Page 1

XL-UH260

SERVICE MANUAL

No. S2603XLUH260/

MICRO COMPONENT SYSTEM

CONTENTS

CONTENTS

PRECAUTIONS FOR USING LEAD-FREE SOLDER

CHAPTER 1. GENERAL DESCRIPTION

[1] IMPORTANT SERVICE NOTES ........... .......1-1

[2] SPECIFICATIONS........................................1-2

[3] NAMES OF PARTS......................................1-3

CHAPTER 2. ADJUSTMENTS

[1] CD Section....................................................2-1

[2] TEST MODE.................................................2-2

[3] Standard Specification of Stereo System

Error Message Display Contents..................2-4

[4] CD Changer Mechanism Section ................2-5

MODEL

XL-UH260 Micro Component System consisting of

XL-UH260 (main unit) and CP-UH260 (speaker system).

• In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified

be used.

CHAPTER 5. CIRCUIT DESCRIPTION

[1] WAVEFORMS OF SERVO CIRCUIT..............5-1

[2] VOLTAGE................................................ ......5-3

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS

LAYOUT

[1] NOTES ON SCHEMA TIC DIAGRAM.............6-1

[2] TYPES OF TRANSISTOR AND LED.............6-1

[3] WIRING SIDE OF PWB/SCHEMATIC

DIAGRAM.......................................................6-2

CHAPTER 7. FLOWCHART

[1] TROUBLESHOOTING....................................7-1

XL-UH260

CHAPTER 3. MECHANICAL DESCRIPTION

[1] REMOVING AND REINSTALLING THE MAIN

PARTS..........................................................3-1

[2] DISASSEMBLY.............................................3-3

CHAPTER 4. DIAGRAMS

[1] BLOCK DIAGRAM........................................4-1

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safety and performance of the set.

– 1

CHAPTER 8. OTHERS

[1] FUNCTION TABLE OF IC ..............................8-1

[2] FL DISPLAY..................................................8-10

Parts Guide

This document has been published to be used for after

sales service only.

The contents are subject to change without notice.

Page 2

XL-UH260

PRECAUTIONS FOR USING LEAD-FREE SOLDER

1. Employing lead-free solder

"MAIN, POWER, SPEAKER, REFLASH MICOM, DISPLAY, USB, JACK, LED, SUB, CD MP3, SPEAKER LED

PWB, CD MOTOR (PWB ONLY), CD CHANGER (PWB ONLY)" of this model employs lead-free solder.

The LF symbol indicates lead-free solder, and is attached on the PWB and service manuals.The alphabetical

character following LF shows the type of lead-free solder.

Example:

Indicates lead-free solder of tin, silver and copper.

2. Using lead-free wire solder

When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with

conventional lead wire solder may cause damage or accident due to cracks.use a dedicated soldering bit, if you

are not familiar with how to obtain lead-free wire solder or soldering bit, contact

branch in your area.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by

40 C, we recommend you to use a dedicated soldering bit, if you are nto familiar with how to obtain lead-free

wire solder or soldering bit, contact our service station or service branch in your area.

our service station or service

Soldering

3.

As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead

solder by 40 C,and as it has poor solder wettability, you may be apt to keep the soldering bit in contact with the

PWB for extended period oftime. However, since the land may be peeled of for the maximum heat-resistance

temperature of parts may be exceeded,

remove the bit from the PWB as soon as you confirm the steady soldering condition. Lead-free solder contains

more tin, and the end of the soldering bit may be easily corrected. Make sure to turn on and off the power of the

bit as required. If a different type of solder stays on the tip of the soldering bit,it is alloyed with lead-free solder.

Clean the bit after every use of it. When the tip of the soldering bit is blackened during use, file it with steel wool

or fine sand paper. Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Ref No.

PWB-A 92LPWB6480MANS

PWB-B 92LPWB6480DPLS

PWB-C

PWB-D

PWB-E

PWB-F

Parts No.

92LPWB6475CDUS

92LPWB6274LEDS

QPWBF0027AWZZ

QPWBF1055AWZZ

MAIN (A1), POWER (A2), SPEAKER (A3), REFLASH MICOM (A4)

DISPLAY (B1), USB (B2), JACK (B3), LED (B4), SUB (B5)

CD MP3

SPEAKER LED

CD MOTOR (PWB ONLY)

CD CHANGER (PWB ONLY)

Description

– 2

i

Page 3

XL-UH260

CHAPTER 1.

FOR A COMPLETE DESCRIPTION OF THE OPERATION OF

THIS UNIT, PLEASE REFER TO THE OPERATION MANUAL.

BEFORE RETURNING THE AUDIO PRODUCT

(Fire & Shock Hazard)

Before returning the audio product to the user, perform

the following safety checks.

1. Inspect all lead dress to make certain that leads are not

pinched or that hardware is not lodged between the

chassis and other metal parts in the audio product.

2. Inspect all protective devices such as insulating

materials, cabinet, terminal board, adjustment and

compartment covers or shields, mechanical insulators

etc.

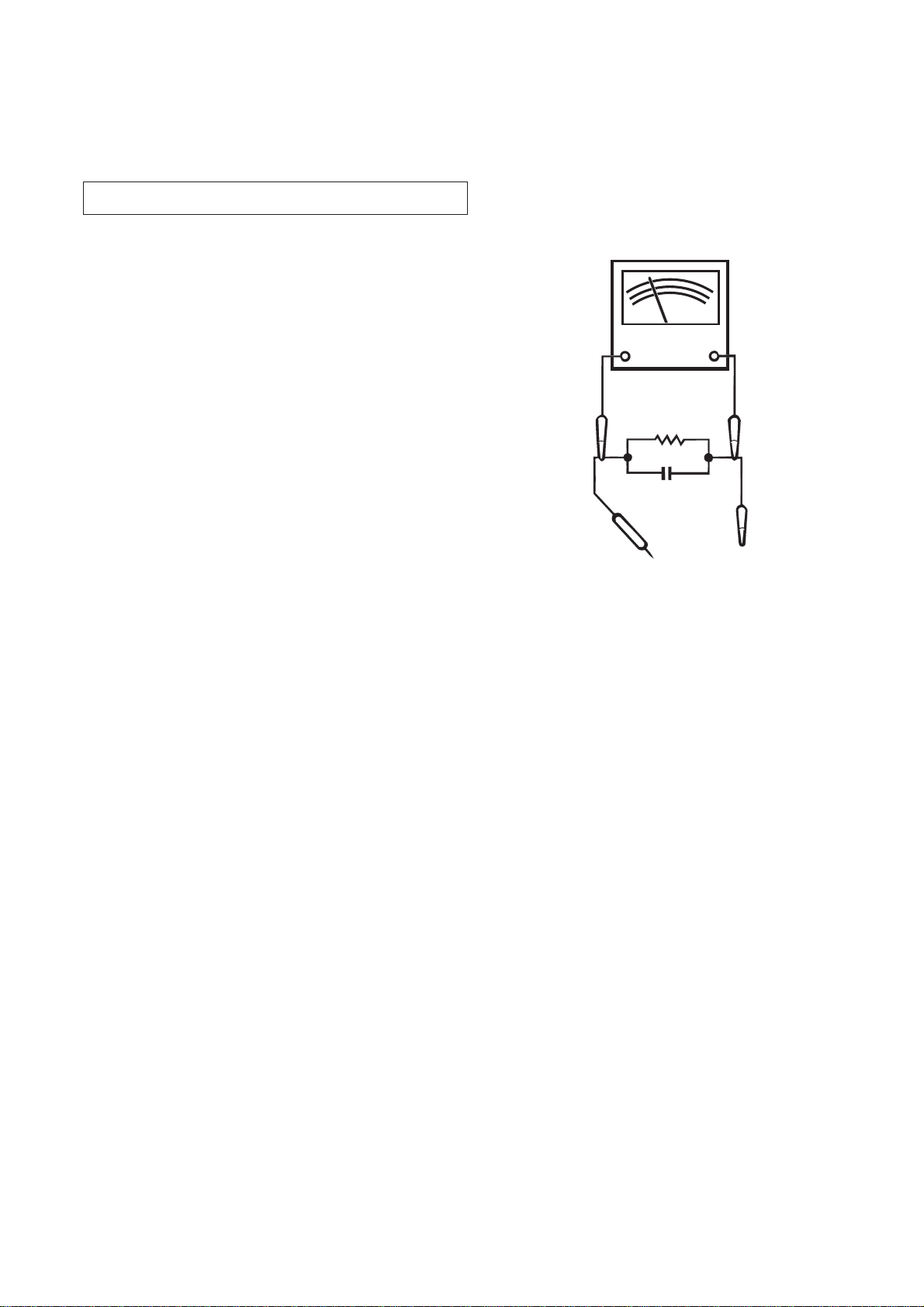

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

Plug the AC line cord directly into a 120 volt AC outlet.

*

* Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in series

with all exposed metal cabinet parts and a known

earth ground, such as conduit or electrical ground

connected to earth ground.

Use a VTVM or VOM with 1000 ohm per volt, or

*

higher, sensitivity to measure the AC voltage drop

across the resistor (See diagram).

* Connect the resistor connection to all exposed metal

parts having a return path to the chassis (antenna,

metal cabinet, screw heads, knobs and control shafts,

escutcheon, etc.) and measure the AC voltage drop

across the resistor.

GENERAL DESCRIPTION

VTVM

AC SCALE

1.5k ohms

10W

0.15 µ F

TO EXPOSED

TEST PROBE

METAL PARTS

All check must be repeated with the AC line cord plug

connection reversed.

Any reading of 0.3 volt RMS (this corresponds to 0.2

milliamp. AC.) Or more is excessive and indicates a

potential shock hazard which must be corrected before

returning the audio product to the owner.

CONNECT TO

KNOWN EARTH

GROUND

1 – 3

1 – 1

Page 4

XL-UH260

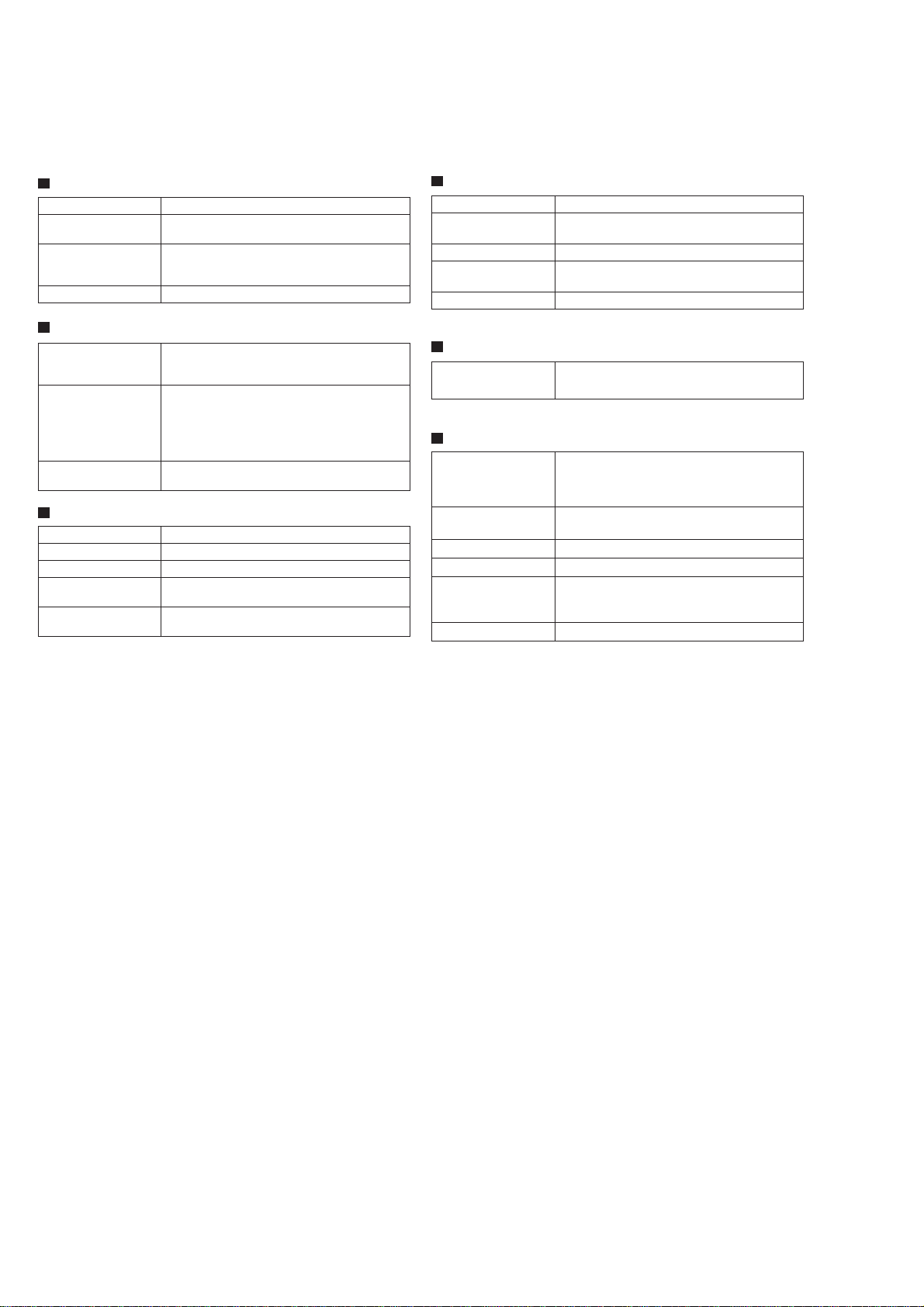

[2]

SPECIFICATIONS

General

Power source AC 120 V, 60 Hz

Power

consumption

Dimensions Width: 6-3/4" (175 mm)

Weight 12.4 lbs. (5.6 kg)

96 W

Height: 9-1/2" (240 mm)

Depth: 12-1/5" (315 mm)

Amplifier

Output power 115 watts minimum RMS per channel into 6

Output terminals Speakers: 6 ohms

Input terminals Video/Auxiliary (audio signal):

ohms from 100 Hz to 20 kHz, 10% total harmonic distortion

Headphones: 16 - 50 ohms

(recommended: 32 ohms)

Subwoofer pre-out (audio signal):

200 mV/10 k ohms at 70 Hz

500 mV/47 k ohms

USB

Class Mass storage class

Support File MP3/WMA (do not support DRM file)

Format support FAT 16 or FAT 32

Bitrate support MP3 (32 ~ 320 kbps)

Other MP3 lD3 - tag only supports version 1.x

WMA (64 ~ 160 kbps)

USB supports version 2.0

CD player

Type 5-disc multi-play compact disc player

Signal readout Non-contact, 3-beam semiconductor laser

D/A converter 1-bit D/A converter

Frequency

response

Dynamic range 90 dB (1 kHz)

pickup

20 - 20,000 Hz

Tuner

Frequency range FM: 87.5 - 108 MHz

AM: 530 - 1,720 kHz

Speaker

Type 2-way type light-up speaker system

2" (5 cm) tweeter

5-1/8" (13 cm) woofer

Maximum input

power

Rated input power 115 W

Impedance 6 ohms

Dimensions Width: 6-1/2" (165 mm)

Weight 6.21 lbs. (2.8 kg/each)

230 W

Height: 10-1/4" (260 mm)

Depth: 10-13/16" (275 mm)

1 – 4

1 – 2

Page 5

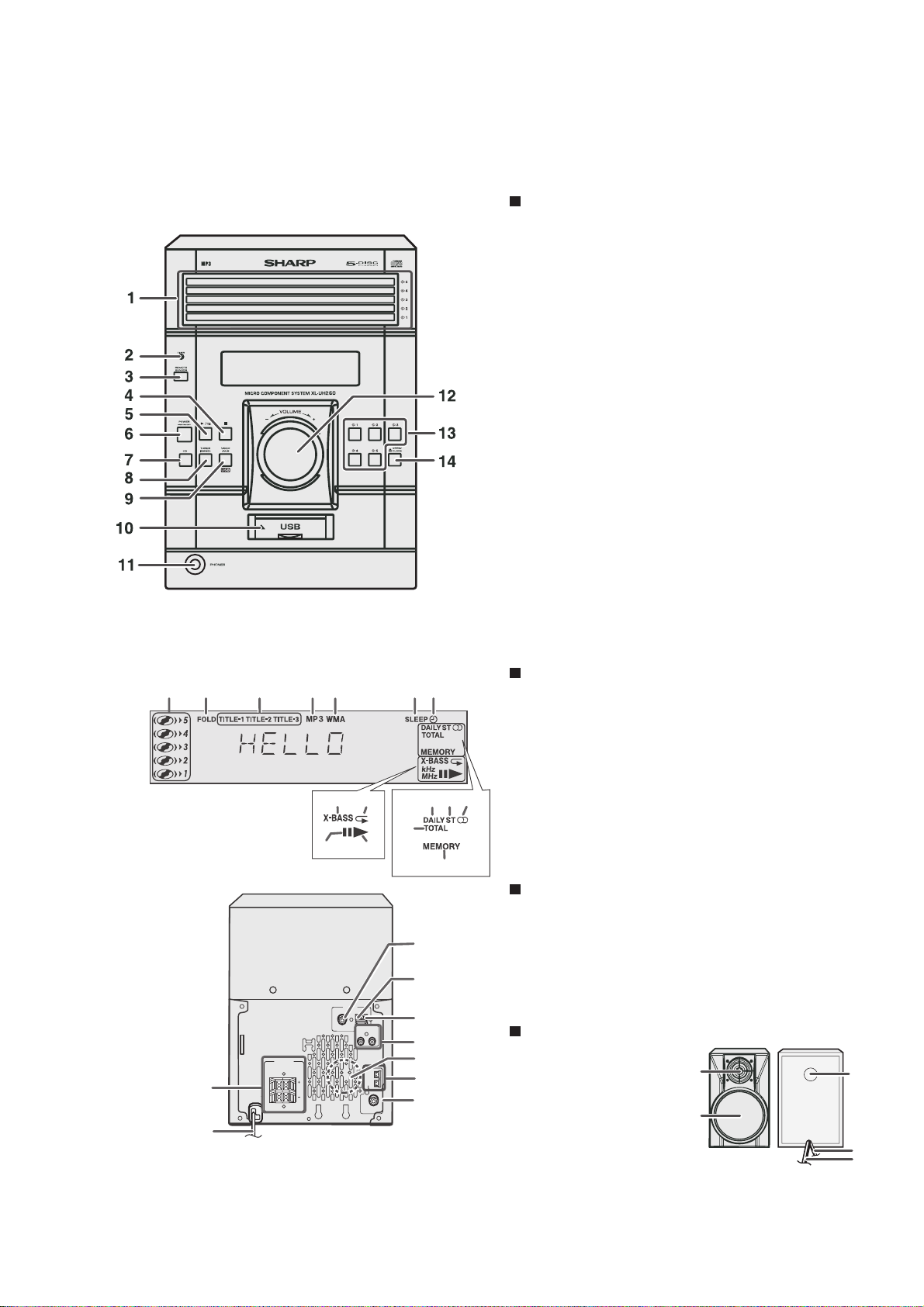

[3]

NAMES OF PARTS

XL-UH260

Controls and indicators

Front panel

1. Disc Trays

2. Timer Indicator

3. Remote Sensor

4. Disc or USB Stop Button

5. Disc or USB Play or Repeat Button

6. Power ON/STANDBY Button

7. CD Button

8. Tuner (Band) Button

9. Video/Auxiliary/USB Button

10. USB Terminal

11. Headphone Jack

12. Volume Control

13. Disc Number Select Buttons

14. Disc Tray Open/Close Button

12 3 45 67

13 14

9 10 11

8

15

16

12

3

4

ANTENNA

FM

GND

AM

75 OHMS

VIDEO/AUX I

RIGHTLEFT

SPEAKER

S

RATED SPEAKER IMPEDANCE

:

6 OHMS MIN

.

1

AC INPUT

RIGHT

LEFT

T

S

P

H

R

U

G

I

E

-

R

T

AK

H

E

G

FT

I

E

L

SP

L

R

E

T

F

U

O

OO

E

W

R

B

P

U

S

5

N

6

7

8

9

2

Display

1. Disc Number Indicators

2. MP3/WMA Folder Indicator

3. MP3/WMA Title Indicators

4. MP3 Indicator

5. WMA Indicator

6. Sleep Indicator

7. Timer Play Indicator

8. MP3/WMA Total Indicator

9. Daily Timer Indicator

10. FM Stereo Mode Indicator

11. FM Stereo Receiving Indicator

12. Memory Indicator

13. Extra Bass Indicator

14. Disc or USB Repeat Play Indicator

15. Disc or USB Pause Indicator

16. Disc or USB Play Indicator

Rear panel

1. Speaker Terminals

2. AC Power Cord

3. FM 75 Ohms Antenna Jack

4. AM Antenna Ground Terminal

5. AM Loop Antenna Terminal

6. Video/Auxiliary (Audio Signal) Input Jacks

7. Cooling Fan

8. Speaker Light-up Jacks

9. Subwoofer Pre-output Jack

Speaker system

1.Tweeter

2.Woofer

3.Bass Reflex Duct

4.

Speaker Light-up Wire

Speaker Wire 5.

