Page 1

TopPage

XR-40X/XR-41X/XG-F260X

SERVICE MANUAL

No. S57J1XR-40X//

MULTIMEDIA PROJECTOR

XR-40X

XR-41X

MODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its original condition and only parts identical to those specified should be used.

XG-F260X

OUTLINE

This Service Manual covers the differences from XR-30X/XG-F210X. For other technical information, refer to the XR30S/XR-30X/XG-F210X (No. S47E3XR-30XS/) Service Manual.

CONTENTS

OUTLINE AND MODIFIED PARTS LIST

OUTLINE.............................................................i

MODIFIED PARTS..............................................i

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY

NOTES...............................................................ii

Precautions for using lead-free solder ............. vii

Parts Guide

CHAPTER 1. OPERATION MANUAL

[1] Specifications ................................................. 1-1

CHAPTER 2. ELECTRICAL ADJUSTMENT

[1] ELECTRICAL ADJUSTMENT........................ 2-1

[2] Adjustment mode process menu.................... 2-4

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Page 2

XR-40X/XR-41X/XG-F260X

XR-40X

OUTLINE AND MODIFIED PARTS LIST

Service Manual

OUTLINE

This Service Manual covers the differences from XR-30X/XG-F210X. For other technical information, refer to the XR-30S/XR-30X/XG-F210X (No.

S47E3XR-30XS/) Service Manual.

MODIFIED PARTS

(XR-30X/XG-F210X → XR-40X/XR-41X/XG-F260X)

Ref.No. Description XR-30X/XG-F210X XR-40X/XR-41X/XG-F260X Note

PRINTED WIRING BOARD ASSEMBLIES

BALLAST POWER Ass'y DSETUE149FMG0 ← -

BALLAST CONTROL Unit DUNTKE150WEF0 ← -

PHOTO SENSOR Unit DUNTKE151WEF0 ← -

R/C RECEIVER Unit DUNTKE152WEF0 ← -

MAIN Unit DUNTKE153FMF0 (XR-30X) DUNTKE153FMF2 (XR-40X/41X) No parts changed

MAIN Unit DUNTKE153FMF4 (XG-F210X) DUNTKE153FMF3 (XG-F260X) No parts changed

DMD Unit DUNTKE154WEF0 ← -

CABINET AND MECHANICAL PARTS : Please refer to a Parts Guide.

OPTICAL MECHANISM PARTS : Please refer to a Parts Guide.

SUPPLIED ACCESSORIES : Please refer to a Parts Guide.

PACKING PARTS AND ACCESSORIES : Please refer to a Parts Guide.

SERVICE JIGS AND EQUIPMENT(USE FOR SERVICING) : Please refer to a Parts Guide.

i

Page 3

XR-40X

SAFETY PRECAUTION

IMPORTANT SERVICE SAFETY NOTES

IMPORTANT SERVICE SAFETY NOTES (for USA)

Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the chassis

and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

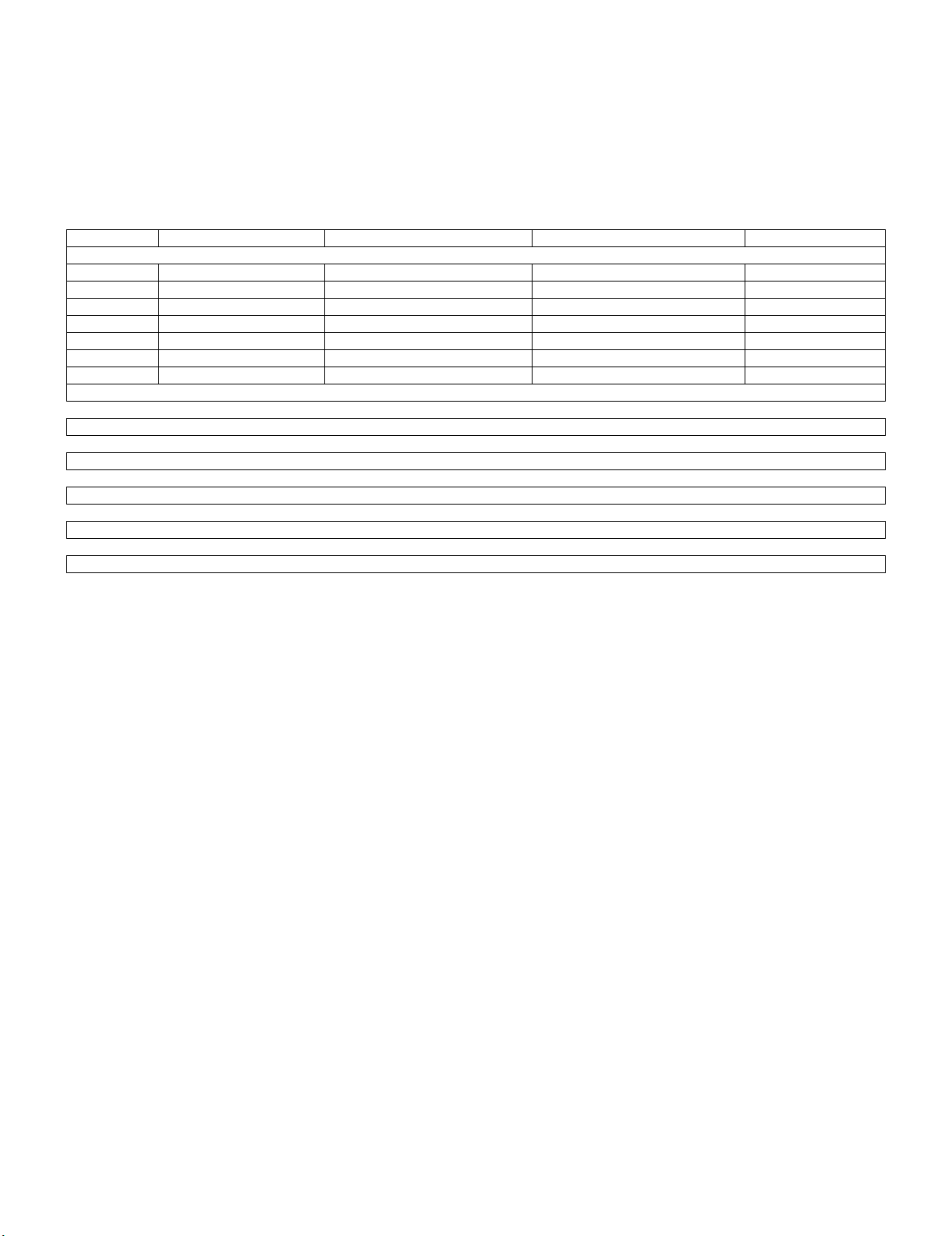

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

Plug the AC cord directly into a 120 - volt AC outlet,

(Do not use an isolation transformer for this test).

Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

XR-40X/XR-41X/XG-F260X

Service Manual

Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC plug

connection reversed. (If necessary, a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.4 volts RMS (this corresponds to 0.27

milliamp. AC.) or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the unit to the owner.

DVM

AC SCALE

1.5k ohm

10W

0.15 µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICE

Many electrical and mechanical parts in DLP

Projector have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “ ”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

R

replacement parts must be identical to those used in

the original circuit. The use of a substitute replacement

parts which do not have the same safety characteristics

as the factory recommended replacement parts shown

in this service manual, may create shock, fire or other

hazards.

WARNING: The bimetallic component has the primary

conductive side exposed. Be very careful in

handling this component when the power is on.

ii

Page 4

XR-40X/XR-41X/XG-F260X

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. N'entreprendre aucune modification de tout circuit.

C'est dangereux.

2. Débrancher le récepteur avant toute réparation.

VERIFICA TIONS CONTRE L'INCEN-DIE ET

LE CHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer

les vérifications suivantes.

1. Inspecter tous les faisceaux de câbles pour s'assurer

que les fils ne soient pas pincés ou qu'un outil ne soit

pas placé entre le châssis et les autres pièces

métalliques du récepteur.

2. Inspecter tous les dispositifs de protection comme les

boutons de commande non-métalliques, les isolants, le

dos du coffret, les couvercles ou blindages de réglage

et de compartiment, les réseaux de résistance-capacité,

les isolateurs mécaniques, etc.

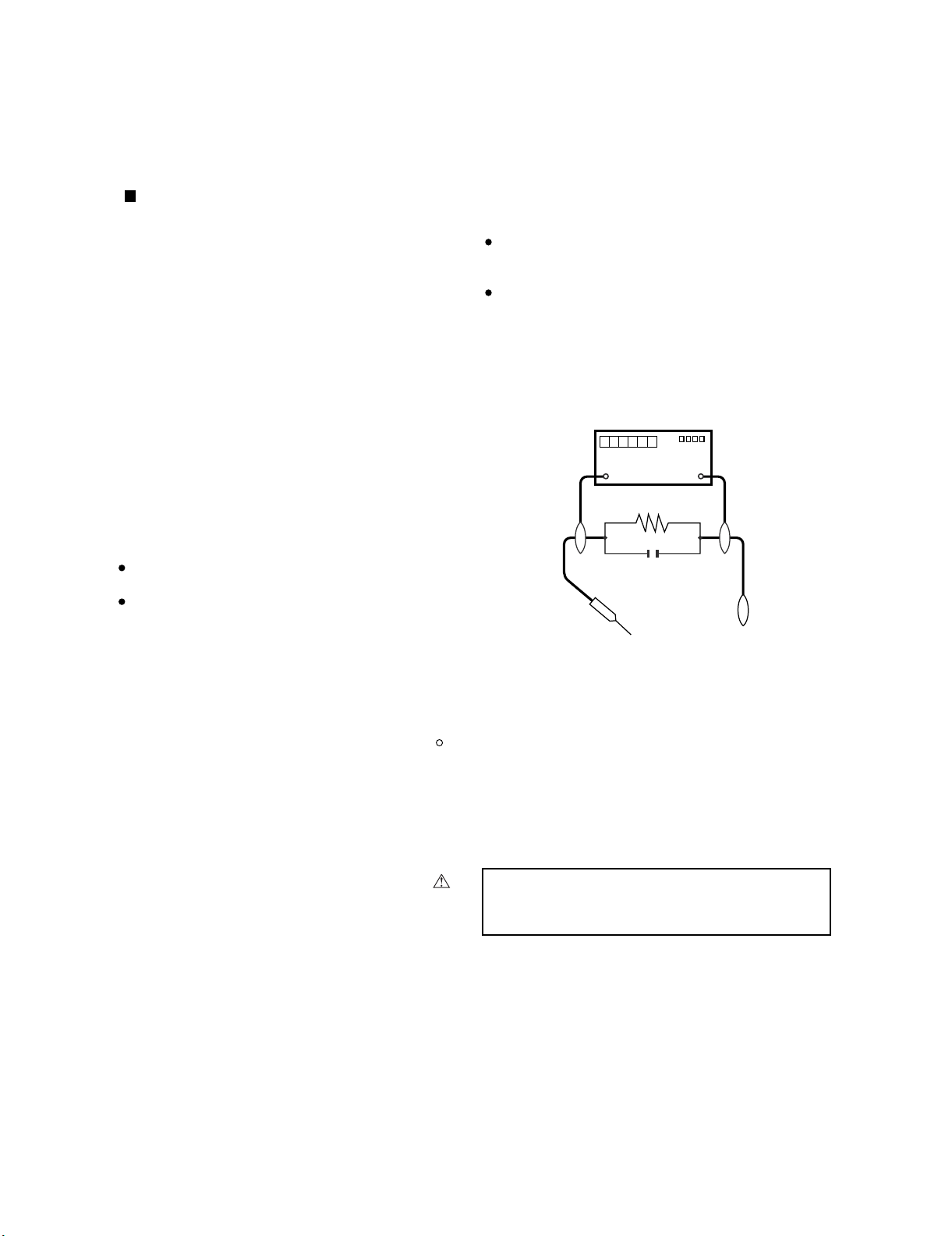

3. S'assurer qu'il n'y ait pas de danger d'électrocution en

vérifiant la fuite de courant, de la facon suivante:

Brancher le cordon d'alimentation directem-ent à une

prise de courant de 120 - V. (Ne pas utiliser de

transformateur d'isolation pour cet essai).

A l'aide de deux fils à pinces, brancher une résistance

de 1.5 kΩ 10 watts en parallèle avec un condensateur

de 0.15µF en série avec toutes les pièces métalliques

exposées du coffret et une terre connue comme une

conduite électrique ou une prise de terre branchée à la

terre.

Utiliser un voltmètre CA d'une sensibilité d'au moins

5000Ω/V pour mesurer la chute de tension en travers

de la résistance.

Toucher avec la sonde d'essai les pièces métalliques

exposées qui présentent une voie de retour au châssis

(antenne, coffret métallique, tête des vis, arbres de

commande et des boutons, écusson, etc.) et mesurer la

chute de tension CA en-travers de la résistance. Toutes

les vérifications doivent être refaites après avoir inversé

la fiche du cordon d'alimentation. (Si nécessaire, une

prise d'adpatation non polarisée peut être utilisée dans

le but de terminer ces vérifications.)

La tension de pointe mesurèe ne doit pas dépasser 0.4V

(correspondante au courant CA de pointe de 0.27mA).

Dans le cas contraire, ilyaunepossibilité de choc

électrique qui doit être supprimée avant de rendre le

récepteur au client.

