Shelley SSD-SAD-SMDP1-GH User Manual

Specification Line

Delfield

™

®

®

Installation, Use and Care Manual

Please read this manual completely before attempting to install or operate this equipment! Notify carrier

of damage! Inspect all components immediately. See page 3.

IMPORTANT INFORMATION

READ BEFORE USE

PLEASE SAVE THESE INSTRUCTIONS!

February 2011

Deleld

Important Warning And Safety Information

WARNING

Read this manual thoroughly before operating, installing, or performing maintenance

on the equipment.

FAILURE TO FOLLOW INSTRUCTIONS IN THIS MANUAL CAN CAUSE PROPERTY

DAMAGE, INJURY OR DEATH.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

UNLESS ALL COVER AND ACCESS PANELS ARE IN PLACE AND PROPERLY SECURED,

DO NOT OPERATE THIS EQUIPMENT.

DAMP OR WET HANDS MAY STICK TO COLD SURFACES.

ALLOW HEATED EQUIPMENT TO COOL DOWN BEFORE ATTEMPTING TO CLEAN OR

SERVICE.

CAUTION

Observe the following:

• Minimum clearances must be maintained.

• Keep the equipment area free and clear of combustible material.

• Allow adequate clearance for air openings.

• Operate equipment only on the type of electricity indicated on the specification

plate.

• Unplug the unit before making any repairs.

• Retain this manual for future reference.

2

Specification Line

Contents

Serial Number .......................................................................3

Receiving And Inspecting The Equipment ............................3

Model Numbers ....................................................................4

Introduction ..........................................................................5

Specifications ..................................................................6-12

Installation .................................................................... 13-14

Electronic Temperature Control Operation .................... 15-16

Evaporator Fan Operation ...................................................17

Heated Cabinet Operation ...................................................18

Maintenance ..................................................................19-20

Wiring Diagrams ........................................................... 21-29

Compressor Diagrams ........................................................30

Replacement Parts ........................................................ 31-35

Serial Number Location

The serial number is on the identification plate that also

includes the model number. A typical identification plate

is shown below. On refrigeration and freezer unit the

identification plate is located inside the right most door near

the top front corner of the right interior wall. On heated units,

the identification plate is located in the shroud area on the

right side panel.

Always have the serial number of your unit available when

calling for parts or service. A complete list of authorized

Delfield parts depots can be found at www.delfield.com.

©2011 The Delfield Company. All rights reserved. Reproduction without

written permission is prohibited. “Delfield” is a registered trademark of The

Delfield Company.

COVINGTON, TENNESSEE

Standard Labor Guidelines ..................................................36

Standard Two Year Warranty ..............................................37

Additional Three Year Warranty ..........................................38

Notes ..................................................................................39

Receiving And Inspecting The Equipment

Even though most equipment is shipped crated, care should be

taken during unloading so the equipment is not damaged while

being moved into the building.

1. Visually inspect the exterior of the package an skid or

container. Any damage should be noted and reported to the

delivering carrier immediately.

2. If damaged, open and inspect the contents with the carrier.

3. In the event that the exterior is not damaged, yet upon

opening, there is concealed damage to the equipment notify

the carrier. Notification should be made verbally as well as

in written form.

4. Request an inspection of the concealed equipment.

This should be done within 10 days from receipt of the

equipment.

5. Check the lower portion of the unit to be sure legs or casters

are not bent.

6. Also open the compressor compartment housing and

7. Freight carriers can supply the necessary forms upon

8. Retain all crating material until an inspection has been made

Uncrating the Equipment

First cut and remove the banding from around the crate. Remove

the front of the crate material, use of some tools will be required.

If the unit is on legs remove the top of the crate as well and lift

the unit off the skid. If the unit is on casters it can be "rolled" off

the skid.

visually inspect the refrigeration package. Be sure lines are

secure and base is still intact.

request.

or waived.

3

Deleld

Model Numbers

Series

S=Specification

Line

Finish

S=Stainless interior &

exterior

A=Stainless exterior,

aluminum interior

M=Stainless front,

aluminum sides and

interior

Temp

R=Refrigerator

F=Freezer

H=Heated

D=Dual Temp

T=Thaw

W=Wine

Configuration

None=Reach-in

PT=Pass Thru

RI=Roll-in

RT=Roll Thru

FF=Fish Drawers

RL=Refrigerator Left

FL=Freezer Left

TR=Top Refrigerator

BR=Bottom Refrigerator

TP=Top Refrigerator Pass Thru

BP=Bottom Refrigerator Pass Thru

RP=Refrigerator Left Pass Thru

FP=Freezer Left Pass Thru

Section

1=1 Section

2=2 Section

3=3 Section

Size

None=Standard

N=Narrow

S=Shallow

System

None=Standard

E=Export Voltage

R=Remote

Doors

S=Solid Full

SH=Solid Half

G=Hinged Glass Full

GH=Hinged Glass Half

SL=Sliding Glass Full

SLH=Sliding Glass Half

SLS=Sliding Solid Full

SLSH=Sliding Solid Half

D=Drawers

4

Specification Line

Introduction

Model numbers starting with the letters “SS” have a stainless

steel exterior and interior. Model numbers starting with the letters

“SA” have an aluminum interior and a stainless steel exterior.

Model numbers starting with the letters “SM” have an aluminum

interior and exterior with a stainless steel front and shroud. Door

gaskets are magnetic and mount to the door, snapping in place

and are removable without tools. Keyed door lock is mounted

in the door next to the handle.

Doors can be removed from the cabinet without the use of

tools. Each door has two edge mount, self-closing, cam lift

style hinges.

Refrigeration System

All components are mounted to the exterior cabinet ceiling,

outside the food zone and are assembled as one-piece and can be

removed as one-piece. Environmentally friendly R404A refrigerant

is used. The system has the capability of maintaining between 27°F

and 40°F (-3°C and 4°C) in heavy use food service operations.

Refrigerant is metered using a highly responsive thermostatic

expansion valve. Systems are controlled using Delfield’s ETC1

Electronic Temperature Control. It provides improved pull down

times, reducing compressor cycling and longer compressor life

with lower energy consumption. Control system uses adaptive

defrost to assure evaporator coil is free of ice and operating at

optimum efficiency. Evaporator condensate is eliminated using

an energy efficient hot gas system.

Freezer Refrigeration System

All components are mounted to the exterior cabinet ceiling, outside

the food zone and are assembled as one-piece and can be removed

as one-piece. Environmentally friendly R404A refrigerant is used.

The system has the capability of maintaining between -5°F and

0°F (-21°C and -18°C) in heavy use food service operations.