1

2

3

4

5

1 – 5

1 – 3

Page 6

XL-UH260

1

11

7

12

8

13

2

9

14

15

16

17

18

10

19 20

3

2221

23 24

4

5

25

6

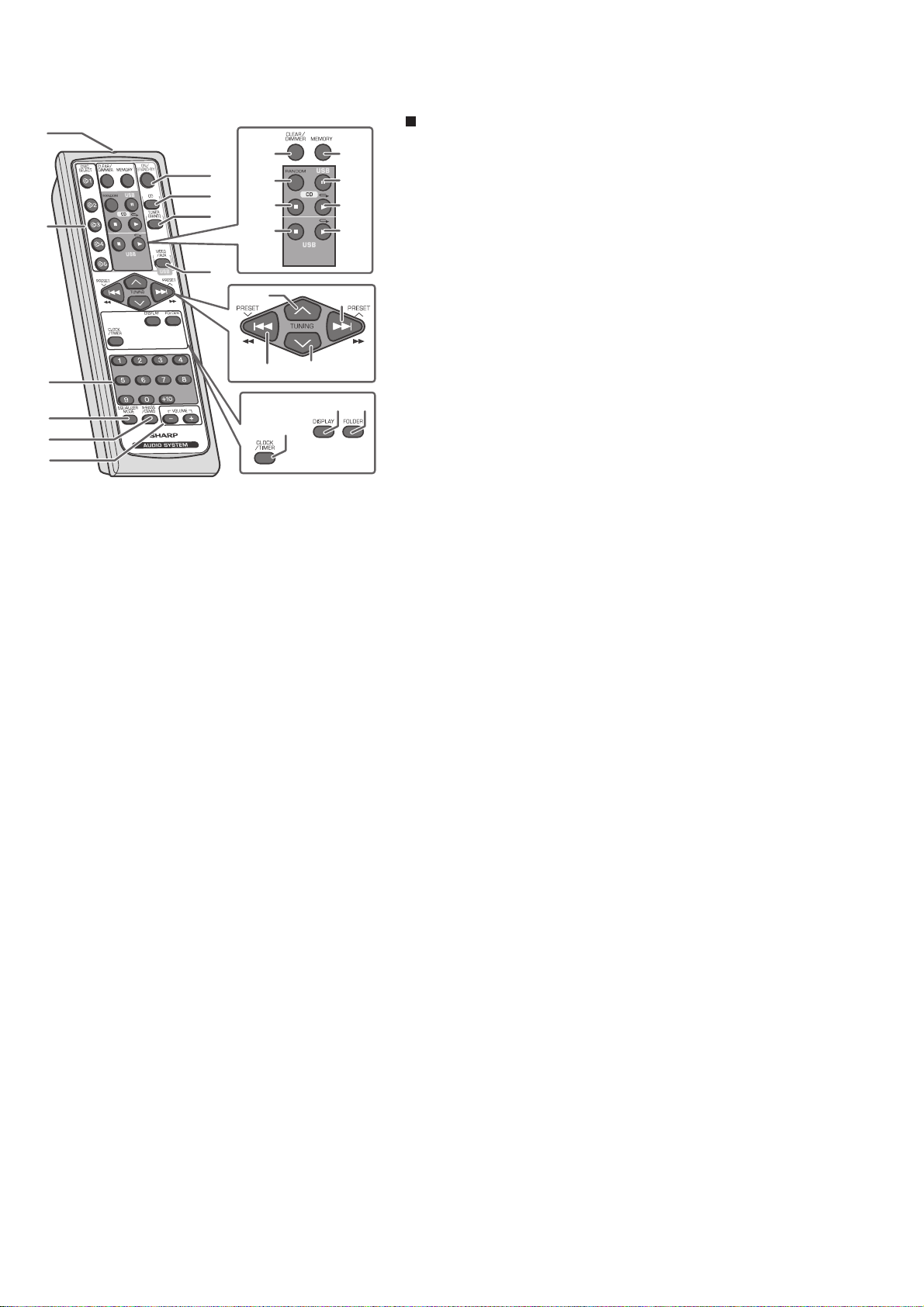

Remote control

1. Remote Control Transmitter

2. Disc Number Select Buttons

3. Disc Direct Search Buttons

4. Equalizer Mode Select Button

5. Extra Bass/Demo Button

6. Volume Up and Down Buttons

7. Power On/Stand-by Button

8. CD Button

9. Tuner (Band) Button

10. Video/Auxiliary/USB Button

11. Disc Clear/Dimmer Button

12. Disc Random Button

13. Disc Stop Button

14. USB Stop Button

15. Memory Button

16. Disc/USB Pause Button

17. Disc Play or Repeat Button

18. USB Play or Repeat Button

19. Tuning Up Button

20. CD Track Up or Fast Forward, Tuner Preset Up,

Time Up Button

21. CD Track Down or Fast Reverse, Tuner Preset Down,

Time Down Button

22. Tuning Down Button

23. Display Button

24. Folder Button

25. Clock/Timer Button

1 – 6

1 – 4

Page 7

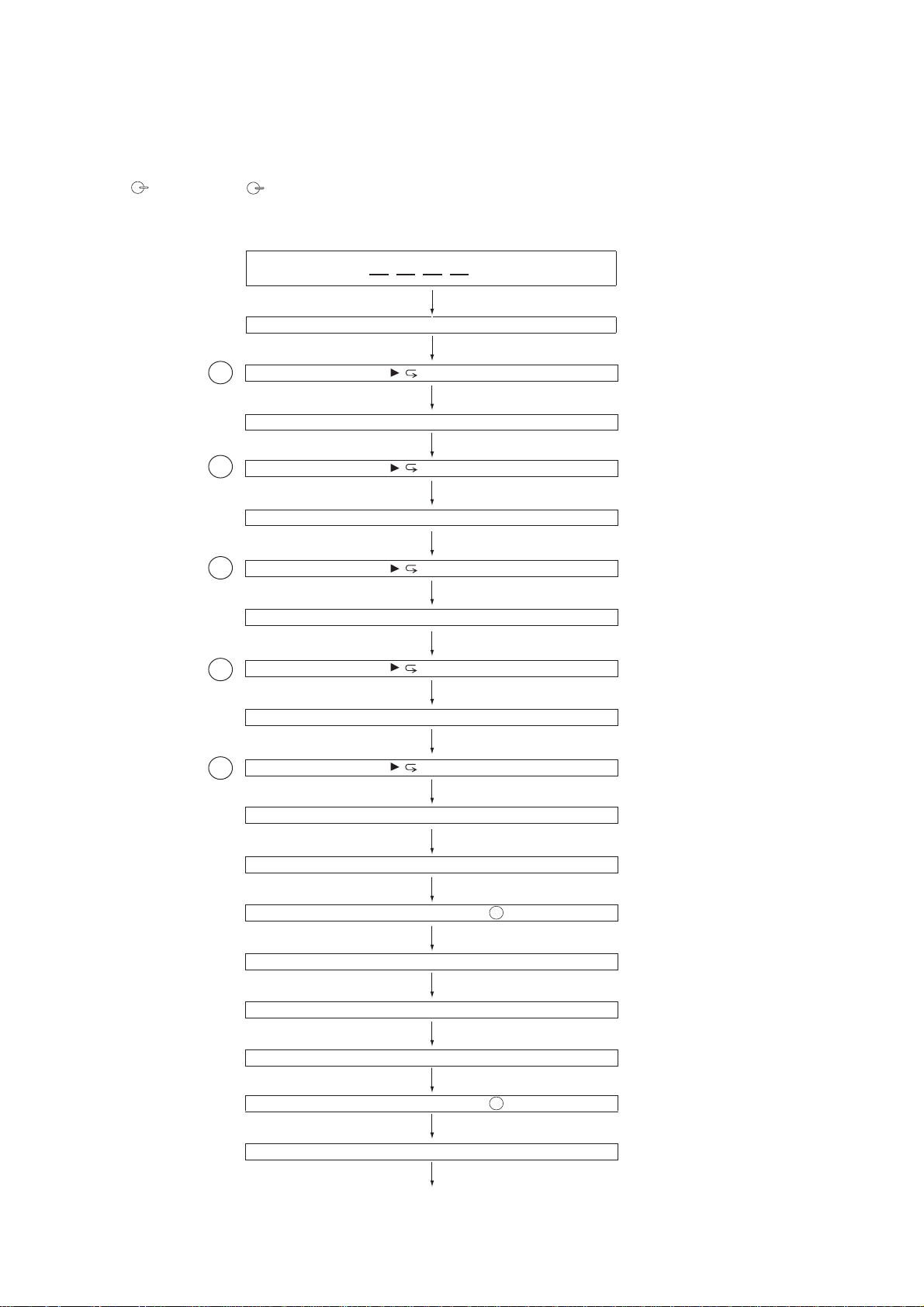

CHAPTER 2. ADJUSTMENTS

[1] CD SECTION

1. CD SECTION

• Adjustment

Since this CD system incorporates the following auto-

matic adjustment functions, readjustment is not

needed when replacing the pickup. Therefore, different PWBs and pickups can be combined freely.

Each time a disc is changed, these adjustments are

performed automatically. Therefore, playback of each

disc can be performed under optimum conditions.

Items adjusted automatically

1) Offset adjustment (The offset voltage between the

head amplifier output and the VREF reference voltage is compensated inside the IC.)

* Focus offset adjustment

* Tracking offset adjustment

2) Tracking balance adjustment

3) Gain adjustment (The gain is compensated inside the

IC so that the loop gain at the gain crossover frequency will be 0 dB.)

* Focus gain adjustment

XL-UH260

* Tracking gain adjustment

2. CD ERROR CODE DESCRIPTION

Error Explanation

10* CAM error. Can't detect CAM switch when CAM is moving.

11* When it detect cam operation error during initialize process.

20* TRAY error. Can't detect TRAY switch when TRAY is mov-

ing.

21* When it detect TRAY operation error during initialize pro-

cess.

* 'CHECKING'

If Error is detected, 'CHECKING' will be displayed

instead of 'ER-CD**'. 'ER-CD**' display will only be

displayed when error had been detected for the 5

times.

th

2 – 1

Page 8

XL-UH260

[2] TEST MODE

• Setting the test mode

During stand-by mode, press STOP button while pres sing down the button and button. Then, press

3

the CD button to enter the test mode.

4

\

Step

Step

Step

Step

C DTEST

OPEN/CLOSE operation is using manual. IL isn’t done

/

1

2

3

4

<< >> key input.

Laser ON.

/

<< >> key input.

Focus ON

/

<< >> key input.

CLV Servo ON

/

<< >> key input.

Tracking Servo ON

IL isn’t done

Step

/

5

Hold down << CD >> key for more than 2 sec.

Start Auto Adjustment at current pick-up location.

<< >> key input.

Reading Sub-code and Display

<<STOP>> key input.

STOP and return to Step

<<STOP>> key input.

STOP and return to Step

Everytime << DISPLAY >> key input

1

1

2 – 2

Page 9

a) Focus Balance = FB : XX

b) Focus Gain = FG : XX

c) Tracking Balance = TB : XX

d) Tracking Gain = TG : XX

e) Focus Offset = FOFF : XX

f) Tracking Offset = TOFF : XX

g) RFRP = RFRP : XX

h) Focus Error

(RW Judgement) = RW : XX - XX =XX

i) Focus Error

(Other than RW Judgement) = DA : XX - XX =XX

<<STOP>> key input.

XL-UH260

STOP and return to Step

Note

Sliding the PICKUP with<< >>, << >> button can be set

in STOP mode or play mode.

During at Step , if press << >> for more than 1 sec, it directly

goes to step .

To cancel: Power OFF

1

5

/

1

2 – 3

Page 10

XL-UH260

[3] Standard Specification of Stereo System Error Message Display Contents

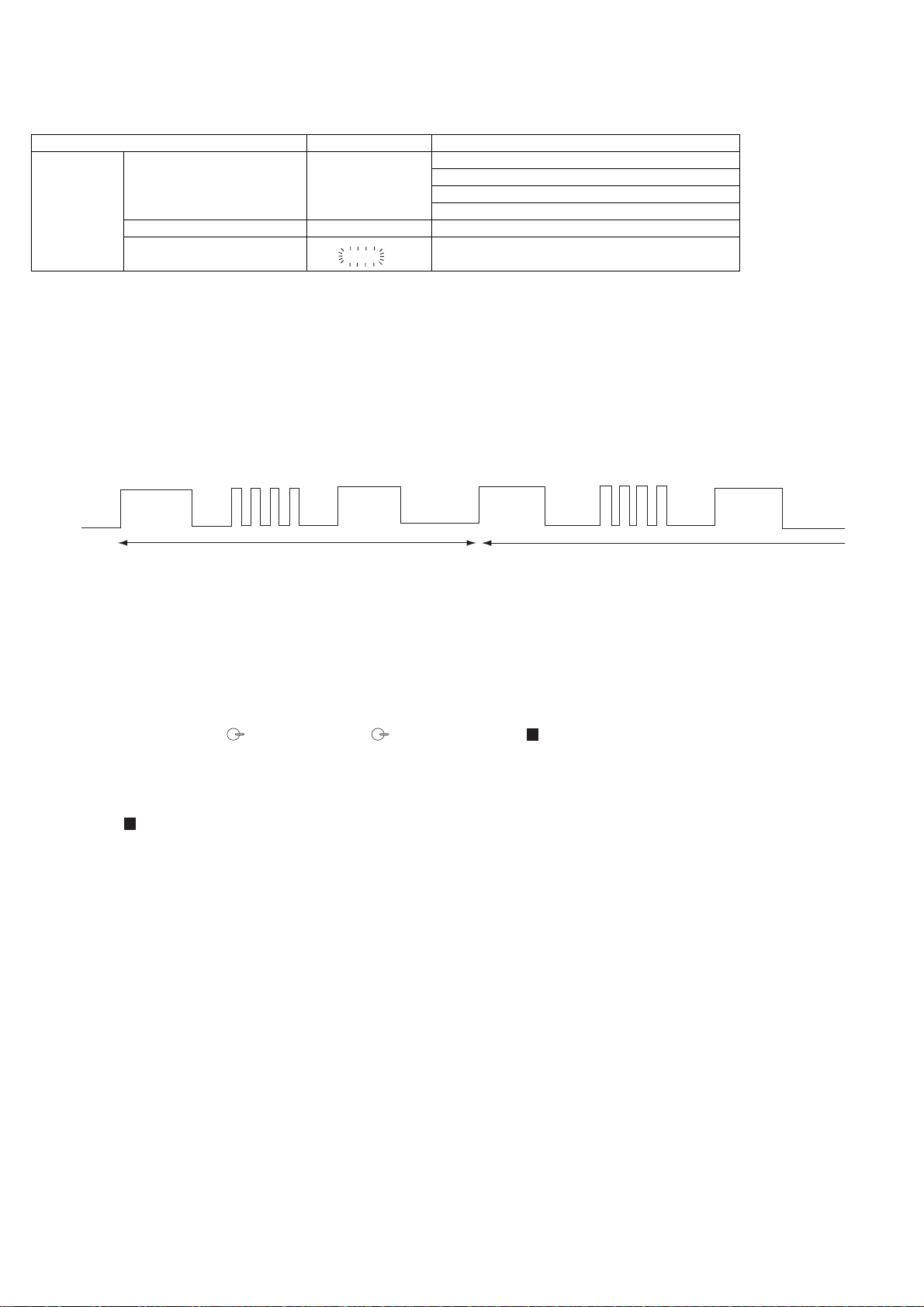

Error Contents DISPLAY Notes

CD CD Changer Mechanism Error. ‘ER-CD**’ (*) 10: CAM SW Detection NG during normal operation

11: CAM SW Detection NG during initialize process

20: TRAY SW Detection NG during normal operation

21: TRAY SW Detection NG during initialize process

Focus Not Match/IL Time Over. ‘NO DISC’

TUNER PLL Unlock.

87.50

FM MHz

(*) CHECKING:

If CD changer mechanism error is detected, 'CHECKING' will be display instead of 'ER-CD**'. 'ER-CD**' display will only

be display when error had been detected for the 5

th

times.

Speaker abnormal detection and +B PROTECTION display

In case speaker abnormal detection or +B PROTECTION had occurred, the unit will automatically enter to stand-by

mode and Timer indicator will flashing as below.

Example:In case of speaker abnormal

PLL Unlock.

ON

FLASHING FLASHING

ON ON ON

TIMER

LED OFF OFF

NO NO. 1.1

NO. 2

1

FRAME

OFF

OFF OFF OFF OFF

NO. 2

(REPEAT)

NO. 1 : +B PROTECTION

NO. 2 : Speaker abnormal

BEFORE TRANSPORTING THE UNIT

The following process need to be taken after set tapering/parts replacement.

1. Press the POWER ON/STAND-BY button to enter stand-b y mode.

2. While pressing down the button and the button, press the button. The Micro Computer version number

3

4

will be displayed as

"XL-U-****” and " FW****_V**”.

