Page 1

VL-SDPOU

SHARI=

SERVICE MANUAL

LIQUID CRYSTAL DIGITAL CAMCORDER

MODEL VL-SD20U

In the interests of user-safety (Required by safety regula-

countries) the set should be restored

some

in

tions

original condition and only parts

be used.

/-

1 . IMPORTANT SERVICE NOTES.. .................................................................................................... l-l

2. SPECIFICATIONS

3. PART NAMES.. ................................................................................................................................ 3-l

4. DISASSEMBLY OF THE SET

5. MECHANISM ADJUSTMENT JIGS AND PARTS

6. INSPECTION AND MAINTENANCE

ITEMS AND INTERVALS

7. MECHANICAL ADJUSTMENTS AND CHECKS

8. TAPE RUNNING ADJUSTMENT

9. MECHANICAL SECTION ASSEMBLY AND PARTS REPLACEMENT

(DISASSEMBLY AND REASSENBLY).

lO.ADJUSTING THE ELECTRICAL CIRCUITS

11 .USEFUL TIPS ................................................................................................................................ 1 l-l

12.SIGNAL FLOW DIAGRAMS .......................................................................................................... 12-1

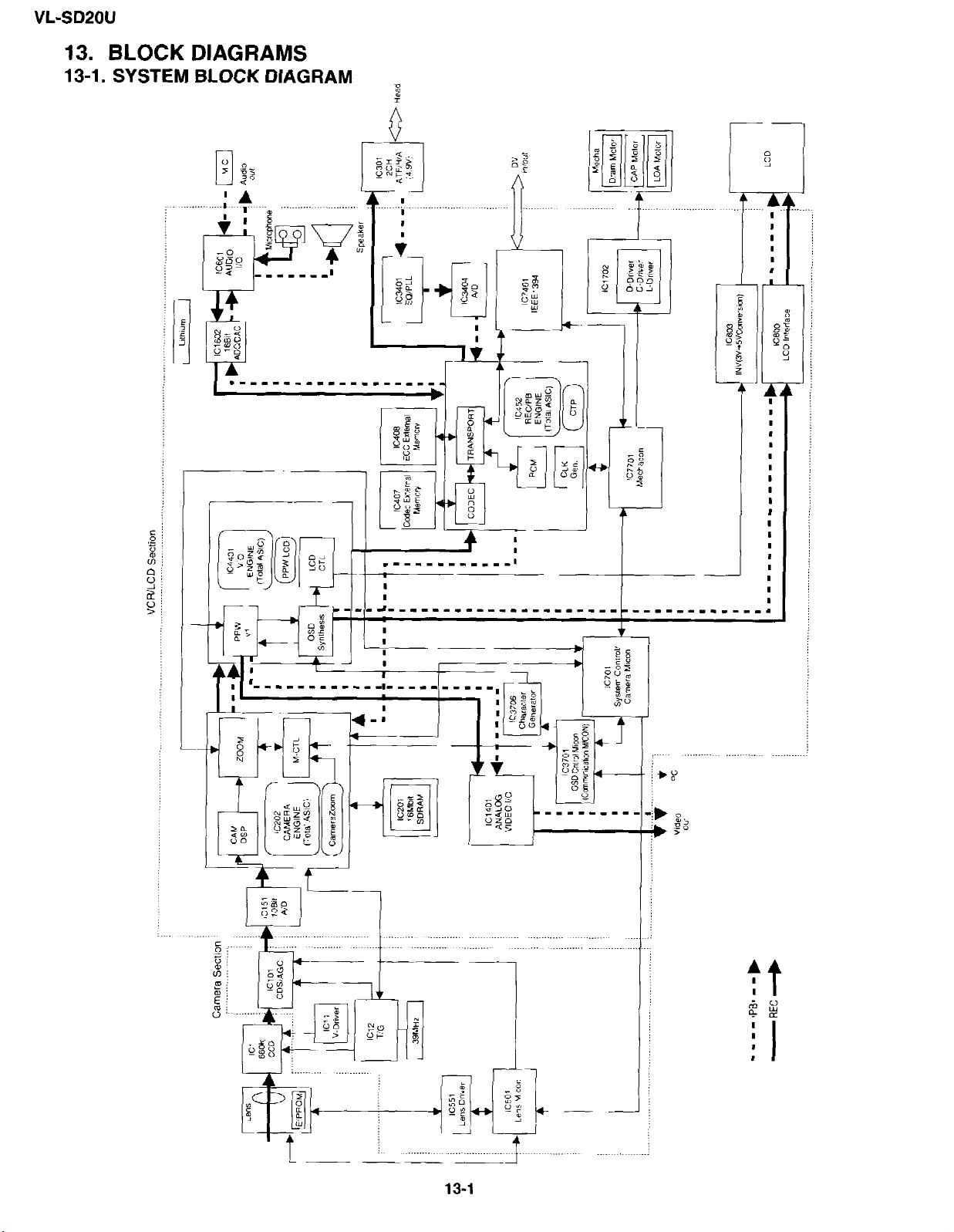

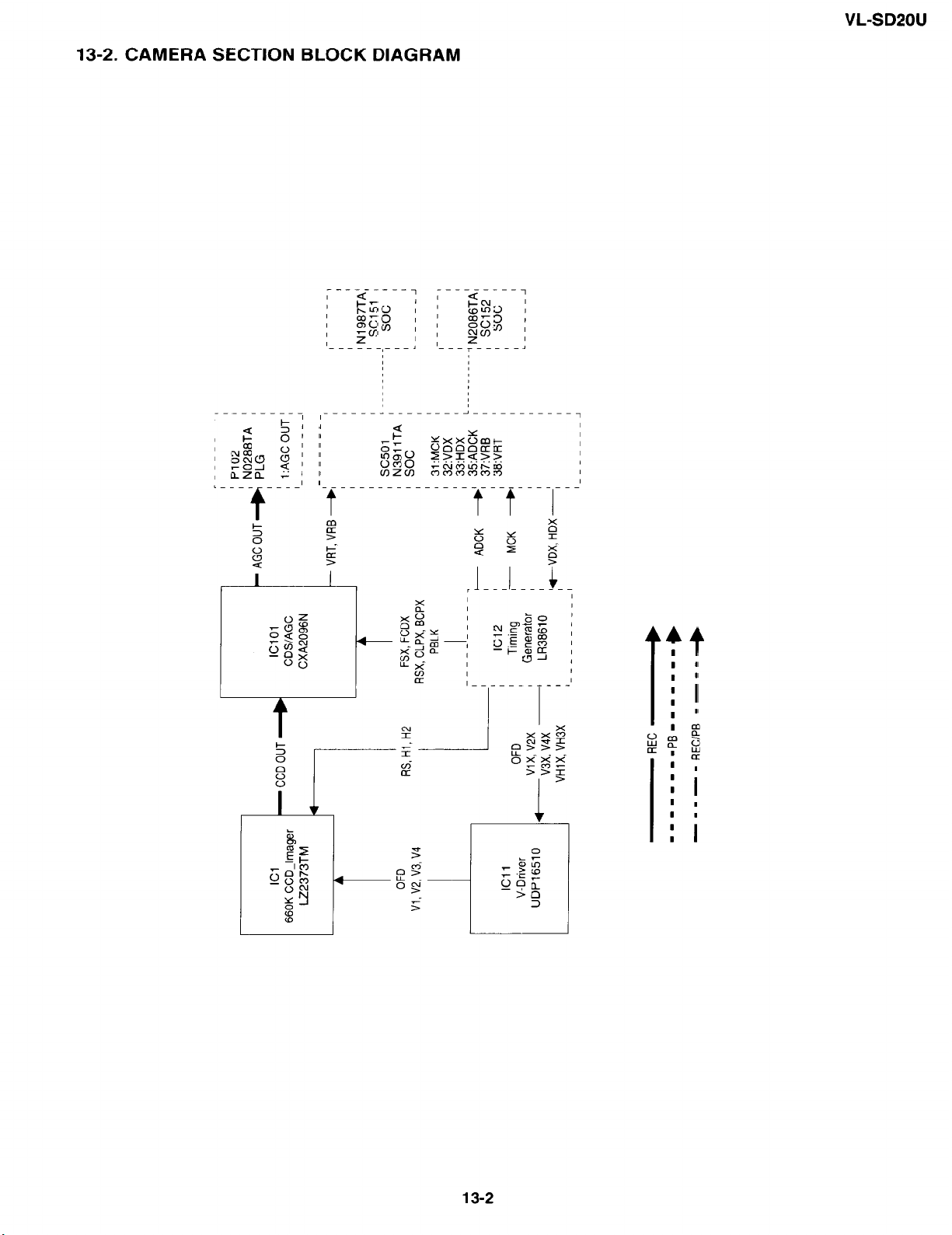

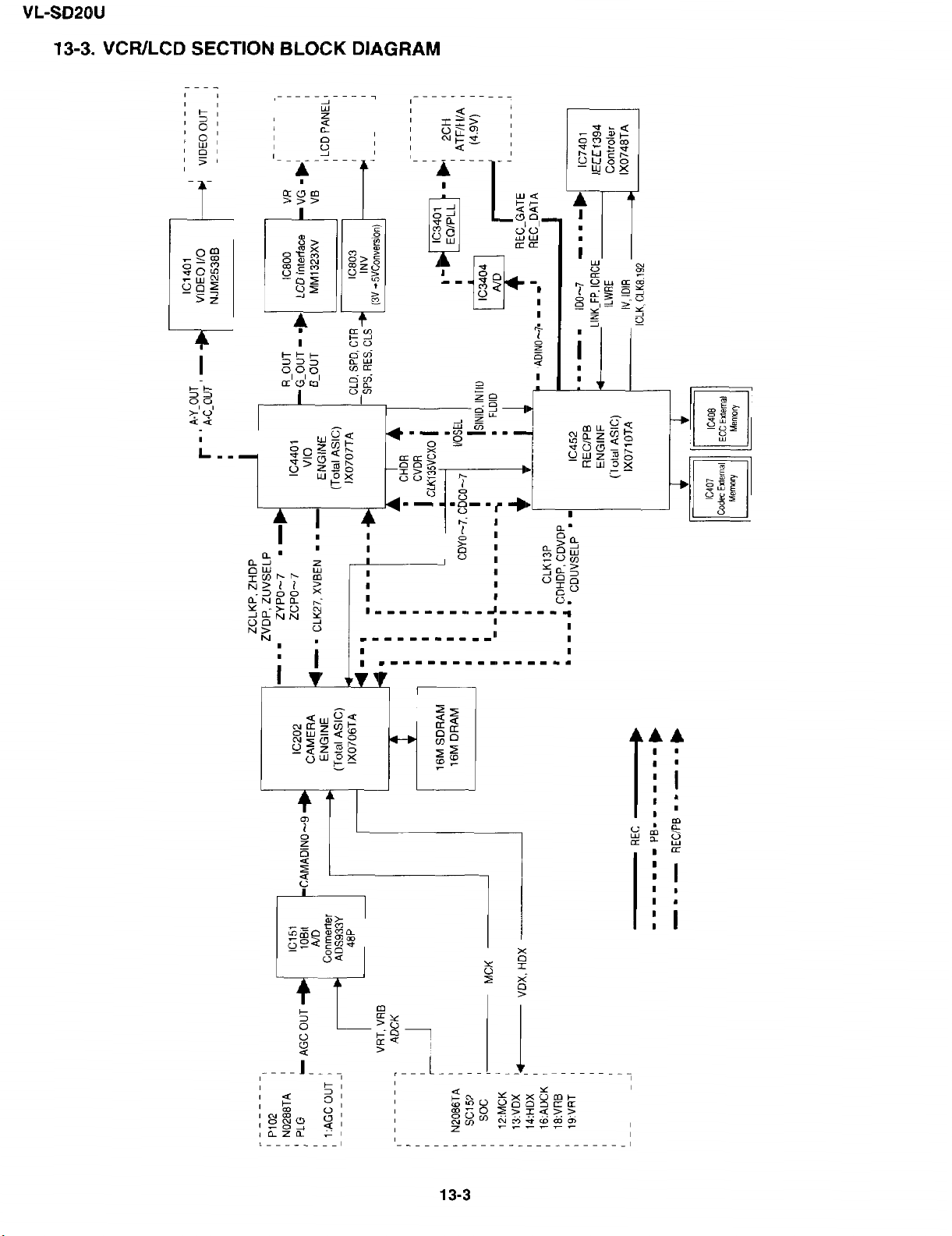

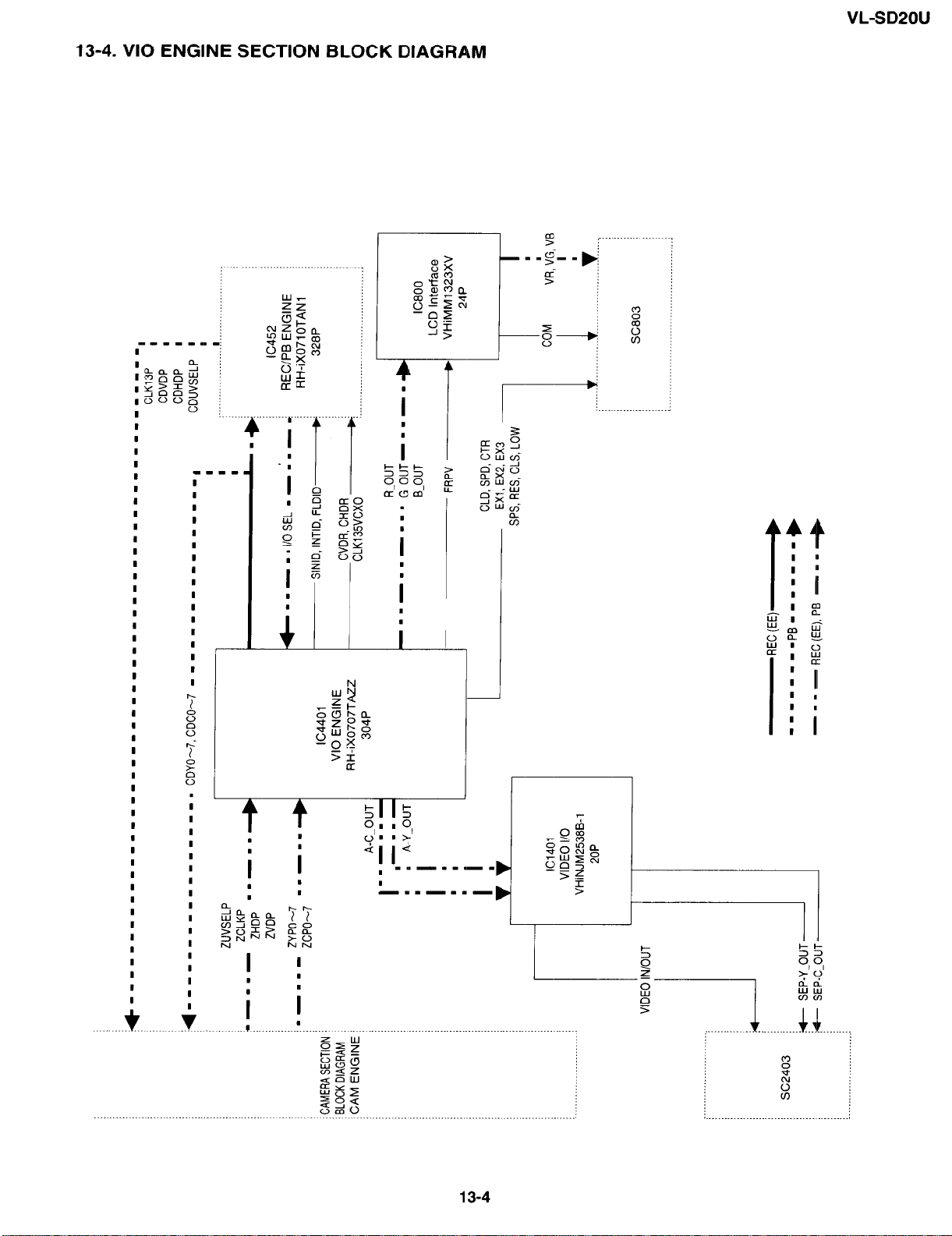

13.BLOCK DIAGRAMS ...................................................................................................................... 13-l

