Page 1

WATER BATHS

MODELS:

SWB2 / SWB2-2

SWB7 / SWB7-2

SWB15 / SWB15-2

SWB23 / SWB23-2

SWB715 / SWB 715-2

Previously known as

W2M / W2M-2,

W6M / W6M-2,

W14M / W14M-2,

W20M / W20M-2,

W614M / W614M-2

115v/220v and PC Models

MICROPROCESSOR CONTROLLED

INSTALLATION AND OPERATION MANUAL

Revised: November 13, 2013

4861626

Page 2

These units are TUV CUE listed as water baths for professional, industrial or educational use where the

preparation or testing of materials is done at approximately atmospheric pressure and no flammable,

volatile or combustible materials are being heated. These units have been tested to the following

requirements:

CAN/CSA C22.2 No. 61010-1:2012

CAN/CSA C22.2 No. 61010-2-010 + R:2009

UL 61010-1:2004 + R:2005-07 + R:2008-10

UL 61010A-2-010:2002

UL 61010-1:2012

EN 61010-1:2010

EN 61010-2-010:2003

IEC 61010-1:2010

IEC 61010-2-010:2003

Sheldon Manufacturing Inc.

P.O. Box 627

Cornelius, Oregon 97113

EMAIL: tech@Shellab.com

INTERNET: http://www.Shellab.com

PHONE: 1-800-322-4897 (503) 640-3000

FAX: (503) 640-1366

2 Microprocessor Control Water Baths

Page 3

3

TABLE OF CONTENTS

INTRODUCTION ........................................................................................................................................... 4

General Safety Considerations ........................................................................................................ 4

RECEIVING YOUR UNIT .............................................................................................................................. 5

Inspection Guidelines ....................................................................................................................... 5

Returning Shipment.......................................................................................................................... 5

Recording Data Plate Information .................................................................................................... 5

GRAPHIC SYMBOLS .................................................................................................................................... 6

INSTALLATION ............................................................................................................................................. 7

Environmental Conditions ................................................................................................................ 7

Power Source ................................................................................................................................... 7

Location ............................................................................................................................................ 7

Lifting and Handling .......................................................................................................................... 7

Cleaning and Decontamination ........................................................................................................ 7

CONTROLS OVERVIEW .............................................................................................................................. 8

Power Switch .................................................................................................................................... 8

Main Temperature Controller ........................................................................................................... 8

Fuses................................................................................................................................................ 8

Over Temperature Limit Thermostat (OTL) ..................................................................................... 8

Heating Activated ............................................................................................................................. 8

Over Temperature Activated Light ................................................................................................... 8

OPERATION ................................................................................................................................................. 9

Turning On the Unit .......................................................................................................................... 9

Setting Main Temperature Control ................................................................................................... 9

Calibrating the Main Temperature Control ....................................................................................... 9

Setting the Overtemperature Limit Thermostat .............................................................................. 10

Bath Cover Assembly ..................................................................................................................... 10

MAINTENANCE .......................................................................................................................................... 11

Cleaning ........................................................................................................................................ 11

Disinfecting ................................................................................................................................... 11

Heating and Water Level ................................................................................................................ 11

Test-tube Racks ............................................................................................................................. 12

TROUBLESHOOTING ................................................................................................................................ 13

Service ........................................................................................................................................... 14

PARTS LIST ................................................................................................................................................ 15

UNIT SPECIFICATIONS ............................................................................................................................. 17

SCHEMATICS ............................................................................................................................................. 20

Microprocessor Control Water Baths

Page 4

Section

1

INTRODUCTION

Thank you for choosing a general purpose water bath. These units are not intended for use at hazardous or

household locations.

Before you use the unit, read this entire manual carefully to understand how to install, operate, and maintain the unit

in a safe manner. Your satisfaction with the unit will be maximized as you read about its safety and operational

features.

Keep this manual on-hand so it can be used by all operators of the unit. Be sure all operators of the unit are given

appropriate training before you put the unit in service.

Note: Use the unit only in the way described in this manual. Failure to follow the guidelines and

instructions in this manual may be dangerous and illegal.

General Safety Considerations

Your water bath and its recommended accessories have been designed and tested to meet strict safety

requirements.

For continued safe operation of your water bath, always follow basic safety precautions including:

Read this entire manual before using the water bath.

Be sure you follow any city, county, or other ordinances in your area regarding the use of this unit.

Use only approved accessories. Do not modify system components. Any alterations or modifications

to your water bath may be dangerous and will void your warranty.

Always plug the unit’s power cord into a grounded electrical outlet that conforms to national and local

electrical codes. If the unit is not grounded, parts such as knobs and controls may conduct electricity

and cause serious injury.

Do not connect the unit to a power source of any other voltage or frequency beyond the range stated

on the power rating overlay at the rear of the unit.

