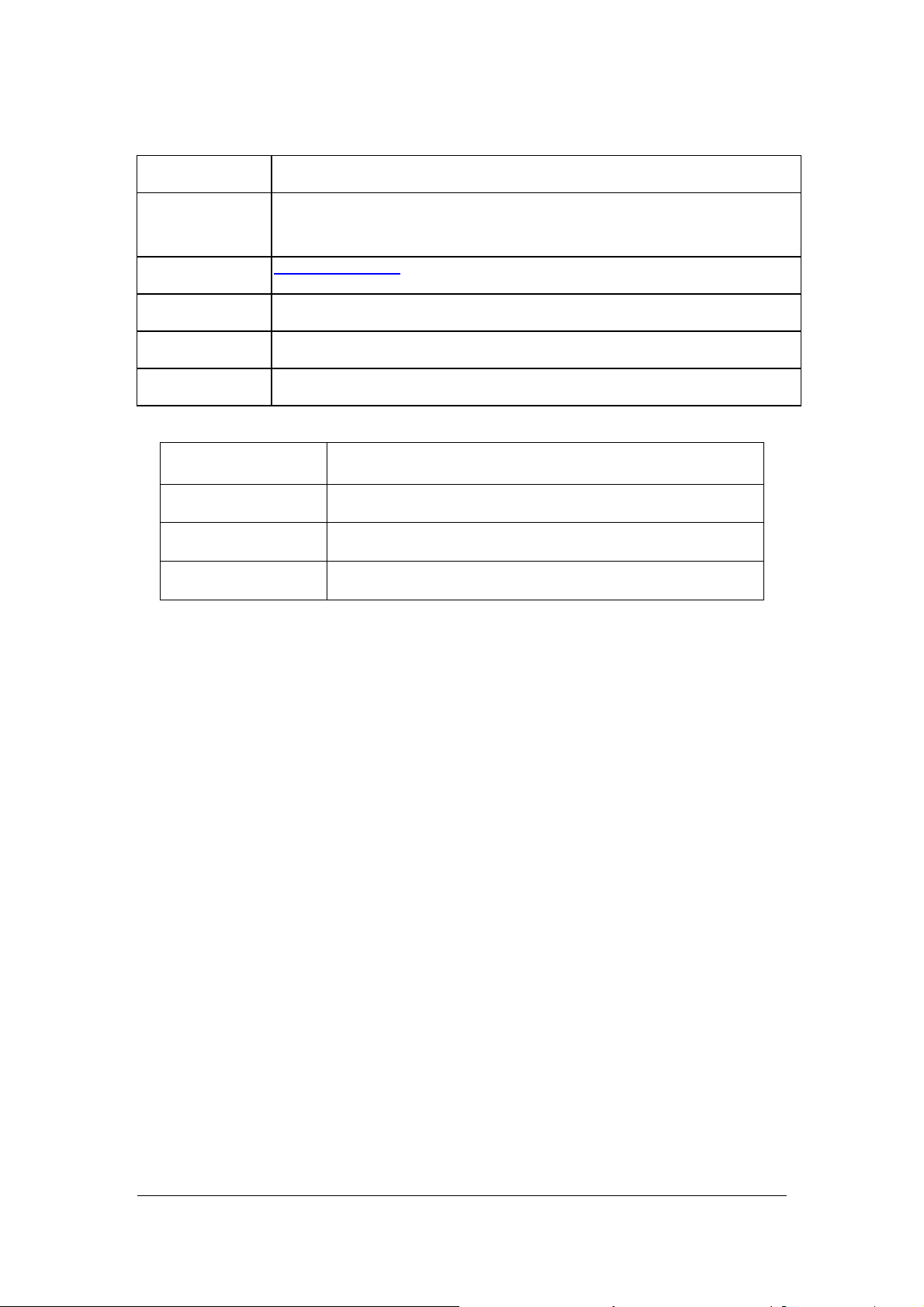

Table 2-1 Power Supply Requirement

Analyzer (outside China)

Analyzer (China)

Pneumatic unit (outside China)

Pneumatic unit (China)

Voltage Frequency Power

a.c. 110V/115V ±10% 50/60Hz ±2Hz 500VA

a.c. 220V/230V±10% 50/60Hz ±2Hz 500VA

(220V/230V)±10%~

a.c. 110V/115V±10% 60Hz ±2Hz 600VA

a.c. 220V/230V±10%

(220V)±10%~

2.3 Dimension and Weight

Table2-2 Analyzer Dimension and Weight

Analyzer

Pneumatic unit

Dimension (width x depth x height mm) Weight(Kg)

680×850×700 ≤125

310×480×430 ≤20

50Hz/60Hz±2Hz 500VA

50Hz ±2Hz 450VA

60Hz ±2Hz 300 VA

50Hz ±1Hz 400VA

2.4 Measurement Mode

There are 8 measurement modes altogether:

CBC, CBC+DIFF, CBC+DIFF+RET, CBC+RET, RET, CBC+DIFF+NRBC,

CBC+DIFF+RET+NRBC and CBC+NRBC.

2.5 Sample Types

The supported sample types are:

1) anticoagulated venous blood (use EDTAK2 or EDTAK3 as the anticoagulant, for whole

blood analysis)

2) capillary blood (for predilute analysis)

2-1

2.6 Minimum Sample Volume

To ensure the effective analysis of samples, the minimum sample volumes are specified as

follows:

1) Autoloading mode: ≥1ml

2) Open vial mode: ≥0.5ml (excluding predilute mode)