3. Turn the VOLUME KNOB until FL will display “INIT_ _MENU.”

4. Press the button until "WAIT"--> "FINISHED" appears.

5. Unplug the AC cord and the unit is ready for transporting.

2 – 4

Page 11

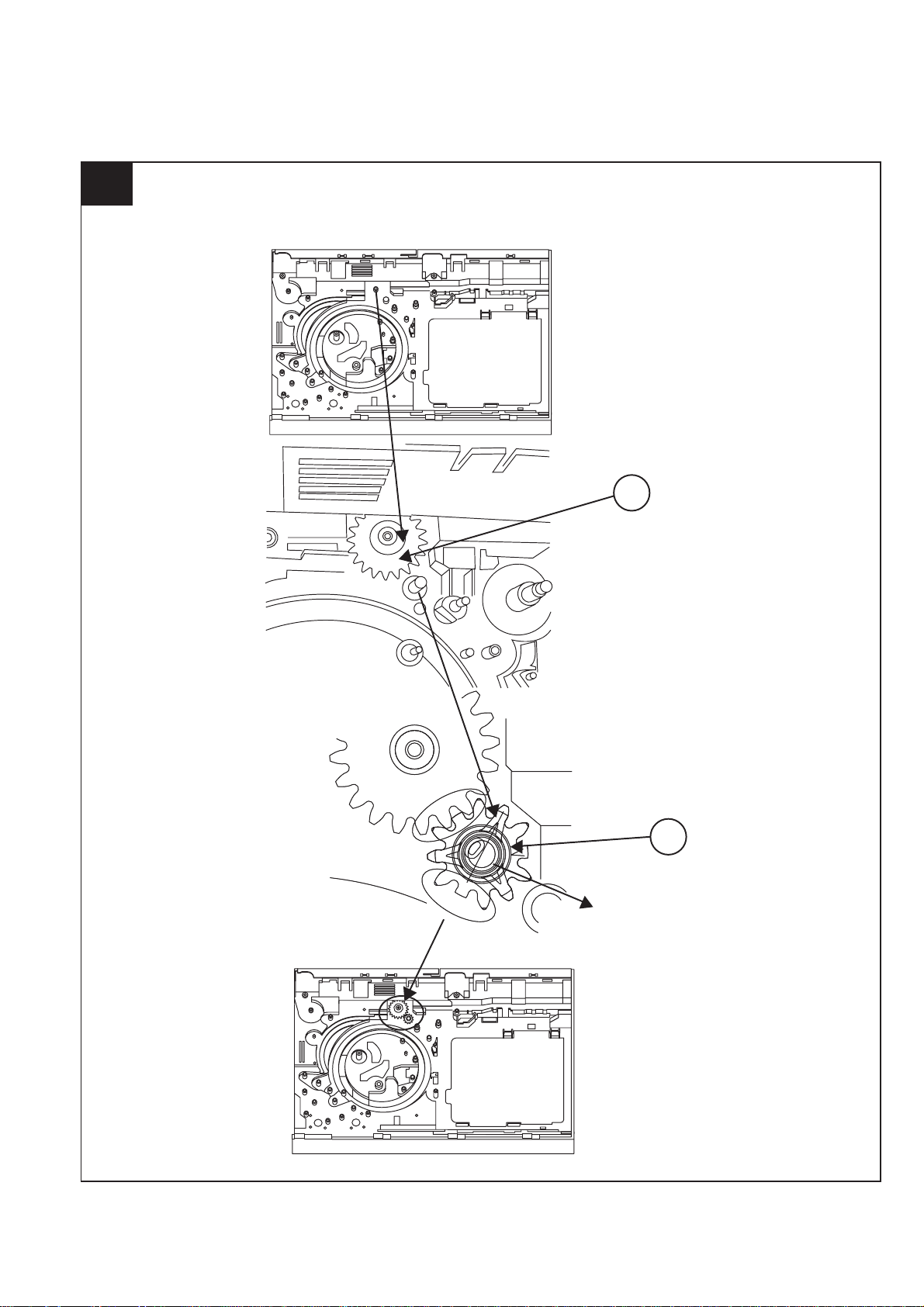

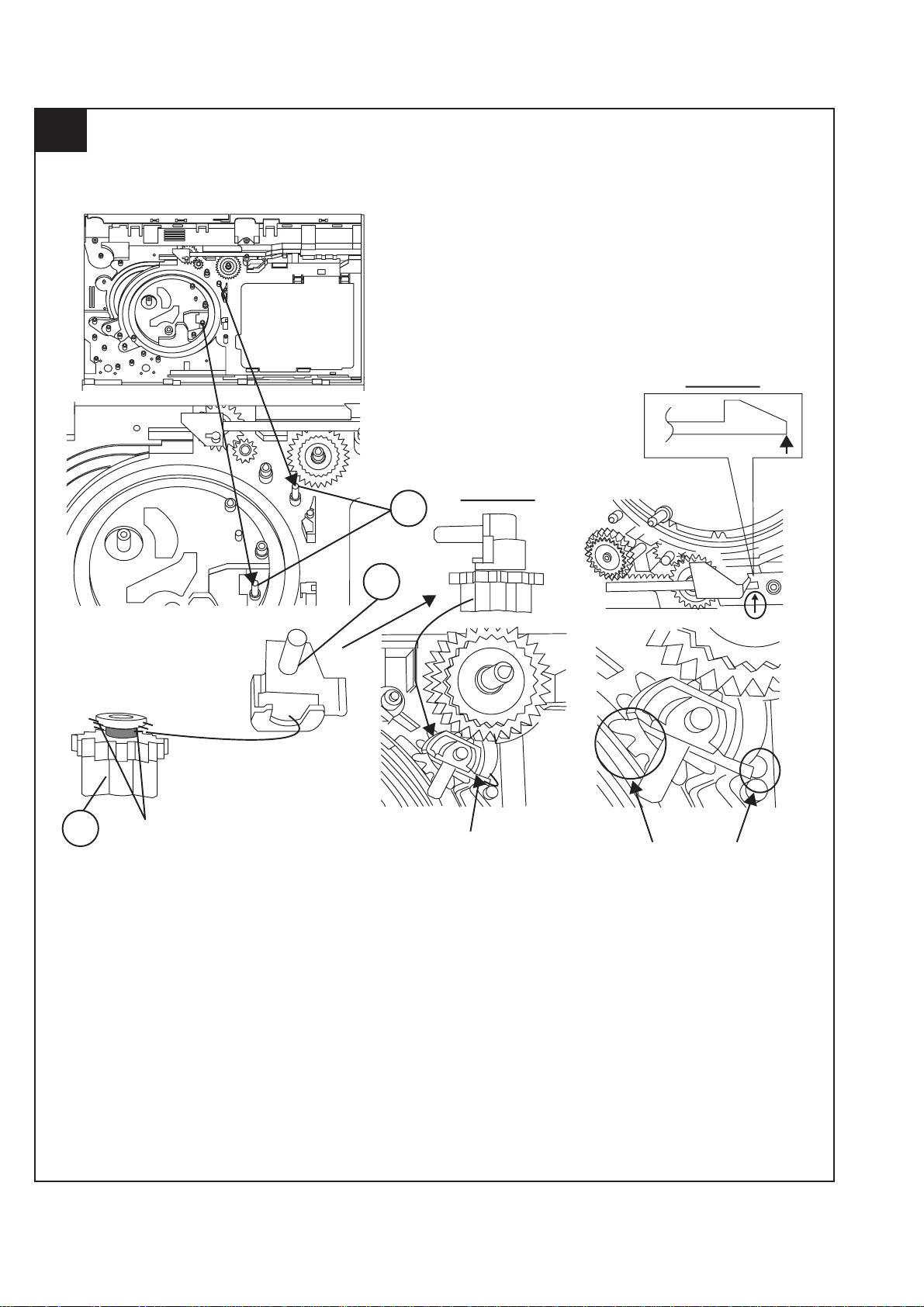

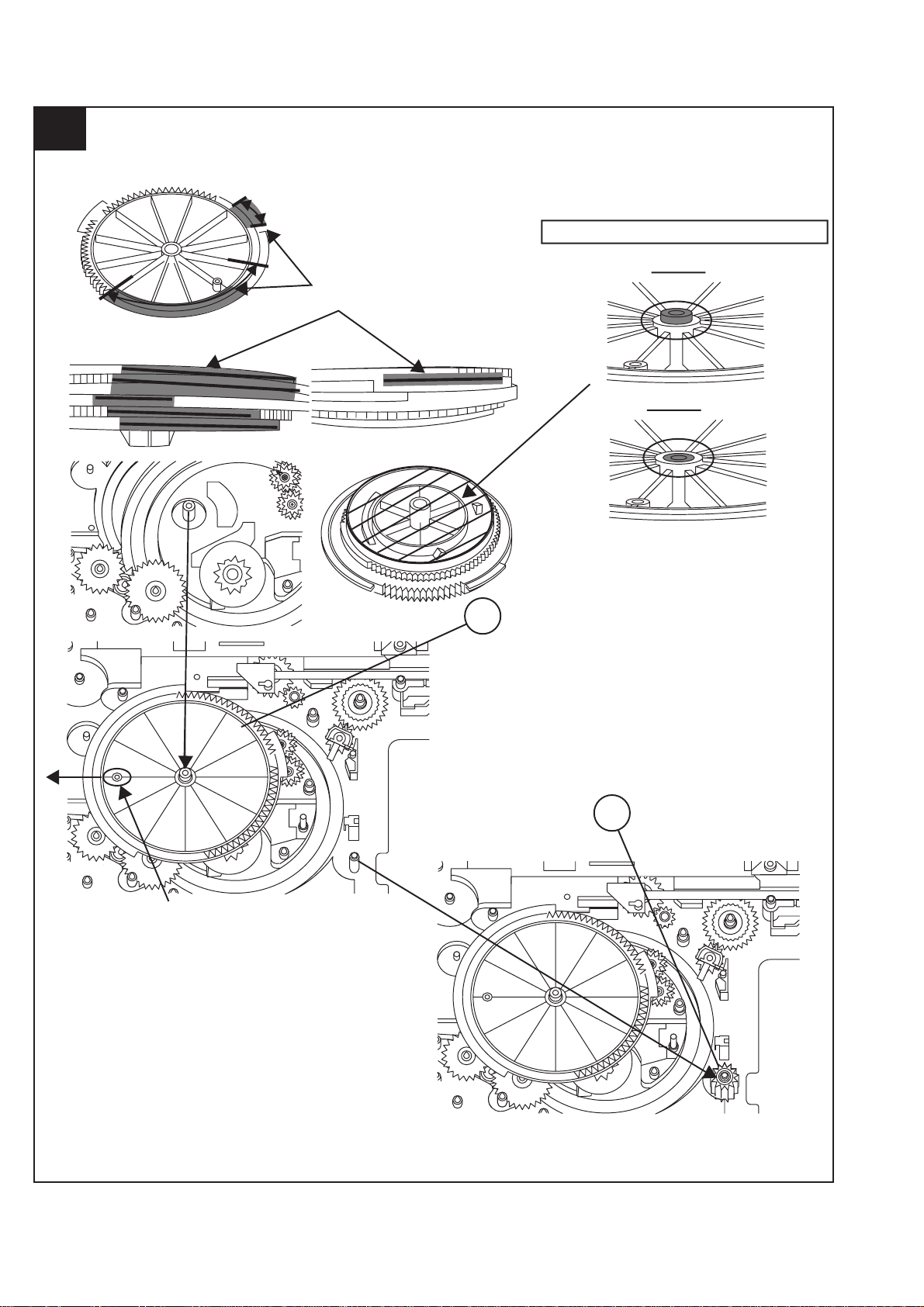

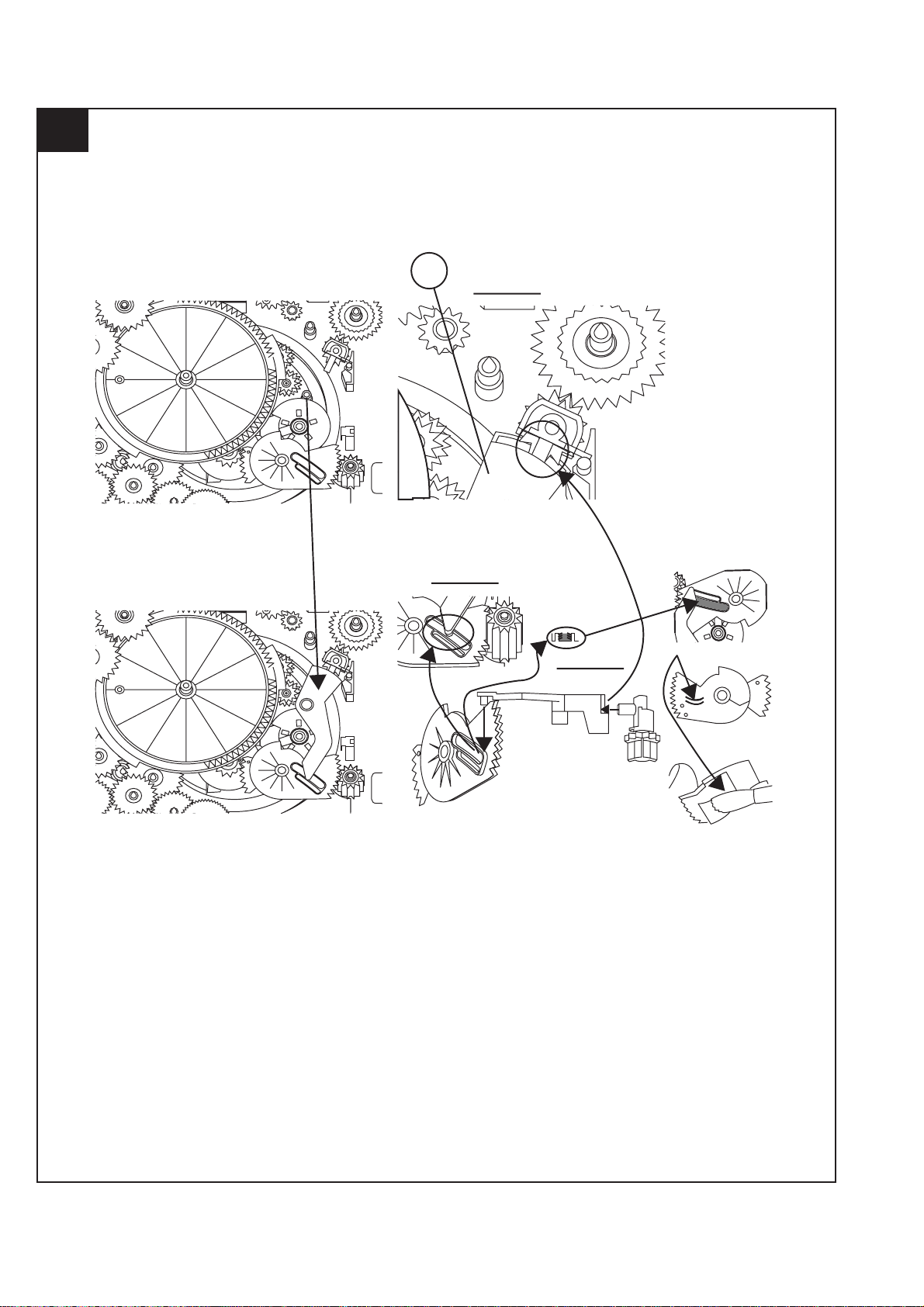

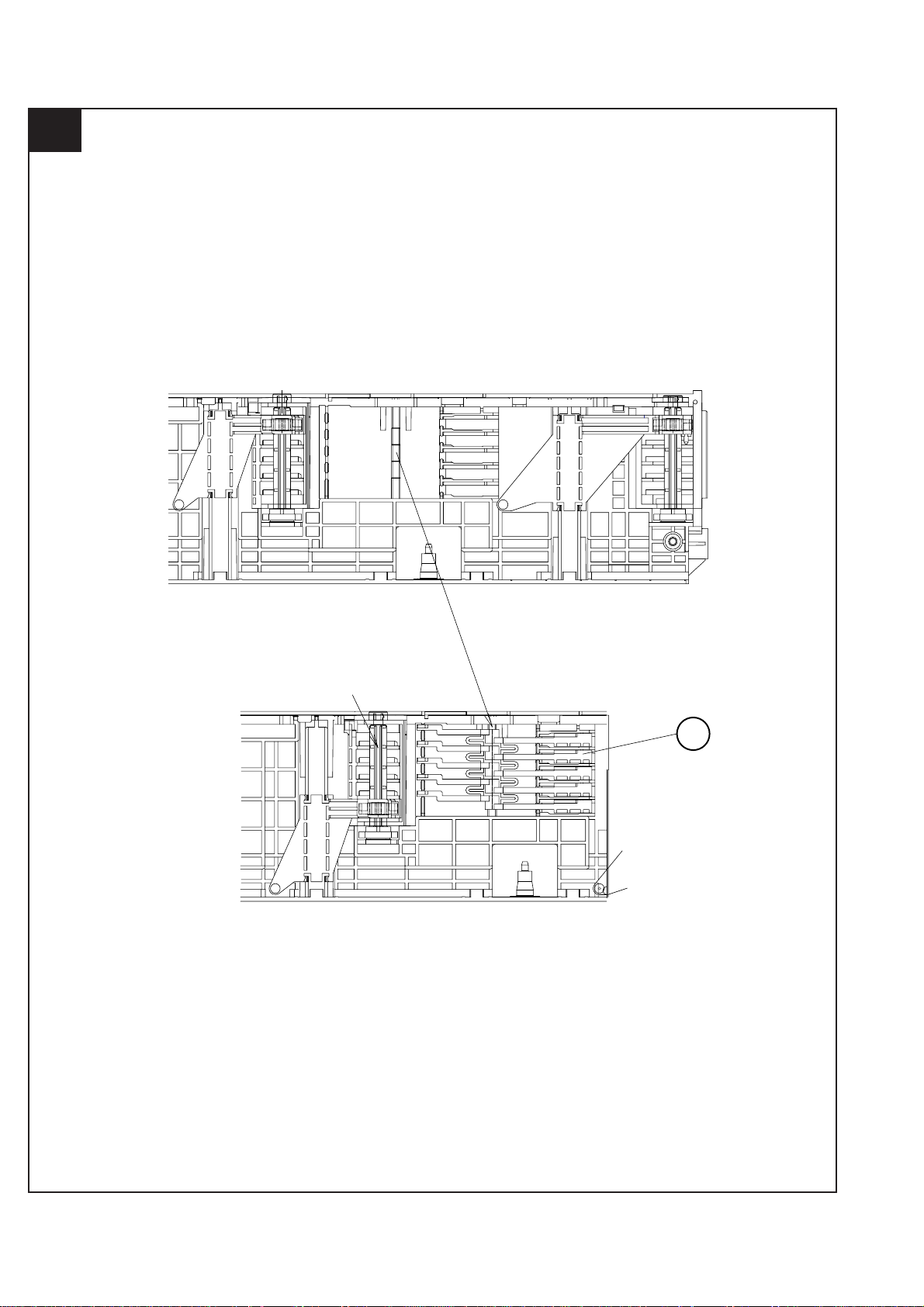

[4] CD Changer mechanism section

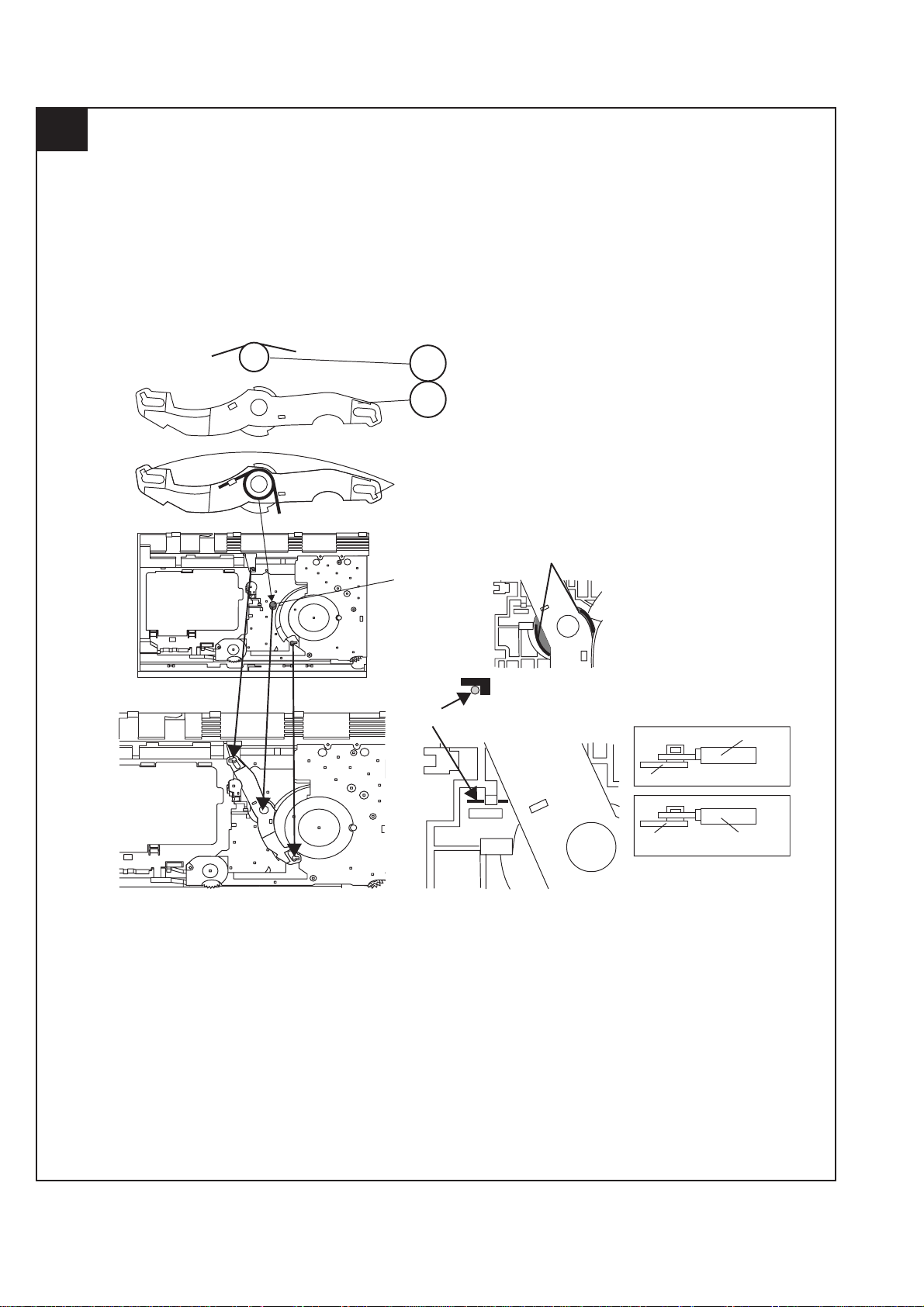

• All numbers in the drawing correspond to those in parts guide (CHANGER MECHANISM PARTS).