Do not modify the power cord provided with the unit. If the plug does not fit an outlet, have a proper

outlet installed by a qualified electrician.

Avoid damaging the power cord. Do not bend it excessively, step on it, place heavy objects on it. A

damaged cord can easily become a shock or fire hazard. Never use a power cord after it has become

damaged.

Do not position equipment in a manner that prohibits access to power cord.

Do not attempt to move the unit during operation or before the unit has been allowed to cool.

Microprocessor Control Water Baths 4

Page 5

Model Number

Serial Number

Part Number

Voltage

Section

2

RECEIVING YOUR UNIT

Before leaving our factory, all units are packaged in high quality shipping materials designed to provide

protection from transportation related damage.

Once a unit leaves our factory, safe delivery becomes the responsibility of the carrier who is liable for loss

or damage to your unit. Damage sustained during transit is not covered under your unit warranty.

When you receive your unit, inspect it for concealed loss or damage to its interior and exterior. Should you

find any damage to the unit, follow the carrier’s procedure for claiming damage or loss.

Inspection Guidelines

Carefully inspect the shipping carton for damage. If the carton is damaged, report the damage to the

carrier service that delivered the unit.

If the carton is not damaged, open the carton and remove its contents. Verify that all of the following

equipment is included in the crate:

One (1) water bath

One (1) bath cover, two (2) for SWB715 & SWB715-2 (W614M W614M-2)

One (1) magnetic thermometer clip

One (1) power cord

Carefully check all packaging before discarding. Save the shipping carton until you are sure everything is

in order.

Returning Shipment

If you must return the unit for any reason, first contact your service representative for authorization. You

will be asked to provide the data plate information. See Recording Data Plate Information.

Recording Data Plate Information

Once you have determined the unit is free from damage, locate the data plate at the back of the unit. The

data plate indicates your unit’s model number and serial number. Record this information below for future

reference.