2.7 Throughput

1) Autoloading mode

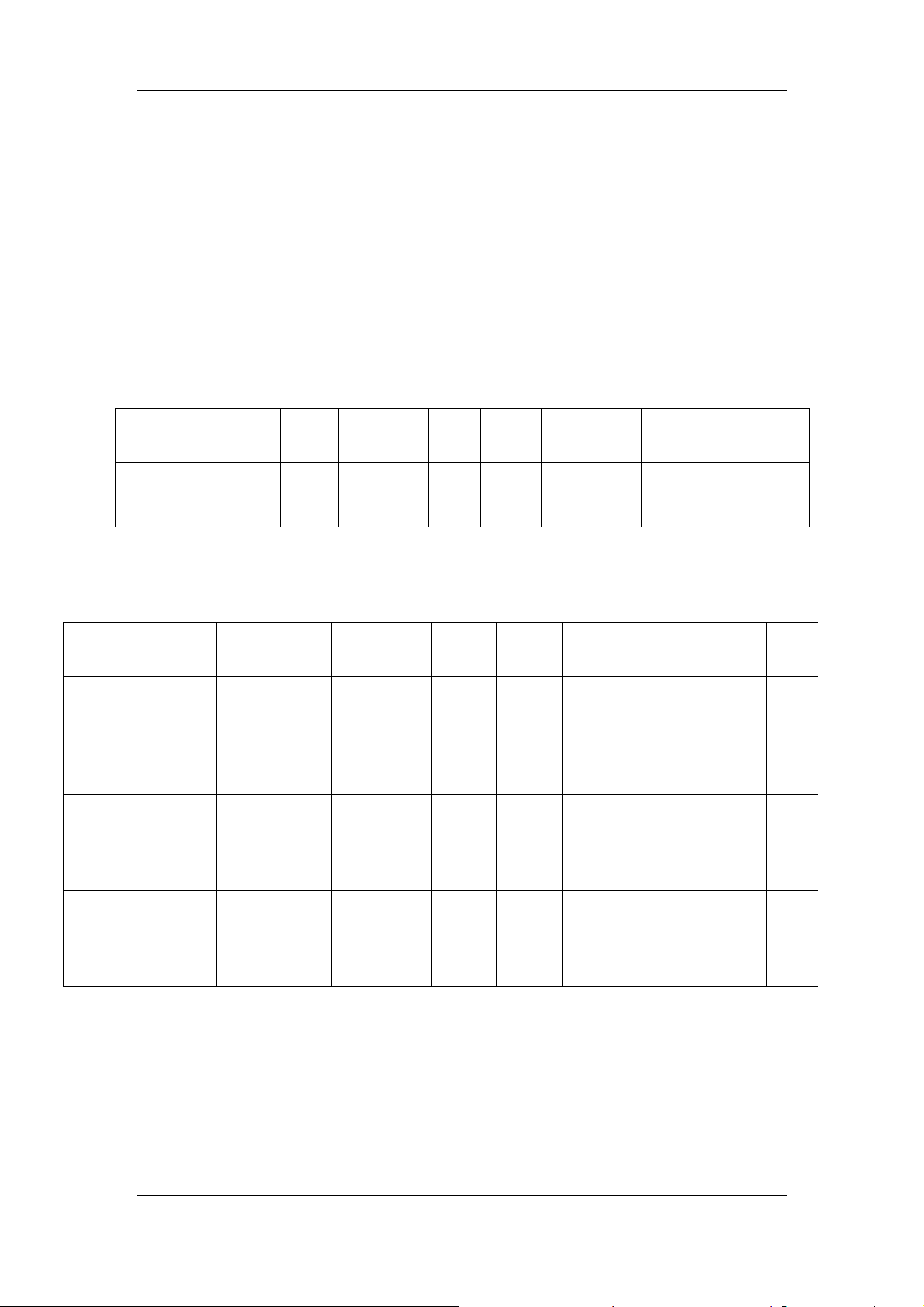

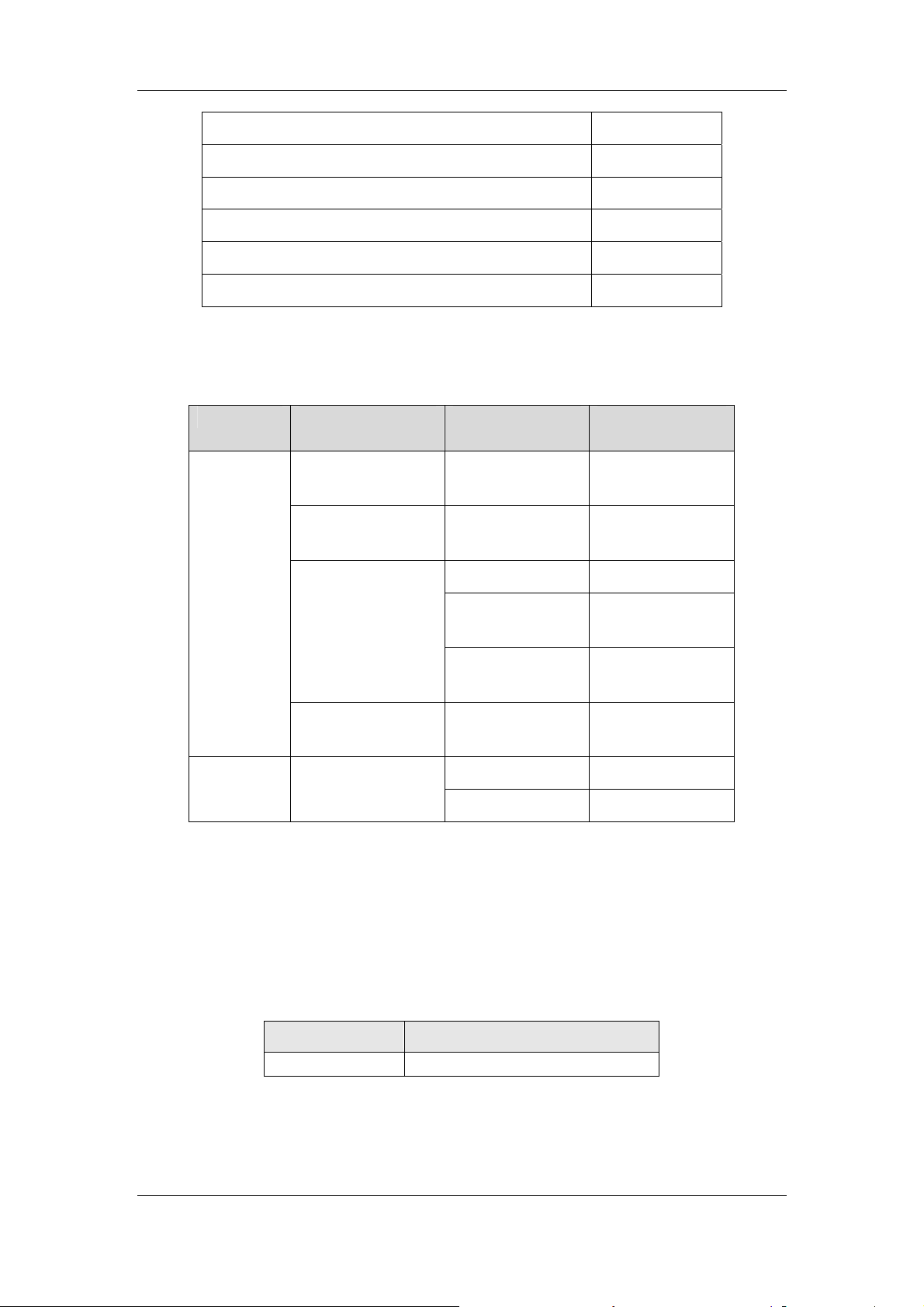

Table 2-3 Throughput of auto-loading mode

Measurement

Mode

Throughput

(analyses/hour)

2) Open-vial mode

CBC CBC+

Whole blood mode

(continuous

analyses)

(analyses/hour)

Whole blood mode

(single analysis)

CBC CBC+

DIFF

125 125 90 90 125 125 90 90

DIFF

125 125 90 90 125 125 90 90

75 75 60 60 75 75 60 60

CBC+DIFF

+RET

Table 2-4 Throughput of open-vial mode

CBC+DIFF

+RET

CBC+

RET

CBC+

RET

CBC+

NRBC

CBC+

NRBC

CBC+DIFF+

NRBC

CBC+DIFF

+NRBC

CBC+DIFF+

RET+NRBC

CBC+DIFF+

RET+NRBC

RET

RET

(analyses/hour)

Predilute mode

(single analysis)

(analyses/hour)

2.8 Capacity of the Autoloader

Each tube rack can be loaded with 10 tubes.

The autoloader can be loaded with 10 tube racks at the most.

The maximum capacity of a single loading is 100 tubes.

36 36 30 30 36 36 30 30

2-2

2.9 Performance Specifications

2.9.1 Sample Aspiration Volumes

OV-WB mode: 150ul

AL-WB mode: 200ul

OV-PD mode: 40 ul

2.9.2 General Performance Requirements

Table 2-5 General performance requirements

Items Temperature Design Requirement

Requirement of startup time

(the time taken from power-on

to ready-for-analysis)

Requirement of shutdown time

15℃~32℃

15℃~22℃

23℃~40℃

15℃~32℃

No more than 30 minutes

(normal and abnormal startup)

No more than 15 minutes

No more than 10 minutes

No more than 15 minutes

(normal shutdown)

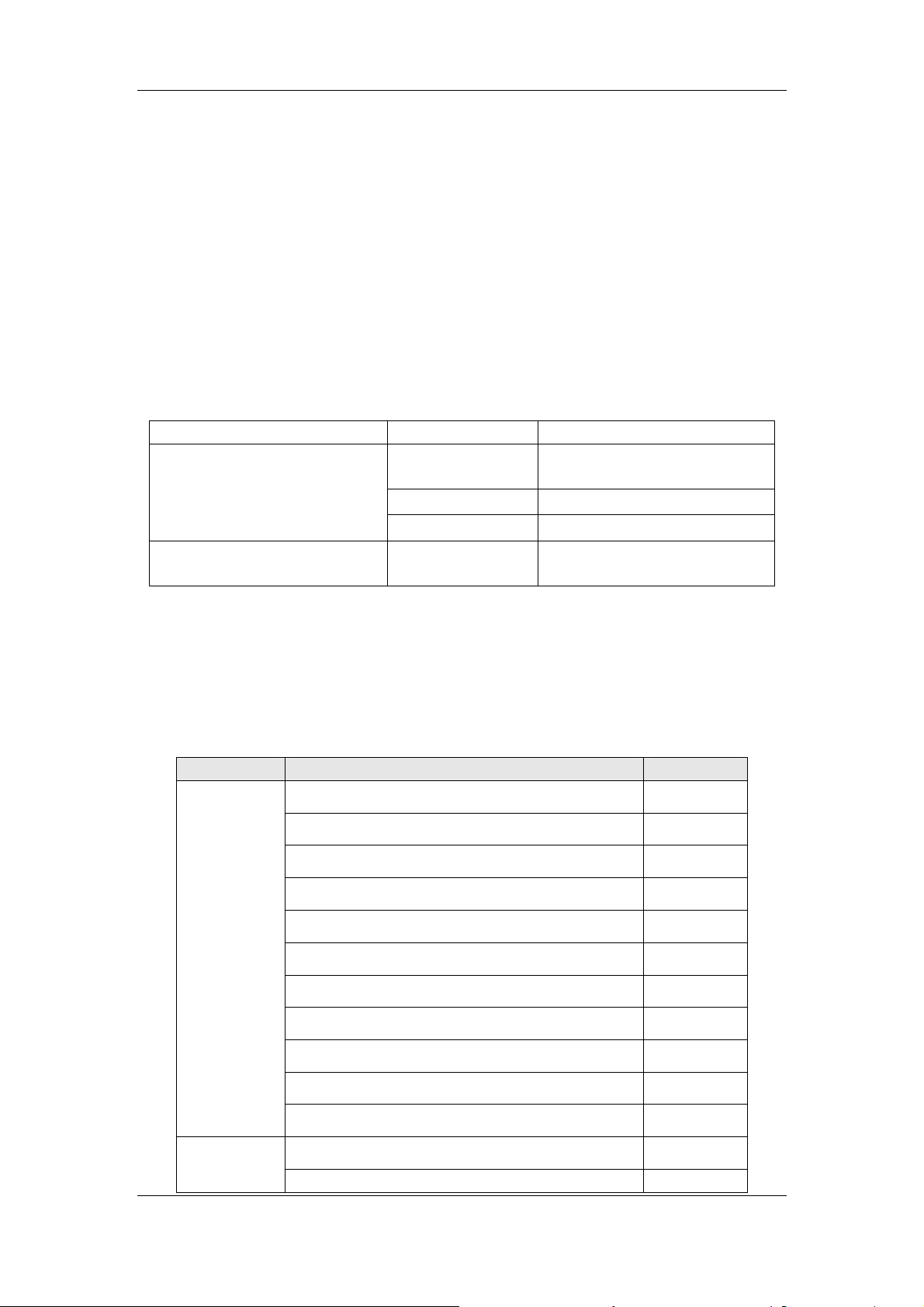

2.9.3 Analysis Parameters

1) 33 reporting parameters

Table 2-6 Reporting parameters

Clone Name Abbreviation

White Blood Cell count WBC

Basophils number Bas#

Basophils percentage Bas%

Leukon (11 parameters)