1

141

XL-UH260

2 – 5

140

HALF GEAR

MUST BE ARRANGED AS SHOWN

Page 12

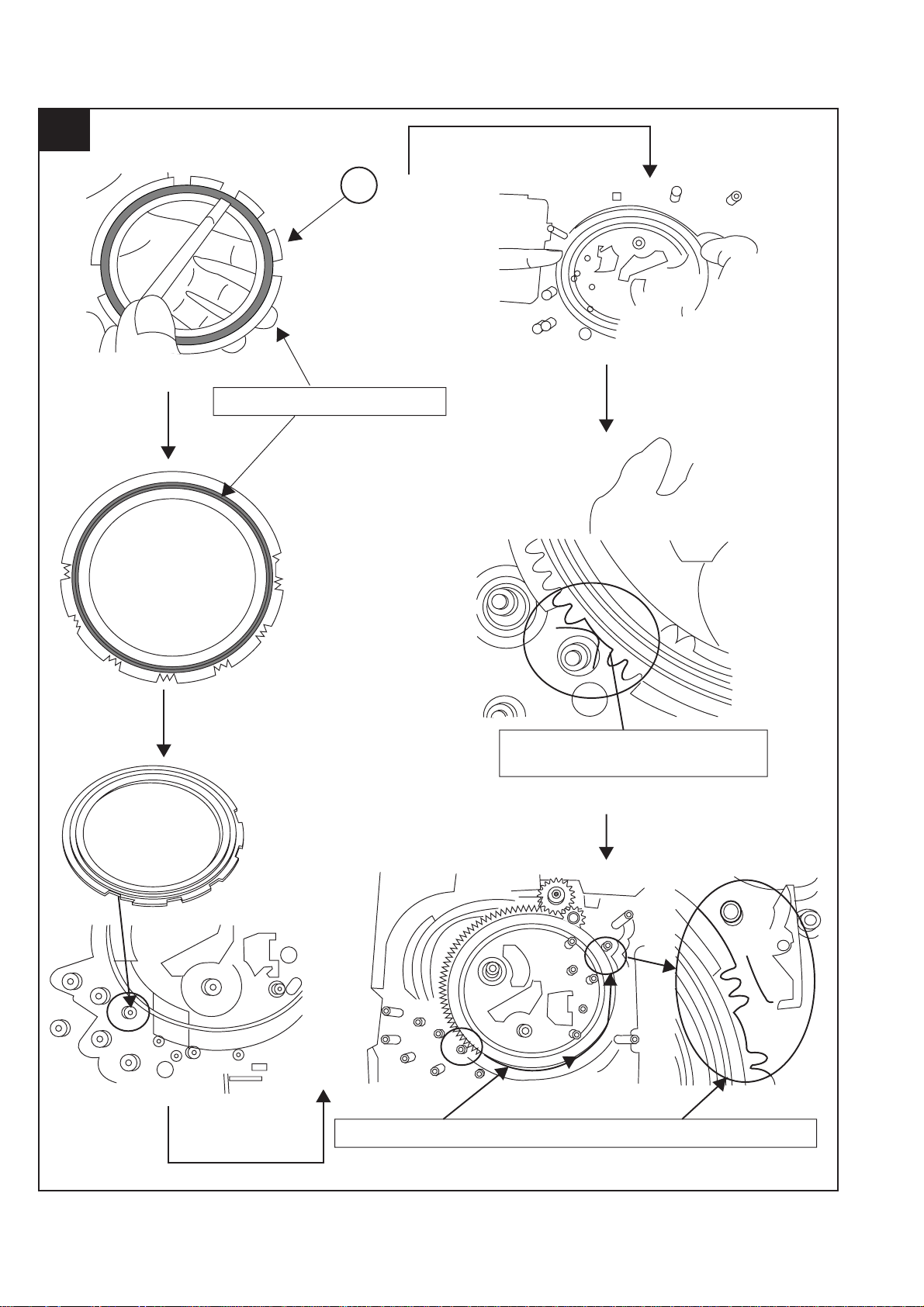

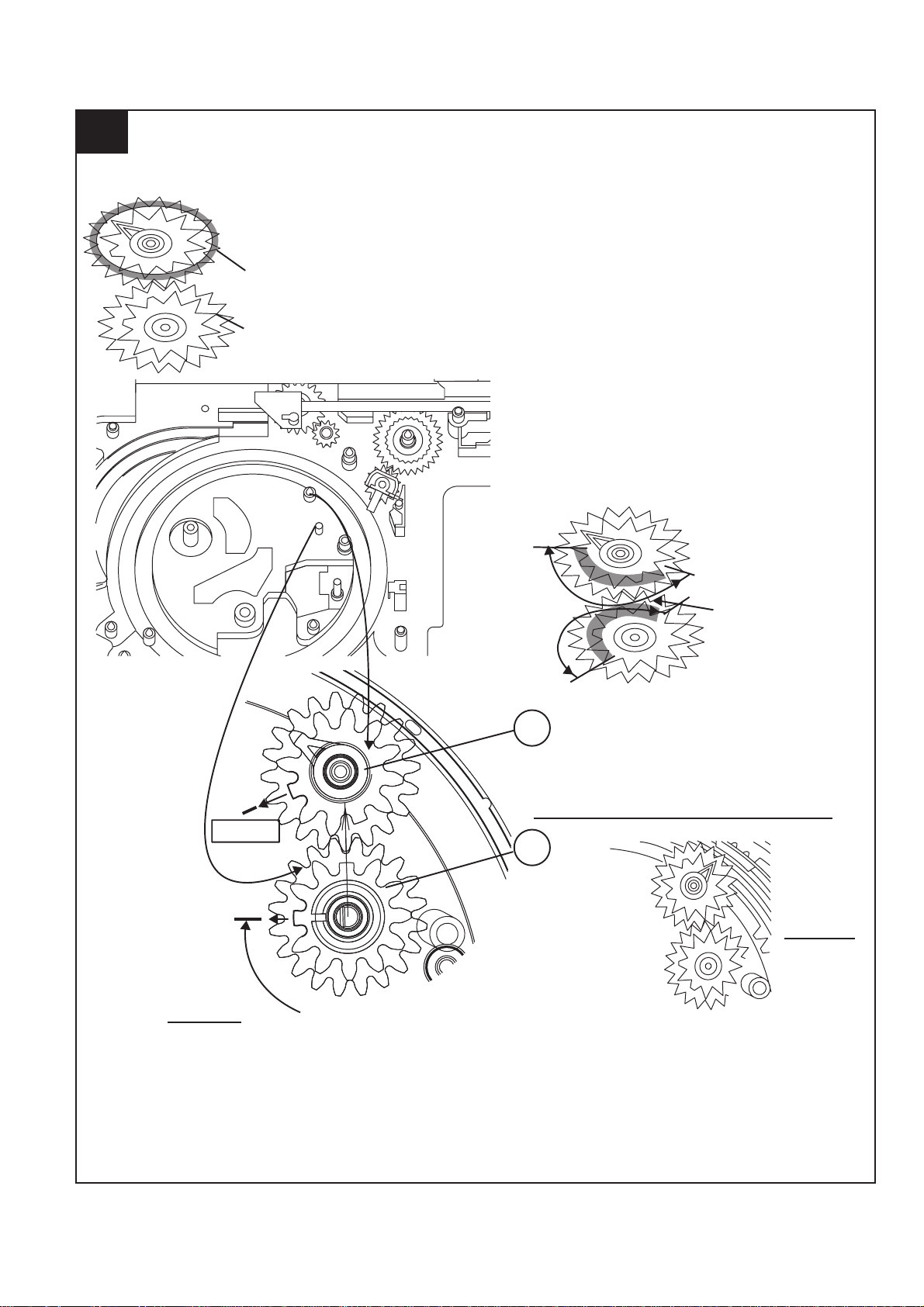

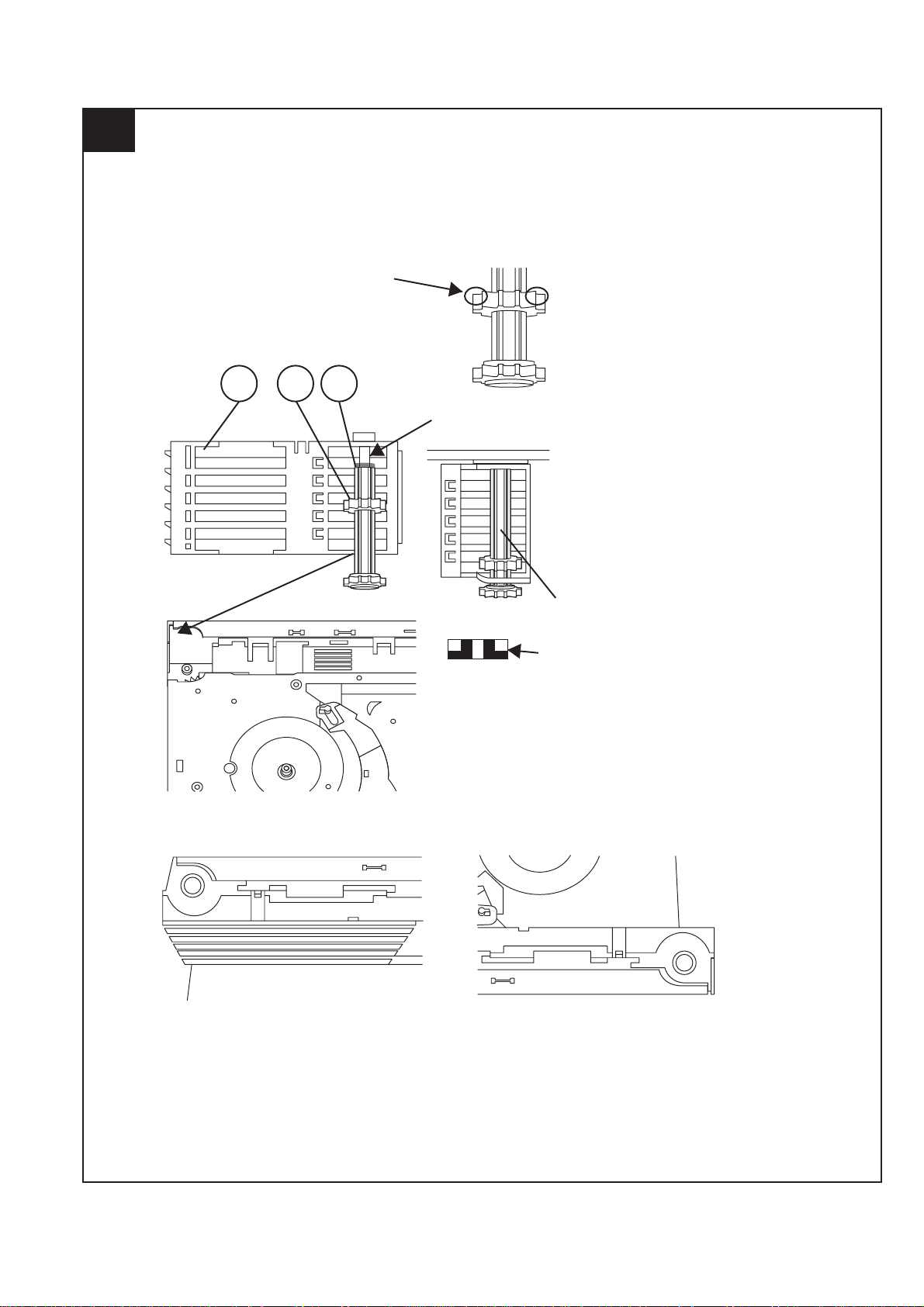

XL-UH260

2

139

APPLY SANKOL SHS1001 BEFORE FIX

FIX ITEM 139 ACCORDING TO THE

PICTURE AS SHOWN ABOVE

ROTATE MODE BIG GEAR UNTIL REACH AS SHOWN IN PICTURE

2 – 6

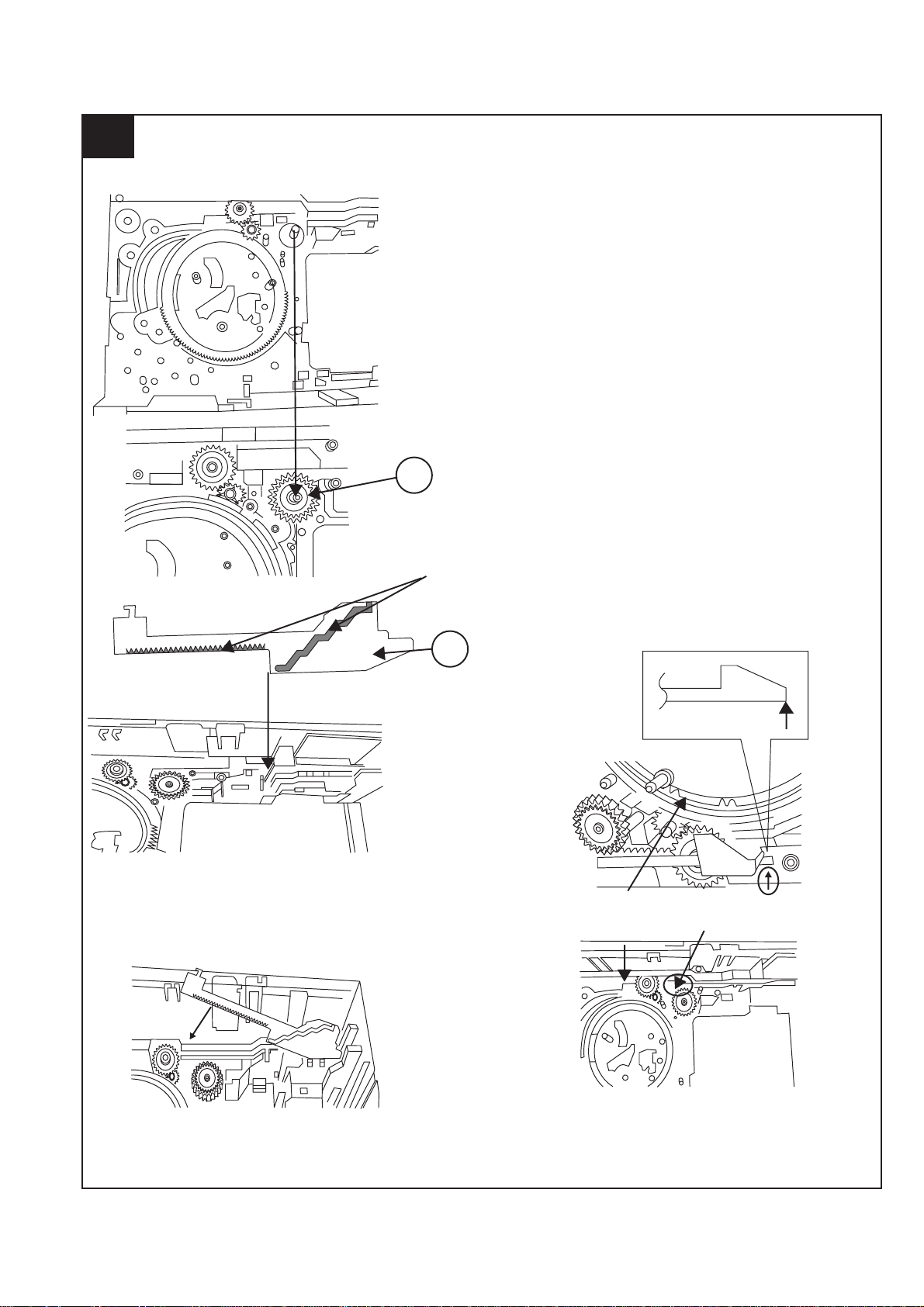

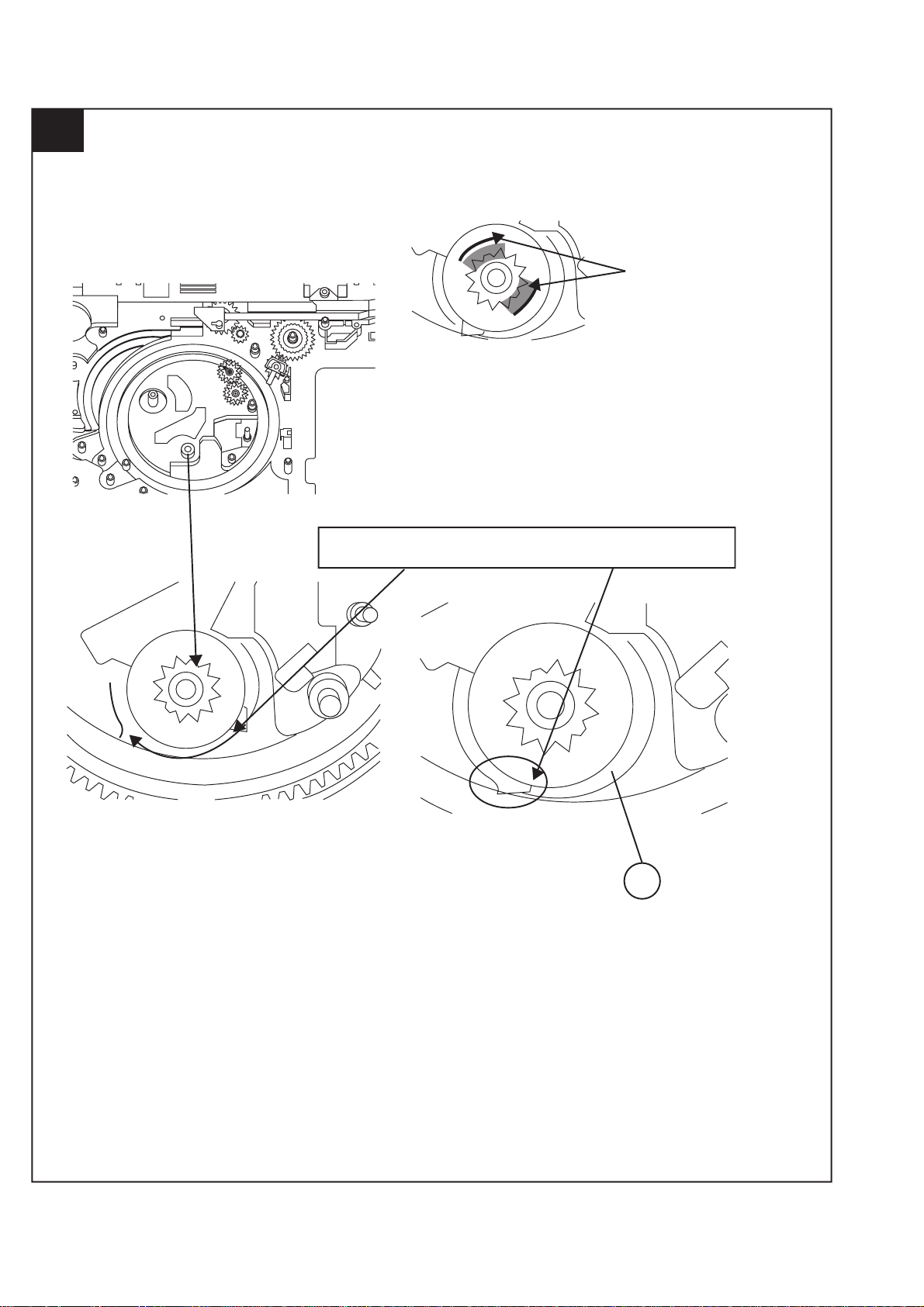

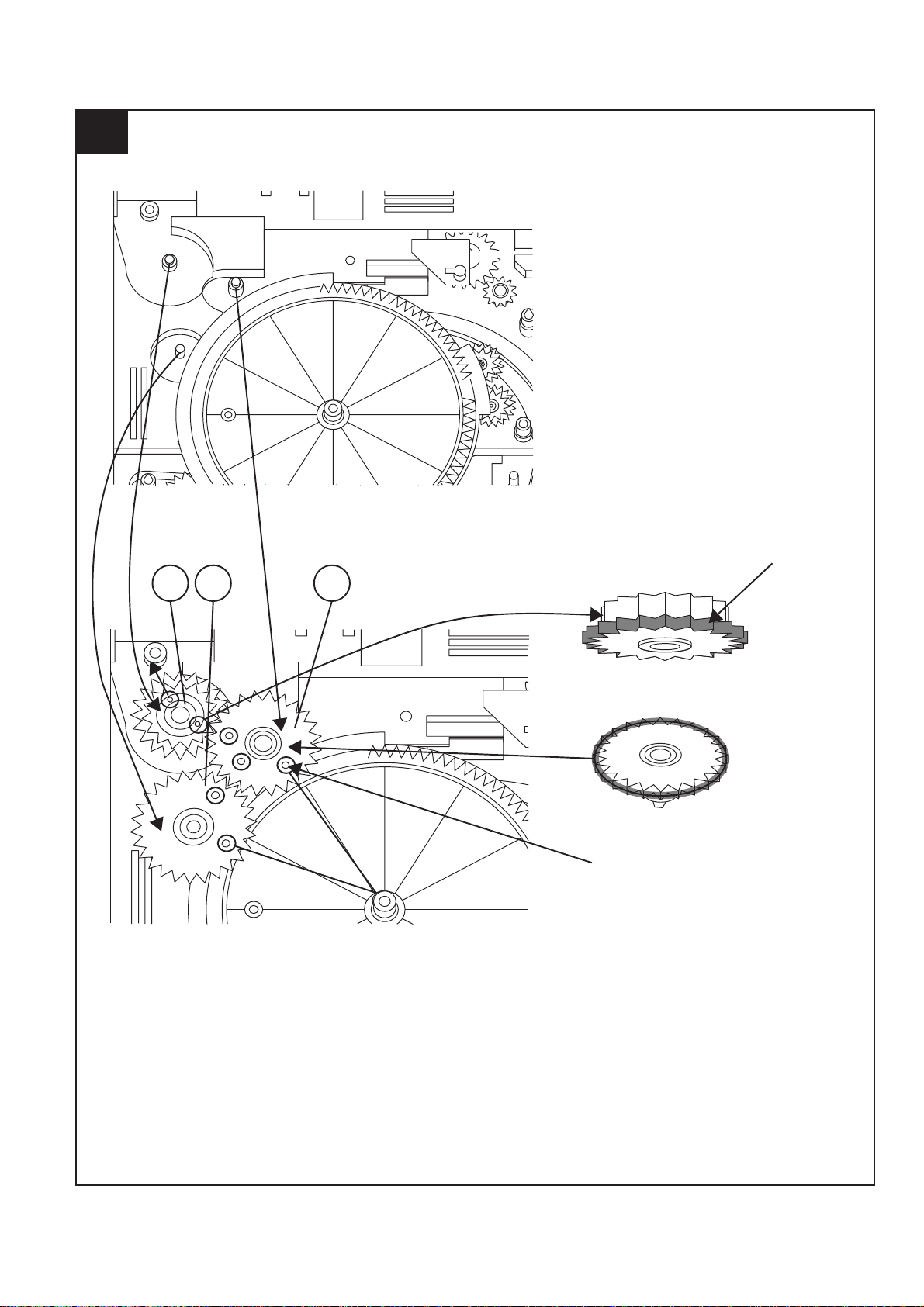

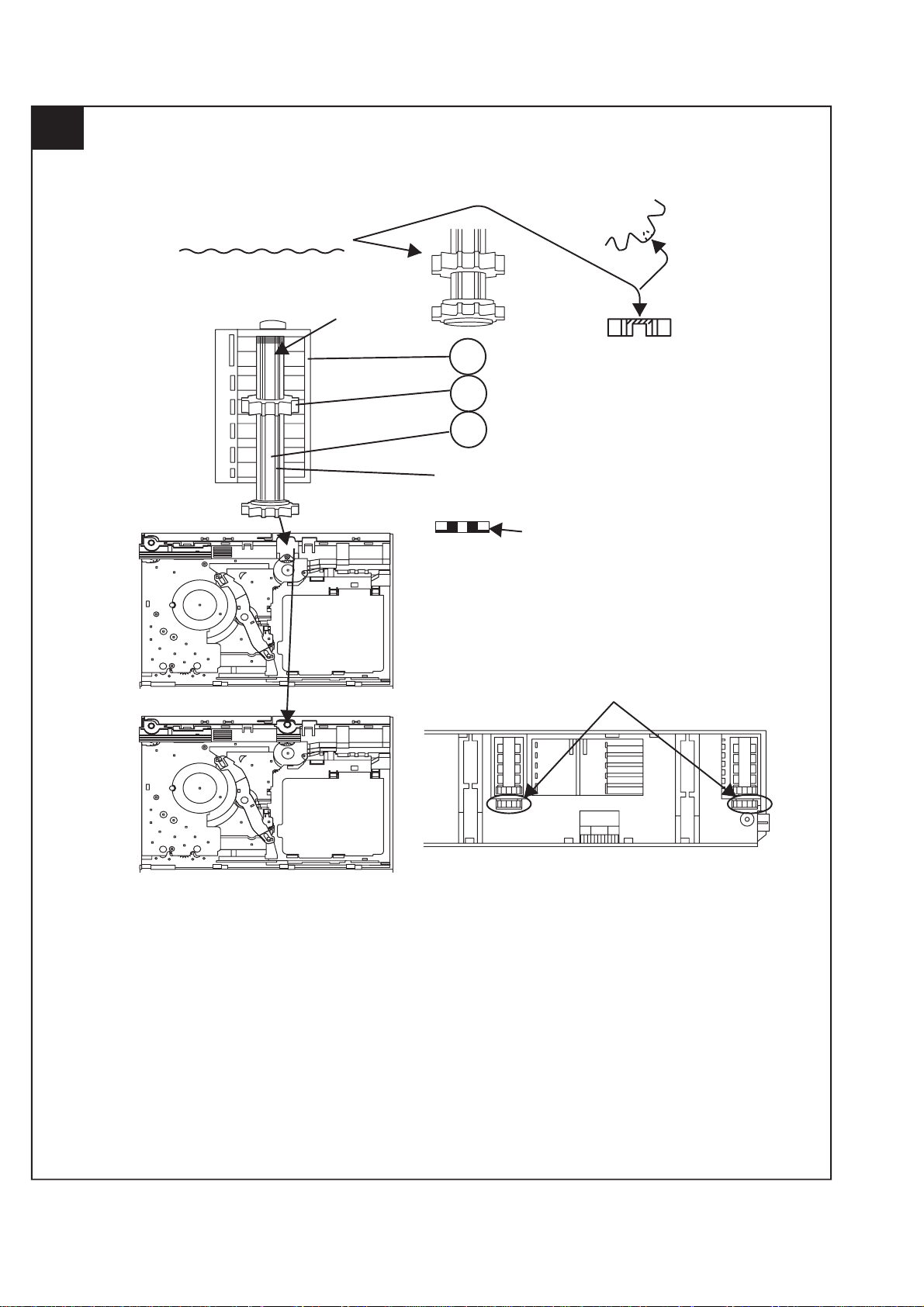

Page 13

3

XL-UH260

143

APPLY GREASE SC141

112

PULL THE LEVER UNITIL

REACH THE ARROW MARK

2 – 7

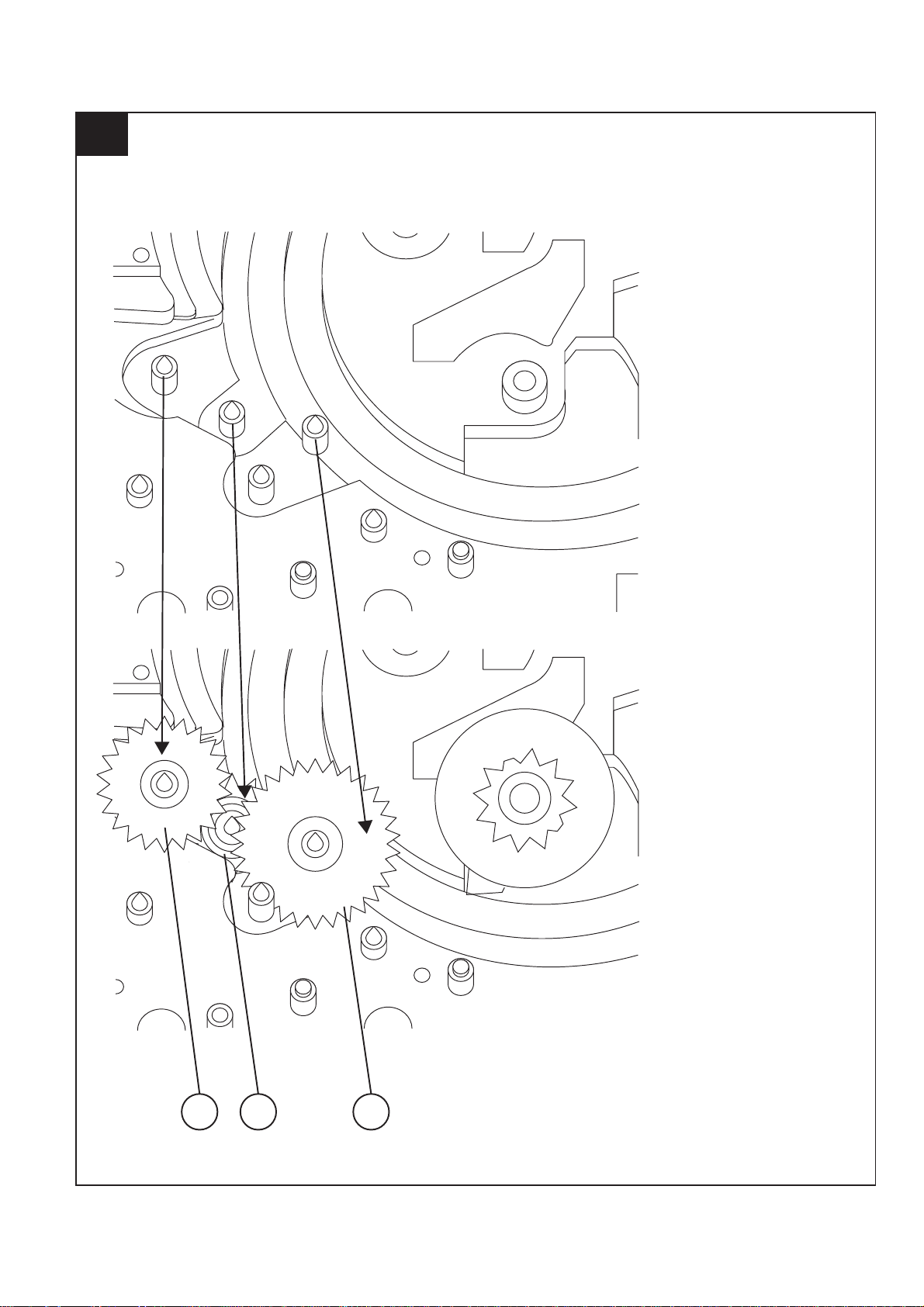

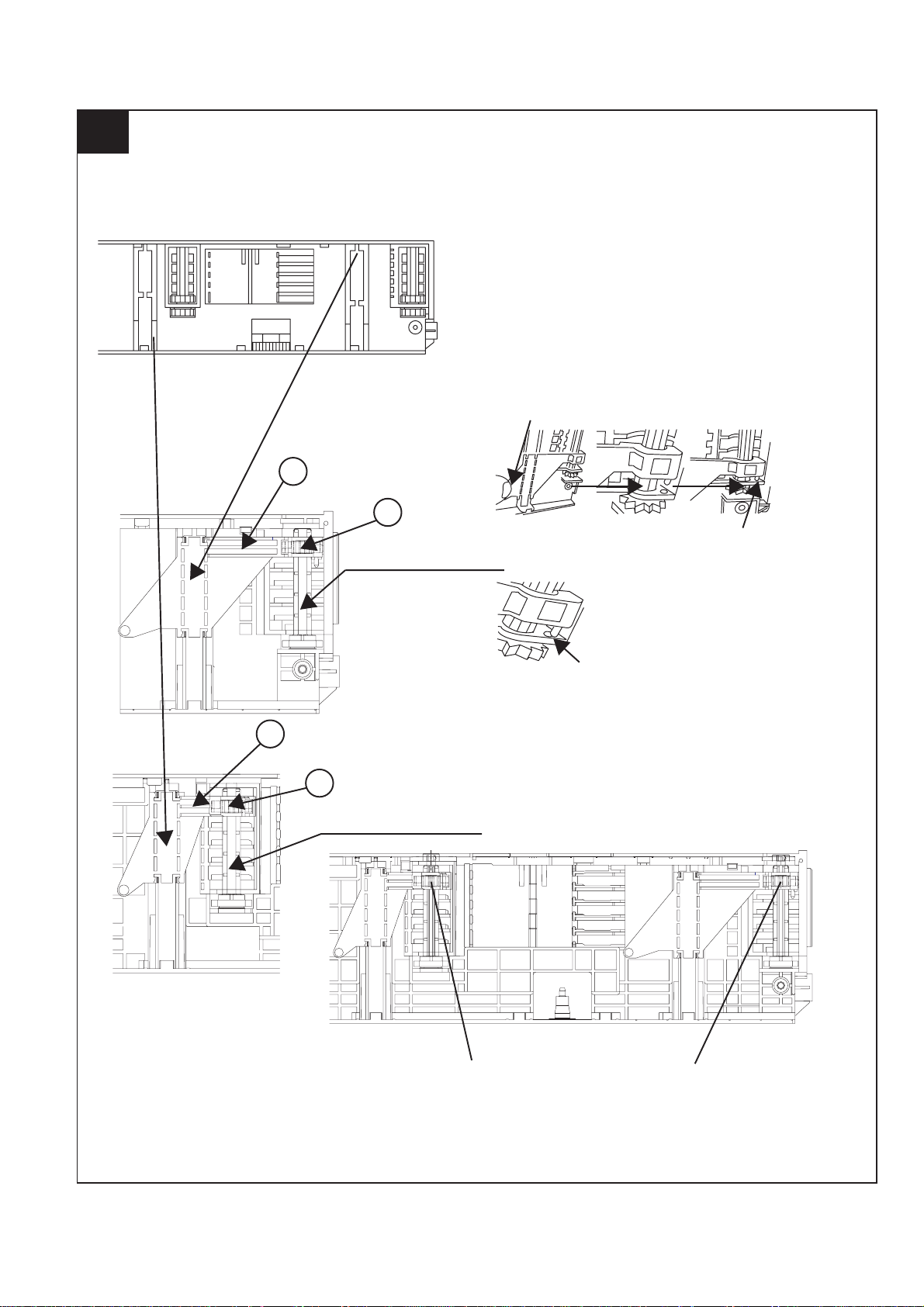

Page 14

XL-UH260

4

FIGURE 2

FIGURE 1

152

142

APPLY GREASE SC141

118

SLOT CLAMP

SWITCH ARM INSIDE BASE SLOT

HALF GEAR MUST BE

ARRANGED AS SHOWN

2 – 8

Page 15

5

XL-UH260

APPLY GREASE SC141 AT BOTTOM SIDE

OF GEAR FOLLOW MARKING (REFER TO GRAY AREA)

NO NEED TO APPLY GREASE AT BOTTOM

SIDE

FIGURE 1

APPLY GREASE SC141

AT TOP SIDE OF GEAR

FOLLOW MARKING

(REFER TO GRAY AREA)

127

IF DIRECTION IS OTHER THAN DIRECTION

SHOWN IN FIGURE 1, IT IS INCORRECT

CORRECT

128

INCORRECT

BLACK MARK

2 – 9

Page 16

XL-UH260

6

APPLY GREASE SC141

AT HALF GEAR AREA

ROTATE CLOCKWISE UNTIL REACH HERE (MAXIMUM)

129

2 – 10

Page 17

7

XL-UH260

151150149

2 – 11

Page 18

XL-UH260

8

THE SHOWN AREAMUST FREE FROM GREASE

CORRECT

GREASE SC141 APPLICATION LENGTH

GREASE APPLICATION PORTION

INCORRECT

SHOWN HOLE MUST FACING ARROW DIRECTION

124

131

2 – 12