Refrigerant is metered using a highly responsive thermostatic

expansion valve. System is controlled using Delfield’s ETC1

Electronic Temperature Control, which provides improved pull

down times, reducing compressor cycling and longer compressor

life with lower energy consumption. Control system uses adaptive

defrost to assure evaporator coil is free of ice and operating at

optimum efficiency. Evaporator condensate is eliminated using

an energy efficient hot gas system.

Service Alert

During normal operation the evaporator fan may cycle

and/or pulse independently of the compressor. Consult

the service manual or contact Technical Support at

1-800-733-8829 if you are unsure of the proper

function.

Dual Temperature Refrigeration/Freezer

Each compartment has its own separate refrigeration system.

Condensing units are located on top of the cabinet, outside

the food zone, behind the upper shroud. Evaporator coils are

located inside the cabinet mounted to the interior ceiling of each

compartment. Defrost is automatic. Condensate travels down

a tube in the cabinet sidewall to a receptacle mounted to the

exterior bottom of the cabinet where it evaporates with the aid of

an electric heater. Each compartment’s temperature is individually

monitored and controlled with Delfield's ETC1 Electronic

Temperature Control. Two exterior digital thermometers monitor

temperature. Refrigerator compartment maintains temperature

between 33°F and 41°F (1°C and 5°C). Freezer compartment

maintains temperature between -5°F and +5°F (-21°C and -15°C).

Refrigerant is metered using a highly responsive thermostatic

expansion valve.

Ready Thaw

Ready Thaw is designed to thaw frozen food under controlled

temperature conditions in approximately 18 hours and then

hold it at normal refrigerator temperatures. This unit uses a

standard refrigeration system mounted to the exterior cabinet

ceiling coupled with a heater and fan mounted in the center of

the refrigerated cabinet. The unit will operate as a standard

refrigerator and maintain a temperature of between 33°F and

41°F (1°C and 5°C)until a quantity of frozen product drops the

temperature below 20°F (7°C). The control will then automatically

cycle the heater and fan to begin the thaw process. After the

product is thawed, the electronic control will turn off the heater

and fan and return to standard refrigeration operation.

Heating System

Heating system cabinets are designed to maintain temperatures

between 120°F and 200°F (49°C and 93°C). Heating elements

are helical shaped, with tubular fins. A circulating fan provides

uniform airflow in the cabinet. The entire heating system is

mounted to the exterior of the cabinet ceiling, outside the food

zone. It is assembled as one piece and can be removed as one

piece. An adjustable electronic thermostat controls temperature.

The system ON/OFF switch is located on the front exterior of

the cabinet.

