Sharp VL-RDI U Service Manual

VL-RDl U

SHARI= SERVICE MANUAL

S58Q2VL-RDI U/

LIQUID CRYSTAL DIGITAL CAMCORDER NTSC

MODEL VL-RDI u

In the interests of user-safety (Required by safety regulations in some countries) the-set should be restored to its 1

original condition and only parts identical to those specified

be used.

/

- CONTENTS

1.

2.

3.

4.

5.

6.

7.

8.

9.

Page

IMPORTANT SERVICE NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..*..*........................

l-l

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~................................................

2-l

PART NAMES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~.............................................................................................

3-l

DISASSEMBLY OF THE SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~................

4-l

MECHANISM ADJUSTMENT JIGS AND PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~.

5-l

INSPECTION AND MAINTENANCE

ITEMS AND INTERVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

MECHANICAL ADJUSTMENTS AND CHECKS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1

TAPE RUNNING ADJUSTMENT . . . . . . . . . . . . . . . . . ..*.................................................................................

8-l

MECHANICAL SECTION ASSEMBLY AND PARTS REPLACEMENT

(DISASSEMBLY AND REASSENBLY)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..~............

9-l

1 O.ADJUSTlNG THE ELECTRICAL CIRCUITS

.................................................................................

IO-I

11 .USEFUL TIPS ................................................................................................................................

II-I

12.SIGNAL FLOW DIAGRAM

.............................................................................................................

12-I

13.BLOCK DIAGRAM ........................................................................................................................

13-1

14.SCHEMATIC DIAGRAM ................................................................................................................

14-1

1 SSEMICONDUCTOR LEAD IDENTIFICATION

...............................................................................

15-1

16.PRINTED WIRING BOARD ASSEMBLIES

“” 1 6-l

...................................................................................

17.REPLACEMENT PARTS LIST

....................................................................................................... 17-l

18.PACKING OF THE SET .................................................................................................................

18-I

SHARP CORPORATION

This document has been published to be used for

after sales service only.

‘\:

The contents are subject to change without notice.

VL-RDI U

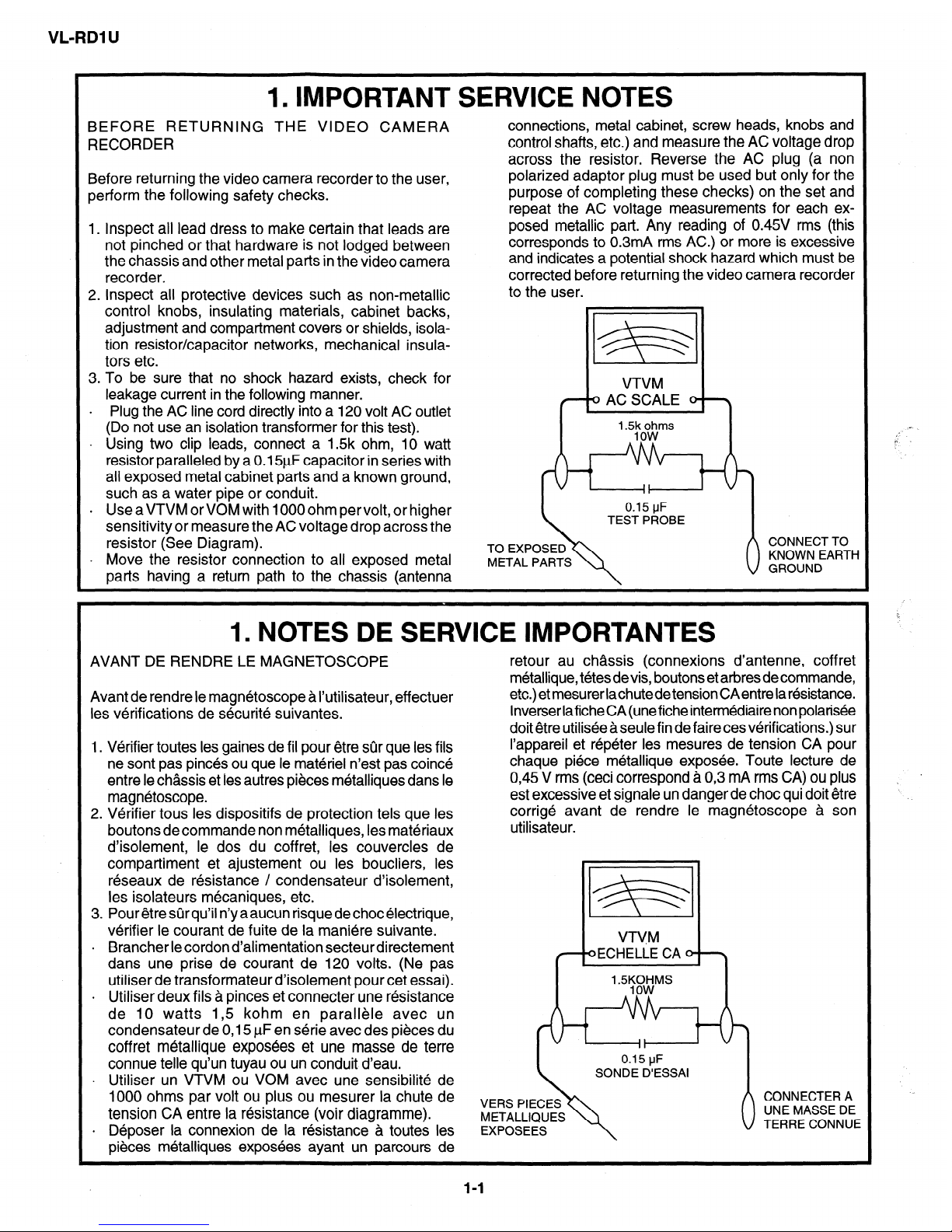

1. IMPORTANT SERVICE NOTES

BEFORE RETURNING THE VIDEO CAMERA

RECORDER

Before returning the video camera recorder to the user,

perform the following safety checks.

1. Inspect all lead dress to make certain that leads are

not pinched or that hardware is not lodged between

the chassis and other metal parts in the video camera

recorder.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields, isolation resistor/capacitor networks, mechanical insulators etc.

connections, metal cabinet, screw heads, knobs and

control shafts, etc.) and measure the AC voltage drop

across the resistor. Reverse the AC plug (a non

polarized adaptor plug must be used but only for the

purpose of completing these checks) on the set and

repeat the AC voltage measurements for each exposed metallic part. Any reading of 0.45V rms (this

corresponds to 0.3mA rms AC.) or more is excessive

and indicates a potential shock hazard which must be

corrected before returning the video camera recorder

to the user.

3. To be sure that no shock hazard exists, check for

leakage current in the following manner.

l Plug the AC line cord directly into a 120 volt AC outlet

(Do not use an isolation transformer for this test).

. Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.151_1F capacitor in series with

ali exposed metal cabinet parts and a known ground,

such as a water pipe or conduit.

VTVM

0 AC SCALE 0 \

’ -5g000Gms

. UseaVTVMorVOMwithlOOOohmpervolt,orhigher

sensitivity or measure the AC voltage drop across the

resistor (See Diagram).

l Move the resistor connection to all exposed metal

parts having a return path to the chassis (antenna

METAL PARTS

1. NOTES DE SERVICE IMPORTANTES

AVANT DE RENDRE LE MAGNETOSCOPE

retour au chassis (connexions d’antenne, coff ret

m&allique, t&es devis, boutons et arbres de commande,

Avant de rendre le magnetoscope a I’utilisateur, eff ectuer

etc.) et mesurer lachutedetension CAentre la resistance.

les verifications de securite suivantes.

lnverserlaficheCA(uneficheintermediairenonpolarisee

doit etre utilisee a seule fin de faire ces verifications.) sur

1. Verifier toutes les gaines de fil pour etre sijr que les fils

I’appareil et &peter les mesures de tension CA pour

ne sont pas pin&s ou que le materiel n’est pas coin&

chaque piece metallique exposee. Toute lecture de

entre le chassis et les autres pieces metalliques dans le

0,45 V rms (ceci correspond a 0,3 mA rms CA) ou plus

magnetoscope.

est excessive et signale un danger de choc qui doit etre

2. Verifier tous les dispositifs de protection tels que les

corrige avant de rendre le magnetoscope a son

boutons de commande non metalliques, les materiaux

utilisateur.

d’isolement, le dos du coffret, les couvercles de

compartiment et ajustement ou les boucliers, les

reseaux de resistance / condensateur d’isolement,

les isolateurs mecaniques, etc.

3. Pour etre sur qu’il n’y a aucun risque de choc electrique,

verifier le courant de fuite de la maniere suivante.

VTVM

l Brancher le cordon d’alimentation secteur directement

dans une prise de courant de 120 volts. (Ne pas

oECHELiE CA 0 \

utiliser de transformateur d’isolement pour cet essai).

l Utiliser deux fils a pinces et connecter une resistance

de 10 watts I,5 kohm en parallele avec un

condensateur de 0,15 PF en serie avec des pieces du

coffret metallique exposees et une masse de terre

connue telle qu’un tuyau ou un conduit d’eau.

l Utiliser un VTVM ou VOM avec une sensibilite de

1000 ohms par volt ou plus ou mesurer la chute de

tension CA entre la resistance (voir diagramme).

METALLIQUES

l Deposer la connexion de la resistance & toutes les

pieces metalliques exposees ayant un parcours de

l-l

VL-RDl UJ

WARNING :TO REDUCETHE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE

THIS APPLIANCE TO WET LOCATIONS.

A

I

0

CAUTION: TO REDUCE THE RISK OF ELECTRIC

SHOCK. DO NOT REMOVE COVER. NO

USERSERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user of uninsulated

voltage within the unit that can cause dangerous electric shocks.

This symbol alerts the user that there are

important operating and maintenance instructions in the literature accompanying this unit.

CAUTION

This symbol mark means following.

For continued protection against fire haz-

ard, replace only with same type fuse.

(CPI ; 1.25A 24V, CP2; 1.25A 24V, CP3;

1.25A 24V)

Camcorder

only

All-ENTION: POUR REDUIRE LES RESQUES D’INCENDIE OU DE CHOC ELECTRIQUE,

NE PAS EXPOSER CET APPAREIL A LA PLUIE OU A L’HUMIDITE.

A

I

a

ATTENTION: AFIN DE REDUIRE LES RISQUES DE

CHOC ELECTRIQUE, NE PAS RETIRER LE

COUVERCLE, AUCUN ORGANE INTERNE

NE PEUT ETRE REPARE PAR

L’UTIUSATEUR, CONFIER L’APPAREIL A

UN DEPANNEUR QUALIFIE.

Ce symbole signale a I’utilisateur la presence

d’une tension non isolee a I’interieur de I’appareil

qui peut etre la cause de secousses electriques

dangereuses.

Ce symbole avertit I’utilisateur que des instructions importantes relatives a I’utilisation

et al’entretien se trouvent dans le manuel

accompagnant I’appareil.

ATPENTION

Ce symbole signifie que f’on devra uti- Camcorder

liser un fusible de meme type (CPl; seulement

1,25A 24V, CP2; 1,25A 24V, CP3; 1,25A

24V) pour assurer la securite.

1-2

VL-RDl U

/fj CAUTION

BEFORE BATTERY DESTROY

NICKEL-CADMIUM BAl-lERY

The following program is available in the United States. Please consult local environmental

authorities concerning the availability of this or other programs in your area.

The RBRCTM Seal

SHARP participates in the RBRCTM* Nickel-Cadmium Battery Recycling Program in the United

States. The RBRCTM Seal on our battery pack contained in our product indicates that SHARP is

voluntarily participating in an industry program to collect and recycle these batteries. The RBRCTM

program provides you with a convenient alternative to placing spent Nickel-Cadmium battery packs into

the trash or municipal waste stream, which is illegal in some areas. At the end of their useful life, the

Nickel-Cadmium battery can be dropped off at the nearest collection center for recycling. For information

on the nearest collection center, call I-800-8-BATTERY or your local recycling center. If you are located

outside the United States, contact your local authorities for information concerning proper disposal and/

or recycling of this battery. SHARP’s involvement in this program is part of our commitment to protecting

our environment and conserving natural resources.

[Footnote] *RBRCTM is trademark of the Rechargeable Battery Recycling Corporation.

.

NICKEL-METAL HYDRIDE BATTERY

LITHIUM or LITHIUM-ION BATTERY

SEALED LEAD BATTERY

Battery disposal

Contains the above (Rechargeable) Battery. must be recycled or disposed of properly.

Remove the Battery from the products and contact Federal or State Environmental Agencies for

information on recycling and disposal options.

1-3

VL-RDI U

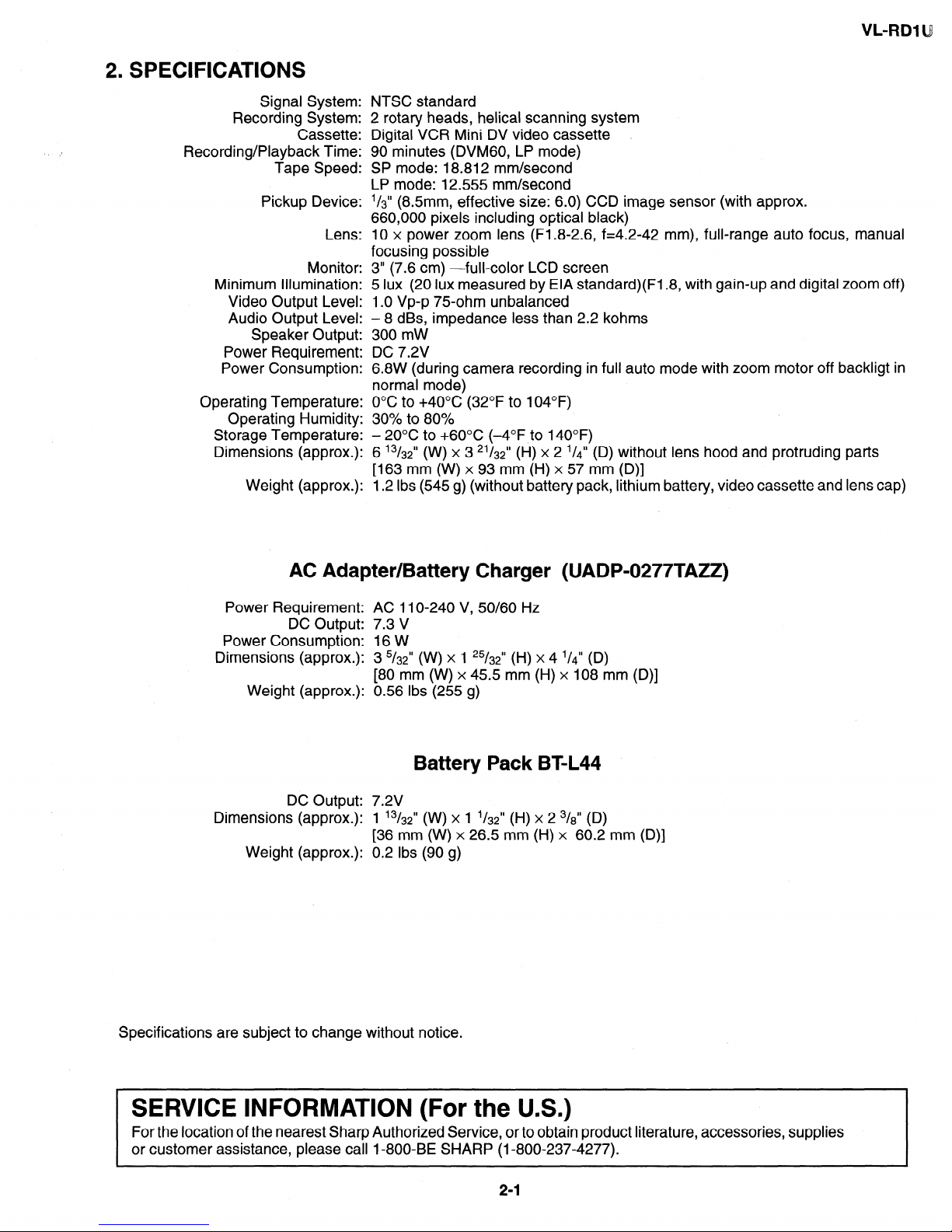

2. SPECIFICATIONS

Signal System:

Recording System:

Cassette:

Recording/Playback Time:

Tape Speed:

Pickup Device:

Lens:

Monitor:

Minimum Illumination:

Video Output Level:

Audio Output Level:

Speaker Output:

Power Requirement:

Power Consumption:

Operating Temperature:

Operating Humidity:

Storage Temperature:

Dimensions (approx.):

Weight (approx.):

NTSC standard

2 rotary heads, helical scanning system

Digital VCR Mini DV video cassette

I

90 minutes (DVMGO, LP mode)

SP mode: 18.812 mm/second

LP mode: 12.555 mm/second

l/3” (8.5mm, effective size: 6.0) CCD image sensor (with approx.

660,000 pixels including optical black)

10 x power zoom lens (F1.8-2.6, f=4.2-42 mm), full-range auto focus, manual

focusing possible

3” (7.6 cm) -full-color LCD screen

5 lux (20 lux measured by EIA standard)(Fl.8, with gain-up and digital zoom off)

1 .O Vp-p 75-ohm unbalanced

- 8 dBs, impedance less than 2.2 kohms

300 mW

DC 7.2V

6.8W (during camera recording in full auto mode with zoom motor off backligt in

normal mode)

0°C to +4O”C (32°F to 104°F)

30% to 80%

- 20°C to +6O”C (-4°F to 140°F)

6 13/3$ (W) x 3 21/3$ (H) x 2 I/$’ (D) without lens hood and protruding parts

[I63 mm (W) x 93 mm (H) x 57 mm (D)]

1.2 Ibs (545 g) (without battery pack, lithium battery, video cassette and lens cap)

AC Adapter/Battery Charger (UADP-0277TAZZ)

Power Requirement: AC 11 O-240 V, 50/60 Hz

DC Output: 7.3 V

Power Consumption: 16 W

Dimensions (approx.): 3 5/32” (W) x 1 25/32” (H) x 4 l/d” (D)

[80 mm (W) x 45.5 mm (H) x 108 mm (D)]

Weight (approx.): 0.56 Ibs (255 g)

Battery Pack BT-L44

DC Output: 7.2V

Dimensions (approx.): 1 ‘3/32” (w) x 1 ‘/32” (H) x 2 3/$ (D)

[36 mm (W) x 26.5 mm (H) x 60.2 mm (D)]

Weight (approx.): 0.2 Ibs (90 g)

Specifications are subject to change without notice.