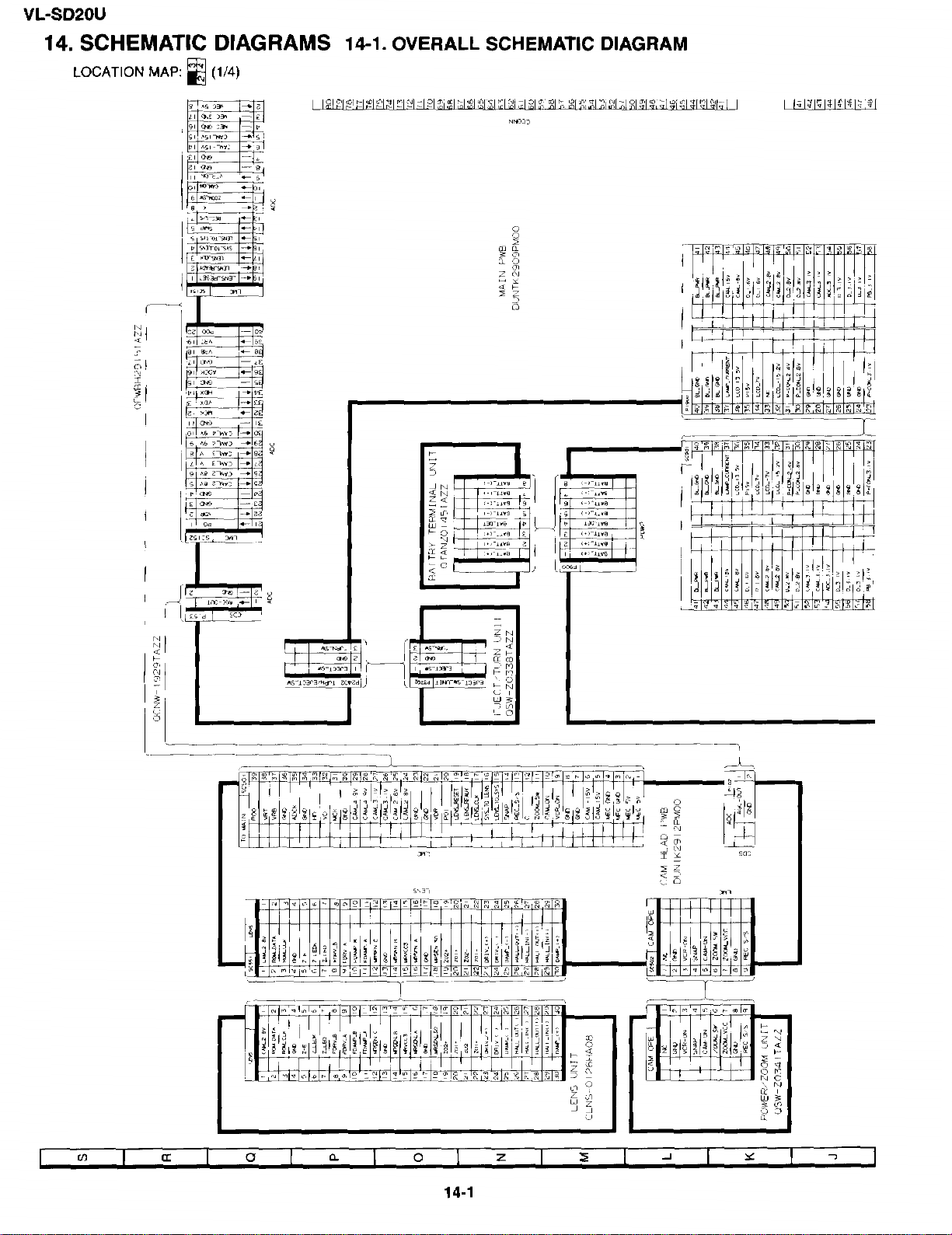

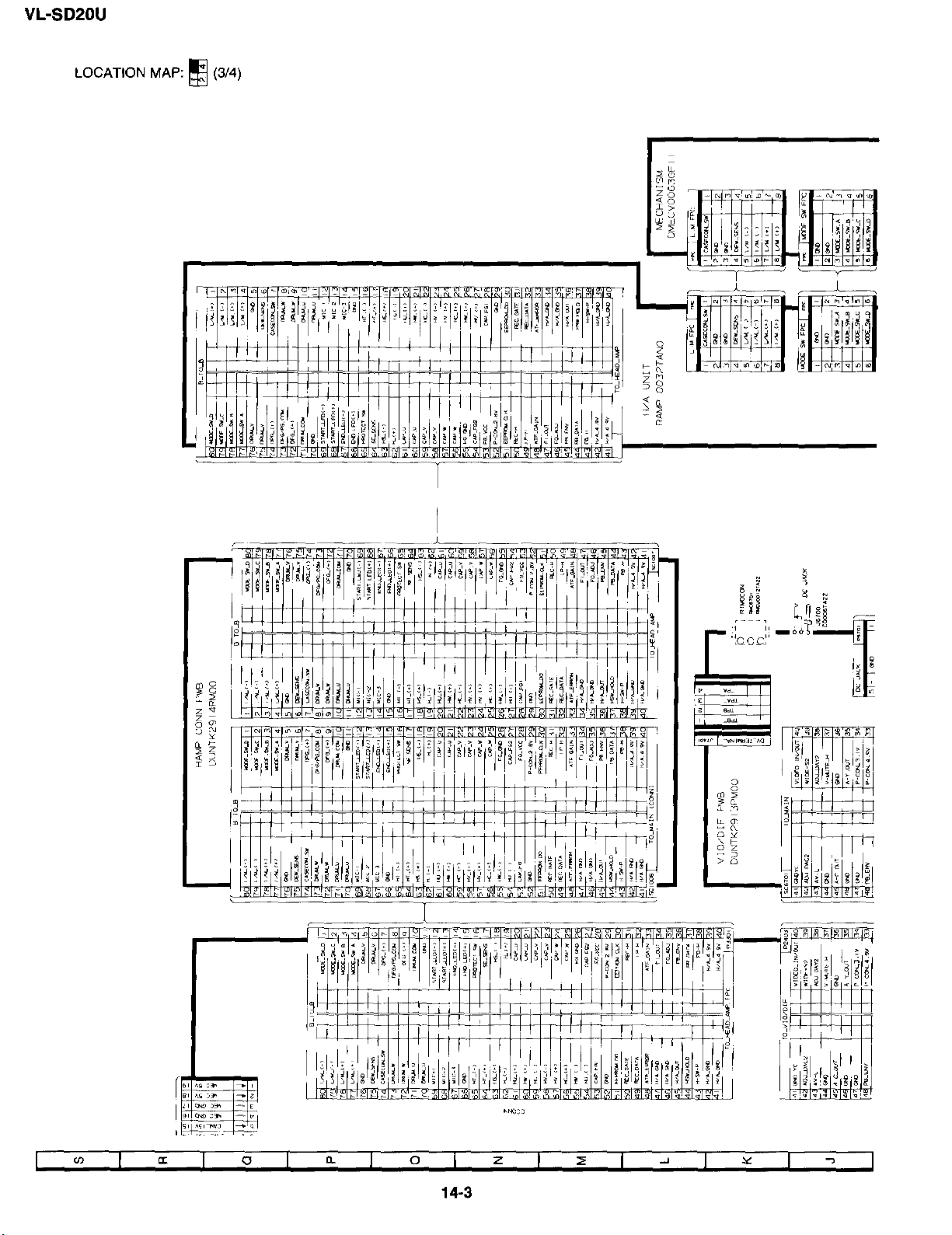

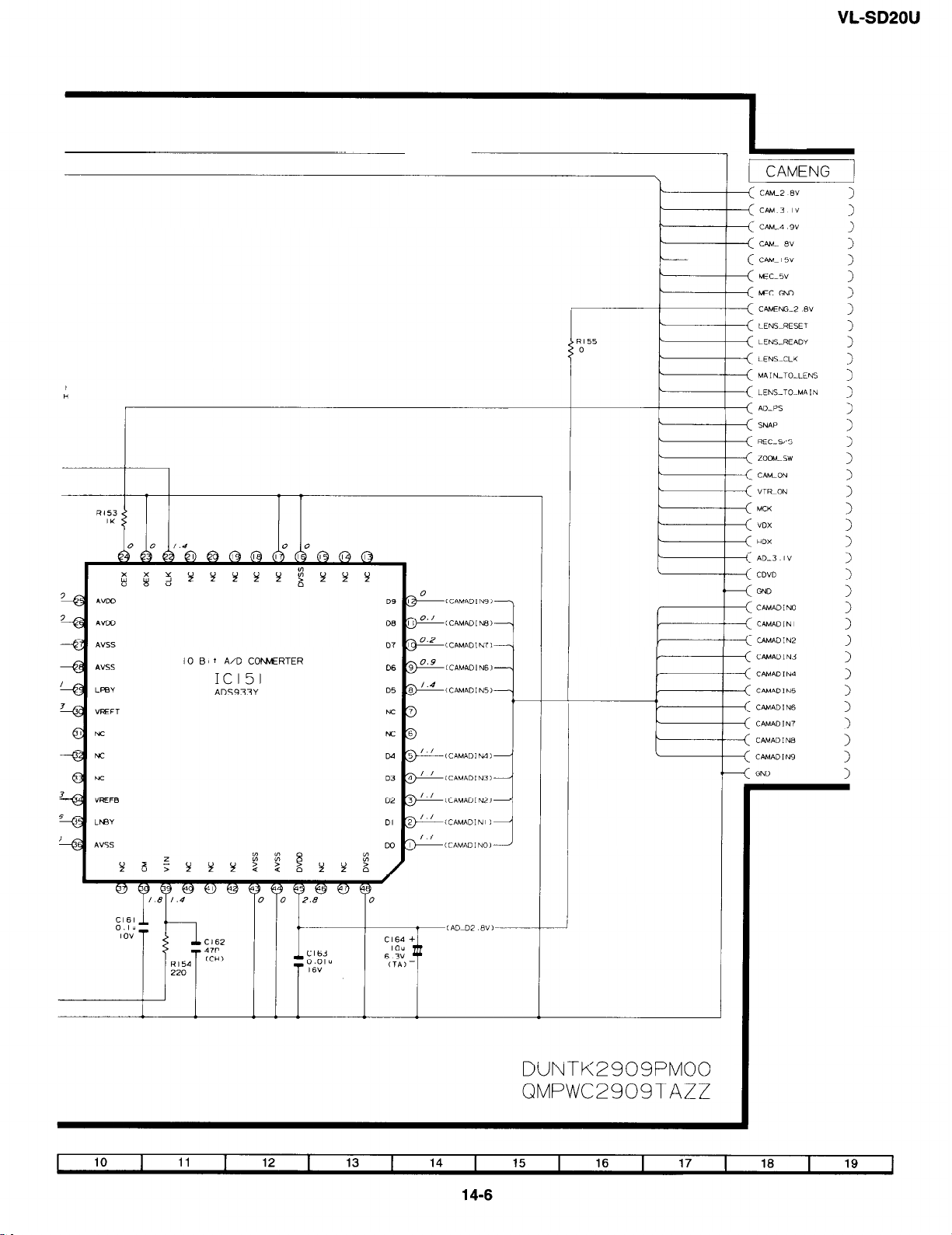

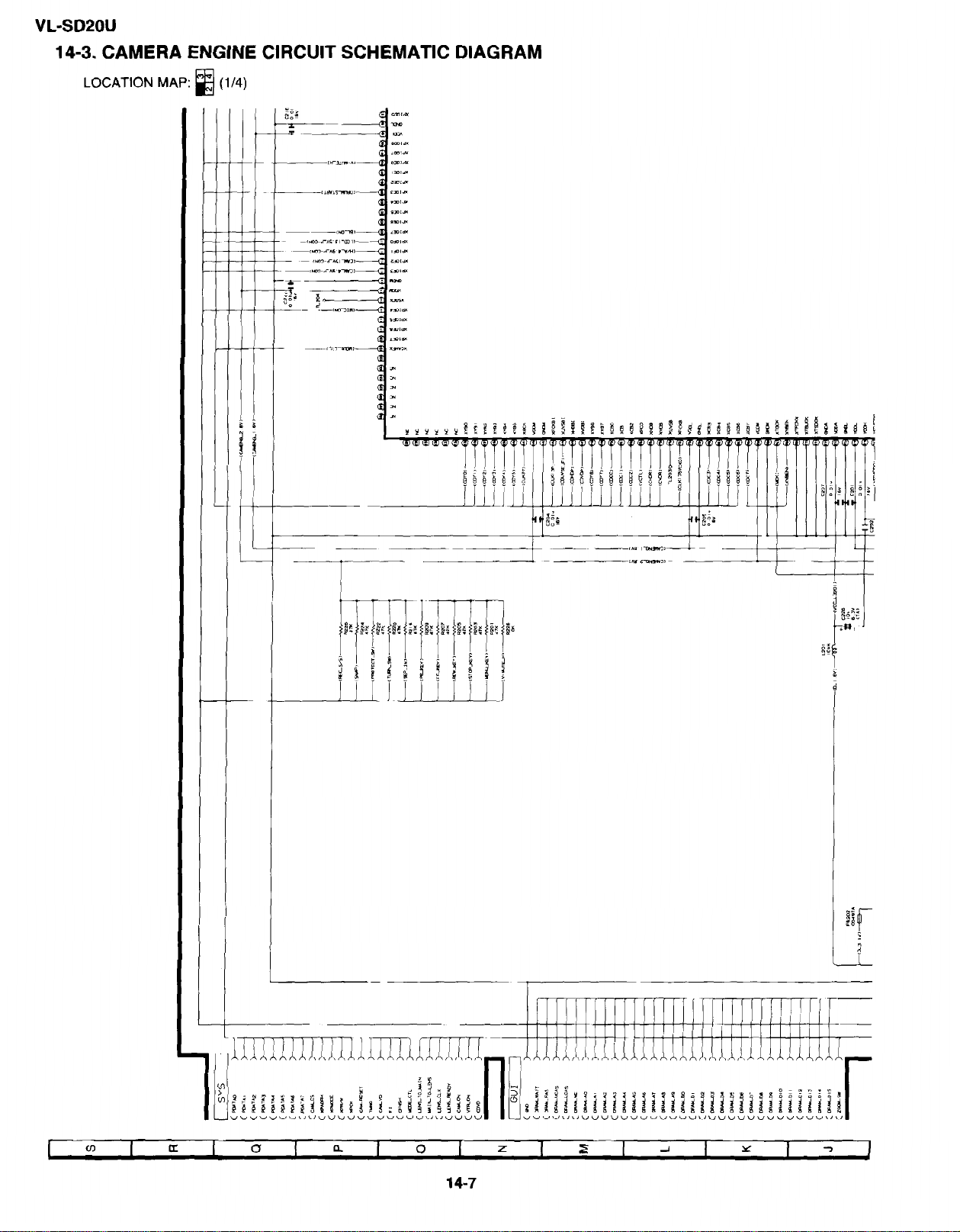

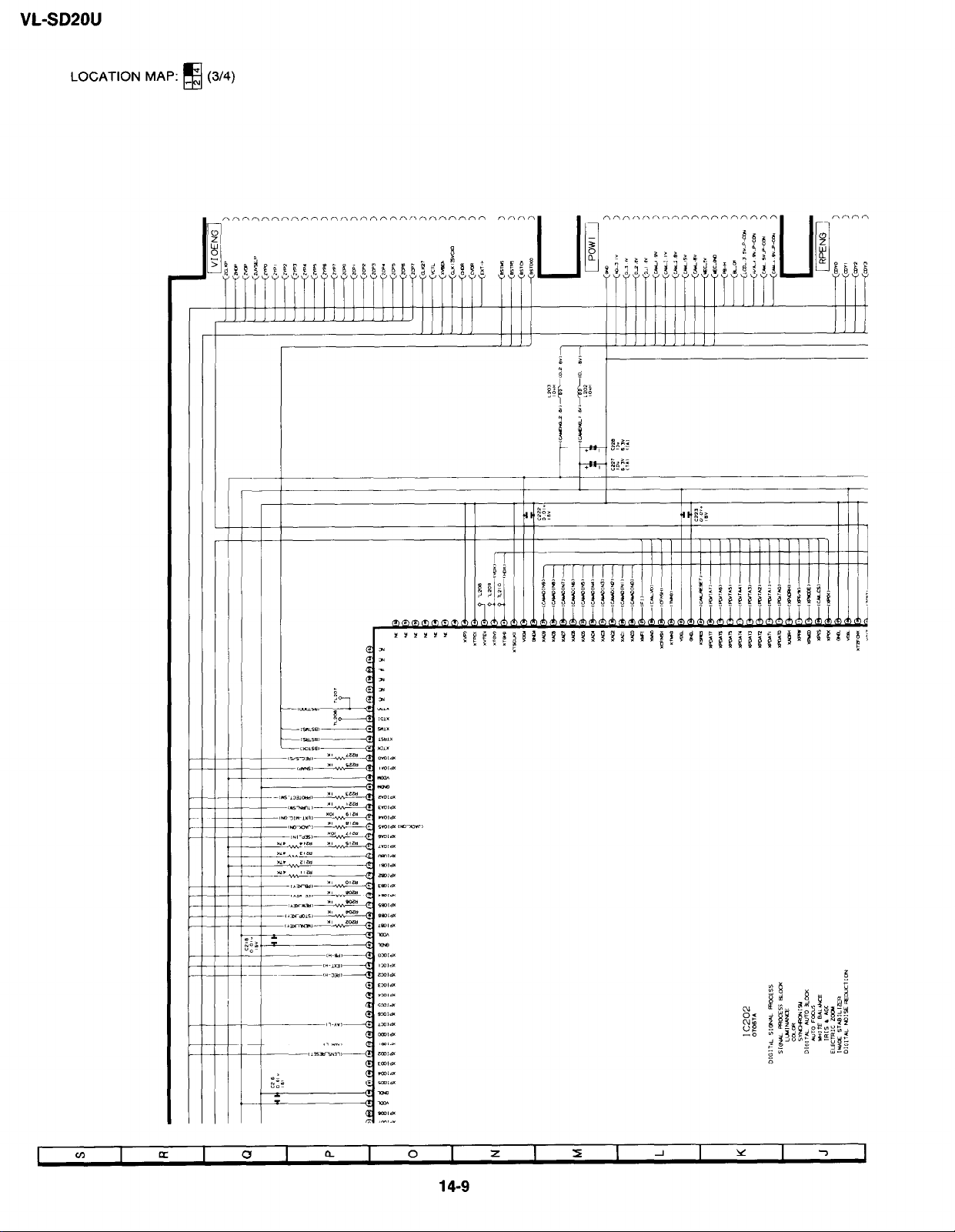

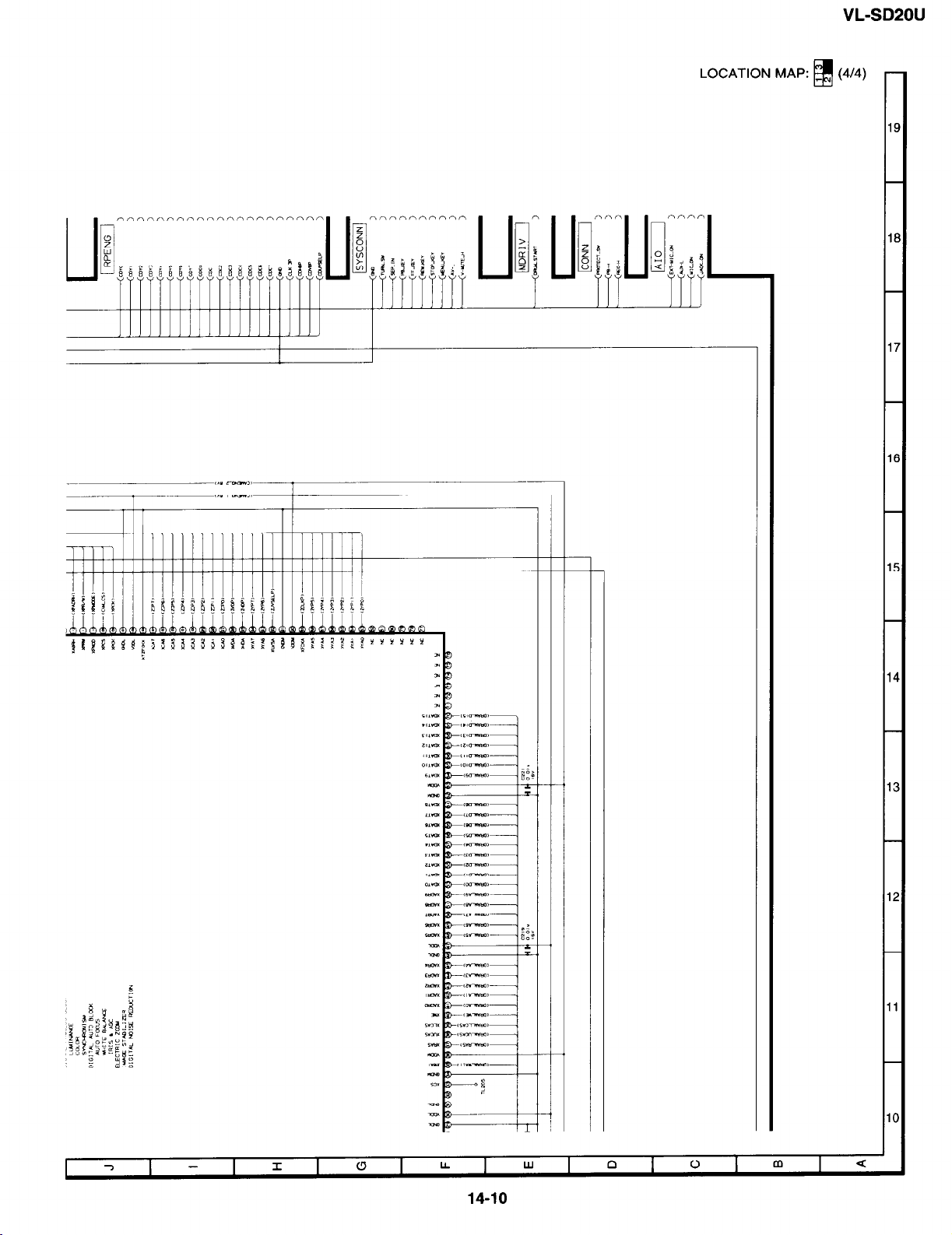

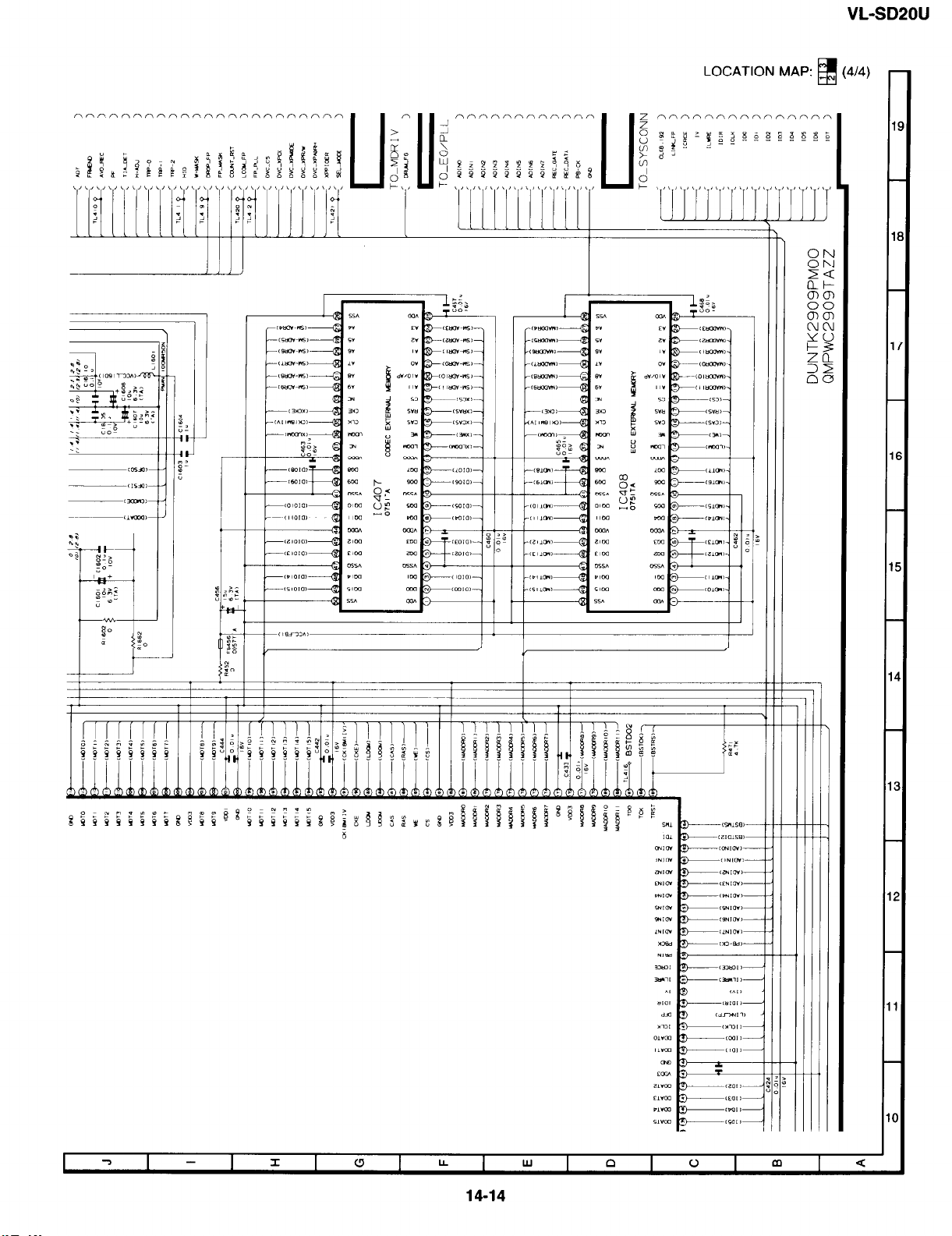

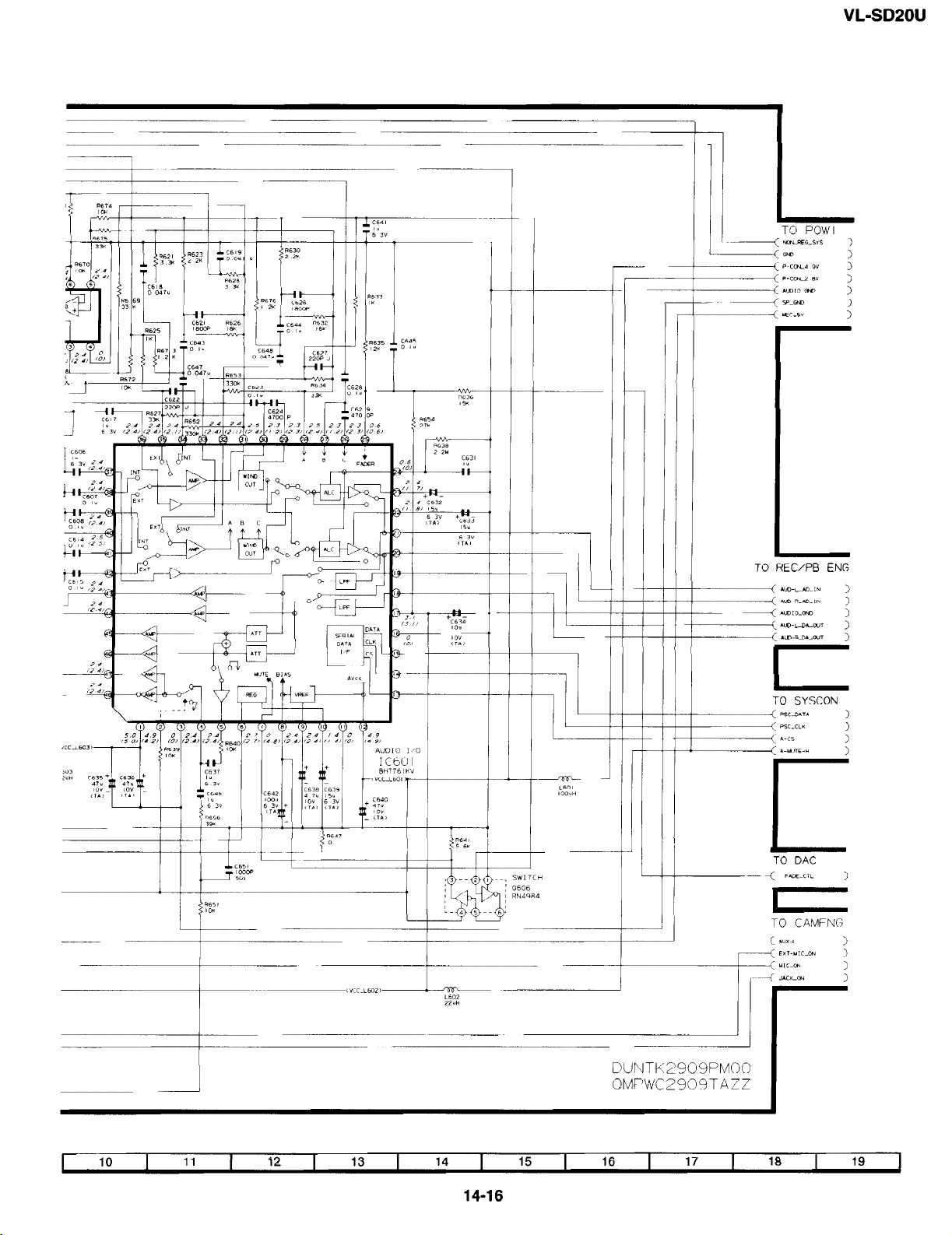

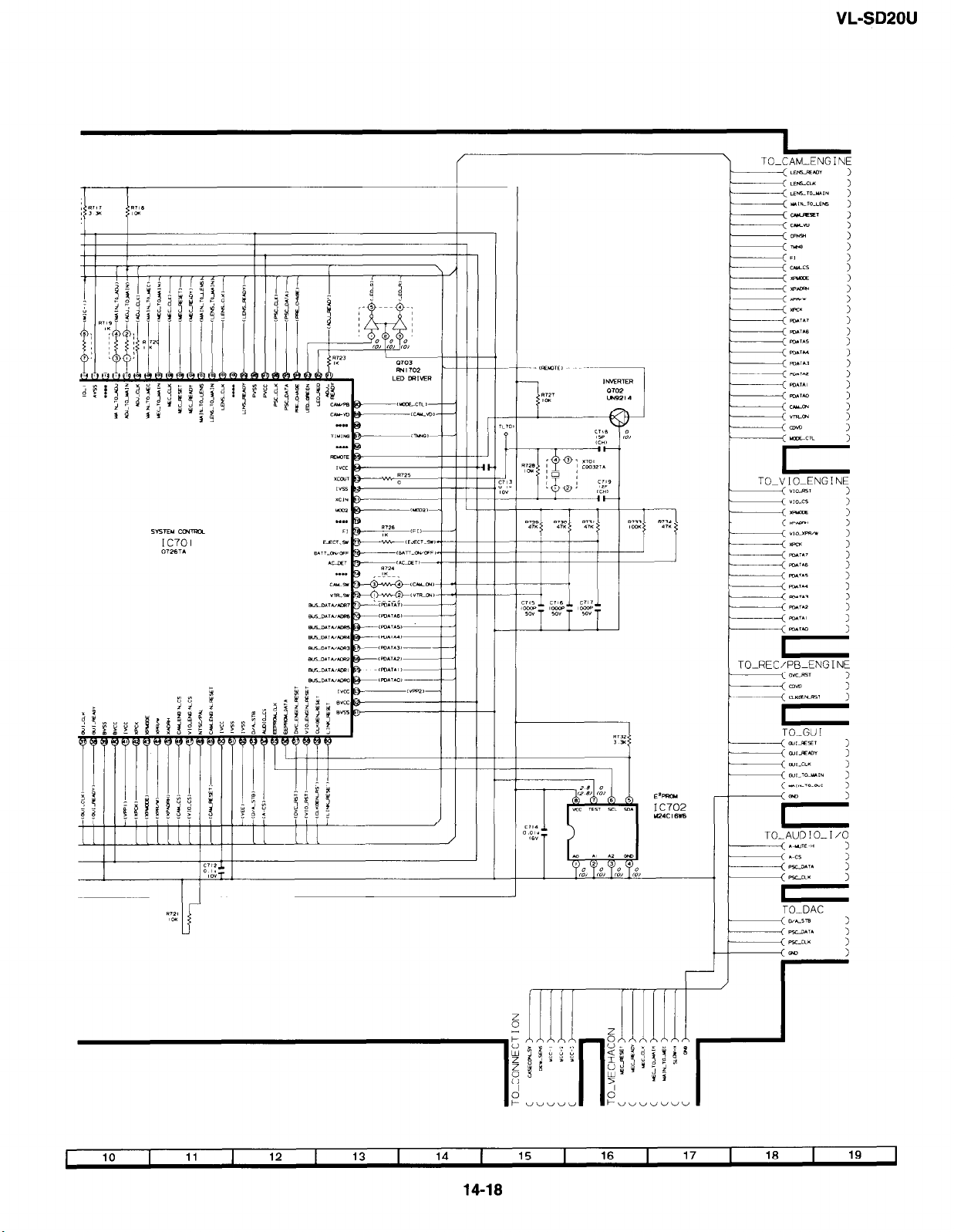

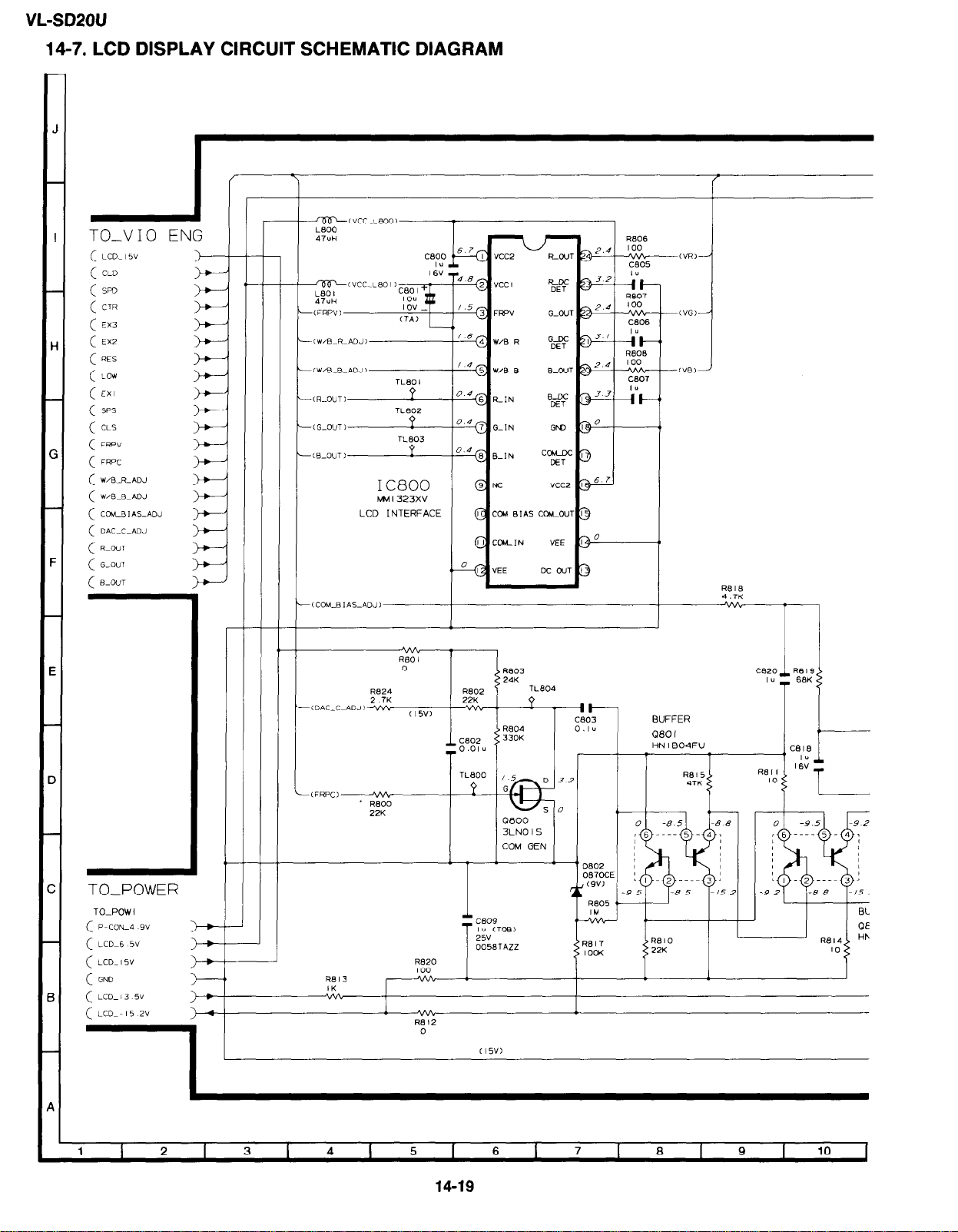

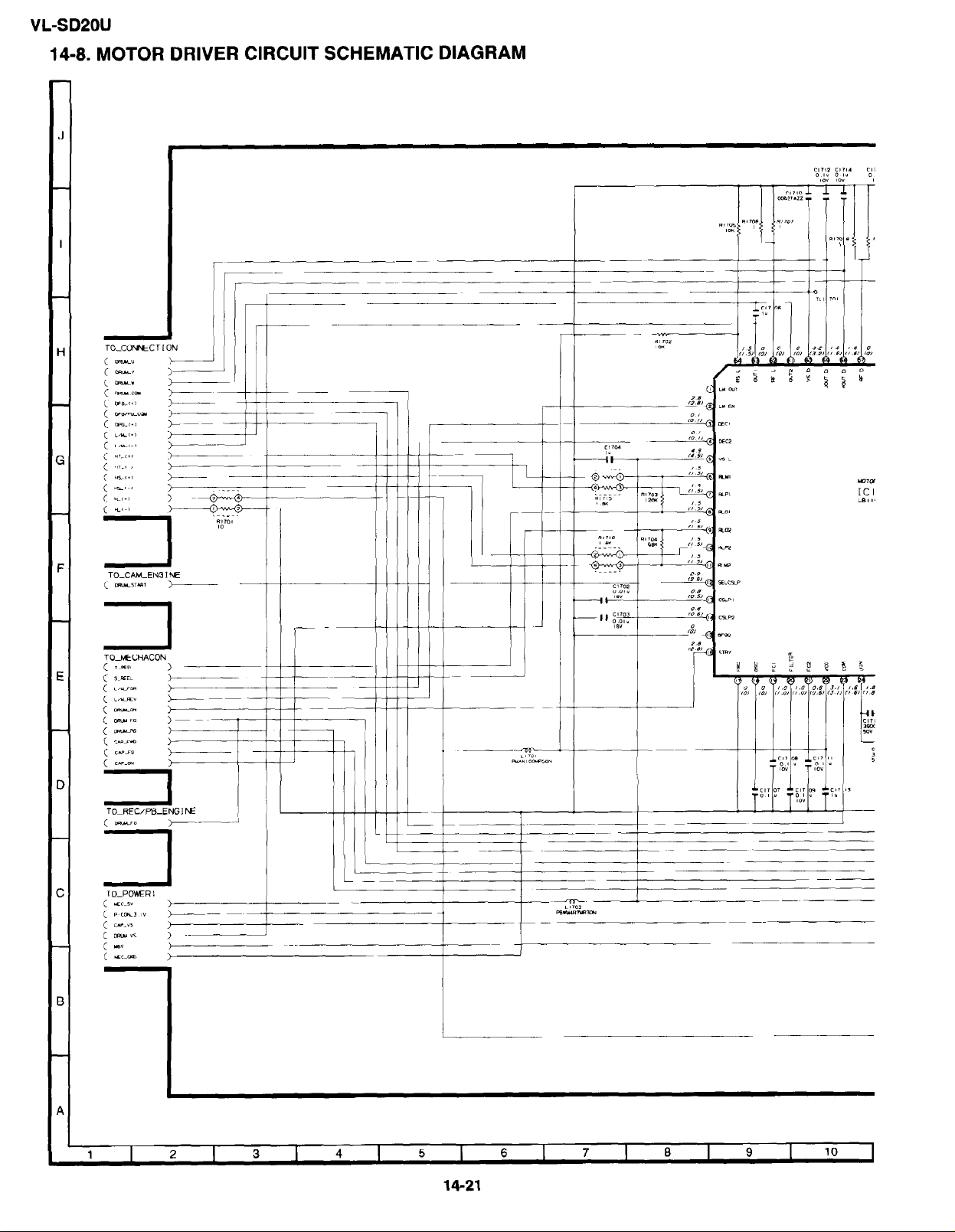

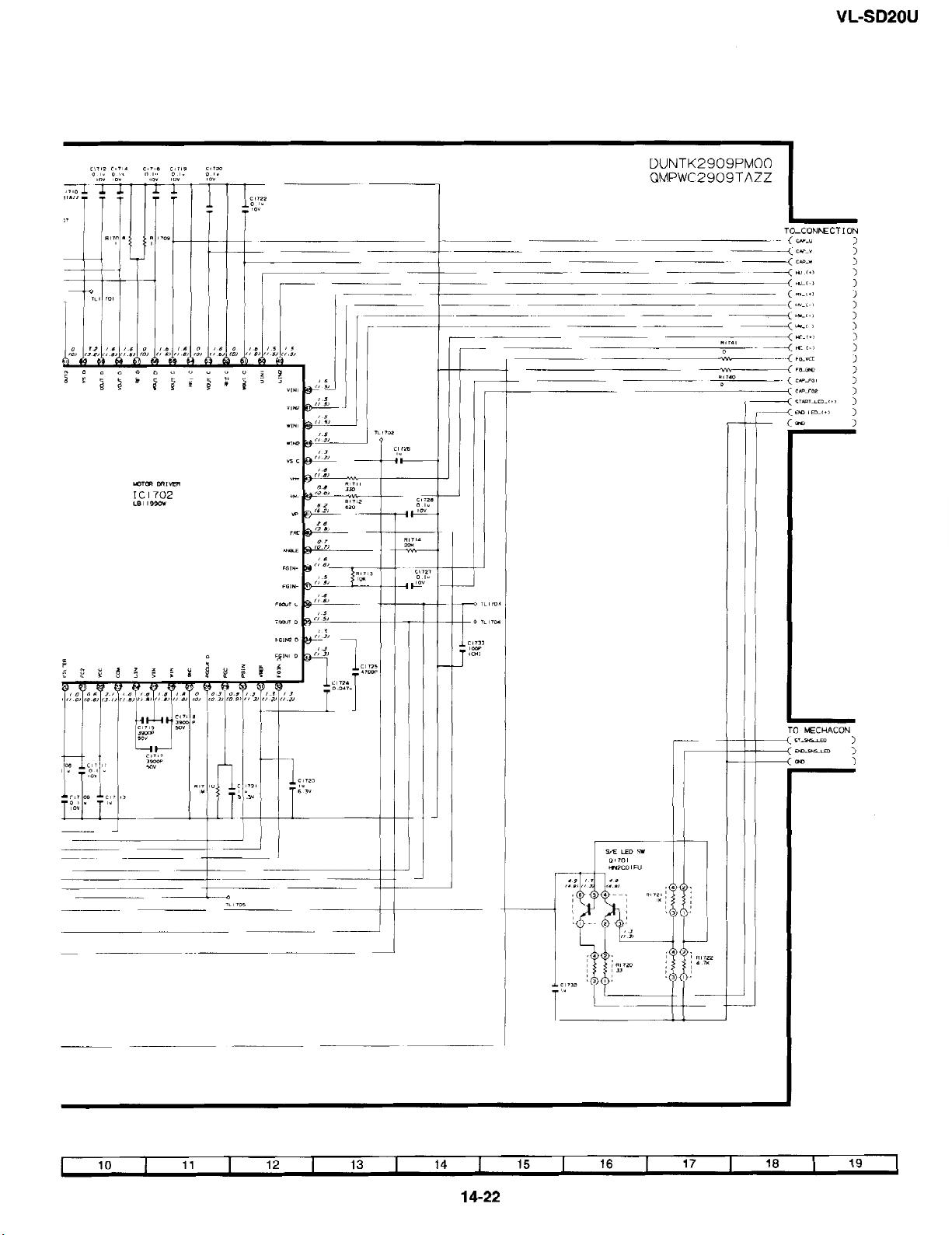

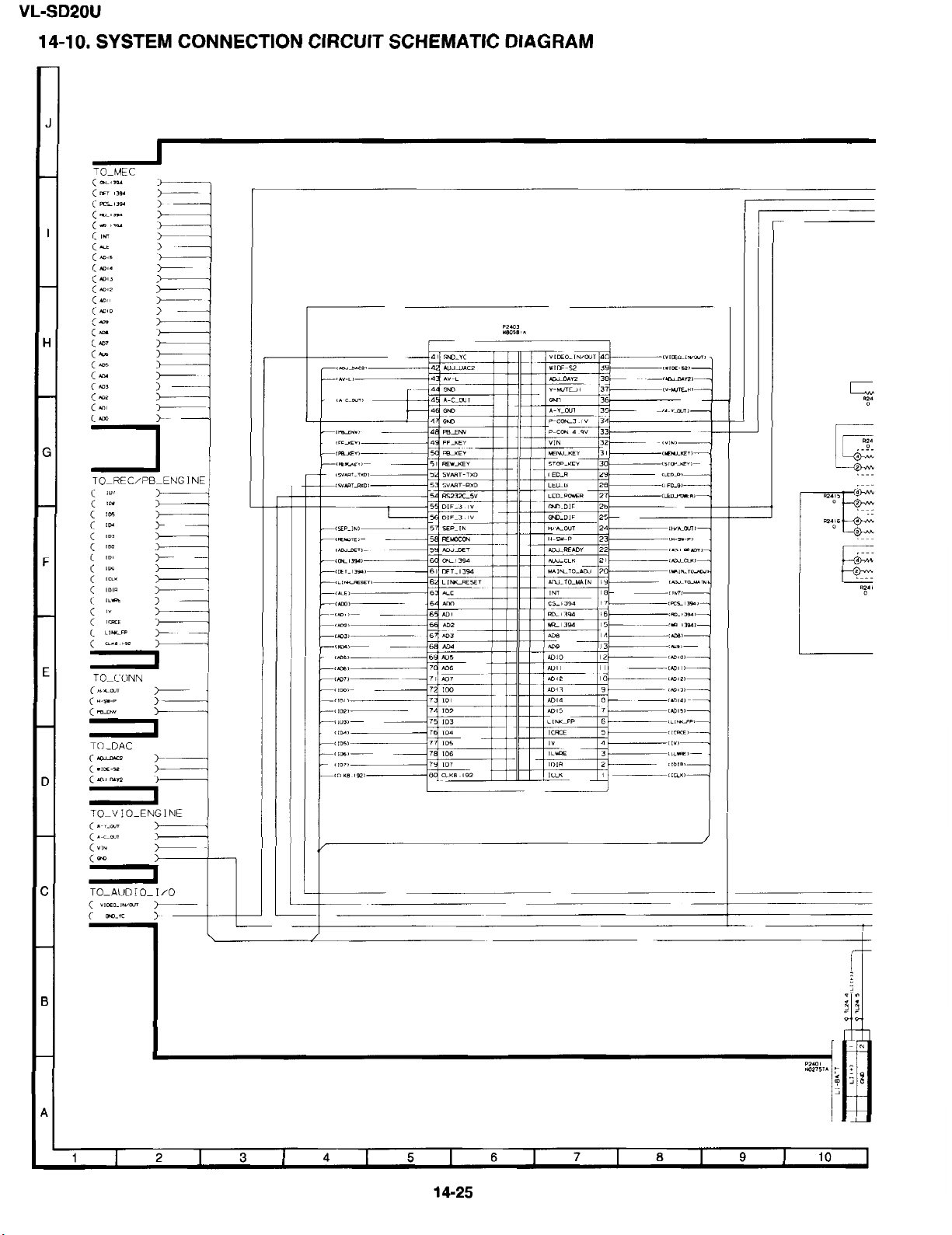

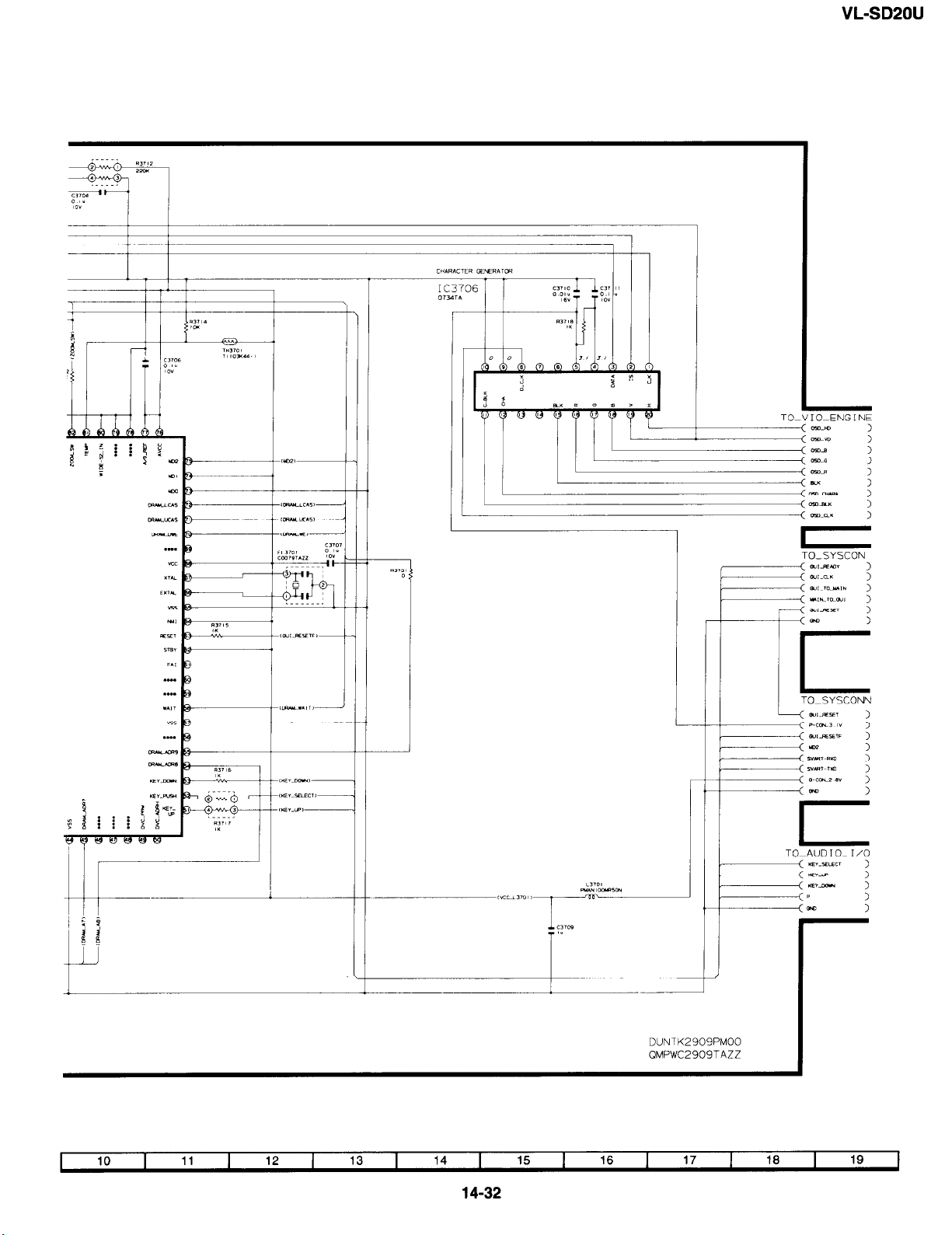

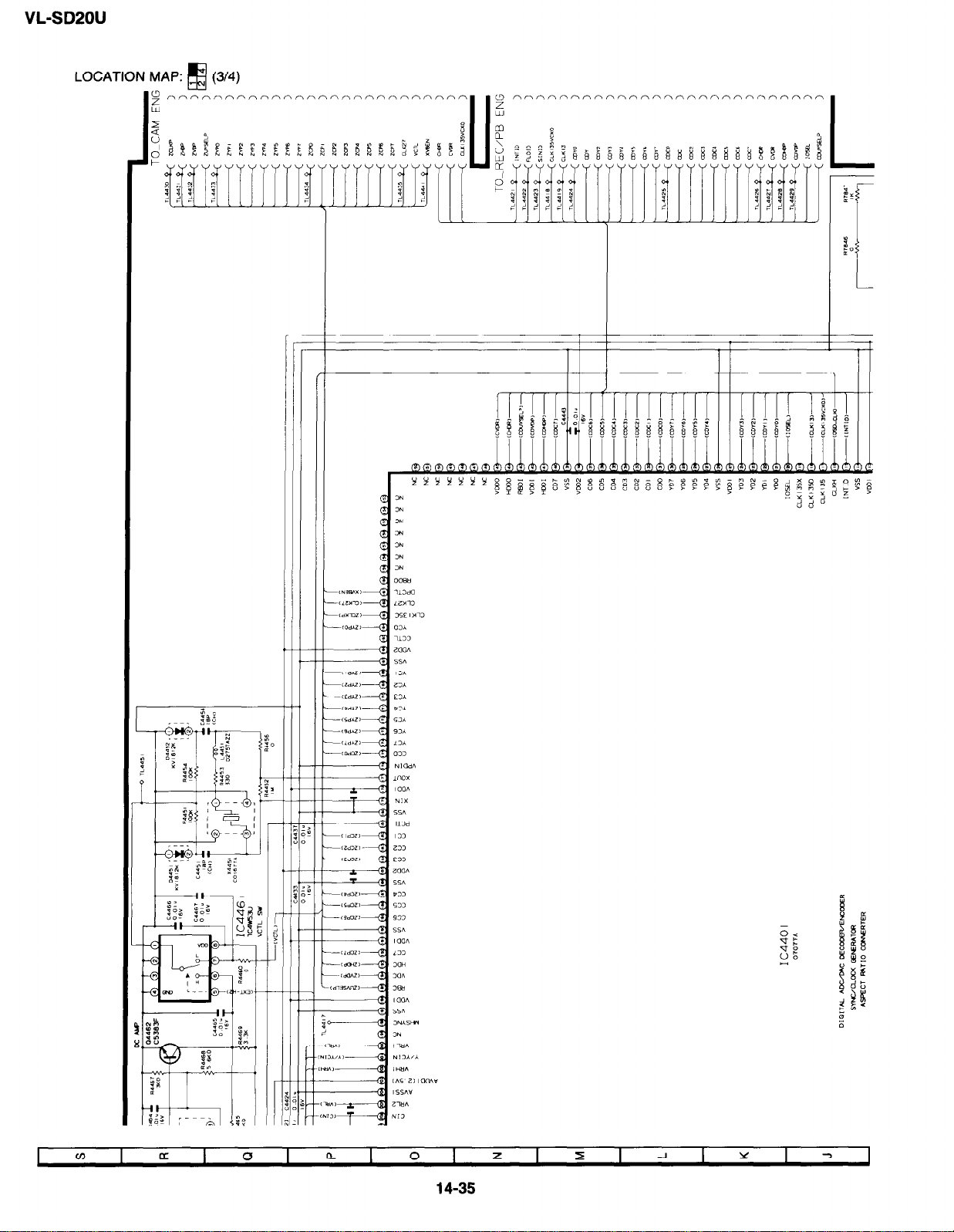

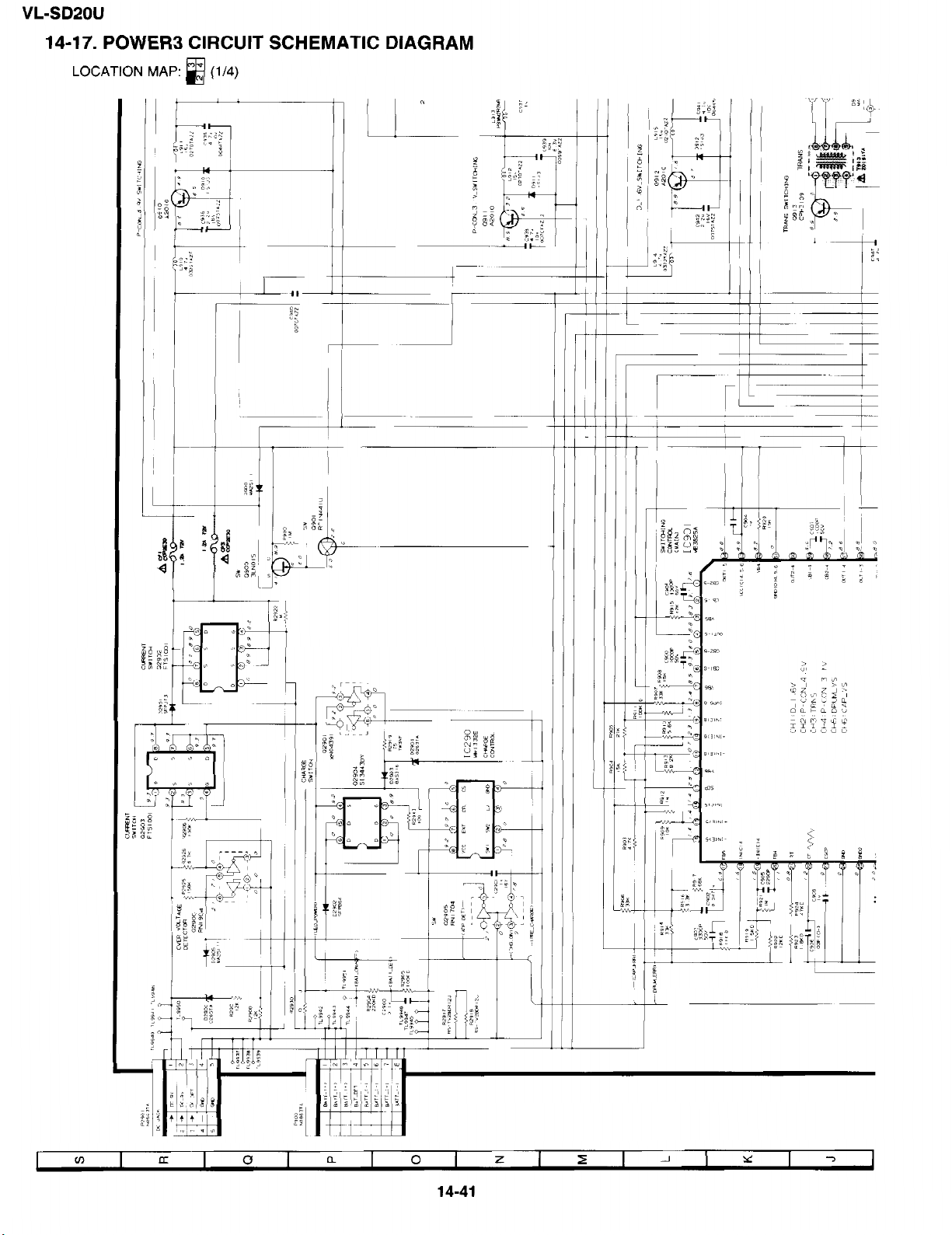

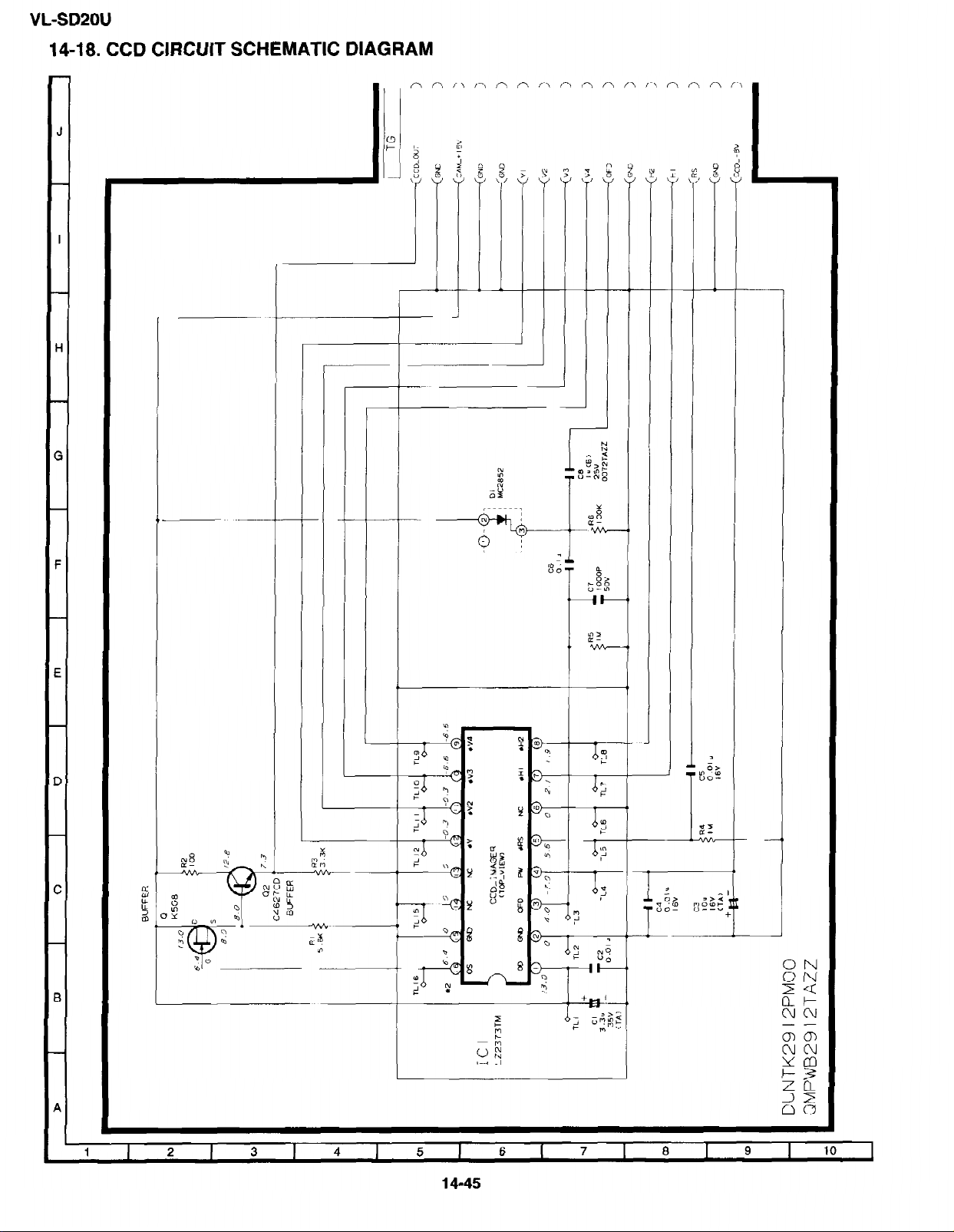

14SCHEMATIC DIAGRAMS

15SEMICONDUCTOR LEAD IDENTIFICATION

1 G-PRINTED WIRING BOARD ASSEMBLIES

17.REPLACEMENT PARTS LIST

18.PACKlNG OF THE SET.. ............................................................................................................... 18-l

........................................................................................................................... 2-1

........................................................................................................

............................................................................................................... .6-l

..................................................................................................... 8-l

..............................................................................................................

.......................................................................................................

CONTENTS

..........................................................................

............................................................................

.........................................................................................

.................................................................................

...............................................................................

...................................................................................

identical to those specified

S79K7VL-SD20U

NTSC

its

to

Page ’

.4-l

.5-l

.7-l

.9-l

10-l

14-1

15-1

16-1

17-1

J

SHARP CORPORATlON

This document has been published to be used for

after sates service only.

The contents are subject to change without notice.

Page 2

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VIDEO CAMERA

RECORDER

Before returning the video camera recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the video camera

recorder.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

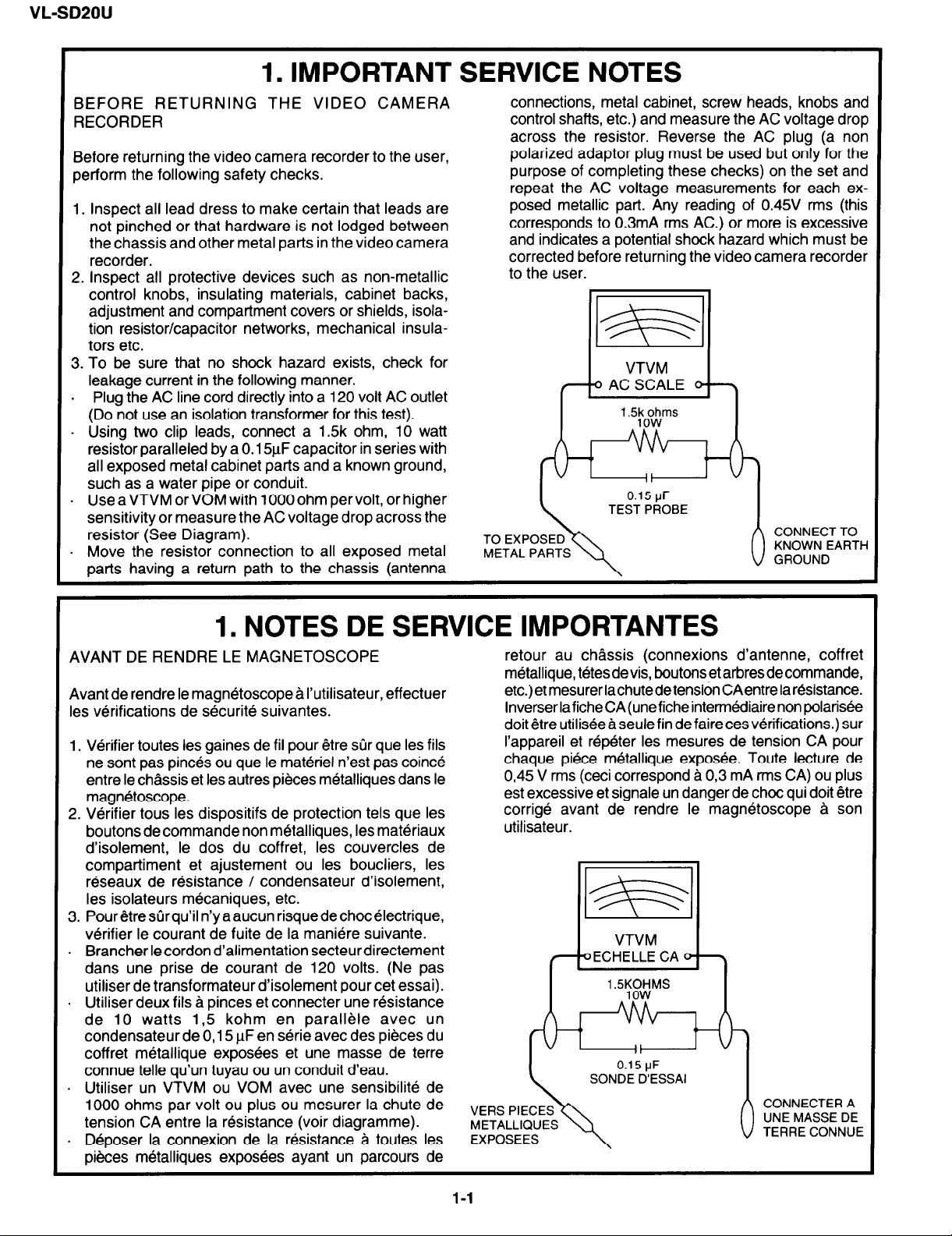

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

- Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

Using two clip leads, connect a 1.5k ohm, IO watt

resistor paralleled by a 0.15uF capacitor in series with

all exposed metal cabinet parts and a known ground,

such as a water pipe or conduit.

Use a VTVM or VOM with 1000 ohm per volt, or higher

sensitivity or measure the AC voltage drop across the

resistor (See Diagram).

Move the resistor connection to all exposed metal

parts having a return path to the chassis (antenna

connections, metal cabinet, screw heads, knobs and

control shafts, etc.) and measure the AC voltage drop

across the resistor. Reverse the AC plug (a non

polarized adaptor plug must be used but only for the

purpose of completing these checks) on the set and

repeat the AC voltage measurements for each ex-

posed metallic part. Any reading of 0.45V rms (this

corresponds to 0.3mA rms AC.) or more is excessive

and indicates a potential shock hazard which must be

corrected before returning the video camera recorder

to the user.

0.15 pF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO

KNOWN EARTH

GROUND

1. NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE MAGNETOSCOPE

Avant de rendre le magnetoscope a I’utilisateur, effectuer

les verifications de securite suivantes.

1. Verifier toutes les gaines de fil pour 6tre sirr que les fils

ne sont pas pin&s ou que le materiel n’est pas coin&

entre le chassis et les autres pieces metalliques dans le

magnetoscope.

2. Verifier tous les dispositifs de protection tels que les

boutons decommande non metalliques, les materiaux

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

reseaux de resistance / condensateur d’isolement,

les isolateurs mecaniques, etc.

3. Pouretresfirqu’il n’yaaucun risquedechocelectrique,

verifier le courant de fuite de la maniere suivante.

Brancher lecordon d’alimentation secteurdirectement

dans une prise de courant de 120 volts. (Ne pas

utiliser de transformateur d’isolement pour cet essai).

Utiliser deux fils a pinces et connecter une resistance

de 10 watts I,5 kohm en parallele avec un

condensateur de 0,15 uF en serie avec des pieces du

coffret metallique exposees et une masse de terre

connue telle qu’un tuyau ou un conduit d’eau.

Utiliser un VTVM ou VOM avec une sensibilite de

1000 ohms par volt ou plus ou mesurer la chute de

tension CA entre la resistance (voir diagramme).

Deposer la connexion de la resistance a toutes les

pieces metalliques exposees ayant un parcours de

retour au chassis (connexions d’antenne, coffret

metallique, tetesdevis, boutonsetarbresdecommande,

etc.) et mesurer lachutede tension CAentre la resistance.

lnverserlaficheCA(uneficheintem+diairenonpolarisee

doitgtreutiliseeBseulefindefairecesverifications.)sur

I’appareil et repeter les mesures de tension CA pour

chaque piece metallique exposee. Toute lecture de

0,45 V rms (ceci correspond a 0,3 mA rms CA) ou plus

est excessive et signale un danger de choc qui doit etre

corrige avant de rendre le magnetoscope a son

utilisateur.

VTVM

r-oECHELLE CA *-

’ .TGMS

SONDE D’ESSAI

CONNECTER A

METALLIQUES

EXPOSEES

UNE MASSE DE

TERRE CONNUE

l-l

Page 3