5

Deleld

Specifications

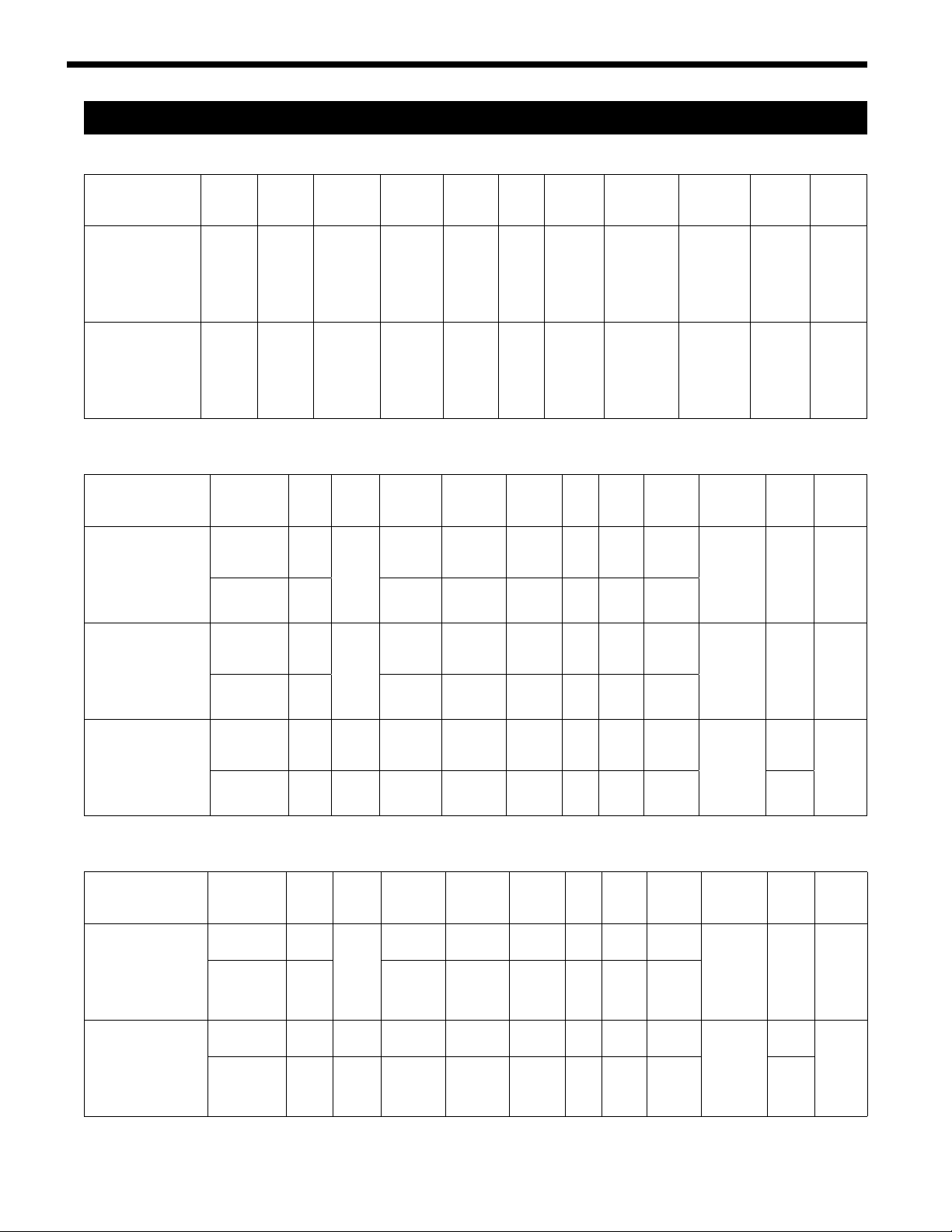

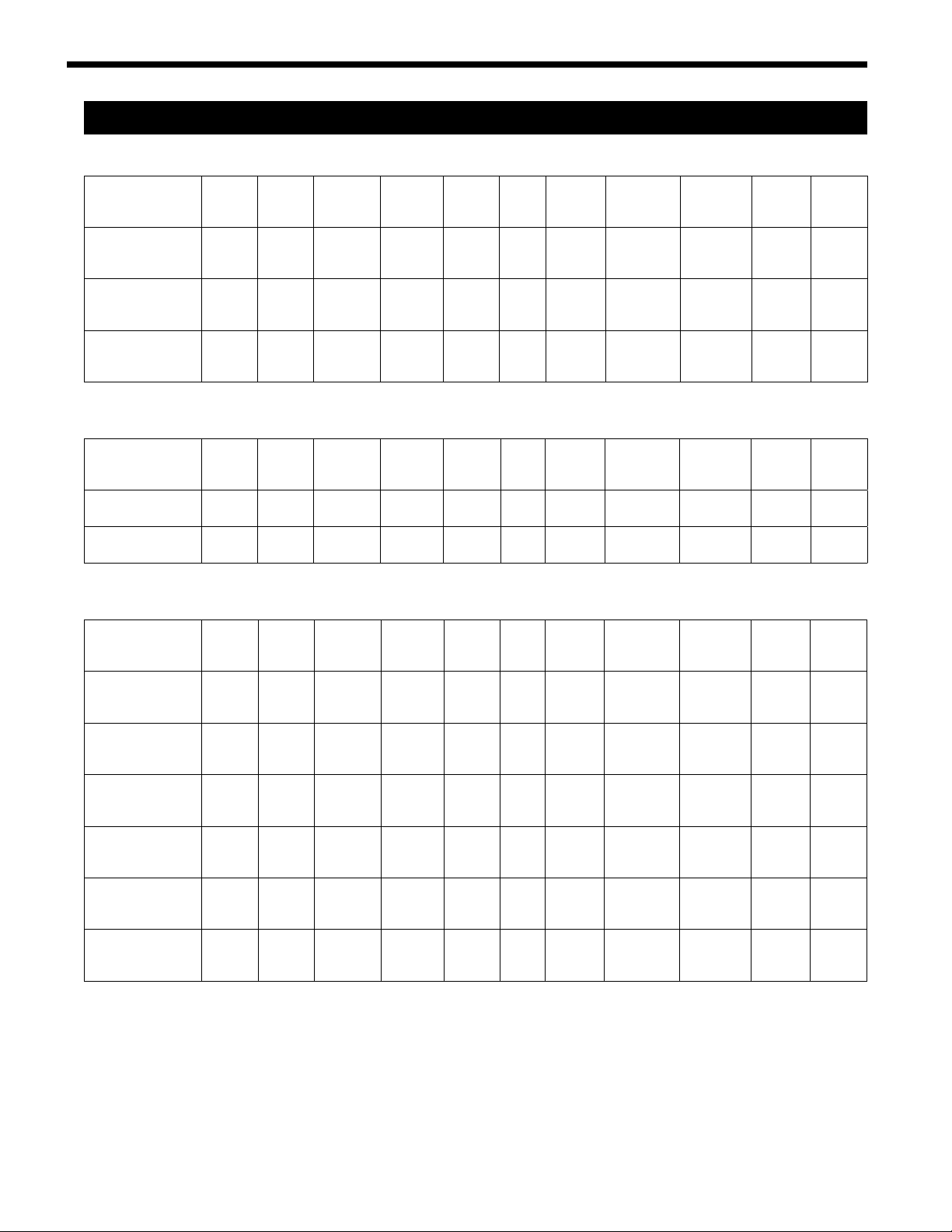

Reach-In Refrigerators - Hinged Doors - Standard Width & Depth

Model Voltage Amps

SSR1-S,SH,G,GH

SAR1-S,SH,G,GH

SMR1-S,SH,G,GH

SSR2-S,SH,G,GH

SAR2-S,SH,G,GH

SMR2-S,SH,G,GH

SSR3-S,SH,G,GH

SAR3-S,SH,G,GH

SMR3-S,SH,G,GH

115 6.8 24.96 12.81 3 1/4 2092 12.5 418lbs/

115 9.0 51.92 27.54 6 1/3 3226 19 650lbs/

115 16.0 78.89 42.47 9 1/2 5465 24 830lbs/

Storage

Capacity

3

Ft

Reach-In Refrigerators - Hinged Doors - Narrow Width

Model Voltage Amps

SSR1N-S,SH

SAR1N-S,SH

SMR1N-S,SH

SSR1N-G,GH

SAR1N-G,GH

SMR1N-G,GH

SSR2N-S,SH

SAR2N-S,SH

SMR2N-S,SH

SSR2N-G,GH

SAR2N-G,GH

SMR2N-G,GH

115 6.8 20.97 10.59 3 1/4 2092 12.5 398lbs/

115 6.8 20.97 10.59 3 1/4 2092 12.5 398lbs/

115 9.0 43.94 23.10 6 1/3 3226 19 588lbs/

115 9.0 43.94 23.10 6 1/3 3226 19 588lbs/

Storage

Capacity

3

Ft

Shelf

Capacity

2

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

No. Of

Shelves

H.P. BTU/HR

H.P. BTU/HR

R-404A

Charge Oz.

R-404A

Charge Oz.

Shipping

Weight

190kg

295kg

376kg

Shipping

Weight

181kg

181kg

267kg

267kg

NEMA

Plug

5-15P 2.64

5-15P 4.51

5-20p 5.51

NEMA

Plug

5-15P 3.16

5-15P 4.04

5-15P 4.31

5-15P 5.95

Energy

(KWH)

Energy

(KWH)

Reach-In Refrigerators - Hinged Doors - Shallow Depth

Model Voltage Amps

SSR1S-S,SH

SAR1S-S,SH

SMR1S-S,SH

SSR1S-G,GH

SAR1S-G,GH

SMR1S-G,GH

SSR2S-S,SH

SAR2S-S,SH

SMR2S-S,SH

SSR2S-G,GH

SAR2S-G,GH

SMR2S-G,GH

SSR3S-S,SH

SAR3S-S,SH

SMR3S-S,SH

SSR3S-G,GH

SAR3S-G,GH

SMR3S-G,GH

115 6.8 18.25 12.81 3 1/4 2092 12.5 396lbs/

115 6.8 18.25 12.81 3 1/4 2092 12.5 396lbs/

115 7.8 37.96 27.54 6 1/3 2488 19 586lbs/

115 7.8 37.96 27.54 6 1/3 2488 19 586lbs/

115/

208-230

115 8.9 57.57 42.47 9 1/2 3637 17 795lbs/

Storage

Capacity

3

Ft

7.8 57.57 42.47 9 1/2 5465 24 795lbs/

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

R-404A

Charge Oz.