Neutrophils number Neu#

Neutrophils percentage Neu%

Eosinophils number Eos#

Eosinophils percentage Eos%

Lymphocytes number Lym#

Lymphocytes percentage Lym%

meters)

(6para

clone

Monocytes number Mon#

Monocytes percentage Mon%

RET

Reticulocyte percentage RET%

Reticulocyte number RET#

2-3

Immature reticulocyte fraction IRF

Low fluorescent ratio LFR

Middle fluorescent ratio MFR

High fluorescent ratio HFR

Red Blood Cell count RBC

Hemoglobin Concentration HGB

(6 parameters)

RBC clone (10 parameters)

PLT clone

Mean Corpuscular Volume MCV

Mean Corpuscular Hemoglobin MCH

Mean Corpuscular Hemoglobin

Concentration

Red Blood Cell Distribution Width Coefficient

of Variation

Red Blood Cell Distribution Width Standard

Deviation

Hematocrit HCT

Nucleated red blood cell number NRBC#

Nucleated red blood cell percentage NRBC%

Platelet count PLT

Mean Platelet Volume MPV

Platelet Distribution Width PDW

Plateletcrit PCT

Platelet-large cell ratio P-LCR

MCHC

RDW-CV

RDW-SD

Platelet-large cell count P-LCC

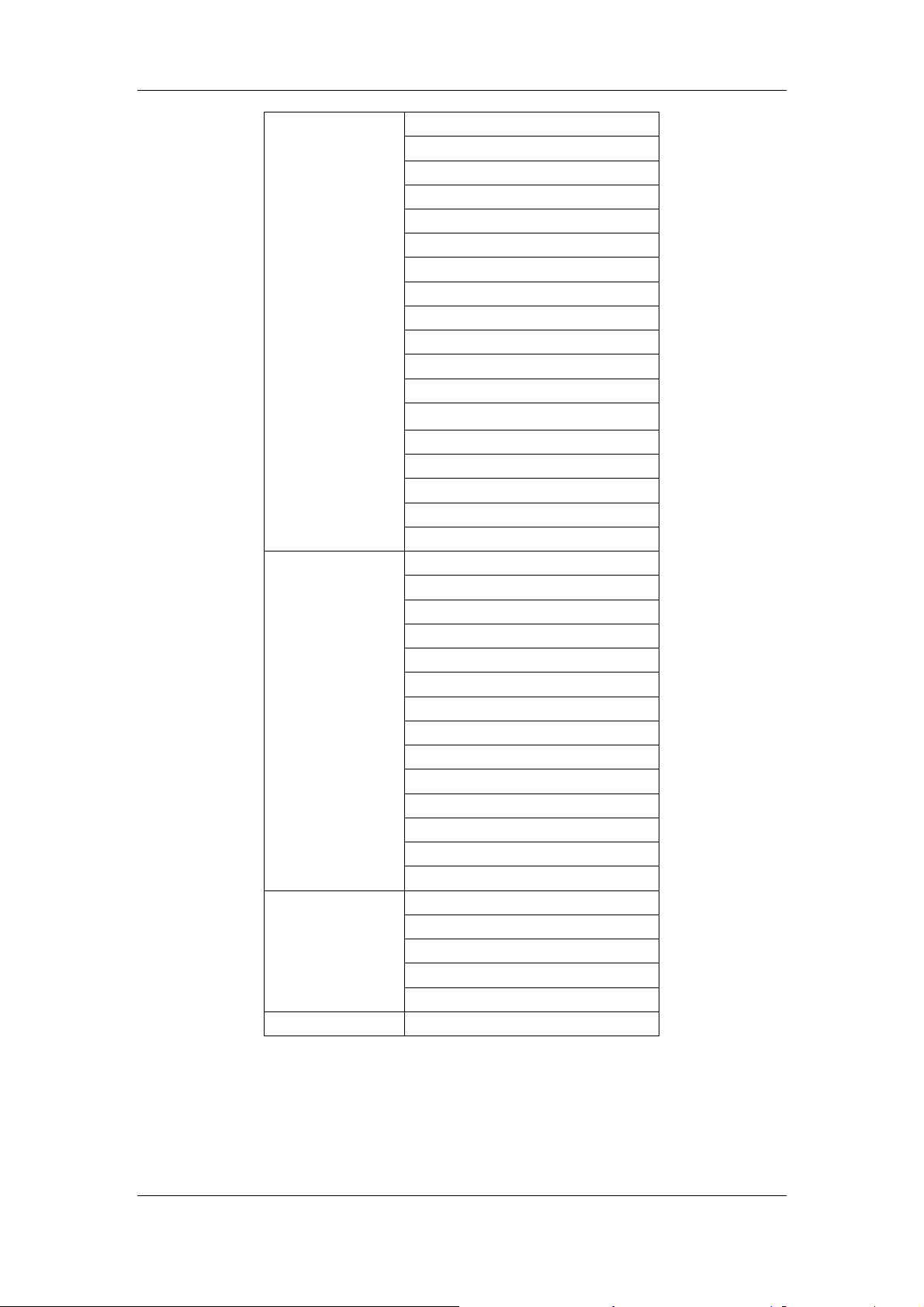

2) 14 RUO parameters

High fluorescent Cell number

High fluorescent Cell percentage

Immature Granulocyte

Immature Granulocyte percentage

Optical Red Blood Cell count

Optical Platelet count

Platelet count- Impedance

Optical white blood cell count

Table 2-7 RUO parameters

Name

Abbreviation

HFC#

HFC%

IMG#

IMG%

RBC-O

PLT-O

PLT-I