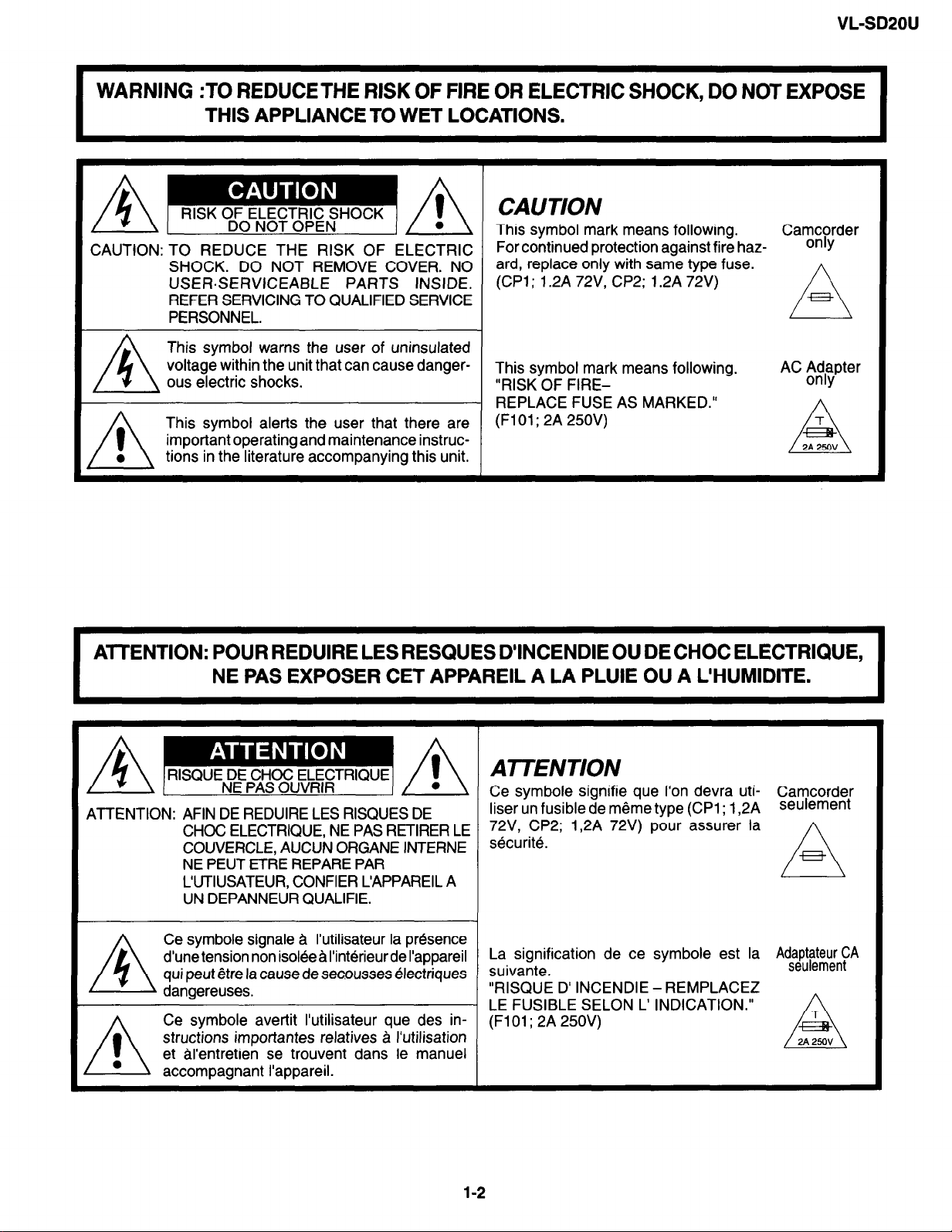

WARNING :TO REDUCETHE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS APPLIANCE TO WET LOCATIONS.

CAUTION

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK. DO NOT REMOVE COVER. NO

USERSERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user of uninsulated

voltage within the unit that can cause danger-

A

I

0

n

ous electric shocks.

This symbol alerts the user that there are

important operating and maintenance instructions in the literature accompanying this unit.

This symbol mark means following.

For continued protection against fire hazard, replace only with same type fuse.

(CP1; 1.2A 72V, CP2; 1.2A 72V)

This symbol mark means following.

“RISK OF FIREREPLACE FUSE AS MARKED.”

(Fl 01; 2A 250V)

Ca!xder

AC 2:layPter

A

VL-SDSOU

ATTENTION: POUR REDUIRE LES RESQUES D’INCENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APPAREIL A LA PLUIE OU A L’HUMIDITE.

RISQUE DE CHOC ELECTRIQUE

ATTENTION: AFIN DE REDUIRE LES RISQUES DE

Ce symbole signale a I’utilisateur la presence

dune tension non isolee a I’interieur de I’appareil

A

I

0

n

qui peut etre la cause de secousses dlectriques suivante.

dangereuses.

Ce symbole aver-tit I’utilisateur que des in- (FlOl ; 2A 250V)

structions importantes relatives B I’utilisation

et Bl’entretien se trouvent dans le manuel

accompagnant I’appareil.

NE PAS OUVRIR

CHOC ELECTRIQUE, NE PAS RETIRER LE

COUVERCLE, AUCUN ORGANE INTERNE

NE PEUT ETRE REPARE PAR

L’UTIUSATEUR, CONFIER L’APPAREIL A

UN DEPANNEUR QUALIFIE.

n

I

.

ATTENTION

Ce symbole signifie que I’on devra uti- Camcorder

liser un fusible de meme type (CPl ; 1,2A seulement

72V, CP2; 1,2A 72V) pour assurer la

securite.

La signification de ce symbole est la

“RISQUE D’ INCENDIE - REMPLACEZ

LE FUSIBLE SELON L’ INDICATION.”

1-2

Page 4

A CAUTION

BEFORE BATTERY DESTROY

W NICKEL-CADMIUM BATTERY

The following program is available in the United States. Please consult local environmental

authorities concerning the availability of this or other programs in your area.

The RBRCW Seal

SHARP participates in the RBRCTM* Nickel-Cadmium Battery Recycling Program in the United

States. The RBRCTM Seal on our battery pack contained in our product indicates that SHARP is

voluntarily participating in an industry program to collect and recycle these batteries. The RBRCTM

program provides you with a convenient alternative to placing spent Nickel-Cadmium battery packs into

the trash or municipal waste stream, which is illegal in some areas. At the end of their useful life, the

Nickel-Cadmium battery can be dropped off at the nearest collection center for recycling. For information

on the nearest collection center, call 1-800-8-BATTERY or your local recycling center. If you are located

outside the United States, contact your local authorities for information concerning proper disposal and/

or recycling of this battery. SHARP’s involvement in this program is part of our commitment to protecting

our environment and conserving natural resources.

[Footnote] ‘RBRCTM is trademark of the Rechargeable Battery Recycling Corporation.

q NICKEL-METAL HYDRIDE BAlTERY

q LITHIUM or LITHIUM-ION BATTERY

n SEALEDLEADBAlTERY

Battery disposal

Contains the above (Rechargeable) Battery. must be recycled or disposed of properly.

Remove the Battery from the products and contact Federal or State Environmental Agencies for

information on recycling and disposal options.

1-3

Page 5

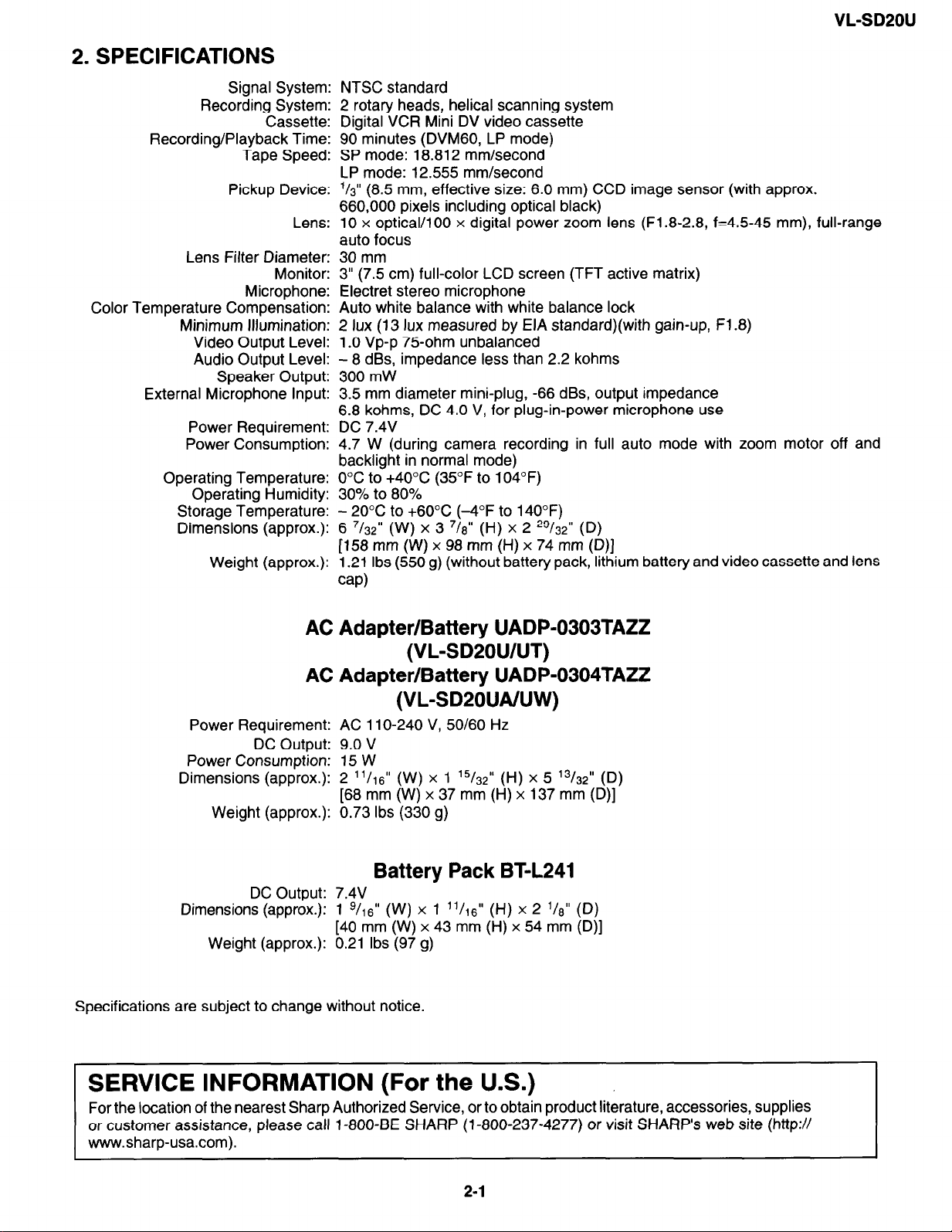

2. SPECIFICATIONS

Signal System:

Recording System:

Cassette:

Recording/Playback Time:

Tape Speed:

Pickup Device:

Lens:

Lens Filter Diameter:

Monitor:

Microphone:

Color Temperature Compensation:

Minimum Illumination:

Video Output Level:

Audio Output Level:

Speaker Output:

External Microphone Input:

Power Requirement:

Power Consumption:

Operating Temperature:

Operating Humidity:

Storage Temperature:

Dimensions (approx.):

Weight (approx.):

NTSC standard

2 rotary heads, helical scanning system

Digital VCR Mini DV video cassette

90 minutes (DVMGO, LP mode)

SP mode: 18.812 mm/second

LP mode: 12.555 mm/second

l/s” (8.5 mm, effective size: 6.0 mm) CCD image sensor (with approx.

660,000 pixels including optical black)

10 x optical/l 00 x digital power zoom lens (F1.8-2.8, f=4.5-45 mm), full-range

auto focus

30 mm

3” (7.5 cm) full-color LCD screen (TFT active matrix)

Electret stereo microphone

Auto white balance with white balance lock

2 lux (13 lux measured by EIA standard)(with gain-up, F1.8)

1 .O Vp-p 75-ohm unbalanced

- 8 dBs, impedance less than 2.2 kohms

300 mW

3.5 mm diameter mini-plug, -66 dBs, output impedance

6.8 kohms, DC 4.0 V, for plug-in-power microphone use

DC 7.4V

4.7 W (during camera recording in full auto mode with zoom motor off and

backlight in normal mode)

0°C to +4O”C (35°F to 104°F)

30% to 80%

- 20°C to +6O”C (-4°F to 140°F)

6 7/32” (W) X 3 ‘18” (H) X 2 2Q/32” (D)

[158 mm (W) x 98 mm (H) x 74 mm (D)]

1.21 Ibs (550 g) (without battery pack, lithium battery and video cassette and lens

Adapter/Battery UADP-0303TAZZ

AC

(VL-SD20UNT)

Adapter/Battery UADP-0304TAZZ

AC

(VL-SD20UAAJW)

Power Requirement:

DC Output:

Power Consumption:

Dimensions (approx.):

Weight (approx.):

AC 1 lo-240 V, 50160 Hz

9.0 v

15w

2 ‘l/,6” (W) x 1

[68 mm (W) x 37 mm (H) x 137 mm (D)]

0.73 Ibs (330 g)

Battery Pack BT-L241

DC Output:

Dimensions (approx.):

Weight (approx.):

Specifications are subject to change without notice.

7.4v

1 ‘/,6” (w) X 1 “/,ij” (H) X 2 l/8” (D)

[4O mm (W) x 43 mm (H) x 54 mm (D)]

0.21 Ibs (97 g)

15/32” (H) X 5 13/32” (D)

1 SERVICE INFORMATION (For the U.S.)

For the location of the nearest Sharp Authorized Service, or to obtain product literature, accessories, supplies

or customer assistance, please call 1-800-BE SHARP (l-800-237-4277) or visit SHARP’s web site (http://

www.sharp-usa.com).