Shipping

Weight

180kg

180kg

266kg

266kg

361kg

361kg

NEMA

Plug

5-15P 2.66

5-15P 3.55

5-15P 2.98

5-15P 5.24

N/A 7.49

N/A 9.14

Energy

(KWH)

6

Specification Line

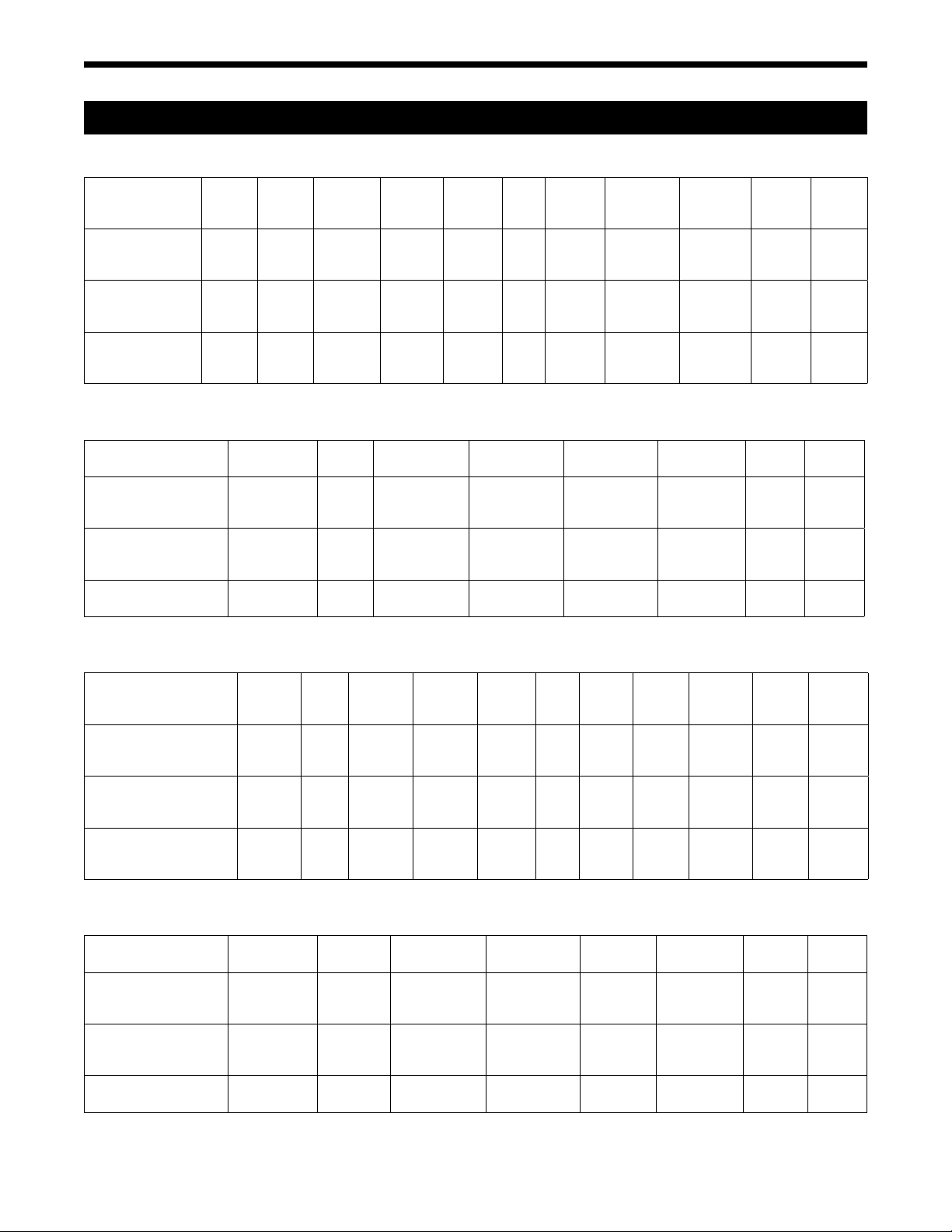

Specifications, continued

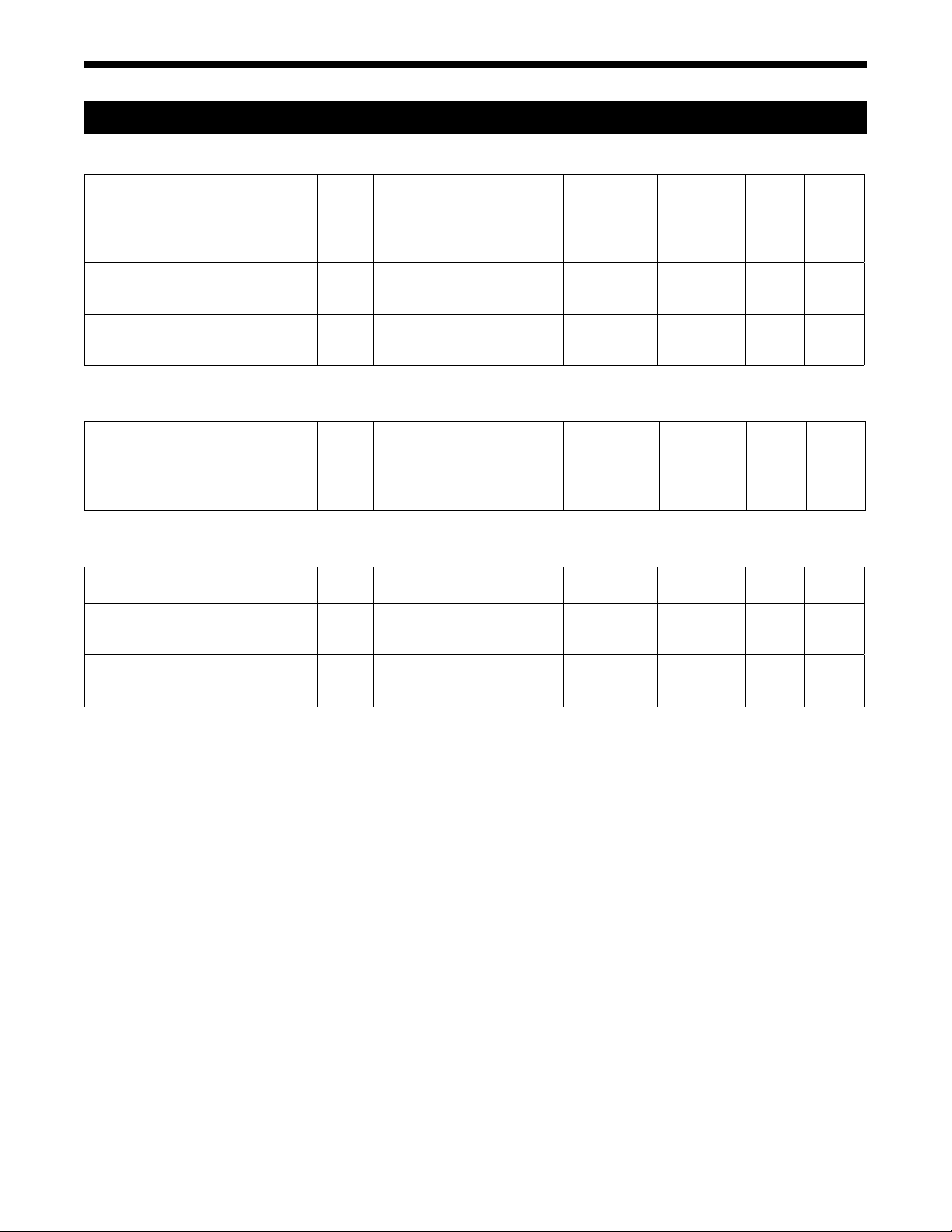

Reach-In Refrigerators - Sliding Doors

Model Voltage Amps

SSR2-SLS,SLSH,

115 9.0 51.92 27.54 6 1/3 3226 19 670lbs/

Capacity

3

Ft

SLG,SLGH

SAR2-SLS,SLSH,

SLG,SLGH

SMR2-SLS,SLSH,

SLG,SLGH

Storage

SSR2S-SLS,SLSH,

115 7.8 37.96 27.54 6 1/3 2488 12.5 670lbs/

SLG,SLGH

SAR2S-SLS,SLSH,

SLG,SLGH

SMR2S-SLS,SLSH,

SLG,SLGH

Reach-In Refrigerator/Freezer Combinations - Dual Temps - Hinged Doors - Standard Width & Depth

Model Section V Amps

SSDTR1-SH,

SSDBR1-SH,

SADTR1-SH,

SADBR1-SH,

SMDTR1-SH,

SMDBR1-SH

SSDTR1-GH,

SSDBR1-GH,

SADTR1-GH,

SADBR1-GH,

SMDTR1-GH,

SMDBR1-GH

SSDRL2-S,SH,G,GH

SSDFL2-S,SH,G,GH

SADRL2-S,SH,G,GH

SADFL2-S,SH,G,GH

SMDRL2-S,SH,G,GH

SMDFL2-S,SH,G,GH

Refrigerator 115 12.0 10.81 4.23 2 1/5 1543 11 525lbs/

Freezer 115 10.81 4.23 2 1/4 1260 12

Refrigerator 115 12.0 10.81 4.23 2 1/5 1543 11 525lbs/