Page 19

9

138

126

125

XL-UH260

APPLY GREASE SC141

AT BOTTOM SIDE

ONLY

TR-RE JOINT GEAR C

2 – 13

APPLY GREASE SC141 ONLY AT TOP SIDE GEAR

MUST BE FIXED ACCORDINGLY TO

THE HOLE'S

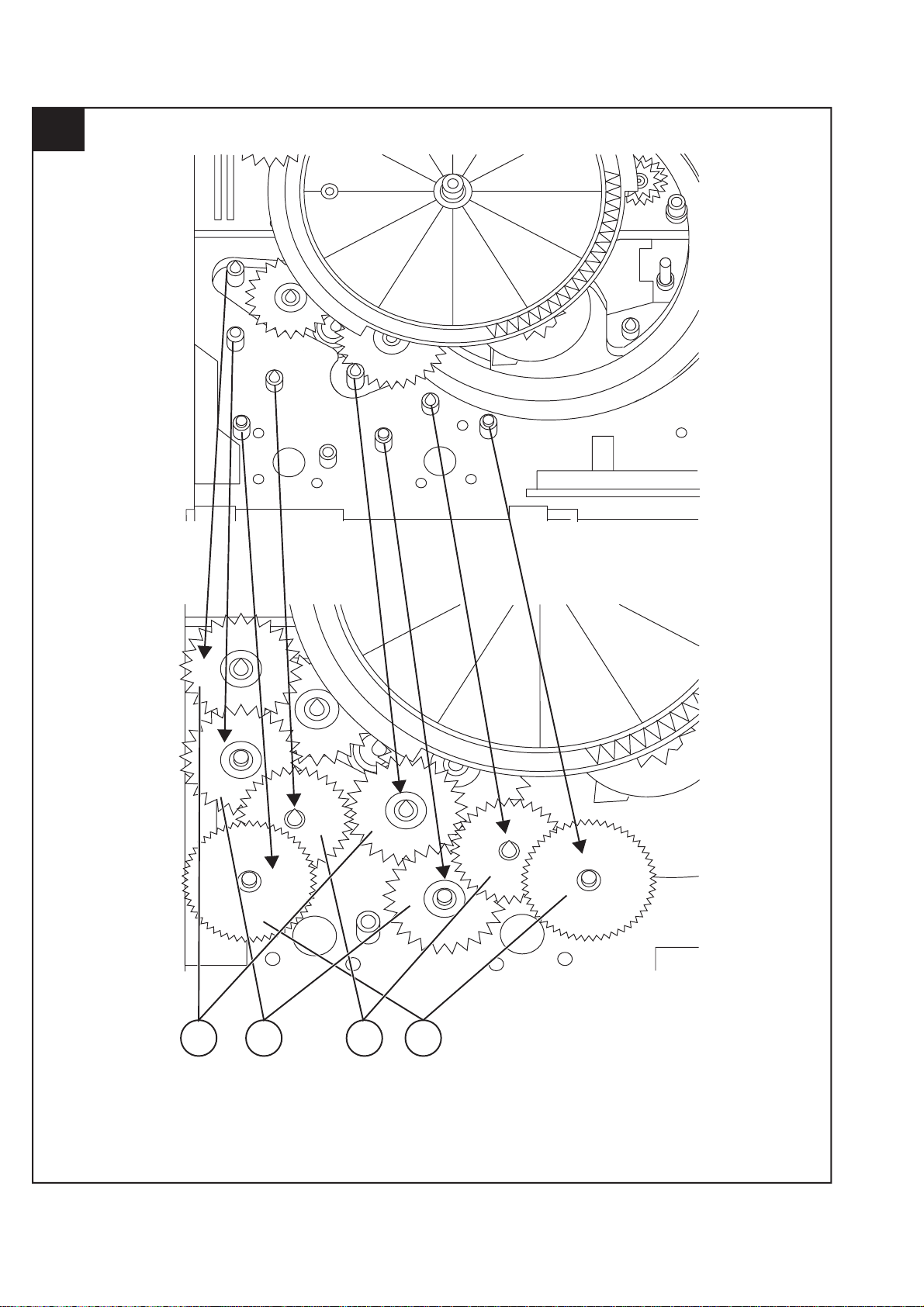

Page 20

XL-UH260

10

148

147

146

145

2 – 14

Page 21

11

XL-UH260

121

144

WHEN FIXING ITEM 144 MUST FOLLOW AS SHOWN

APPLY GREASE SC141

130

2 – 15

Page 22

XL-UH260

12

117

FIGURE 2

FIGURE 1

APPLY GREASE

SC141

FIGURE 3

APPLY GREASE SC141

2 – 16

Page 23

13

XL-UH260

ITEM 133 , 134 MUST APPLY GREASE SC141

ON TOP SIDE GEAR ONLY

134

GEAR 112 GEAR 112

133

132

CORRECT

TOP VIEW AFTER

BEING ASSEMBLED

INCORRECT

IT IS INCORRECT TO

FIX IT IN REVERSED

DIRECTION

2 – 17

Page 24

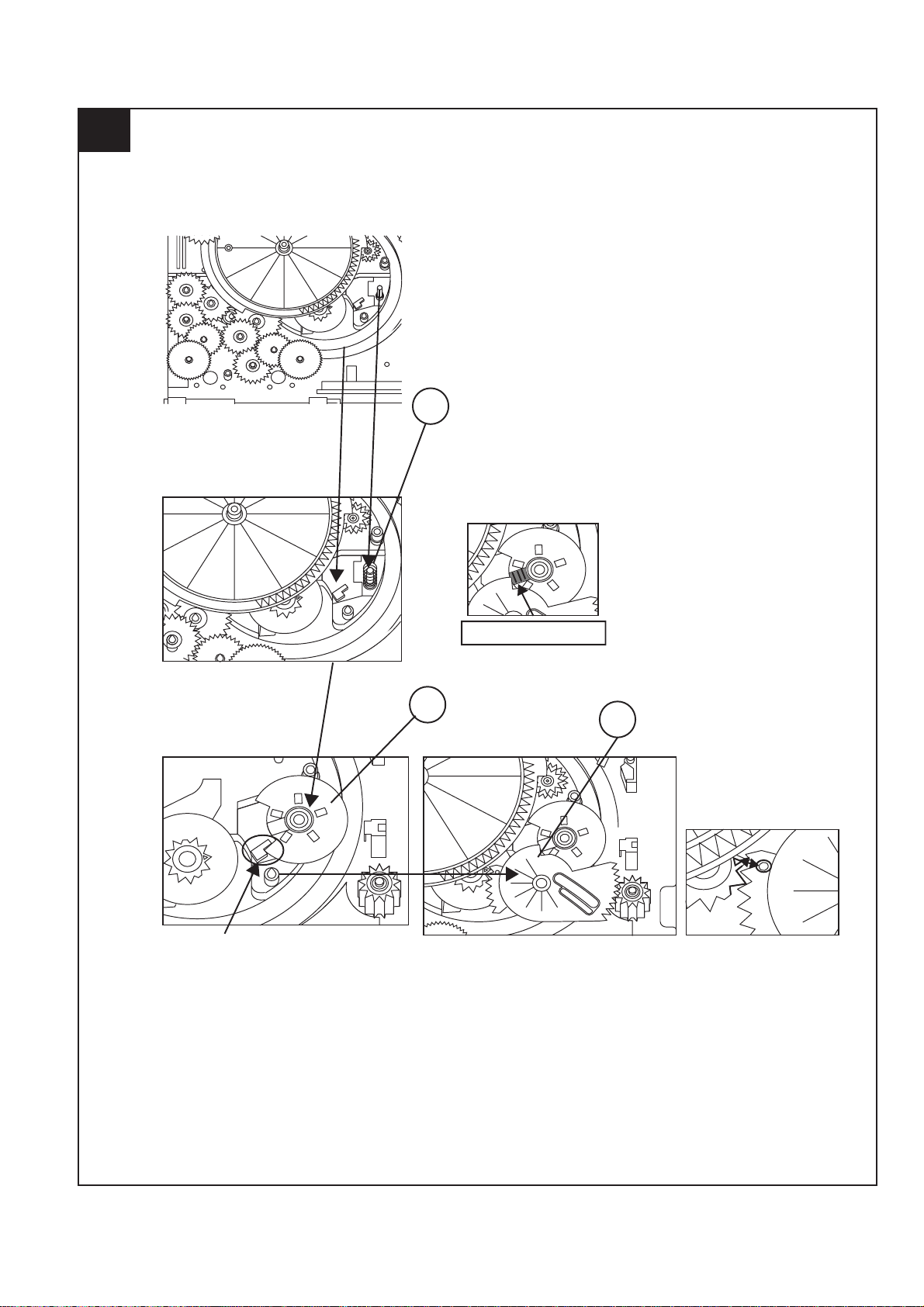

XL-UH260

14

APPLY GREASE SC141

BEFORE FIX

MOVE 112 UNTIL TOUCH THE WALL

B

DURING GEAR A ROTATE

MUST PRESS SHOWN AREA

A

AND LEVER B WILL MOVE

ARROW DIRECTION THEN

FIX PART 108

SCREW TORQUE

+0.5

2 kgf-cm

-0

108

803 x6

APPLY GREASE SC141

CONFIRM WHETHER

FIXED

PROPELY OR NOT

2 – 18

Page 25

15

XL-UH260

APPLY GREASE SC141

113

BEHIND THE LEVER NEED TO APPLY GREASE SC141

PULL IT THEN LEVER WILL

MOVE IN

2 – 19

Page 26

XL-UH260

16

123

115

APPLY GREASE SC141

APPLY GREASE SC141 BEFORE FIX

APPLY GREASE

SC141 AT BOSS

SPRING MUST BE ARRANGED UNDER THE HOOK

BOARD R

BOARD R

LR JOINT LEV

LR JOINT LEV

2 – 20

Page 27

17

XL-UH260

IT IS INCORRECT IF ASSEMBLED IN

A REVERSED DIRECTION

103

137

136

APPLY GREASE SC141

BIG SLOT MUST FACING OUT

WHEN FIX AND AFTER FIXED TO BASE CHASSIS.