DVM

ECHELLE CA

1.5k ohm

10W

µ

F

0.15

SONDE D'ESSAI

AUX PIECES

METALLIQUES

EXPOSEES

BRANCHER A UNE

TERRE CONNUE

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à DLP présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent pas

évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “ ” et hachurées dans la

R

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par l’usine,

indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

AVERTISSEMENT: La composante bimétallique dispose du

conducteur primaire dénudé. Faire attention

lors de la manipulation de cette

composante sous tension.

iii

Page 5

XR-40X/XR-41X/XG-F260X

NOTE TO SERVICE

PERSONNEL

//////////////////////////////////////////////////////////////

UV-RADIATION PRECAUTION

//////////////////////////////////////////////////////////////

The light source, lamp, in the projector emits small

amounts of UV-Radiation.

AVOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D’ENTRETIEN

//////////////////////////////////////////////////////////////

PRECAUTION POUR LES RADIATIONS UV

//////////////////////////////////////////////////////////////

La source de lumière, la lampe, dans le projecteur émet

de petites quantités de radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE DES

YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours porter des lunettes de soleil lors d’un entretien

du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du boîtier

de lampe.

3. Do not operate for more than 2 hours with the enclosure

removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing the

lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type AN-XR30LP

rated 200W DC.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of explosion.

Be sure to follow installation instructions described

below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le coffret

retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du remplacement

de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type. Type

AN-XR30LP, caractéristique 200W-DC.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la lampe

avec soin.

iv

Page 6

XR-40X/XR-41X/XG-F260X

////////////////////////////////////////////////////////////////

UV-RADIATION PRECAUTION (Continued)

////////////////////////////////////////////////////////////////

Lamp Replacement

Note:

Since the lamp reaches a very high temperature during

units operation replacement of the lamp should be

done at least one hour after the power has been turned

off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2

.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the devices

since the stabilizer generates high voltages at its start.

////////////////////////////////////////////////////////////////

PRECAUTION POUR LES RADIA TIONS UV (Suite)

////////////////////////////////////////////////////////////////

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur .

[N’utiliser qu’un remplacement d’origine.]

DANGER ! –– Ne jamais mettre sous tension sans la

lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

2

1

Lampe

2

Reflecteur

Since small amounts of UV-radiation are emitted

from an opening between the exhaust fans, it is recommended to place the cap of the optional lens on

the opening during servicing to avoid eye and skin

exposure.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre les ventilateurs aspirants, il est recommandé de placer le capuchon de

l’optique optionnelle sur l’ouverture pendant l’entretien

pour éviter une exposition des yeux et la peau.

v

Page 7

XR-40X/XR-41X/XG-F260X

WARNING: High brightness light source, do not stare into the beam of light, or view directly. Be especially

careful that children do not stare directly into the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW.

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE CABINET.

NO USER-SERVICEABLE PARTS EXCEPT LAMP UNIT.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

CAUTION

(POWER Unit)

6.3A 250V

AVERTISSEMENT: Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

For continued

protection against a

risk of fire, replace

only with same type

6.3A, AC250V fuse.

(F701)

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

AVERTISSEMENT: AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE PAS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ÉLECTROCUTION. NE

PASR ETIRER LES VIS Á

L’EXCEPTION DE LA VIS DE

REPARATION UTILISATEUR

SPECIFIEES

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REPARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REPARATION, S’ADRESSER A UN

TECHNICIEN D’ENTRETIEN QUALIFIE.

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

PRECAUTION

(Unité de PUTSSANCE)

6.3A 250V

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible 6.3A,AC250V

du même type.

(F701)