Freezer 115 10.81 4.23 2 1/4 1260 12

Refrigerator 115 6.8 24.96 12.81 3 1/4 2092 12.5 730lbs/

Freezer 115 7.8 24.96 12.81 3 1/2 1516 12.5 5-15P

Shelf

Capacity

2

Ft

Storage

Capacity

3

Ft

No. Of

Shelves

Shelf

Capacity

2

Ft

H.P. BTU/HR

No. Of

Shelves

H.P.

R-404A

Charge Oz.

R-404A

BTU/

Charge

HR

Oz.

Shipping

Weight

304kg

304kg

Shipping

Weight

238kg

238kg

331kg

NEMA

Plug

(KWH)

5-15P N/A

5-15P N/A

Energy

NEMA

Plug

Energy

(KWH)

5-20P 6.95

5-20P N/A

5-15P N/A

Pass-Thru Refrigerator/Freezer Combinations - Dual Temps - Hinged Doors - Standard Width & Depth

Model Section V Amps

SSDTP1-SH,GH

Refrigerator 115 14.0 12.19 4.23 2 1/5 1543 10 525lbs/

SSDBP1-SH,GH

SADTP1-SH,GH

SADBP1-SH,GH

Freezer 115 12.19 4.23 2 1/3 1260 12

SMDTP1-SH,GH

SMDBP1-SH,GH

SSDRP2-S,SH,

Refrigerator 115 6.8 24.96 12.81 3 1/4 2092 19 730lbs/

SSDFP2-S,SH

SADRP2-S,SH,

SADFP2-S,SH

Freezer 115 11.5 24.96 12.81 3 3/4 1923 12.5 5-15P

SMDRP2-S,SH,

SMDFP2-S,SH

Storage

Capacity

3

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P.

BTU/

HR

R-404A

Charge

Oz.

Shipping

Weight

238kg

331kg

NEMA

Energy

Plug

(KWH)