Table 1. Data Plate Information

5 Microprocessor Control Water Baths

Page 6

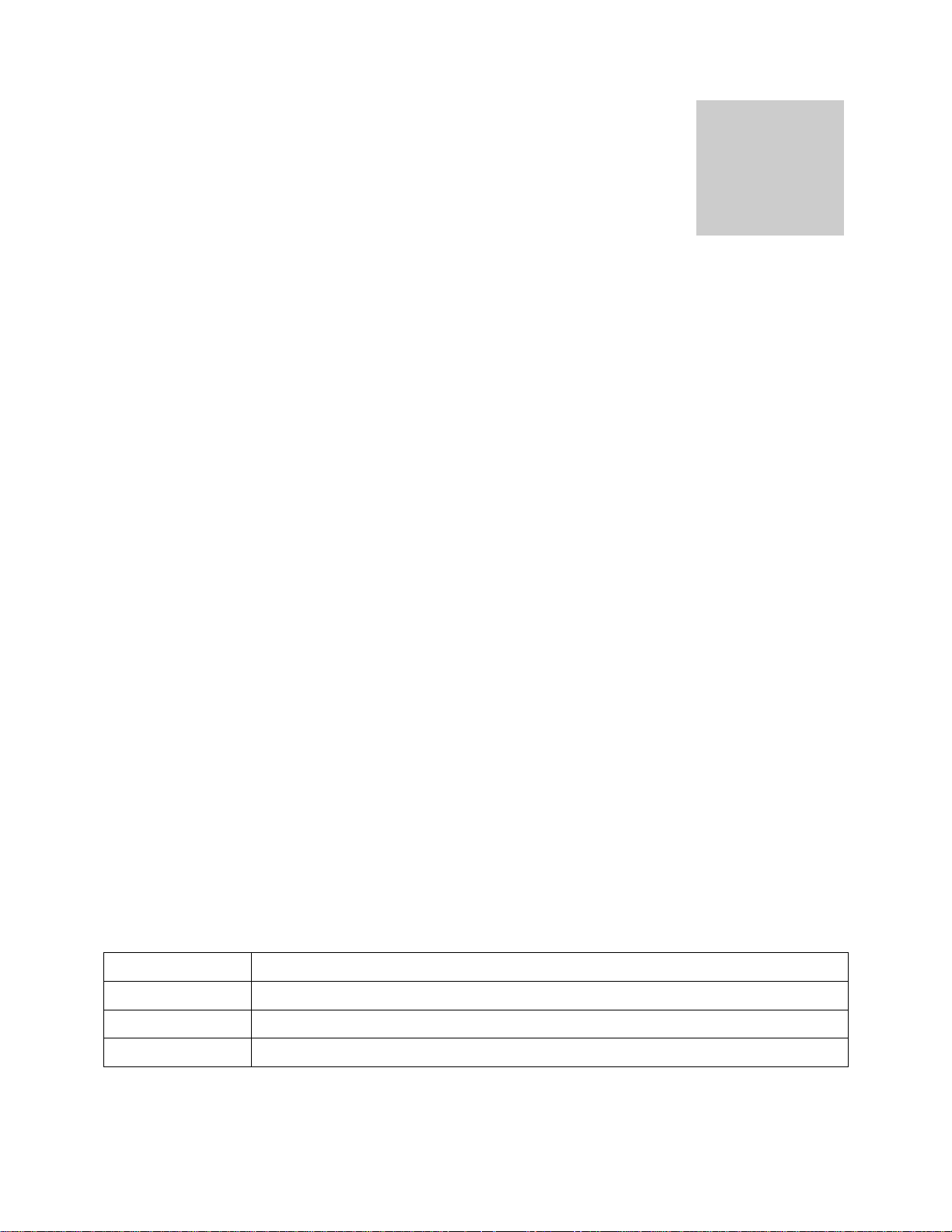

Symbol

Identification

Indicates that you should consult your operator’s manual for further instructions.

Indique que l'opérateur doit consulter le manuel d'utilisation pour y trouver les instructions

complémentaires.

Indicates “Temperature”

Repère "température"

Indicates “Over Temperature Protection”

Signale un "dépassement de température"

Indicates “AC Power”

Repère "secteur AC"

I

Indicates the power is “ON”

Repère de la position "MARCHE" de l'interrupteur d'alimentation

O

Indicates the power is “OFF”

Repère de la position "ARRÊT" de l'interrupteur d'alimentation

Indicates “Protective Earthground”

Repère de la "terre de protection"

Indicates “Up” and “Down” respectively

Touches de déplacements respectifs vers le "HAUT" et le "BAS"

Indicates “Manually Adjustable”

Signale un élément "réglable manuellement"

Indicates “Potential Shock Hazard” behind partition

Signale un "risque potentiel d'électrocution" au-delà de la cloison.

Indicates “Hot Surface”

Signale une “surface à haute température”

Indicates “Unit should be recycled” (Not disposed of in land-fill).

Indique “l’appareil doit être recyclé“ (Ne pas jeter dans une décharge)

Section

3

GRAPHIC SYMBOLS

Your unit is provided with a display of graphic symbols that should help in identifying user adjustable

components.

Table 2. Symbols

Microprocessor Control Water Baths 6

Page 7

Section

4

INSTALLATION

Your satisfaction and safety require a complete understanding of this unit. Read the instructions

thoroughly and be sure all operators are given adequate training before attempting to put the unit in

service.

This equipment must be used only for its intended application; any alterations or modifications will void

your warranty. Local city, county, or other ordinances may govern the use of this equipment. If you have

any questions about local requirements, please contact the appropriate local agency. The end user may

perform installation.

Environmental Conditions

Under normal circumstances these units are intended for use indoors, at room temperatures between 18

and 40C, at no greater than 80% relative Humidity (at 25C) and with a supply voltage that does not vary

by more than 10% from the data plate rating. This equipment should not be operated at an altitude

exceeding 2000 meters. Installation category is II, pollution degree 2. Customer service should be

contacted for operating conditions outside of these limits.

Power Source

Check the data plate for voltage, cycle, and ampere requirements. If matched to your power source, plug

the power cord into a grounded outlet.

Voltage should not vary more than ± 10% from the data plate rating.

These units are intended for 50/60-HZ application. A separate circuit is recommended to prevent damage

to the unit due to overloading or circuit failure.

Location

In selecting a location, consider all conditions that might affect performance, such as heat from radiators,

ovens, autoclaves, etc. Avoid direct sun, fast-moving air currents, heating and cooling ducts, and high

traffic areas. Allow a minimum of 10 cm between the unit and any walls or partitions that might obstruct

free airflow.

Lifting and Handling

These units are heavy and care should be taken to use appropriate lifting devices that are sufficiently

rated for these loads. The unit should be completely restrained from tipping during lifting or transport. All

moving parts such as trays or covers should be removed during transfer to prevent shifting and damage.

The bottom of the unit is hot during operation as is the water in the tank. Always allow the unit to cool

before attempting to move it.

Cleaning and Decontamination

In the event hazardous material is spilled onto or into the equipment appropriate decontamination must be

carried out. If there is any doubt about the compatibility of decontamination or cleaning agents with parts

of the equipment or with material contained, please contact the manufacturer.

Units are cleaned at the factory, but not sterilized. Remove any racks if assembled and clean the bath

with a disinfectant that is suitable for your application. See MAINTENANCE for cleaning instructions and

precautions.

7 Microprocessor Control Water Baths

Page 8

Section

5

CONTROLS OVERVIEW

This section provides an overview of the panel controls. See Figure 1 for an illustration of the panel

controls.