AFTER ASSEMBLY, CONFIRM WITH FREE DROP TEST

GEAR POSITION DURING FIXING

2 – 21

Page 28

XL-UH260

18

IT IS INCORRECT IF ASSEMBLED IN

A REVERSED DIRECTION

APPLY GREASE SC141

104

135

136

BIG SLOT MUST FACING OUT

WHEN FIX AND AFTER FIXED TO BASE CHASSIS

AFTER ASSEMBLY, CONFIRM WITH FREE DROP TEST

GEAR POSITION DURING FIXING

CONFIRM BOTH GEARS SIT PROPERLY AND LOCKED

2 – 22

Page 29

19

XL-UH260

AFTER FIX OUTER UP/DOWN LEVER HOLD AS SHOWN PORTION AND

MOVE UP/DOWN THEN CONFIRM WHETHER LEVER GO INSIDE THE

HOLE OR NOT

120

137

119

BIGGER SLOT FACING OUT

135

BIGGER SLOT FACING OUT

IT IS CORRECT IF THE LEVER HOLD

ENTERS THE HOLE

IT IS INCORRECT IF THE LEVER HOLD DOES NOT

ENTER THE HOLE

ALL OF THIS 135 AND 137 GEAR FIX TOGETHER WITH 119

AND 120 LEVER ( MOVE TOGETHER )

2 – 23

Page 30

XL-UH260

20

BIGSLOTFACINGOUT

110

2 – 24

Page 31

21

XL-UH260

PUSH THE LEVER ACCORDING TO ARROW

DIRECTION THEN FIX

WHEN FIXING MAIN BASE ASSEMBLY FOLLOW ACCORDING TO PICTURE 1

PICTURE 1

CORRECT INCORRECT INCORRECT

MAKE SURE MECHA HOLDER SHAFT FIX PROPERLY TO LEVER

PICTURE 3

PICTURE 2

2 – 25

Page 32

XL-UH260

22

APPLY SANKOL (SHS1001)

101

102

APPLY SANKOL

(SHS1001) ON TOP

APPLY SANKOL (SHS1001) INSIDE

THE SLOT & OTHER SHOWN PORTION

APPLY SANKOL

(SHS1001)

APPLY SANKOL (SHS1001) AT

TRAY SLIDING PORTION

FIX TRAY NO 1 FIRST THAN

FOLLOW OTHER

APPLY SANKOL (SHS1001) AT BACK PORTION

COSMO GUIDE TRAY HAVE

MARKING AS SHOWN

2 – 26

Page 33

23

GEAR UP/DOWN BOARD

111

APPLY GREASE SC141 AT INNER & OUTER GEAR SLIDING PORTION

WHEN FIX GEAR UP/

DOWN BOARD THE

TWO LEVER MUST AT

PARALLEL LINE AND

POSITIONED AT TOP

MAX SIDE

XL-UH260

2 – 27

AFTER ASSEMBLY GEAR UP/DOWN BOARD

Page 34

XL-UH260

24

SCREW TORQUE

+0.5

3 kgf-cm

-0

ROTATE THE GEAR TO MOVE UP 111 GEAR

UP AND DOWN BOARD BEFORE SCREW

804

2 – 28

Page 35

25

XL-UH260

AFTER ASSEMBLY TOP PLATE

FIX THE FFC

FFC4

AFTER PUSH, MAKE SURE SNAP PROPERLY

AFTER FIX, PUSH FOLLOW ARROW DIRECTION

BEFORE LOCK

AFTER LOCK

BACK

PORTION

107

122

BEFORE LOCK

PRESS IN

SLOT IN

BEFORE LOCK

AFTER LOCK

AFTER LOCK

MUST CONFIRM

MUST CONFIRM

2 – 29

Page 36

XL-UH260

26

CORRECT

INCORRECT

CAUTION

1. MAKE SURE NO PWB CHIP INSIDE SET .( BEFORE FIX MAKE

SURE PWB IS FREE FROM DUST , GREASE & ETC )

803

2 – 30

Page 37

27

APPLY GREASE SC141

THE TWO SLOT MUST FREE

FROM GREASE SC141

APPLY GREASE SC141

BELOW THE MARKING

FOR BOTH PORTION

XL-UH260

ASSEMBLY SEQUENCE

1. APPLY GREASE SC141 TO MAIN BASE

GREASE SC141 APPLICATION AREA

ALL BOSS

APPLY GREASE

SC141

CAUTION

TRAY SLIDING

AREA MUST

FREE FROM

GREASE SC141

APPLY GREASE

SC141

APPLY GREASE

APPLY GREASE SC141 AT WALL

APPLY GREASE

SC141

SC141

105

APPLY GREASE SC141

AT BOTH SLOT

APPLY GREASE SC141 AT 3 HALF MOON

1 RIB ONLY

APPLY GREASE

SC141

APPLY GREASE SC141

INSIDE SLOT

2 – 31

Page 38

XL-UH260

28

REFERENCE ONLY

MOTOR GEAR HEIGHT FROM

MAIN BASE 12.2

+

0.1

-

0.1

-

+

12.2

MOTOR SCREWING HOLE

MUST HAVE GAP

M1,2

801

-0

13.8 + 0.2

APPLY GREASE SC141

SCREW TORQUE

1.5 + 0.5

-0

AFTER SCREW MOTOR, CONFIRM THE

ARRANGEMENT AS IN FIGURE 2

FIGURE 2

2 – 32

Page 39

29

APPLY SANKOL (SHS1001)

XL-UH260

3.1 + 0.1

SHAFT X 3 DIM AFTER INSERTION

MUST CONFIRM EVERYDAY

109-2

APPLY GREASE AT THE SLIDING PORTION

114

116

UP / DOWN

HOLDER CHANGE

TO NATURE

COLOR

SANKOL

APPLICATION AREA

(SHS1001)

APPLY GREASE SC141

2 – 33

Page 40

XL-UH260

30

BEFORE MELT IT

AFTER MELT IT ( MUST FLAT )

WHEN FITTING STABILIZER PLATE TO STABILIZER,

ROTATE STABILIZER ANTI CLOCKWISE BY JIG

( STRICTLY CANNOT FIT USING HAND)

( BY HAND CANNOT X )

BELOW

AFTER ASSEMBLED TO

HOLDER, STABILIZER

NEED TO BE CLEANED

WITH ALCOHOL DISC

TOUCHING SURFACE

2 – 34

Page 41

31

XL-UH260

106

APPLY GREASE SC141

MUST MAKE SURE SNAP PROPERLY BOTH SIDE

ALL SURFACE MUST TOUCH

CORRECT INCORRECT

GAP

INCORRECT

2 – 35

Page 42

XL-UH260

32

NO GAP HAVE GAP

CORRECT INCORRECT

2 – 36

Page 43

XL-UH260

CHAPTER 3.

MECHANICAL DESCRIPTION

[1] REMOVING AND REINSTALLING THE MAIN PARTS

1. CD MECHANISM SECTION

Perform steps 1, 2, 9, 10, 11 and 12 of the disassembly

method to remove the CD mechanism.

1.1. Remove the pickup. (See Fig. 1)

1. Remove the stop washer (A1) x 1 pc., to remove the gear

(A2) x 1 pc.

2. Remove the screws (A3) x 2 pcs., to remove the shaft

(A4) x 1 pc.

3. Remove the pickup.

Note

After removing the connector for the optical pickup from

the connector wrap the conductive aluminium foil around

the front end of connector so as to protect the optical

pickup from electrostatic damage.

(A3)x2

φ2.6x6mm

2.1. How to remove CD Disc (See Fig. 2~5)

1. When CD is at play position (Figure 2), rotate reduction

gear C clock-wise as shown in Figure 3 Until disc tray

is at stock position, then rotate further to eject the disc

tray so that CD can be removed from the tray.

CD Disc

Disc Tray

Guide Tray

CD At play position.

CD Disc

CD Mechanism

Shaft

(A4)x1

Gear

(A2)x1

Stop Washer

(A1)x1

Pickup Unit

Figure 1

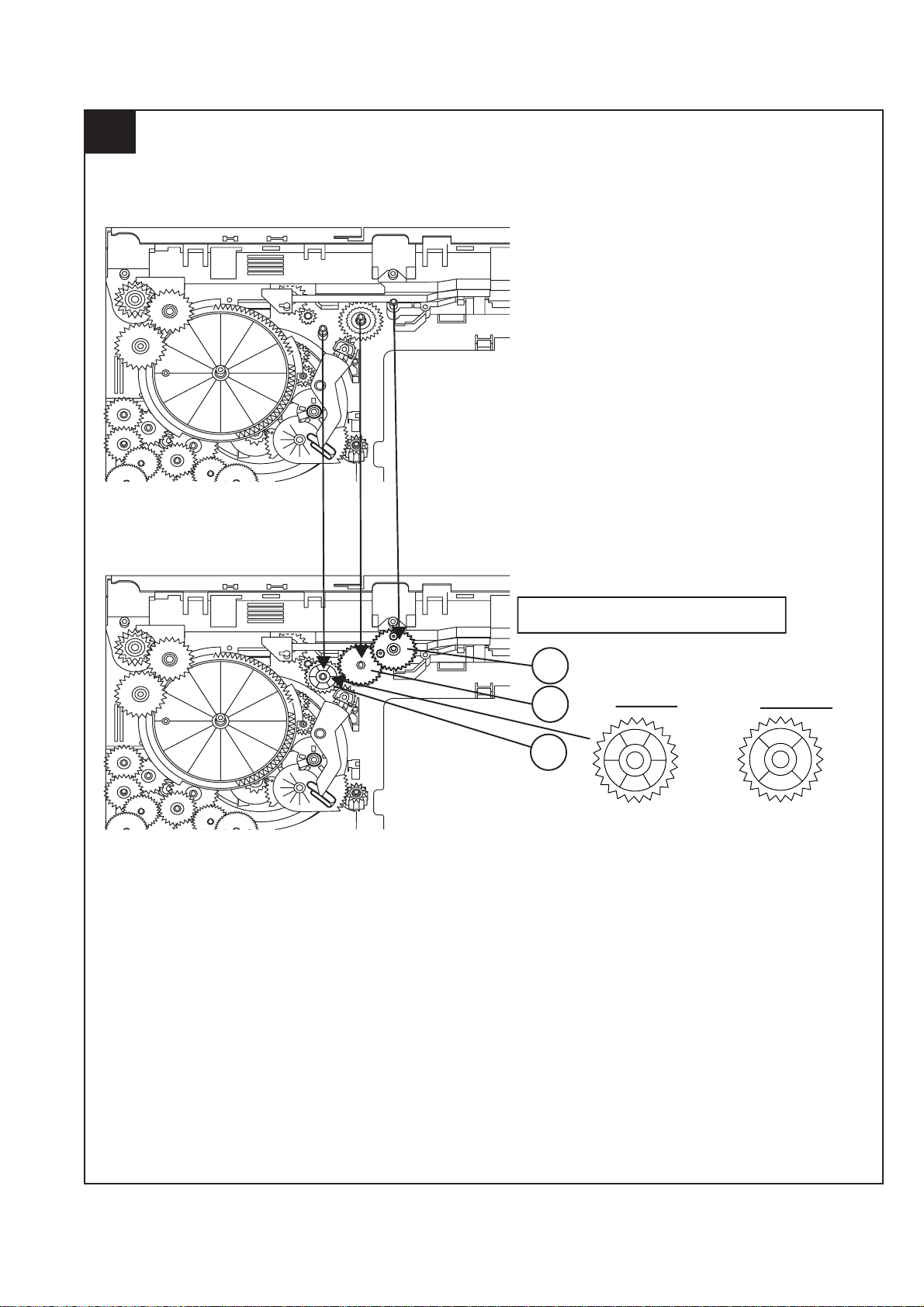

2. CHANGER MECHANISM SECTION

Perform steps 1, 2, 9 and 10 of the disassembly method to

remove the CD changer mechanism.

CD At stalk position.

Figure 2

Reduction gear C

Front Rear

Figure 3

2. In another case, if CD mechanism is at tray No.1 play

position and to remove CD located in tray No.3, the

procedure is as follows:

If the gear up down board is located at tray No.1 position,

then rotate gear clock-wise until it at stock position.

Rotate reduction gear D clockwise (Figure 4) to move the

CD mechanism to tray No.3 position.This is confirmed by

checking the gear up down board position by the marking

as indicated on the main chassis as shown in Figure 5.

3 – 1

Page 44

XL-UH260

Reduction gear D

Up Down

Figure 4

Gear up down board

Mark 1

(DISC 1)

Mark 3 Mark 5

(DISC 3)

Mark 2 Mark4

(DISC 2)

(DISC 4)

(DISC 5)

Figure 5

2.2. How to Remove the tray motor/main cam motor/5Changer Motor PWB (See Fig. 1)

1.Remove the screws (A1)x 2 pcs., to remove tray motor/main cam

motor/5-Changer Motor PWB.

Changer Mechanism Unit

Main Cam Motor

(A1)X2

φ2x10mm

Tray Motor

5-Changer

Motor PWB

Figure 1

NOTE:There are 2 more screws tighten the motors at the bottom of

main chassis. Before performing procedure 1 above, disc stop

spring, top plate sear up down board and trays must be

removed, then only the 2 screws can be untighten.

3 – 2

Page 45

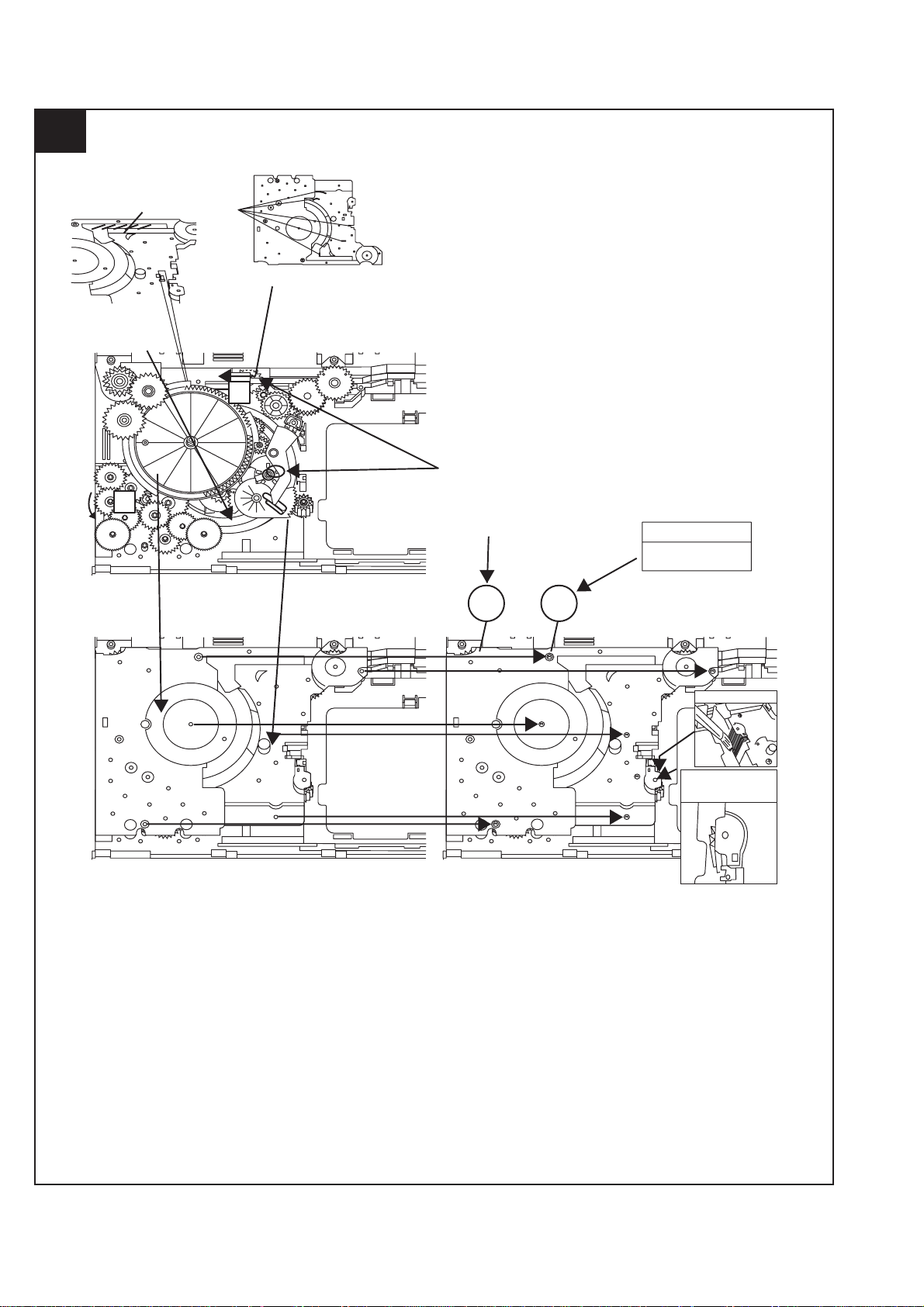

[2] DISASSEMBLY

XL-UH260

Caution on disassembly

Follow the below-mentioned notes when disassembling

the unit and reassembling it, to keep it safe and ensure

excellent performance:

1) Take cassette tape and compact disc out of the unit.

2) Be sure to remove the power supply plug from the

wall outlet before starting to disassemble the unit.

3) Take off nylon bands or wire holders where they

need to be removed when disassembling the unit.

After servicing the unit, be sure to rearrange the

leads where they were before disassembling.

4) Take sufficient care on static electricity of integrated

circuits and other circuits when servicing.

STEP REMOVAL PROCEDURE FIGURE

1 Top Cabinet 1. Screw…………..……….(A1) X 6 1

2 Side Panel (Left/ 2. Screw……….…………..(B1) X 8 1

Right)

3 CD Changer unit 1. Screw…………..……….(C1) X 2 2

2. Hook ……………………(C2) X 2

3. Socket………………..…(C3) X 2

4. Flat Cable ……… …….(C4) X 2

4 Rear Panel with 1. Screw………..………….(D1) X 2

Speaker PWB and

Refresh PWB

2. Socket………………..…(D2) X 1

3. Flat Cable ……… …….(D3) X 1

4

5 Front Panel 1. Screw………………..….(E1) X 2 3

2. Flat Cable ………..…….(E2) X 2

3. Socket……..……………(E3) X 1

4. Hook …………….…...…(E4) X 2

6 Main PWB 1. Screw………………..….(F1) X 4 3

2. Socket……..……………(F2) X 2

7 Power PWB 1. Screw………………..….(G1) X 4 3

8 Speaker PWB 1. Screw…….…………..….(H1) X 2 4

9 Refresh PWB 1. Screw…….…………..….(J1) X 1 4

10 Display PWB

1. Knob……..…………..….(K1) X 1

2. Nut…………....……..…..(K2) X 1

5

3. Washer…………....…….(K3) X 1

4. Screw…………....……...(K4) X 6

11 USB PWB 1. Screw………………..….(L1) X 2 5

12 Jack PWB 1. Screw………………..….(M1) X 1 5

13 CD MP3 PWB 1. Screw…….………….….(N1) X 2 6

2. Flat Cable ………..…….(N2) X 2

3. Socket……..……………(N3) X 1

14 CD Mechanism 1. Screw…….………….….(P1) X 4 6

2. Changer Chassis……….(P2)X 4

7

Note:

After removing the connector for the optical pickup from

the connector, wrap the conductive aluminium foil around

the front end of the connector so as to protect the optical

pickup from electrostatic damage.

(A1)x2

3x12mm

(B1)x2

3x10mm

Side Panel

(Right)

(A1)x2

3x12mm

(B1)x2

3x10mm

Rear Panel

CD Changer Unit

Refresh PWB

Rear Panel

Speaker PWB

Power PWB

(B1)x2

3x10mm

(D1)x4

3x10mm

(E4)x1

(F2)x1

(G1)x4

4x6mm

Top Cabinet

Figure 1

CD Servo PWB

Figure 2

PULL

Figure 3

(F1)x2

3x6mm

(E3)x1

Main PWB

(B1)x2

3x10mm

PULL

(C1)x1

3x10mm

Hook

(C2)x1

(F1)x2

3x10mm

(C4)x2

Front Panel

(C3)x2

Front panel

(F2)x1

Side Panel

(Left)

Front Panel

(D2)x1

(E1)x2

3x10mm

(D3)x1

PULL

(A1)x2

3x12mm

Hook

(C2)x1

PULL

(C1)x1

3x10mm

(E2)x2

Hook

(E4)x1

3 – 3

Page 46

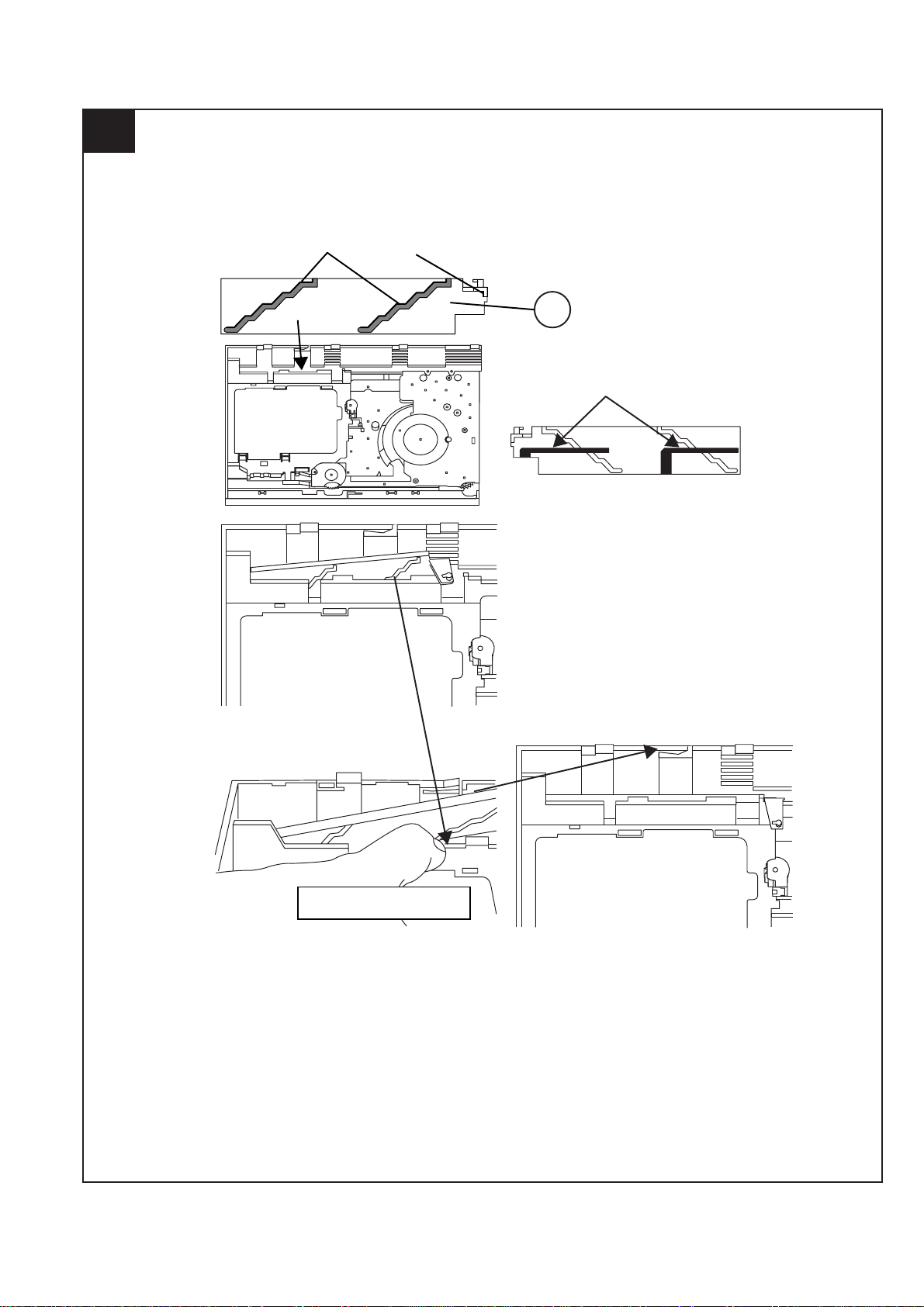

XL-UH260

Refresh PWB

Speaker PWB

(K4)x6

2.6x10mm

Rear Panel

Display PWB

USB PWB

Figure 4

Front Panel

(J1)x1

3x10mm

(K2)x1

(K3)x1

(H1)x2

3x10mm

(K1)x1

(P2)x4

Special

CD Mechanism

CD Changer Unit

Figure 7

STEP PROCEDURE FIGURE

1 Woofer 1. Front Panel………….…..(A1) X 1

2 Tweeter 1. Screw…….……….....….(B1) X 2

REMOVAL

8

2. Socket…….…….…….…(A2) X 1

3. Screw…….…….…….….(A3) X 2

4. Screw…….…….…….….(A4) X 4

(L1)x2

2.6x10mm

Figure 5

CD Changer

Unit

(P1)x2

3x10mm

Jack PWB

(M1)x1

Special

(N1)x2

(N2)x2

(P1)x2

3x10mm

(N3)x1

Front Panel

(A1)x1

(B1)x2

3x10mm

TWEETER

WOOFER

(A4)x4

4x16mm

(A2)x1

LED PWB

LED PWB

Figure 8

Speaker Box

(A3)x2

Ø3x10mm

Screwdriver

Figure 6

3 – 4

Page 47

-MEMO-

XL-UH260

3 – 5

Page 48

XL-UH260

CHAPTER 4. BLOCK DIAGRAM

A

B

C

D

E

F

G

H

1

23456

Figure 1: CD MP3 BLOCK DIAGRAM (1/2)