5-20P N/A

5-15P N/A

7

Deleld

Specifications, continued

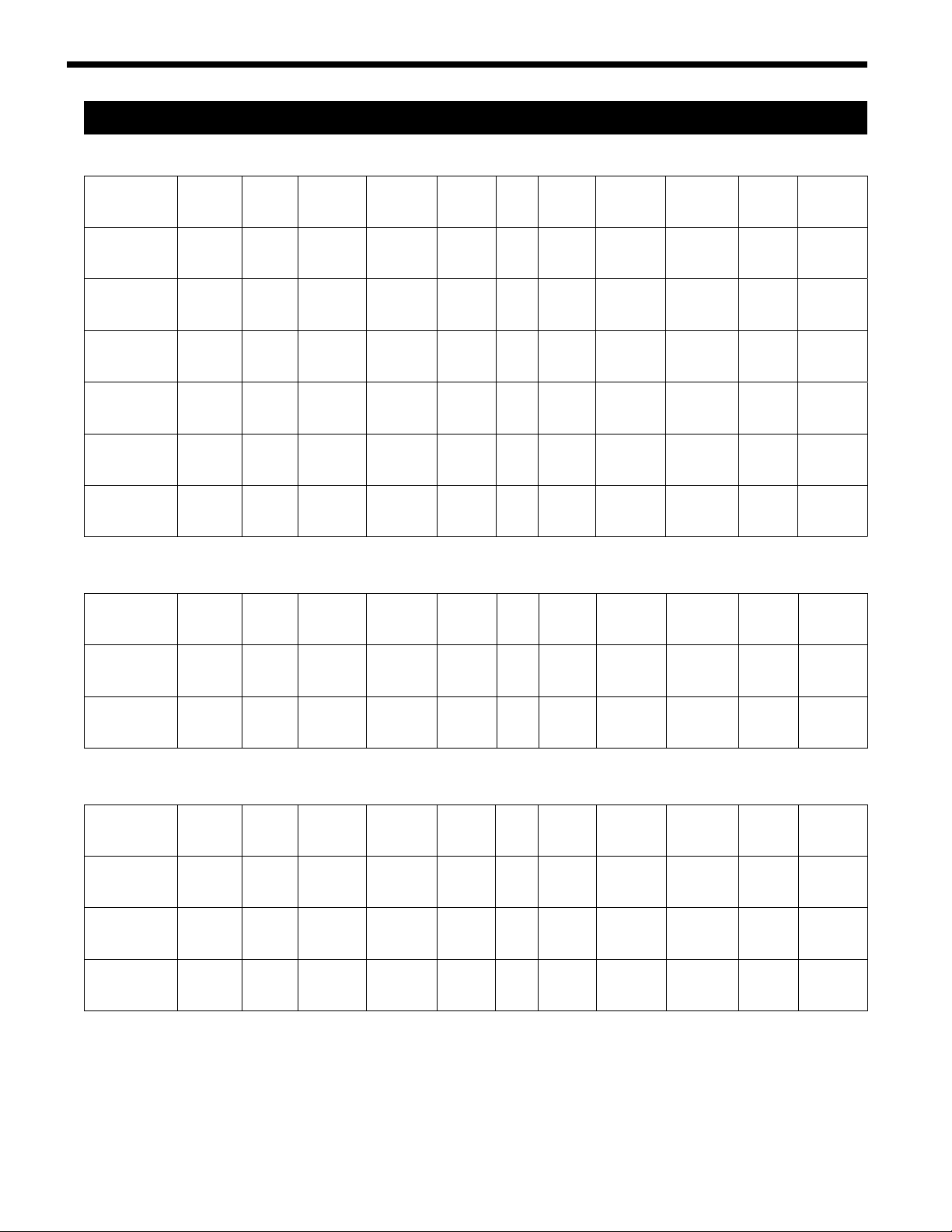

Reach-In Hot Food Cabinets - Hinged Doors - Standard Width & Depth

Model Voltage Amps

SSH1-S,SH,G,GH

SAH1-S,SH,G,GH

SMH1-S,SH,G,GH

SSH2-S,SH,G,GH

SAH2-S,SH,G,GH

SMH2-S,SH,G,GH

SSH3-S,SH,G,GH

SAH3-S,SH,G,GH

SMH3-S,SH,G,GH

120/208-240 9.0 24.96 12.81 3 418lbs/190kg N/A N/A

120/208-240 16.0 51.92 27.54 6 650lbs/295kg N/A N/A

120/208-240 17.8 78.89 42.47 9 830lbs/376kg N/A N/A

Storage

Capacity Ft

Reach-In Hot Food Cabinets - Hinged Doors - Narrow Width

Model Voltage Amps

SSH2N-S,SH

SAH2N-S,SH

SMH2N-S,SH

120/208-240 16.0 43.94 27.54 6 588lbs/267kg N/A N/A

Storage

Capacity Ft

Shelf Capacity

3

Shelf Capacity

3

2

Ft

2

Ft

No. Of Shelves

No. Of Shelves

Shipping

Weight

Shipping

Weight

NEMA

Plug

NEMA

Plug

Energy

(KWH)

Energy

(KWH)

Pass-Thru Hot Food Cabinets - Hinged Doors - Standard Width & Depth

Model Voltage Amps

SSHPT1-S,SH

SAHPT1-S,SH

SMHPT1-S,SH

SSHPT2-S,SH

SAHPT2-S,SH

SMHPT2-S,SH

Storage

Capacity Ft

120/208-240 9.0 26.96 12.81 3 398lbs/181kg N/A N/A

120/208-240 16.0 51.92 27.54 6 650lbs/295kg N/A N/A

Shelf Capacity

3

2

Ft

No. Of Shelves

Shipping

Weight

NEMA

Plug

Energy

(KWH)

8

Specification Line

Specifications, continued

Reach-In Freezers - Hinged Doors - Standard Width & Depth

Model Voltage Amps

SSF1-S,SH

115 7.8 24.96 12.81 3 1/2 1516 12.5 440lbs/

SAF1-S,SH

SMF1-S,SH

SSF1-G,GH

115 11.5 24.96 12.81 3 3/4 1923 12.5 440lbs/

SAF1-G,GH

SMF1-G,GH

SSF2-S,SH

115 14.3 51.92 27.54 6 3/4 2648 17 710lbs/

SAF2-S,SH

SMF2-S,SH

SSF2-G,GH

SAF2-G,GH

115/

208-230

SMF2-G,GH

SSF3-S,SH

SAF3-S,SH

115/

208-230

SMF3-S,SH

SSF3-G,GH

SAF3-G,GH

115/

208-230

SMF3-G,GH

Storage

Capacity

3

Ft

10.0 51.92 27.54 6 1 4793 30 710lbs/

10.0 78.89 42.47 9 1 4793 30 960lbs/

11.4 78.89 42.47 9 1 5940 72 960lbs/

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

R-404A

Charge

Oz.

Shipping

Weight

200kg

200kg

322kg

322kg

435kg

435kg

NEMA

Plug

Energy

(KWH)

5-15p 7.63

5-15p 11.29

5-20P 15.16

N/A 19.95

N/A 16.26

N/A 29.07

Reach-In Freezers - Hinged Doors - Narrow Width

Model Voltage Amps

SSF1N-S,SH

115 7.8 20.97 10.59 3 1/2 1516 12.5 408lbs/

SAF1N-S,SH

SMF1N-S,SH

SSF2N-S,SH

115 14.3 43.94 23.10 6 3/4 2648 17 680lbs/

SAF2N-S,SH

SMF2N-S,SH

Storage

Capacity

3

Ft

Shelf

Capacity

2

Ft

Reach-In Freezers - Hinged Doors - Shallow Depth

Model Voltage Amps

SSF1S-S,SH

115 7.8 18.25 8.98 3 1/2 1516 12.5 406lbs/

SAF1S-S,SH

SMF1S-S,SH

SSF2S-S,SH

115 11.5 37.96 19.04 6 3/4 1923 17 676lbs/

SAF2S-S,SH

SMF2S-S,SH

SSF3S-S,SH

SAF3S-S,SH

115/

208-230

SMF3S-S,SH

Storage

Capacity

3

Ft

11.5 57.67 29.10 9 1 4793 30 909lbs/

Shelf

Capacity

2

Ft

No. Of

Shelves

No. Of

Shelves

H.P. BTU/HR

H.P. BTU/HR

R-404A

Charge

Oz.

R-404A

Charge

Oz.