2-1

Page 6

VL-SDSOU

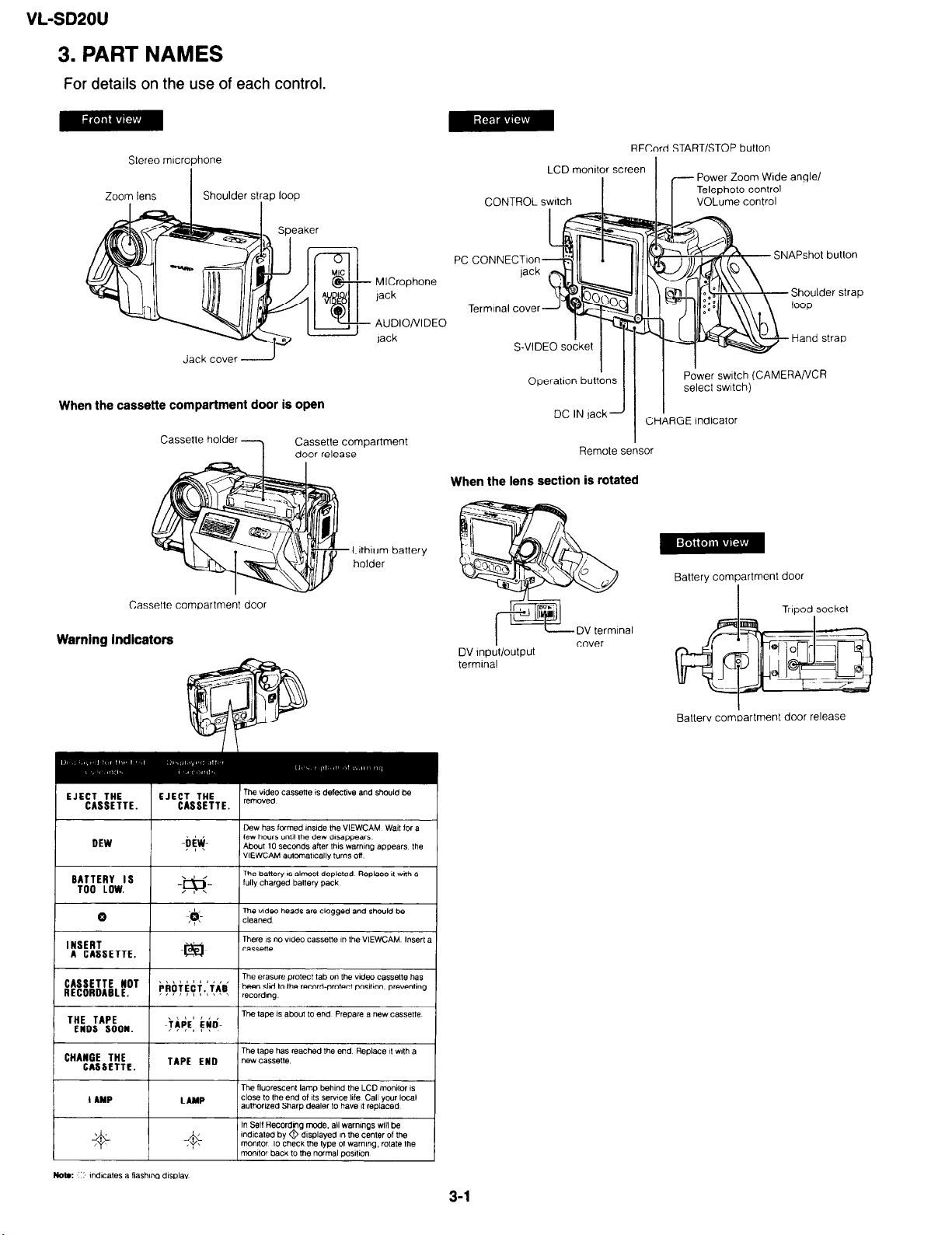

3. PART NAMES

For details on the use of each control.

RECord START/STOP bulton

Power Zoom Wide anqle/

Jack cover 1

When the cassette compartment door is open

Cassette holder

1

Cassette compartment door

Cassette compartment

door release

Warning Indicators

MICrophone

jack

AUDIO/VIDEO

jack

ILIthnrm battery

holder

PC CONNECTion

Terminal cover

S-VIDEO socket

Operation buttons

DC IN lack

J

Remote sensor

When the lens section is rotated

DV InDut/output

Pdwer switch (CAMERA/VCR

select switch)

CHARGE Indicator

Battery compartment door

SNAPshot button

Shoulder strap

loop

Hand strap

EJECT THE

CASSETTE. CASSETTE. removed

/ DEW ( -+‘+ /

I Q

INSERT

A CASSETTE.

CASSETTE NOT

RECORDABLE.

THE TAPE

ENDS SOON.

CHANGE THE

CASSETTE.

LAMP

:. lndlcates a flashing d,?.play

M0t.z

EJECT THE

-;*-

1 -?#- 1 cleaned

_bkbiihi ‘iii_

, I , I 1 I’, s _ \ record,ng

~j+E’ kid-

/ I , I

TAPE END

LAMP

The video cassette IS defective and should be

Dew has fwmed wwde the VIEWCAM Wait for a

lew hours until the dew disappears

Abwl 10 seco”ds atrer th,s warn,ng appears. the

VIEWCAM automatically f”r”s 0”

The battery IS almost depleted Replace 11 wLh a

fully charged battery pack

The video heads are clogged and should be

There IS no video cassette I” the VIEWCAM Inserf a

cassette

The era?.ure protect tab on the video cassette has

been slid to the record-protect pos~ton. preventing

The tape IS about to end Prepare a new cassefte

The tape has reached the end Replace I, w,,h a

new cassette

The fluorescent lamp behlnd the LCD monitor IS

close to the end of 1,s serwce lkle Call your local

autlwrlzed Sharp dealer to have It replaced

In Self Recording mode. all warnings wll be

lndlcated by @ dlsplayed I” the center of the

monitor To check the type 01 warning, rotate the

momtor back to the normal posltlo”

Batterv comoartment door release

I

3-1

Page 7

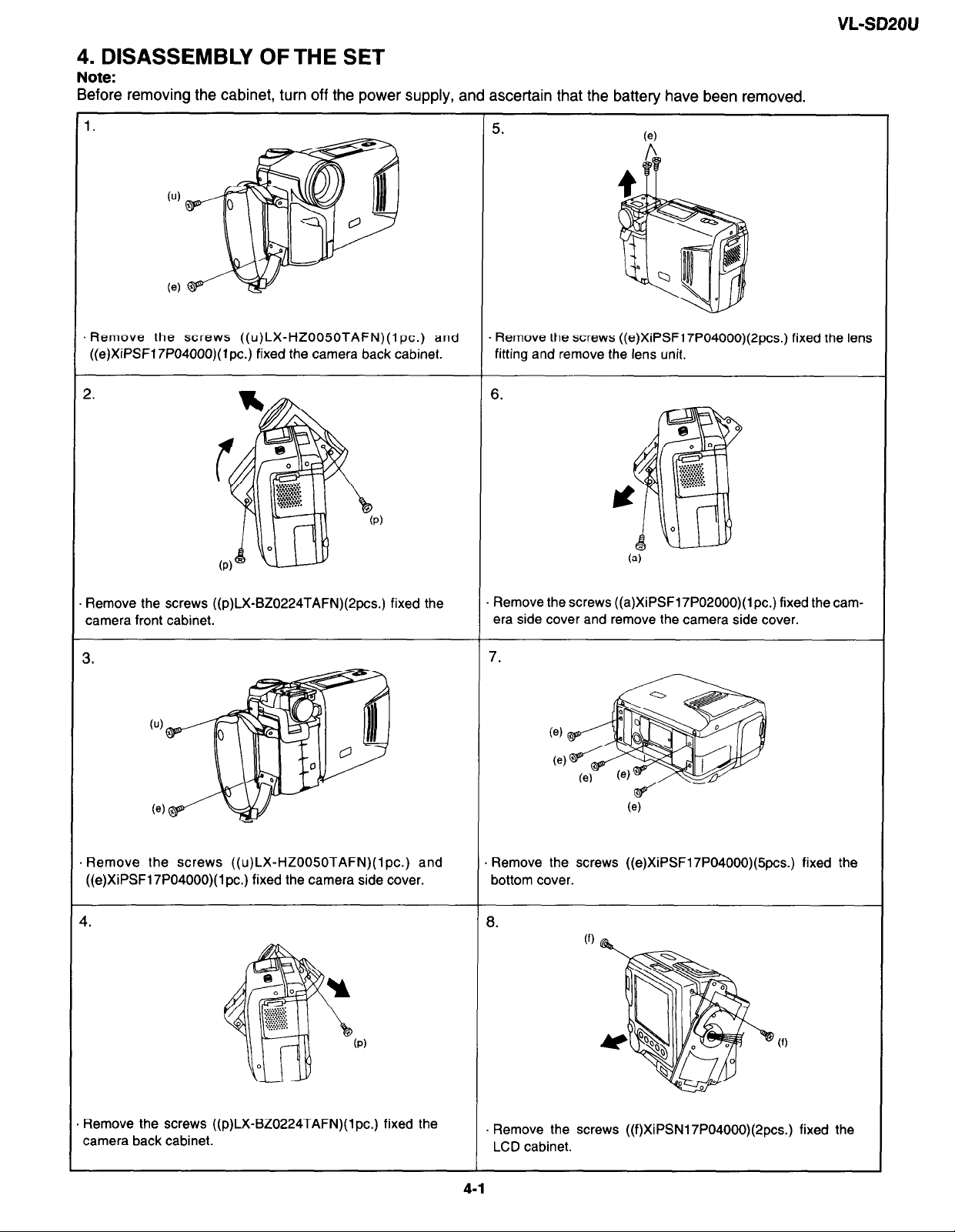

4. DISASSEMBLY OFTHE SET

Note:

Before removing the cabinet, turn off the power supply, and ascertain that the battery have been removed.

VL-SD2OU

Remove the screws ((u)LX-HZ0050TAFN)(lpc.) and

((e)XiPSF17PO4000)( 1 PC.) fixed the camera back cabinet.

>

_.

P)

Remove the screws ((p)LX-BZO224TAFN)(2pcs.) fixed the

camera front cabinet.

3.

. Remove the screws ((e)XiPSF17PO4000)(2pcs.) fixed the lens

fitting and remove the lens unit.

6.

. Remove the screws ((a)XiPSF17P02000)(1pc.) fixed the cam-

era side cover and remove the camera side cover.

7.

(e)

Remove the screws ((u)LX-HZ0050TAFN)(lpc.) and

((e)XiPSF17P04000)(1pc.) fixed the camera side cover.

. .

(P)

Remove the screws ((p)LX-BZ0224TAFN)(lpc.) fixed the

camera back cabinet.

(e)

. Remove the screws ((e)XiPSF17P04000)(5pcs.) fixed the

bottom cover.

8.

(f)

Remove the screws ((f)XiPSN17PO4000)(2pcs.) fixed the

LCD cabinet.

4-1

Page 8

VL-SD20U

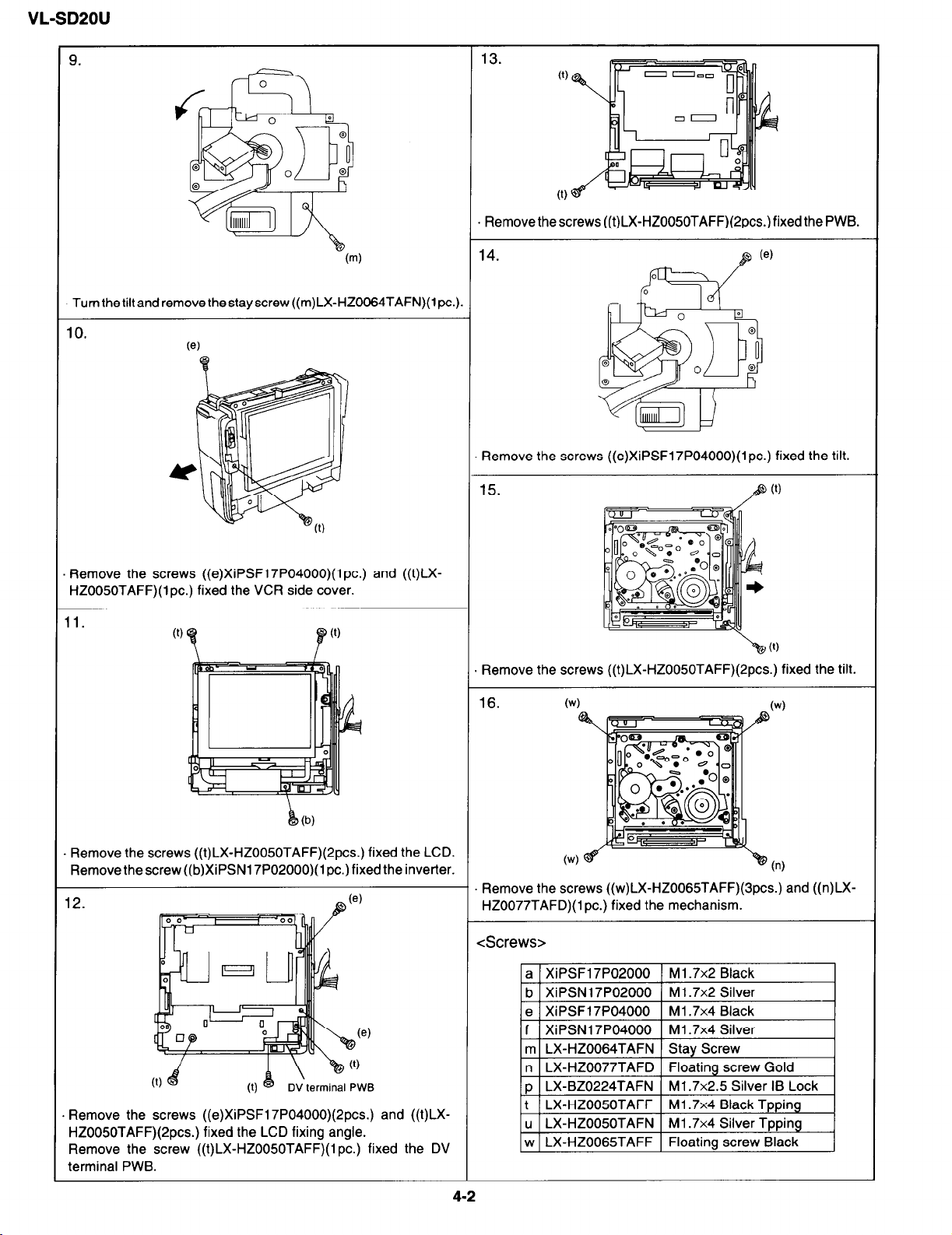

9.

(m)

Tumthetiltandremovethestayscrew ((m)LX-HZ0064TAFN)(lpc.).

10.

Remove the screws ((t)LX-HZ0050TAFF)(2pcs.)fixed the PWB.

Remove the screws ((e)XiPSF17P04000)(lpc.) fixed the tilt.

Remove the screws ((e)XiPSF17P04000)(1pc.) and ((t)LXHZ0050TAFF)(lpc.) fixed the VCR side cover.

Remove the screws ((t)LX-HZ0050TAFF)(2pcs.) fixed the LCD.

Removethescrew((b)XiPSN17P02000)(1pc.)fixedtheinverter.

12.

15.

* (0

\

Remove

16.

the screws ((t)LX-HZOO50TAFF)(2pcs.) fixed the tilt.

Y

w Gf

Remove the screws ((w)LX-HZOOSSTAFF)(3pcs.) and ((n)LXHZ0077TAFD)(l PC.) fixed the mechanism.

b(n)

DV terminal PWB

Remove the screws ((e)XiPSFi 7PO4000)(2pcs.) and ((t)LXHZ0050TAFF)(2pcs.) fixed the LCD fixing angle.

Remove the screw ((t)LX-HZ0050TAFF)(lpc.) fixed the DV

terminal PWB.

<Screws>

a 1 XiPSF17PO2000 ) M1.7~2 Black

4-2

Page 9

VL-SDPOU

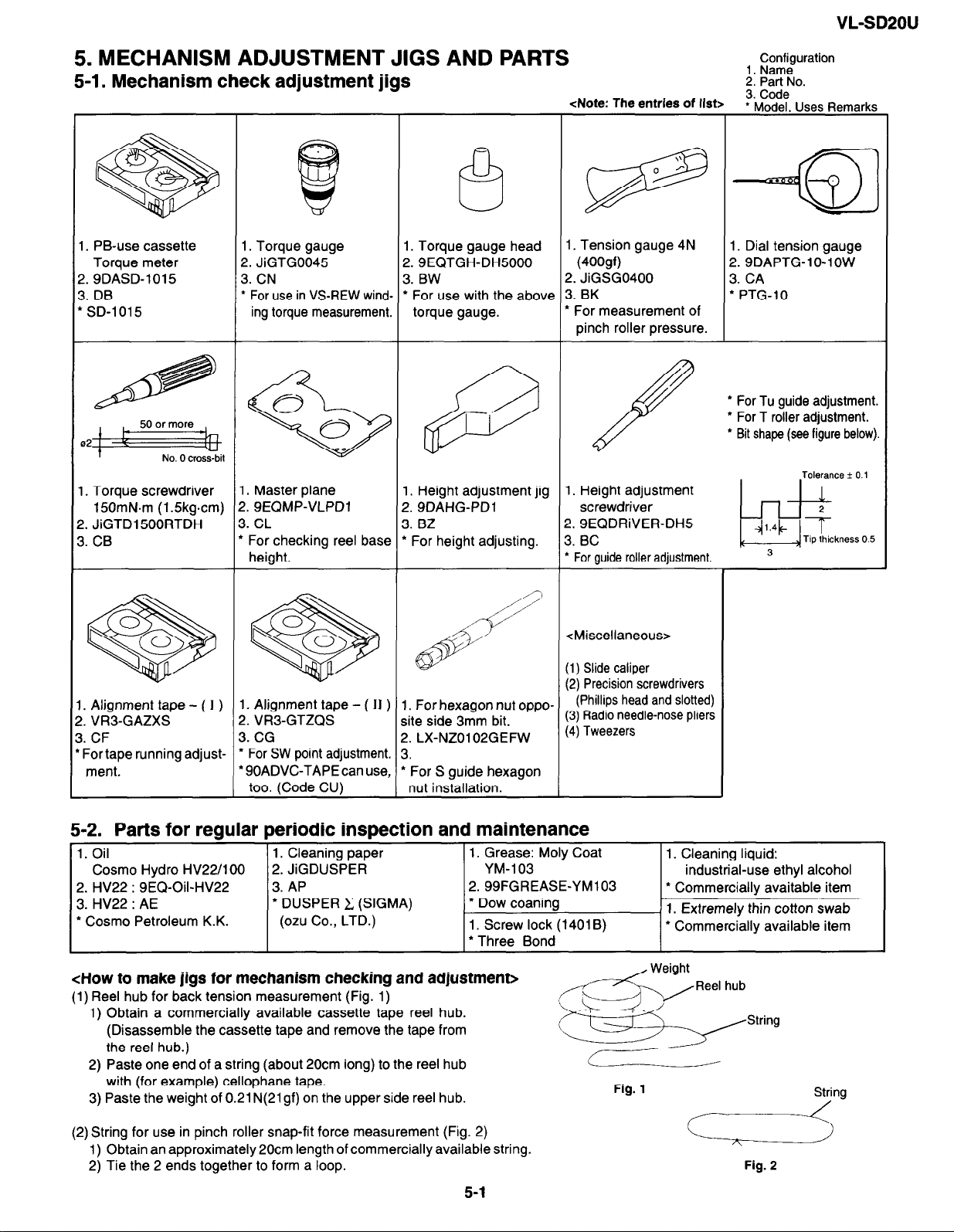

5. MECHANISM ADJUSTMENT JIGS AND PARTS

5-l. Mechanism check adjustment jigs

. PB-use cassette

Torque meter

!. 9DASD-1015

I. DB

SD-1015

. Torque screwdriver

15OmN.m (15kgcm)

I. JiGTD1500RTDH

;. CB

I. Torque gauge I. Torque gauge head

?. JiGTG0045 !. 9EQTGH-DH5000

3. CN 3. BW

’ For use in VS-REW wind-

ing torque measurement.

Master plane

!: SEQMP-VLPDl

I. CL

For checking reel base

For use with the above

torque gauge.

I. Height adjustment jig

!. SDAHG-PDI

). BZ

For height adjusting.

height.

<Note: The entries of list>

Tension gauge 4N

‘(400gf)

!. JiGSG0400

1. BK

For measurement of

pinch roller pressure.

Height adjustment

screwdriver

I. SEQDRiVER-DH5

1. BC

For guide roller adjustment.

Configuration

1. Name

2. Pan No.

3. Code

l Model, Uses Remarks

1. Dial tension gauge

2. SDAPTG-1 O-l OW

3. CA

l PTG-10

l For Tu guide adjustment.

l For T roller adjustment.

’ Bit shape (see figure below).

Tolerance k 0.1

:Miscellaneous>

1) Slide caliper

2) Precision screwdrivers

. Alignment tape - ( 1 )

. VR3-GAZXS

. CF

Fortape running adjust-

ment.

I. Alignment tape - ( II )

!. VR3-GTZQS

I. CG

For SW point adjustment.

SOADVC-TAPE can use,

too. ICode CU)

. For hexagon nut oppo#ite side 3mm bit.

!. LX-NZO102GEFW

For S guide hexagon

nut installation.

(Phillips head and slotted)

3) Radio needle-nose pliers

4) Tweezers

5-2. Parts for regular periodic inspection and maintenance

1. Oil

Cosmo Hydro HV22/100

2. HV22 : 9EQ-Oil-HV22

3. HV22 : AE

l Cosmo Petroleum K.K.

1. Cleaning paper

2. JiGDUSPER

3. AP

l DUSPER C (SIGMA)

(ozu Co., LTD.)

<How to make jigs for mechanism checking and adjustment>

(1) Reel hub for back tension measurement (Fig. 1)

1) Obtain a commercially available cassette tape reel hub.

(Disassemble the cassette tape and remove the tape from

the reel hub.)

2) Paste one end of a string (about 20cm long) to the reel hub

with (for example) cellophane tape.

3) Paste the weight of 0.21 N(21 gf) on the upper side reel hub.

1. Grease: Moly Coat

YM-103

2.99FGREASE-YM103

* Dow coaning

1. Screw lock (14018)

l Three Bond

Fig. 1

1. Cleaning liquid:

industrial-use ethyl alcohol

l Commerciallv avaitable item

1. Extremely thin cotton swab

l Commercially available item

String

String

(2) String for use in pinch roller snap-fit force measurement (Fig. 2)

1) Obtain an approximately 20cm length of commercially available string.

2) Tie the 2 ends together to form a loop.

5-l

r\

Fig. 2

Page 10

VL-SDPOU

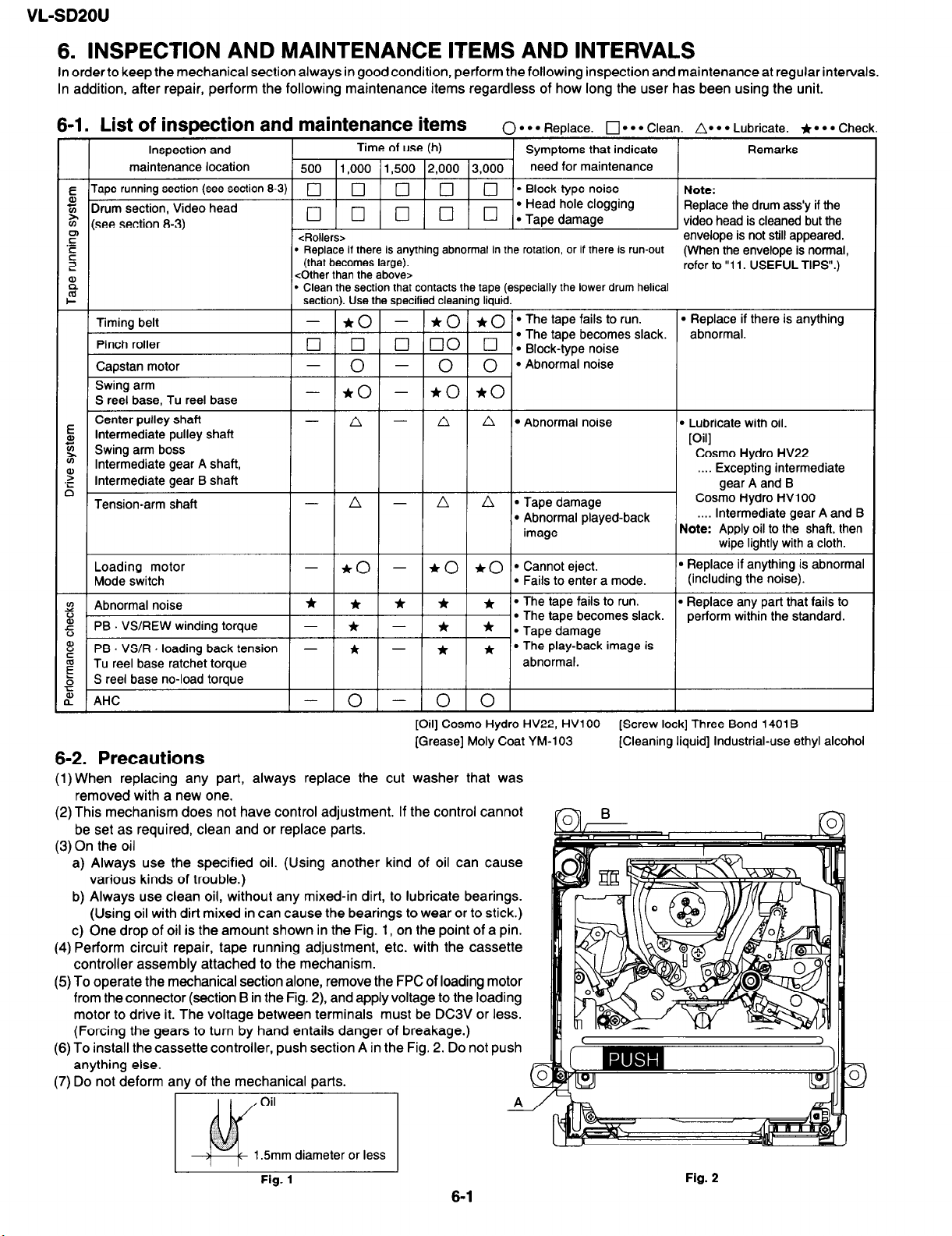

6. INSPECTION AND MAINTENANCE ITEMS AND INTERVALS

In order to keep the mechanical section always in good condition, perform the following inspection and maintenance at regular intervals.

In addition, after repair, perform the following maintenance items regardless of how long the user has been using the unit.

6-1. List of inspection and maintenance items

0 l l l Replace. 0. l l Clean. A* l l Lubricate. ** l l Check.

l Head hole clogging

specially the lower drum helical

l The tape becomes slack.

l Block-type noise

l Abnormal noise

Replace the drum a&y if the

video head is cleaned but the

envelope is not still appeared.

(When the envelope is normal,

refer to “11. USEFUL TIPS”.)

[Oil] Cosmo Hydro HV22, HVl 00 [Screw lock] Three Bond 1401 B

[Grease] Moly Coat YM-103

6-2. Precautions

(1) When replacing any part, always replace the cut washer that was

removed with a new one.

(2) This mechanism does not have control adjustment. If the control cannot

be set as required, clean and or replace parts.

(3) On the oil

a) Always use the specified oil. (Using another kind of oil can cause

various kinds of trouble.)

b) Always use clean oil, without any mixed-in dirt, to lubricate bearings.

(Using oil with dirt mixed in can cause the bearings to wear or to stick.)

c) One drop of oil is the amount shown in the Fig. 1, on the point of a pin.

(4) Perform circuit repair, tape running adjustment, etc. with the cassette

controller assembly attached to the mechanism.

(5) To operate the mechanical section alone, remove the FPC of loading motor

from the connector (section B in the Fig. 2), and apply voltage to the loading

motor to drive it. The voltage between terminals must be DC3V or less.

(Forcing the gears to turn by hand entails danger of breakage.)

(6) To install the cassette controller, push section A in the Fig. 2. Do not push

anything else.

(7) Do not deform any of the mechanical parts.

l The tape becomes slack.

l The play-back image is

[Cleaning liquid] industrial-use ethyl alcohol

perform within the standard.

Fig. 1

6-1

Page 11

VL-SDPOU

7. MECHANICAL ADJUSTMENTS AND CHECKS

The items discussed here relate to general on-site servicing (field servicing). Adjustments and replacements that require

sophisticated facilities, jigs and technology are omitted.

In addition, in order to maintain the characteristics that the unit has when it is new, not only are inspection and maintenance necessary,

but it is absolutely necessary that, for example, the tape not be damaged, and always use jigs for adjustments that require them.

<Precautions>

(1) Always set the power supply and state of the unit as follows Illfor mechanism adjustments and checks.

AC adapter used, with cassette controller assembly

AC adapter used, without cassette controller assembly (Independent Mechanism) [

DCBV, without cassette controller assembly (Independent Mechanism) 1

(2) When performing checks with a DCBV power supply and independent mechanism, disconnect the loading motor FPC from the

connector.

(3) Always run the tape with the cassette controller assembly attached.

7-1. Checking the playback (recording) winding torque 1 AC adapter used, with cassette controller assembly 1

(1) Set the torque cassette with the cassette controller assembly attached, then, in SP recording mode (playback mode if a signal has

already been recorded in SP mode on the tape), confirm that the torque on the winding side is within the standard.

<Winding torque standard in record (playback) mode>

(If there is torque ripple, read the center value.)

0.70 f 0.35mN.m (7.0 f 3.5gfcm),

ripple 0.2mN.m (2gfcm) or less

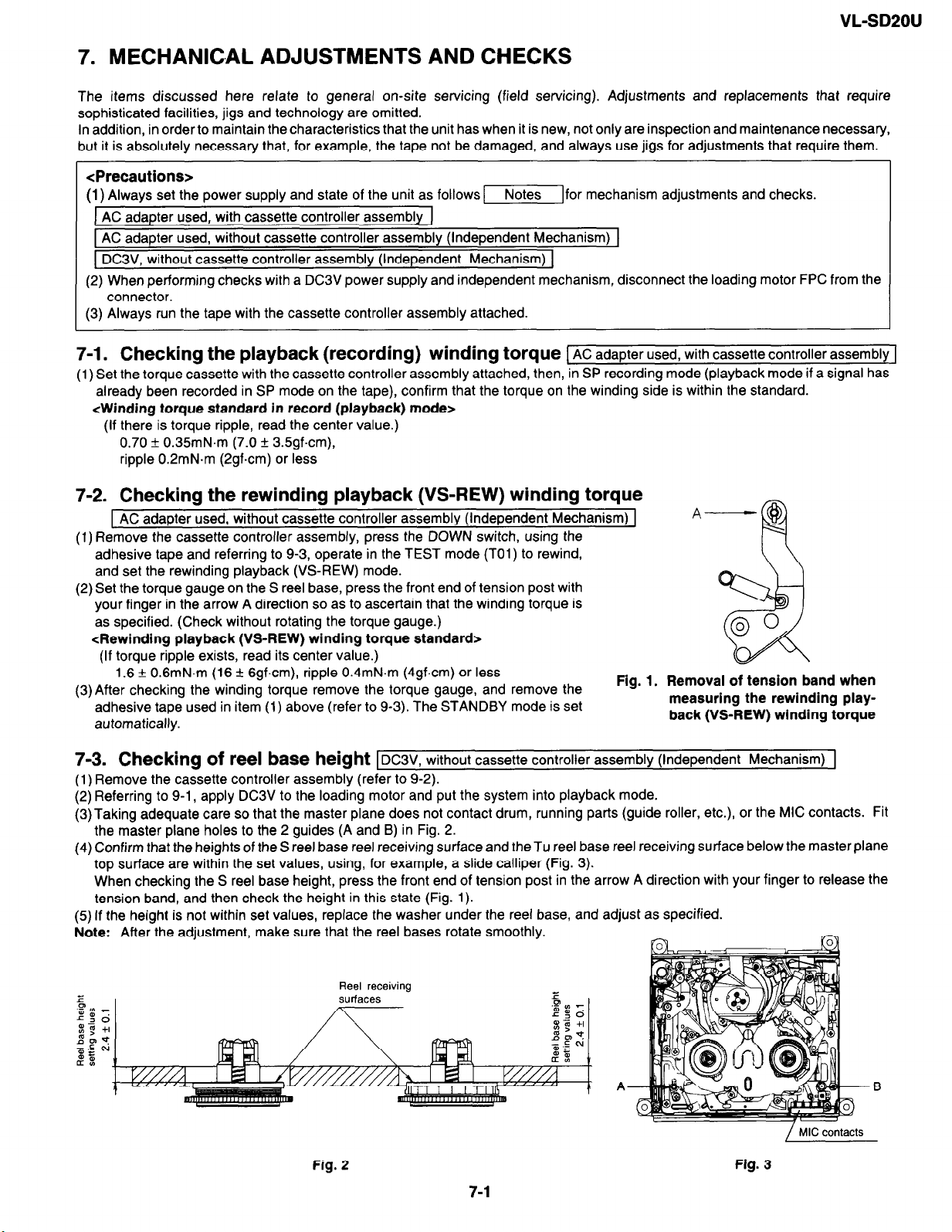

7-2. Checking the rewinding playback (VS-REW) winding torque

1 AC adapter used, without cassette controller assembly (Independent Mechanism) 1

(1) Remove the cassette controller assembly, press the DOWN switch, using the

adhesive tape and referring to 9-3, operate in the TEST mode (TOl) to rewind,

and set the rewinding playback (VS-REW) mode.

(2) Set the torque gauge on the S reel base, press the front end of tension post with

your finger in the arrow A direction so as to ascertain that the winding torque is

as specified. (Check without rotating the torque gauge.)

<Rewinding playback (VS-REW) winding torque standard>

(If torque ripple exists, read its center value.)

1.6 % 0.6mN.m (16 + Ggfcm), ripple 0.4mN.m (4gfcm) or less

(3)After checking the winding torque remove the torque gauge, and remove the

adhesive tape used in item (1) above (refer to 9-3). The STANDBY mode is set

automatically.

Fig. 1. Removal of tension band when

measuring the rewinding playback (VS-REW) winding torque

-

7-3. Checking of reel base height [DC3V, without cassette controller assembly (Independent Mechanism) 1

(1) Remove the cassette controller assembly (refer to 9-2).

(2) Referring to 9-1, apply DCBV to the loading motor and put the system into playback mode.

(3)Taking adequate care so that the master plane does not contact drum, running parts (guide roller, etc.), or the MIC contacts. Fit

the master plane holes to the 2 guides (A and B) in Fig. 2.

(4) Confirm that the heights of the S reel base reel receiving surface and the Tu reel base reel receiving surface below the master plane

top surface are within the set values, using, for example, a slide calliper (Fig. 3).

When checking the S reel base height, press the front end of tension post in the arrow A direction with your finger to release the

tension band, and then check the height in this state (Fig. 1).

(5) If the height is not within set values, replace the washer under the reel base, and adjust as specified.

Note: After the adjustment, make sure that the reel bases rotate smoothly.