Figure 1. Control Panel

Power Switch

The Green I/O (On/Off) power switch controls all power to the unit. It must be in the I position to be ON and the

green power on light illuminated before any systems are operational. The on/off switch must remain easily

accessible at all times. The W614M is equipped with separate switches for each tank.

Main Temperature Controller

This control is marked SET TEMPERATURE and consists of the digital display and UP and DOWN arrow pads for

inputting set point temperatures and calibration. Separate controls are used on the W614M to control temperature in

the respective tanks.

Fuses

The fuses are located at the back of the unit within the power inlet plug and 220v units also have a fuse holder

located next to the inlet. The fuses act as a circuit breaker and will cut off power to the unit if there is an electrical

surge or malfunction. The cause should be determined and corrected before placing the fuse. Fuses must be in

place for the unit to operate.

Over Temperature Limit Thermostat (OTL)

This controller is marked “Set Over Temp Control” and is completely independent of the Temperature Controller. The

OTL guards against any failure of the Temperature Controller that would allow the temperature to rise past set point.

If the temperature rises to the OTL set point, the OTL takes control of the heating element and allows continued use

of the water bath until the problem can be resolved or service can be arranged. The OTL is manually adjusted with a

screwdriver or coin so accidental adjustment cannot occur. The W614M has separate controls for each of the tanks.

Heating Activated

This light is ON when the Temperature Controller has activated the heating element to reach and maintain set point.

Over Temperature Activated Light

This light is ON when the Over Temperature Limit Thermostat has been activated. Under normal operating

conditions this light should never be on.

Microprocessor Control Water Baths 8

Page 9

Section

6

OPERATION

Warning: These baths are not intended for use as acid baths. Use as an acid bath will cause severe

damage to bath components and void your warranty. Do not use deionized water, tap water,

or chemicals. USE DISTILLED WATER ONLY.

Attention : Ces bains d'eau ne sont pas conçus pour les acides. Utiliser un tel bain comme bain d'acide

l'endommagera gravement et annulera la garantie. Ne pas utiliser d'eau désionisée, d'eau

du robinet ni de produits chimiques. UTILISER EXCLUSIVEMENT DE L'EAU DISTILLÉE.

Turning On the Unit

To turn on the unit, perform the following steps:

1. Check power supply against unit serial plate; they must match.

2. Plug service cord into the electrical outlet. If supplied with a detachable cordset, plug the female end

into the unit inlet and the male plug into the power supply. Verify that units requiring a fuse have the

fuse installed in the power inlet.

3. Fill bath to your required depth with DISTILLED WATER. DO NOT USE TAP WATER, DEIONIZED

WATER, OR CHEMICALS. For singer or larger tank, normal depth is 5 ½ inches (14 cm), but depth

must be at least 2 inches (5 cm) over the bottom of the rack. For shallow tank, normal depth is 2/3

full, but depth must beat least 2 inches (5 cm). Check water level frequently, add water to appropriate

levels if needed. At higher operating temperatures, or under circumstances where a cover cannot be

used, it will be necessary to check the water level more frequently.

4. Push the Main power switch to the ON position and turn the Over Temperature Limit Thermostat to its

maximum position, clockwise.

Setting Main Temperature Control

To enter set point mode on the control, push and release either the Up or Down arrow pad one time and

the digital display will start to blink from bright to dim. While blinking, the digital display shows the set

point that can be changed using the UP or DOWN arrow pads. If the arrow pads are not pressed for five

(5) seconds, the display will stop blinking and will revert to reading the actual temperature in the bath.

Allow at least two (2) hours for the temperature to stabilize.

Warning: If the tank boils dry while containing plastic ware, the plastic can melt. If you intend to use

Attention : Si la cuve vient à s'assécher tandis qu' elle contient des ustensiles en plastique, le plastique

Calibrating the Main Temperature Control

We recommend that you calibrate your unit once it has been installed in its working environment and the

chamber temperature has been stable at the set point for several hours.

Microprocessor Control Water Baths 9

test tube racks, remember that plastic coated wire racks may wear and expose metal that

can cause damage. Preferably, use all plastic racks.

risque de fondre. Si des râteliers à tubes à essais constitués d'une ossature métallique

gainée de plastique sont utilisés, prendre garde que le plastique peut fondre ou s'user et

découvrir des parties métalliques risquant d'endommager différentes pièces. Il est

préférable d'utiliser des râteliers à tubes entièrement en plastique.

Page 10

6

9850563

Handle Part #3800609

1. Place a calibrated reference thermometer in the bath (a thermometer clip is provided with the

accessories package). (See Figure 2 for placement.) Allow the thermometer to reach temperature and

remain stable for one (1) hour.

2. Compare the reading on the reference thermometer with the temperature control display. If there is a

difference, put the display into calibrate mode by pressing both the Up and Down arrow pads at the

same time until the two (2) outside decimal points begin to blink.