WBC-O

2-4

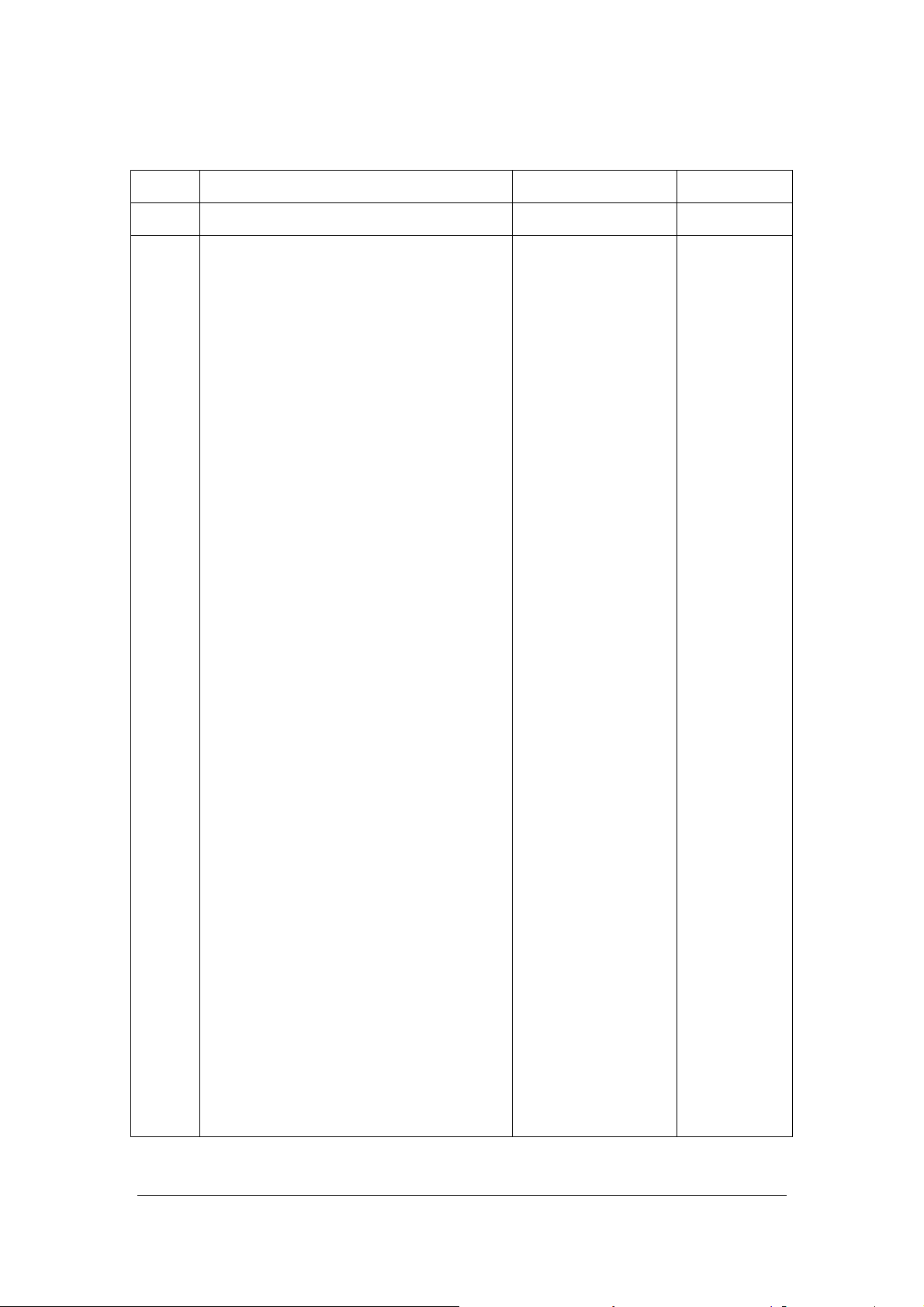

3) Graphs

Type Channel Name Three-dimensional

White blood cell count -DIFF

White blood cell count –BASO

White blood cell count-NRBC

Platelet Distribution Width Standard Deviation

Infected RBC number

Infected RBC ratio

Table 2-8 Graphs

DIFF optical

channel

BASO optical

channel

DIFF Scattergram

BASO

Scattergram

RET Scattergram

WBC-D

WBC-B

WBC-N

PDW-SD

INR#

INR‰

Scattergram

Yes

No

Yes

Scattergram

Histogram

RET optical

channel

NRBC optical

channel

RBC sheath fluid

impedance channel

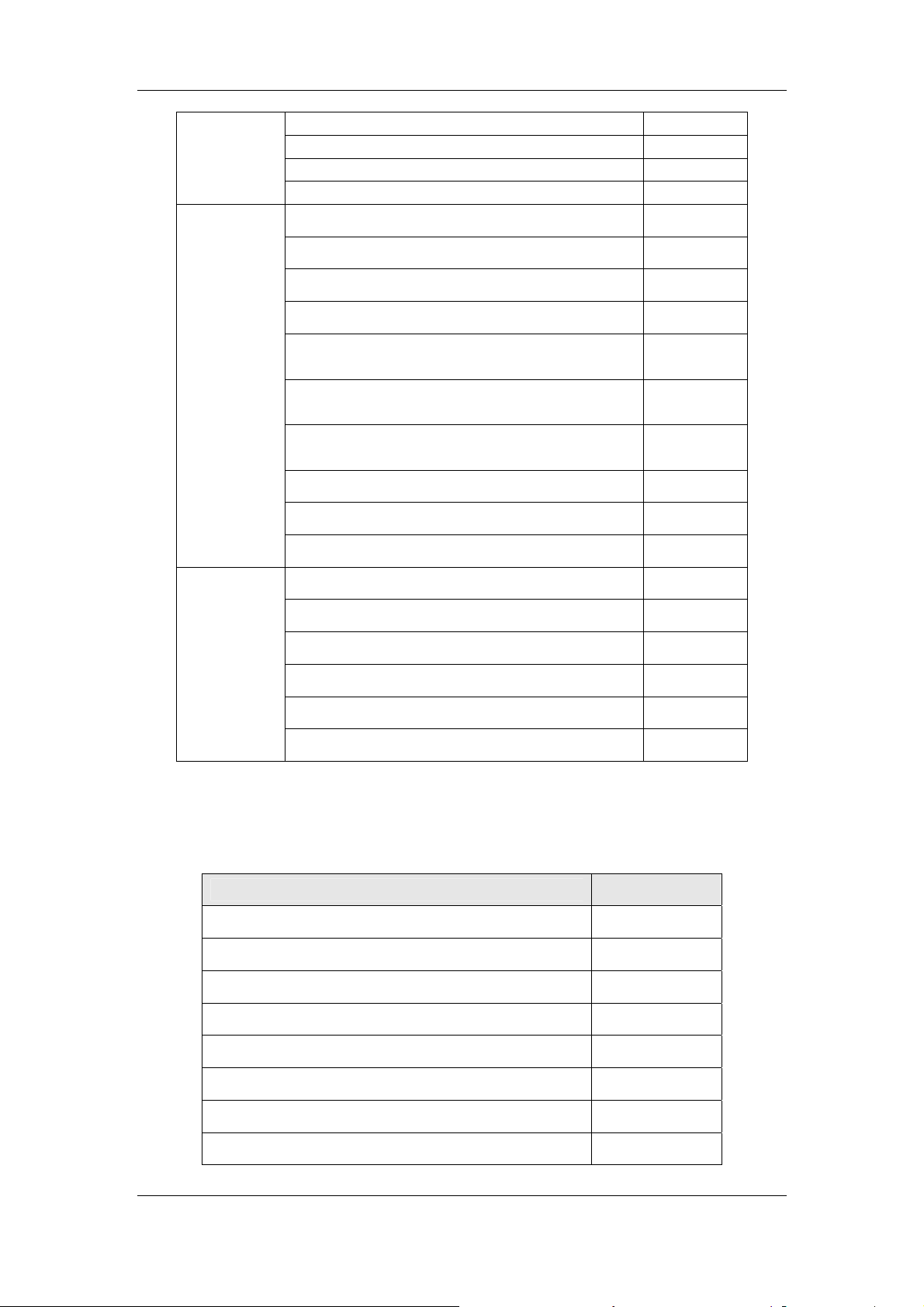

2.9.4 Flag Messages

Clone Name

PLT-O

Scattergram

RET-EXT

Scattergram

NRBC

Scattergram

RBC Histogram

PLT Histogram

Table 2-9 Flag messages

No

No

Yes

/

/

WBC WBC Abn Scattergram

2-5

NRBC Abn Scattergram

Neutropenia

Neutrophilia

Lymphopenia

Lymphocytosis

Monocytosis

Eosinophilia

Basophilia

Leukocytopenia

Leukocytosis

NRBC present

Blasts?

Abn Lympho/ Blasts?

Immature Gran?

Left Shift?

Atypical Lympho?

NRBC?

RBC Lyse resistance?

RBC Abn Distribution

RET Abn Scattergram

Dimorphic Population

Reticulocytosis

Anisocytosis

Microcytosis

RBC

Macrocytosis

Hypochromia

Anemia

Erythrocytosis

RBC Aggulutination?

Turbudity/HGB Interference?

Iron Deficiency?

Fragments?

PLT Abn Scattergram

PLT Abn Distribution

PLT

Thrombocytopenia

Thrombocytosis

PLT Clumps?