vi

Page 8

XR-40X/XR-41X/XG-F260X

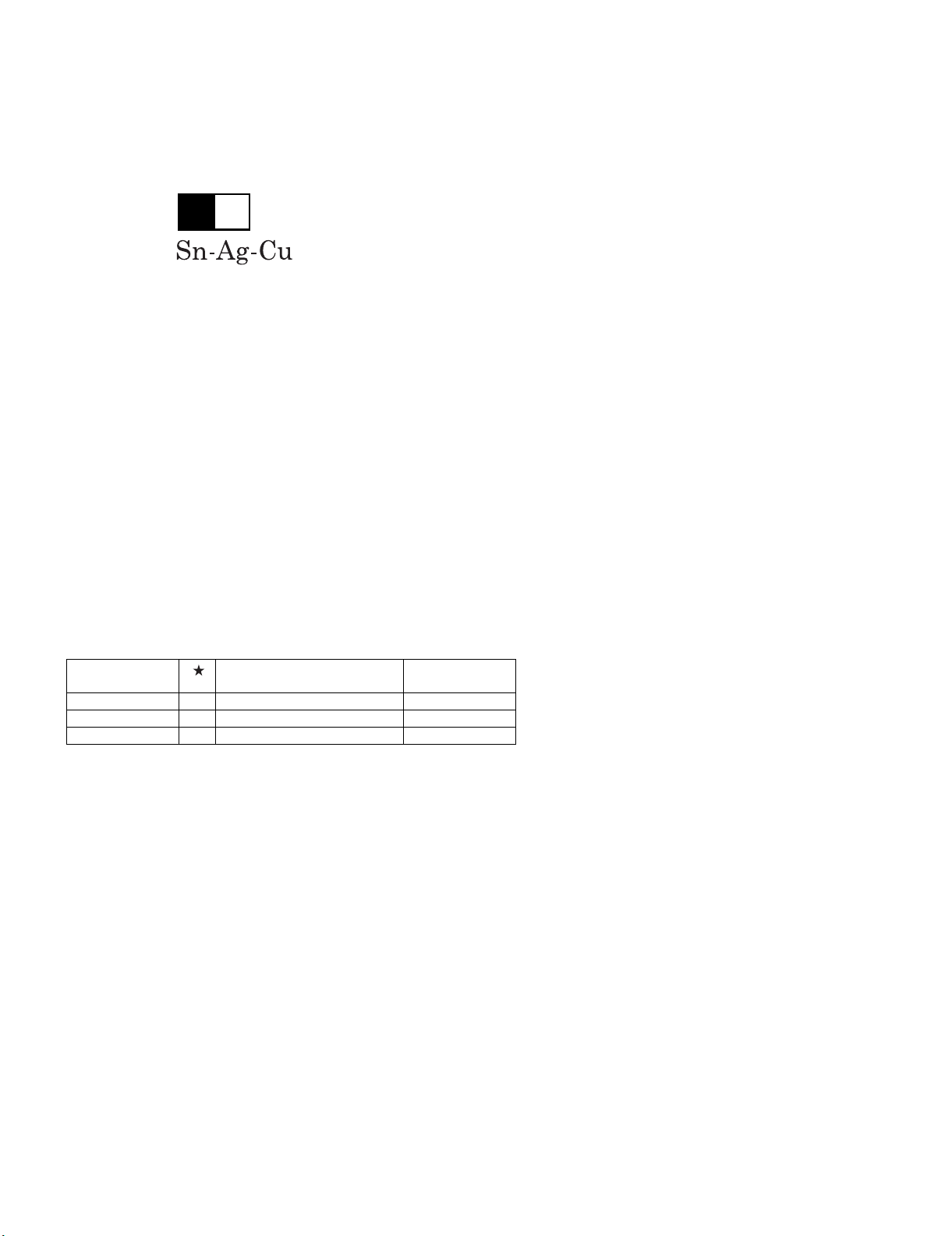

Precautions for using lead-free solder

Employing lead-free solder

• "PWBs" of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

L Fa

Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Part No. Description Code

ZHNDAi123250E J φ0.3mm 250g(1roll) BL

ZHNDAi126500E J φ0.6mm 500g(1roll) BK

ZHNDAi12801KE J φ1.0mm 1kg(1roll) BM

vii

Page 9

XR-40X

CHAPTER 1. OPERATION MANUAL

[1] Specifications

XR-40X/XR-41X/XG-F260X

Service Manual

Model

Display device

Resolution

Lens

Input terminal

Output terminal

Control, others

Speaker

Projection lamp

Rated voltage

Rated frequency

Input current

Power consumption (Standby)

Operation temperature

Cabinet

Dimensions (main body only)

Weight (approx.)

F number

Zoom

Focus

DVI-D (Compatible with HDCP)

DVI-I (Compatible with HDCP)

RGB/Component (mini D-sub 15 pin)

S-Video (mini DIN 4 pin)

Video (RCA)

Audio (ø3.5 mm stereo minijack)

Audio (RCA)

RGB/Component (mini D-sub 15 pin)

Audio (ø3.5 mm stereo minijack)

USB (Type B)

RS-232C (mini DIN 9 pin)

XR-40X/XR-41X/XG-F260X

0.55" DLP Chip

XGA

(1024 x

F2.5–2.6

Manual, x 1.15 (f = 20.4 – 23.5 mm)

Manual

XR-40X/XR-41X

XG-F260X

x1

x1

x1

x1

x 1 (L/R)

x1

x1

x1

x1

2 W (Mono)

200 W

AC 100 – 240 V

50/60 Hz

2.9 A

283 W (4.3 W) with AC 100 V

270 W (4.4 W) with AC 240 V

41°Fto95°F(+5°Cto+35°C)

Plastic

41

/64"x333/64"x107/16"

10

(270 (W) x 89 (H) x 265 (D) mm)

6.4 lbs. (2.9 kg)

768)

x1

x1

As a part of policy of continuous improvement, SHARP reserves the right to make design and

specification changes for product improvement without prior notice. The performance specification figures indicated are nominal values of production units. There may be some deviations from

these values in individual units.

1 – 1

Page 10

XR-40X/XR-41X/XG-F260X

XR-40X

CHAPTER 2. ELECTRICAL ADJUSTMENT

Service Manual

[1] ELECTRICAL ADJUSTMENT

No. Adjusting point Adjusting conditions Adjusting procedure

1 EEPROM

initialization

2 Model setting (Process menu)

3 Adjustment of CW index 1. Signal input: Send 256 STEP color bar.

1. Turn on the power (with the lamp on) and

warm up the set for 15 minutes.

1. Select the following group and subject.

Group: CONFIRM

Subject: MODEL

XGA series (XGA60HZ),

2. Select the following group and subject.

Group: ADJUST CW/Auto KS

Subject: CW-INDEX.

•Make the following settings.

Press S2551 to call the process mode and execute

"SS2" on SS menu.

1. Set as below.

XR-40X : 1

XR-41X : 4

XG-F260X : 3

1. The signal is input into computer 1.

2. Select the adjustment item and adjust the lamp gra dation patterns of RGBW so that smooth patterns

without noise appear.

W

R

G

B

4 R/G/B contrast adjustment

(manual or automatic)

5 RGB white balance adjustment 1. 50% gray pattern signal is input into com-

6 sRGB white balance adjustment 1. 50% gray pattern signal is input into com-

1. Select the following group and subjects.

Group : ADJUST

AD/DLP

Subject : R-CONT

G-CONT

B-CONT

(Process GAMMA interlock)

2. Amplitude level 96% (0.67Vpp) the signal

is input into computer 1.

XGA series (XGA60HZ)

puter 1.

XGA series (XGA60HZ)

2. Select the following group and subjects.

Group : ADJUST

AD/DLP

Subject : R-GAIN

G-GAIN

B-GAIN

puter 1.

XGA series (XGA60HZ)

2. Select the following group and subjects.

Group : CONFIRM/DLP

Subject : S-G-OS

S-B-OS

Check items

1. Measure chromaticity of the 96% white wind pattern

using CA100.

2. On the screen where bit dropouts occur, raise the

values of R/G/B-Contrast. Adjust the values so that

bright red, green, and blue bit dropouts appear on

a black background; and amounts of change in x

value of R and y values of G/B become 100/1000

or more.

3. If adjustment is performed manually watching the

screen, make adjustment so that bright red, green,

and blue bit dropouts appear on more than half of

the screen.

1. Raise the values of two of R/G/B-GAIN (default:

100) so that the following chromaticity values are

obtained using CL200.

x value: 295 ± 5

y value: 310 ± 5

1. Adjust S-G-OS and S-B-OS so that the following

chromaticity values are obtained using CL200.

x value: 313 ± 5

y value: 329 ± 5

No. Adjusting point Adjusting conditions Adjusting procedure

1 1 Adjustment of RGB brightness 1. Select the following group and subjects.

Group : CONFIRM/AD

Subject : R-BRIGHT

G-BRIGHT

B-BRIGHT

(Process GAMMA interlock)

1. Check the fixed value.

Fixed value : 127

2 – 1

Page 11

XR-40X/XR-41X/XG-F260X

No. Adjusting point Adjusting conditions Adjusting procedure

2 Adjustment of Component offset 1. Feed 10-step signal with 480P component

3 Adjustment of DLP Brightness 1. Select the following group and subject.

4 Video Contrast adjustment 1. Feed NTSC 100% wind pattern signal.

5 Adjustment of Video Brightness 1. Feed NTSC 100% wind pattern signal.

6 Adjustment of Video Tint 1. Feed split color bar.

7 Adjustment of Video color satura-

tion

8 RGB tone reproduction adjust-

ment

100% amplitude.