3. When the decimal points are blinking, press the Up or Down arrow pad to adjust the display to match

the reference thermometer. If the arrow pads are not pressed within five (5) seconds the display will

revert to showing the temperature within the bath.

4. Allow the unit to stabilize again, and repeat calibration if necessary.

5. On the W614M, both tanks will need to be calibrated individually.

Setting the Overtemperature Limit Thermostat

To set the Over Temperature Limit Thermostat, perform the following steps:

1. Verify that the Limit Thermostat was set to its maximum position to allow the water bath to stabilize.

2. Turn the Limit Thermostat counterclockwise until the Safety indicator light turns on.

3. Turn the Limit Thermostat clockwise until the OTL indicator light turns off.

4. Turn the thermostat clockwise again, two (2) of the smallest divisions on its scale past the point where

the indicator light went out. This will set the Safety Thermostat at approximately 1C above the Main

Temperature set point.

Figure 2. Thermometer Placement

Note: Water bath thermometer must be placed so that the bulb is always fully immersed. The thermometer

must not touch the sides or the bottom of the bath tank.

Bath Cover Assembly

To assemble the bath cover, perform the following steps:

1. Insert two (2) self-tapping screws through the respective cover holes and into the holes in the handle,

leaving the first self-tapping screw loose to assure proper alignment. See Figure 3. Firmly fasten both

screws into place. Do not over-tighten.

Figure 3. Bath Cover Assembly

10 Microprocessor Control Water Baths

Page 11

Section

7

MAINTENANCE

Warning: Prior to any maintenance or service on this unit, disconnect the power cord from the power

supply and the drain water from the tank. Before reattaching the unit to its power supply, be

sure all volatile and flammable cleaners are evaporated and dry.

Avertissement: Avant d'effectuer toute maintenance ou entretien de cet appareil, débrancher le cordon

secteur de la source d'alimentation. Avant de reconnecter l'appareil sur le secteur,

s'assurer que tous les produits de nettoyage volatiles et inflammables sont complètement

évaporés.

Cleaning

The unit chamber should be cleaned and disinfected prior to use.

To clean the water bath, perform the following steps:

1. Clean the water bath with mild soap and water solution. DO NOT USE chlorine-based bleaches, as

they will damage the tank interior. DO NOT USE spray cleaners that may contain solvents, which

could leak through openings and cracks and harm electrical part coatings. Failure to do this may

permanently damage the unit.

2. Clean water bath with a damp cloth with cleaning solution. Wipe the water bath clean.

Disinfecting

Disinfect the bath on a regular basis. To disinfect the incubator, perform the following steps.

1. Disinfect the bath, including all corners, using a suitable disinfectant. DO NOT USE spray

disinfectants that might leak through openings and cracks and get on electrical components, or that

may contain solvents, corrosives, or abrasives that will harm the stainless steel coatings

2. If a hazardous material/substance has been spilled in the unit, immediately initiate your site’s

Hazardous Material Spill Containment protocol. Contact your local Site Safety Officer and follow

instructions per the policy and procedures established for your site.

3. There are many commercially available disinfectants available that are non-corrosive and nonabrasive and suitable for use on stainless steel surfaces. Contact your local Site Safety Officer for

detailed information for the proper disinfectants suitable for your operation.

Warning: Never clean the unit with alcohol or flammable cleaners and assure all volatile or flammable cleaners

are evaporated and dry before reattaching the unit to the power supply.

Avertissement: Ne jamais nettoyer l'appareil à l'alcool ou avec des nettoyants inflammables et veiller à ce que

les produits volatils ou inflammables soient entièrement évaporés avant de rebrancher le

content d'alimentation de l'appareil.

No maintenance is required on electrical components. If the incubator fails to operate as specified, please

review the Troubleshooting section prior to calling for service.

Heating and Water Level

The heating element of this bath does not contact the tank bottom, thus will not burn out if the tank is allowed

to run dry. However, a tank going dry during operation can strain interior surfaces so this should not be

Microprocessor Control Water Baths 11

Page 12

6

allowed to occur. During operation a minimum of 5cm (two inches) of distilled water should be in the tank.

Check water bath water level frequently, add water as needed. Please note that at higher operating

temperatures, or in applications where a cover is not used, more frequent water level checking is required.

Test-tube Racks

If the water bath tank boils dry while containing plastic-ware, the plastic will melt. If you intend to use testtube racks that are wire or plastic-coated wire that may wear and expose metal, damage may occur to the

tank. It is recommended that all-plastic racks be used, and that the tank never be allowed to boil dry.

12 Microprocessor Control Water Baths

Page 13

Problem

Possible Cause

Solution

Temperature too high

Insufficient

quantity of water.

Fill bath a minimum of three-fourths (3/4) full with water.

Main controller set

too high

See Setting Main Temperature Control

Main controller

failed on

Call customer service.