Overall judgment Pancytopenia

2-6

2.9.5 Measurement and Display Range

1) Condition

WBC 0~500×109/L

RBC 0~8.00×1012/L

HGB 0~250g/L

PLT 0~5000×109/L

HCT

RET%

RET#

0~75%

0~30%

0~0.8×10

12

/L

2) Display range

WBC 0.00~999.99×109/L

Neu%/Lym%/ Mon%/ Eos%/ Bas%

0~100%

RBC 0.00~99.99×1012/L

HGB 0~300g/L

PLT 0~9999×109/L

HCT

0.0~100.0%

MCV (0.0-250.0)fL

RET%

RET#

0~100%

0.0000~9.9999×10

12

/L

NRBC%

0~9999.99%

NRBC# 0~9999.99×109/L

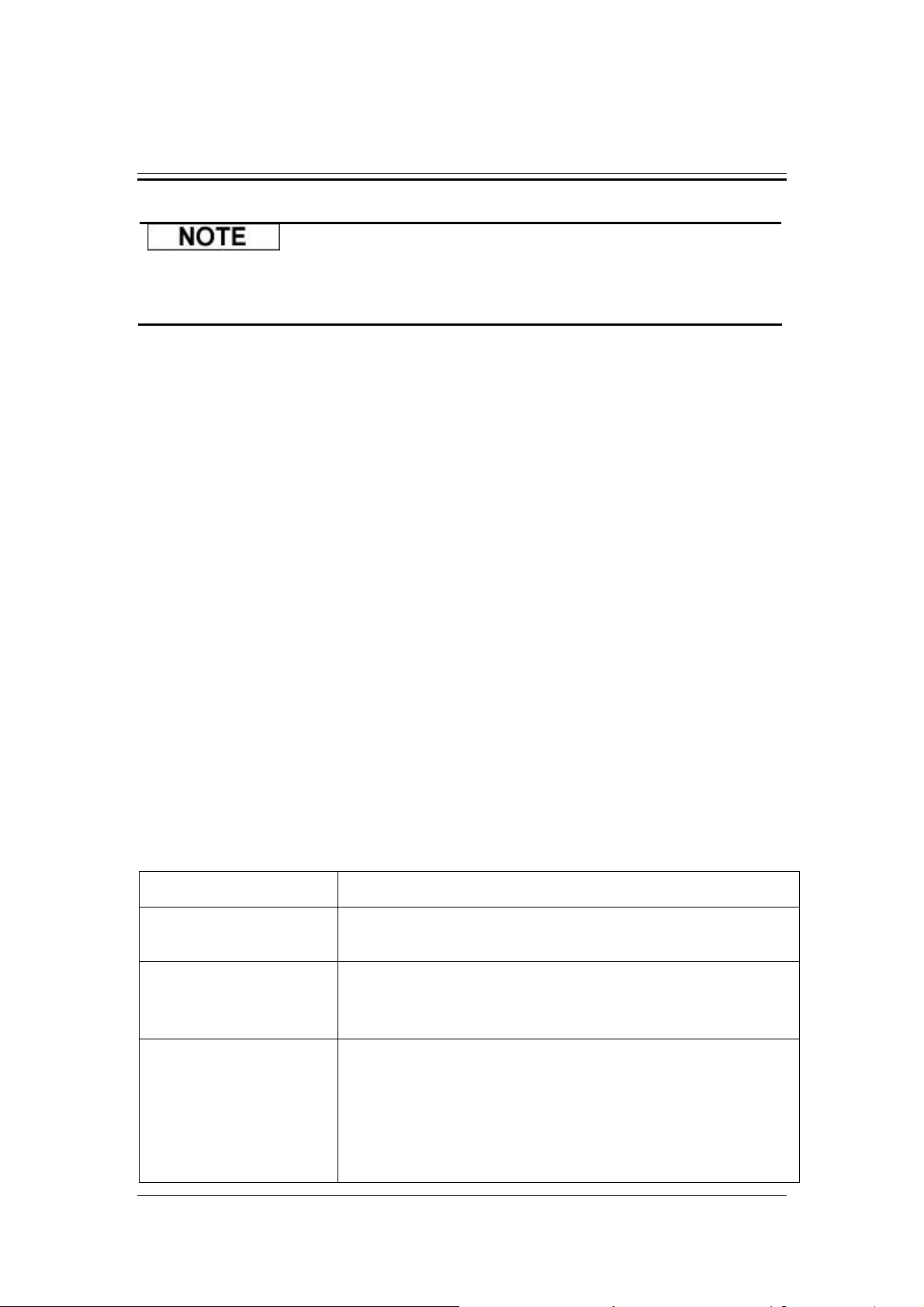

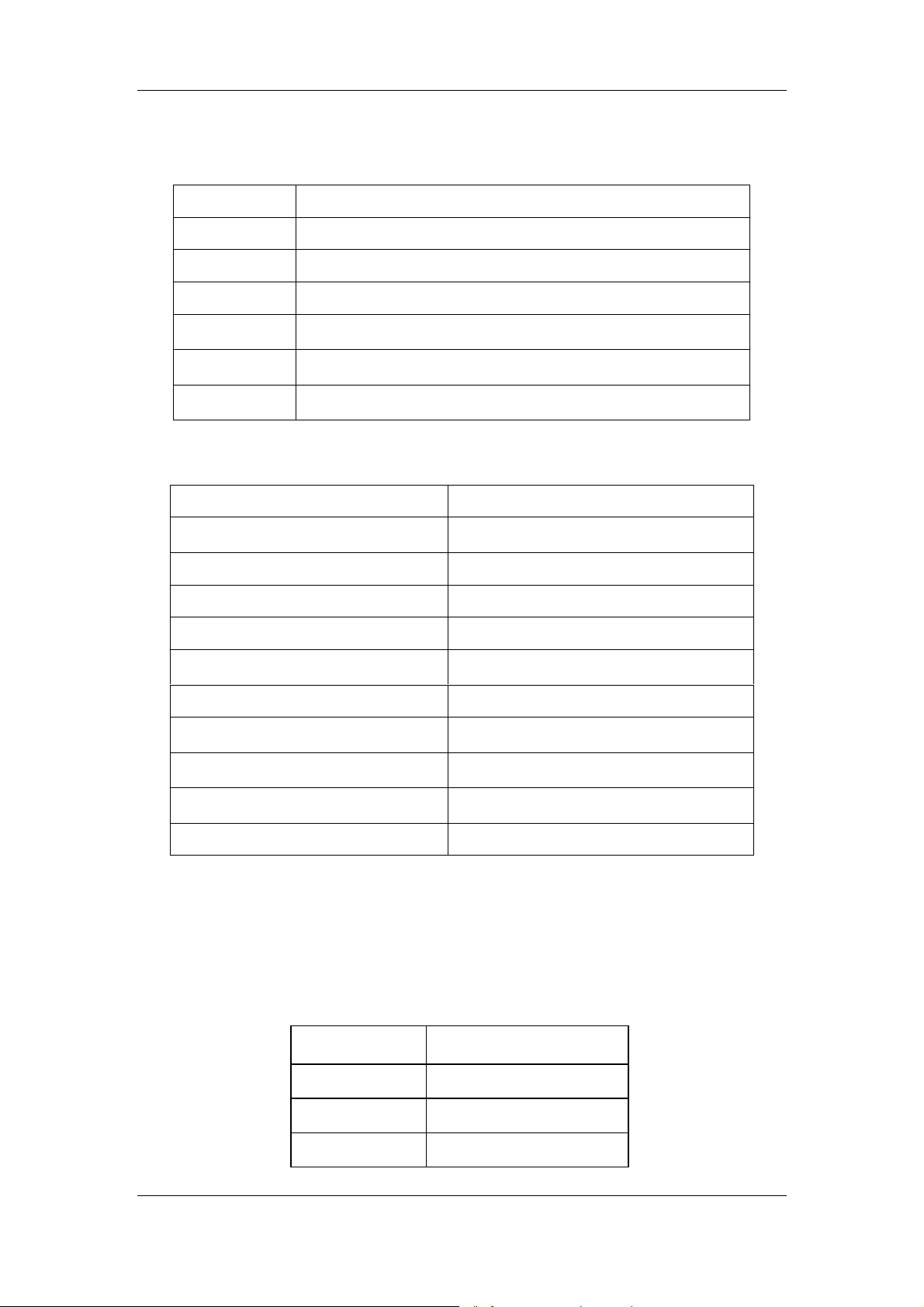

2.9.6 Background requirement

Background analysis method: run diluent sample and get the analysis result.

The background specification of BC-6800 is as follows:

Table 2-10 Background requirements

Parameter Background requirement

WBC

WBC-D

WBC-N

≤ 0.1 × 10

≤ 0.2 × 10

≤ 0.2 × 10

2-7

9

/ L

9

/ L

9

/ L

X

X

X

RBC

RBC-O

≤ 0.02× 10

≤ 0.02× 10

12

/ L

12

/ L

HGB ≤1 g/L

PLT

PLT-O

≤ 5 × 10

≤ 5 × 10

9

/ L

9

/ L

2.9.7 Carryover

Carryover analysis method: analyze 3 high value samples consecutively when the

analyzer is under stable conditions, and then analyze 3 low value samples immediately,

then calculate the carryover rate per the following equation.