Reel receiving

Fig. 2

/ MC contacts

Fig. 3

7-1

Page 12

VL-SDPOU

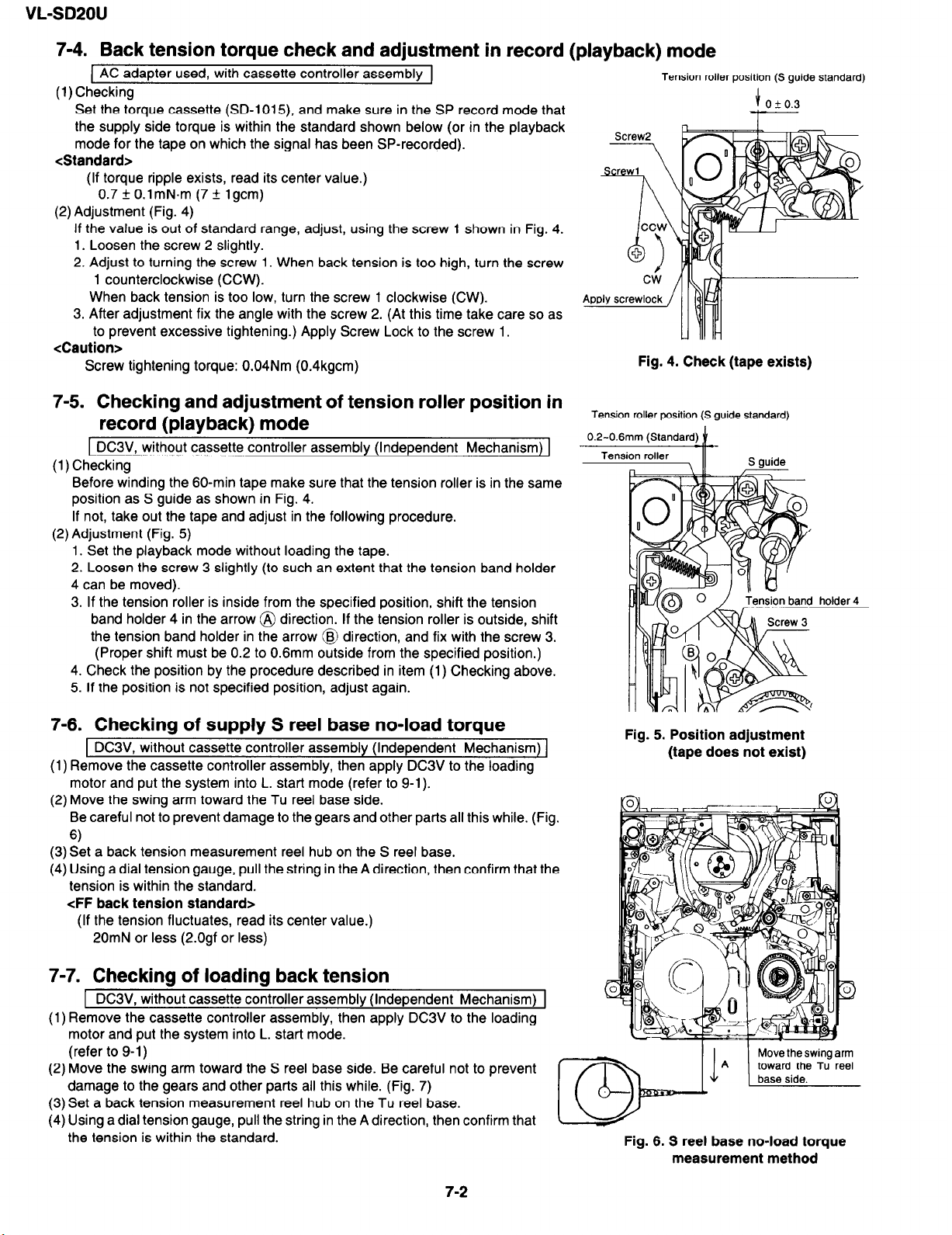

7-4. Back tension torque check and adjustment in record (playback) mode

1 AC adapter used, with cassette controller assembly 1

(1) Checking

Set the torque cassette (SD-1015), and make sure in the SP record mode that

the supply side torque is within the standard shown below (or in the playback

mode for the tape on which the signal has been SP-recorded).

<Standard>

(If torque ripple exists, read its center value.)

0.7 f 0.lmN.m (7 f lgcm)

(2) Adjustment (Fig. 4)

If the value is out of standard range, adjust, using the screw I shown in Fig. 4.

1. Loosen the screw 2 slightly.

2. Adjust to turning the screw 1. When back tension is too high, turn the screw

1 counterclockwise (CCW).

When back tension is too low, turn the screw 1 clockwise (CW).

3. After adjustment fix the angle with the screw 2. (At this time take care so as

to prevent excessive tightening.) Apply Screw Lock to the screw 1.

<Caution>

Screw tightening torque: 0.04Nm (0.4kgcm)

Fig. 4. Check (tape exists)

Tension roller position (S guide standard)

0 lt 0.3

J

7-5. Checking and adjustment of tension roller position in

record (playback) mode

DC3V, without cassette controller assembly (Independent Mechanism)

(1) Checking

Before winding the 60-min tape make sure that the tension roller is in the same

position as S guide as shown in Fig. 4.

If not, take out the tape and adjust in the following procedure.

(2) Adjustment (Fig. 5)

1. Set the playback mode without loading the tape.

2. Loosen the screw 3 slightly (to such an extent that the tension band holder

4 can be moved).

3. If the tension roller is inside from the specified position, shift the tension

band holder 4 in the arrow @ direction. If the tension roller is outside, shift

the tension band holder in the arrow @ direction, and fix with the screw 3.

(Proper shift must be 0.2 to 0.6mm outside from the specified position.)

4. Check the position by the procedure described in item (1) Checking above.

5. If the position is not specified position, adjust again.

7-6. Checking of supply S reel base no-load torque

DCSV, without cassette controller assembly (Independent Mechanism)

(1) Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into L. start mode (refer to 9-l).

(2) Move the swing arm toward the Tu reel base side.

Be careful not to prevent damage to the gears and other parts all this while. (Fig.

6)

(3) Set a back tension measurement reel hub on the S reel base.

(4) Using a dial tension gauge, pull the string in the A direction, then confirm that the

tension is within the standard.

<FF back tension standard>

(If the tension fluctuates, read its center value.)

20mN or less (2.0gf or less)

Tension roller position (S guide standard)

,- ,Sguide

Fig. 5. Position adjustment

(tape does not exist)

7-7. Checking of loading back tension

1 DC3V, without cassette controller assembly (Independent Mechanism) 1

(1) Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into L. start mode.

(refer to 9-l)

Move the swing arm toward the S reel base side. Be careful not to prevent

(2)

damage to the gears and other parts all this while. (Fig. 7)

~ , Set a back tension measurement reel hub on the Tu reel base.

(3)

(4) Using a dial tension gauge, pull the string in the A direction, then confirm that

the tension is within the standard.

7-2

[i A

j ;fi&?::i ~

B

Fig. 6. S reel base no-load torque

measurement method

Page 13

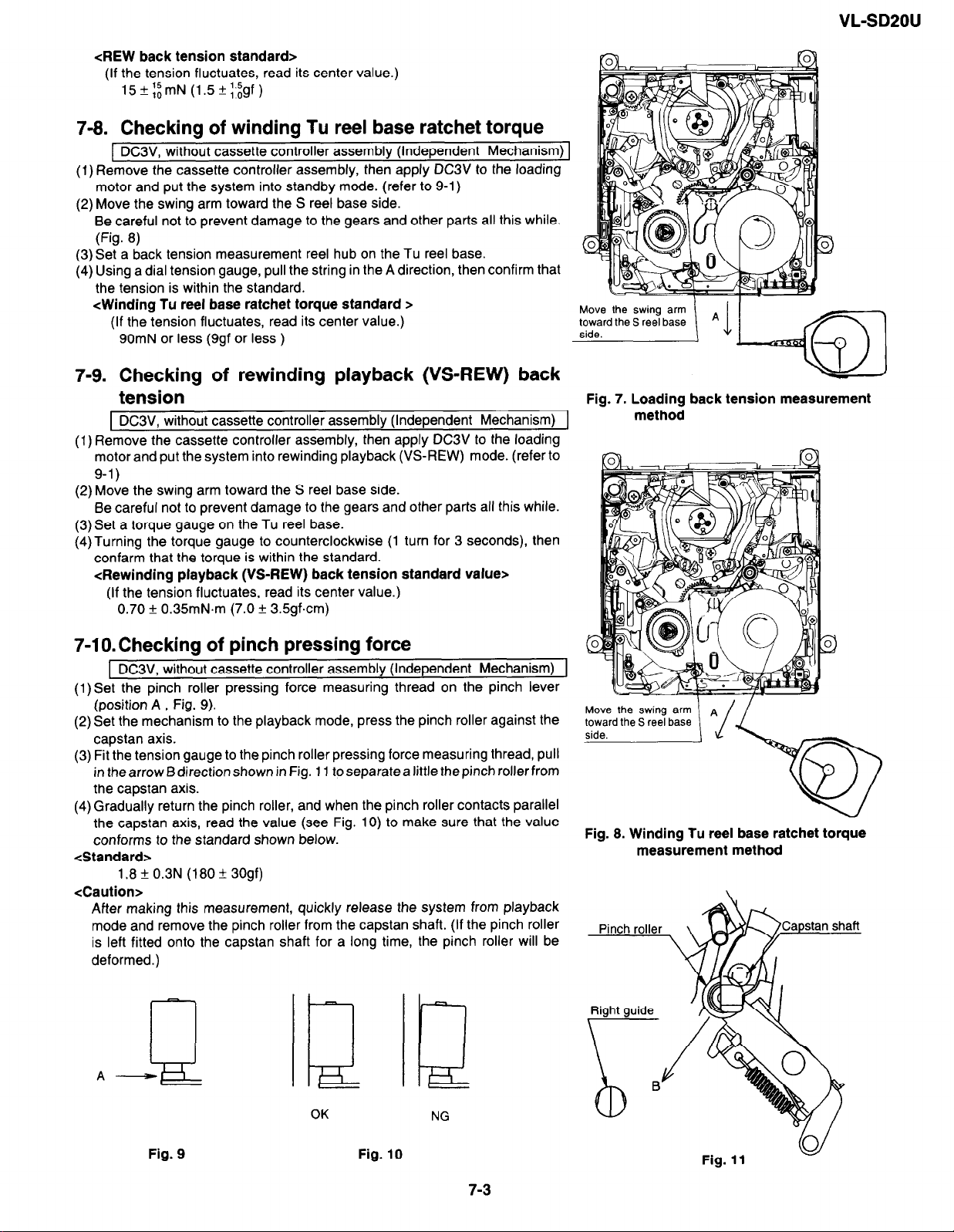

4tEW back tension standard>

(If the tension fluctuates, read its center value.)

15?:~mN(1.5+~.~gf)

7-8. Checking of winding Tu reel base ratchet torque

1 DC3V, without cassette controller assembly (independent Mechanism) 1

(1) Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into standby mode. (refer to 9-1)

(2) Move the swing arm toward the S reel base side.

Be careful not to prevent damage to the gears and other parts all this while.

(Fig. 8)

(3) Set a back tension measurement reel hub on the Tu reel base.

(4) Using a dial tension gauge, pull the string in the A direction, then confirm that

the tension is within the standard.

<Winding Tu reel base ratchet torque standard >

(If the tension fluctuates, read its center value.)

90mN or less (9gf or less )

7-9. Checking of rewinding playback (VS-REW) back

tension

1 DC3V, without cassette controller assembly (Independent Mechanism) 1

(1) Remove the cassette controller assembly, then apply DC3V to the loading

motor and put the system into rewinding playback (VS-REW) mode. (refer to

9-l)

(2) Move the swing arm toward the S reel base side.

Be careful not to prevent damage to the gears and other parts all this while.

(3) Set a torque gauge on the Tu reel base.

(4) Turning the torque gauge to counterclockwise (1 turn for 3 seconds), then

confarm that the torque is within the standard.

<Rewinding playback (VS-REW) back tension standard value>

(If the tension fluctuates, read its center value.)

0.70 f 0.35mN.m (7.0 f 3.5gf.cm)

VL-SDSOU

Fig. 7. Loading back tension measurement

method

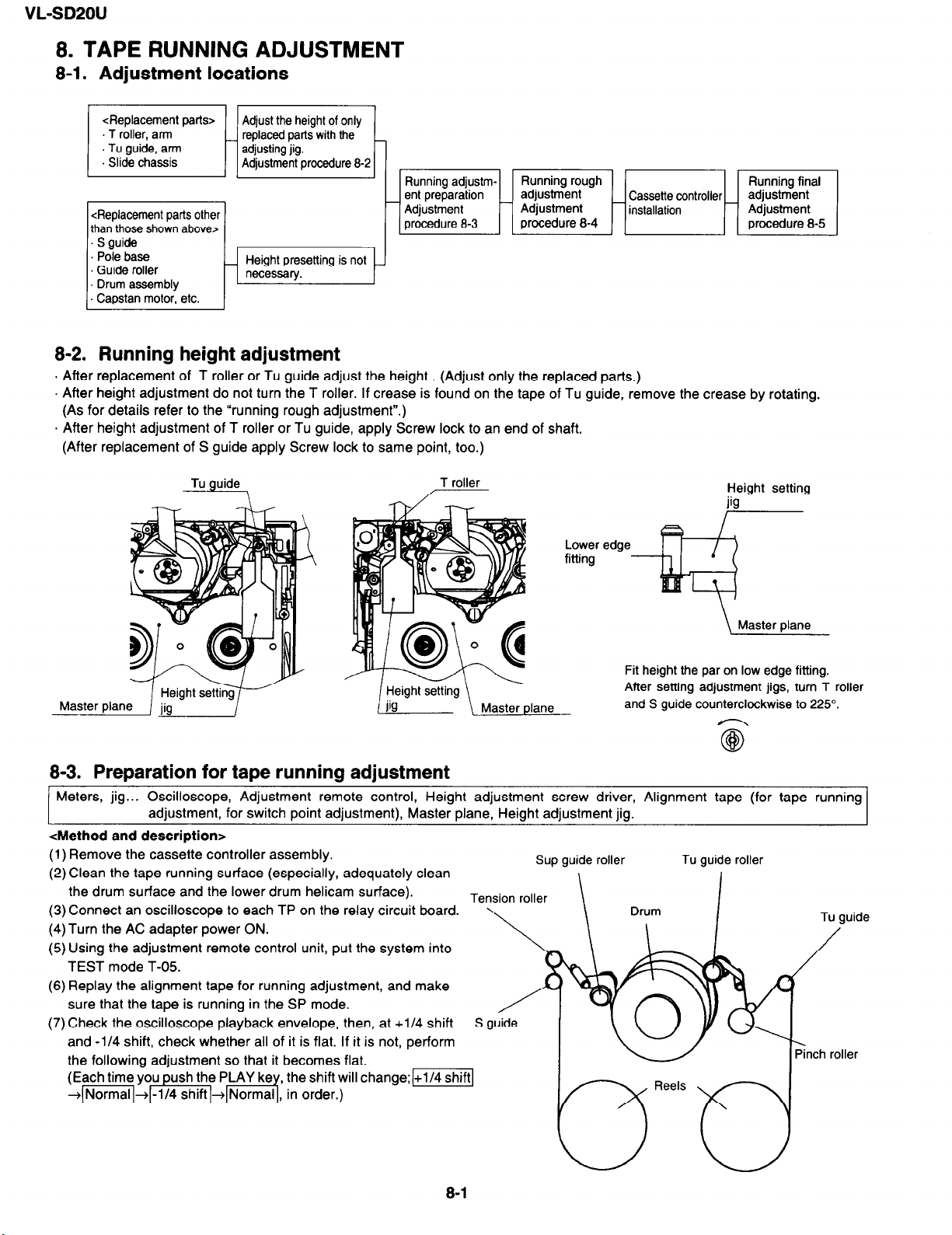

7-lO.Checking of pinch pressing force

1 DCSV, without cassette controller assembly (Independent Mechanism) ]

(l)Set the pinch roller pressing force measuring thread on the pinch lever

(position A , Fig. 9).

(2) Set the mechanism to the playback mode, press the pinch roller against the

capstan axis.

(3) Fit the tension gauge to the pinch roller pressing force measuring thread, pull

in the arrow B direction shown in Fig. 11 to separate a little the pinch roller from

the capstan axis.

(4) Gradually return the pinch roller, and when the pinch roller contacts parallel

the capstan axis, read the value (see Fig. 10) to make sure that the value

conforms to the standard shown below.

<Standard>

1.8 f 0.3N (180 f 30gf)

<Caution>

After making this measurement, quickly release the system from playback

mode and remove the pinch roller from the capstan shaft. (If the pinch roller

is left fitted onto the capstan shaft for a long time, the pinch roller will be

deformed.)

A-

D

D D

Fig. 8. Winding Tu reel base ratchet torque

measurement method

Fig. 9

OK

NG

Fig. 10

7-3

Page 14

VL-SDPOU

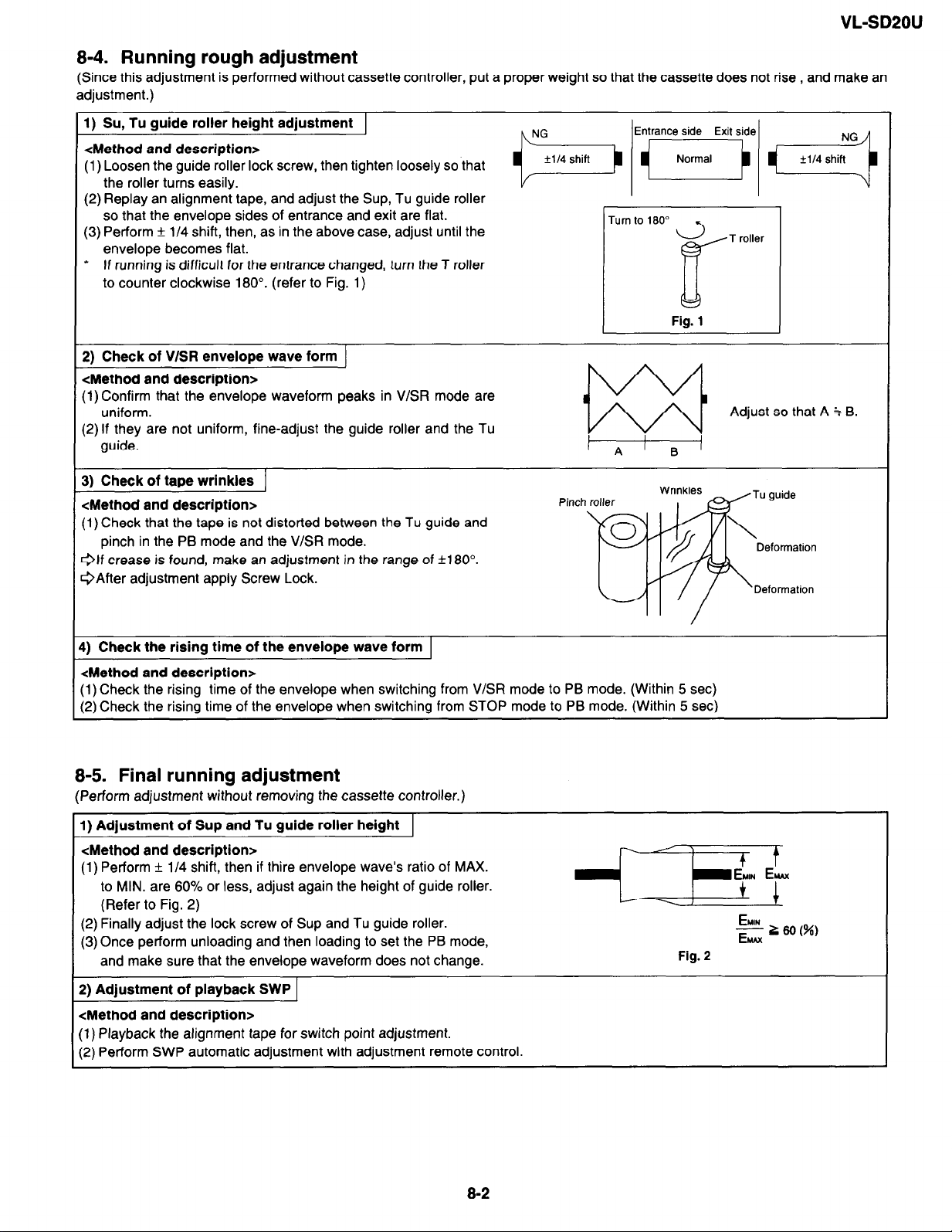

8. TAPE RUNNING ADJUSTMENT

8-l. Adjustment locations

<Replacement parts other

than those shown above>

_

Adjust the height of only

replaced parts with the

adjusting jig.

Adjustment procedure 8-2

_

Running adjustment preparation

Adjustment

procedure 8-3

Running rough

adjustment

Adjustment

procedure 8-4 procedure 8-5

Cassette controller

installation

Running final

adjustment

Adjustment

8-2. Running height adjustment

. After replacement of T roller or Tu guide adjust the height . (Adjust only the replaced parts.)

After height adjustment do not turn the T roller. If crease is found on the tape of Tu guide, remove the crease by rotating.

(As for details refer to the “running rough adjustment”.)

. After height adjustment of T roller or Tu guide, apply Screw lock to an end of shaft.

(After replacement of S guide apply Screw lock to same point, too.)

, T roller

Lower edge

fitting

Height setting

jig

8-3. Preparation for tape running adjustment

Meters, jig.. .

<Method and description>

(1) Remove the cassette controller assembly.

(2) Clean the tape running surface (especially, adequately clean

the drum surface and the lower drum helicam surface).

(3) Connect an oscilloscope to each TP on the relay circuit board.

(4) Turn the AC adapter power ON.

(5) Using the adjustment remote control unit, put the system into

TEST mode T-05.

(6) Replay the alignment tape for running adjustment, and make

sure that the tape is running in the SP mode.

(7) Check the oscilloscope playback envelope, then, at +1/4 shift

and -l/4 shift, check whether all of it is flat. If it is not, perform

the following adjustment so that it becomes flat.

Oscilloscope, Adjustment remote control, Height adjustment screw driver, Alignment tape (for tape running

adjustment, for switch point adjustment), Master plane, Height adjustment jig.

, the shift will change;l+l/4

Fit height the par on low edge fitting.

After setting adjustment jigs, turn T roller

-

Sup guide roller

Tension roller

and S guide counterclockwise to 225”.

\ \ Drym 1

S

Master plane

n

Tu guide roller

Tu/guide

8-1

Page 15

VL-SDPOU

8-4. Running rough adjustment

(Since this adjustment is performed without cassette controller, put a proper weight so that the cassette does not rise , and make an

adjustment.)

1) Su, Tu guide roller height adjustment

<Method and description>

(1) Loosen the guide roller lock screw, then tighten loosely so that

the roller turns easily.

(2) Replay an alignment tape, and adjust the Sup, Tu guide roller

so that the envelope sides of entrance and exit are flat.

(3) Perform f l/4 shift, then, as in the above case, adjust until the

envelope becomes flat.

l If running is difficult for the entrance changed, turn the T roller

to counter clockwise 180”. (refer to Fig. 1)

2) Check of VlSR envelope wave form

<Method and description>

(1)Confirm that the envelope waveform peaks in V/SR mode are

uniform.

(2) If they are not uniform, fine-adjust the guide roller and the Tu

guide.

V

rum to 180”

T roller

Fig. 1

Adjust so that A _; B.

3) Check of tape wrinkles

<Method and description>

Pinch roller

(1) Check that the tape is not distorted between the Tu guide and

pinch in the PB mode and the V/SR mode.

3lf crease is found, make an adjustment in the range of _+180”.

*After adjustment apply Screw Lock.

I) Check the rising time of the envelope wave form 1

(Method and description>

1) Check the rising time of the envelope when switching from V/SR mode to PB mode. (Within 5 set)

12) Check the rising time of the envelope when switching from STOP mode to PB mode. (Within 5 set)

8-5. Final running adjustment

(Perform adjustment without removing the cassette controller.)

1) Adjustment of Sup and Tu guide roller height

<Method and description>

(1) Perform +_ l/4 shift, then if thire envelope wave’s ratio of MAX.

to MIN. are 60% or less, adjust again the height of guide roller.

(Refer to Fig. 2)

(2) Finally adjust the lock screw of Sup and Tu guide roller.

(3) Once perform unloading and then loading to set the PB mode,

and make sure that the envelope waveform does not change.

Fig. 2

Deformation

2) Adjustment of playback SWP

<Method and description>

(1) Playback the alignment tape for switch point adjustment.

(2) Perform SWP automatic adjustment with adjustment remote control.

8-2

Page 16

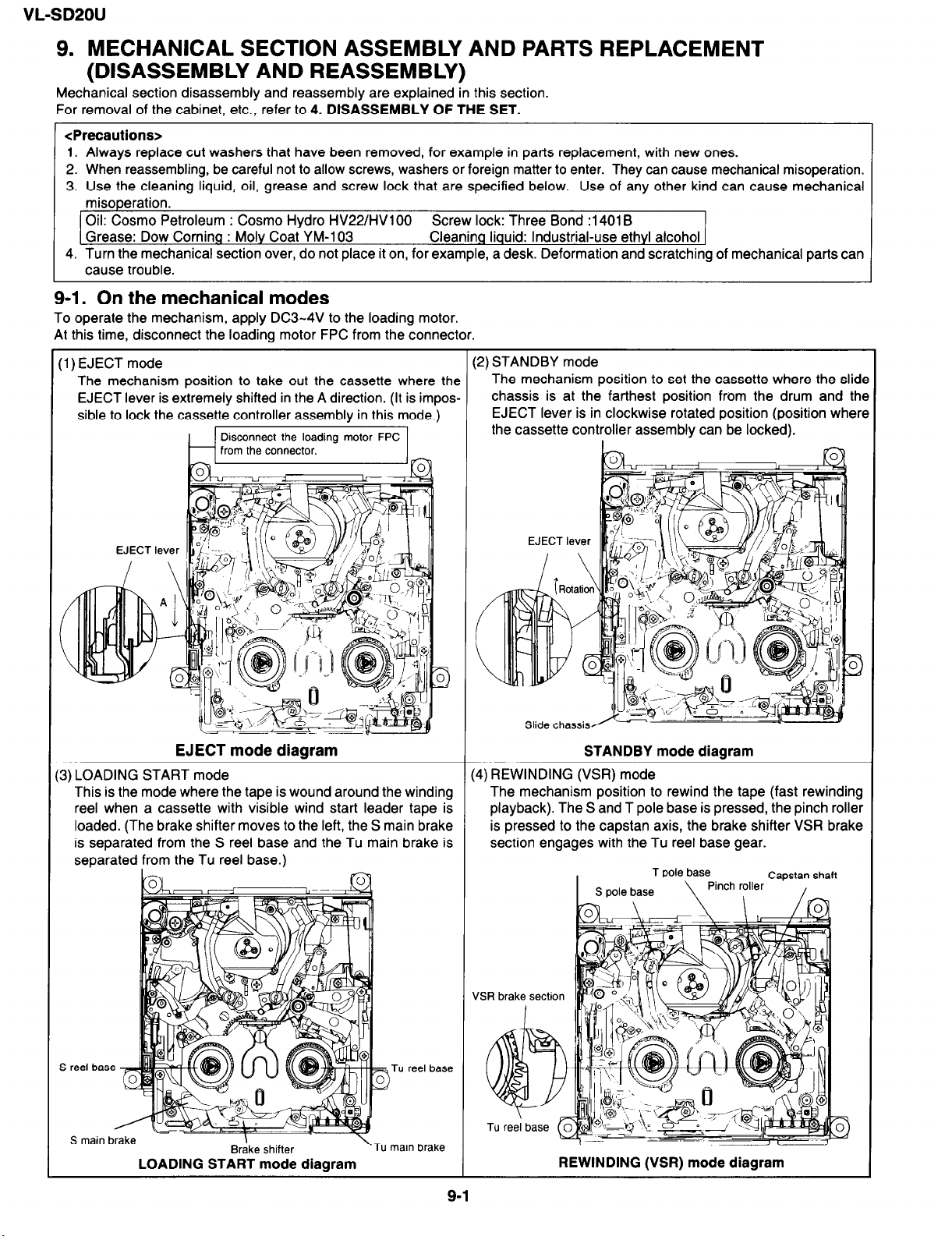

9. MECHANICAL SECTION ASSEMBLY AND PARTS REPLACEMENT (DISASSEMBLY AND REASSEMBLY)

Mechanical section disassembly and reassembly are explained in this section.

For removal of the cabinet, etc., refer to 4. DISASSEMBLY OF THE SET.

<Precautions>

1. Always replace cut washers that have been removed, for example in parts replacement, with new ones.

2. When reassembling, be careful not to allow screws, washers or foreign matter to enter. They can cause mechanical misoperation.

3. Use the cleaning liquid, oil, grease and screw lock that are specified below. Use of any other kind can cause mechanical

misoperation.

Oil: Cosmo Petroleum : Cosmo Hydro HV22/HVlOO Screw lock: Three Bond :14OlB

Grease: Dow Corning : Moly Coat YM-103

4. Turn the mechanical section over, do not place it on, for example, a desk. Deformation and scratching of mechanical parts can

cause trouble.

9-1. On the mechanical modes

To operate the mechanism, apply DC3-4V to the loading motor.

At this time, disconnect the loading motor FPC from the connector.

Cleaning liquid: Industrial-use ethyl alcohol

[I) EJECT mode

The mechanism position to take out the cassette where the

EJECT lever is extremely shifted in the A direction. (It is impos

sible to lock the cassette controller assembly in this mode.)

EJECT lever

EJECT mode diagram

3) LOADING START mode

This is the mode where the tape is wound around the winding

reel when a cassette with visible wind start leader tape is

loaded. (The brake shifter moves to the left, the S main brake

is separated from the S reel base and the Tu main brake is

separated from the Tu reel base.)

(2) STANDBY mode

The mechanism position to set the cassette where the slide

chassis is at the farthest position from the drum and the

EJECT lever is in clockwise rotated position (position where

the cassette controller assembly can be locked).

EJECT lever

I \

STANDBY mode diagram

:4) REWINDING (VSR) mode

The mechanism position to rewind the tape (fast rewinding

playback). The S and T pole base is pressed, the pinch roller

is pressed to the capstan axis, the brake shifter VSR brake

section engages with the Tu reel base gear.

Capstan shaft

S reel base

S main brake

\

Brake shifter

LOADING START mode dianram

Tu reel base

\

Tu main brake

REWINDING (VSR) mode diagram

Page 17

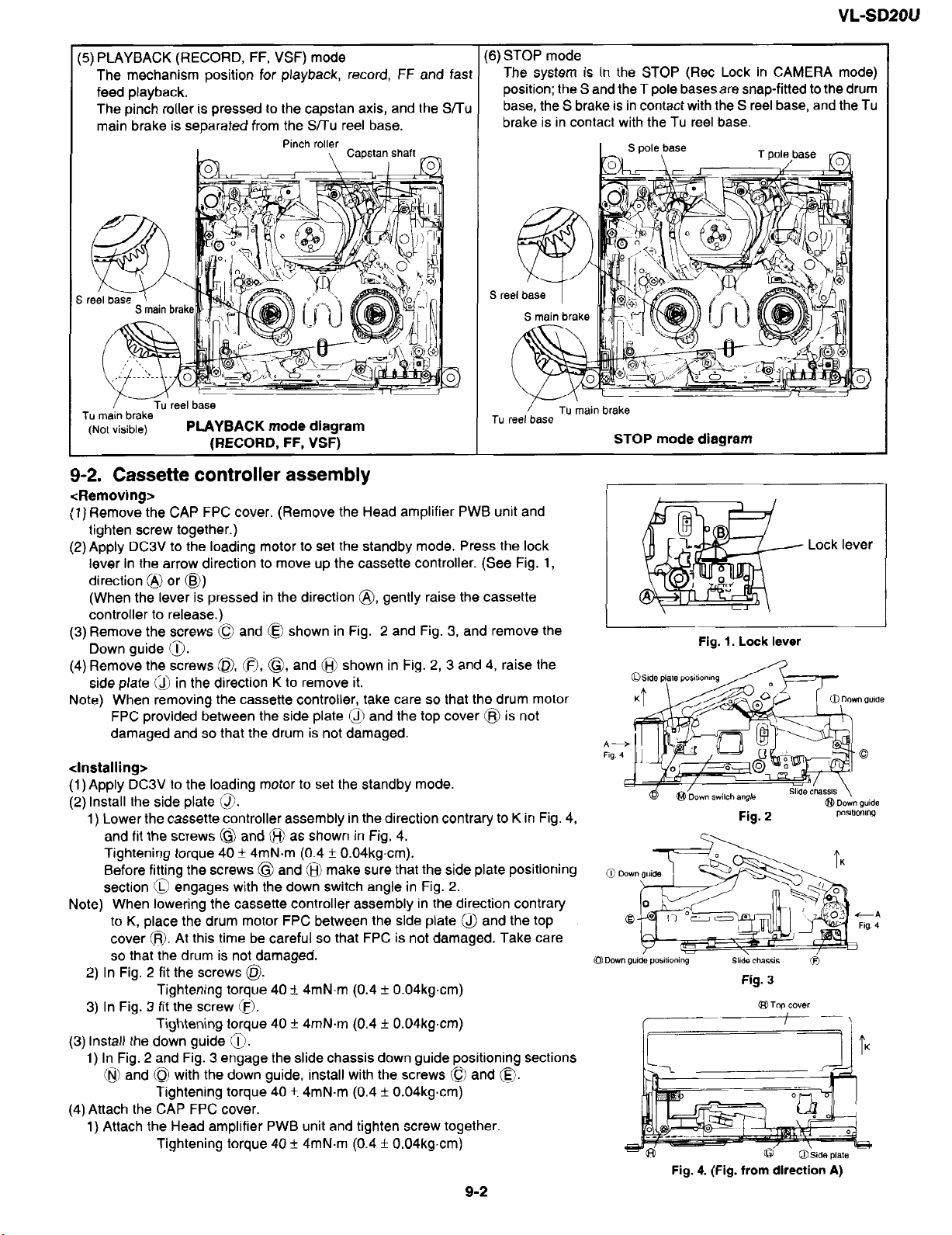

15) PLAYBACK (RECORD, FF, VSF) mode

The mechanism

feed

playback.