1 SERVICE INFORMATION (For the U.S.)

I

For the location of the nearest Sharp Authorized Service, or to obtain product literature, accessories, supplies

or customer assistance, please call I-800-BE SHARP (I-800-237-4277).

2-1

VL-RDl U

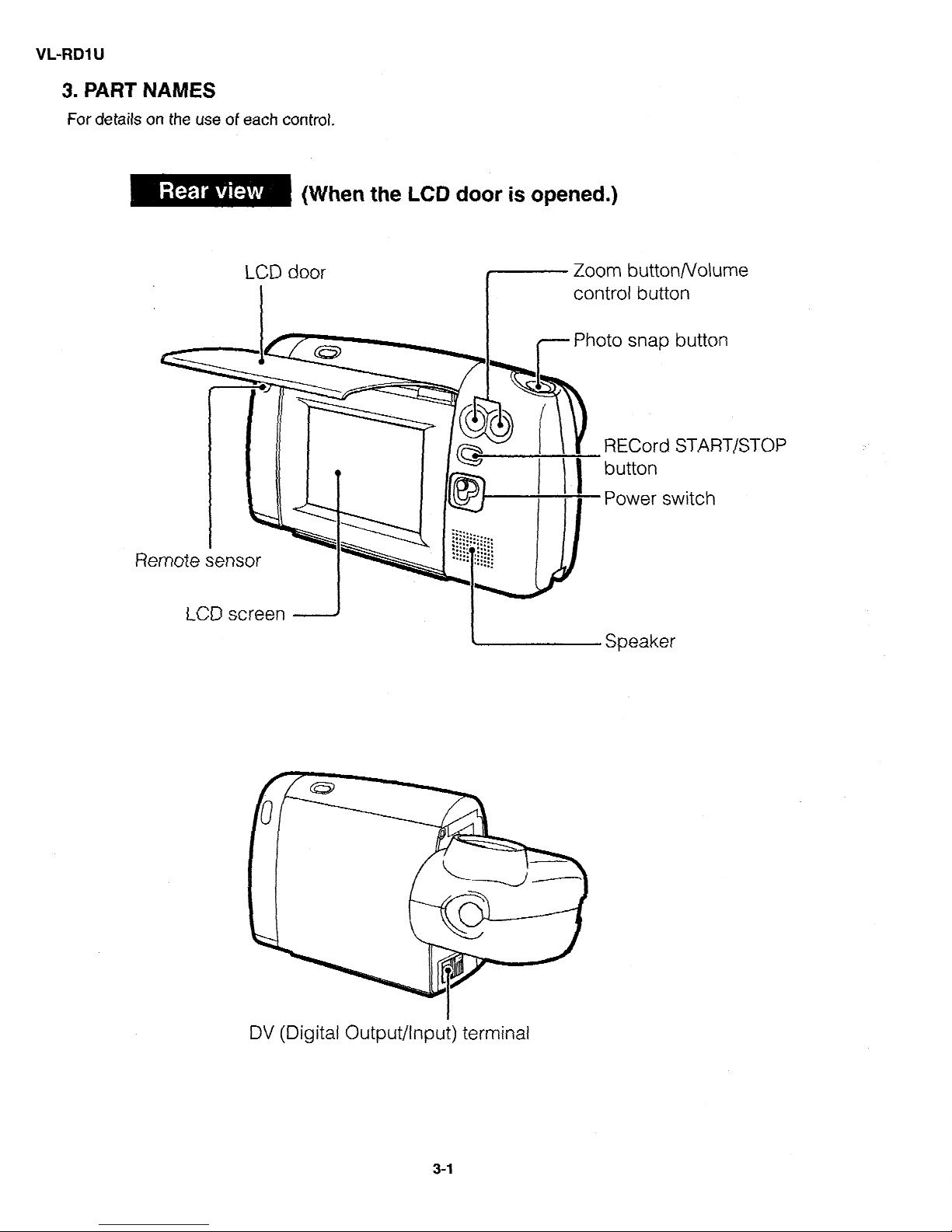

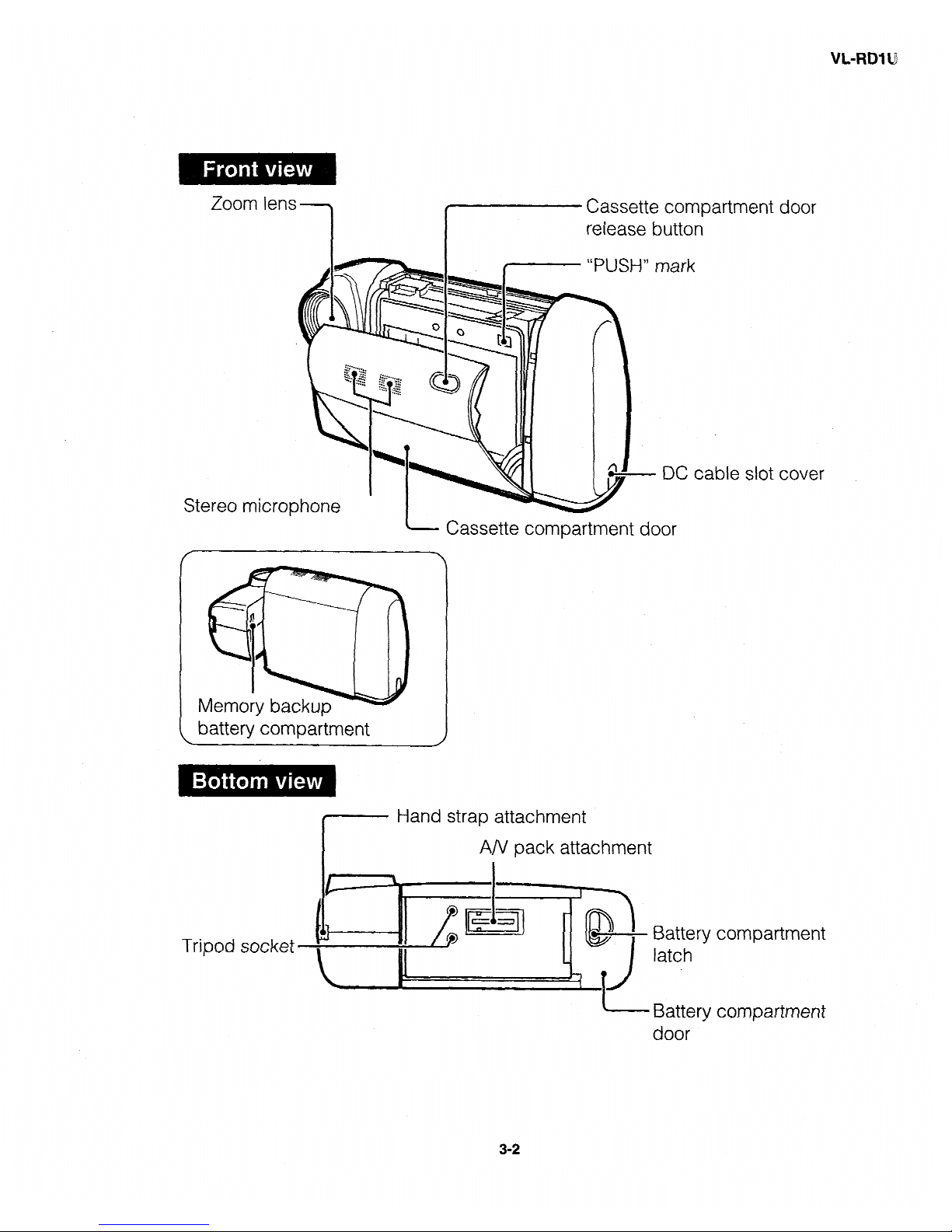

3. PART NAMES

For details on the use of each control.

Zoom button/Volume

Photo

snap button

RECord START/STOP

Remote sensor

DV (Digital Output/Input) terminal

3-1

VL-RDI

U

Zoom

Stereo

t-r

lens

1

micro

lark

DC

Cassette compartment door

partment door

1

cable slot cover

battery compartment

I----- Hand strap attachment

I

A/V pack attachment

Tripod socket

Battery compartment

latch

Battery compartment

door

VL-RDl U

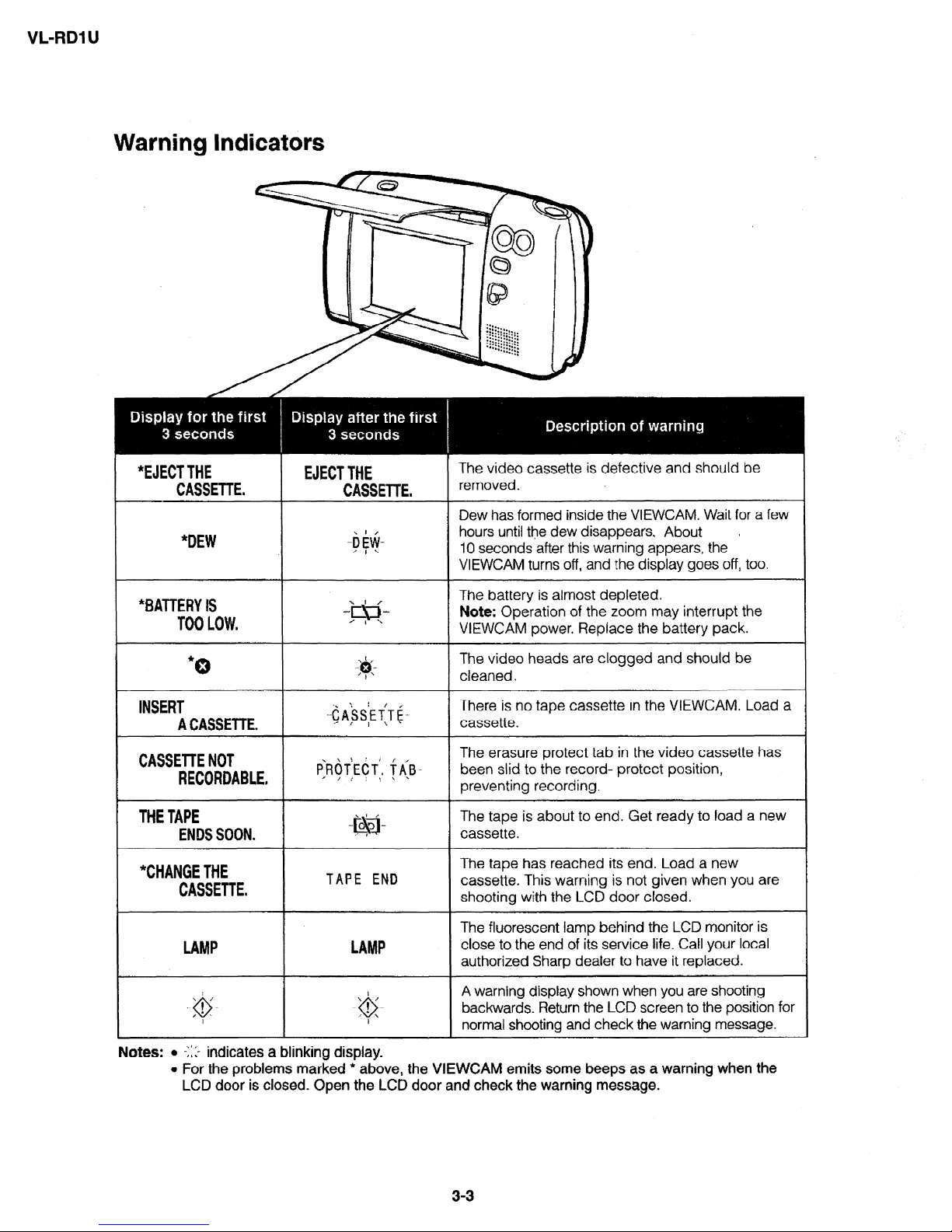

Warning Indicators

*EJECTTHE

EJECTTHE

CASSETTE.

CASSETTE.

The video cassette is defective and should be

removed.

*DEW

j Dew has formed inside the VIEWCAM. Wait for a few

hours until the dew disappears. About

I

IO seconds after this .warning appears, the

VIEWCAM turns off, and the display goes off, too,

*BATTERY6

TOOLOW.

/

-“Y!.!-

’ I L

The battery is almost depleted.

Note: Operation of the zoom may interrupt the

VIEWCAM power. Replace the battery pack.

*

0

The video heads are clogged and should be

cleaned.

INSERT

ACASSETTE.

There is no tape cassette in the VIEWCAM. Load a

cassette.

CASSElTENOT

RECORDABLE,

The erasure protect tab in the video cassette has

been slid to the record- protect position,

preventing recording.

THETAPE

ENDSSOON. (

The tape is about to end. Get ready to load a new

cassette.

"CHANGETHE

CASSETTE.

TAPE END

The tape has reached its end. Load a new

cassette. This warning is not given when you are

shooting with the LCD door closed.

LAMP

The fluorescent lamp behind the LCD monitor is

close to the end of its service life. Call your local

authorized Sharp dealer to have it replaced.

. . ’ 1

‘...

9

, l . .

.- ’ ; t._

0

:-

2

A warning display shown when you are shooting

backwards_ Return the LCD screen to the position for

normal shooting and check the warning message.

Notes: l -1: :.-

indicates a blinking display.

l For the problems marked * above, the VIEWCAM emits some beeps as a warning when the

LCD door is closed. Open the LCD door and check the warning message.

3-3

VL-RDl lJ

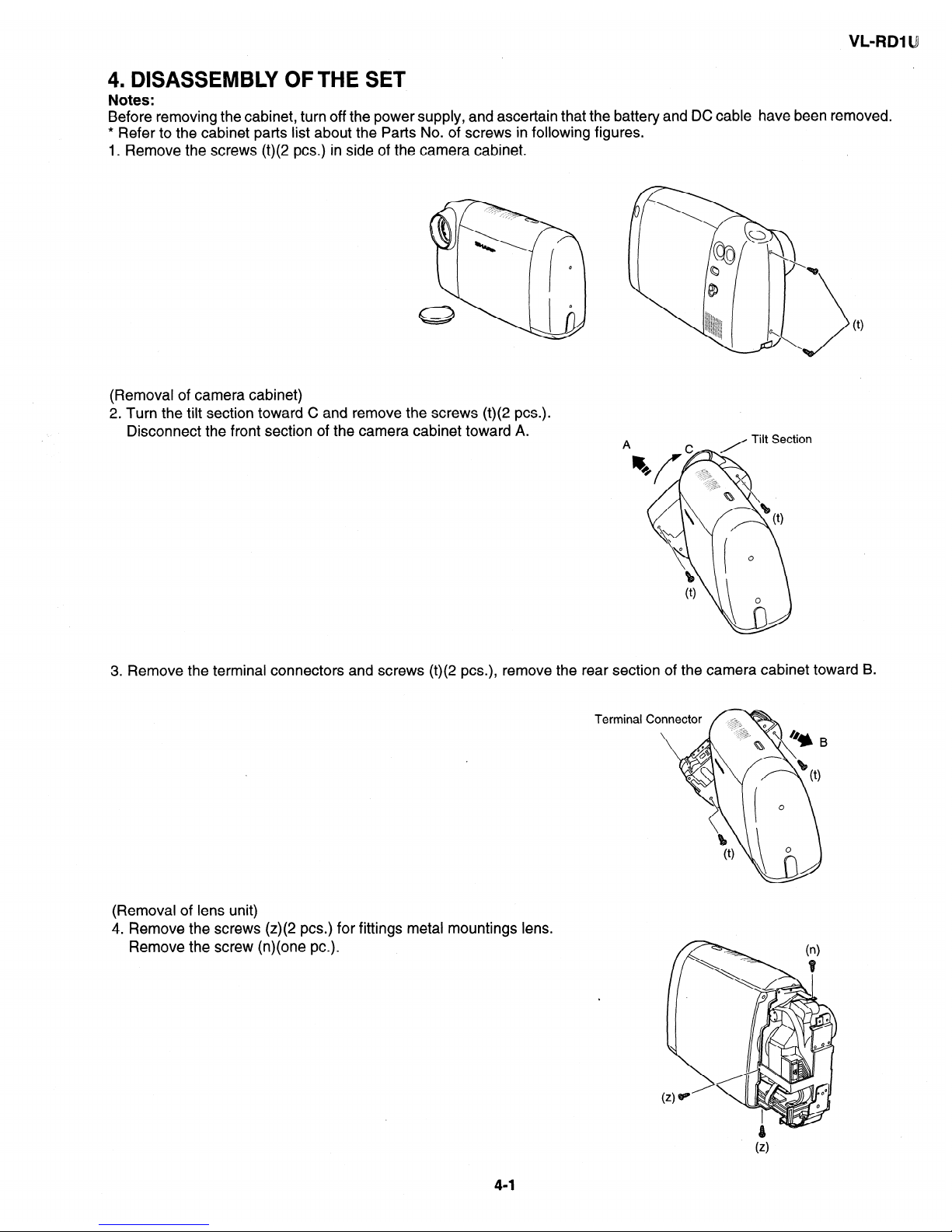

4. DISASSEMBLY OFTHE SET

Notes:

Before removing the cabinet, turn off the power supply, and ascertain that the battery and DC cable have been removed.

* Refer to the cabinet parts list about the Parts No. of screws in following figures.

1. Remove the screws (t)(2 PCS.) in side of the camera cabinet.

(Removal of camera cabinet)

2. Turn the tilt section toward C and remove the screws (t)(2 PCS.).

Disconnect the front section of the camera cabinet toward A.