Shipping

Weight

185kg

308kg

Shipping

Weight

184kg

307kg

412kg

NEMA

Plug

Energy

(KWH)

5-15p 7.58

5-20P 11.13

NEMA

Plug

Energy

(KWH)

5-15p 8.04

5-15P 10.55

N/A 19.78

9

Deleld

Specifications, continued

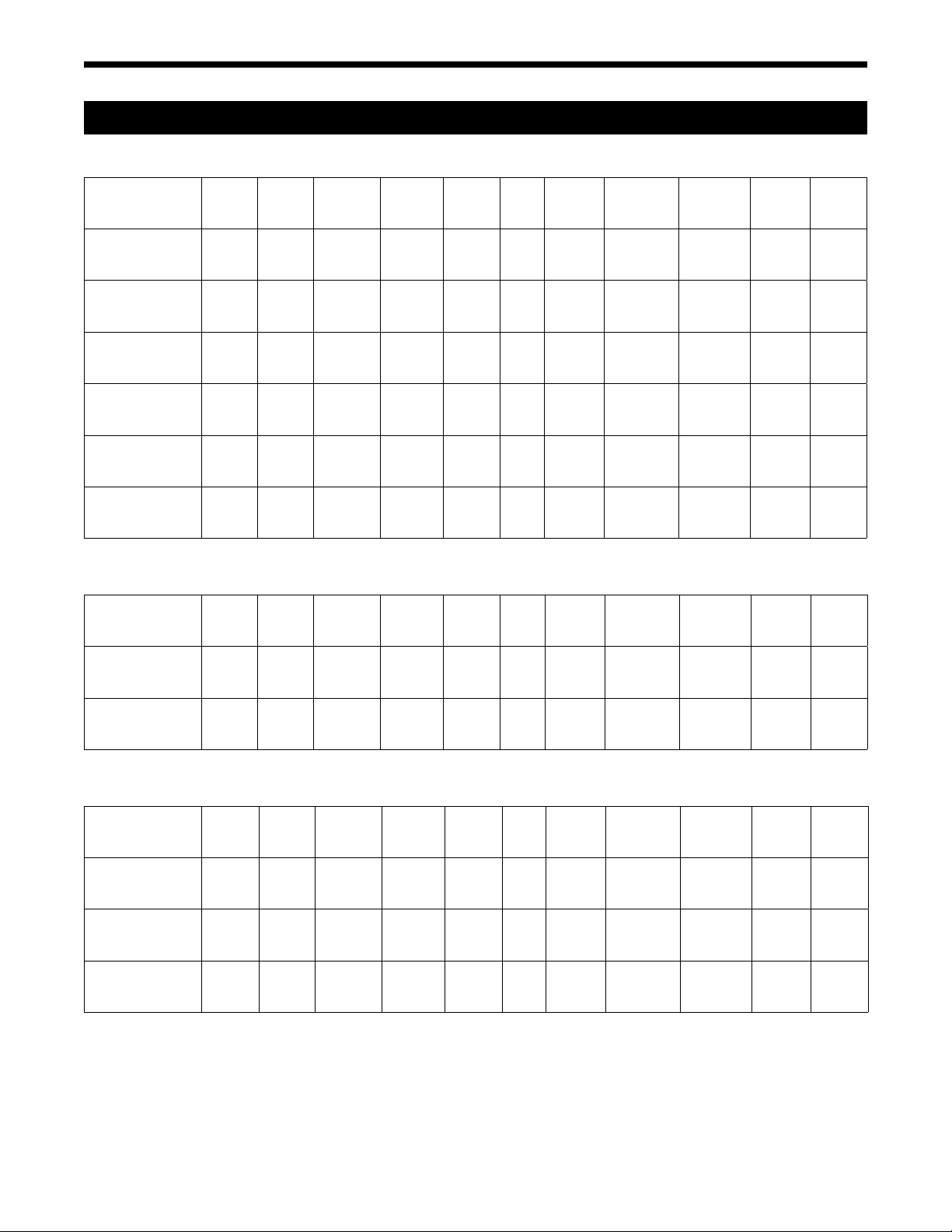

Pass-Thru Refrigerators - Hinged Doors - Standard Width

Model Voltage Amps

SSRPT1-S,SH

SARPT1-S,SH

SMRPT1-S,SH

SSRPT1-G,GH

SARPT1-G,GH

SMRPT1-G,GH

SSRPT2-S,SH

SARPT2-S,SH

SMRPT2-S,SH

SSRPT2-G,GH

SARPT2-G,GH

SMRPT2-G,GH

SSRPT3-S,SH

SARPT3-S,SH

SMRPT3-S,SH

SSRPT3-G,GH

SARPT3-G,GH

SMRPT3-G,GH

115 6.8 26.64 12.81 3 1/4 2092 12.5 455lbs/

115 7.8 26.64 12.81 3 1/3 2488 12.5 455lbs/

115 16.0 55.42 27.54 6 1/2 5465 24 700lbs/

115 16.0 55.42 27.54 6 1/2 5465 24 700lbs/

115 16.0 84.19 42.47 9 1/2 5465 24 972lbs/

115/

208-230

Storage

Capacity

3

Ft

12.4 84.19 42.27 9 3/4 7569 48 972lbs/

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

R-404A

Charge Oz.

Shipping

Weight

206kg

206kg

318kg

318kg

441kg

441kg

NEMA

Plug

5-15P 3.14

5-15P 4.58

5-20P 5.96

5-20P 8.16

N/A 8.84

N/A 14.50

Energy

(KWH)

Pass-Thru Refrigerators - Hinged Doors - Shallow Depth

Model Voltage Amps

SSRPT1S-S,SH

SARPT1S-S,SH

SMRPT1S-S,SH

SSRPT2S-S,SH

SARPT2S-S,SH

SMRPT2S-S,SH

115 7.8 18.25 8.98 3 1/3 2488 12.5 455lbs/

115 16.0 37.96 19.04 6 1/2 5465 24 700lbs/

Storage

Capacity

3

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

Pass-Thru Freezers - Hinged Doors - Standard Width

Model Voltage Amps

SSFPT1-S,SH

SAFPT1-S,SH

SMFPT1-S,SH

SSFPT2-S,SH

SAFPT2-S,SH

SMFPT2-S,SH

SSFPT3-S,SH

SAFPT3-S,SH

SMFPT3-S,SH

115 11.5 26.64 12.81 3 3/4 1923 12.5 672lbs/

115/

208-230

115/

208-230

Storage

Capacity

3

Ft

10.0 55.42 27.54 6 1 4793 30 1001lbs/

10.0 84.19 42.27 9 1-1/2 5185 64 1268lbs/

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

H.P. BTU/HR

R-404A

Charge Oz.