Display reads "HI" or "400"+

Probe is unplugged

Call customer service.

Probe is broken or

wire to the sensor is

broken.

Call customer service.

Temperature spikes over set

point and then settles to set

point.

Calibration issue

Recalibrate.

Temperature is too low

Over Temperature

Limit is set too low.

See Setting Main Temperature Control.

Bath temperature

not recovered from

water being added.

Wait for display to stop changing.

Unit not recovered

from power failure

or being turned off.

Bath will need a minimum of 2 hours to warm up and stabilize.

Main controller

failure

Confirm with front panel lights that controller is calling for heat.

Display reads "LO" but heating

all the time

Control failure

Call customer service.

Section

8

TROUBLESHOOTING

Should the unit malfunction, use this section to determine the problem and resolution. Troubleshooting

topics include:

Temperature

Miscellaneous

Warning: These baths are not intended for use as acid baths. Use as an acid bath will cause severe

damage to bath components and void your warranty. Do not use deionized water, tap water,

or chemicals. USE DISTILLED WATER ONLY.

Attention : Ces bains d'eau ne sont pas conçus pour les acides. Utiliser un tel bain comme bain d'acide

l'endommagera gravement et annulera la garantie. Ne pas utiliser d'eau désionisée, d'eau

du robinet ni de produits chimiques. UTILISER EXCLUSIVEMENT DE L'EAU DISTILLÉE.

Temperature Troubleshooting

13 Microprocessor Control Water Baths

Page 14

Problem

Possible Cause

Solution

Unit will not heat over a

temperature that is below set

point

OTL has activated.

Confirm that set point is set high enough and that the Over

Temperature Safety is not activated.

Temperature

calibration is not

correct.

Check calibration. Using independent thermometer, follow

instructions in Calibration.

Unit will not heat up at all

Controller Fault.

Do all controller functions work? Controller failure-call

Customer Service.

OTL has activated.

Set the Over Temperature Thermostat higher.

Indicated bath temperature

unstable

Insufficient

quantity of water.

Fill bath a minimum of three-fourths (3/4) full with water.

Fluctuating by ±

0.1?

May be normal, especially without the use of bath cover.

Ambient room

temperature is

radically changing

Temperature fluctuation due to door opening or room airflow

from heaters or air conditioning. Stabilize ambient conditions.

Bath not full

Assure that the bath is at least 1/3 full.

Electrical noise

Remove nearby sources of RFI including motors, arcing relays

or radio transmitters

Bad connection on

temperature sensor

or faulty sensor

Call customer service.

Will not maintain set point

Insufficient

quantity of water.

Fill bath a minimum of three-fourths (3/4) full with water.

Temperature set

too low.

Assure that set point is at least 5 degrees over ambient room

temperature.

Ambient

temperature too

high.

See if ambient is fluctuating.

Cannot adjust set points or

calibration

Controller hangs

up.

Turn entire unit off and on to reset. If repeatedly happens, call

Customer Service.

Calibrated at one temperature,

but not at another

Set point too far

from calibration

point.

This can be a normal condition when operating temperature

varies widely. For maximum accuracy, calibration should be

done as close to the set point temperature as possible.

Problem

Possible Cause

Solution

Water Leaking

Leak / Corrosion

Shut the unit off and call Customer Service. Service

Tank Discoloration

Wrong type of

water

Assure that clean, distilled water is used. Deionized water, tap

water and chemicals should never be used in the tank.

USE DISTILLED WATER ONLY.

Sample Spills

Assure that no test samples have leaked into bath water.

Metal Racks

No metallic products should be in the tank with the exception of

the oscillation rack.

Unit will not turn on

No power.

Check wall power source.

Fuse blown.

Check fuse/circuit breaker on unit or in wall.

Miscellaneous Troubleshooting

Service

If this product should require service, contact your customer service representative.

14 Microprocessor Control Water Baths

Page 15

Description

100-120V

220-240V

Element

SWB2 (W2)

SWB2-2, (W2-2)

SWB7 (W6M)

SWB7-2 (W6M-2)

SWB715 (W614 Small)

SWB715-2 (W614-2 Small)

9570704

9570575

Element

SWB15 (W14M)

SWB15-2 (W14M-2)

SWB715 Large (W614 Large)

SWB715-2 Large (W614M-2 Large)

9570695

9570696

Element

SWB23 (W20M)

SWB23-2 (W20M-2)

9570582

9570583

Fuse - 10.0 AMP

3300516

3300516

Fuse - 6.3 AMP

3300515

3300515

Gable Covers

SWB2 (W2M)

SWB2-2 (W2M-2)

SWB7 (W6M)

SWB7-2 (W6M-2)

9751191

9751191

Gable Covers

SWB15 (W14M)

SWB15-2 (W14M-2)