(0

3. Remove the terminal connectors and screws (t)(2 PCS.), remove the rear section of the camera cabinet toward B.

Terminal

(Removal of lens unit)

4. Remove the screws (z)(2 PCS.) for fittings metal mountings lens.

Remove the screw (n)(one PC.).

4-1

VL-RDl U

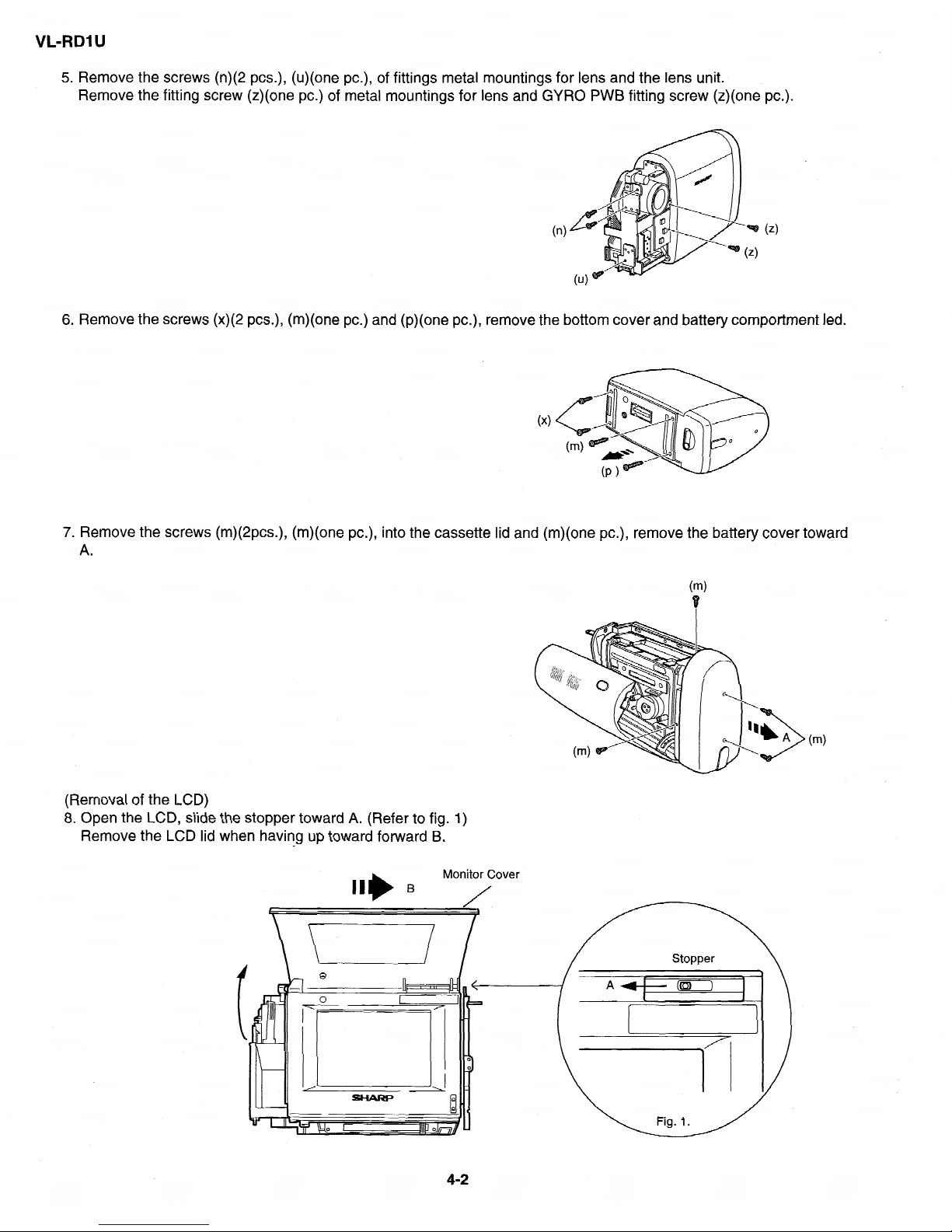

5. Remove the screws (n)(2

PCS.),

(u)(one

PC.), of

fittings metal mountings for

lens and the

lens unit.

Remove the fitting screw

(z)(one

PC.) of metal mountings for

lens

and GYRO PWB

fitting

screw (z)(one

PC.).

( >

n

6. Remove

the screws

(x)(2

PCS.), (m)(one PC.) and (p)(one

PC.),

remove the

bottom

cover

and battery comportment led.

7. Remove

the screws (m)(2pcs.), (m)(one PC.),

into the cassette lid and (m)(one PC.),

remove the battery cover toward

A.

( )

m

t

( >

m

(Removal of the LCD)

8. Open the LCD, slide the stopper toward A. (Refer to fig. 1)

Remove the LCD lid when having up toward forward B.

Monitor Cover

B

I

/

Stopper

\

4-2

VL-RI31 UJ

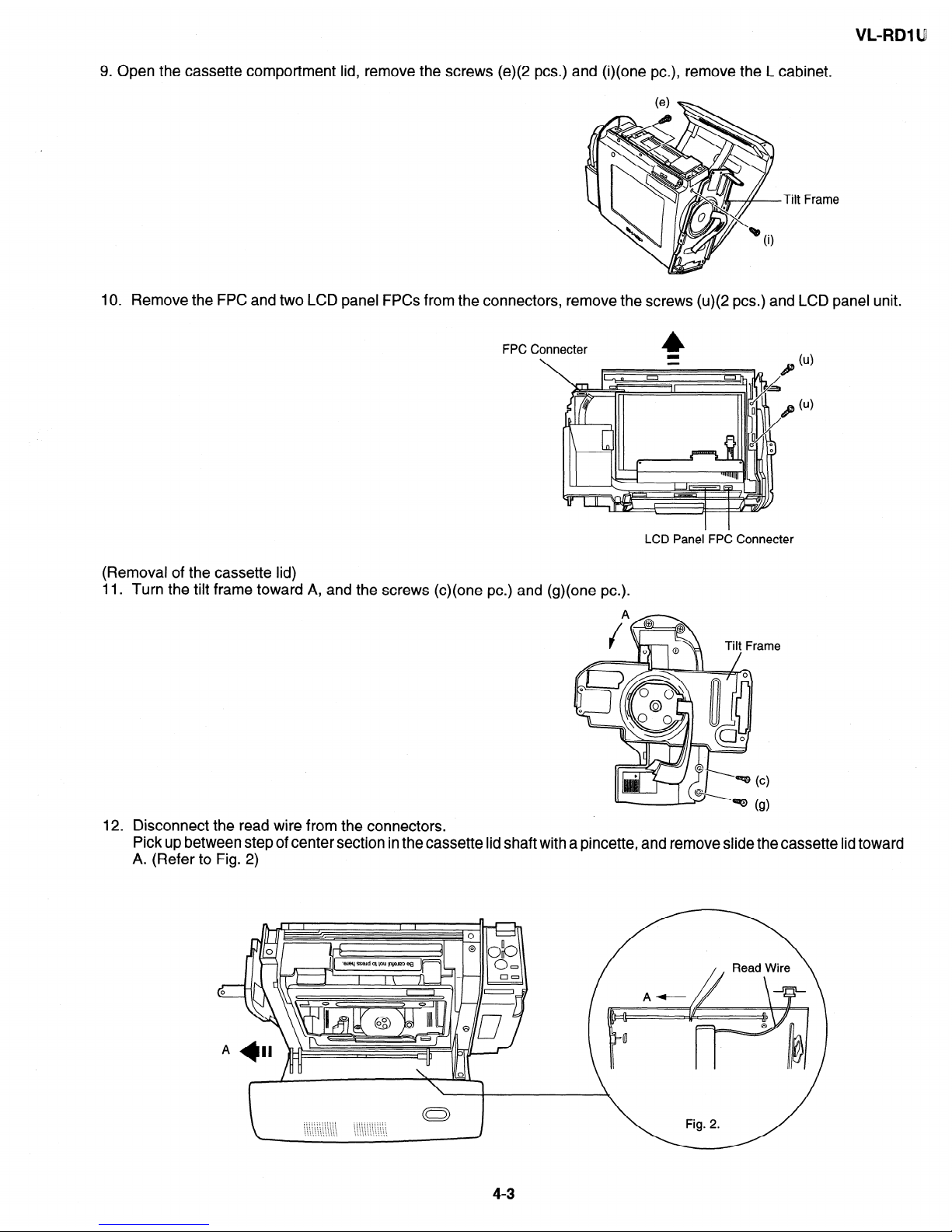

9. Open the cassette comportment lid, remove the screws (e)(2 PCS.) and (i)(one PC.), remove the L cabinet.

Tilt Frame

10. Remove the FPC and two LCD panel FPCs from the connectors, remove the screws (u)(2 PCS.) and LCD panel unit.

FPC Conn

\

ecter

LCD Panel FPC Connecter

(Removal of the cassette lid)

11. Turn the tilt frame toward A, and the screws (c)(one PC.) and (g)(one PC.).

ie

12. Disconnect the read wire from the connectors.

Pick up between step of center section in the cassette lid shaft with a pincette, and remove slide the cassette lid toward

A. (Refer to Fig. 2)

c

0

A

4-3

VL-RDl U

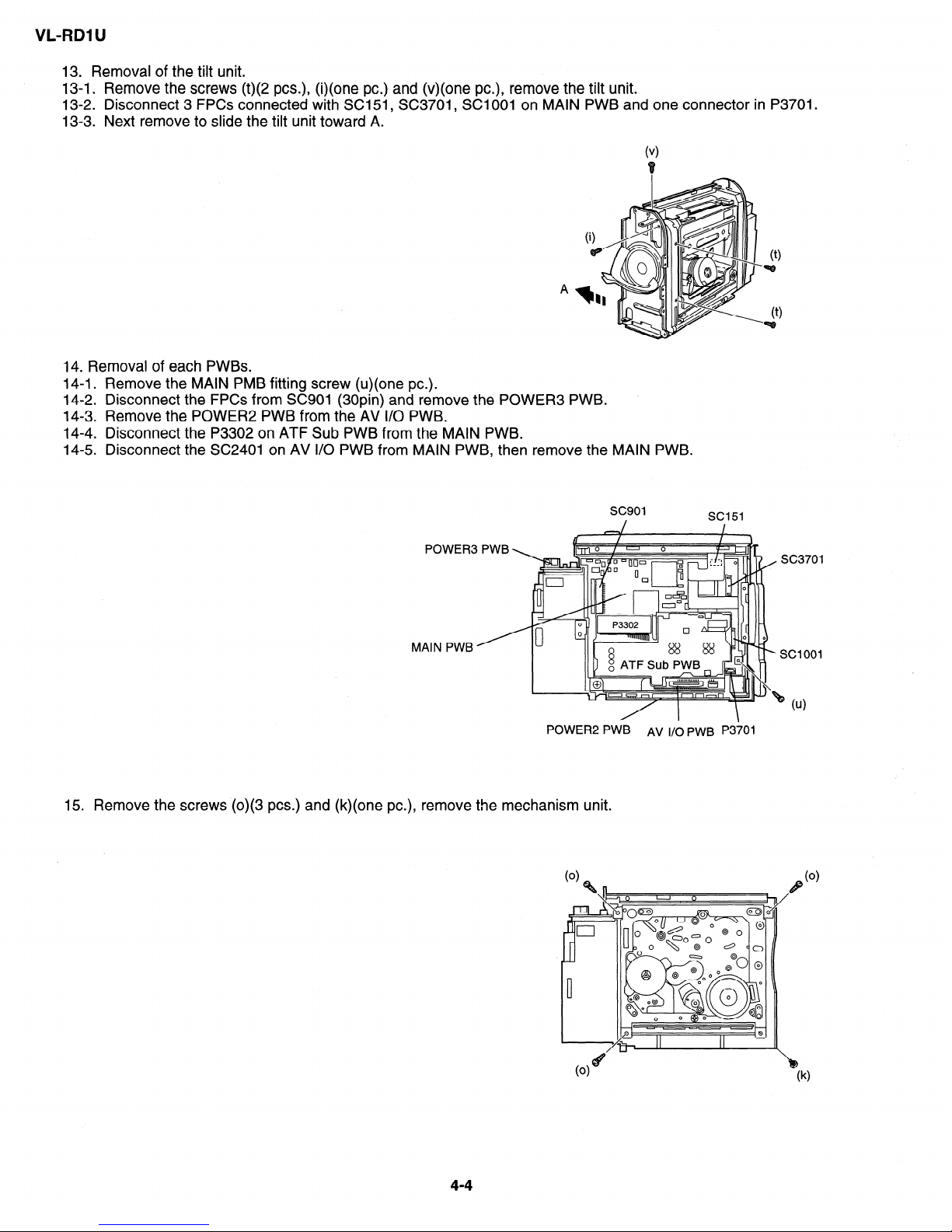

13. Removal of the tilt unit.

13-1. Remove the screws (t)(2 PCS.), (i)(one PC.) and (v)(one PC.), remove the tilt unit.

13-2. Disconnect 3 FPCs connected with SC151, SC3701, SC1 001 on MAIN PWB and one connector in P3701.

13-3. Next remove to slide the tilt unit toward A.

( 1

v

I?

(9

w

A

(9

T9

14. Removal of each PWBs.

14-1. Remove the MAIN PMB fitting screw (u)(one PC.).

14-2. Disconnect the FPCs from SC901 (30pin) and remove the POWER3 PWB.

14-3. Remove the POWER2 PWB from the AV I/O PWB.

14-4. Disconnect the P3302 on ATF Sub PWB from the MAIN PWB.

14-5. Disconnect the SC2401 on AV I/O PWB from MAIN PWB, then remove the MAIN PWB.

POWER3 PWB

MAIN PWB’

POWER2 PWB

AV i/O PWB P3701

15. Remove the screws (0)(3 PCS.) and (k)(one PC.), remove the mechanism unit.

4-4

VL-RDl U

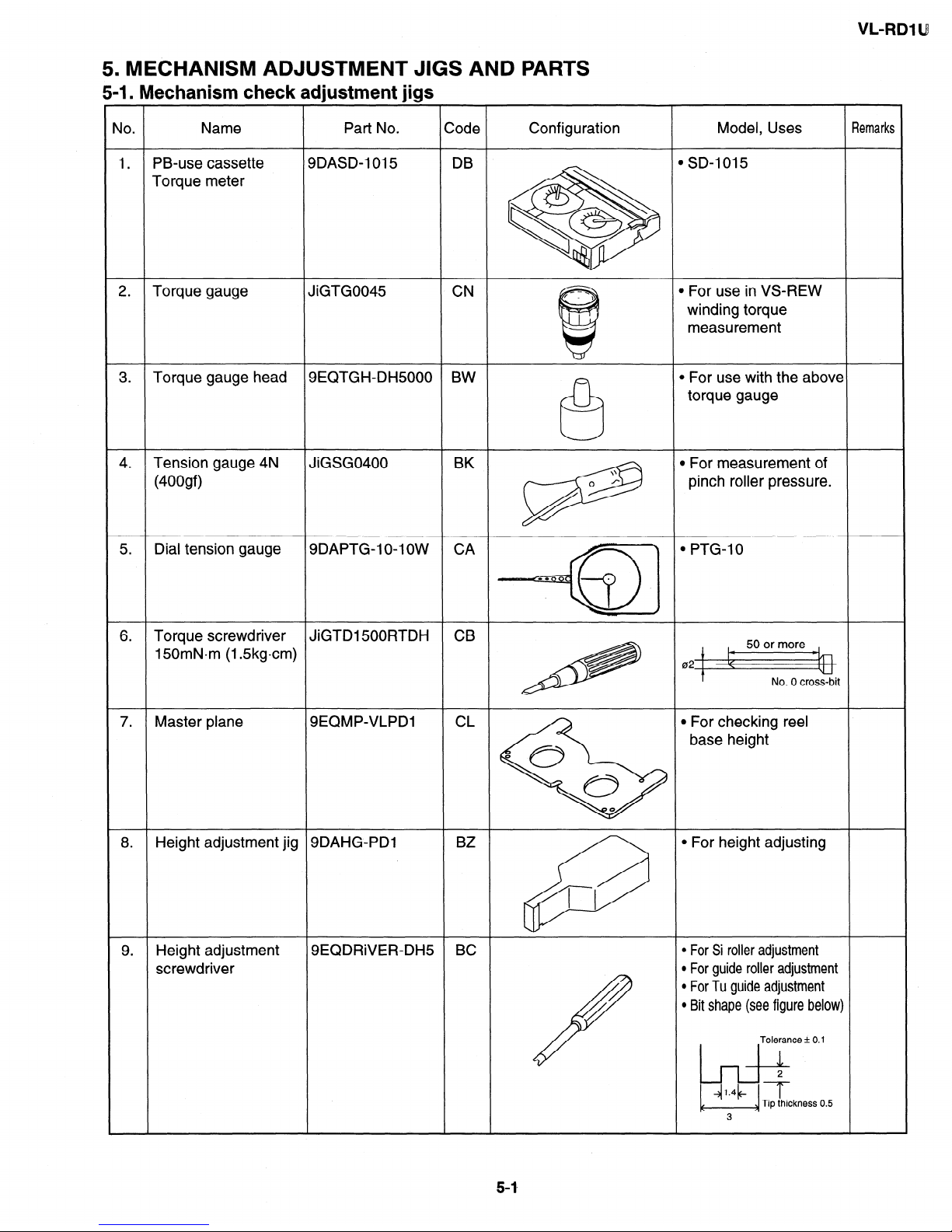

5. MECHANISM ADJUSTMENT JIGS AND PARTS

5-1. Mechanism check adjustment jigs

Name

Part No. ;ode

Configuration

Model, Uses

\lO.

lemarks

1. PB-use cassette

Torque meter

)DASD-1015 DB

1 SD-l 015

2. Torque gauge

JiGTG0045 CN

1 For use in VS-REW

winding torque

measurement

3. Torque gauge head

3EQTGH-DH5000 BW

b For use with the above

torque gauge

4.