2. Select the following group and subjects.

Group : CONFIRM/AD

Subject : C-R-OS

C-B-OS

(Process GAMMA interlock)

Group : CONFIRM/DLP

Subject :R-BLK

G-BLK

B-BLK

(Process GAMMA interlock)

(Signal with burst)

2. Select the following group and subjects.

Group : CONFIRM/VIDEO

Subject : V-CONT

(Signal with burst)

2. Select the following group and subject.

Group : CONFIRM/VIDEO

Subject : V-BRIGHT

2. Select the following group and subject.

Group : CONFIRM/VIDEO

Subject : V-HUE

1. Select the following group and subject.

Group : CONFIRM/VIDEO

Subject : V-COLOR

1. Feed the SMPTE pattern signal. 1. Make sure the 100% and 95% white as well as the

1. Check the fixed value.

C-R-OS : 257

C-B-OS : 257

1. Check the fixed value.

Fixed value : 256

1. Check the fixed value.

Fixed value : 124

1. Check the fixed value.

Fixed value : 68

1. Check the fixed value.

Fixed value : 128

1. Check the fixed value.

Fixed value : 154

0% and 5% black gradations are visible.

9 VIDEO white balance adjustment 1. Feed the 50% gray signal.

2. Select the following group and subjects.

Group :CONFIRM/VIDEO

Subject : V-R-OS

V-B-OS

10 White balance checking and

readjustment

11 Off-timer performance 1. Select the following group and subjects.

12 Thermistor performance checking 1. Heat the thermistor with a hair dryer. 1. Make sure that the temperature is indicated.

13 Auto sync performance checking 1. Feed the phase check pattern signal. 1. In the VGA, SVGA, XGA and SXGA modes, make

14 DVI input operation check Send the video signal to the DVI terminal. 1. For XR-40X/XR-41X, check that an image is prop-

15 Monitor out check 1. Send signals to COMPUTER 1 and COM-

1. RGB Input

sRGB Input

VIDEO Input

DTV Input

DVD Input

Group :CONFIRM/CHECK

Subject : TEMP-OFF

PUTER 2.

2. Connect another monitor to the monitor

out.

3. Connect the audio OUT.

1. V-R-OS is 132.

V-B-OS is 132.

Check that there is no deviation of white balance with

the monitor.

1. Select OFF from the process mode.

Make sure the off-timer starts with 5 minutes

onscreen and count one minute in one second.

And then indication is 0 minute, the power supply of

the set is cut off.

sure the Clock, Phase, H-Pos and V-Pos settings

can be automatically adjusted.

erly projected through the digital input.

2. For XG-F260X, check that an image is properly pro

jected through the digital input and analog input.

1. Check that the same images as seen on the screen

appear on the connected monitor and that the

sound from the sound source connected to the

audio OUT is heard.

2 – 2

Page 12

XR-40X/XR-41X/XG-F260X

No. Adjusting point Adjusting conditions Adjusting procedure

16 RS232C operation check 1. Connect the unit and a PC with the

RS232C cable.

17 Model name and version check 1. Select the following group.

Group : INFO/VERSION.

18 Setup guide screen check 1. Turn on the power after making the setup

guide display ON setting or factory setting

(SS4, etc.).

19 Delivery settings 1. Make the following settings.

Destination Process Remote control

adjustment adjustment

USA SS4 Factory setting at 4

Others SS3 Factory setting at 3

* Writing a software program (before main PWB is mounted)

Use the DLP Composer Lite Ver. 4.2 to download the firmware.

After writing the specified version of firmware to the PWB using the RS232C cable, check the version of the written firmware.

If no software program is written, all three LEDs light up in the chassis inspection process.

1. Send a command from the PC, and check it func tions correctly.

1. The model name appears in the MODEL field, and

the firmware version in the VERSION field. Check

that they are correct.

1. Check that the 4-split screen is displayed correctly

and the display contents are correct.

Calling and quitting the process mode with the control keys on this model.

* Although it is possible for the process OUT to exit using the process menu, the IN/OUT toggle command is also available considering the existing

specification.

1) Calling and quitting

With the menu not displayed, press the "ENTER", "ENTER", "VOL+", "VOL-", "ENTER", "ENTER" and "MENU" keys on the remote control or on

the main unit.

2) Others

Press the S2551 process key (toggle) on the main PWB to call and quit the process menu.

NOTE: When adjusting in the process mode, set a signal with a vertical frequency of 60 Hz or no signal. (May not be properly adjusted with other sig-

nals.)

Resetting the lamp timer for this model

1) Resetting procedure

In Stand-by, run this command to clear the operating time of the lamp to 0 and turn on the power.

Press and hold " ", "ENTER", and "MENU", and then press the "STANDBY/ON" key of the set.

Forced disabling of the System-Lock of this model

1) Disabling procedure

With System-Lock input window onscreen, press the "MENU", "ENTER", "ENTER", "MENU", "ENTER", "ENTER" and "MENU" keys, in this order,

on the remote controller.

2 – 3

Page 13

[2] Adjustment mode process menu

XR-40X/XR-41X/XG-F260X

1st Layer 2nd Layer Default

ADJUST CW/Auto KS CW-INDEX 20

CAL

K-SENS (0)

AD/DLP R-CONT 110

G-CONT 110

B-CONT 110

R-GAIN 100

G-GAIN 100

B-GAIN 100

SS SS1 —

SS2 —

SS3 —

SS4 —

SS5 —

SS6 —

CONFIRM AD R-BRIGHT 127

G-BRIGHT 127

B-BRIGHT 127

C-R-OS 257

C-B-OS 257

DLP R-BLK 256

G-BLK 256

B-BLK 256

S-R-OS 128

S-G-OS 128

S-B-OS 128

VIDEO V-CONT 124

V-BRIGHT 68

V-COLOR 154

V-HUE 128

V-R-OS 132

V-G-OS 128

V-B-OS 132

OFFSET-MODE 0

OFFSET-CONT 0

OFFSET-BRI 0

MODEL MODEL-SELECT 0

CHECK LED-CHK 0

TEMP-OFF —

INFO VERSION MODEL —

VER. —

PATTERN RGB 1

RGB50 1

CORSS 1

STEP 1

COLOR 1

CHR 1

LAMP CURRENT 0

HISTORY1 0

HISTORY2 0

HISTORY3 0

HISTORY4 0

TOTAL 0

TEMP/FAN TEMP1 —

TEMP2 —

FAN0 3

FAN1 3

FAN2 3

1st Layer 2nd Layer Default

OTHER SPECIAL USB-MODE 0

HDCP-MODE 0

PULSE-MODE 0

EDID EEP-SELECT 1

EEP-WP 0

EXIT

2 – 4

Page 14

XR-40X/XR-41X/XG-F260X

1. Adjustment of ballast unit output power (lamp power)

1. List of parts requiring adjustment

When replacing the following parts, adjust the ballast unit output power (lamp power).

Part name Ref No. Part code

1 Cement resistor R923 RR-FZA002WJZZ

2 Ballast Control PWB —— DUNTKE150WEF0

3 Ballast microprocessor IC7707 RH-iXC103WJZZQ

4 5V regulator IC7704 VHiTA78L05F-1Y

5 Ballast Switching Control IC7701 VHiM51995AF-1Y

2. Adjustment jigs

The following jigs are required for adjusting the ballast unit output power (lamp power).