(%)Carryover ×=

-

-

Table 2-11 Carryover requirements

Parameter Unit High value

sample

WBC ×109/L > 15.0 < 3.0 ≤1.0%

Low value

sample

result sample level-low hirdTresult sample level-lowFirst

result sample level-low hirdTresult sample level-high hirdT

Carryover

100

%

RBC ×1012/L > 6.0 < 2.00 ≤1.0%

HGB g/L > 200 < 40 ≤1.0%

HCT % >54.0 <18.0 ≤1.0%

PLT ×109/L > 300 < 100 ≤1.0%

RBC-O ×1012/L > 6.0 < 2.00 ≤1.5%

WBC-D ×109/L > 15.0 < 3.0 ≤1.0%

WBC-N ×109/L > 15.0 < 3.0 ≤1.5%

2.9.8 Reproducibility

Reproducibility analysis method: select a qualified sample and analyze it for 10

consecutive times, and then calculate the CV (%) and absolute deviation D of each

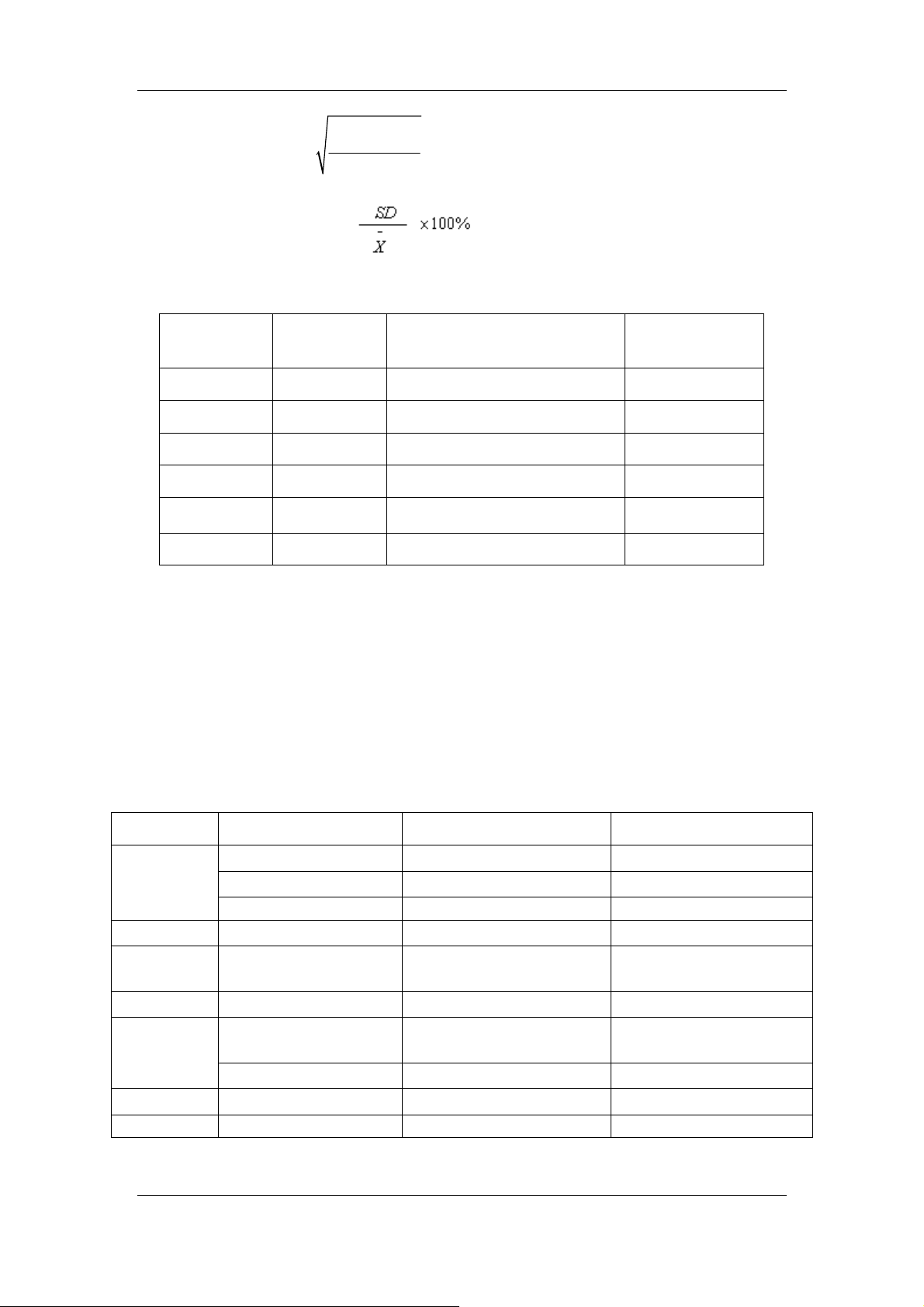

parameter. Calculation method:

n

∑

i

1

i

=

; n: analysis times

n

Mean(

−

)=

−

Absolute deviation di =xi -

2-8

X

−

2

X

−

i

−

; i: the parameter result of the ith analysis

1

Standard deviation (SD)=

()

∑

n

Coefficient variation (CV)%=

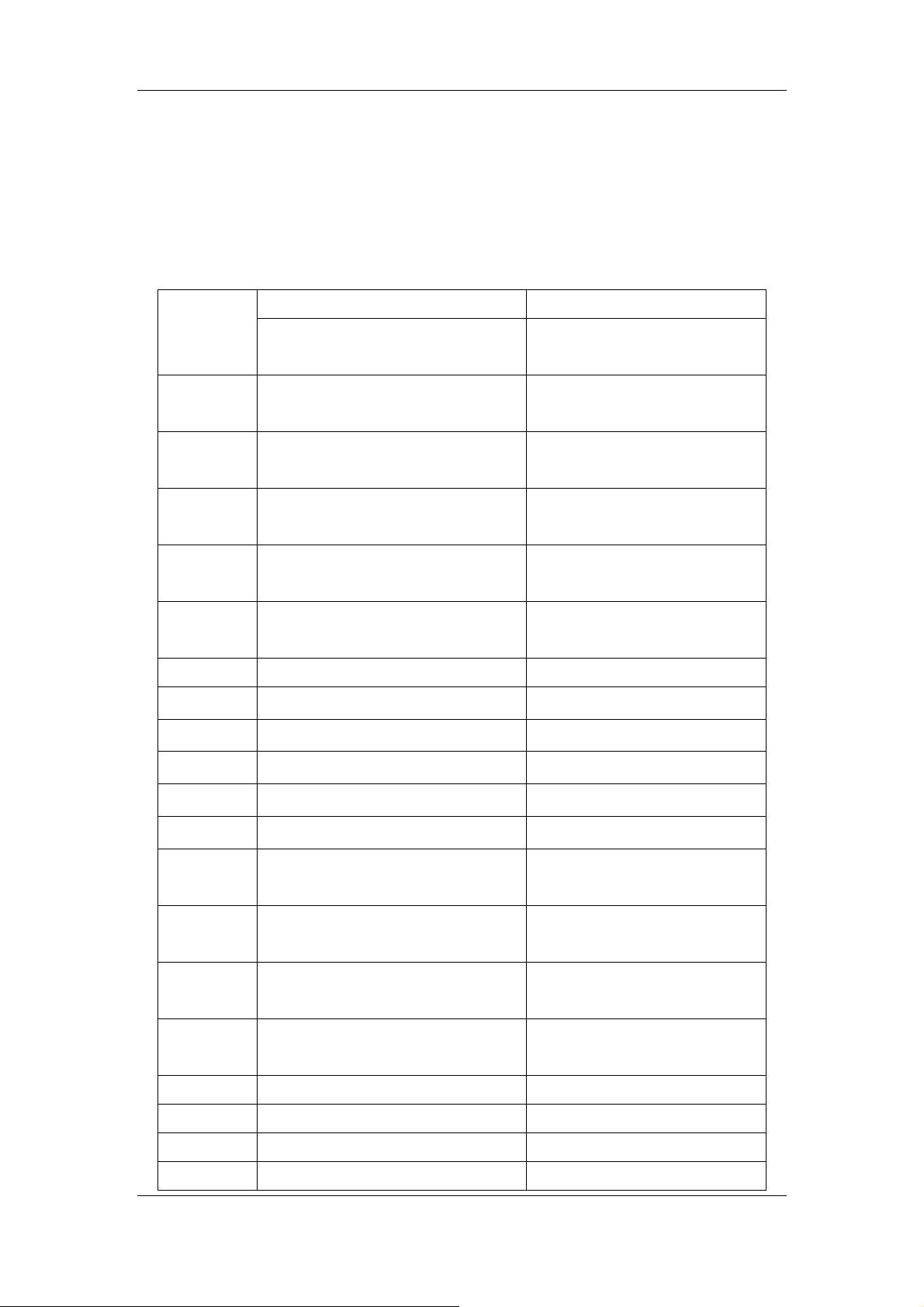

Table 2-12 Reproducibility requirements

Parameter Range

9

WBC

RBC

HGB

MCV

HCT

PLT

≥4×10

≥3.5×10

(110-180)g/L

(80-100)fL

(30~50)%

≥100×10

/L

12

/L

9

/L

Whole blood (CV/Absolute

deviation d*)

≤2.5% ≤4.0%

≤1.5% ≤2.0%

≤1.0% ≤2.0%

≤1.0% ≤3.0%

≤1.5% ≤3.0%

≤4.0% ≤8.0%

Predilute (CV)

*Note: absolute deviation d= measured value- mean of measured value.

**Note: Range=maximum measured value- minimum measured value.

2.9.9 Linearity

Prepare samples of different concentrations, analyze the samples, and calculate slope

coefficient and intercept in the linearity regression equation. Then calculate the theoretical

value and the deviation between the theoretical value and the test value.