The

pinch

main

brake is

Tu main brake

(Not

visible)

position for playback,

roller

is

pressed to the capstan axis,

separated

I

PLAYBACK mode

from

the

Pinch

S/Tu

roller

diagram

(RECORD, FF, VSF)

record,

and

reel

base.

CaDstan shaft

FF

and

the SITU

(6) STOP

fast

_

Tu

mode

The system is in the STOP (Ret

position; the S

base, the

brake

is in contact

/

reel

base

and

the T pole

S

brake is in contact with

with

the Tu reel

Tu main

brake

bases are snap-fitted to the drum

Lock

in CAMERA mode)

the S

reel base, and the

base.

Tu

STOP mode diagram

9-2. Cassette

controller assembly

<Removing>

(1) Remove the

CAP FPC cover. (Remove the Head amplifier PWB unit and

tighten screw together.)

(2) Apply DCBV to the loading motor to set the standby mode. Press the lock

lever in the arrow direction to move

up the cassette controller. (See Fig. 1,

direction @ or 0)

(When the lever is pressed in the direction 8, gently raise the cassette

controller to release.)

(3) Remove the screws

0 and @ shown in Fig. 2 and Fig. 3, and remove the

Down guide 0.

(4) Remove the screws

side

plate @ in the direction K

Note) When removing the cassette controller, take

@, 0, 0, and @I shown in Fig. 2, 3 and 4, raise

to remove it.

care so that the drum motor

the

FPC provided between the side plate @ and the top cover @ is not

damaged and so that the drum is not damaged.

<Installing>

(1) Apply DC3V

to

the loading motor to set the standby mode.

(2) Install the side plate 0.

1) Lower the cassette controller assembly in

the direction contrary to K in Fig. 4,

and fit the screws @ and @ as shown in Fig. 4.

Tightening torque 40 f 4mN.m (0.4 + 0.04kgcm).

Before fitting the screws @ and @j) make sure that the side plate positioning

section 0 engages with the down switch angle in Fig. 2.

Note) When lowering the cassette controller assembly in the direction contrary

to K, place the drum motor FPC between the side plate 0 and the top

cover 0. At this time be careful so that FPC is not damaged. Take care

so that the drum is not damaged.

2) In Fig. 2 fit the screws 0.

Tightening torque 40 + 4mN.m (0.4 + 0.04kgcm)

3) In Fig. 3 fit the screw 0.

Tightening torque 40 f 4mN.m (0.4 f 0.04kgcm)

(3) Install the down guide 0.

1) In Fig. 2 and Fig. 3 engage the slide chassis down guide positioning sections

@ and 0 with the down guide, install with the screws 0 and 0.

Tightening torque 40 f 4mN.m (0.4 f 0.04kgcm)

(4) Attach the CAP FPC cover.

1) Attach the Head amplifier PWB unit and tighten screw together.

Tightening torque 40 + 4mN.m (0.4 + 0.04kgcm)

AFig.

0 Down guide positioning

@/Down

Fig. 1.

switch

Lock

angle

Fig.

2

Slide chassis

Fig. 3

@Top

lever

Lock lever

Slide

ChasslS

cover

\

@J Down guide

posltlcfllng

9-2

Fig. 4. (Fig. from direction A)

Page 18

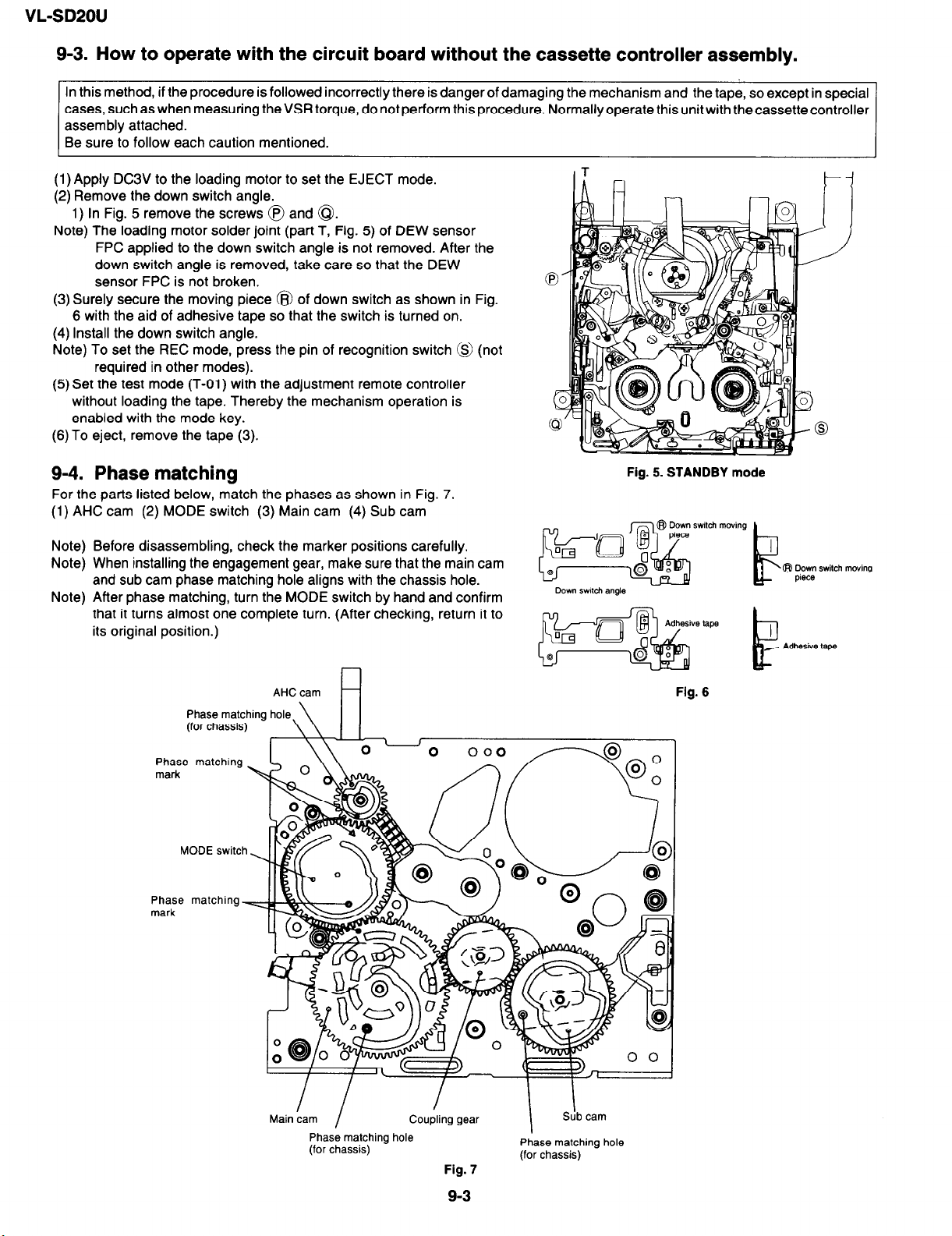

9-3. How to operate with the circuit board without the cassette controller assembly.

In this method, if the procedure is followed incorrectly there is danger of damaging the mechanism and the tape, so except in special

cases, such as when measuring the VSR torque, do not perform this procedure. Normally operate this unit with the cassette controller

assembly attached.

Be sure to follow each caution mentioned.

(1) Apply DC3V to the loading motor to set the EJECT mode.

(2) Remove the down switch angle.

1) In Fig. 5 remove the screws @ and @.

Note) The loading motor solder joint (part T, Fig. 5) of DEW sensor

FPC applied to the down switch angle is not removed. After the

down switch angle is removed, take care so that the DEW

sensor FPC is not broken.

(3) Surely secure the moving piece @ of down switch as shown in Fig.

6 with the aid of adhesive tape so that the switch is turned on.

(4) Install the down switch angle.

Note) To set the REC mode, press the pin of recognition switch @ (not

required in other modes).

(5) Set the test mode (T-01) with the adjustment remote controller

without loading the tape. Thereby the mechanism operation is

enabled with the mode key.

(6) To eject, remove the tape (3).

9-4. Phase matching

For the parts listed below, match the phases as shown in Fig. 7.

(1) AHC cam (2) MODE switch (3) Main cam (4) Sub cam

Note)

Before disassembling, check the marker positions carefully.

Note)

When installing the engagement gear, make sure that the main cam

and sub cam phase matching hole aligns with the chassis hole.

Note)

After phase matching, turn the MODE switch by hand and confirm

that it turns almost one complete turn. (After checking, return it to

its original position.)

Phase matching hole

(for chassis)

Phase matching

mark

MODE switch

Phase matching

mark

Fig. 5. STANDBY mode

iv9 tape

Fig. 6

@ Down switch moving

piece

Main cam /

Phase matching hole

(for chassis)

Coupling gear

Fig. 7

9-3

Sib cam

I

t

Phase matching hole

(for chassis)

Page 19

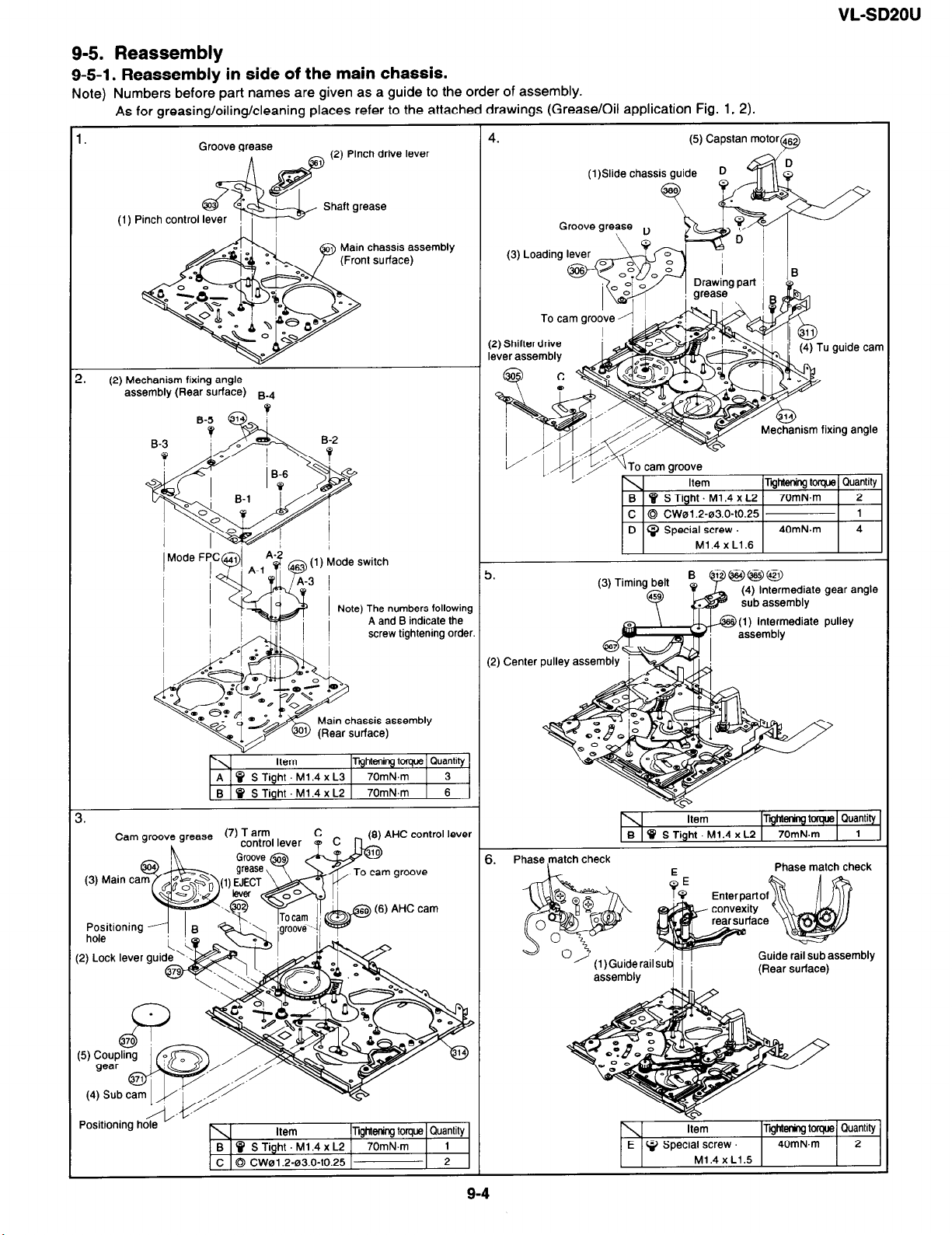

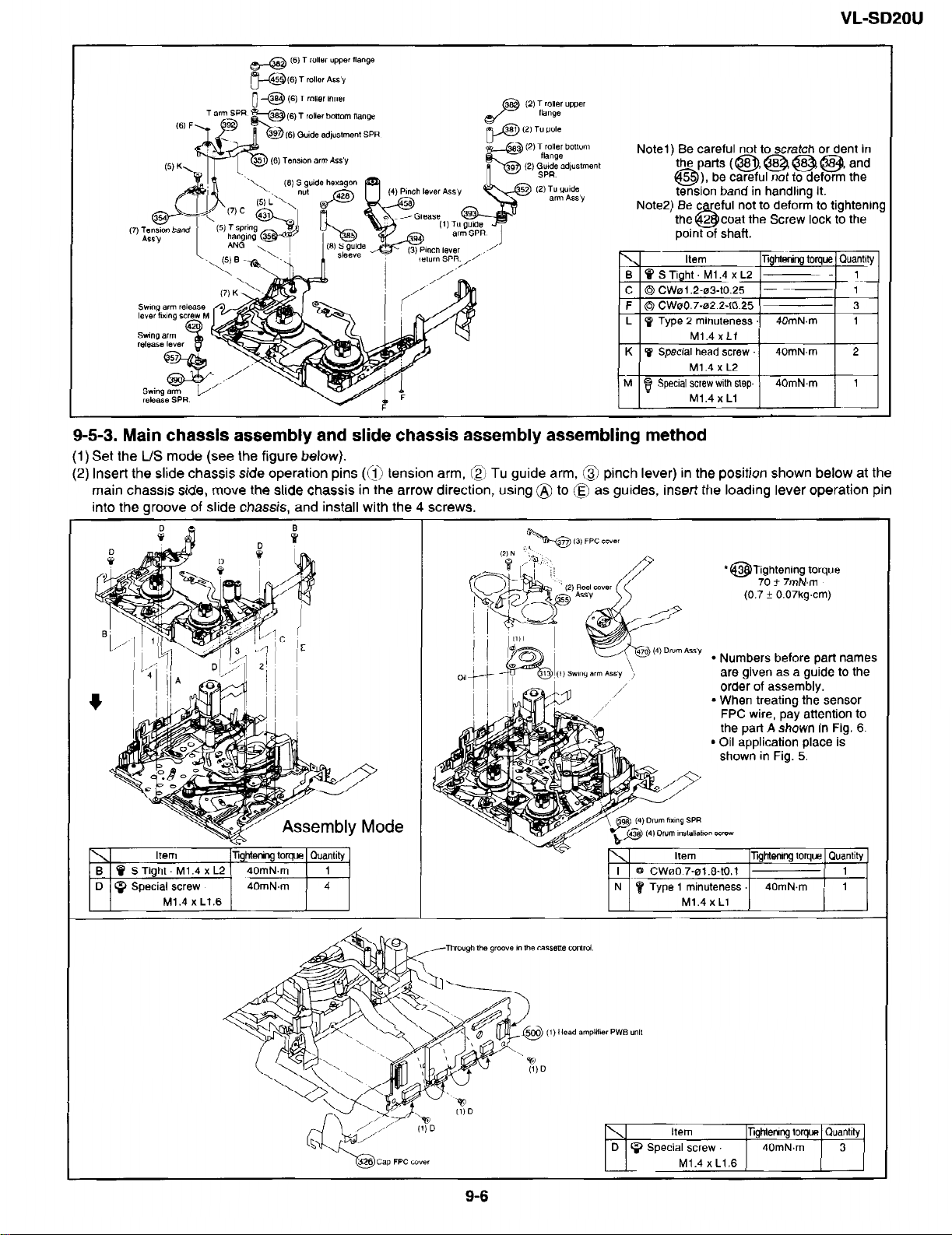

9-5. Reassembly

9-5-l. Reassembly in side of the main chassis.

Note) Numbers before part names are given as a guide to the order of assembly.

As for greasing/oiling/cleaning places refer to the attached drawings (Grease/Oil application Fig. 1, 2).

VL-SD20U

1.

(1) Pinch control lever

>

_. (2) Mechanism fixing angle

assembly (Rear surface) B-4

Groove grease

I

/Ai! I

(2) Pinch drive lever

Main chassis assembly

Note) The numbers following

A and B indicate the

screw tightening order

I

(2) Shifterdrive

lever assembly

(2) Center pulley asse

(5) Capstan

,,‘m q

ID 19Specl

ial screw

Ml .4 x L1.6

motor@

MeXnism fixing anale

40mN.m

@@@

(4) Intermediate gear angle

sub assembly

(1) Intermediate pulley

, 1

1 4

2) Lock lever guid

Positioning h;e

n chassis

Item

A @ S Tight Ml.4 x L3 70mN.m 3

B @ S Tight Ml.4 x L2 70mN.m

Item

9 S Tight. Ml.4 x L2 1 70mN.m 1

assembly

TgMening torque Quantity

AHC control lever

ImgMeNng torque 1 Quantity

6

Item

B 1’9 S Tight. Ml.4 x L2 I 70mN.m I

Item

1

E Q Special screw

M1.4xL1.5

ITtthteNng toqus 1 Quantity

1

eck

Guide rail sub assembly

(Rear surface)

TghteNrg torque Quantity

40mN.m 2

Page 20

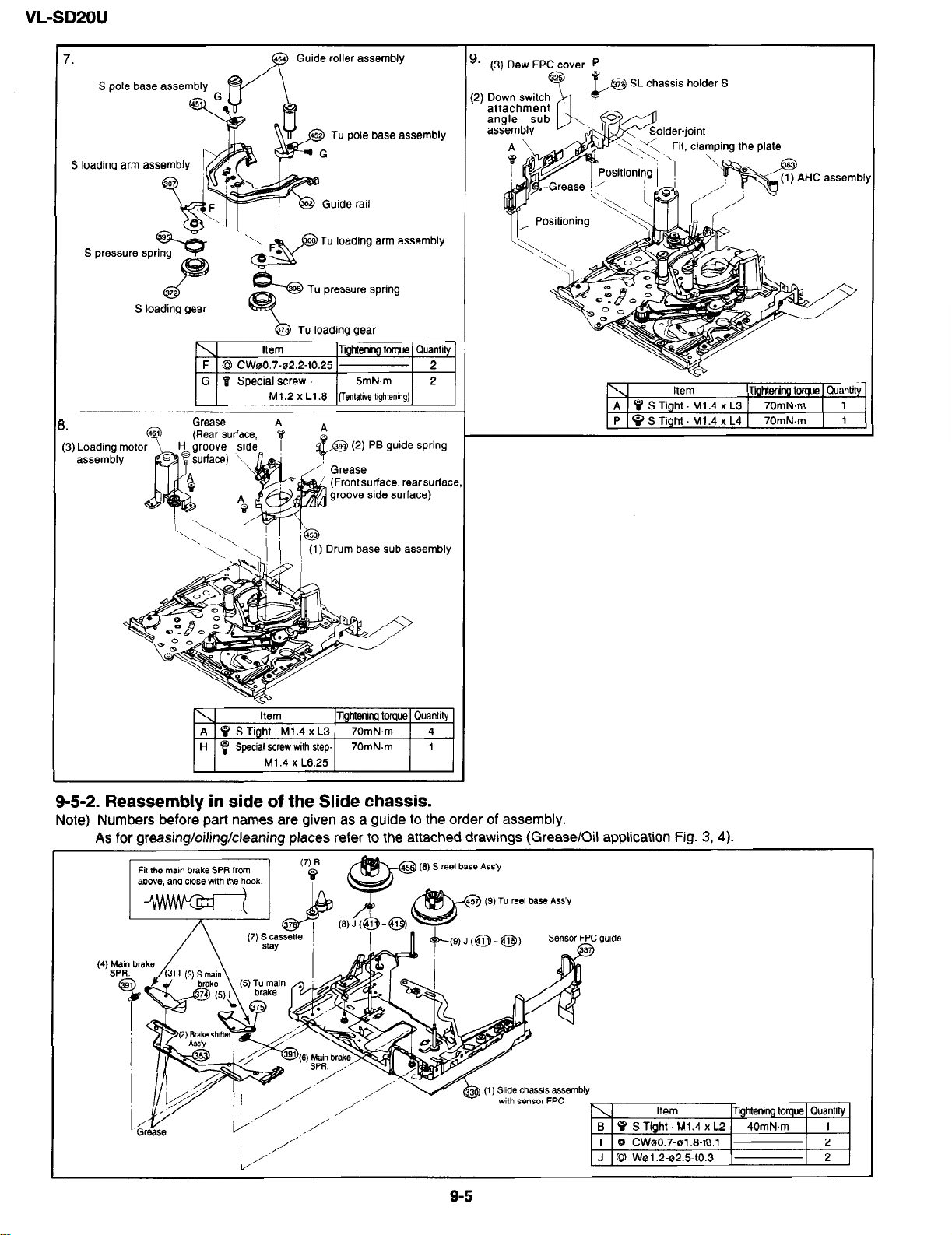

VL-SD20U

7.

loading arm

S

pressure

S

S

pole b

d

S loading

gear

2?

M

roller assembly

Guide

Tu

uide rail

Tu

pressure spring

Tu

pole

loading

base assembly

assembly

arm

Dew

(3)

‘.

Down switch@f

2,

FPC cover

P

&,@)

SL

chassis

holder

S

Loading

3)

assembly

moto

Item

CW00.7-02.2-10.25

F @

G t Special

screw

Ml .2 x L1.8

I\ ’

/F) Drum base sub

/

’ .l> lx

A

Ii

/

Item

‘@ S Tight Ml.4 x L3

0 Special screw with step 70mN.m 1

Ml .4 x L8.25

Tightening 1~ Quantity

5mN.m

(Tentative tIghten

(2) PB guide spring

urface, rearsurface

side surface)

TghterIng torque Quantity

70mN.m

2

2

assembly

4

\

A ‘@

P 9

Item

Tight Ml .4 x

S

Ml.4 x L4

Tight

S

Tgkning torque

70mN.m

L3

7OmN-m

Quantity

1

1

9-5-2. Reassembly in side of the Slide chassis.

Numbers before part names are given as a guide to the

Note)

As for greasing/oiling/cleaning places refer to the attached drawings (Grease/Oil application Fig. 3, 4).

order of assembly.

(8) S reel base Ass’y

(9)

(s)J(@‘-@)

(1)

9-5

base Ass’y

Tu reel

s

Slide chassis assembly

with sensor FPC

B S Tight Ml.4 x L2

CW00.7-01.8~to.1 2

1 0

J @ W01.2-02.5-to.3 2

Item

Tgmening torque Quantity

40mN.m

1

Page 21

VL-SDPOU

t-l

Notel) Be careful

the

(2)

14,

Plneh

,ewr

ASS’”

-

Tu Qulde

arm

A&y

@$I), be

t=sion band in

Note2)

Be careful not to

theecoat

~

1

L

IQ

Type2 minuteness .I 40mN.m

K

I I

M

fj

Ml

‘Q

Special

M1.4xL2

Special screw with step.

M1.4xLl

parts

(a, @ @

careful

.4 x

Ll

head screw

not

to

scratch or dent

@,

not to

deform

handling

it.

deform to tightenin!

the Screw lock to the

1 1 1

40mN.m

I I

40mN.m

and

the

2

1

in

J

9-5-3. Main chassis assembly and slide chassis assembly assembling method

(1) Set the US mode (see the figure below).

(2) Insert the slide chassis side operation pins (0 tension arm, @ Tu guide arm, @ pinch lever) in the position shown below at the

main chassis side, move the slide chassis in the arrow direction, using

into the aroove

of slide chassis,

and install with the 4

screws.

@ to @ as guides,

insert the loading lever operation pin

‘@Tightening torque

70

+ 7mN.m

(0.7 * 0.07kgcm)

l

Numbers

are given as

order

l

When treating the sensor

before part names

a

guide to the

of assembly.

FPC wire, pay attention to

the

part A shown in Fig. 6.

l

Oil application place is

shown in Fig. 5.

9-6

D 9 Special screw

Ml.4 xL1.6

Tightening torque Quantity

40mN.m

3

Page 22

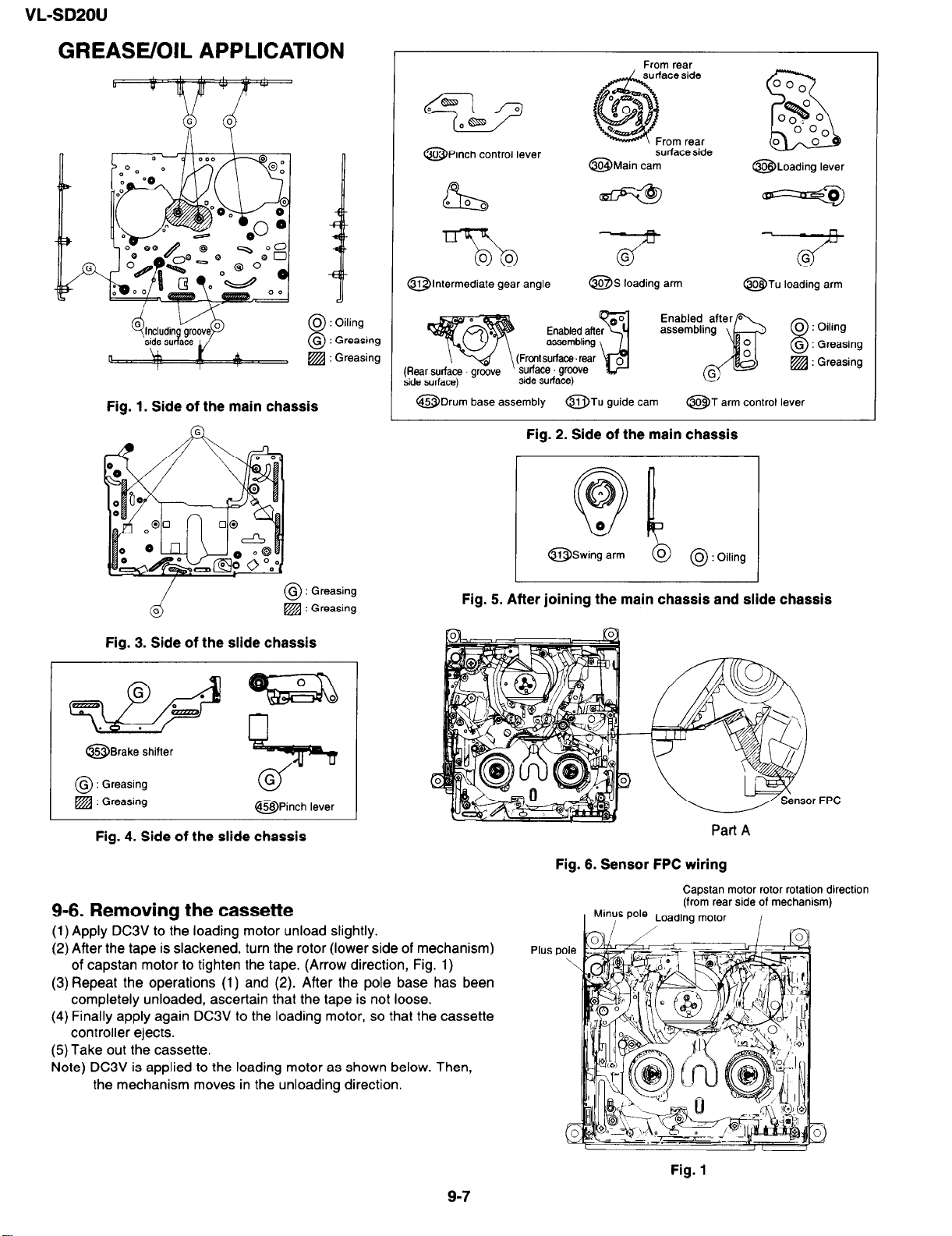

VL-SDPOU

fil!lB

GREASE/OIL APPLICATION

Fig. 1. Side of the main chassis

From rear

ace side

rom rear

@Pinch control lever

@Main cam

7

@Intermediate gear angle

@Drum base assembly @ITu guide cam @T arm control lever

Fig. 2. Side of the main chassis

r I

@S loading arm

surfaceside

G

000

0

@Loading lever

arc==@

7

@Tu loading arm

-ii

00: 0

0 00

0

Fig. 5. After joining the main chassis and slide chassis

Fig. 3. Side of the slide chassis

@Brake shifter

@ : Greasing

q : Greasing

Fig. 4. Side of the slide chassis

@@Pinch lever

9-6. Removing the cassette

(1) Apply DC3V to the loading motor unload slightly.

(2) After the tape is slackened, turn the rotor (lower side of mechanism)

of capstan motor to tighten the tape. (Arrow direction, Fig. 1)

(3) Repeat the operations (1) and (2). After the pole base has been

completely unloaded, ascertain that the tape is not loose.

(4) Finally apply again DC3V to the loading motor, so that the cassette

controller ejects.

(5) Take out the cassette.

Note) DC3V is applied to the loading motor as shown below. Then,

the mechanism moves in the unloading direction.

@Swing arm

I

I

Fig. 6. Sensor FPC wiring

Min’f’ pole Loading motor

PIUS p

6 @:Oiling 1

Part A

Capstan motor rotor rotation direction

(from rear side of mechanism)

/

Fig. 1

9-7

Page 23

VL-SDPOU

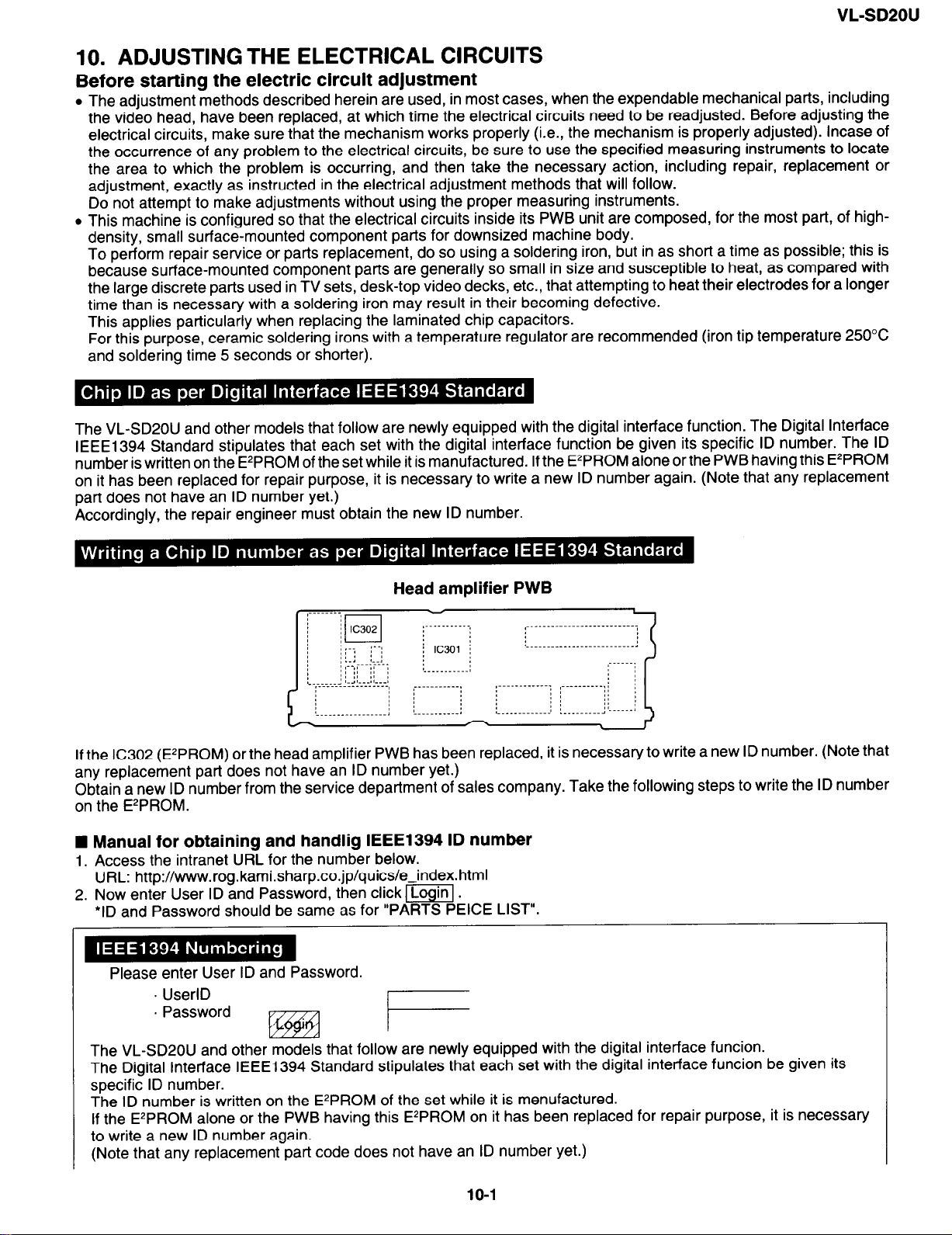

10. ADJUSTING THE ELECTRICAL CIRCUITS

Before starting the electric circuit adjustment

l The adiustment methods described herein are used, in most cases, when the expendable mechanical parts, including

the video head, have been replaced, at which time the electrical circuits need to be readjusted. Before adjusting the

electrical circuits, make sure that the mechanism works properly (i.e., the mechanism is properly adjusted). lncase of

the occurrence of any problem to the electrical circuits, be sure to use the specified measuring instruments to locate

the area to which the problem is occurring, and then take the necessary action, including repair, replacement or

adjustment, exactly as instructed in the electrical adjustment methods that will follow.

