Page 1

Sheldon Water

Purification Kit

Installation Guide

SWPK

SHELDON WATER PURIFICATION KIT

Page 2

SWPK INSTALLATION

Revised: May 8, 2014

Part Number (Guide): 9920698

Sheldon Manufacturing

300 N. 26th Ave

Cornelius, OR 97113

EMAIL: tech@shellab.com

PHONE 1-800-322-4897

(503) 640-3000

INTRODUCTION

The SWPK Sheldon Water Purification Kit is designed to remove particulates and calcium from

water sources for the SHC10, SCH10R, SHC28, and SHC28R Humidity Chambers and their 230

volt variants, as well as the SCO26H and SCO26H-2 Humidified CO2 Incubators*. The kit also

adjusts water pH and water resistance to levels that will not corrode the units’ interiors, or adversely

affect the performance of steamers and other major components. This installation guide covers how

to install the SWPK.

*These units were previously designated the HC9, HC9R, HC30, HC30R, and 2428H.

TAP WATER

This purification kit is intended to purify standard tap water. Do not connect it to a deionized water

source. Use of deionized water will likely cause corrosive damage to major functional components

and the metal interior surfaces of humidity chambers and humidified CO2 Incubators.

WATER OUTPUT EXPECTATION

18 megohm-cm of resistivity can be achieved with the SWPK. The Absorber filter removes free

chlorine, organics, phosphate complexes, and turbidity. The Universal filter removes ionizable

constituents, except free carbon dioxide and silica. The Universal filter reduces the ion

concentration level equivalent to a single distillation.

WATER PRESSURE

The SWPK is designed to work with tap water sources that provide 60 – 70 Pounds per Square

Inch of water pressure. Do not connect the SWPK to sources that exceed 120 PSI!

The regulator should be set to supply 5 PSI to the water filters.

2 | P a g e

Page 3

Component

Part Number*

Box Cover

5431008

4.57m (15ft) of Tubing, ¼ inch OD

8500516

Filter Cartridge Absorber

Assembly (Replacement)

2800534

Filter Cartridge Assembly

Universal (Replacement)