Part name Part code

1 Adjustment jig (resistance load 25 Ω) RUNTZA018WJZZ

2 Connecting cord (conversion cable) QCNWKA020WJZZ

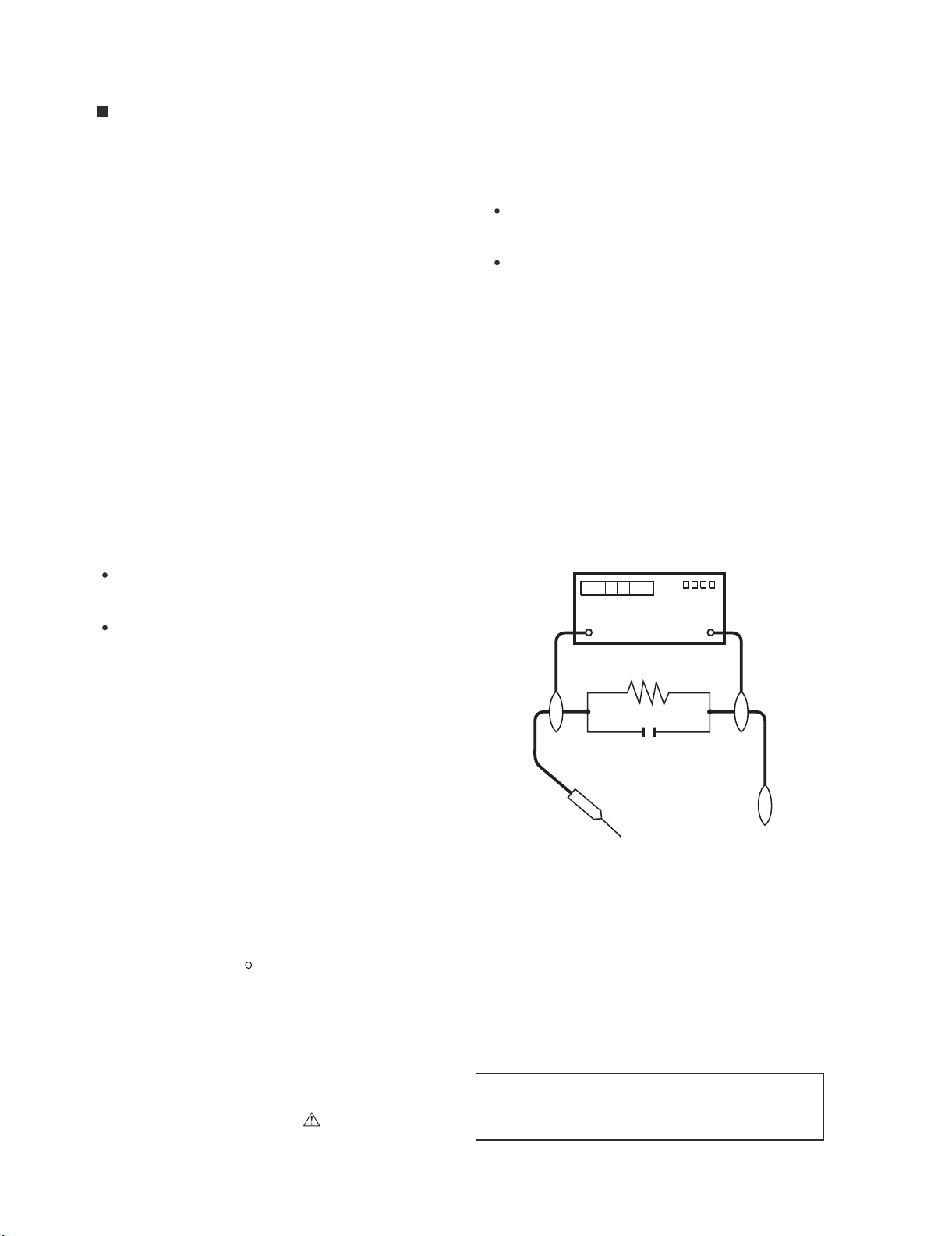

3. Ballast unit output power (lamp power) adjustment method

Adjust the ballast unit output power (lamp power) in the following method.

[Setting method]

XR-40X

XR-41X

XG-F260X

Projector

Ballast Unit

Lamp Cable

Connecting Cord

(QCNWKA020WJZZ)

Tester

(Voltage)

TP1

Adjustment Jig

(RUNTZA018WJZZ)

TP2

2. Adjustment method

1) Unplug the ballast unit lamp cable of the projector from the lamp and connect the cable to the connecting cord

(QCNWKA020WJZZ).

2) Connect the connecting cord (QCNWKA020WJZZ) to the adjustment jig (RUNTZA018WJZZ).

3) Connect TP1 of the adjustment jig (RUNTZA018WJZZ) to the negative terminal of the tester and TP2 to the positive terminal.

4) Turn on the projector.

5) Check the Lamp setting to “Bright”.

6) Ageing the projector for 60 seconds or more.

7) Adjust the volume resistor (R7805) of the ballast control PWB (DUNTKE150WEF0) so that the voltage of the tester reaches 71±0.5V.

Adjustment value: 71±0.5V

CAUTION: (1) Caution for electric shock: Do not touch the test points TP1 and TP2 of the adjustment jig when supplying power since a high voltage

and large current is applied to them.

(2) Caution for heat: Be careful that the resistance load of the adjustment jig produces a high temperature when supplying power.

(3) Connection of the lamp cable: Check that the lamp cable and connecting cord (QCNWKA020WJZZ) are connected securely.

Poor connection may cause smoking or ignition due to arc discharge.

2 – 5

Page 15

PartsGuide

XR-40X/XR-41X/XG-F260X

PARTS GUIDE

MULTIMEDIA PROJECTOR

XR-40X

XR-41X

Note:

The reference numbers on the PWB are arranged

in alphabetical order.

CONTENTS

[1] PRINTED WIRING BOARD

ASSEMBLIES

[2] CABINET AND MECHANICAL

PARTS

[3] OPTICAL MECHANISM PARTS

MODELS

[4] SUPPLIED ACCESSORIES

[5] PACKING PARTS

(NOT REPLACEMENT ITEM)

[6] SERVICE JIGS AND EQUIPMENT

(USE FOR SERVICING)

XG-F260X

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these

parts with specified ones for maintaining the safety and performance of the set.