9751184

9751184

Gable Covers

SWB23 (W20M)

SWB23-2 (W20M-2)

9751185

9751185

Cable Covers

SWB715 (W614M)

SWB715-2 (W614M-2)

9751191

9751184

9751191

9751184

Microprocessor Main Temp Control

SWB2 / SWB-2 (W2M / W2M-2)

SWB7 / SWB7-2 (W6M / W6M-2)

SWB15 / SWB15-2 (W14M / W14M-2)

SWB23 / SWB23-2 (W20M / W20M-2)

SWB715 / SWB715-2 (W614M / W614M-2)

1750960

1750957

1750955

1750953

1750957/1750955

1750961

1750958

1750956

1750954

1750958/1750956

Over Temperature Limit Control

1750747

1750747

Pilot Lamp Green

4650554

4650554

Pilot Lamp Red

4650553

4650553

Power Cord

1800510

1800500

Power Switch

7850553

7850553

Section

9

PARTS LIST

15 Microprocessor Control Water Baths

Page 16

Rubber Feet with Screws

2700513

2700513

Tank Gasket

3450538

3450538

Tanks

SWB2 (W2M)

SWB2-2 (W2M-2)

7930521

7930521

Tanks

SWB7 (W6M)

SWB7-2 (W6M-2)

SWB715 (W614M)

SWB715-2 (W614M-2)

7930523

7930523

Tanks

SWB15 (W14M)

SWB15-2 (W14M-2)

SWB715 (W614M)

SWB715-2 (W614M-2)

7930525

7930525

Tanks

SWB23 (W20M)

SWB23-2 (W20M-2)

7930524

7930524

16 Microprocessor Control Water Baths

Page 17

Section

10

Model

Shipping

Net

SWB2 SWB2-2

(W2M W2M-2)

21 lbs.

9.53 kg.

14 lbs.

6.35 kg.

SWB7 SWB72-2

(W6M W6M-2)

21 lbs.

9.53 kg.

14 lbs.

6.35 kg.

SWB15 SWB15-2

(W14M W14M-2)

26.5 lbs.

12.02 kg.

18 lbs.

8.16 kg.

SWB23 / SWB2302

(W20M W20M-2)

29 lbs.

13.15 kg.

25 lbs.

11.34 kg.

SWB715 SWB715-2

(W614M W614M-2)

42 lbs.

19.05 kg.

39 lbs.

17.69 kg.

Model

Exterior WxDxH

Interior WxDxH

SWB2 SWB2-2

(W2M W2M-2)

14.75 x 12.25 x 12.1 in.

37.47 x 31.12 x 30.73 cm.

11.8 x 5.8 x 2.5 in.

29.98 x 14.73 x 6.35 cm.

SWB7 SWB72-2

(W6M W6M-2)

14.75 x 12.25 x 12.1 in.

37.47 x 31.12 x 30.73 cm.

11.8 x 5.8 x 6 in.

29.98 x 14.73 x 15.24 cm.

SWB15 SWB15-2

(W14M W14M-2)

14.75 x 19 x 12.1 in.

37.47 x 48.26 x 31.12 cm.

11.8 x 12.8 x 6 in.

29.98 x 32.51 x 15.24 cm.

SWB23 / SWB2302

(W20M W20M-2)

14.75 x 25 x 12.1 in.

37.47 x 63.50 x 31.12 cm.

11.5 x 19.5 x 6 in.

29.21 x 49.53 x 15.24 cm.

SWB715 SWB715-2

(W614M W614M-2)

14.75 x 12.25 x 12.1 in. (small)

14.75 x 19 x 12.1 in. (large)

37.47 x 31.12 x 30.73 cm. (small)

37.47 x 48.26 x 31.12 cm (large)

11.8 x 5.8 x 6 in. (small)

11.8 x 12.8 x 6 in.(large)

29.98 x 14.73 x 15.24 cm. (small)

29.98 x 32.51 x 15.24 cm. (large)

UNIT SPECIFICATIONS

Table 3. Weight

Table 4. Dimensions

17 Microprocessor Control Water Baths

Page 18

Model

Liters/Fill Line

Liters/Flush

SWB2 SWB2-2

(W2M W2M-2)

1.6

2.4

SWB7 SWB72-2

(W6M W6M-2)

4.7

5.75

SWB15 SWB15-2

(W14M W14M-2)

11.225

14.75

SWB23 / SWB2302

(W20M W20M-2)

14

17

SWB715 SWB715-2

(W614M W614M-2)

4.7 (small tank)

11.225 (large tank)

5.75 (small tank)

14.75 (large tank)

Model

Range

Uniformity

Sensitivity

SWB2 SWB2-2

(W2M W2M-2)

Amb. +5C to 80˚C

+.2C @ 37C

+ .1C

SWB7 SWB72-2

(W6M W6M-2)