2800533

Push-to-Connect Fitting 1/8 Inch

NPT, for ¼ Inch OD Tubing

3100795

Push-to-Connect Fitting 1/4 Inch

NPT, for ¼ Inch OD Tubing

3100796

Push-to-Connect Elbow, 1/8 Inch

NPT Pipe, for ¼ Inch OD Tubing

3100791

2 Quick Release Pins

3800633

4 Self-Tapping Sheet Metal

Screws

7360536

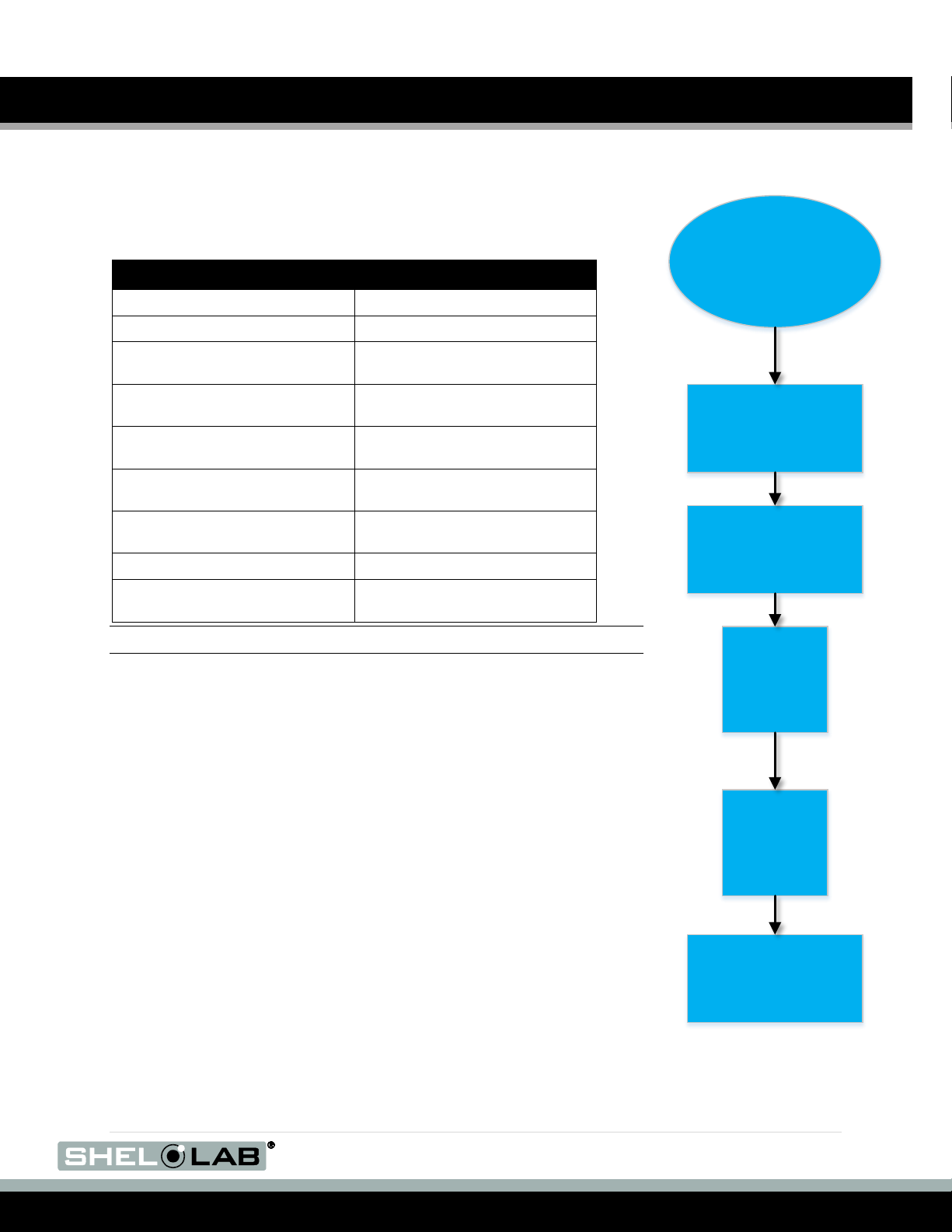

Water Source

Regulator

Absorber

Filter

Universal

Filter

Push-to-Connect

Fitting

(Back of the Unit)

Valve

Water Flow

SWPK INSTALLATION

COMPONENTS

The SWPK Assembly comes provided with the following components:

Note: All parts numbers may be subject to future revisions.

WATER TUBING

The SWPK is provided with a length of approximately 4.57 meters (15 feet)

of black, 1/8 inch ID ¼ inch OD tubing. This tubing is intended to be cut by

the end-user. It should be used to connect the SPWK output to the push-toconnect adaptor on the incubator or humidity cabinet.

A section of the line can also be used to connect the chamber’s or

incubator’s condensation drain to a collection vessel or drainage system.

The end-user is responsible for providing an adaptor and tubing to connect

their water source to the SWPK’s ¼ inch push-to-connect regulator.

Please see the plumbing diagram on the next page.

3 | P a g e

Page 4

Replacement Line

SWPK INSTALLATION

Plumbing Diagram

FILTER REPLACEMENT

The black Absorber filter is an active charcoal filter. It will last six (6)

months to (1) one year depending on the water quality of your laboratory or

workspace water source, and the humidity setting of the incubator or

humidity cabinet.

The mix-colored universal filter will gradually turn yellow, starting at the

top, and moving to the bottom while in use. The filter’s lifespan is highly

dependent on local water quality, and the filter should be replaced when it

has turned yellow down to the blue replacement line on the filter’s label.

4 | P a g e

Page 5

SWPK INSTALLATION

INSTALLATION PROCEDURE

Complete the steps below (described in detail on the following pages) to install the SWPK:

1. Install the Water Filters

2. Mount the SWPK Assembly on the Unit

3. Connect the Water Input Line to the Filter

4. Connect the Water Output Line to the Filter

5. Secure the Water Output Line

6. Threading the Water Input and Output Lines

7. Mount the Protective Box Cover

8. Secure the Protective Box Cover

9. Install a Push-To-Connect Fitting

10. Connect Output Line to Unit

11. Connect to Water Source

12. Connect the Condensation Drainage Line

5 | P a g e

Page 6

Figure 1: SWPK Assembly

Installing the Universal Filter

Steps 1 and 2

SWPK INSTALLATION

1) INSTALL THE WALTER FILTERS

Install the Walter Filters on the SPWK Assembly

1. Insert the top nipple of the light colored Universal Filter into

the receiving nut on the top right side of the SWPK

Assembly

Figure 2: Details of Step 1

2. Insert the bottom nipple of the Universal Filter into the

receiving slot at the bottom of the Assembly.

Figure 3: Details of Step 2 and 3

3. Turn the disk-shaped Finger Adjustment Nut on the bottom receiver clockwise. This will

exert pressure on the filter, mating the top and bottom nipples to their receivers. Tighten

using finger strength until the disk will no longer turn.

4. Repeat the above steps for installing the black Absorber Filter on the left side of the SWPK

Assembly.

6 | P a g e

Page 7

SWPK INSTALLATION

2) MOUNTING THE SWPK

The SWPK unit can be mounted on your laboratory or workspace wall, or on a Sheldon humidified

chamber or incubator. Four (4) self-tapping sheet metal screws are included with each SWPK for

mounting on Sheldon units. Verify that there are no critical components, electrical wires, or fluid

containment vessels beneath the drilling site. Always depower and unplug the unit prior to drilling.