R-404A

Charge Oz.

Shipping

Weight

206kg

318kg

Shipping

Weight

305kg

454kg

575kg

NEMA

Plug

5-15P N/A

5-20P N/A

NEMA

Plug

5-15p 11.30

N/A 14.26

N/A 33.00

Energy

(KWH)

Energy

(KWH)

10

Specification Line

Specifications, continued

Wine Cabinet Reach-In - Hinged Doors - Standard Width & Depth

Model Voltage Amps

SSW1-S, SH, G, GH

115 6.8 24.96 12.81 3 1/4 2092 12.5 418lbs/

Capacity

3

Ft

SAW1-S, SH, G, GH

SMW1-S, SH, G, GH

Storage

SSW2-S, SH, G, GH

115 9.0 51.92 27.54 6 1/3 3226 19 650lbs/

SAW2-S, SH, G, GH

SMW2-S, SH, G, GH

SSW3-S, SH, G, GH

115 16.0 78.89 42.47 9 1/2 5465 24 830lbs/

SAW3-S, SH, G, GH

SMW3-S, SH, G, GH

Fish Drawer Reach-In - Four Fish Drawers Per Section

Model Voltage Amps

SSRFF1 115 6.8 24.96 N/A N/A 1/4 2092 12.5 418lbs/

SSRFF2 115 9.0 51.92 N/A N/A 1/3 3226 19 650lbs/

Storage

Capacity

3

Ft

Shelf

Capacity

2

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

No. Of

Shelves

H.P. BTU/HR

H.P. BTU/HR

R-404A

Charge Oz.

R-404A

Charge Oz.

Shipping

Weight

190kg

295kg

376kg

Shipping

Weight

190kg

295kg

NEMA

Plug

Energy

(KWH)

5-15P N/A

5-15P N/A

5-20P N/A

NEMA

Plug

Energy

(KWH)

5-15P N/A

5-15P N/A

Roll-In Refrigerators

Model Voltage Amps

SSRRI1-S

SARRI1-S

SMRRI1-S

SSRRI1-G

SARRI1-G

SMRRI1-G

SSRRI2-S

SARRI2-S

SMRRI2-S

SSRRI2-G

SARRI2-G

SMRRI2-G

SSRRI3-S

SARRI3-S

SMRRI3-S

SSRRI3-G

SARRI3-G

SMRRI3-G

208-230

Storage

Capacity

3

Ft

Shelf

Capacity

2

Ft

No. Of

Shelves

H.P. BTU/HR

R-404A

Charge Oz.

Shipping

Weight

115 6.8 36.15 N/A N/A 1/4 2092 12.5 476lbs/

216kg

115 7.8 36.15 N/A N/A 1/3 2488 12.5 476lbs/

216kg

115 9.0 74.72 N/A N/A 1/3 3226 24 768lbs/

348kg

115 16.0 74.72 N/A N/A 1/2 5465 24 768lbs/

348kg

115 16.0 113.28 N/A N/A 1/2 5465 24 1044lbs/

4774kg

115/

10.0 113.28 N/A N/A 3/4 6920 48 1044lbs/

4774kg

NEMA

Plug

Energy

(KWH)

5-15P 3.79

5-15P 5.46

5-15P 5.86

5-20P 9.28

5-20p 7.56

N/A 17.12

11

Deleld

Specifications, continued

Roll-In Freezers

Model Voltage Amps

SSFRI1-S

115 7.8 36.15 N/A N/A 1/2 1516 12.5 497lbs/

Capacity

3

Ft

SAFRI1-S

SMFRI1-S

Storage

SSFRI2-S

SAFRI2-S

115/

208-230

10.0 74.12 N/A N/A 1 4793 30 824lbs/

SMFRI2-S

SSFRI3-S

SAFRI3-S

115/

208-230

11.8 113.28 N/A N/A 1-1/2 5394 64 1128lbs/

SMFRI3-S

Hot Food Roll-Ins

Model Voltage Amps

SSHRI1-S,G

SAHRI1-S,G

SMHRI1-S,G

SSHRI2-S, G

SAHRI2-S, G

SMHRI2-S, G

SSHRI3-S, G 120/208-240 17.8 113.28 N/A N/A 1008lbs/

120/208-240 9.0 36.15 N/A N/A 459lbs/

120/208-240 16.0 74.72 N/A N/A 704lbs/

Shelf

Capacity

2

Ft

Storage

Capacity Ft

No. Of

Shelves

3

H.P. BTU/HR

Shelf

Capacity Ft

No. Of Shelves

2

R-404A

Charge Oz.

Shipping

Weight

Shipping

Weight

208kg

319kg

457kg

225kg

374kg

512kg

NEMA

Plug

Energy

(KWH)

5-15p 11.57

N/A 21.02

N/A 25.70

NEMA

Plug

Energy

(KWH)

N/A N/A

N/A N/A

N/A N/A

Roll-Thru Refrigerators - Hinged Doors

Storage

Capacity

Ft

11.3 120.90 N/A N/A 3/4 7569 48 1116lbs/

SSRRT1-S

SARRT1-S

SMRRT1-S

SSRRT2-S

SARRT2-S

SMRRT2-S

SSRRT3-S

SARRT3-S

SMRRT3-S

Model Voltage Amps

115 7.8 38.58 N/A N/A 1/3 2488 12.5 514lbs/

115 16.0 79.74 N/A N/A 1/2 5465 24 776lbs/

115/

208-230

Roll-Thru Hot Food Cabinets - Hinged Doors

Model Voltage Amps

SSHRT1-S

SAHRT1-S

SMHRT1-S

SSHRT2-S

SAHRT2-S

SMHRT2-S

SSHRT3-S

SAHRT3-S

120/208-240 9.0 38.58 N/A N/A 519lbs/

120/208-240 16.0 79.74 N/A N/A 836lbs/

120/208-240 17.8 120.90 N/A N/A 985lbs/

3

Capacity Ft

Shelf

Capacity

Ft

Storage

2

3

No. Of

Shelves

Shelf Capacity

2

Ft

H.P.

BTU/

HR

No. Of

Shelves

R-404A

Charge

Oz.

Shipping

Weight

233kg

352kg

506kg

Shipping

Weight

235kg

379kg

447kg

NEMA

Plug

Energy

(KWH)

5-15P 3.97

5-20P 6.77

N/A 8.01

NEMA

Plug

Energy

(KWH)

N/A N/A

N/A N/A

N/A N/A

12

Loading...

Loading...