Do not attempt to make adjustments without using the proper measuring instruments.

.

This machine is configured so that the electrical circuits inside its PWB unit are composed, for the most part, of highdensity, small surface-mounted component parts for downsized machine body.

To perform repair service or parts replacement, do so using a soldering iron, but in as short a time as possible; this is

because surface-mounted component parts are generally so small in size and susceptible to heat, as compared with

the large discrete parts used in TV sets, desk-top video decks, etc., that attempting to heat their electrodes for a longer

time than is necessary with a soldering iron may result in their becoming defective.

This applies particularly when replacing the laminated chip capacitors.

For this purpose, ceramic soldering irons with a temperature regulator are recommended (iron tip temperature 250°C

and soldering time 5 seconds or shorter).

The VLSD20U and other models that follow are newly equipped with the digital interface function. The Digital Interface

IEEE1394 Standard stipulates that each set with the digital interface function be given its specific ID number. The ID

number is written on the E2PROM of the set while it is manufactured. If the E*PROM alone or the PWB having this E*PROM

on it has been replaced for repair purpose, it is necessary to write a new ID number again. (Note that any replacement

part does not have an ID number yet.)

Accordingly, the repair engineer must obtain the new ID number.

Head amplifier PWB

If the IC302 (E*PROM) or the head amplifier PWB has been replaced, it is necessary to write a new ID number. (Note that

any replacement part does not have an ID number yet.)

Obtain a new ID number from the service department of sales company. Take the following steps to write the ID number

on the E*PROM.

n Manual for obtaining and handlig IEEE1394 ID number

1. Access the intranet URL for the number below.

URL: http://www.rog.kami.sharp.co.jp/quics/e_index.html

2. Now enter User ID and Password, then click [Loginl .

*ID and Password should be same as for “PARTS PEICE LIST”.

Please enter User ID and Password.

. UserlD

. Password

tZ&!Zl I==

The VL-SD20U and other models that follow are newly equipped with the digital interface funcion.

The Digital Interface IEEE1 394 Standard stipulates that each set with the digital interface funcion be given its

specific ID number.

The ID number is written on the E*PROM of the set while it is menufactured.

If the E*PROM alone or the PWB having this E*PROM on it has been replaced for repair purpose, it is necessary

to write a new ID number again.

(Note that any replacement part code does not have an ID number yet.)

1 o-1

Page 24

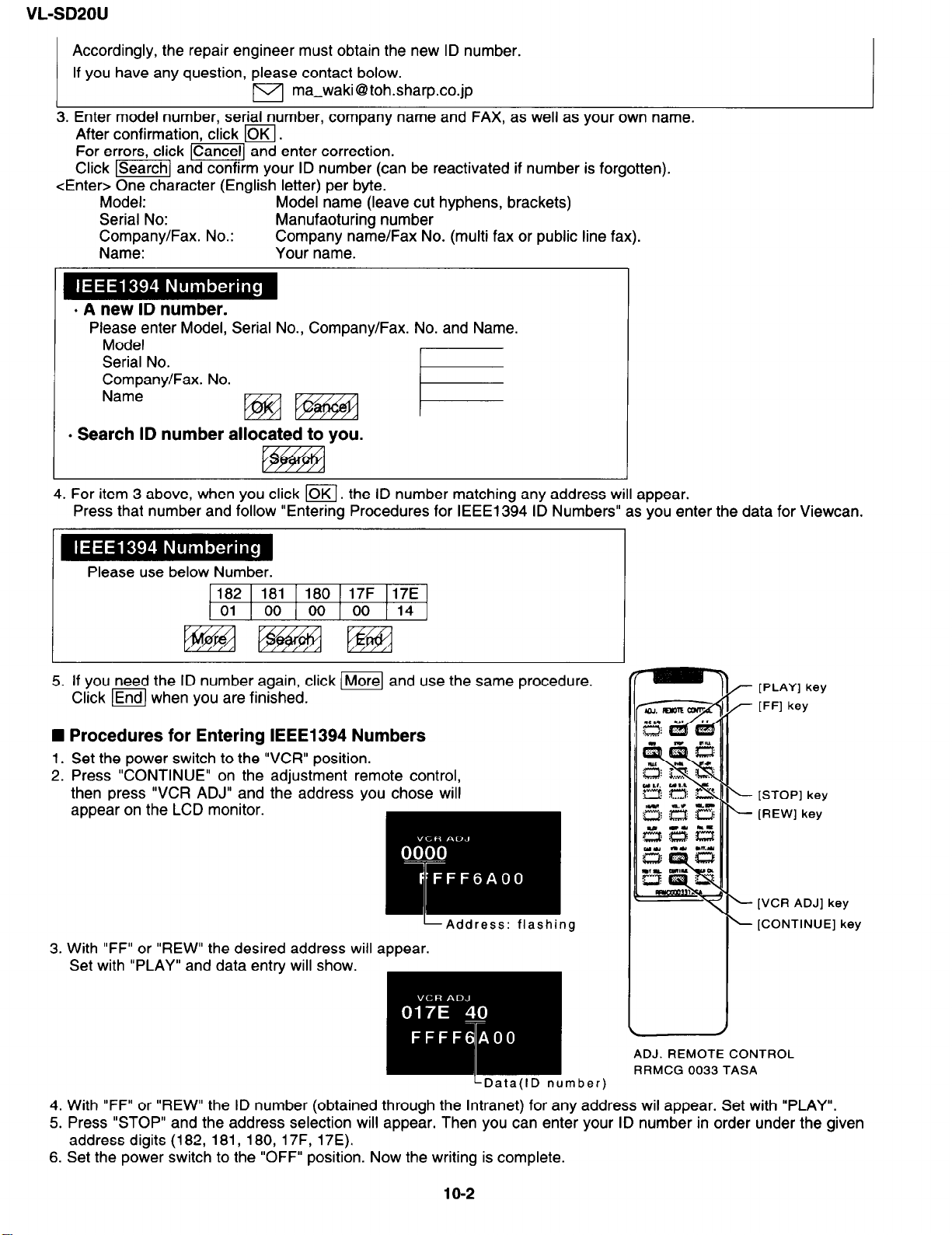

VL-SDPOU

Accordingly, the repair engineer must obtain the new ID number.

If you have any question, please contact bolow.

1\/1 ma_waki@ toh.sharp.co.jp

3. Enter model number, serial number, company name and FAX, as well as your own name.

After confirmation, click m.

For errors, click I(=ancell and enter correction.

Click ISearcFi] and confirm your ID number (can be reactivated if number is forgotten).

<Enter> One character (English letter) per byte.

Model: Model name (leave cut hyphens, brackets)

Serial No:

Manufaoturing number

Company/Fax. No.: Company name/Fax No. (multi fax or public line fax).

Name: Your name.

- A new ID number.

Please enter Model, Serial No., Company/Fax. No. and Name.

Model

Serial No.

Company/Fax. No.

Name

. Search ID number allocated to you.

4. For item 3 above, when you click m. the ID number matching any address will appear.

Press that number and follow “Entering Procedures for IEEE1394 ID Numbers” as you enter the data for Viewcan.

Please use below Number.

182 1 181 1 180 1 17F 117E

G & bl”

5. If you need the ID number again, click w] and use the same procedure.

Click IEndJ when you are finished.

[PLAY] key

r PI key

n Procedures for Entering IEEE1394 Numbers

1.

Set the power switch to the “VCR” position.

2.

Press “CONTINUE” on the adjustment remote control,

then press “VCR ADJ” and the address you chose will

appear on the LCD monitor.

LAddress: flashing

3. With “FF” or “REW” the desired address will appear.

Set with “PLAY” and data entry will show.

L [STOP] key

L [REW] key

L [VCR ADJ] key

L [CONTINUE] key

ADJ. REMOTE CONTROL

mber)

RRMCG 0033 TASA

4. With “FF” or “REW” the ID number (obtained through the Intranet) for any address wil appear. Set with “PLAY”.

5. Press “STOP” and the address selection will appear. Then you can enter your ID number in order under the given

address digits (182, 181, 180, 17F, 17E).

6. Set the power switch to the “OFF” position. Now the writing is complete.

1 o-2

Page 25

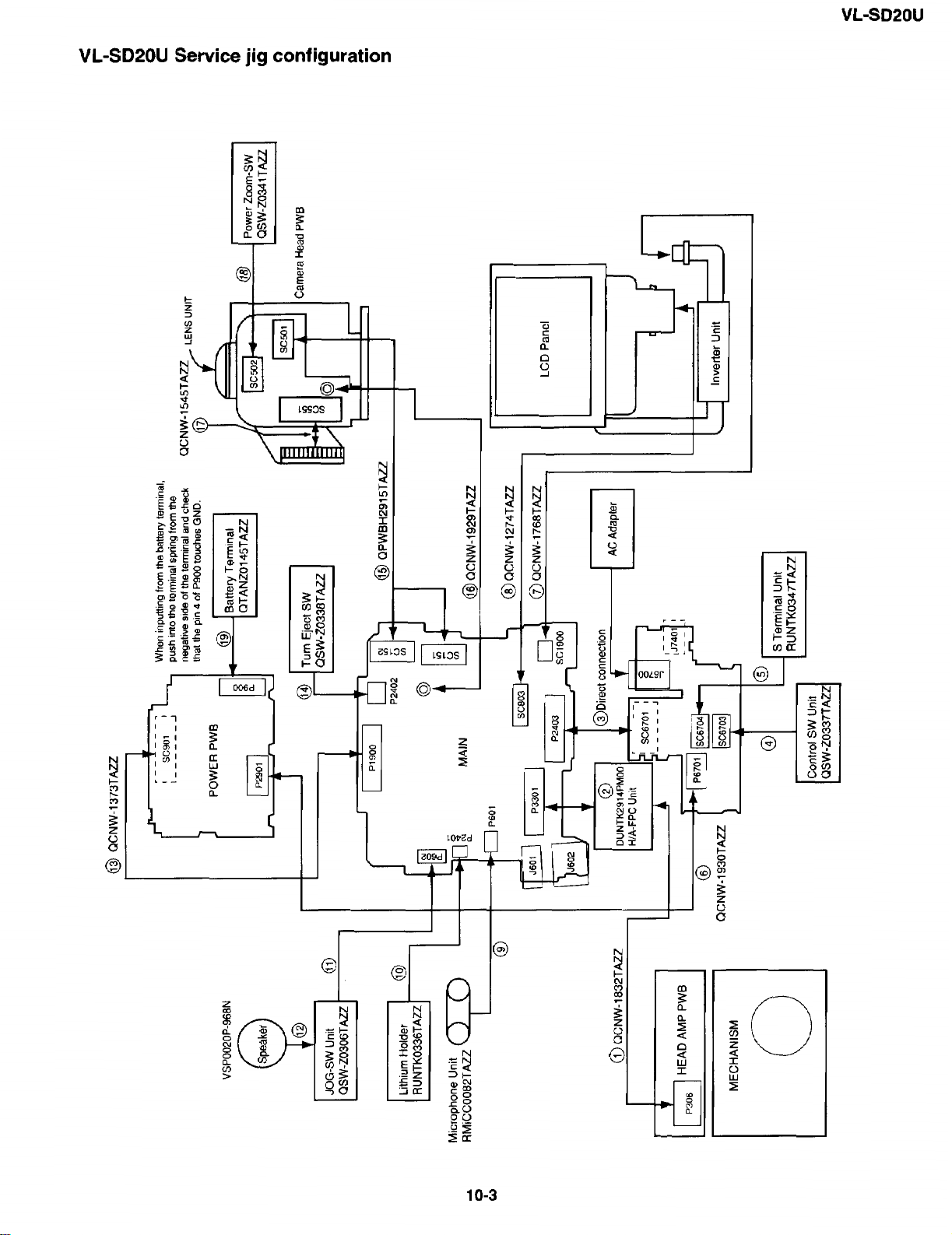

PWB

terminal,

battery

inputting from the

When

push !nto the terminal spring from the

J

----

1

-SC? -

_

r--

I

I

QCNW-1373TAZZ

@

QCNW-1545TAZZ LE,.,S “,.,,T

check

touches GND.

terminal and

the

P900

of

4 of

negative side

that the pin

0 f

POWER PWB

45TAU

Battery Terminal

QTANZOI

1 @,

8

0

, t

P2901

n

Head

I

QPWBH2915TAZZ

@

4

8

T I

P2402 -

P1900

I

QCNW-1929TAZZ

@

MAIN

5

%

I

c

LCD Panel

I

AC Adapter

-1

@ QCNW-1274TAZZ

@Direct connection

I 0

VSPOO20P-968N

QSW-Z0306TAZZ

Microphone Unit

RMiCC0082TAZZ 07

7”‘““’ -

I

0

I

6) QCNW-1832TAZZ

QCNW-1930TAZZ \

J

HEAD AMP PWB

MECHANISM

I

s

i,

Page 26

VL-SDPOU

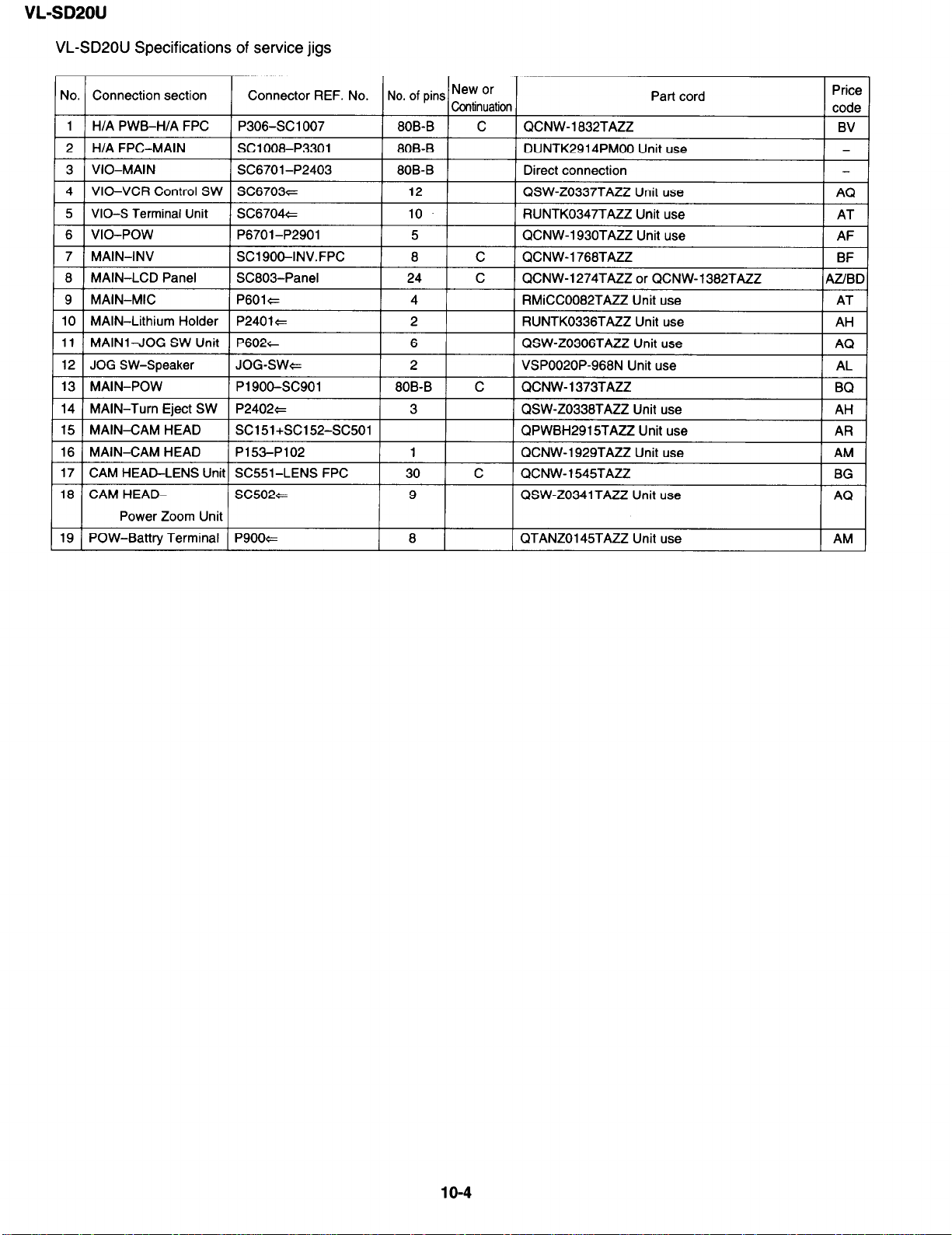

VL-SD20U Specifications of service jigs

1 o-4

Page 27

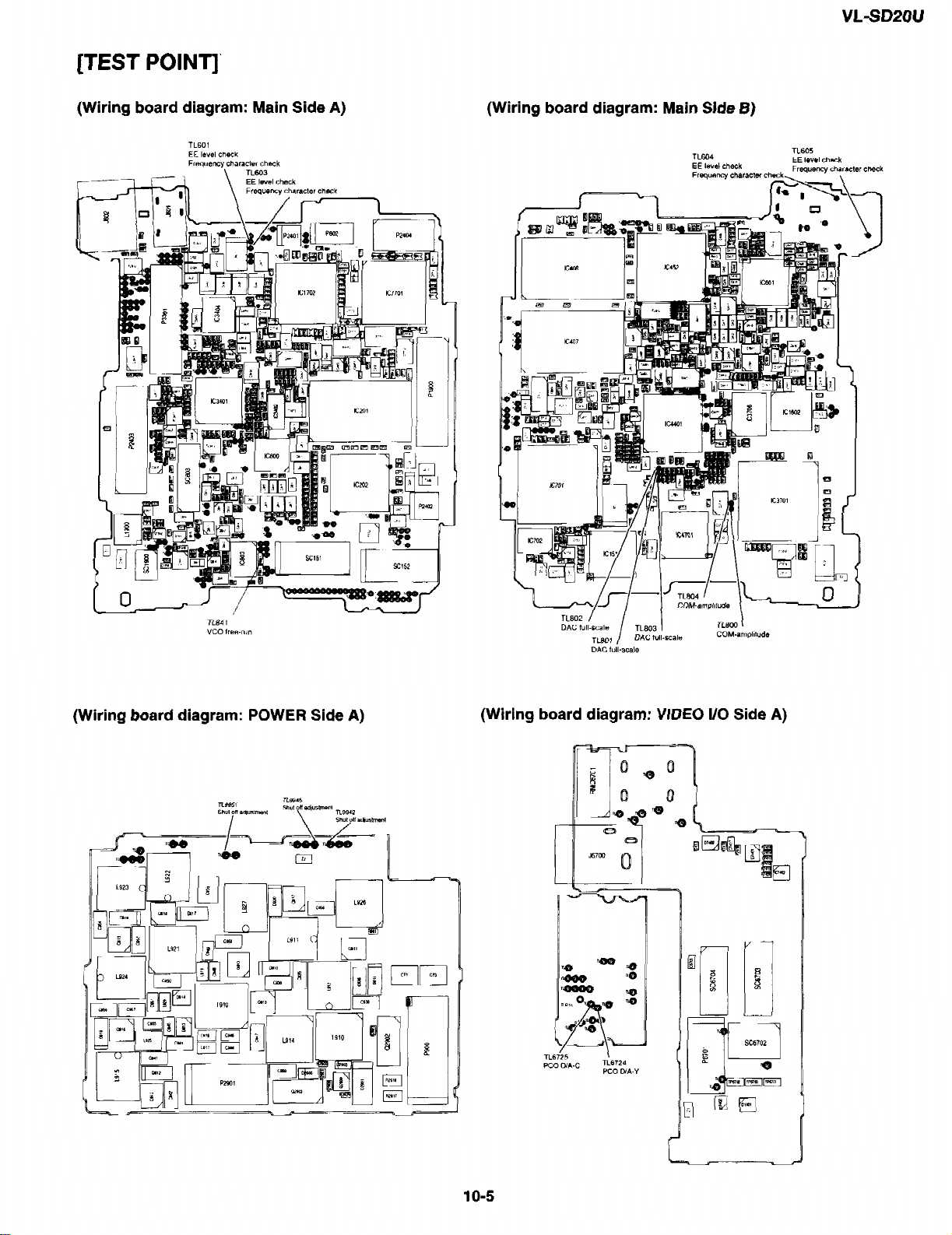

[TEST POINT]‘

VL-SDPOU

(Wiring board diagram: Main Side A)

(Wiring board diagram:

Main Side B)

(Wiring board diagram: POWER Side A)

II a” 1 I

n

II -=

(Wiring board diagram: VIDEO l/O Side A)

I c I

1 o-5

Page 28

VL-SDPOU

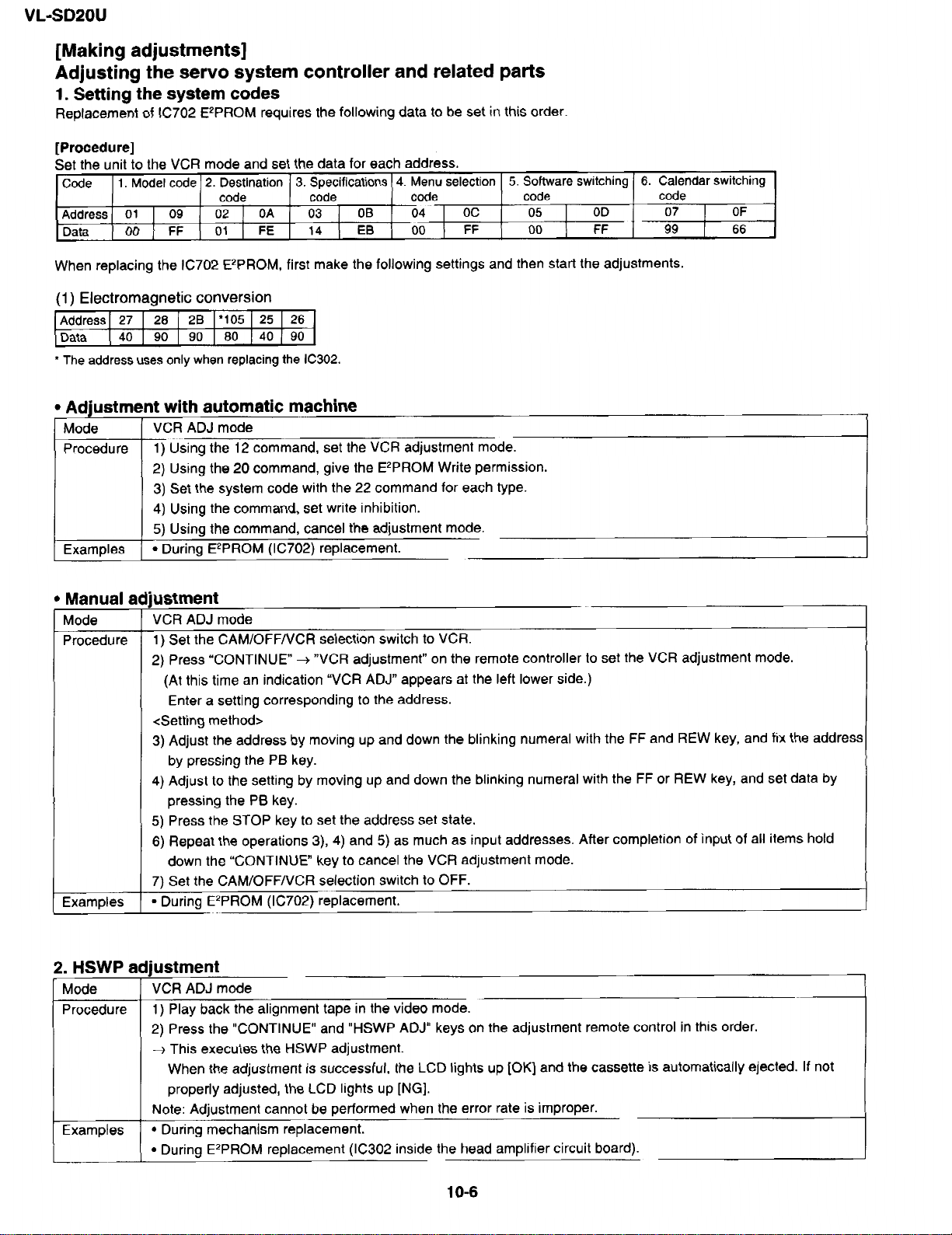

[Making adjustments]

Adjusting the servo system controller and related parts

Setting the system codes

1.

Replacement of IC702 E’PROM requires the following data to be set in this order.

[Procedure]

Set the unit to the VCR mode and set the data

Destination 3. Specifications 4. Menu selection 5.

Code

1. Model code

2.

code

OA

1

FF

02

01 1 FE

Address

Data

01 1 09

1

00

for each address.

code code code

1 oc

03

14

OB

(

EB

1

04

00

FF 00

1

Software switching 6. Calendar switching

code

05

OD

1

FF 99 1

(

07 1

OF

66

When replacing the IC702 E2PROM, first make the following settings and then

(1) Electromagnetic conversion

26

I

25

I

1’105

28

28 1

Address1 27

Data

The address uses only when replacing the IC302.

l

Adjustment with automatic machine

l

Mode VCR ADJ mode

Procedure

Examples

Manual

l

I

Procedure

Examples

I

1 90

40

I

80

40 I 90 I 90

1

1) Using the 12 command, set the VCR adjustment mode.

2) Using the 20 command, give the E2PROM Write permission.

3) Set the system code with the 22 command for each type.

4) Using the command, set write inhibition.

5) Using the command, cancel the adjustment mode.

l During E2PROM (IC702) replacement.

a

justment

VCR ADJ mode

1) Set the CAM/OFF/VCR selection switch to VCR.

2) Press “CONTINUE” + “VCR adjustment” on the remote controller to set the VCR adjustment mode.

(At this time an indication “VCR ADJ” appears at the left lower side.)

<Setting methods

3) Adjust the address by moving up and down the blinking numeral with the FF and REW key, and fix the address

4) Adjust to the setting by moving up and down the blinking numeral with the FF or REW key, and set data by

5) Press the STOP key to set the address set state.

6) Repeat the operations 3), 4) and 5) as much as input addresses. After completion of input of all items hold

7) Set the CAM/OFF/VCR selection switch to OFF.

l During E’PROM (IC702) replacement.

I

Enter a setting corresponding to the address.

by pressing the PB key.

pressing the PB key.

down the “CONTINUE” key to cancel the VCR adjustment mode.

start the adjustments.

2. HSWP i

Mode

L

Procedure

Examples

L

justment

VCR ADJ mode

1) Play back the alignment tape in the video mode.

2) Press the “CONTINUE” and “HSWP ADJ” keys on the adjustment remote control in this order.

+ This executes the HSWP adjustment.

When the adjustment is successful, the LCD lights up [OK] and the cassette is automatically ejected. If not

properly adjusted, the LCD lights up [NG].

Note: Adjustment cannot be performed when the error rate is improper.

During mechanism replacement.

l

During E’PROM replacement (IC302 inside the head amplifier circuit board).

l

1 O-6

Page 29

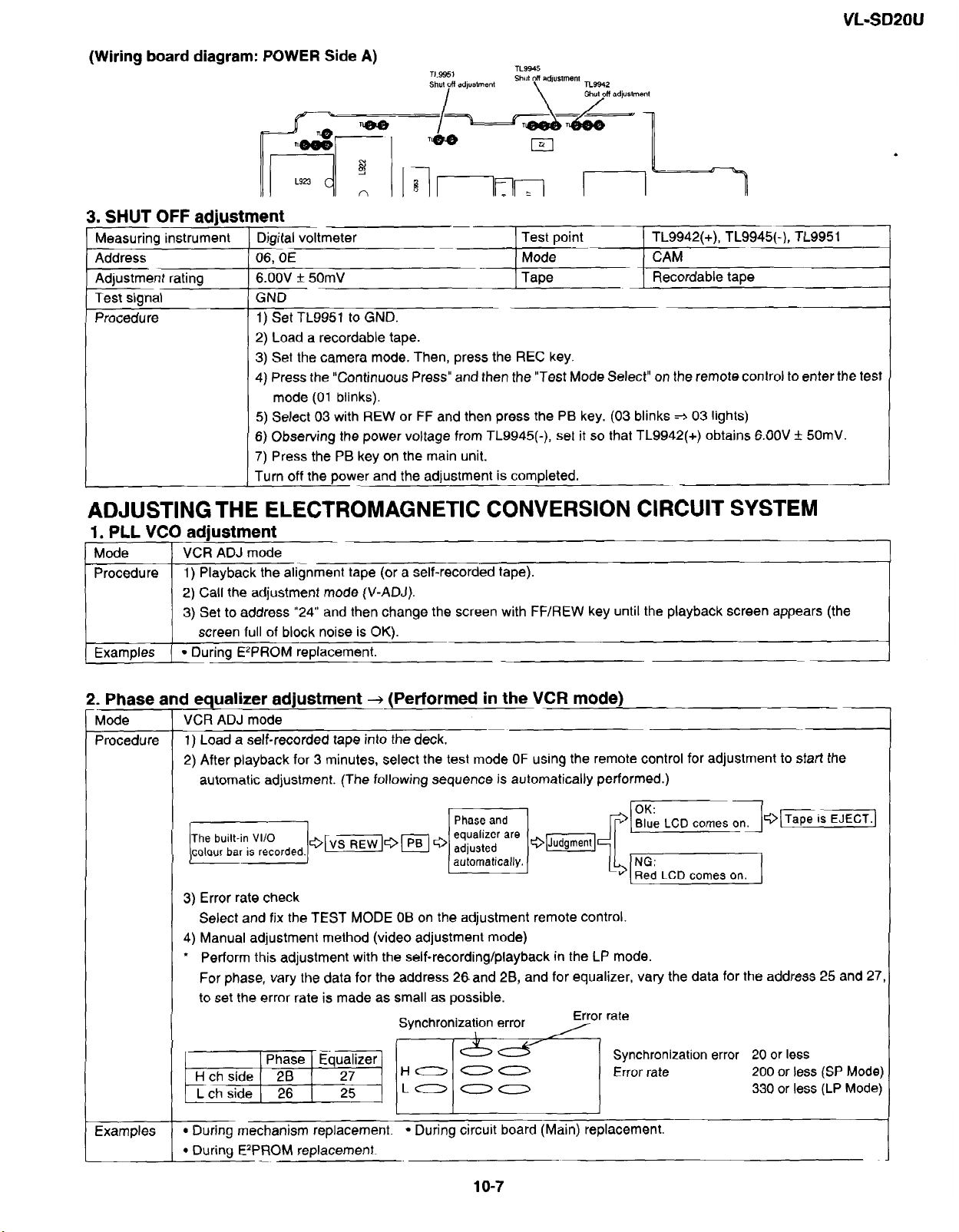

VL-SDSOU

(Wiring

3.

SHUT

Measuring

Address

Adjustment

Test signal

Procedure

board

diagram:

OFF adjustment

instrument

rating

1

1

POWER Side A)

Digital

voltmeter

06, OE

6.OOV + 50mV

GND

1)

Set

TL9951

2)

Load a recordable tape.

3)

Set

the

4) Press

5)

6) Observing

7) Press the PB key

Turn off the power and the adjustment is completed.

the “Continuous

mode (01

Select 03 with REW or FF and

SND.

to

(

camera mode. Then, press the REC

Press” and

blinks).

then

the

power voltage

on the main unit.

from TL9945(-), set it so that TL9942(+) obtains 6.OOV

then the

press

Test point

Mode

Tape

key.

“Test

the PB key. (03 blinks ti

TL9942(+),

CAM

Recordable

Mode Select” on the

TL9945(-), TL9951

tape

remote

control to enter the

03

lights)

.

test

f 50mV.

ADJUSTING THE ELECTROMAGNETIC CONVERSION CIRCUIT SYSTEM

1. PLL VCO adjustment

Mode

Procedure

I I

Examples

2. Phase and equalizer adjustment + (Performed in the VCR mode)

Mn&

. ..___

Procedure

VCR ADJ mode

1) Playback the alignment tape (or

2) Call the adjustment mode

3) Set to

l

During E2PROM replacement.

1

VCR ADJ

_ - ..- _ ..___

1) Load a

2) After playback for 3 minutes, select the test mode OF using the remote control for adjustment to start the

4) Manual adjustment method (video adjustment mode)

l

address “24” and then change the screen

screen full of block noise is OK).

mode

self-recorded

automatic adjustment. (The following sequence is automatically performed.)

Select and fix the TEST MODE OB on the adjustment remote control.

Perform this adjustment with the self-recording/playback in the LP mode.

For phase, vary the data for the address 26and 28, and for equalizer, vary the data for the address 25 and 27

to set the error rate is made as small as possible.

tape into the deck.

a self-recorded tape).

(V-ADJ).

with FF/REW key until

the playback screen appears (the

Examples

WJ w r;;:Y:z~a~ion error ~~~~~~ ~;;~~~~;

l

l

During mechanism replacement.

l

During E*PROM replacement.

During circuit board (Main) replacement.