Tension gauge 4N

(400gf)

JiGSG0400 BK

B For measurement of

pinch roller pressure.

\\

0 /*

P@

5. Dial tension gauge

CA

b PTG-10

3DAPTG-1 O-l OW

6. Torque screwdriver

150mNom (1.5kgcm)

JiGTD1500RTDH CB

I

50 or more

b-q-j

021 1

No. 0 cross-bit

7. Master plane

SEQMP-VLPDI CL

0

0

\

0

0

l For checking reel

base height

8. Height adjustment jig

SDAHG-PDI

BZ

l For height adjusting

66

1 I

9. Height adjustment

screwdriver

9EQDRiVER-DH5 BC

l For Si roller adjustment

l For guide roller adjustment

l For Tu guide adjustment

l Bit shape (see figure below

/

Tolerance & 0.1

Tip thickness 0.5

3

VL-RDl U

(3) Radio needle-nose pliers

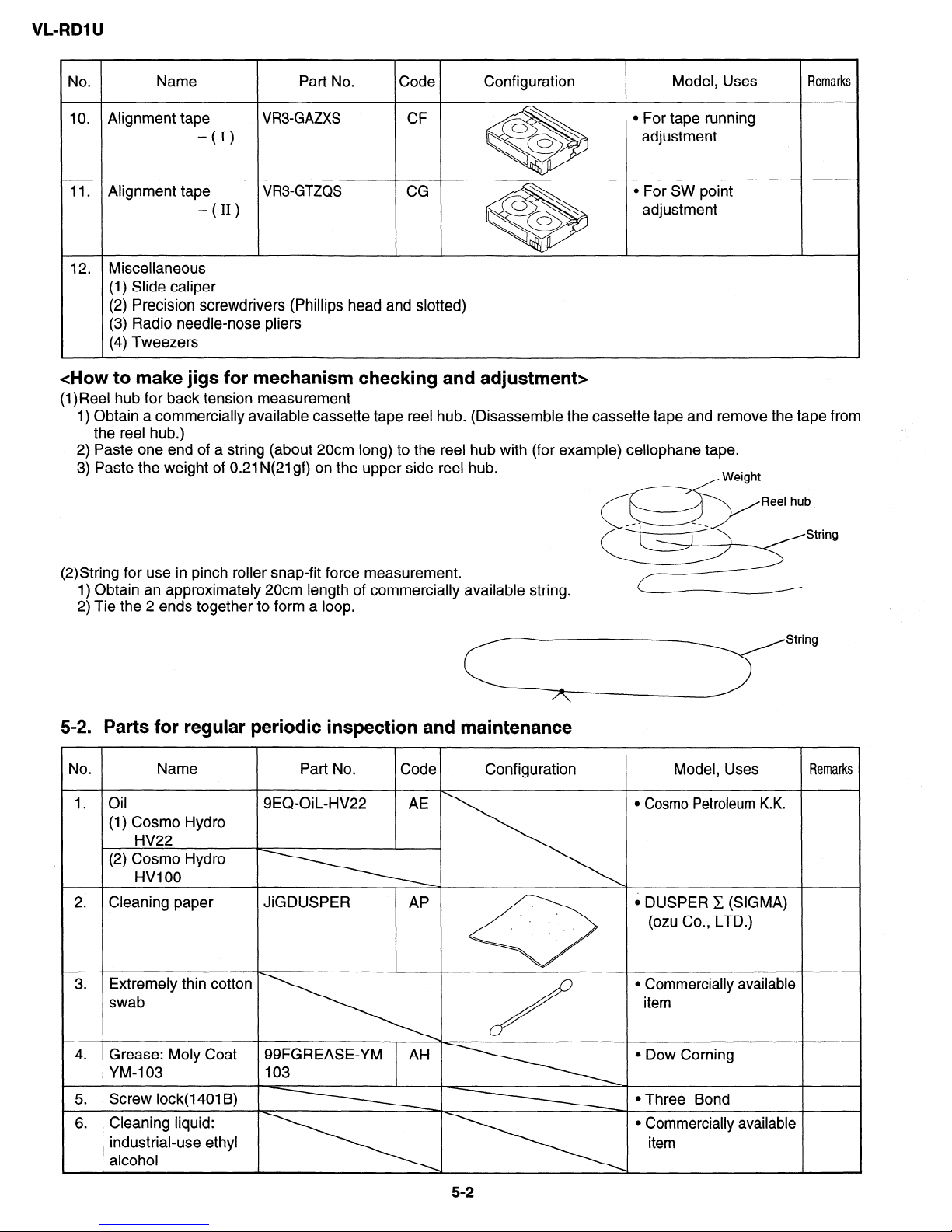

<How to make jigs for mechanism checking and adjustment>

(1)Reel hub for back tension measurement

1) Obtain a commercially available cassette tape reel hub. (Disassemble the cassette tape and remove the tape from

the reel hub.)

2) Paste one end of a string (about 20cm long) to the reel hub with (for example) cellophane tape.

3) Paste the weight of 0.21 N(21gf) on the upper side reel hub.

(2)String for use in pinch roller snap-fit force measurement.

1) Obtain an approximately 20cm length of commercially available string.

2) Tie the 2 ends together to form a loop.

5-2. Parts for regular periodic inspection and maintenance

Jo.

Name

1. . 011

(1) Cosmo Hydro

HV22

(2) Cosmo Hydro

HVI 00

2. Cleaning paper

Part No. Code

Configuration

Model, Uses

Remarks

9EQ-OiL-HV22 AE

l Cosmo Petroleum K.K.

JiGDUSPER

AP

6 DUSPER C (SIGMA)

. . .

. .

*

(ozu Co., LTD.)

. .

\

3.

Extremely thin cotton

swab

\ /

l Commercially available

item

4. Grease: Moly Coat 99FGREASE-YM AH

l Dow Corning

YM-103 103

5.

Screw lock(l401 B)

l Three Bond

6. Cleaning liquid:

l Commercially available

industrial-use ethyl

alcohol

VL-RDl lJ

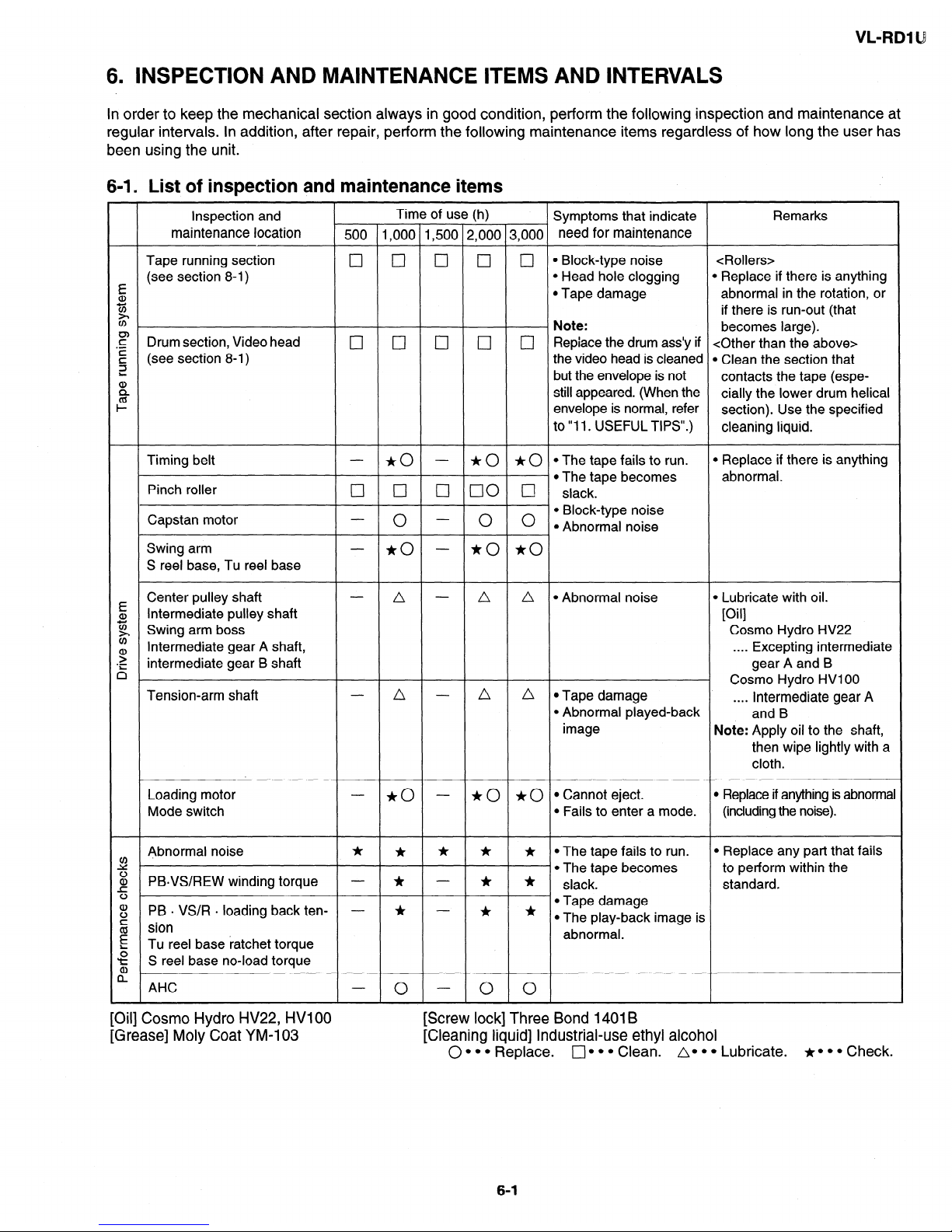

6. INSPECTION AND MAINTENANCE ITEMS AND INTERVALS

In order to keep the mechanical section always in good condition, perform the following inspection and maintenance at

regular intervals. In addition, after repair, perform the following maintenance items regardless of how long the user has

been using the unit.

6-l. List of inspection and maintenance items

Inspection and

Time of use (h)

Symptoms that indicate

Remarks

maintenance location

500 1,000 1,500 2,000 3,000 need for maintenance

Tape running section

cl q q

q

cl

l Block-type noise <Rollers>

E

(see section 8-1)

l Head hole clogging

l Replace if there is anything

a,

l Tape damage

abnormal in the rotation, or

z

z?

if there is run-out (that

Note:

F

becomes large).

.-

Drum section, Video head

0 17 [7 0

E

0 Repiace the drum ass’y if <Other than the above>

the video head is cleaned l Clean the section that

3

(see section 8-l)

:

but the envelope is not

contacts the tape (espe-

%

still appeared. (When the

cially the lower drum helical

I-

envelope is normal, refer

section). Use the specified

to “11. USEFUL TIPS”.)

cleaning liquid.

Timing belt

- *o -

* 0 * 0 l The tape fails to run.

l Replace if there is anything

abnormal.

Pinch roller

III 0 q 00 @

- l The tape becomes

slack.

Capstan motor

0

0 0

l Block-type noise

l Abnormal noise

Swing arm

- *o

- *o *o

S reel base, Tu reel base

E

Center pulley shaft

a,

Intermediate pulley shaft

5

g Swing arm boss

g

Intermediate gear A shaft,

‘iT:

intermediate gear B shaft

n

Tension-arm shaft

A - A a @Abnormal noise l Lubricate with oil.

[O II

i

Cosmo Hydro HV22

. . . . Excepting intermediate

gear A and B

Cosmo Hydro HVIOO

n - a a l Tape damage

. . . . Intermediate gear A

l Abnormal played-back

and B

image

Note: Apply oil to the shaft,

then wipe lightly with a

cloth.

Loading motor

- *o -

* 0 * 0 l Cannot eject.

l Replace if anything is abnormal

Mode switch l Fails to enter a mode.

(including the noise).

Abnormal noise

:

Ir * * * jt .The tape fails to run.

l Replace any part that fails

l The tape becomes

to perform within the

:

PBYS/REW winding torque - Ir - * *

slack.

standard.

a>

PB + VS/R . loading back ten- - * - * *

l Tape damage

:

sion

l The play-back image is

g

abnormal.

5

Tu reel base ratchet torque

‘t 2 S reel base no-load torque

AHC

0

0

0

[Oil] Cosmo Hydro HV22, HVIOO [Screw lock] Three Bond 1401 B

[Grease] Moly Coat YM-103 [Cleaning liquid] Industrial-use ethyl alcohol

0 l l l Replace.

q l l l Clean. A. l l Lubricate.

+P l l Check.

6-1

VL-RDl U

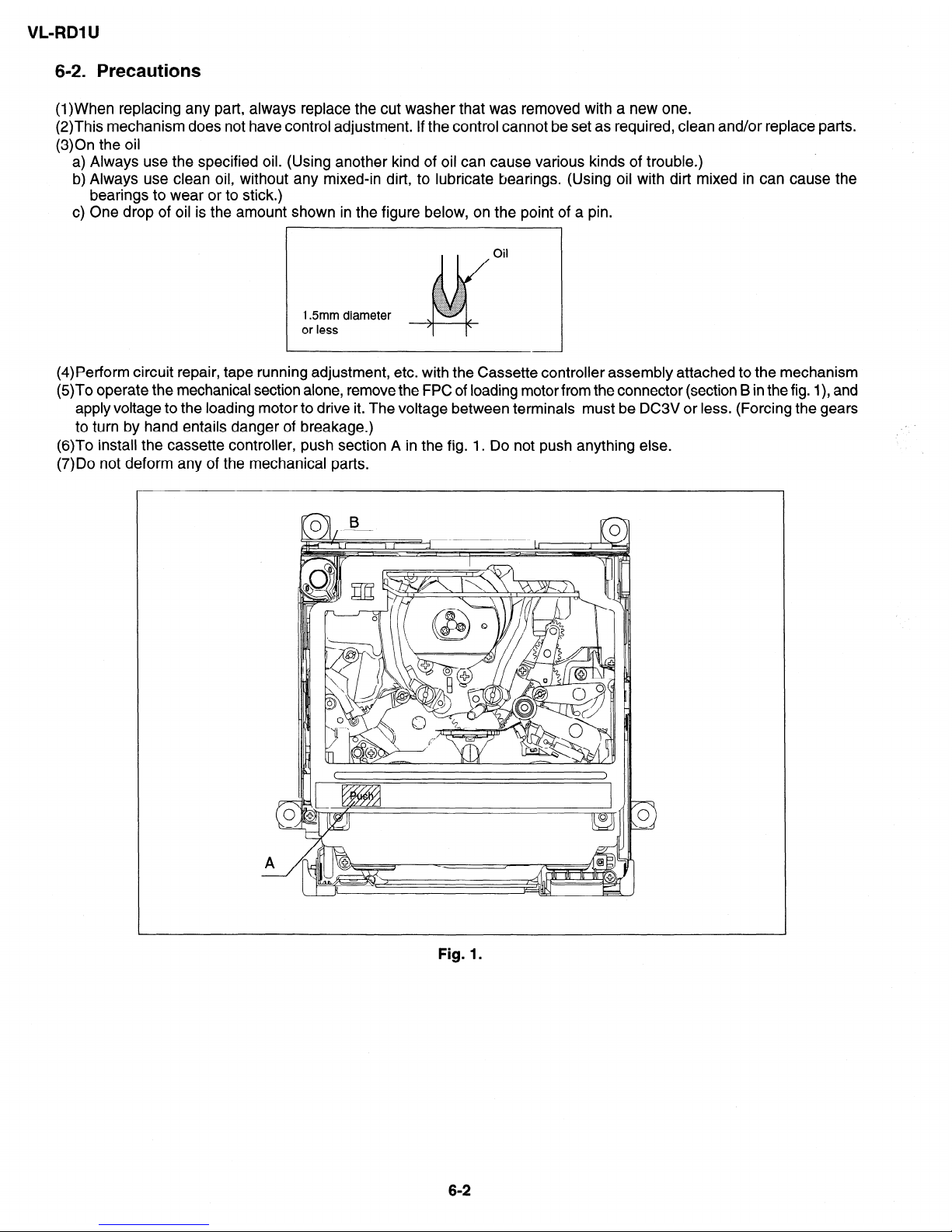

6-2. Precautions

(l)When replacing any part, always replace the cut washer that was removed with a new one.

(2)This mechanism does not have control adjustment. If the control cannot be set as required, clean and/or replace parts.

(3)On the oil

a) Always use the specified oil. (Using another kind of oil can cause various kinds of trouble.)

b) Always use clean oil, without any mixed-in dirt, to lubricate bearings. (Using oil with dirt mixed in can cause the

bearings to wear or to stick.)

c) One drop of oil is the amount shown in the figure below, on the point of a pin.

.:.:

..:.:.

::::

. .

.::::::. .g.

.:.:.:;

N

::;:3;:>:

j j::::

,.;:z::.:

::::: j::::. ,.,...,...

.~.~.~.~.~.: .::::~.:.:.~

. . . ..L...

1.5mm diameter

?:Z:C, .Z:F

..:.:::::y..

or less

Oil

(4)Perform circuit repair, tape running adjustment, etc. with the Cassette controller assembly attached to the mechanism

(5)To operate the mechanical section alone, remove the FPC of loading motor from the connector (section B in the fig. I), and

apply voltage to the loading motor to drive it. The voltage between terminals must be DC3V or less. (Forcing the gears

to turn by hand entails danger of breakage.)

(6)To install the cassette controller, push section A in the fig. 1. Do not push anything else.

(7)Do not deform any of the mechanical parts.

Fig. 1.

6-2

VL-RDl U

7. MECHANICAL ADJUSTMENTS AND CHECKS

The items discussed here relate to general on-site servicing (field servicing). Adjustments and replacements that require

sophisticated facilities, jigs and technology are omitted.

1 n addition, in order to maintain the characteristics that the unit has when it is new, not only are inspection and maintenance

necessary, but it is absolutely necessary that, for example, the tape not be damaged, and always use jigs for adjustments

that require them.

<Precautions>

(1) Always set the power supply and state of the unit as follows for mechanism adjustments and checks.