4 – 1

Page 49

XL-UH260

7

8 9 10 11 12

Figure 2: CD MP3 BLOCK DIAGRAM (2/2)

4 – 2

Page 50

XL-UH260

T

A

AC_RLY

SPK_DET

LED708

BI703

CNP703

B

C

D

E

F

G

H

NC

+B2

CNP301

L

R

JK690

FROM

CD/MP3 SECTION

CHASSIS_GND

FM_DET

TUN_SM

R_CH

+9V

L_CH

CHASSIS_GND

DO

CL

DI

CE

CNP601

1

2

3

4

TO CD/MP3

VIDEO/AUX

TUNER

CNP601

SECTION

L

R

L

R

AUDIO PROCESSOR

L

R

8.5V

+B1

+B3

9

8

7

6

5

+B_PROTECT

SERVO_+5V

+B4

SW_+5V

TUNER PACK UNIT

RTUNSA007AWZZ

DI

IC601

CE

CLK

LC75341

+B2

10V

+B2

13V

Q860

+B7

A_5V

SP_DE

VH+

VLVL+

IC704

VOLTAGE

REGULATOR

L_OUT

R_OUT

VH-

D801

D802

Q901

Q904

F802

4A 125V

F801

4A 125V

F804

2A 125V

F803

2A 125V

Q801

D842-D845

+B4

(SW_+5V)

TUN_SM/SPAN

-20DB_ATT

P_IN

VL-

R

L

Q601

Q602

Q603

Q604

UNSW_5.6V

+B9

8.5V

10V

13V

5.1V

VL+

IC851

AN80T53

VOLTAGE

REGULATOR

-VF

VF2

VF1

IC852

7805

VOLTAGE

REGULATOR

IC854

78L05

VOLTAGE

REGULATOR

Q841

1

23456

Figure 3: MAIN, DISPLAY & POWER BLOCK DIAGRAM (1/2)

4 – 3

Page 51

BI703

SP_DET

CNP703

+B2

VR701

JOG

VOLUME

Q706

XL-UH260

FL701

+B

+B8

FL DISPLAY

IC701

DRIVER IC

+B9

VF1

-VP

LED707

Q705

PHOTO

DO

CL

DI

CE

A_+10V

Q704

TO CD/

MP3 SECTION

IC702

GND

VF2

TIMER

LED

+B8

VCC

+B8

F802

4A 125V

F801

4A 125V

2A 125V

2A 125V

Q801

Q901

Q904

F804

F803

KEY

SW707-SW712

SW704-SW706

SW701-SW703

SP_RLY

T.F

PT801

SYSTEM

MICROCOMPUTER

AVCC

+B8

VSS

VCC

AC 120V.60 Hz

RESET

XL701

+B8

XL702 DIMM_LED

RL914

RELAY

REMOTE

SENSOR

RX701

+B3

SO901

SPEAKER

TERMINAL

QS15

JK701

HEADPHONES

JK953

SUB-WOOFER

OUT-PUT

F805

+B8

4A 125V

RL841

Q905

AC RELAY

AC POWER

SUPPLY CORD

IC705

VOLTAGE

REGULATOR

TO MICOM

REFRESH

TO CD/

MP3 SECTION

Q701

IC703

RESET CCT

QS01

IC503

KIA4558F

+B9

SP_LED

QS11

CNS01

CNS02

QS03

QS05

LIGHT UP

TO SPEAKER

FAN MOTOR

DRIVER

Q906

M971

(A_5V)

+B7

D842-D845

PT841

POWER

TRANSFORMER

(SUB)

7

8 9 10 11 12

Figure 4: MAIN, DISPLAY & POWER BLOCK DIAGRAM (2/2)

4 – 4

Page 52

XL-UH260

CHAPTER 5.

CIRCUIT DESCRIPTION

[1] WAVEFORM OF SERVO CIRCUIT

1

33

IC3

2

34

IC3

1

33

IC3

IC3

IC3

IC3

IC3

1

33

6

41

1

33

5

24

IC3

4

IC3

IC3

IC5

6

41

4

11

IC3

7

17

IC3

31

8

19

IC3

6

41

1

33

9

13

IC3

1

IC3

33

10

IC5

11

IC5

5

12

11

IC3

24

5 – 1

Page 53

12

IC6

XL-UH260

34

13

IC6

14

IC6

IC6

15

18

IC6

19

IC6

20

IC6

49

16

IC6

57

17

56

IC6

38

39

8

9

21

5 – 2

Page 54

XL-UH260

[2] IC VOLTAGE

IC 701IC 702

PIN

VOLTAGE

1 0 51 3.272v 1 -27.47 41 -27.39 1 0 1 51.9v

2 0 52 3.106v 2 -27.42 42 -29.62 2 0 2 23.32v

3 0 53 3.269v 3 -27.43 43 -27.39 3 0 3 11.25v

4 0 54 3.268v 4 27.44 44 -29.62 4 4.96v 4 11.29v

5 0 55 3.106v 5 -27.43 45 -27.39 5 4.95v 5 -23.31v

6 0 56 3.202v 6 -25.32 46 -24.65 6 4.92v 6 -51.8v

7 0 57 3.202v 7 -27.42 47 -22.38 7 4.95v 7 0

8 0 58 3.202v 8 -27.43 48 -27.06 8 4.96v 8 0

9 0 59 3.202v 9 -27.43 49 -22.69 9 4.94v 9 0

10 0.417v 60 0 10 -27.42 50 -29.61 10 4.95v 10 0

11 0.643v 61 0 11 -27.43 51 -25.17 11 4.94v 11 0

12 3.177v 62 3.205v 12 -27.46 52 -25.16 12 4.94v 12 -50.4v

13 1.493v 63 0 13 3.2 53 -25.18 13 4.94v 13 50.6v

14 0 64 0 14 0.9 54 -25.17 14 4.94v 14 0

15 1.385v 65 0 15 2.175 55 -25.16 15 4.94v 15 0

16 3.204v 66 0 16 1.496 56 -29.61 16 4.97v 16 -56.1v

17 3.202v 67 0 17 0 57 -25.15 17 4.94v 17 0

18 1.292v 68 0 18 0 58 -25.17 18 4.94v 18 0

19 0 69 0 19 3.264 59 -27.4 19 4.94v

20 3.164v 70 0 20 1.468 60 3.266 20 4.94v

21 3.201v 71 0 21 1.493 61 -29.61 21 4.96v

22 0 72 0 22 0 62 -29.61 22 4.96v

23 0 73 0 23 -18.54 63 -29.61 23 9.94v

24 0 74 0 24 -29.63 64 -27.41 24 3.221v

25 0 75 0 25 -29.62

26 0 76 0 26 -27.4

27 0 77 0 27 -29.61

28 3.201v 78 0 28 -29.61

29 0 79 0 29 -29.61

30 0 80 0 30 29.61 1 5.06v 1 19.56v 1 2.566v

31 1.496v 81 0 31 -27.28 2 12.83v 2 0 2 2.567v

32 3.201v 82 0 32 -29.81 3 19.6v 3 5.16v 3 2.543v

33 2.175v 83 0 33 -27.64 4 0 4 0

34 0.904v 84 0 34 -29.62 5 18.66v 5 2.578v

35 3.202v 85 3.204v 35 -29.16 6 9.95v 6 2.604v

36 0 86 3.203v 36 -29.05 7 8.4v 7 2.601v

37 0 87 0 37 -24.26 8 12.67v

38 0 88 0 38 -29.3

39 0 89 3.261v 39 -27.37

40 0 90 3.266v 40 -29.3

41 0 91 3.048v 1 18.73v

42 0 92 1.639v 2 0.696v

43 0 93 3.164v 3 6.02v

44 0 94 3.130v

45 2.409v 95 3.166v

46 3.188v 96 0

47 0 97 3.264v

48 0.881v 98 3.260v

49 0 99 3.205v

50 0 100 0

PIN

NO

VOLTAGE

PIN PIN PIN PIN

VOLTAGE VOLTAGE

NONO

NO

PIN

NO

IC 851

VOLTAGE

IC601

VOLTAGE

NO NO

IC 852

PIN

VOLTAGE

NO

IC 854

PIN

VOLTAGE

NO

PIN

NO

IC 901

VOLTAGE

IC S01

VOLTAGE

5 – 3

Page 55

A) IC 1 (CD Pre Amp) B) IC 2 (Motor Driver)

XL-UH260

No. Voltage No. No.

13.2 1 25

21.6 2 26

31.6 3 27

41.6 4 28

51.6 5 29

60 6 30

72.6 7 31

80 8 32

91.6 9 33

10 1.6 10 34

11 1.6 11 35

12 1.1 12 36

13 2 13

14 1.6 14

15 1.6 15

16 1.6 16

17 0.7 17

18 1.6 18

19 1.2 19

20 1.5 20

21 2.3 21

22 0.8 22

23 1.6 23

24 0 24

C) IC 3 (CD DSP)

No. Voltage No.

11.733

21.634

3035

41.636

53.237

63.238

7039

8040

91.141

10 0 42

11 1.5 43

12 0 44

13 0 45

14 3.2 46

15 3.2 47

16 1.6 48

17 0 49

18 1.2 50

19 3.2 51

20 1.6 52

21 1 53

22 0 54

23 1.5 55

24 1.6 56

25 3.2 57

26 1.6 58

27 1.6 59

28 0.7 60

29 1.6 61

30 1 62

31 1.6 63

32 1.6 64

Voltage

1.6

1.6

1.6

1.2

1.5

0

3.2

1.6

1.6

0

0

0

0

1.4

1.5

3.2

0

1.6

3.2

1.6

1.6

0

3.2

0

0

0

0

0

0

3.2

3.2

3.2

3.1

3.1

3.1

3.1

3.1

3.2

0

4.4

7

3.2

1.6

1.6

1.6

1.6

1.6

1.6

1.6

1.6

3.1

3.1

2.4

3.1

3.1

2.4

VoltageVoltage

1.6

0

7

7

7

0

0

0

0

0

3.1

3.1

Q1 Q2

No. No.

11.5 1 5

2 2.6 2 3.2

3 3.2 3 4.3

Q3 Q4

No. No.

11

22

33

Q5

No.

1

2

3

Q9 Q10

No. No.

11

22

33

Q11 Q12

No. No.

11

22

33

Voltage

20

03.2

0

Q7

Voltage

5

5

4.3

Voltage Voltage

3.3

2.7

3.3

Voltage

5.1

4.4

5.1

No.

VoltageVoltage

Voltage

0

Voltage

1

2

3

0

3

0

0

3.3

0

Voltage

0

3

0

5 – 4

Page 56

XL-UH260

g

g

C) IC 4 (MP3 WMA Decoder) D) IC 5 (DAC)

No. Voltage No. No.

11.533 1

23.234 2

3035 3

4036 4

5037 5

63.238

7039

83.340

93.341

10 0 42

11 0 43

12 1.8 44

13 1.7 45

14 0 46

15 1.7 47

16 1.6 48

17 2.4 49

18 3 50

19 2.4 51

20 1.7 52

21 1.5 53

22 0 54

23 0 55

24 0 56

25 0 57

26 0 58

27 0 59

28 0 60

29 0 61

30 0 62

31 0 63

32 3.3 64

E) IC 6 (USB Host mp3 Interface Controller)

No. Voltage No.

11.433

21.534

33.335

4036

5037

63.338

72.439 7

8040

93.341

10 1.6 42

11 1.6 43

12 2.2 44

13 1.6 45

14 0 46

15 3.3 47

16 1.3 48

17 1 49

18 1.1 50

19 0 51

20 0 52

21 0 53

22 0 54

23 0 55

24 3.3 56

25 1.8 57

26 0 58

27 1.2 59

28 0 60

29 3.3 61

30 1.4 62

31 1.5 63

32 3.3 64

Voltage

3.3

0

0

0

0

0

0

1.5

0

3.3

0

0

0

0

0

0

0

0

0

0

0

0

1.5

0

1.5

0.7

0.7

0

0

3.3

0

0.7

Voltage

3.1

1.8

1.6

1.5

1

3.1

3.2

0

1.6

1.3

3.3

3.3

3.3

0

1.6

1.7

3.2

1.5

1.2

0

0

0

3.3

2.9

0

0

2.9

3.3

0

2.7

1

1.4

6

7

8

9

10

11

12

13

14

15

16

G) IC 8 (CMOS 1.5v)

No.

1

2

3

H) IC 9 (CMOS 3.3v)

No.

1

2

3

F) IC 7 (USB Flash)

No.

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Votage

1.5

1.8

0

1.7

5.1

5.1

5.1

5.1

0.4

2.5

2.5

2.5

0

5.1

0

0

Volta

0

3.5

1.5

Volta

0

5.1

3.3

Voltage

0

0

0

0

0

0

0

0

0

0

0

0

0

3.3

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

3.3

3.3

e

e

5 – 5

Page 57

XL-UH260

CHAPTER 6. CIRCUIT SCHEMATICS AND PARTS LAYOUT

[1] Notes on schematic diagram

• Resistor:

To differentiate the units of resistors, such symbol

as K and M are used: the symbol K means 1000

ohm and the symbol M means 1000 kohm and the

resistor without any symbol is ohm-type resistor.

Besides, the one with “Fusible” is a fuse type.

• Capacitor:

To indicate the unit of capacitor, a symbol P is

used: this symbol Pmeans pico-farad and the

unit of the capacitor without such a symbol is

microfarad. As to electrolytic capacitor, the

expression "capacitance/withstand voltage is used".

(CH), (TH), (RH), (UJ): Temperature compensation

(ML): Mylar type

(P.P.): Polypropylene type

REF. NO DESCRIPTION POSITION

SW701 DISC4 ON—OFF

SW702 DISC5 ON—OFF

SW703 OPEN/CLOSE ON—OFF

SW704 DISC1 ON—OFF

SW705 DISC2 ON—OFF

SW706 DISC3 ON—OFF

SW707 POWER ON/STAND-BY ON—OFF

SW708 PLAY/PAUSE ON—OFF

SW709 STOP

SW710 VIDEO/AUX/USB

SW711 TUNER (BAND)

SW712 CD

VR701 VOLUME

ON—OFF

ON—OFF

ON—OFF

ON—OFF

MAX —MIN

• Schematic diagram and Wiring Side of P.W.Board for this

model are subject to change for improvement without prior

notice.

•

The indicated voltage in each section is the one measured

by Digital Multimeter between such a section and the

chassis with no signal given.

1. In the tuner section,

indicates AM

indicates FM stereo

2. In the CD section, the CD is stopped.

• Parts marked with “

“ ( )

are important for

maintaining the safety of the set. Be sure to replace

these parts with specified ones for maintaining the safety

and performance of the set.

[2] Types of Transistor and LED

FRONT

VIEW

ECB

(S)(G)(D)

(1)(2)(3)

KTA1271 Y

KTA1274 Y

KIA78L05

TOP VIEW

KDS184

KDS160

KTC3199 GR

KTC3203 Y

KTC3205 Y

B

(3)

TOP

VIEW

E

(1)

KRA102 S

KRC107 S

KRC102 S

KRC104 S

KTA1504 Y

KTC3875 GR

KTC1544 T

KTC3265 Y

FRONT

VIEW

AC AC

TS10B05G

TS4B05G

6 – 1

(2)

C

DS1SS119

FRONT

VIEW

343VC3F

SDPB50CD

SDPB40F2A

TOP VIEWTOP VIEW

1N404S

1N4148H

FRONT

VIEW

ECB

KIA7805A

Page 58

XL-UH260

A

B

C

D

E

F

FM SIGNAL

G

H

1

23456

Figure 6-1: POWER SCHEMATIC (1/2)

6 – 2

Page 59

XL-UH260

7

8 9 10 11 12

Figure 6-1: POWER SCHEMATIC (2/2)

6 – 3

Page 60

XL-UH260

A

B

C

C694

1/50V

C693

1/50V

CD SIGNAL

AUX SIGNAL

D

E

F

G

NC

NC

NC

NC

H

1

23456

Figure 6-2: MAIN SCHEMATIC (1/2)

6 – 4

Page 61

REFLASH MICOM PWB-A4

FOR FLASH USB MICOM IC ONLY

30

CNPU1

CNPU1

CWYH30AWZZ

CWYH30AWZZ

GND

VCC

NC

A6

29

A4

28

A0

27

26

I/0

A2

25

I/03

24

23

22

I/06

CE

21

20

A10

A11

19

A8

18

A14

17

I/04

16

15

WE

14

A5

13

A1

12

D0

11

A3

10

I/02

9

A7

8

A12

7

I/07

6

OE

5

A9

4

A15

3

A13

2

I/05

1

A6

14

A4

13

A0

12

11

I/0

A2

10

I/03

9

GND

8

I/06

7

CE

6

5

A10

A11

4

A8

3

A14

2

I/04

1

VCC

15

WE

14

A5

13

A1

12

D0

11

A3

10

I/02

9

A7

8

A12

7

I/07

6

OE

5

A9

4

A15

3

A13

2

I/05

1

FROM CD MP3 PWBFROM CD MP3 PWB TO ROM WRITERTO ROM WRITER

XL-UH260

CNPU2

CNPU2

EP53254

EP53254

CNPU3

CNPU3

EP53254

EP53254

NC

NC

7

8 9 10 11 12

Figure 6-2: MAIN SCHEMATIC (2/2)

6 – 5

Page 62

XL-UH260

A

LUG 3

LUG 2

B

JACK PWB

TO MAIN SECTION

C

D

E

F

G

H

1

23456

Figure 6-3: DISPLAY SCHEMATIC (1/2)

6 – 6

Page 63

XL-UH260

7

8 9 10 11 12

Figure 6-3: DISPLAY SCHEMATIC (2/2)

6 – 7

Page 64

XL-UH260

A

B

C

CD SIGNAL

D

E

F

G

CD MOTOR PWB-E

4

3

2

1

TRAY CHANGER MOTOR

PWB-F

4

3

2

1

H

1

23456

Figure 6-4: CD MP3 SCHEMATIC (1/2)

6 – 8

Page 65

XL-UH260

270P

CNP6

WYP30AW

1mm Pitch

7

8 9 10 11 12

CNPU1

TO REFRESH PWB

Figure 6-4: CD MP3 SCHEMATIC (2/2)

6 – 9

Page 66

XL-UH260

A

B

SPEAKER PWB-A3

SPEAKER

TERMINAL

-

SO901

COLOR TABLE

RED

RD(R)

GR

GREEN

WH

WHITE

BL

BLUE

GY

GRAY

OR

ORANGE

LEFTRIGHT

+

VL

VIOLET

FROM MAIN PWB-A1

C

D

E

F

BI901

TO DISPLAY PWB-B1

FROM CD MP3 PWB

-

4321

+

MAIN PWB-A1

1

6

C

N

P

7

A10

1

9

8

7

6

5

1IB

4

3

2

1

C

N

S

6

0

1

10 12 14 16

2468

11 13 15

13579

123456789

ECB

TO POWER PWB-A2

G

H

C

N

B

S

I

8

8

0

0

1

1

TO DISPLAY PWB-B3

11

1

0

GR

1

9

C

N

P

8

0

1

1

0

9

WH

8

GR

8

2

BL

1

RD

67

3

GY

5

WH

4

BL

3

754

2

OR

1

6

VL

FW901

15

2345 6

910 1187654321

Lead-free solder indication

Lead-free solder is used in the MAIN,SPEAKER PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

Figure 6-5: WIRING SIDE OF MAIN PWB (TOP VIEW) (1/2)

6 – 10

Page 67

XL-UH260

ANTENNA

FM

GND

246810

1357911

TUNER PACK

AM

TO

TUNER PACK

11

TO MAIN

PWB-A1

CNP301

1

TO CD MP3 PWB

CNP6

1

11

123456789

1

13579

2

46810

1011 12 1314

1214 1618 2022 2426 28 30

111315 1719 2123 2527 29

123456789

FFC6

30

1011 12 1314 15

REFLASH MICOM PWB-A4

Lead-free solder indication

Lead-free solder is used in the REFLASH MICOM PWB

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

JK690

VIDEO/AUX

IN

CHASSIS

GND

RIGHTLEFT

M971(202-3)

FANMOTOR

REDMARK

BK

1

8

9

10

11

12

13

14

15

18

17

16

R

I

G

1

H

S

T

PSMORF

L

AE

TFE

REK

JK953

SUBWOOFER

PRE-OUT

L

EP

A

EK

PUTHGI

R

MAIN PWB-A1

5

CNP902

2

12

1

2

12

3

4

HW

RG

RG

DR

12 3 4

CNS902

7

ECB

6

5

4

3

2

BR

2

1

CNS971

TO SPEAKERPWB-A3

7

8 9 10 11 12

Figure 6-5: WIRING SIDE OF MAIN PWB (TOP VIEW) (2/2)

6 – 11

Page 68

XL-UH260

A

B

C

POWER PW B -A2

SUB POWER TRANSFORMER

PT841

5

6

7

8

9

1

MAIN POWER TRANSFORMER

.