Table 2-13 Linearity requirements

Parameter Condition Whole blood mode Predilute mode

(0 ~ 100.00)×109/L

WBC

(100.01 ~ 350.00)×109/L

(350.01 ~ 500)×10

9

/L ±11% ±11%

RBC (0 ~ 8.00)×1012/L

HGB (0-250)g/L

HCT

PLT*

RET%

(0~75)% ±1.0%(HCT value) or ±2% ±2.0%(HCT value) or ±4%

(0 ~ 1000)×109/L

(1001 ~ 5000)×10

9

/L

(0~30)% ±0.3%(RET value) or ±20%

±0.20×10

±6% ±6%

±0.03×10

±2g/L or ±2%

±10×10

±6%

9

/L or ±2%

12

/L or ±2%

9

/L or ±5% ±10×109/L or ±10%

±0.50×10

±0.05×10

±20×10

9

/L or ±5%

12

/L or ±5%

±2g/L or ±3%

±4g/L or ±4%

9

/L or ±10%

±10%

/

RET# (0 ~ 0.8)×1012/L ±0.015×1012/L or ±20% /

* Note: PLT linearity may not meet the requirement, it is mainly determined by RBC

concentration.

2-9

2.9.10 Deviation between Different Modes

The way to measure deviation between different modes: perform calibration under each

mode using fresh blood or calibrator, then analyze a normal fresh blood sample for 5 times

under the autoloading mode, open vial whole blood mode and open vial predilute mode

respectively, and calculate the deviations of the parameters between the modes.

Table 2-14 Requirements of deviations under different modes

Autoloading and open vial mode Open vial and predilute mode

Parameter

Relative deviation or absolute

deviation requirement

WBC ±5% or ±0.4×109/L

RBC ±2% or ±0.1×1012/L

HGB ±2% or ±4g/L

HCT ±2% or ±0.3HCT%

PLT ±7% or ±20×109/L

Neu%

Lym%

Mon%

Eos%

±5.0% ±9.0%

±4.0% ±9.0%

±3.0% ±6.0%

±2.0% ±3.0%

Relative deviation or absolute

deviation requirement

9

±5% or ±0.4×10

±10% or ±0.8×10

±2% or ±0.1×10

±4% or ±0.2×10

/L

9

/L

12

/L

9

/L

±2% or ±4g/L

±4% or ±6g/L

±2% or ±0.3HCT%

±4% or ±0.6HCT%

9

9

/L

/L

±7% or ±20×10

±14% or ±30×10

Bas%

NRBC%

RET#

±20% or ±2.0NRBC% /

±1.0% ±3.0%

±20% or ±0.015×10

12

/L

±20% or ±0.015×10

±30% or ±0.02×10

RET%

±20% or ±0.3 RET%

±20% or ±0.3 RET%

±30% or ±0.45 RET%

RBC-O ±20%

PLT-O ±20%

LFR

MFR

HFR

IRF

±30% or ±10 LFR%

±30% or ±10 MFR%

±30% or ±5 HFR%

±30% or ±10 IRF%

2-10

±20%

±30%

±20%

±30%

12

/L

12

/L

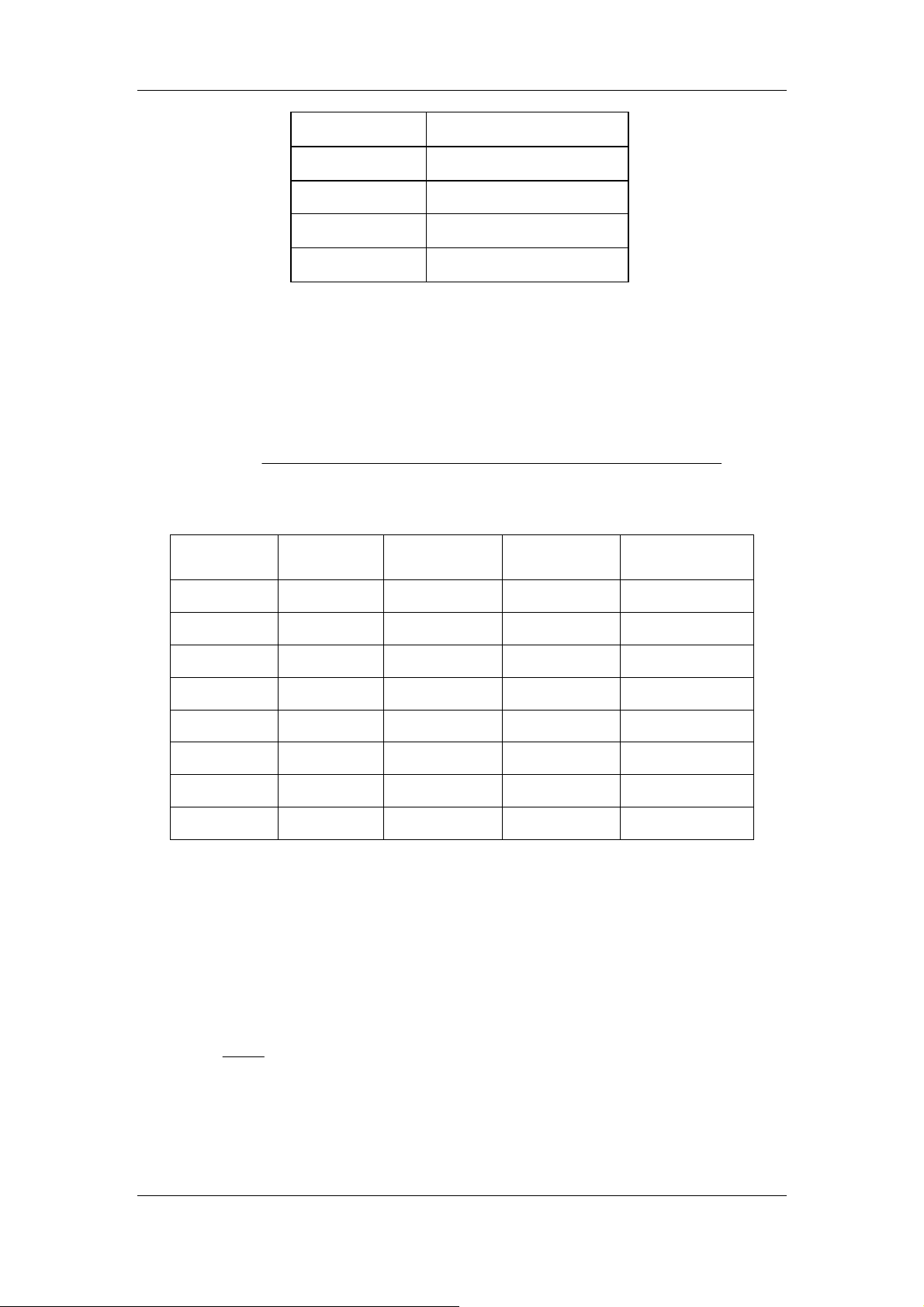

2.9.11 Correlation Requirements of the Analyzer and

Comparator

1. Requirements of Deviation of the Analyzer and Comparator

Analyzer a fresh blood sample or calibrator with traceability for 5 consecutive times on a

comparator of good conditions and calculate the mean of each parameter. Take the means as

targets, and calibrate the analyzer to be tested with the sample or calibrator mentioned above.

When the calibration finishes, test another fresh blood samples for 5 times on the two

analyzers respectively and calculate the deviation rate of the means of each parameter.

Deviation requirements: WBC - ≤ ±3%, RBC - ≤ ±2%, HGB- ≤ ±2%, PLT - ≤ ±5%, HCT or MCV

- ≤ ±2%.

2. Correlation Requirements of the Analyzer and Comparator

Test at least 100 fresh anticoagulated venous blood samples (able to cover the reportable

range as much as possible, with at least 50 abnormal samples) for 2 times on the comparator

and the analyzer respectively, calculate the mean and the correlation coefficient R.