1 o-7

Page 30

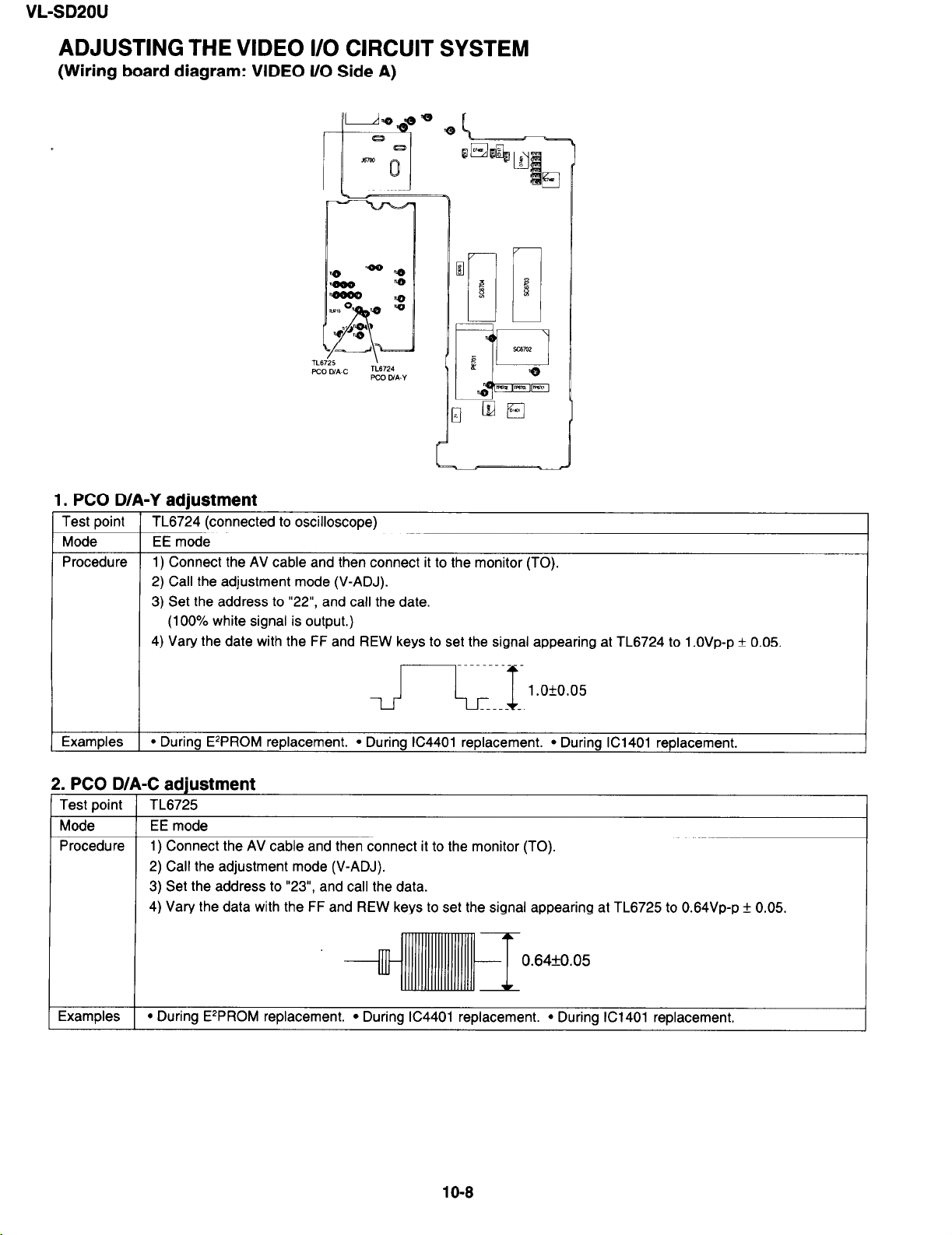

VL-SD20U

ADJUSTING THE VIDEO I/O CIRCUIT SYSTEM

(Wiring board diagram: VIDEO l/O Side A)

1. PC0 D/A-Y adjustment

Test point

Mode

Procedure

Examples l During E*PROM replacement. l During IC4401 replacement. l During IC1401 replacement.

IIIX

Test point

Mode

Procedure

E

TL6724 (connected to oscilloscope)

EE mode

F

1) Connect the AV cable and then connect it to the monitor (TO).

2) Call the adjustment mode (V-ADJ).

3) Set the address to “22”, and call the date.

(100% white signal is output.)

4) Vary the date with the FF and REW keys to set the signal appearing at TL6724 to 1 .OVp-p + 0.05.

A. 2. PC0 D/r

-C adjustment

TL6725

EE mode

1) Connect the AV cable and then connect it to the monitor (TO).

2) Call the adjustment mode (V-ADJ).

3) Set the address to “23”, and call the data.

4) Vary the data with the FF and REW keys to set the signal appearing at TL6725 to 0.64Vp-p + 0.05.

0.64310.05

Examples l During E2PROM replacement. l During IC4401 replacement. l During IC1401 replacement.

l----

1 O-8

Page 31

ADJUSTING THE LCD CIRCUIT

l

To

make

this

adjustment,

set

the

TL341

VCO free-run

backlight switch

to the

“NORMAL”

position.

-J

TL802

/

DAC full-scale

TLEOl

DAC full-scale

DAC

full-scale

COM-amplitude

(Wiring board diagram: MAIN Side A)

1. VCO free-run adjustment

Test point TL841

Address

Mode CAM

Procedure

Adjustment 15734kHz f 1OOHz

rating

Examples

t

2.

DAC full-scale adjustment

Test point

Address

Mode

Procedure

Adjustment

rating

Examples

VCR ADJ 32

1) Change the VCR ADJ address

2) Connect the Frequency counter to TL841 and adjust it to the specified with the VCR ADJ address 32.

3) Set the VCR ADJ address 93 to FF.

Note: When the LCD screen disappears during the data setting at the address 93,

In this case, you can check the address and data by the OSD display of monitor output.

l

During IC702 (E*PROM) replacement.

TL801 (R OUT), TL802 (G OUT), TL803 (B OUT)

VCR ADJ 3D (R), VCR ADJ 3E (G), VCR ADJ 3F (B)

CAM

1) Output the picture to the monitor in the CAM mode.

(While adjusting, no picture appears on the LCD screen. Check the address and data by the OSD display of

monitor output.)

2) Change the VCR ADJ addresses 83, CO and 93 to 00,OO and 77, respectively.

3) Adjust the output voltage of TL801 with the VCR ADJ address 30 and the DC voltage with a digital voltmeter to

the adjustment standard value. At this time, adjust them so that the average of both TP voltage values

corresponds to the standard center value.

4) Adjust the output voltage of TL802rTL803 with the VCR ADJ address 3E/3F and the DC voltage with a digital

voltmeter to the adjustment standard value. (The same as (2))

5) Set all the data of changed addresses to FF.

0.78OVp-p + 1 OmVDC

l

During IC702 (E’PROM) replacement.

93 to DF.

(Wiring board diagram: MAIN

Adjustment procedure and connecting same as the VCR section.

l

During IC4401

l

During IC4401 replacement.

replacement.

keep

Side

changing

B)

the data.

1 o-9

Page 32

VL-SDPOU

3. COM-Amplitude adjustment

TL804

ooint

Test

1

Address VCR ADJ

Mode

Procedure

1

29

CAM

1) Set TL800 to GND.

2) Adjust the output voltage of TL804 with the address 29

adjustment standard value.

V f 50m V

Adjustment

6.55

ratina

I Examoles

I

4. COM-Bias adjustment

point

Test

Address

Mode

Input Signal

Procedure 1) Input white 40% signal

LCD panel daisplay area

VCR ADJ 33

VCR AV input

40% White

illuminometer (TOPCON IM-3)

the

2) Set

off the

(Shut

3) Minimize the ripple of output waveform of illuminometer.

gray scale)

(or

external

signal

as

light.)

AV input.

on the

panel surface.

LCD

and

DC voltage

the

with

a

digital voltmeter

to the

I

I

Adjustment Minimum

rating

Examples

Set the point to

During IC702 (E*PROM) replacement.

l

Durina LCD oanel reolacement.

l

make the black portion blackest.

During circuit board (MAIN) replacement.

l

5. White Balance adjustment

Test point LCD panel daisplay area

Address VCR ADJ 84 (R), VCR ADJ 86 (6)

Mode

Procedure 1) Feed 40% white signal to the AV input jacks and the standard monitor.

Adjustment Set of the atandard W=VF-HL3-136

rating

Remark Make this adjustment after 5-minute or longer aging.

Examples

VCR AV input

2) Set the Color luminance meter (TOPCON BM-5) on the LCD panel surface.

(Shut off the external light.)

3) Adjust the VCR ADJ addresses 84 and

86 until it became the same as that of the standard monitor.

Set of the limit R=VF-HLl-048 G=VF-HLl-050 B=VF-HLl-052

During circuit board (MAIN) replacement.

During IC702 (E2PROM) replacement.

l

During LCD panel replacement.

l

l

Response time

0.6 sec.

:

10-10

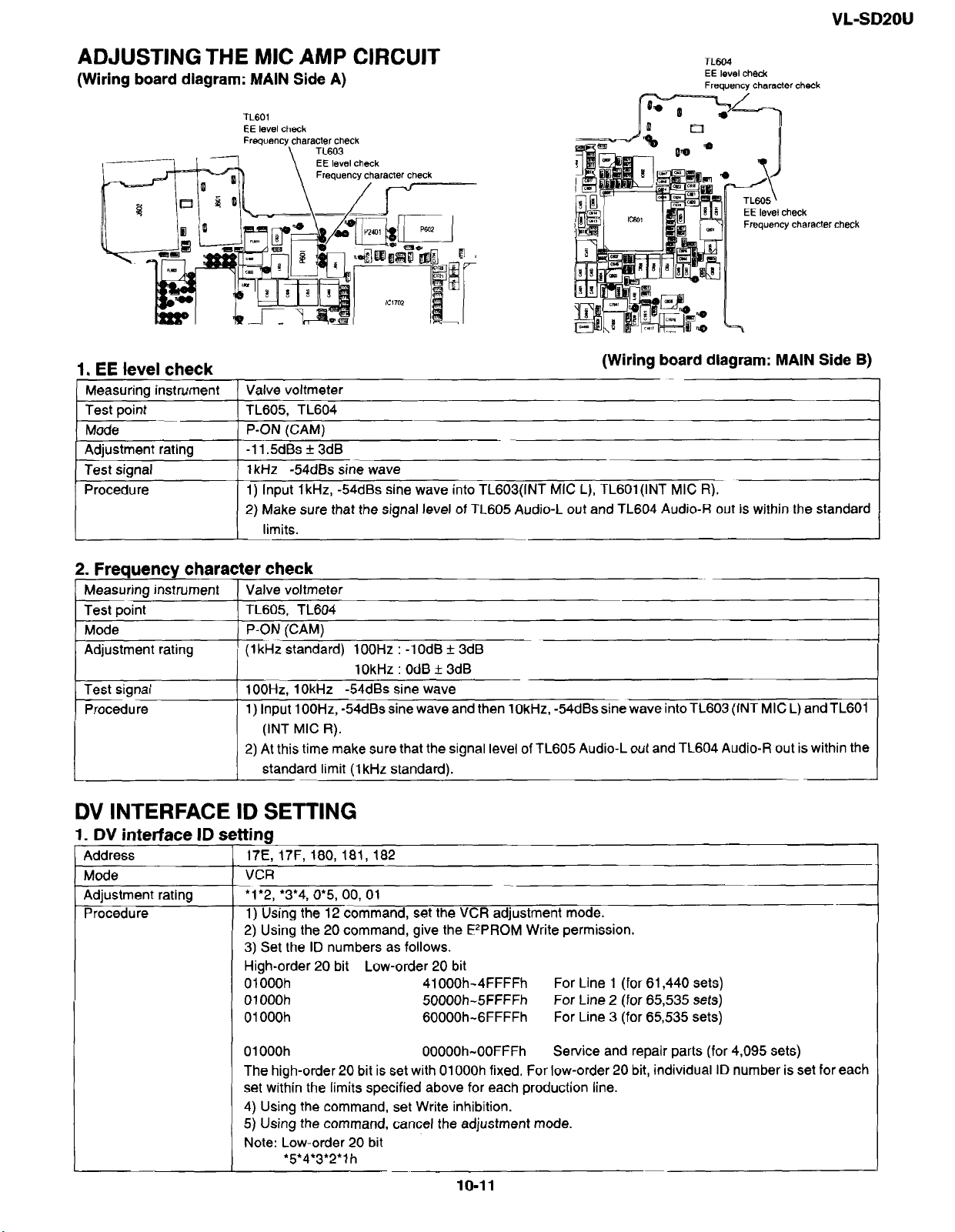

Page 33

VL-SDPOU

ADJUSTING THE

(Wiring board diagram:

MIC AMP

MAIN

Side A)

TL601

EE level

check

Frequency character

\

1.

EE

level

check

Measuring instrument Valve voltmeter

Test point

Mode

Adjustment rating -11.5dBs

Test signal

Procedure

TL605, TL604

P-ON (CAM)

f 3dB

1 kHz -54dBs sine wave

1) Input 1 kHz, -54dBs sine wave into TL603(INT MIC L), TLGOl(INT MIC R).

2) Make sure that the signal level of TL605 Audio-L out and TL604 Audio-R out is within the standard

check

TL603

EE

level

Frequency

CIRCUIT

check

character check

(Wiring board

TL604

EE level

check

Frequency character

check

check

diagram: MAIN Side B)

2. Frequency character check

Measuring instrument

Test point

Mode

Adjustment rating

Test

signal

Procedure

Valve voltmeter

TL605, TL604

P-ON (CAM)

(1

kHz

standard) 1 OOHz

1 OOHz, 1 OkHz -54dBs sine wave

1)

Input 1 OOHz, -54dBs sine wave and then 1 OkHz, -54dBs sine wave into TL603 (INT MIC L) and TL601

(INT MIC R).

2) At this time make sure that the signal level of TL605 Audio-L out and TL604 Audio-R out is within the

standard limit (1 kHz standard).

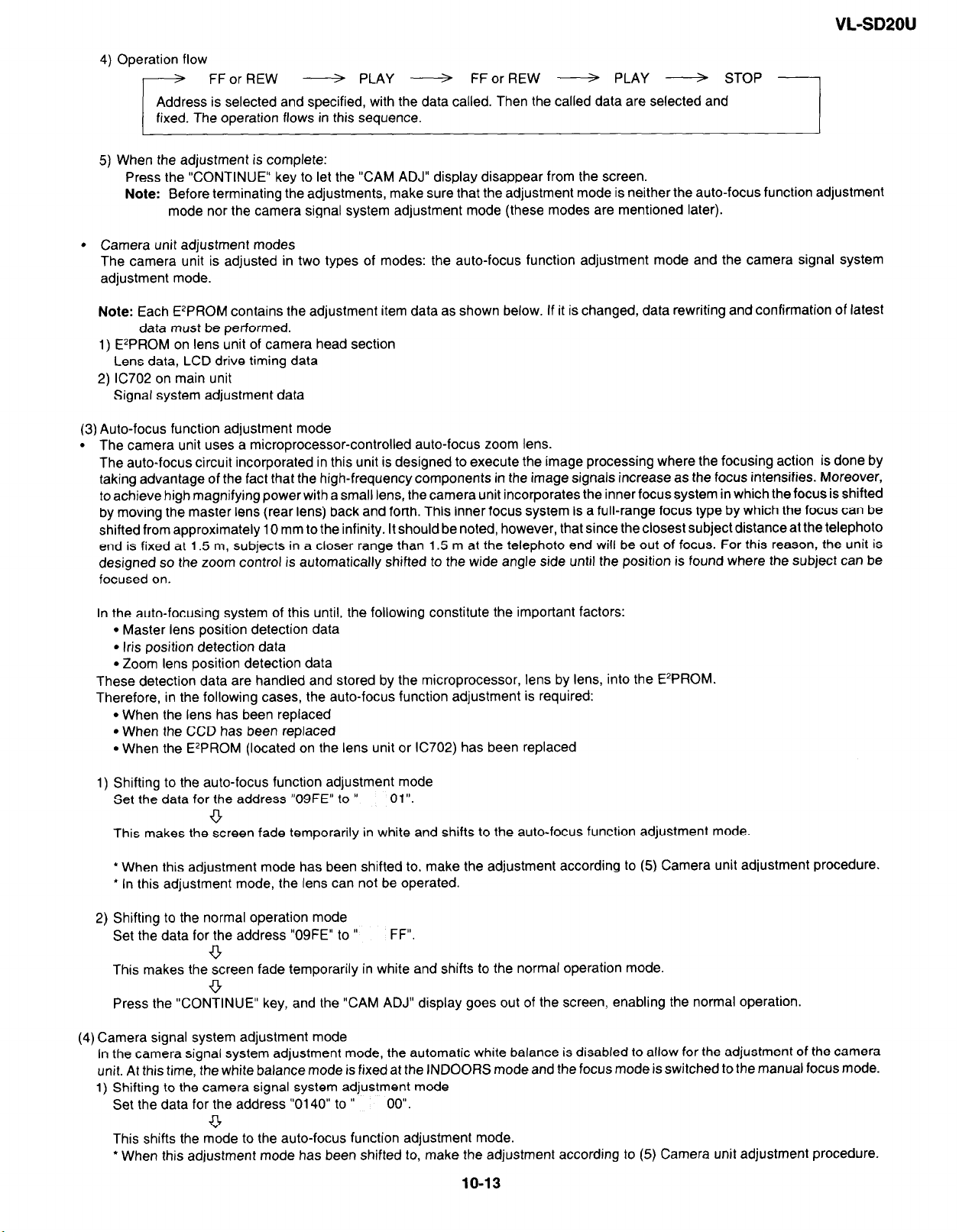

DV INTERFACE ID SETTING

1.

DV interface ID setting

Address

Mode

Adjustment rating

Procedure

17E, 17F, 180, 181, 182

VCR

*1*2,

l 3*4, 0*5, 00, 01

1) Using the 12 command, set the VCR adjustment mode.

2) Using the 20 command, give the E2PROM Write permission.

3) Set the ID numbers as follows.

High-order 20 bit Low-order 20 bit

01 OOOh

01 OOOh 50000h-5FFFFh

01 OOOh 60000h-6FFFFh

1OkHz

:

-1 OdB f 3dB

:

OdB f 3dB

41000h-4FFFFh

For Line 1 (for 61,440 sets)

For Line 2 (for 65,535 sets)

For Line 3 (for 65,535 sets)

01 OOOh

The high-order 20 bit is set with OlOOOh fixed. For low-order 20 bit, individual ID number is set for each

set within the limits specified above for each production line.

4) Using the command, set Write inhibition.

5) Using the command, cancel the adjustment mode.

Note: Low-order 20 bit

OOOOOh-OOFFFh

Service and repair parts (for 4,095 sets)

l 5’4*3*2*1 h

10-11

Page 34

VL-SD20U

1 O-2. Camera Section Adjustments

1 O-2-1. Camera section service

(1) Camera adjustment is performed after the set has been completed.

(2) Subjects, measuring instruments and jigs needed for camera section service and adjustments

l Frequency counter

l Illumination meter

l Color temperature meter

l Color temperature conversion filter

HOYA “LB-1 65”

l Color video monitor

l Video output cable

l AC adapter

l Extension cables

l Remote control unit for servicing

10-2-2. List of camera jigs and tools

1. Gray scale chart

1. Color bar chart

<Note: The entries of list> 1. Name 2. Part No. 3. Cod1

1. Illumination meter

Configuration

1. Color temperature meter

(1600 to 400000 degrees K)

2. JiGMETER-

2. JiGMETER-

1. Color temperature

conversion filter

(3200 degrees K ti 6800

degrees K)

!. JiGHOYA-LB165

2. JiGTH-SSlO

2. RRMCG0033TASA

1. Put/pullet out jig

2.95CM22001

l For the QCNW-1929TAZZ

1. BN

10-2-3. Adjusting the camera unit

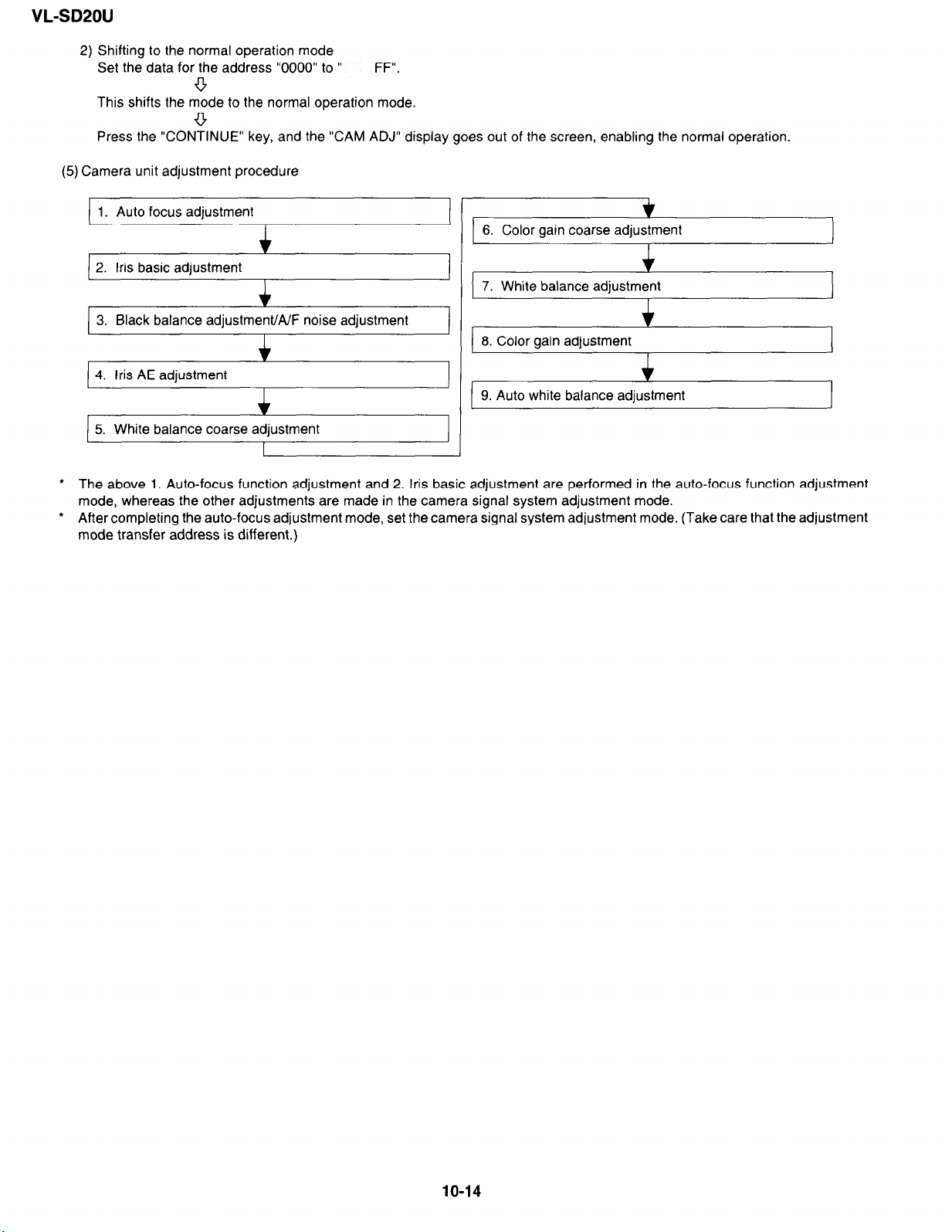

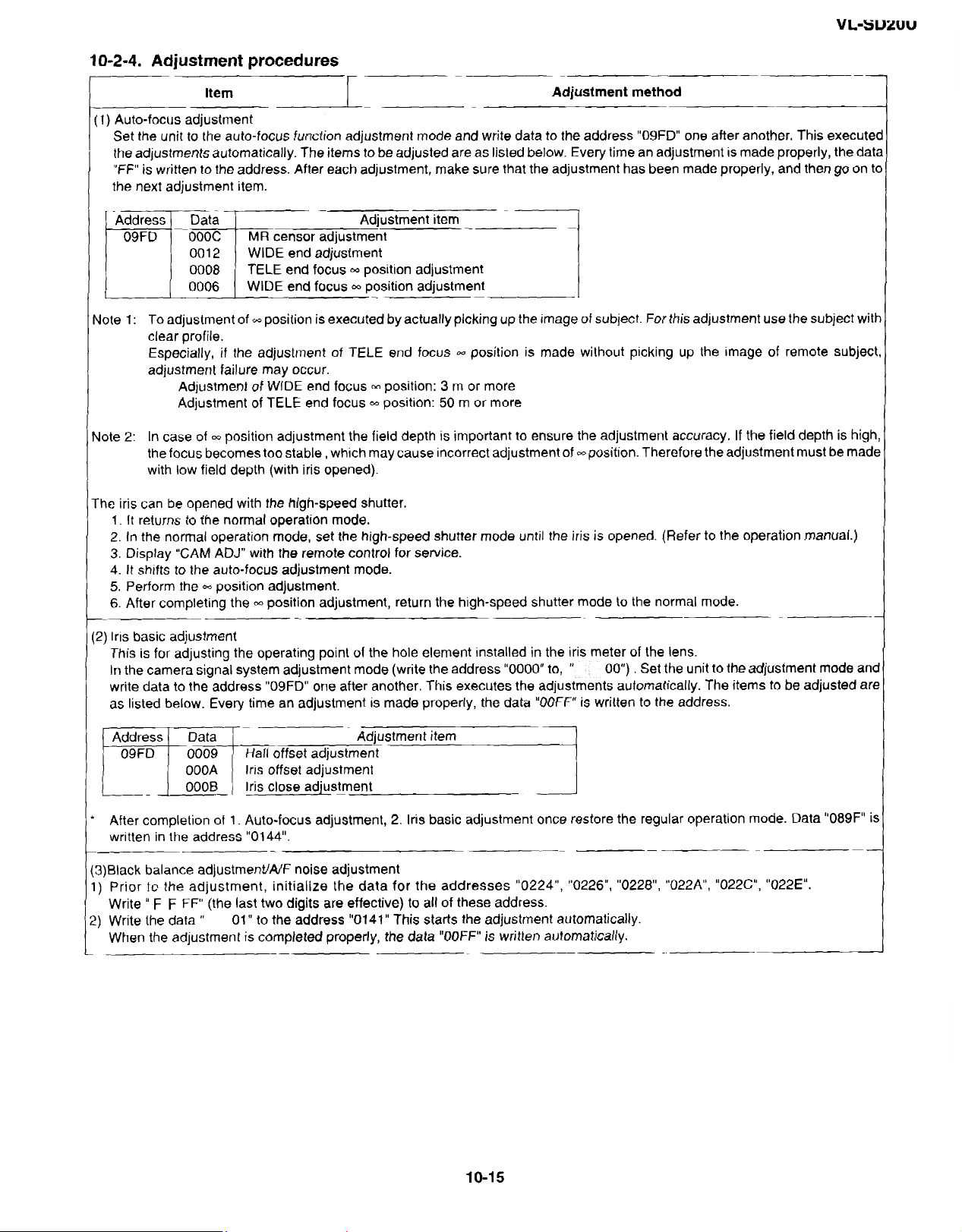

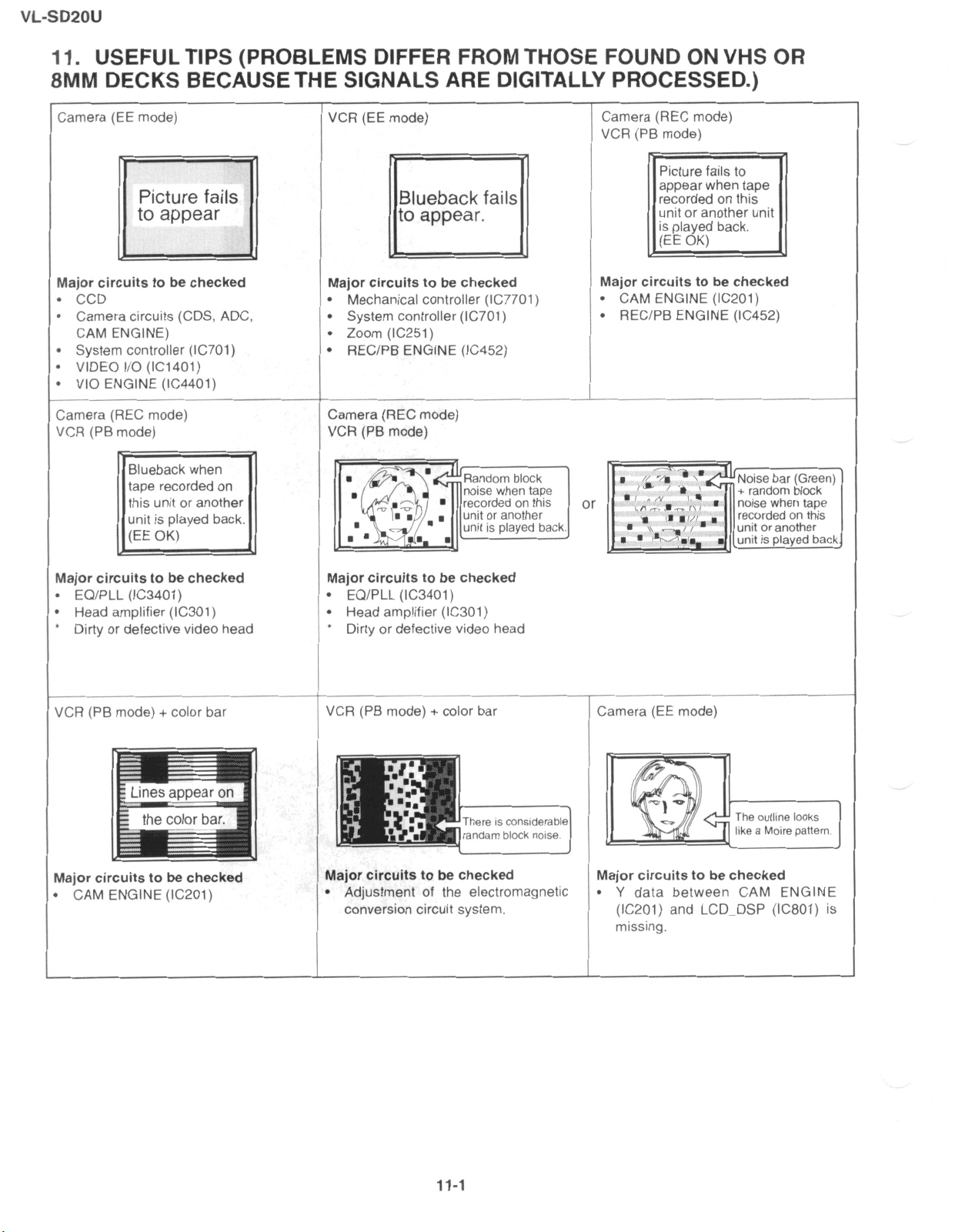

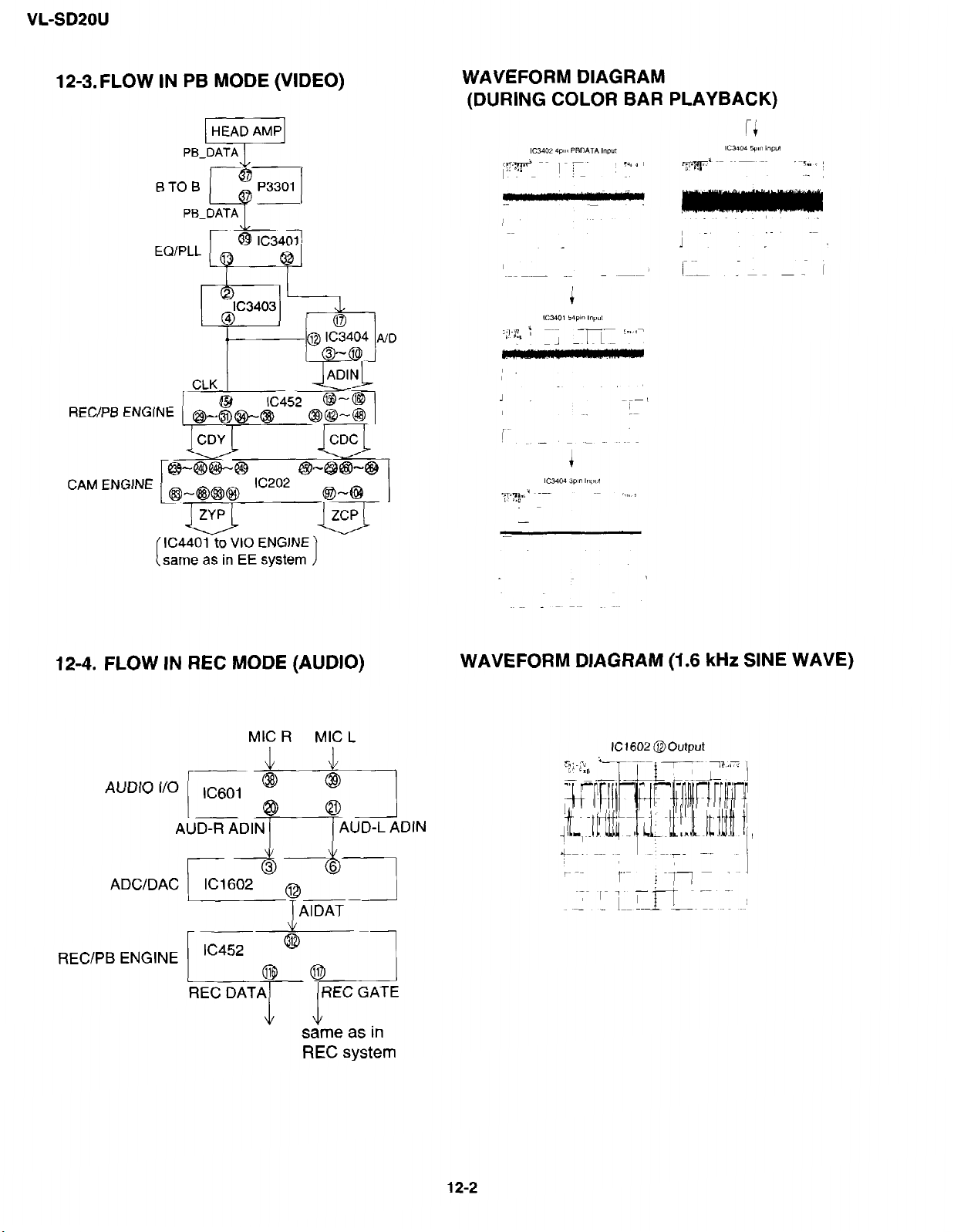

(1) Preparations for adjustments and items to be checked

1) Set up the light box so that the entire pattern is evenly lit. Set the color temperature to 3200°K.