F

.T

AC POWER SUPPLY CORD (223)

AC 120V, 60Hz

4

3

2

1

BK

WH

PT801

7654321

D

17 16 15 14 13 12 11 10 9 8

E

BCE

COLOR TABLE

VL

F

CE

B

OR

BK

WH(W)

GR

RD(R)

BL

GY

G

1

2

3

CNP802

910

123456

12345678

VIOLET

ORANGE

BLACK

WHITE

GREEN

RED

BLUE

GRAY

H

Lead-free solder is used in the POWER PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

Lead-free solder indication

23456

PWB-B1

123456

CNS801

67543128910

FROM MAIN PWB-A1

CNS701

FROM DISPLAY

Figure 6-6: WIRING SIDE OF POWER PWB (TOP VIEW)

6 – 12

Page 69

-MEMO-

XL-UH260

6 – 13

Page 70

XL-UH260

A

B

C

MAIN PWB-A1

D

E

F

G

123456789101112131415161718

H

1

23456

Figure 6-7: WIRING SIDE OF MAIN PWB (BOTTOM VIEW) (1/2)

6 – 14

Page 71

XL-UH260

Lead-free solder indication

Lead-free solder is used in the MAIN PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

7

8 9 10 11 12

Figure 6-7: WIRING SIDE OF MAIN PWB (BOTTOM VIEW) (2/2)

6 – 15

Page 72

XL-UH260

2

P

R

A

B

C

D

123

1

2

3

E

F

1 2 3

2 4 6 8

1 3 5 7 9 11

10 12 14 16

13 15

2 4 6 8

1 3 5 7 9 11

10 1

G

1 16

Lead-free solder indication

Lead-fre

e solder is used in the DISPLAY PWB.

Refe

H

r to "Precautions for handling lead-free solder" for instructions

d precautions.

an

1

2 3 4 5 6

CNP701B

TO MAIN PWB-A1

1

TO CD SE

CN

Figure 6-8: WIRING SIDE OF DISPLAY PWB (TOP VIEW) (1/3)

6 – 16

Page 73

XL-UH260

COLOR

TABLE

RD WH YL GR

GREENYELLOWWHITERED

132

8 1012 14161820

7911

13 15

17 19

CNP5

D SERVO PWB

7

20

246810

1357911

71

RGLYR

RG

DR

LY

FFC705

111

1

23456

CNP4

G

CNS701

TO CD SERVO PWB

CNP802

TO MAIN PWB-A2

8 9 10 11 12

Figure 6-8: WIRING SIDE OF DISPLAY PWB (TOP VIEW) (2/3)

6 – 17

Page 74

XL-UH260

A

COLOR TABLE

BKGYBLACK

GRAY

WH WHITE

2I

B

FROM CD MP3 PWB

B

1234

WH

USB PWB-B2

BK

LUG WIRE BETWEEN

LUG2 (SUB PWB-B5)

AND LUG3 (USB PWB-B2)

JK702

C

D

E

USB JACK

1

1

5

5

FW901

109MTW

SUB PWB-B5

FROM MAIN PWB-A1

JACK PWB-B3

F

JK701

HEADPHONES

YG

KB

BK

GY

307PNC

2

1

TO DISPLAY PWB-B1

G

LED PWB-B4

H

Lead-free solder is used in the USB, SUB, JACK, LED PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-8: WIRING SIDE OF PWB (TOP VIEW) (3/3)

Lead-free solder indication

6 – 18

Page 75

-MEMO-

XL-UH260

6 – 19

Page 76

XL-UH260

A

B

C

DISPLAY PWB-B1

1 2 3 4 5 6 7 8 9 101112131415161718192021222324252627282930

D

E

F

G

Lead-free solder indication

Lead-free solder is used in the DISPLAY PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-9: WIRING SIDE OF DISPLAY PWB (BOTTOM VIEW) (1/3)

6 – 20

Page 77

27 28 29 30 31 32 33 34 35 36 37 38 39 4041 42 43 44 45 46 47 48 49 50 51

XL-UH260

7

8 9 10 11 12

Figure 6-9: WIRING SIDE OF DISPLAY PWB (BOTTOM VIEW) (2/3)

6 – 21

Page 78

XL-UH260

A

C748

C751

B

C

D

SUB PWB-B5

USB PWB-B2

E

F

JACK PWB-B3

G

LED PWB-B4

H

1

2 3 4 5 6

Figure 6-9: WIRING SIDE OF PWB (BOTTOM VIEW) (3/3)

e solder is used in the USB, JACK, LED PWB.

Lead-fre

r to "Precautions for handling lead-free solder" for instructions

Refe

and precautions.

6 – 22

Lead-free solder indication

Page 79

-MEMO-

XL-UH260

6 – 23

Page 80

XL-UH260

A

CD MP3 PWB-C

COLOR TABLE

BR

BROWN

RD(R)

RED

BK

BLACK

GR

B

GREEN

GY GRAY

WH WHITE

YL YELLOW

TO CD PICK-UP

FFCI

16 1

1315

1416

57911

13

4681012

2

C

01

D

MOT

BWP1A

A

I

N

E

9

78

6

NC

P

5

6

10

34

2

1

NC

06P

1

GY

BK

GY

BK

6789

GY

BK

GY

BK

12345

BR

1IB

1

890

7

6

5

34

1

BCE

5

P2

OT

NC

W

P

B

F

B-

NIAM

234

07

6

1

C

7SN

0

6

WH

YL

RD

BK

4

23

1

2IB

G

5

23

1

2 4 6 8 10 12 14 16 20

135791113151719

18

20

19

Lead-free solder indication

Lead-free solder is used in the CD MP3 PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

H

1

23456

Figure 6-10: WIRING SIDE OF CD MP3 PWB (1/2)

FFC702

CNP702

TO DISPLAY PWB-B1

201

6 – 24

Page 81

FFCI

XL-UH260

TO CD MOTOR

PWB-E

CNP2A

3456

G

DR

R

HW

1

HW

1 2 3 4

1

2

4321

ECB

FFC3

1

RE

GN

1PNC

F-

AH

B

W

C

P

D

C

O

T

11

03

4A-BWP

1

UPN

C

TREFLASH MICOMO

C12

R13

13

246

5

7911

CNP3

801

03

9272523212917151311197531

82

62422

20

28

1

614121018642

16 20

18

17 19

19

-B1

1

FFC6

20

20

1357

2

68

4

81

FFC705

CNP705

TO DISPLAY PWB-B1

7

8 9 10 11 12

Figure 6-10: WIRING SIDE OF CD MP3 PWB (2/2)

6 – 25

Page 82

XL-UH260

A

B

C

CD MP3 PWB-C

D

E

F

G

Lead-free solder indication

Lead-free solder is used in the CD MP3 PWB.

H

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

1

23456

Figure 6-11: CD MP3 PWB (BOTTOM VIEW)

6 – 26

Page 83

XL-UH260

CD PICK-UP

A

CNP2A

B

3

4

5

6

M2A

SLED MOTOR

98765

3

1

4

2

15131411

16

1210

CD MOTOR PWB-E

1

1

FFC1

CNW2

WH

BR

WH

RD

FFC3

C

M1A

SPINDLE MOTOR

D

M2

MAIN CAM

MOTOR

E

-

+

M1

TRAY

MOTOR

-

+

1110987654321

CNB1

6

5

4

3

16

6

5

4

3

CNP2

TO CD

MP3 PWB

CNP3

TO CD

MP3 PWB

F

CD CHANGER PWB-F

G

SW4

DISC

RX1

PHOTO

INTERRUPTER

H

The numbers to are waveform numbers shown in page 5-1

1

1

20

2345 6

SW3

TRAY SW2

SW2

TRAY SW1

Figure 6-12: WIRING SIDE OF P.W.BOARD

6 – 27

SW1

CLAMP

& 5-2

11

Lead-free solder indication

Lead-free solder is used in the CD CHANGER, CD MOTOR PWB.

Refer to "Precautions for handling lead-free solder" for instructions

and precautions.

Page 84

XL-UH260

CHAPTER 7. FLOWCHART

[1] TROUBLESHOOTING

1. When the CD does not function

The CD section may not operate when the objective lens of the optical pickup is dirty. Clean the ob jective lens, and

check the playback operation. When this section does not operate even after the above step is taken, check the following items.

Remove the cabinet and follow the trouble shooting instructions.

"Track skipping and/or no TOC (Table Of Contents) may be caused by build up of dust other foreign matter on the laser

pickup lens. Before attempting any adjustment make certain that the lens is clean. If not, clean it as mentioned below."

Turn the power off.

Gently clean the lens with a lens cleaning tissue and a small amount of isopropyl alcohol.

Do not touch the lens with the bare hand.

Parts code

1. CD optical pickup Lens cleaner disc UDSKA0004AFZZ

HOW TO USE

1.

Using the brush in the cleaner cap, apply 1 or 2 drops of the

cleaning fluid to the brush on the CD cleaner disc which has the

mark next to it.

2.

Place the CD cleaner disc onto the CD disc tray with the brush

side down, then press the play button.

3.

You will hear music for about 20 seconds and the CD player will

automatically stop. If it still play continuously, press the stop button.

Cleaning fluid

CAUTION

The CD lens cleaner should be effective for 30-50 operations, however

if the brushes become worn out earlier then please replace the cleaner

disc.

If the CD cleaner brushes become very wet then wipe off any excess

fluid with a soft cloth.

Do not drink the cleaner fluid or allow it contact with the eyes. In the

event of this happening then drink and/or rinse with clean water and

seek medical advice.

The CD cleaner disc must not be used on car CD players or on computer

CD-ROM drives.

All rights reserved. Unauthorized duplicating, broadcasting and renting

this product is prohibited by law.

2. When a CD cannot be played

2.1. Pressing the CD operation key is accepted, but playback does not occur.

1) Focus-RF system check

2) Tracking system check

3) Spin system check

4) PLL system check

Cleaner disc

5) Others

7 – 1

Page 85

XL-UH260

3. When the USB does not function.

3.1. “NO MEDIA” is displayed.

Press the Tray1 CD Eject Button without inserting a disc, and try

starting the playback operation.

1) Check the power to IC6 (OTI6888QFP), IC7 (RHIXA093AW00) and BI2 connector.

2) Check the system microcomputer (especially the

communication line with the USB Host).

3) Check the grounding condition to IC6 (OTI6888QFP),

IC7 (RH-IXA093AW00) and BI2 connector.

IC3

1

33

4. When a USB cannot be played.

4.1. Pressing the USB operation key is accepted,

but playback data does not occur.

1) D+ data line.

IC3

2

34

2) D- data line.

3) Others.

(1) Focus-RF system check.

Although a CD is inserted and the cover is closed,

"NO DISC" is displayed.

1. Does the pickup move? No Sled motor (M2A).

Yes

2. Does the focus (lens) move up and down ?

(Waveform drawing Figure 1)

No Check the focus peripheral circuit.

Figure 1

Yes

3. Is the laser lit ? No Check the laser diode driver Q1 peripheral circuit.

Yes

4. Is the turntable rotating ? No Spindle motor (M1A).

When a disc is loaded, start playback operation.

1. Is focus servo activated ?

(Waveform drawing Figure 2)

Yes

2. Is the RF waveform normal ?

(Waveform drawing Figure 3)

No Pins 2, 3, 15 and 16 on IC1, Pins 1, 2, 15 and 16 on IC2 and pins

29 and 33 on IC3.

Check the laser diode driver Q1 peripheral circuit.

No If the level is not normal.

1

33

IC3

IC3

5

24

IC3

5

24

IC3

4

11

Figure 2

Figure 3

7 – 2

Page 86

XL-UH260

(2) Focus-RF system check.

Check the TE waveform at pin 31 on IC3.

If the waveform shown in Figure 4 appears and soon after NO

DISC appears ?

Yes

No

"Initialization" is possible, but play is not possible ?

Yes

No

"Initialization" is not possible. Data cannot be read. Check the VCO-PLL (Pins 16~19 and 21

The tracking servo is not activated.

Check the peripheral circuits at pins 32, 31 and 34 on IC3, pins

4, 5, 10 and 11 on IC1, pins 17, 18, 35 and 36 on IC2 and FFC1.

A normal jump operation cannot be completed or the beginning

of the track cannot be found.

Check the around pin 34 on IC1.

on IC3) system.

4

31

IC3

1

33

IC3

Figure 4

(3) Spin system check.

Press the OPEN/CLOSE switch without inserting a disc, and

then try starting the play operation.

1. The turntable rotates a little ?

(Waveform drawing Figure 5)

Yes

No

2. The turntable doesn't rotate. Check around pin 41 on IC3, pins 3, 4, 13 and 14 on IC2.

The spin driver circuit is OK.

1

33

IC3

7 – 3

IC3

6

41

Figure 5

Page 87

(4) PLL system check.

XL-UH260

When a disc is loaded, start play operation.

The RF waveform is normal, but the TOC data cannot be read.

Check the IMAX waveform. (Figure 6)

Check around Pins 16~19, and 21 on IC3.

IC3

IC3

IC3

IC3

7

17

8

19

6

41

1

33

Figure 6

(5) Others.

The RF waveform is normal and the time is displayed normally, but no sound is produced. Or the sound has dropouts.

Is pin 11, 12 and 13 on IC5. (Figure 7) No There are too many error flags on a damaged disc which makes

Yes

If OK, Check the unit.

error correction impossible.

Check again using a known good disc.

IC5

10

IC5

IC5

11

9

13

12

11

Figure 7

7 – 4

Page 88

XL-UH260

(6) USB system check.

Press USB funnction, insert the USB memory device into the

USB.

1. Does the device information can display? No Check around pin 56 and 57 or 34, 38, 39 and 49 on IC6.

(Figure 8 & 9)

Yes

2. The waveform and the time is displayed normal, but no

sound is produced.

16

57

IC6

17

56

IC6

Figure 8

18

8

IC6

19

9

IC6

No Check around pin 8, 9 and 21 on IC6. (Figure 10)

pin 11~13 on IC5. (Figure 7)

12

34

IC6

13

49

IC6

14

38

IC6

39

IC6

15

Figure 9

20

IC6

21

Figure 10

7 – 5

Page 89

CHAPTER 8. OTHER

[1] FUNCTION TABLE OF IC

IC2 VHILA6261//-1: Focus/Tracking/Spin/Sled Driver (LA6261)

Pin No. Terminal Name Function

1 FO+ BTL Output pin (+) for focus coil.

2 FO- BTL Output pin (-) for focus coil.

3 SP+ BTL Output pin (+) for spin motor.

4 SP- BTL Output pin (-) for spin motor.

5 SL- BTL Output pin (+) for slide motor.

6 SL+ BTL Output pin (-) for slide motor.

7 PGND1 Power GND for channels 1,2,3 and 4 (BTL).

8 REGIN Regulator pin (External PNP base).

9 PVCC1 Power for channels 1,2,3 and 4 (BTL). (SVCC short-crircuited)

10 REGOUT Regulator pin (External PNP collector).

11 VIN1 Input pin for channel 1

12* VIN1G Input pin for channel 1 (for gain control)

13 VIN2 Input pin for channel 2

14* VIN2G Input pin for channel 2 (for gain control)

15 VIN3 Input pin for channel 3

16* VIN3G Input pin for channel 3 (for gain control)

17 VIN4 Input pin for channel 4

18* VIN4G Input pin for channel 4 (for gain control)

19 FWD5 CH5 Output change pin (FWD). Logic input for bridge.

20 REV5 CH5 Output change pin (REV). Logic input for bridge.

21 VCONT5 Input pin for CH5 output voltage control

22 FWD6 CH6 Output change pin (FWD). Logic input for bridge.

23 REV6 CH6 Output change pin (REV). Logic input for bridge.

24 VCONT6 Input pin for CH5 output voltage control.

25 VREFIN Reference voltage input pin.

26 SGND Signal system GND

27 SVCC Signal system power (PVCC1 short - circuited)

28 PVCC2 Power for channel 5 and 6 (H bridge).

29 MUTE Input pin for BTL mute.

30 PGND2 Power GND for channels 5 and 6 (H bridge).

31 TR+ H bridge Output pin (+) for tray motor.

32 TR- H bridge Output pin (-) for tray motor.

33 CAM+ H bridge Output pin (+) for cam motor.

34 CAM- H bridge Output pin (-) for cam motor.

35 TR+ BTL Output pin (+) for tracking coil.

36 TR- BTL Output pin (-) for tracking coil.

XL-UH260

In this unit, the terminal with asterisk mark (*) is (open) terminal which is not connected to the outside.

* Set power system GND to the minimum potential together with SGND

* Short-circuit three pins of power system SVSS and PVCC1 externally before use.

8 – 1

Page 90

IC2 VHILA6261//-1: Focus/Tracking/Spin/Sled Driver (LA6261)

XL-UH260

Pre DrivePre Drive

+

CH4

36

35

+

-

34

33

32

CH5

31

30

29

28

CH6

1

CH3

+

2

-

3

+

4

-

5

CH2

6

+

+

7

8

+

9

CH1

VOLTAGE

CONTROL AMP

-

+

+

BTL

10

11

12

13

14

15

16

17

18

1k

1k

1k

1k

11k

11k

11k

11k

22k

22k

22k

22k

27

+

+

-

+

+

DUFFER AMP

For 1/2 VCC

DUFFER AMP

For VREF

26

25

24

23

+

+

Refcronce

voltage

TSD

Bandgad

Figure 1 BLOCK DIAGRAM OF IC

Mode

Mode

select

select

22

21

20

19

8 – 2

Page 91

IC601 VHiLC75341/-1: Audio Processor (LC75341)

Pin No. Terminal Name Function

1 DI Serial data and clock input pin for con-

trol.

2 CE Chip enable pin.

Data written into an internal latch in a

timing of "H" to "L".

Each analog switch is activated.

Data transfer enabled at "H" level.

3 VSS Ground pin.

4 LOUT Bass band filter comprising

capacitor and resistor connection pin

and bass/treble output pin.

5 LBASS Bass band filter comprising capacitor

and resistor connection pin.

6 LTRE Treble band filter comprising capacitor

and resistor connection pin.

7 LIN Volume + equaliser output pin.

8 LSEL0 Input selector output pin.

IC601 VHiLC75341/-1: Audio Processor (LC75341)

XL-UH260

Pin No. Terminal Name Function

9-12 L4-1 Input signal pin.

Pin No. Terminal Name Function

13-16 R1-4 Input signal pin.

17 RSEL0 Input selector output pin.

18 RIN Volume + equaliser output pin

19 RTRE Treble band filter comprising cap acitor

and resistor connection pin.

20 RBASS Bass band filter comprising capacitor

and resistor connection pin.

21 ROUT Bass band filter comprising capacitor

and resistor connection pin and bass/

treble output pin.

22 VREF 0.5x VDD voltage generation block

for analog ground. Capacitor of several 10µF to be connected between

VREF and AWSS (VSS) as a counter-

measure against power ripple.

23 VDD Supply pin

24 CLK Serial data and clock input pin for con-

trol.

L4

L3

L2

L1

R1

R2

R3

R4

9

10

11

12

13

14

15

16

AUX

DECK

TUNER

CD

LSEL0

LIN

CONTROL

CIRCUIT

CONTROL

CIRCUIT

CONTROL

CIRCUIT

LTRE

LOUT

LBASS

45678

LVref

CCB

INTERFACE

RVref

3

2

1

24

23

22

VSS

CE

DI

CLK

VDD

VREF

1817

19

RIN

RSEL0

RTRE

Figure 2 BLOCK DIAGRAM OF IC

8 – 3

20 21

RBASS

ROUT

Page 92

IC7 RH-IXA093AW00: USB MICOM

CONNECTION DIAGRAMS

A12

A15NCNCNCYcc

529

A7

A6

6

A5

7

A4

8

9

A3

10

A2

11

A1

12

A0

13

DQ0

DQ1

DQ2

Vss

1323130234

DQ3

DQ4

WE#

DQ5

28

27

26

25

24

23

22

21

DQ6

Figure 3 BLOCK DIAGRAM OF IC

XL-UH260

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

Pin Name

Function

A0-A15 Addresses

DQ0-DQ7

WE#

CE#

OE#

Vcc

Vss

8 Data Input/Outputs

Write Enable

Chip Enable

Output Enable

Supply Voltage

Ground

Table 1 PIN DESCRIPTION

EN29LV512

A0-A15

CE#

OE#

WE#

DQ0-DQ7

Figure 4 LOGIC DIAGRAM

8 – 4

Page 93

IC7 RH-IXA093AW00: USB MICOM

BLOCK DIAGRAM