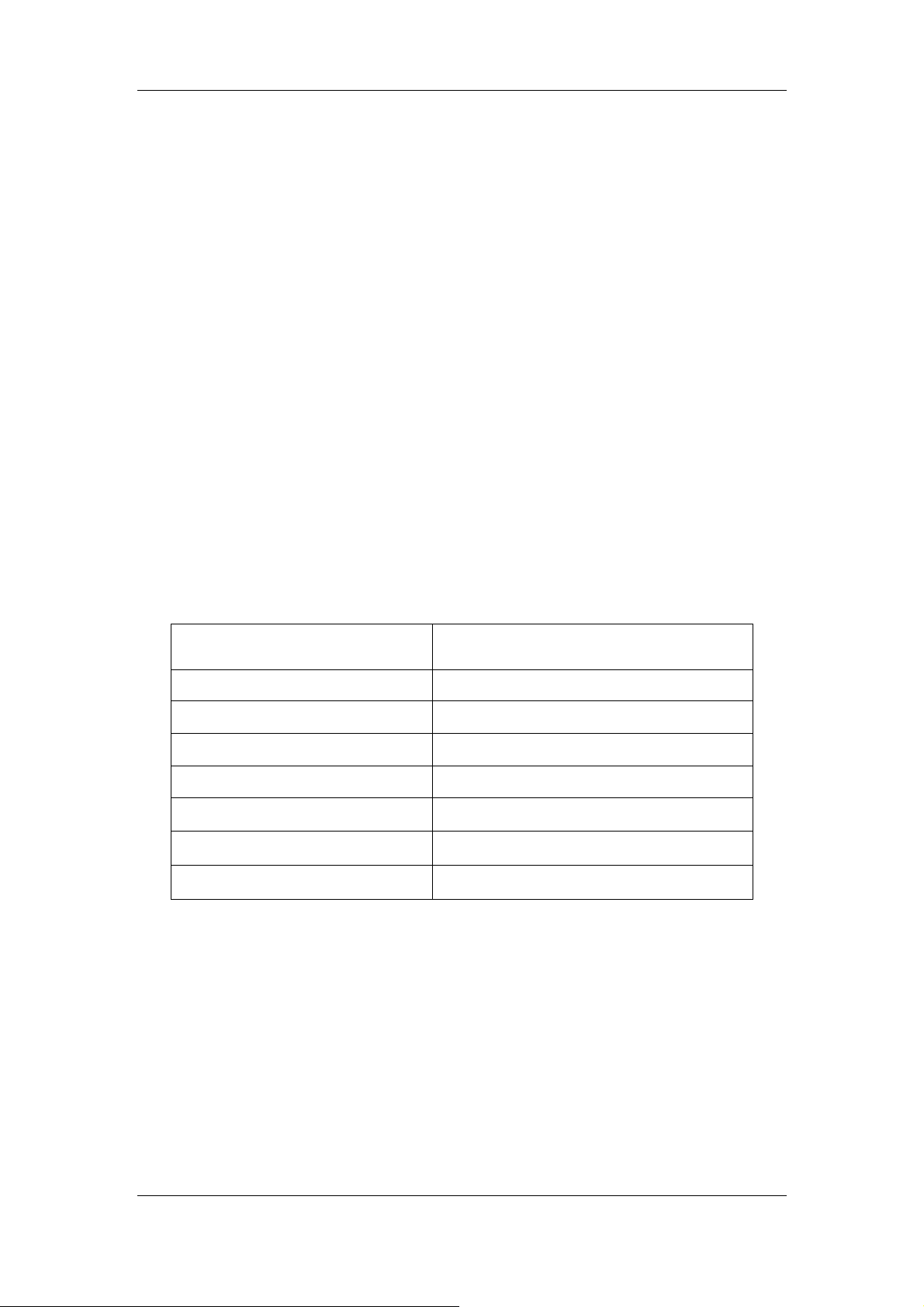

Table 2-15 Requirements on the Comparative Index of the Analyzer and Comparator

Parameter

WBC ≥0.99

RBC ≥0.99

HGB ≥0.98

MCV ≥0.98

PLT ≥0.95

NRBC ≥0.90

RET#/RET% ≥0.90

Comparative Correlation Coefficient of

the Analyzer and Comparator

2.9.12 Correlation and Accuracy Requirements of WBC

Differential and Manual Differential

1. Correlation

Prepare 100 normal samples and 100 abnormal samples, test the samples with the analyzer

and the reference method (manual differential) respectively. Test each sample on the analyzer

twice. Manual differential shall be conducted per the requirement of CLSI H20, 400 cells from

each sample are analyzed, and the mean is calculated. Conduct correlation analysis for

Neu%, Lym%, Mon%, Eos%, Bas% and IG.

2-11

Table 2-16 Correlation Requirements of Differential Parameters

Parameter Correlation Coefficient of WBC Differential of

the Analyzer and Manual Differential

Neu% ≥0.90

Lym% ≥0.90

Mon% ≥0.75

Eos% ≥0.80

Bas% ≥0.50

IG% ≥0.80

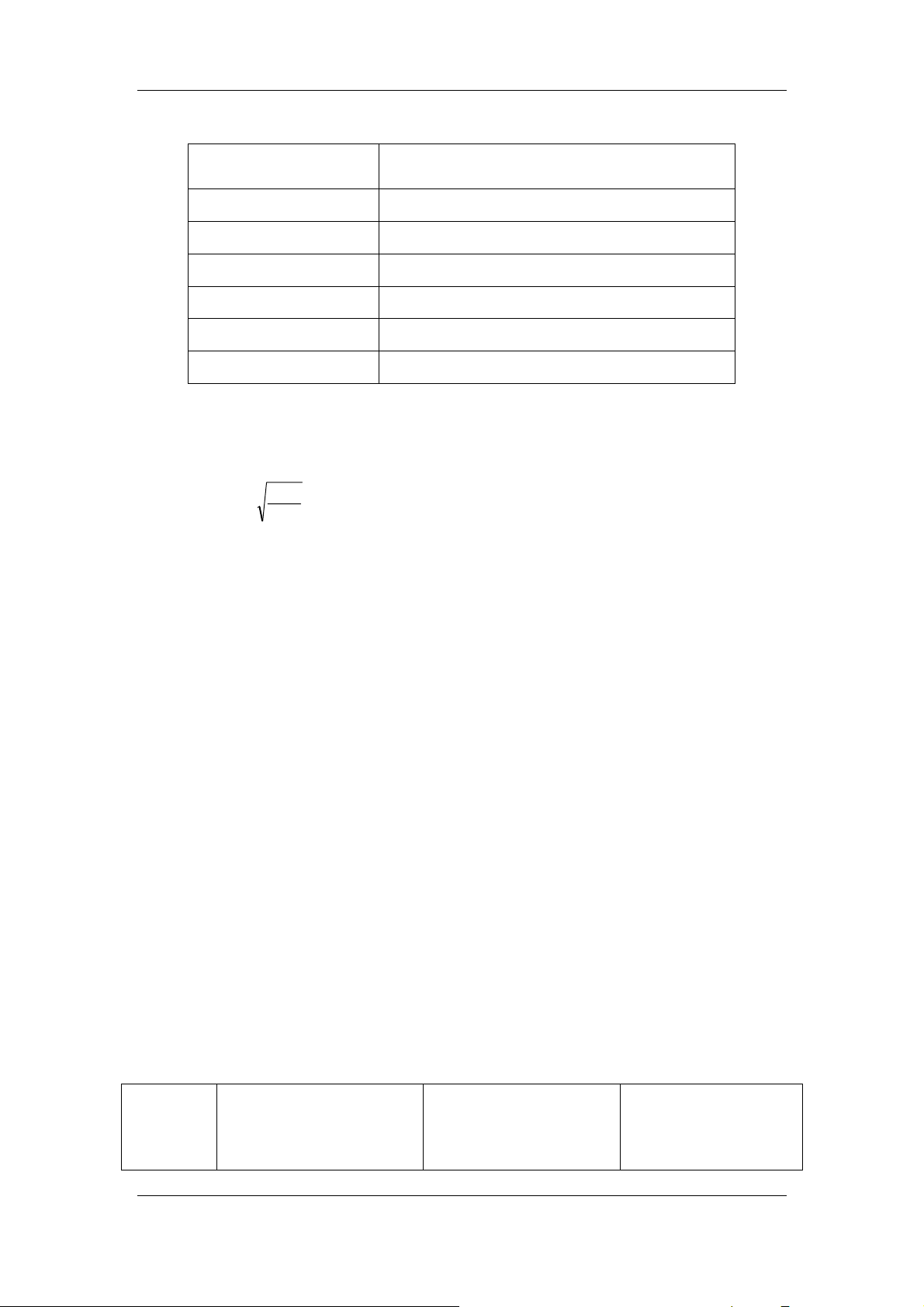

2. Accuracy

Run calculation over results of the 200 samples tested for correlation analysis.

qp×

Equation: SEp=

n

In the equation, n=200; p= mean obtained with the reference method; q=100-p; when freedom

is 199, the t distribution factor of 99% credibility limit =2.57.

Calculating credibility range

The 99% credibility range of a parameter rate: p±2.57×SEp.

Requirement: The Lym%, Neu%, Mon%, Eos% and Bas% results tested by the analyzer

must be within the 99% credibility range of the results tested by the reference method.

2.9.13 Sample Stability

Prepare 5 normal anticoagulated fresh venous blood samples, separate each sample into 17

shares. Test 1 share for twice after it has been prepared for 0.5 hour. Group the other 16

shares into 2 groups, store 1 group in room temperature and the other in the environment of 4

℃. Test 1 share from each group at hour 1, 2, 4, 8, 12, 24, 48 and 72 after they have been

prepared (the samples stored in the environment of 4℃ must be warmed to room temperature

and then mixed). Record the parameter results of each sample and observe the change of

parameter results, histogram and scattergram over time. Calculate the change of parameter

results of each sample over time against the results of the test done at hour 0.5, and

representing the change in absolute or relative deviation.

Parameter

Table 2-17 Sample Stability Requirements

Relative deviation or

absolute deviation

Acceptance Range

Long Term Stability in

Room Temperature

(18℃-26 )℃

2-12

Long Term Stability in

Refrigerated

Temperature (2℃-8 )℃

Loading...

Loading...