1 AC adapter used, with cassette controller assembly 1

07-l Checking the playback (recording) winding torque

07-4 Back tension torque check and adjustment in record (playback) mode

1 AC adapter used, without cassette controller assembly (Independent Mechanism) 1

07-2 Checking the rewinding playback (VS-REW) winding torque

1 DC3V, without cassette controller assembly (Independent Mechanism) 1

07-3 Checking of reel base height

l 7-5 Checking and adjustment of tension roller position in record (playback) mode

07-6 Checking of supply S reel base no-load torque

07-7 Checking of loading back tension

07-8 Checking of winding Tu reel base ratchet torque

07-9 Checking of rewinding playback (VS-REW) back tension

07-10 Checking of pinch pressing force

(2) When performing checks with a DC3V power supply and independent mechanism, disconnect the loading motor

FPC from the connector.

(3) Always run the tape with the cassette controller assembly attached.

7-I. Checking the playback (recording) winding torque

(1)Set the torque cassette with the cassette controller assembly attached, then, in SP recording mode (playback mode

if a signal has already been recorded in SP mode on the tape), confirm that the torque on the winding side is within the

standard.

Winding torque standard in record (playback) mode

0.70 + 0.35mN.m (7.0 + 3.5gfocm),

ripple 0.2mN.m (2gfcm) or less

(If there is torque ripple, read the center value.)

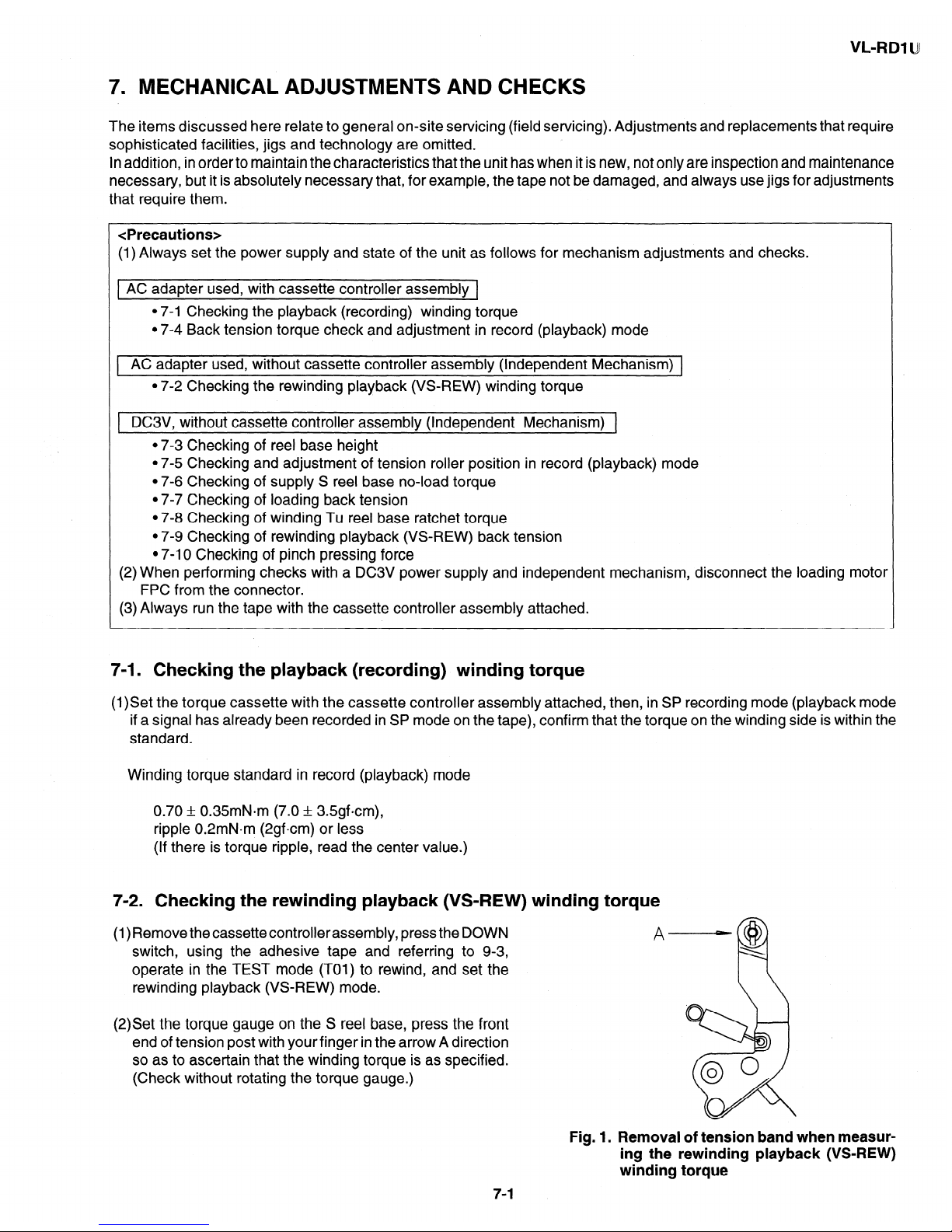

7-2. Checking the rewinding playback (VS-REW) winding torque

(l)Remove thecassettecontrollerassembly, pressthe DOWN

switch, using the adhesive tape and referring to 9-3,

operate in the TEST mode (TOI) to rewind, and set the

rewinding playback (VS-REW) mode.

(2)Set the torque gauge on the S reel base, press the front

end of tension post with your finger in the arrow A direction

so as to ascertain that the winding torque is as specified.

(Check without rotating the torque gauge.)

Fig. 1. Removal of tension band when measur-

ing the rewinding playback (VS-REW)

winding torque

7-1

VL-RDl U

Rewinding playback (VS-REW) winding torque standard

1.6 + O.GmN*m (16 + Ggfcm),

ripple 0.4mN.m (4gfcm) or less

(If torque ripple exists, read its center value.)

(3) After checking the winding torque remove the torque gauge, and remove the adhesive tape used in item (1) above (refer

to 9-3). The STANDBY mode is set automatically.

7-3. Checking of reel base height

(l)Remove the cassette controller assembly (refer to 9-2).

(2)Referring to 9-1, apply DC3V to the loading motor and put the system into playback mode.

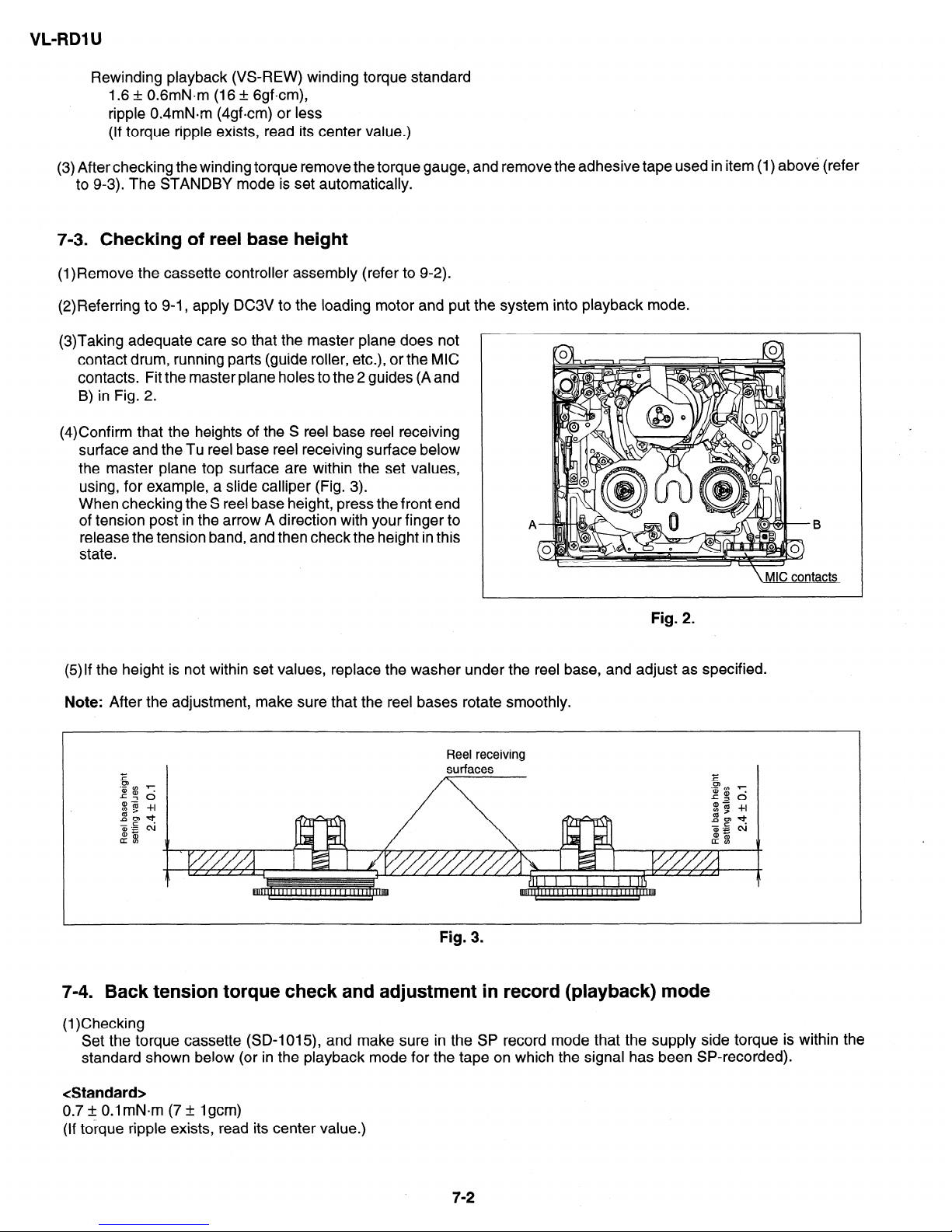

(3)Taking adequate care so that the master plane does not

contact drum, running parts (guide roller, etc.), or the MIC

contacts. Fit the master plane holes to the 2 guides (A and

B) in Fig. 2.

(4)Confirm that the heights of the S reel base reel receiving

surface and the Tu reel base reel receiving surface below

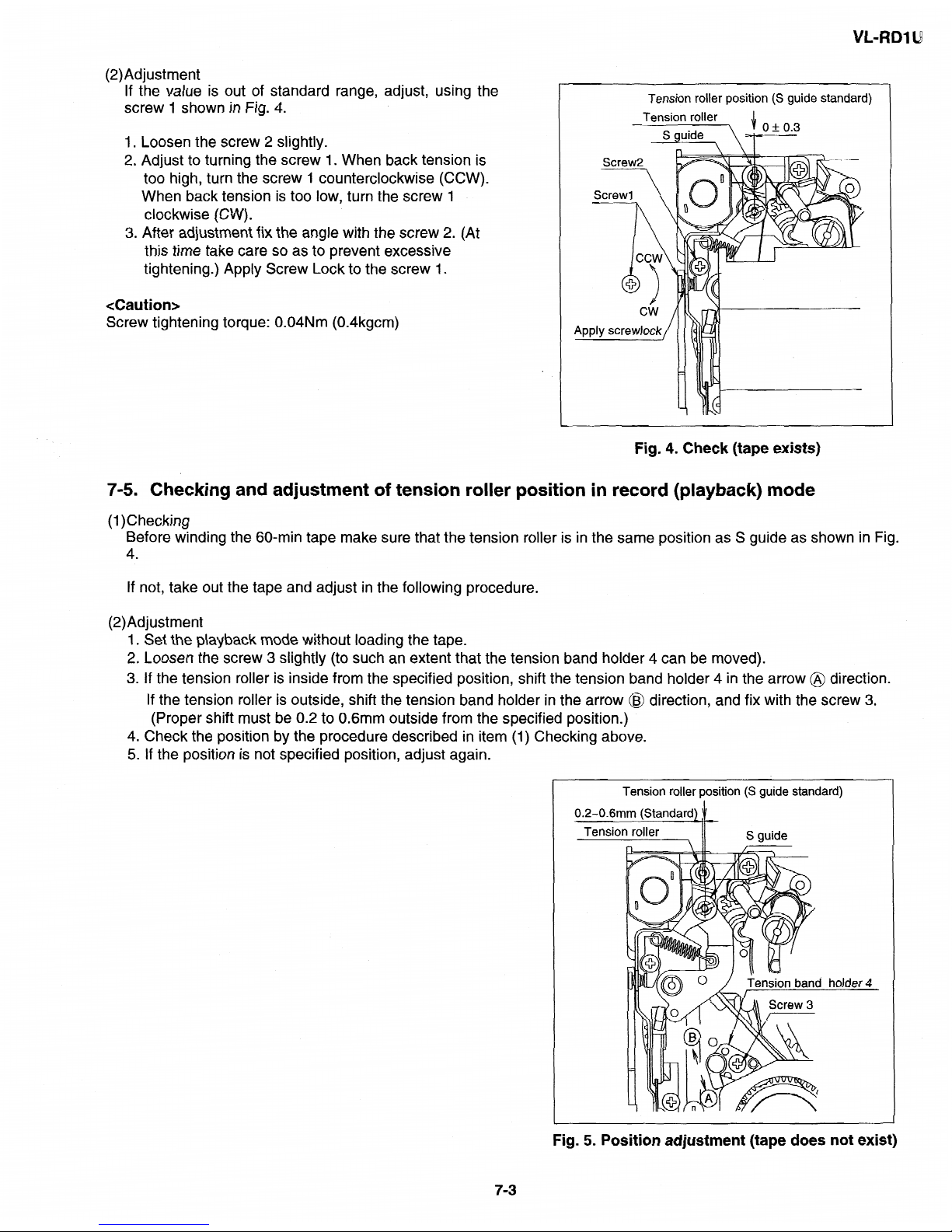

the master plane top surface are within the set values,

using, for example, a slide calliper (Fig. 3).

When checking the S reel base height, press the front end

of tension post in the arrow A direction with your finger to

release the tension band, and then check the height in this

state.

Fig. 2.

(5)If the height is not within set values, replace the washer under the reel base, and adjust as specified.

Note: After the adjustment, make sure that the reel bases rotate smoothly.

Reel receiving

surfaces

Fig. 3.

7-4. Back tension torque check and adjustment in record (playback) mode

(1)Checking

Set the torque cassette (SD-l015), and make sure in the SP record mode that the supply side torque is within the

standard shown below (or in the playback mode for the tape on which the signal has been SP-recorded).

<Standard>

0.7 + 0.1 mN*m (7 + 1 gem)

(If torque ripple exists, read its center value.)

7-2

VL-RDl L4

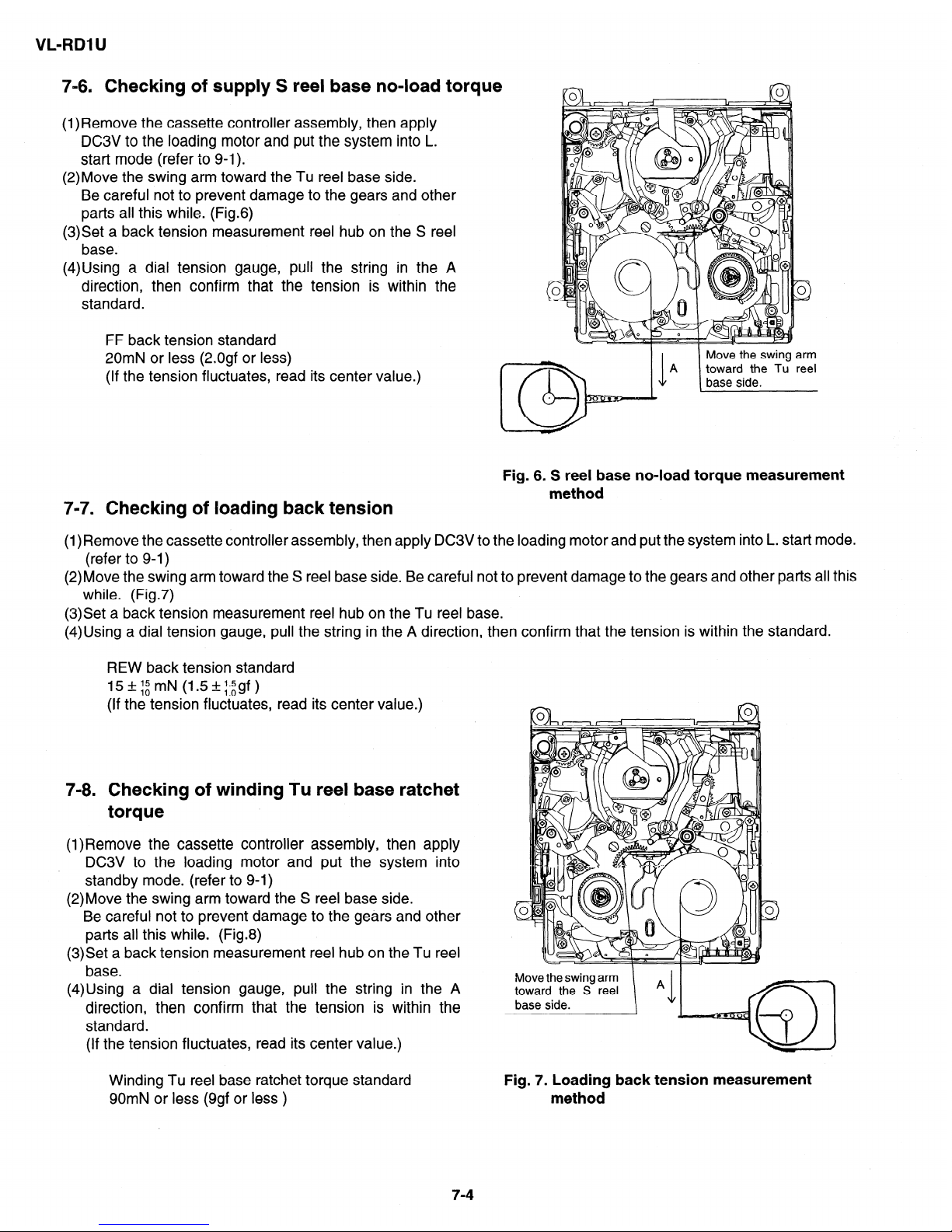

(2)Adjustment

If the value is out

of standard range, adjust, using the

screw

1 shown in Fig. 4.