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 16

XR-40X/XR-41X/XG-F260X

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

[1] PRINTED WIRING BOARD ASSEMBLIES

N DSETUE149FMG0 BZ N J BALLAST POWER Ass'y (with Ballast Control Unit)

N Not Available - N -

N DUNTKE150WEF0 BW N J BALLAST CONTROL Unit

N DUNTKE151WEF0 AY N J PHOTO SENSOR Unit

N DUNTKE152WEF0 AY N J R/C RECEIVER Unit

N DUNTKE153FMF2 DA N J MAIN Unit (XR-40X/41X)

N DUNTKE153FMF3 DB N J MAIN Unit (XG-F260X)

N DUNTKE154WEF0 CN N J DMD Unit (without the DMD chip)

BALLAST POWER Unit Order the BALLAST POWER Ass'y (DSETUE149FMG1) when

replacing ballast power unit (DUNTKE149WEF1).

DESCRIPTION

2

Page 17

[2] CABINET AND MECHANICAL PARTS

18

42

1-2

1-5

1-1

1-3

1-4

1

10

19

40

25

30

40

29

24

6

12

15

2-1

2-1-3

2-1-1

2-1-2

40

41

37

26

2-8

2

2-4

2-6

2-9

2-7

9

40

2-3

2-5

27

16

14

2-2

10

40

34

39

33

39

38

8

4

5

10

17

23

43

45

22

32

2-10

2-11

44

10

31

XR-40X/XR-41X/XG-F260X

3

Page 18

XR-40X/XR-41X/XG-F260X

NO. PARTS CODE

PRICE

RANK

NEW

MARK

[2] CABINET AND MECHANICAL PARTS

1 CBDYTA235WEF0 BR N J Top Body Ass'y (XR-40X)

1 CBDYTA236WEF0 BR N J Top Body Ass'y (XG-F260X)

1 CBDYTA245WEF0 BQ N J Top Body Ass'y (XR-41X)

1-1 Not Available - N - Top Body

1-2 GCOVAC364WJSA AE N J Cover

1-3 HDECPA034WJSA AK N J Decoration Plate

1-4 HiNDPC319WJSA AN N J Indicator (XR-41X)

1-4 HiNDPC319WJSC AM N J Indicator (XR-40X/XG-F260X)

1-5 GCOVAC242WJKB AS N J Cover (XR-40X)

1-5 GCOVAC242WJKC AS N J Cover (XG-F260X)

1-5 GCOVAC242WJKD AS N J Cover (XR-41X)

2 CBDYUA275WEF0 BP N J Bottom Body Ass'y (XR-40X)

2 CBDYUA276WEF0 BP N J Bottom Body Ass'y (XG-F260X)

2 CBDYUA284WEF0 BP N J Bottom Body Ass'y (XR-41X)

2-1 CDORUA075WEF0 AQ N J Lamp Door Ass'y

2-1-1 Not Available - N - Lamp Door

2-1-2 LX-BZA185WJFN AB N J Screw

2-1-3 PSLDHA047WJFW AK N J Shield

2-2 Not Available - N - Bottom Body

2-3 LX-NZ3120CEFW AB J Nut

2-4 LX-NZ3144CEFW AC J Nut, x4

2-5 LX-NZA014WJFW AC J Nut

2-6 QEARPA250WJFW AK N J Bottom Earth Shield

2-7 GLEGPA030WJSA AK J Foot (Rear Adjuster)

2-8 GLEGPA036WJSA AP N J Foot (Front Adjuster)

2-9 PSPAZB478WJZZ AC N J Spacer

2-10 QCNW-F721WJQZ AN N J Connecting Cord

2-11 XEBSN30P10000 AA J Screw

4 ----- - - Refer to Optical Mechanism Parts

5 AN-XR30LP - N J Lamp Unit

6 LHLDFA011WJKZ AC J Holder (Power PWB)

8 LHLDZA849WJKZ AQ N J Holder (Bimetal)

9 LX-BZ3049GEFN AB J Screw, x4

10 LX-BZ3100CEF7 AA J

12 LX-BZA186WJF9 AD N J Screw, x2

14 NFANRA076WJ00 BM N J Fan

15 NFANRA078WJ00 BP N J Fan

16 PCOVPA037WJSA AU J Cover

17 PCOVUA105WJ00 AF N J Cover

18 PCOVZA099WJZZ AE N J Cover

19 PCOVZA100WJZZ AF N J Cover

22 PSLDMB118WJFW AM N J Shield

23 PSLDMB119WJFW AK N J Shield

24 PSLDMB122WJFW AZ N J Shield

25 PSLDMB123WJFW AX N J Shield

26 PSPAGA370WJKZ AP N J Spacer

27 PSPAGA371WJKZ AW N J Spacer

29 PZETKA227WJKZ AX N J Insulator

30 PZETKA233WJKZ AD N J Insulator

31 PZETKA240WJKZ AG N J Insulator

32 QCNW-F711WJQZ AZ J Connecting Cord

!