Amb. +5C to 80˚C

+.2C @ 37C

+ .1C

SWB15 SWB15-2

(W14M W14M-2)

Amb. +5C to 80˚C

+.2C @ 37C

+ .1C

SWB23 / SWB2302

(W20M W20M-2)

Amb. +5C to 80˚C

+.2C @ 37C

+ .1C

SWB715 SWB715-2

(W614M W614M-2)

Amb. +5C to 80˚C

+.2C @ 37C

+ .1C

Table 5. Capacity

Table 6. Temperature

18 Microprocessor Control Water Baths

Page 19

Table 7. Power Requirements

Model

Voltage

Voltage -2 Models

SWB2 SWB2-2

(W2M W2M-2)

Volts 100-120 V~ 3 A 50/60 Hz

Volts 220-240 V~ 2 A 50/60 Hz

SWB7 SWB72-2

(W6M W6M-2)

Volts 100-120 V~ 3 A 50/60 Hz

Volts 220-240 V~ 2 A 50/60 Hz

SWB15 SWB15-2

(W14M W14M-2)

Volts 100-120 V~ 5 A 50/60 Hz

Volts 220-240 V~ 3 A 50/60 Hz

SWB23 / SWB2302

(W20M W20M-2)

Volts 100-120 V~ 5 A 50/60 Hz

Volts 220-240 V~ 3.5 A 50/60 Hz

SWB715 SWB715-2

(W614M W614M-2)

Volts 100-120 V~ 8 A 50/60 Hz

Volts 220-240 V~ 4.5 A 50/60 Hz

8

Microprocessor Control Water Baths 19

Page 20

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750960

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

300W 41.8Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

RED HT

BLACK HT

BLACK HT

WHITE HT

BLACKBLACK

BLACK BLACK

WHITE HT

BLACK

BLACK

BLACK HT

BLACK HT

WHITE HT

WHITE HT

Section

11

SCHEMATICS

WIRE DIAGRAM

SWB2 (W2M)

(9851310)

20 Microprocessor Control Water Baths

Page 21

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750961

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

300W 153.6Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

2800502

EMI FILTER

RED HT

BLACK HT

WHITE HT

BLACK HT

BLACK

WHITE HT

BLACK

BLACK

BLACK

BLACK HT

BLACK HT

BLACK HT

BLACK BLACK

WHITE HT

WHITE HT

WHITE HT

WHITE HT

WIRE DIAGRAM

SWB2-2 (W2M-2)

(9851311)

Microprocessor Control Water Baths 21

Page 22

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750957

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

300W 41.8Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

WIRE DIAGRAM

SWB7 (W6M)

(9851302)

22 Microprocessor Control Water Baths

Page 23

WIRE DIAGRAM

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750958

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

300W 153.6Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

2800502

EMI FILTER

SWB7-2 (W6M-2)

(9851303)

Microprocessor Control Water Baths 23

Page 24

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750955

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

500W 24.5Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

WIRE DIAGRAM

SWB15 (W14M)

(9851304)

24 Microprocessor Control Water Baths

Page 25

WIRE DIAGRAM

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750956

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

600W 90.1Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

2800502

EMI FILTER

SWB15-2 (W14M-2)

(9851305)

Microprocessor Control Water Baths 25

Page 26

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750953

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

500W 24.5Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

WIRE DIAGRAM

SWB23 (W20M)

(9851306)

26 Microprocessor Control Water Baths

Page 27

WIRE DIAGRAM

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750954

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

600W 90.1Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

2800502

EMI FILTER

SWB23-2 (W20M-2)

(9851307)

Microprocessor Control Water Baths 27

Page 28

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750955

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

500W 24.5Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

POWER LIGHT

4650554

TEMPERATURE

CONTROL

17509957

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

300W 41.8Ώ

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

BLACK CHERRY ROUND POWER SWITCH 7850553

14 LITER SECTION

6 LITER SECTION

WIRING DIAGRAM

SWB715 (W614M)

(9851308)

28 Microprocessor Control Water Baths

Page 29

WIRING DIAGRAM

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

FUSED INLET

4200505

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750956

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

600W 90.1Ώ

BLACK CHERRY ROUND POWER SWITCH 7850553

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

2800502

EMI

FILTER

HOT

NEUTRAL

GROUND

LOAD

SENSOR

1

2

4

POWER LIGHT

4650554

TEMPERATURE

CONTROL

1750958

OTP LIGHT

4650553

HEATING LIGHT

4650554

OTP

THERMOSTAT

1750747

300W 153.6Ώ

HOT TERMINAL BLOCK

NEUTRAL TERMINAL BLOCK

BLACK CHERRY ROUND POWER SWITCH 7850553

14 LITER SECTION

6 LITER SECTION

SWB715-2 (W614M-2)

(9851309)

Microprocessor Control Water Baths 29

Loading...

Loading...