Loosen the screw 2 slightly.

Adjust to turning the screw 1. When back tension is

too high, turn the screw 1 counterclockwise (CCW).

When back tension

is

too

low, turn the screw I

clockwise (CW).

After

adjustment fix the

angle with the screw 2. (At

this time take care so as to prevent excessive

tightening.) Apply Screw Lock to the

screw I.

<Caution>

Screw tightening

torque: 0.04Nm (0.4kgcm)

Tension roller position (S guide standard)

Tension

roller

~T\JF

cw

Apply screwlock

Fig. 4. Check (tape exists)

7-5. Checking and adjustment of tension roller position in record (playback) mode

(1)Checking

Before winding the 60-min tape make sure that the tension roller is in the same position as S guide as shown in Fig.

4.

If not, take out the tape and adjust in the following procedure.

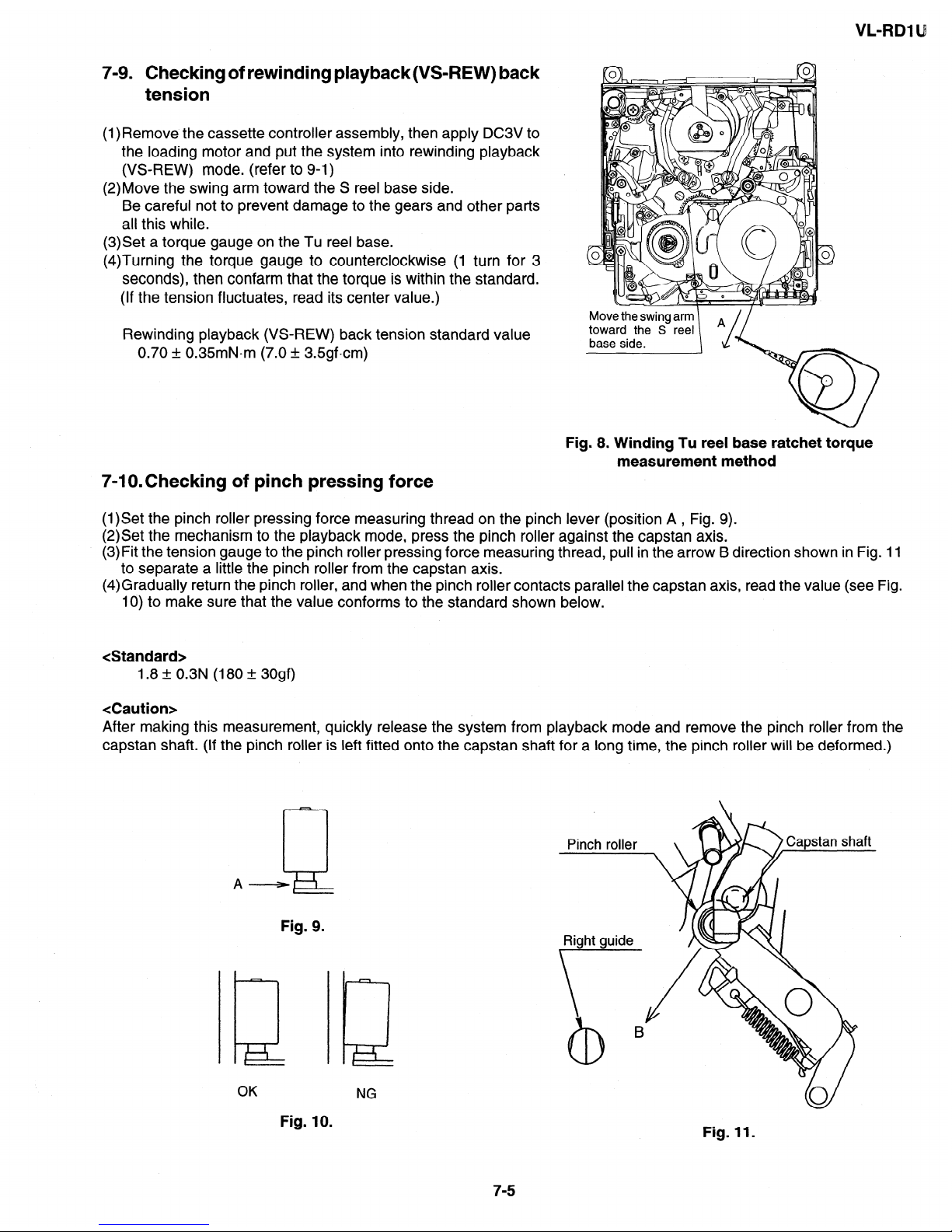

(2)Adjustment

1. Set the playback mode without loading the tape.

2. Loosen the screw 3 slightly (to such an extent that the tension band holder 4 can be moved).

3. If the tension roller is inside from the specified position, shift the tension band holder 4 in the arrow @ direction.

If the tension roller is outside, shift the tension band holder in the arrow @J direction, and fix with the screw 3.

(Proper shift must be 0.2 to 0.6mm outside from the specified position.)

4. Check the position by the procedure described in item (1) Checking above.

5. If the position is not specified position, adjust again.

Tension roller position (S guide standard)

Fig. 5. Position adjustment (tape does not exist)

7-3

VL-RDl U

7-6. Checking of supply S reel base no-load torque

(l)Remove the cassette controller assembly, then apply

DC3V to the loading motor and put the system into L.

start mode (refer to 9-l).

(2)Move the swing arm toward the Tu reel base side.

Be careful not to prevent damage to the gears and other

parts all this while. (Fig.6)

(3)Set a back tension measurement reel hub on the S reel

base.

(4)Using a dial tension gauge, pull the string in the A

direction, then confirm that the tension is within the

standard.

FF back tension standard

20mN or less (2.0gf or less)

(If the tension fluctuates, read its center value.)

Fig. 6. S reel base no-load torque measurement

method

7-7. Checking of loading back tension

(l)Remove the cassette controller assembly, then apply DC3V to the loading motor and put the system into L. start mode.

(refer to 9-l)

(2)Move the swing arm toward the S reel base side. Be careful not to prevent damage to the gears and other parts all this

while. (Fig.7)

(3)Set a back tension measurement reel hub on the Tu reel base.

(4)Using a dial tension gauge, pull the string in the A direction, then confirm that the tension is within the standard.

REW back tension standard

15&igrnN (1.5+gf)

(If the tension fluctuates, read its center value.)

7-8. Checking of winding Tu reel base ratchet

torque

(l)Remove the cassette controller assembly, then apply

DC3V to the loading motor and put the system into

standby mode. (refer to 9-l)

(2)Move the swing arm toward the S reel base side.

Be careful not to prevent damage to the gears and other

parts all this while. (Fig.8)

(3)Set a back tension measurement reel hub on the Tu reel

base.

(4)Using a dial tension gauge, pull the string in the A

direction, then confirm that the tension is within the

standard.

(If the tension fluctuates, read its center value.)

Winding Tu reel base ratchet torque standard

90mN or less (9gf or less )

Move the swing arm

toward the S reel

base side.

Fig. 7. Loading back tension measurement

method

7-4

VL-RDl U

7-9. Checking of rewinding playback(VS-REW) back

tension

(l)Remove the cassette controller assembly, then apply DC3V to

the loading motor and put the system into rewinding playback

(VS-REW) mode. (refer to 9-1)

(2)Move the swing arm toward the S reel base side.

Be careful not to prevent damage to the gears and other parts

all this while.

(3)Set a torque gauge on the Tu reel base.

(4)Turning the torque gauge to counterclockwise (1 turn for 3

seconds), then confarm that the torque is within the standard.

(If the tension fluctuates, read its center value.)

Rewinding playback (VS-REW) back tension standard value

0.70 + 0.35mN.m (7.0 + 3.5gfcm)

base side.

Fig. 8. Winding Tu reel base ratchet torque

measurement method

7-l O.Checking of pinch pressing force

(l)Set the pinch roller pressing force measuring thread on the pinch lever (position A , Fig. 9).

(2)Set the mechanism to the playback mode, press the pinch roller against the capstan axis.

(3)Fit the tension gauge to the pinch roller pressing force measuring thread, pull in the arrow B direction shown in Fig. 11

to separate a little the pinch roller from the capstan axis.

(4)Gradually return the pinch roller, and when the pinch roller contacts parallel the capstan axis, read the value (see Fig.

10) to make sure that the value conforms to the standard shown below.

<Standard>

1.8 + 0.3N (180 + 30gf)

<Caution>

After making this measurement, quickly release the system from playback mode and remove the pinch roller from the

capstan shaft. (If the pinch roller is left fitted onto the capstan shaft for a long time, the pinch roller will be deformed.)

&

A-

Fig. 9.

Fig. 10.

Right guide

\

NG

Fig. 11.

7-5

VL-RDl

U

8. TAPE

RUNNING ADJUSTMENT

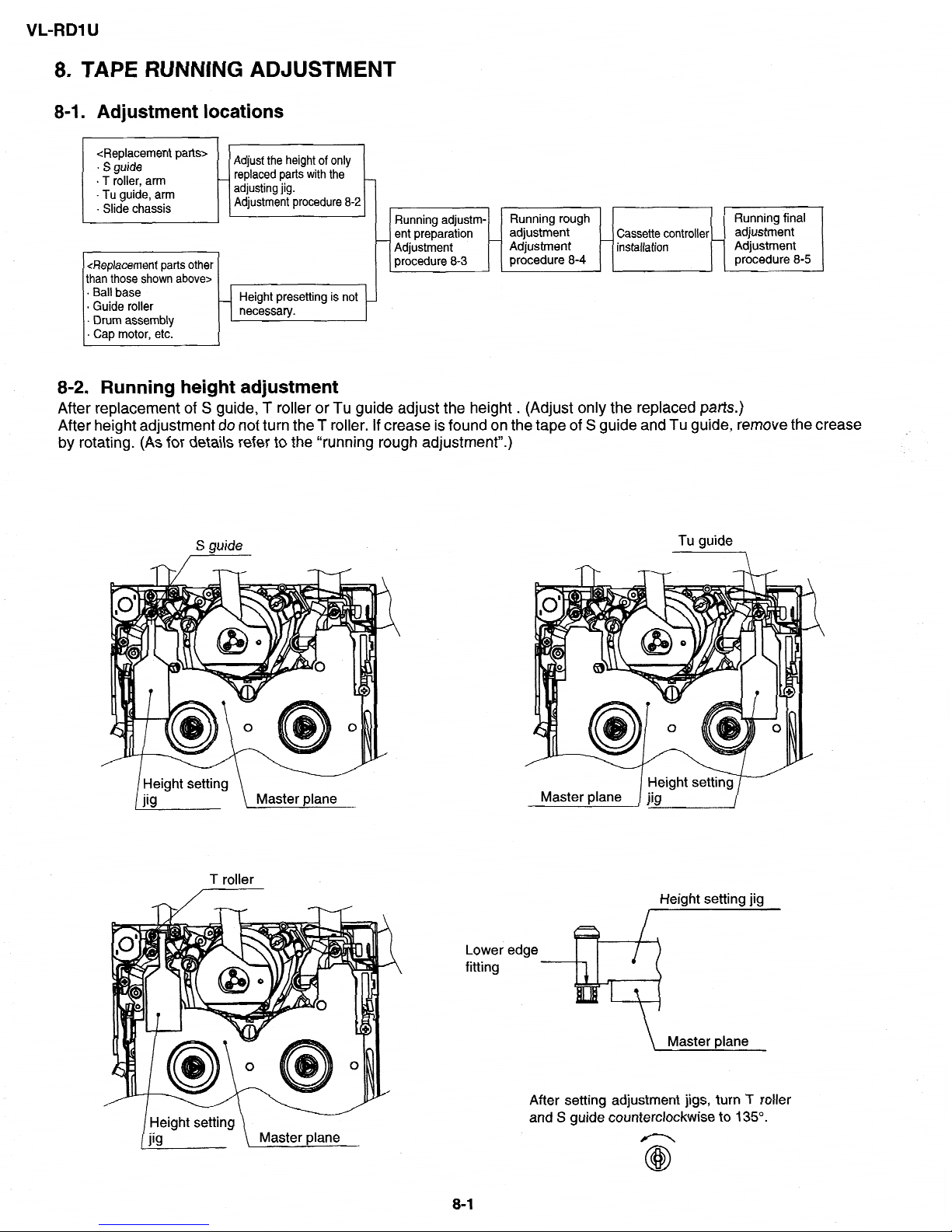

8-l. Adjustment locations

<Replacement parts>

. S guide

- T

roller,

arm

-

Tu guide, arm

-

Slide

chassis

replaced

parts with the

Adjustment

procedure

8-2

<Replacement parts other

than

those

shown

above>

-

Ball base

-

Guide

roller

_

Height

presetting

is

not

_

-

Drum

assembly

necessary.

-

Cap motor, etc.

Running rough

adjustment

Adjustment

procedure

8-4

Cassette controller

installation

Running final

adjustment

Adjustment

procedure

8-5

8-2. Running height

adjustment

After

replacement of S guide, T roller or Tu guide adjust the height

. (Adjust only the replaced parts.)

After height adjustment do

not turn the T roller. If crease is found

on the tape of S guide and Tu guide,

remove

the crease

by rotating.

(As

for details refer

to

the “running rough adjustment”.)

S guide

T roller

Tu guide

rr Master plane

1

Lower edge

fitting

Height setting jig

\ Master plane

After setting adjustment jigs, turn T roller

and S guide counterclockwise to 135”.

8-1

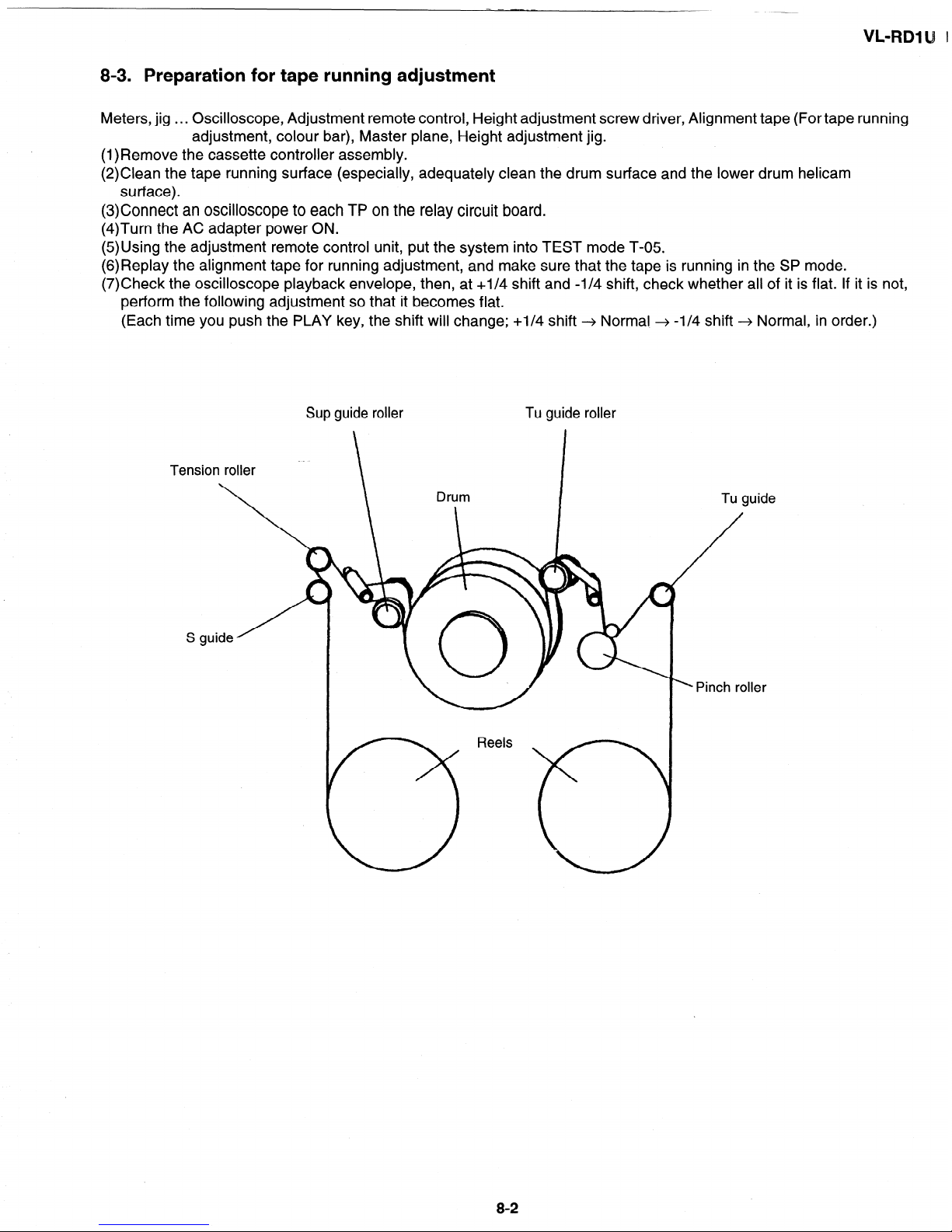

8-3. Preparation for tape running adjustment

Meters, jig

. . . Oscilloscope, Adjustment remote control, Height adjustment screw driver, Alignment tape (For tape running

adjustment, colour bar), Master plane, Height adjustment jig.

(l)Remove the cassette controller assembly.

(2)Clean the tape running surface (especially, adequately clean the drum surface and the lower drum helicam

surface).

(3)Connect an oscilloscope to each TP on the relay circuit board.

(4)Turn the AC adapter power ON.

(5)Using the adjustment remote control unit, put the system into TEST mode T-05.

(6)Replay the alignment tape for running adjustment, and make sure that the tape is running in the SP mode.