33 QCNW-F718WJPZ AY N J Connecting Cord

34 QCNW-F720WJQZ AG N J Connecting Cord

37 RSP-ZA085WJQZ AP J Speaker

38 XBBSN30P06000 AA J Screw

39 XBPSN30P08JS0 AB J Screw, x3

40 XEBSN30P10000 AA J Screw, x18

41 Not Available - N - Serial No Label

42 PCOVWA015WJKZ AC N J Spacer

43 QEARPA256WJFW AB N J Ground-Part

44 QCNW-G254WJQZ AH N J Connecting Cord

45 NSFTZ0134CEFW AD J Shaft, x2 (for DVI Socket )

PAR T

DELIVERY

DESCRIPTION

Screw, x7

4

Page 19

[3] OPTICAL MECHANISM PARTS

4-17

4-33

4-35

4-19

4-35

4-10

4-33

4-33

4-33

4-33

4-32

4-32

4-32

4-33

4-33

4-30

4-24

4-36

4-12

4-18

4-33

4-33

4-31

4-31

4-31

4-33

4-33

4-26

4-31

4-31

4-23

4-14

4-31

4-31

4-31

4-28

4-15

4-20

4-33

4-33

4-21

4-22

4-33

4-33

4-34

4-34

4-33

4-13

4-1

4-4

4-9

4-8

4-7

4-5

4-6

4-2

4-3

11

11

13

13

20

7

35

36

28

21

11

11

13

13

4-33

4-33

4-16

4-11

4-33

4-27

4-29

4-33

4-33

4-33

4-25

XR-40X/XR-41X/XG-F260X

5

Page 20

XR-40X/XR-41X/XG-F260X

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

[3] OPTICAL MECHANISM PARTS

4-1 LANGKB121WJFW AE N J Fixing Metal

4-2 LCHSKA024WJFW BQ N J Chassis

4-3 LHLDZA845WJKZ AN N J Holder

4-4 LX-EZA027WJFN AC N J For Focus Ring, x3

4-5 MSPRPA095WJFW AF N J Spring

4-6 MSPRPA096WJFW AG N J Spring

4-7 MSPRPA097WJFW AK N J Spring

4-8 NFANRA077WJ00 BH N J Fan

4-9 PCOVPA036WJSA AR N J Cover

4-10 PCOVPA038WJSA AS N J Cover

4-11 PCOVZA089WJFW AP N J Cover

4-12 PCOVZA093WJKZ AM N J Cover

4-13 PCOVZA094WJKZ AN N J Cover

4-14 PCOVZA095WJFW AL N J Cover

4-15 PCOVZA096WJFW AG N J C/W Cover

4-16 PDUC-A088WJFW AF N J Exhaust Duct

4-17 PFiLWA120WJZZ CC N J Filter

4-18 PLNS-A059WJZZ BF J Lens

4-19 PLNS-A080WJZZ AT N J Lens

4-20 PLNS-A083WJZZ AT N J Lens

4-21 PLNS-A084WJZZ AT N J Lens

4-22 PLNS-A085WJZZ BD N J Lens

4-23 PMiR-A125WJZZ AU N J Mirror

4-24 PRDARA446WJFW AQ N J Heat Sink

4-25 PSLDHA048WJFW AK N J Shield

4-26 PSLDPA077WJFW AM N J Shield

4-27 PSLDPA072WJKZ AZ N J Shield

4-28 PSLDPA073WJFW AD N J Shield

4-29 RH-HXA040WJQZ AS N J Thermistor

4-30 TLABZB026WJZZ AE J No. Label

4-31 XBBS925P06000 AA J Screw, x9

4-32 LX-BZA205WJFN N J Screw, x3

4-33 XBBSN30P06000 AA J Screw, x22

4-34 XBPSN30P20JS0 AB J

4-35 XEPSN17P05000 AB N J Screw, x2

4-36 PSLDPA078WJFW AF N J Flat Ray Shield

7 LHLDZA612WJFW AL J Holder (Backer Plate)

11 LX-BZA110WJF7 AC J Screw, x4

13 MSPRCA062WJFJ AB J Spring, x4

20 PRDARA445WJFW AZ N J Heat Sink

21 PSHEGA040WJZZ AE J Sheet

28 PSPAZA768WJZZ AD J Spacer

35 QSOCZA114WJZZ BA J Socket

36 RDMDPA027WJZZ CW J DMD Chip, 0.55" XGA

Screw, x2

DESCRIPTION

6

Page 21

[4] SUPPLIED ACCESSORIES

X1 X3

XR-40X/XR-41X/XG-F260X

NO. PARTS CODE

[4] SUPPLIED ACCESSORIES

X1 CCAPHA027WJSA AH N J Lens Cap

X2 GCASNA021WJSA BD N J Storage case (XR-41X/XG-F260X)

!

!

!

!

X3 QACCBA036WJPZ AX J AC Cord (for U.K and Singapore)

X3 QACCDA007WJPZ AR J AC Cord (for U.S.A and Canada, etc.)

X3 QACCLA018WJPZ AU J AC Cord (for Australia, New Zealand and Oceania)

X3 QACCVA011WJPZ AT J AC Cord (for Europe, except U.K)

X4 QCNWGA045WJPZ AU J RGB Cable

X5 QCNWGA091WJPZ AZ N J DIN-D-sub RS-232C adaptor (XG-F260X)

X6 RRMCGA581WJSA BD J Remote Control

X7 TCAUZA187WJZZ AC J WEEE Caution Sheet (Except U.S.A and Canada)

X8 TGAN-A794WJZZ AB N J SEC Warranty (for USA)

X9 TGAN-A811WJZZ AB N J SECL Warranty (for Canada)

X10 TiNS-D050WJZZ AX N J Operation Manual (XR-40X)

X10 TiNS-D109WJZZ AR N J Operation Manual (XG-F260X)

X10 TiNS-D158WJZZ AR N J Operation Manual (XR-41X)

X11 TLABZA956WJZZ AB J WEEE Mark Label (Except U.S.A and Canada)

X12 UDSKAA089WJZZ AM N J CD-ROM (XR-40X/XG-F260X)

X5

PRICE

RANK

NEW

MARK

X2

PAR T

DELIVERY

X4 X6

X10

X12

DESCRIPTION

7

Page 22

XR-40X/XR-41X/XG-F260X

[5] PACKING PARTS (NOT REPLACEMENT ITEM)

For XR-40X For XR-41X/XG-F260X

S6

S7

S3

S6

S1

S8

S3

S8

S10

S4

S5

S9

S11

S11

S2

8

Page 23

XR-40X/XR-41X/XG-F260X

NO. PARTS CODE

PRICE

RANK

NEW

MARK

PAR T

DELIVERY

DESCRIPTION

[5] PACKING PARTS (NOT REPLACEMENT ITEM)

S1 SPAKAA329WJZZ - N - Packing Add. (XR-40X)

S2 SPAKCD451WJZZ - N - Packing Case (XR-40X)

S2 SPAKCD452WJZZ - N - Packing Case (XG-F260X)

S2 SPAKCD508WJZZ - N - Packing Case (XR-41X)

S3 SPAKFB224WJZZ - N - Accessory Case

S4 SPAKPA869WJZZ - N - Wrapping Paper

S5 SPAKXB477WJZZ - N - Packing Add

S6 SSAKA0160CEZZ - N - Polyethylene Bag

S7 SSAKAA097WJZZ - N - Polyethylene Bag (for Storage case) (XR-41X/XG-F260X)

S8 TLABV0003SEZZ - - Model Name Label

S9 TLABVA333WJZZ - - Bar Code Label (for U.S.A, Canada)

S9 TLABVA493WJZZ - - Bar Code Label (for Europe, U.K)

S10 TLABZA610WJZZ - - Recycle Label (for Europe except U.K)

S11 TLABZA957WJZZ - - C.W.Mark, x2 (for Europe and Singapore)

[6] SERVICE JIGS AND EQUIPMENT (USE FOR SERVICING)

N QCNW-C516WJQZ AG J Extension Cable, 3pins L=200mm, Main to Fan, x2

N QCNWKA006WJZZ AX J Extension Cable, 4pins L=500mm, Main to Fan

N QCNWKA008WJZZ AP J Extension Cable, 14pins, Main to Power

N QCNWKA019WJZZ N J Extension Cable, 120pins, Main to DMD

N RUNTZA018WJZZ DR J Adjustment Jig, for the Ballast Unit

N QCNWKA020WJZZ N J Extension Cable, 3 to 2pins

9

Page 24

XR-40X/XR-41X/XG-F260X

COPYRIGHT © 2006 BY SHARP CORPORATION

2007

ALL RIGHTS RESERVED.

No Part of this publication may be reproduced,

stored in a retrieval system, or transmitted in

any from or by any means, electronic, mechanical,

photocopying , recording, or otherwise, without

prior written permission of the publisher.

TQ2222-S YK. DS

SHARP CORPORATION

AV Systems Group

CS Promotion Center

Yaita,Tochigi 329-2193, Japan

Loading...

Loading...