If mounting on a wall or other alternative surface, please contact your facilities department for the

appropriate fasteners.

Figure 4: SWPK Assembly Mounted

(SCO26H / 2428H Incubator)

7 | P a g e

Page 8

SWPK INSTALLATION

3) CONNECT THE WATER INPUT LINE

1. Connect your water input line to the Regulator on the top of the Purification Kit.

Figure 5: Water Input Line Connected to Regulator

2. A section of the included ¼ inch outside dimension tubing may be used for this step.

3. Do not connect the input line to a water source, yet. This will be one of the final steps in the

installation process.

4) CONNECT THE WATER OUTPUT LINE

1. Connect your water output line to the compression fitting of the push-to-connect elbow on

the bottom of the Universal Water Filter body.

Note: Use of one hand to support the push connect elbow when inserting the water line into the

compression fitting is strongly recommended. Too much force may damage the elbow.

Figure 6: Output Line Connected

8 | P a g e

Page 9

SWPK INSTALLATION

2. A section of the included ¼ inch outside dimension tubing may be used for this step.

3. Do not connect the output line to a water source, yet. This will be one of the final steps in

the installation process.

5) SECURE THE WATER OUTPUT LINE

1. Feed the water output line into the support clip located on the left side of the water filter

assembly, adjacent to the Absorber Filter.

Figure 7: Water Output Line Secured

6) THREADING THE WATER INPUT AND OUTPUT LINES

Note: One person should hold the protective box cover of the SWPK near the mounted Filter

Assembly during this step. The other should thread the water lines through it.

1. Thread the water output and input lines through the hole in the protective cover box, on the

top left side of the box.

Figure 8: Water Lines Threaded

9 | P a g e

Page 10

Figure 10: Left Side QR Pin

SWPK INSTALLATION

7) MOUNT THE COVER BOX

1. Locate the slot on the top of the Cover Box.

2. Locate the mounting tab on the top of the SWPK Assembly.

3. Mate the slot on the Box to the tab on the Assembly, so that the Cover Box hangs off the

top of the SWPK Assembly.

Figure 9: Cover Box Mounted

8) SECURE THE COVER BOX

1. Insert the two (2) included Quick Release Pins into their mounting holes on the left and

right sides, at the bottom of the Cover Box.

2. The Pins should pass through both the holes in the Cover Box and the corresponding

mounting holes in the SWPK Assembly.

10 | P a g e

Page 11

Figure 11: Push-to-Connect

Fittings

Figure 12: Stabilizing the

Solenoid During Compression

Fitting Removal

SWPK INSTALLATION

9) INSTALL A PUSH-TO-CONNECT FITTING

The SWPK comes provided with two steel push-to-connect fittings to

replace the copper compression fitting on the back of your humidifier or

incubator. See Figure 11. The push-to-connect fittings allow the output

OD tubing from the water filter to be connected to the unit’s water

injection solenoid.

1. Remove the top cover of the chamber or incubator to access

the water injection solenoid in the control box (the space on top

of the unit where the major electrical components are housed.)

2. Use one wrench inside the control box to stabilize the solenoid.

At the same time, use a second wrench to loosen and remove

the exterior compression fitting that came with your unit. See

Figure 12.

3. Install the push-to-connect fitting (1) on the outside of the unit

that fits the solenoid.

a. Use of thread seal tape (aka PTFE thread tape) on

the threads of the push-to-connect fitting is

recommended to form a durable and tight seal.

b. Use two wrenches when tightening the push-to-

connect fitting. One to tighten, and one to stabilize

the solenoid in the control box.

10) CONNECT THE OUTPUT LINE TO UNIT

1. Make sure that the end of the SWPK’s OD output tubing is cut

so that it forms and even, straight end.

2. Insert the output line into the chamber or incubator’s newly installed exterior push-toconnect fitting.

Note: To remove the OD tubing from the push-to-connect fitting, hold down the sliding ring on the

end of the fitting that mates with the tubing. Then withdraw the line.

11) CONNECT TO WATER SOURCE

1. Connect the SWPK’s Water Input Line to your workspace tap water source.

Note: Do not connect to a deionized water source!

11 | P a g e

Page 12

SWPK INSTALLATION

12) CONNECT THE CONDENSATION DRAIN LINE

A section of the included ¼ inch OD tubing can be used to connect the chamber’s or incubator’s

condensation drain to a collection vessel or drainage system.

1. Connect a water line to the press-to-connect fitting located on the back of the unit.

2. Connect the line to a drainage collection vessel or drainage system.

3. The drain is gravity fed. It is important that the receiving receptacle is located below the

level of the incubator’s or cabinet’s drain valve, and the line travels downward. Otherwise

water will collect inside the unit.

Figure 13: Condensation Drain Compression Fitting

FINISHED

Step 12 concludes the SWPK installation procedure.

12 | P a g e

Page 13

Loading...

Loading...