(7)Check the oscilloscope playback envelope, then, at +I/4 shift and -l/4 shift, check whether all of it is flat. If it is not,

perform the following adjustment so that it becomes flat.

(Each time you push the PLAY key, the shift will change; +I/4 shift -+ Normal -+ -l/4 shift -+ Normal, in order.)

Sup guide roller Tu guide roller

S guide

2

Tension roller

Tu guide

’ Pinch roller

8-2

VL-RDl U

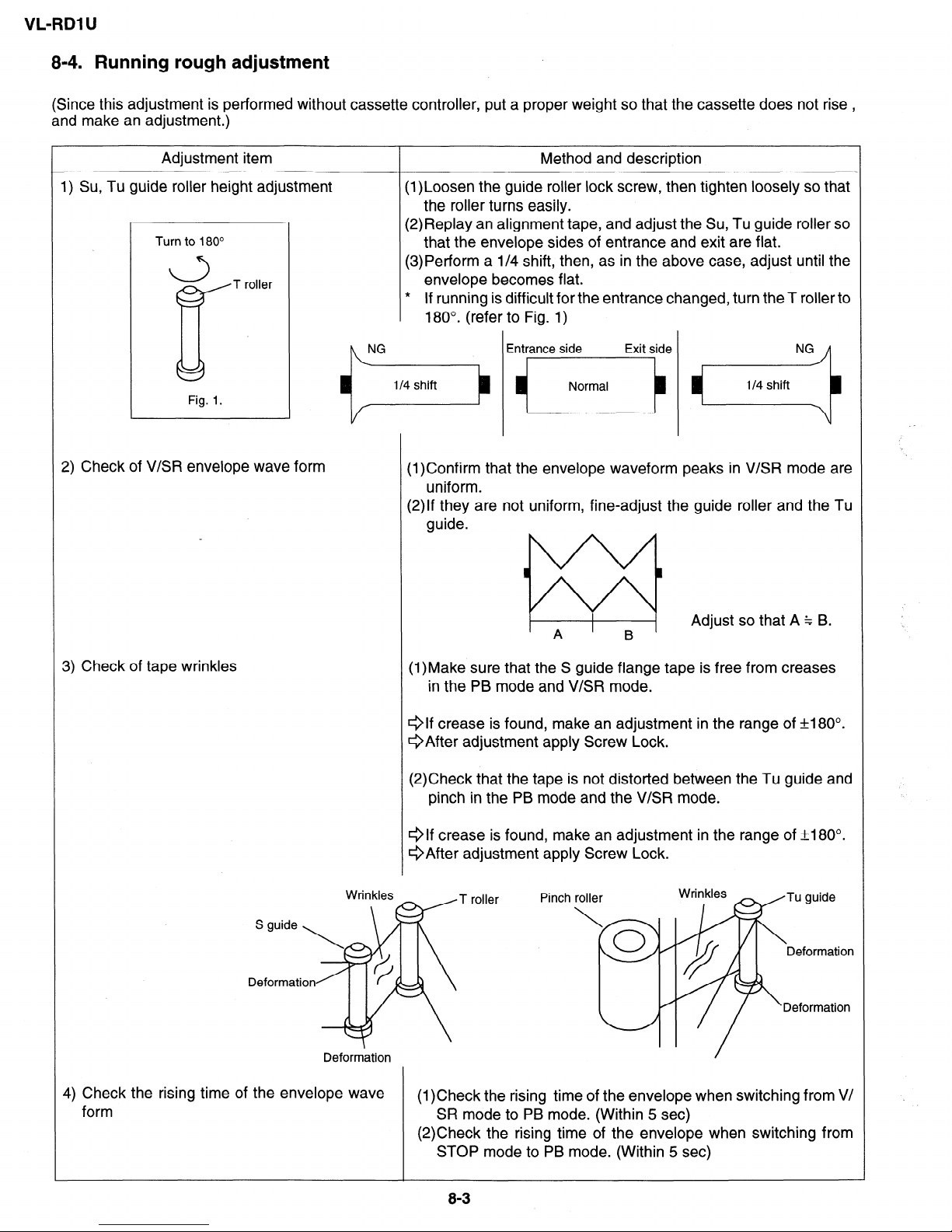

8-4. Running rough adjustment

(Since this adjustment is performed without cassette controller, put a proper weight so that the cassette does not rise ,

and make an adjustment.)

Adjustment item

I

Method and description

Su, Tu guide roller height adjustment

Turn to 180”

L-5

T roller

Fig. 1.

Check of V/SR envelope wave form

(l)Loosen the guide roller lock screw, then tighten loosely so that

the roller turns easily.

(2)Replay an alignment tape, and adjust the Su, Tu guide roller so

that the envelope sides of entrance and exit are flat.

(3)Perform a l/4 shift, then, as in the above case, adjust until the

envelope becomes flat.

* If running is difficult for the entrance changed, turn the T roller to

180”. (refer to Fig. 1)

Entrance side

Exit side

Normal

I

I

(l)Confirm that the envelope waveform peaks in V/SR mode are

uniform.

(2)If they are not uniform, fine-adjust the guide roller and the Tu

guide.

’ A

I

B ’

Adjust so that A % B.

Check of tape wrinkles

(l)Make sure that the S guide flange tape is free from creases

in the PB mode and V/SR mode.

Qlf crease is found, make an adjustment in the range of +180°.

QAfter adjustment apply Screw Lock.

(2)Check that the tape is not distorted between the Tu guide and

pinch in the PB mode and the V/SR mode.

Qlf crease is found, make an adjustment in the range of f180”.

QAfter adjustment apply Screw Lock.

Deformation

T roller

Pinch

Check the rising time of the envelope wave

form

(1)Check the rising time of the envelope when switching from V/

SR mode to PB mode. (Within 5 set)

(2)Check the rising time of the envelope when switching from

STOP mode to PB mode. (Within 5 set)

8-3

VL-RDl U

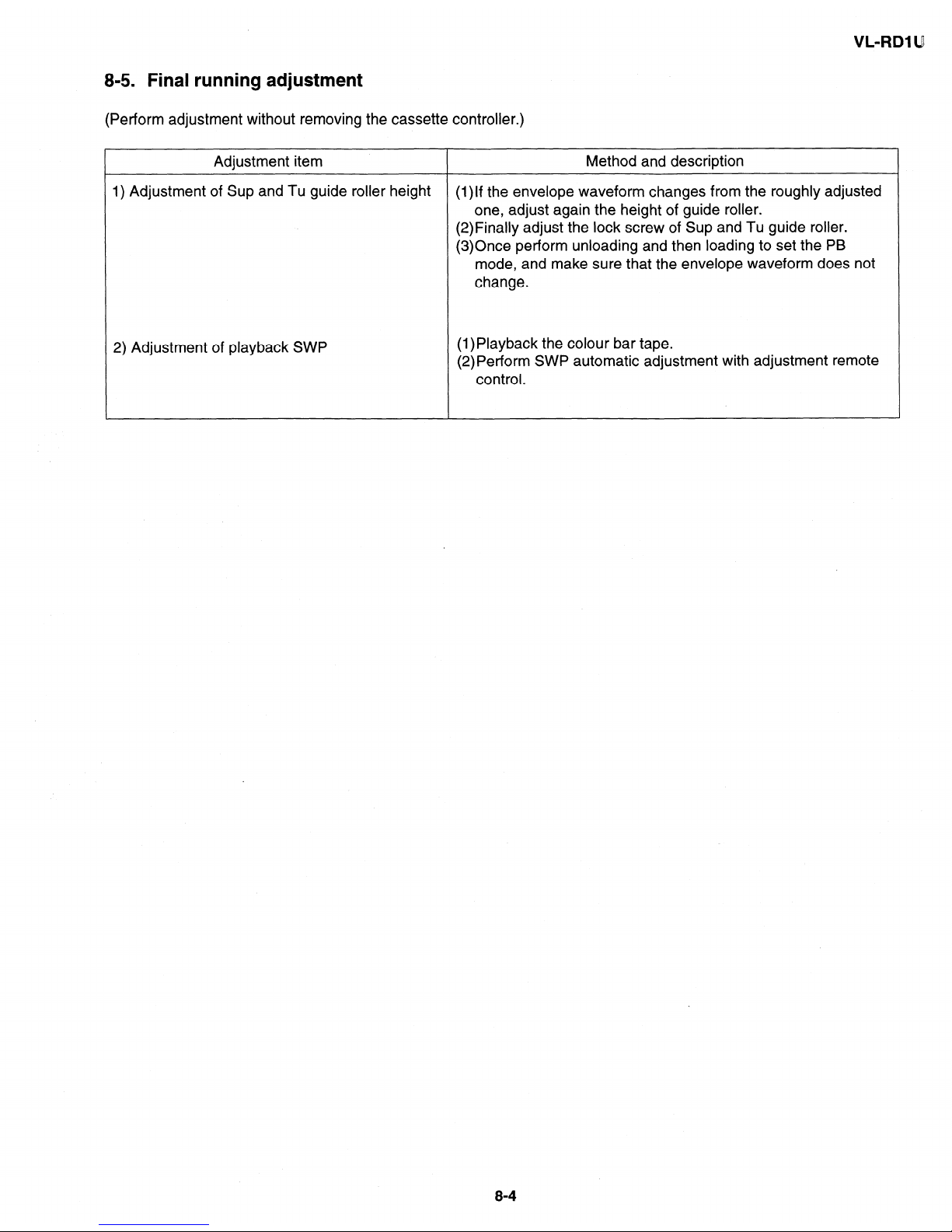

8-5. Final running adjustment

(Perform adjustment without removing the cassette controller.)

Adjustment item Method and description

1) Adjustment of Sup and Tu guide roller height

(1)lf the envelope waveform changes from the roughly adjusted

one, adjust again the height of guide roller.

(2)Finally adjust the lock screw of Sup and Tu guide roller.

(3)Once perform unloading and then loading to set the PB

mode, and make sure that the envelope waveform does not

change.

2) Adjustment of playback SWP

(1)Playback the colour bar tape.

(2) Perform SWP automatic adjustment with adjustment remote

control.

0-4

VL-RDI U

9. MECHANICAL SECTION ASSEMBLY AND PARTS REPLACEMENT

(DISASSEMBLY AND REASSEMBLY)

Mechanical section disassembly and reassembly are explained in this section.

For removal of the cabinet, etc., refer to 4. DISASSEMBLY OF THE SET.

<Precautions>

1. Always replace cut washers that have been removed, for example in parts replacement, with new ones.

2. When reassembling, be careful not to allow screws, washers or foreign matter to enter. They can cause mechanical

misoperation.

3. Use the cleaning liquid, oil, grease and screw lock that are specified below. Use of any other kind can cause

mechanical misoperation.

Oil:

Cosmo Petroleum : Cosmo Hydro HV22/HVlOO

Grease:

Dow Corning : Moly Coat YM-103

Screw lock: Three Bond :1401B

Cleaning liquid: Industrial-use ethyl alcohol

4. Turn the mechanical section over, do not place it on, for example, a desk. Deformation and scratching of mechanical

parts can cause trouble.

9-l. On the mechanical modes

To operate the mechanism, apply DC3-4V to the loadinq motor.

_

At this time, disconnect the loading motor FPC from the connector.

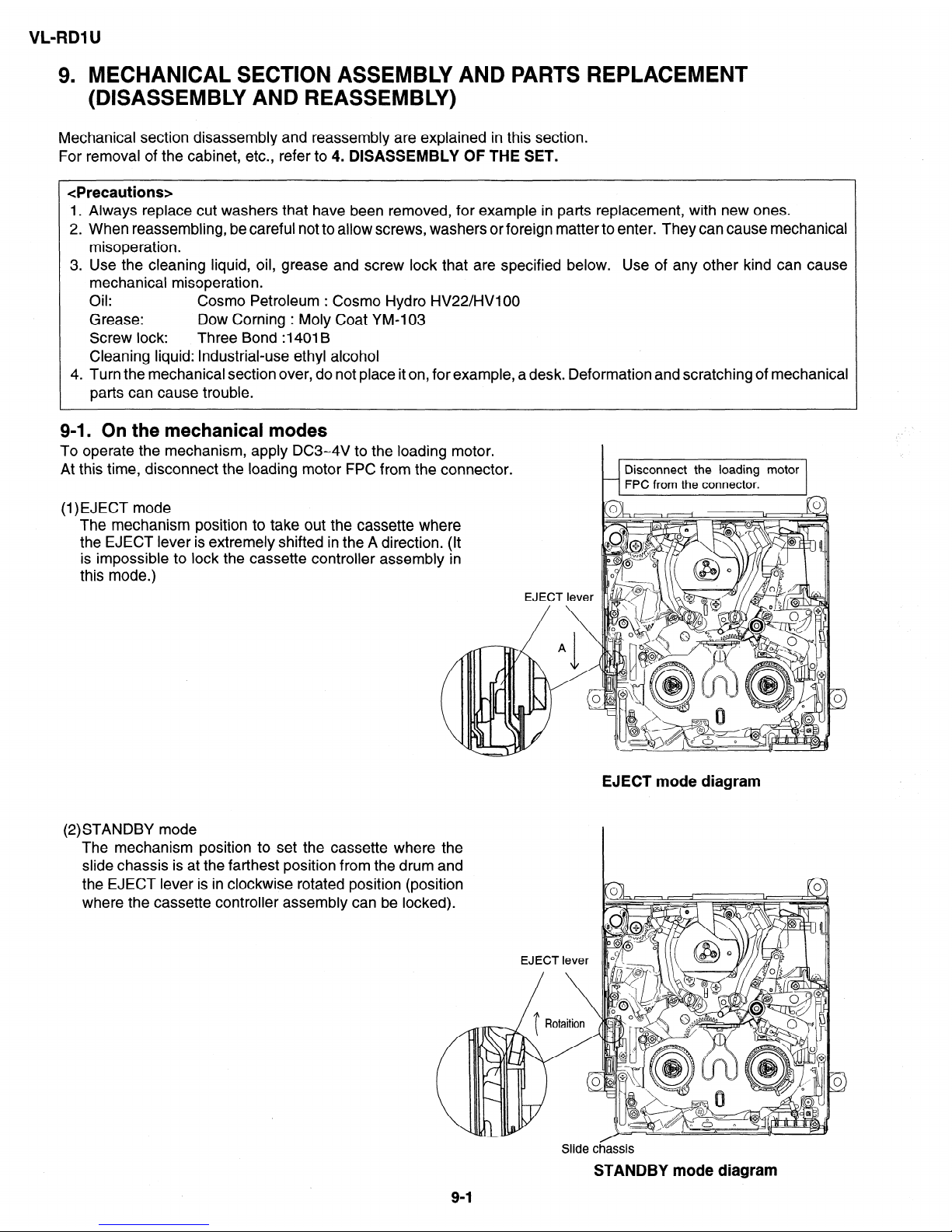

(1)EJECT mode

The mechanism position to take out the cassette where

the EJECT lever is extremely shifted in the A direction. (It

is impossible to lock the cassette controller assembly in

this mode.)

(2)STANDBY mode

The mechanism position to set the cassette where the

slide chassis is at the farthest position from the drum and

the EJECT lever is in clockwise rotated position (position

where the cassette controller assembly can be locked).

EJEC’

T lev

\

EJECT mode diagram

3

0

Slide chassis

STANDBY mode diagram

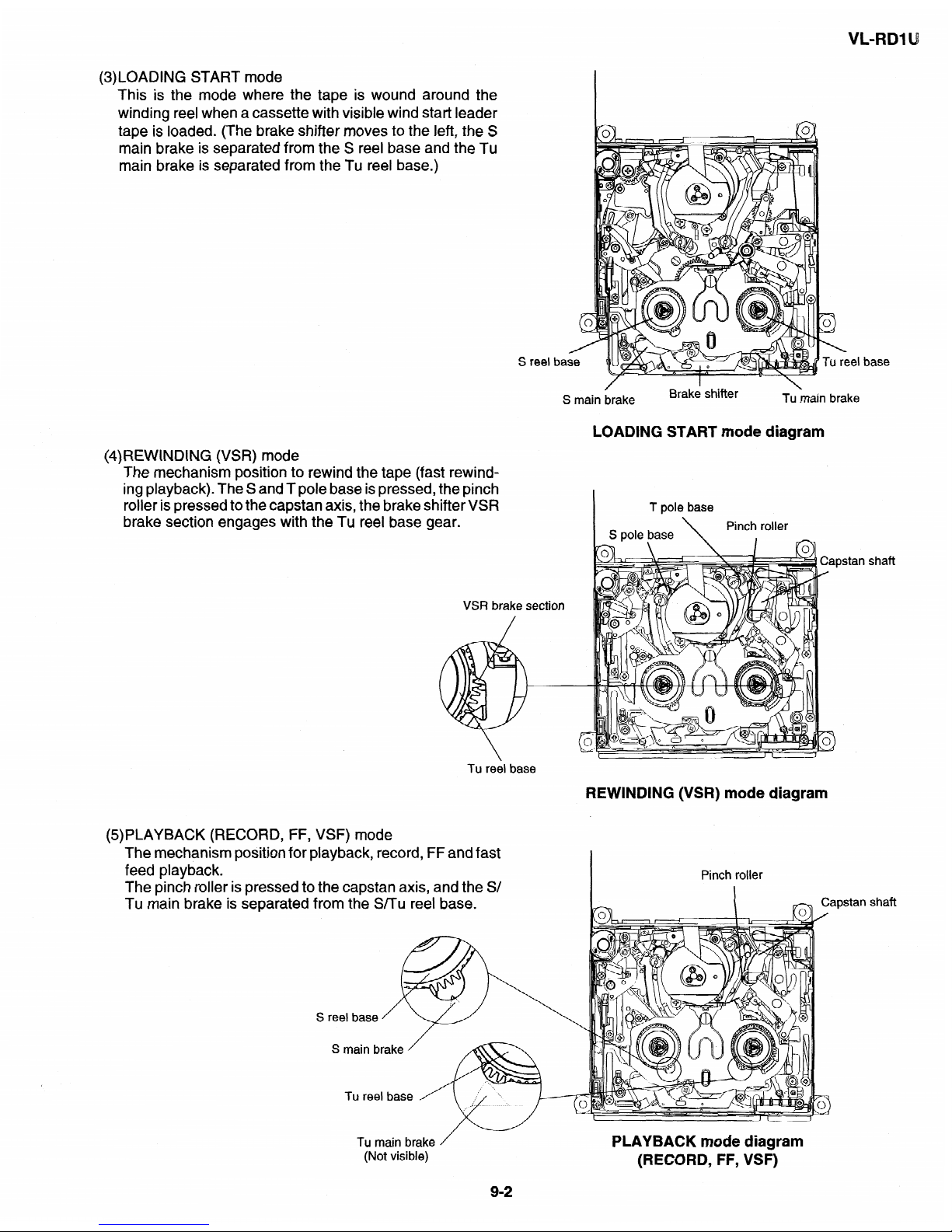

(3)LOADING START

mode

This is the mode where the

tape

is wound

around the

winding reel when a cassette with visible wind start

leader

tape is loaded.

(The

brake shifter

moves

to

the left, the S

main brake is separated from the S reel

base

and

the Tu

main brake is

separated from the Tu reel base.)

\

reel base

(4)REWINDING (VSR) mode

The mechanism position to rewind the tape (fast rewind-

ing playback). The S and T

pole base is pressed, the pinch

roller is pressed to the capstan axis, the brake shifter VSR

brake section engages with the Tu reel base gear.

VSR brake section

Tu reel base

S

main &rake

Brake shifter

Tu ‘main

brake

LOADING START mode diagram

(5)

T pole base

S pole base

\

Pinch roller

I

-

Istan shaft

REWINDING (VSR)

mode

diagram

iPLAYBACK (RECORD, FF, VSF) mode

The mechanism position for playback, record, FF and fast

feed playback.

The pinch roller is pressed to the capstan axis, and the S/

Tu main brake is separated from the Smu reel base.

S main brake /

Tu main brake

/

PLAYBACK mode diagram

(Not visible)

(RECORD, FF, VSF)

9-2

VL-RDl U

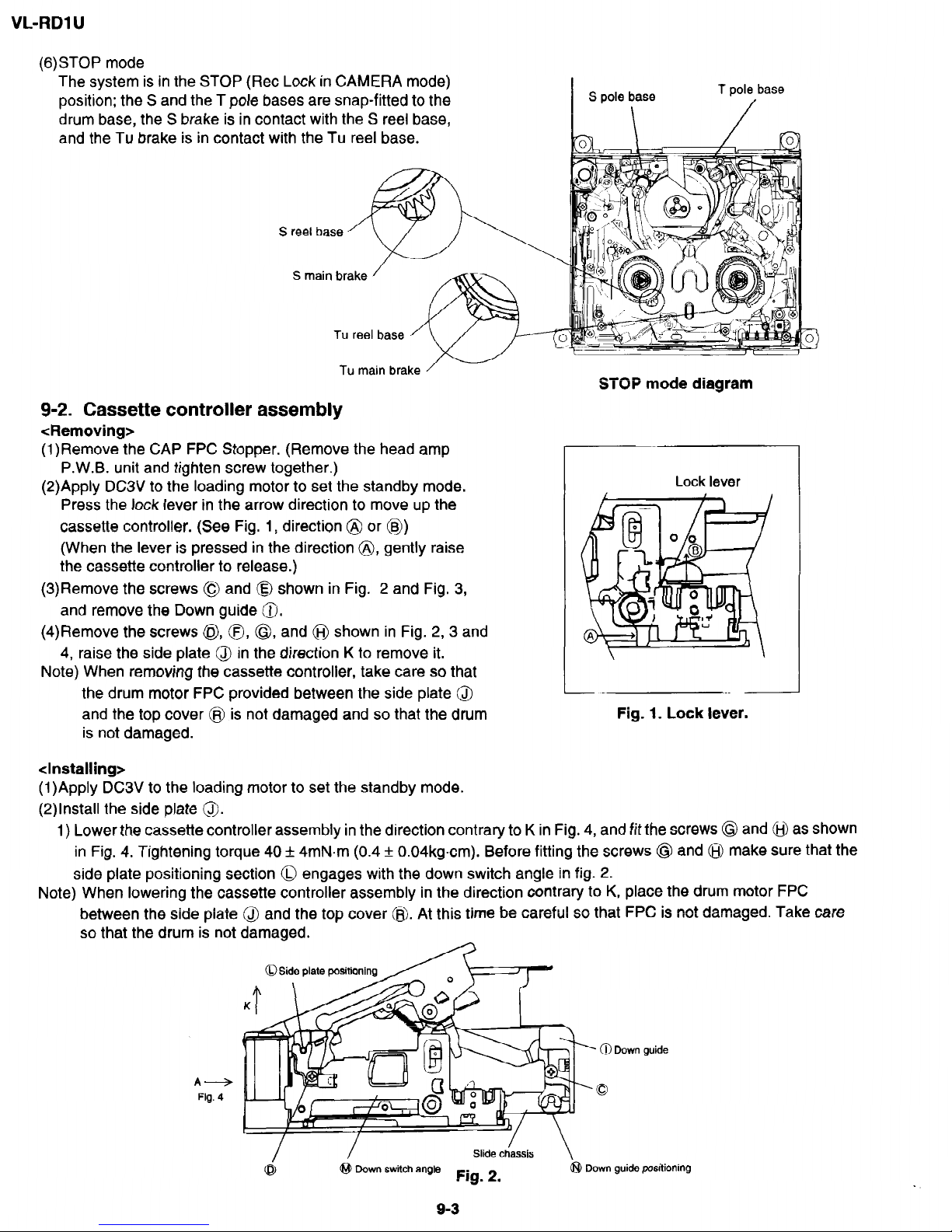

(6)STOP

mode

The system is in the

STOP (Ret Lock in CAMERA mode)

position; the S and the T pole

bases

are

snap-fitted to the

drum base,

the S brake

is in

contact with the S reel base,

and

the

Tu brake

is in

contact with the Tu reel base.

S

main brake

Tu main brake

/-

9-2. Cassette controller assembly

<Removing>

(l)Remove the CAP FPC Stopper. (Remove the head amp

P.W.B. unit and tighten screw together.)

(2)Apply DC3V to the loading motor

to set the standby mode.

Press the lock lever in the arrow direction to move up the

cassette controller. (See Fig. 1, direction @ or @jI)

(When the lever is pressed in

the direction 8, gently raise

the cassette controller to release.)

(3)Remove the screws @ and @ shown in Fig. 2 and Fig. 3,

and remove the Down guide 0.

(4)Remove the screws @,, 0, 0, and @ shown in Fig. 2,3 and

4, raise the side plate

@ in the direction K to remove it.

Note) When removing the cassette controller, take care so that

the drum motor FPC provided between the side plate @

and the top cover @I is not damaged and so that the drum

is not damaged.

STOP

mode

diagram

Lock lever

Fig. 1. Lock lever.

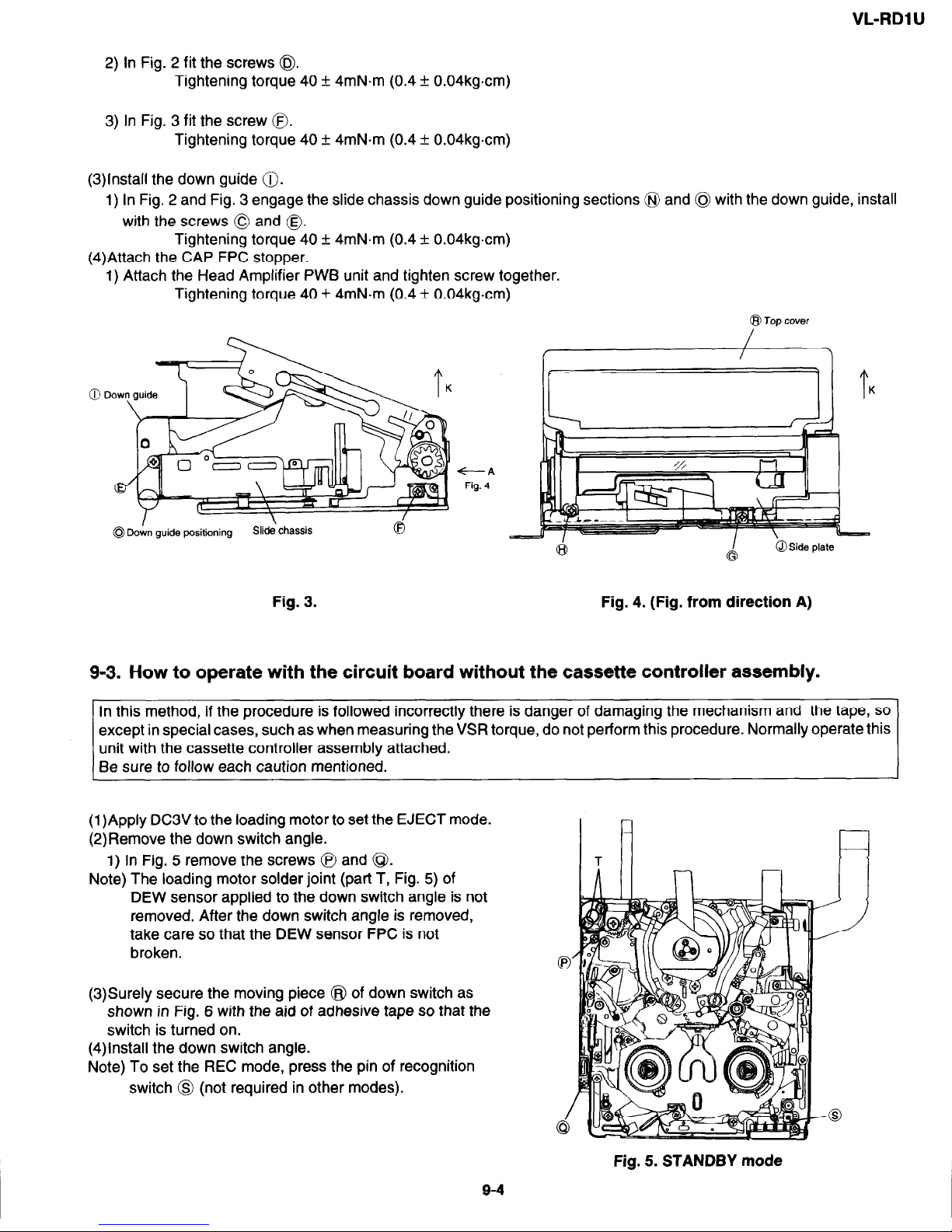

<Installing>

(1)Apply DC3V to the loading motor to set the standby mode.

(2)lnstall the side plate 0.

1) Lower the cassette controller assembly in the direction contrary to K in Fig. 4, and fit the screws @ and @ as shown

in Fig. 4. Tightening torque 40 f 4mN.m (0.4 f 0.04kgcm). Before fitting the screws @ and @ make sure that the

side plate positioning section 0 engages with the down switch angle in fig. 2.

Note) When lowering the cassette controller assembly in the direction contrary to K, place the drum motor FPC

between the side plate @ and the top cover @. At this time be careful so that FPC is not damaged. Take care

so that the drum is not damaged.

OSiie plate positionin

@ Down guide

A+

Fig. 4

0

Down switch angle

Down guide positioning

VL-RDl U

2) In Fig. 2 fit the screws @$.

Tightening torque 40 + 4mN.m (0.4 + 0.04kgcm)

3) In Fig. 3 fit the screw 0.

Tightening torque 40 + 4mN-m (0.4 f 0.04kgcm)

(3)lnstall the down guide 0.

1) In Fig. 2 and Fig. 3 engage the slide chassis down guide positioning sections @ and @ with the down guide, install

with the screws 0 and 0.

Tightening torque 40 + 4mN.m (0.4 f 0.04kg.cm)

(4)Attach the CAP FPC stopper.

1) Attach the Head Amplifier PWB unit and tighten screw together.

Tightening torque 40 f 4mN.m (0.4 f 0.04kgcm)

I

@Down guide positioning

Slide\ chassis

Fig. 3.

+--A

Fig. 4

@J Top cover

r,

Fig. 4. (Fig. from direction A)

9-3. How to operate with the circuit board without the cassette controller assembly.

In this method, if the procedure is followed incorrectly there is danger of damaging the mechanism and the tape, so

except in special cases, such as when measuring the VSR torque, do not perform this procedure. Normally operate this

unit with the cassette controller assembly attached.

Be sure to follow each caution mentioned.

(1)Apply DC3V to the loading motor to set the EJECT mode.

(2)Remove the down switch angle.

1) In Fig. 5 remove the screws @ and @$.

Note) The loading motor solder joint (part T, Fig. 5) of

DEW sensor applied to the down switch angle is not

removed. After the down switch angle is removed,

take care so that the DEW sensor FPC is not

broken.

(3)Surely secure the moving piece @ of down switch as

shown in Fig. 6 with the aid of adhesive tape so that the

switch is turned on.

(4)lnstall the down switch angle.

Note) To set the REC mode, press the pin of recognition

switch @ (not required in other modes).

I l-4

n

Fig. 5. STANDBY mode

9-4

VL-RDl U

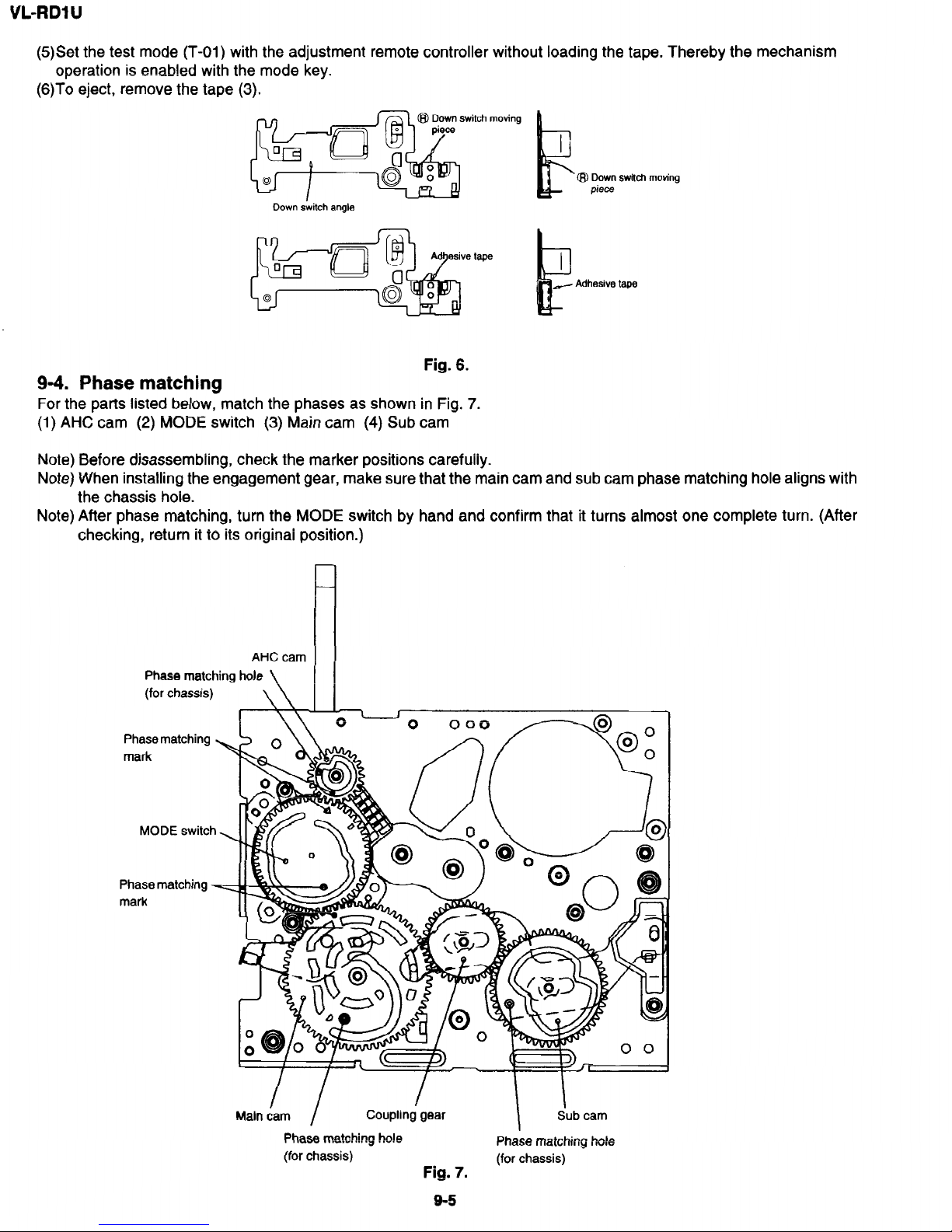

(5)Set the

test

mode

(T-01)

with the

adjustment remote controller without

loading the tape. Thereby

the mechanism

operation

is enabled with the

mode key.

(6)To

eject,

remove the tape (3).

Down

switch

angle

Adhesive

tape

Fig. 6.

9-4.

Phase

matching

For

the parts listed

below,

match

the phases

as shown in

Fig. 7.

(1) AHC cam

(2) MODE

switch (3) Main

cam

(4) Sub

cam

Note) Before disassembling, check the marker positions carefully.

Note) When installing the engagement gear, make

sure that the main cam

and sub cam phase matching hole aligns with

the chassis hole.

Note)

After phase matching, turn the MODE

switch by hand and confirm that it turns almost one complete turn. (After

checking, return it to

its

original position.)

AHC cam

I

Phase

matching hole

(for

chassis)

\I \

Phase matching

mark

?-

0

000 B_ol

MODE switch

Phase matching

mark

Main dam /

Coupling gear

I

Sub cam

Phase matching hole

Phase matching hole

(for chassis)

(for chassis)

Fig. 7.

Loading...

Loading...