Page 1

T

h

e

S

h

arr

p

S

X

&

Models 1075, 1084, 1097, 1099, 1108, 1109, and 1121

Printed In USA 0924

Parts: (800) 634-6359 ext. 571

www.sharppackaging.com

TTMM

T

T

h

h

T

h

e

e

e

S

h

arr

h

a

S

Service & Maintenance Manual

S

p

p

h

S

S

a

X

X

TTM

p

M

wiitt

w

S

X

h

h

&

Prrii

P

ntt

n

err

e

parts@sharppackaging.com

PN: 960714-02B Copyright © 2007

Service: (800) 634-6359 ext. 572

service@sharppackaging.com

Page 2

The safety inform ation pr esented is a g uidel ine that

IMPORTANT SAFETY INFORMATION

SX™

WARNING

Operating machine without safety guards in

death.

WARNING

tangled with the machine. Failure to do so

WARNING

GENERAL WARNING. Indicates information

important to the proper operation of the

WARNING

important to the proper operation of the

CAUTION

prior to performing any maintenance on the

machine.

WARNING

should be followed by all personnel. Anyone

operating or maintaining the equipment should read

and follow all the information in this manual, without

exception.

DEFINITION OF TERMS

Throughout this manual, you will find the

following safety notices with this accompanying

symbol. This symbol signifies important safety

issues regarding the oper ation and maintenanc e of

the Sharp SX™.

equipment. Failure to observe may result in

damage to the equipment and severe bodily

injury or death.

GENERAL CAUTION. Indicates information

equipment. Failure to observe may result in

damage to the equipment.

EQUIPMENT SAFETY FEATURES

The Sharp SX™ is equipped with a polycarbona t e

shield covering the pressure and heated seal bars.

DO NOT operate the unit with the shield removed.

Operating the unit without the safety guards in

place may result in serious bodily injury or

death.

Service and Maintenance Manual 960714-02B © 2007 I2407

SAFETY RULES AND PROCEDURES

The machine requires regular, periodic

maintenance to ensure reliable service. No

maintenance should be performed unless the

safety precautions for maintenance are thoroug hly

understood.

• Follow all instructions in this manual for safe

operation.

• Follow all company and industry standard

safety policies regarding this kind of

machinery that ma y exceed thos e liste d in th is

manual.

• Keep all safety features, guards, interlocks

and sensors in good working order.

• ALWAYS turn off machine power, ensure that

all mechanical motion has stopped and allow

any heated components to cool down before

removing any machine parts.

place may result in serious bodily injury or

Always remove electrical power from the SX

Prior to operating or servicing the SX, remove

any loose jewelry, make certain clothing and

hair are not loose to interfere with or become

could result in severe bodily injury or death.

Page 3

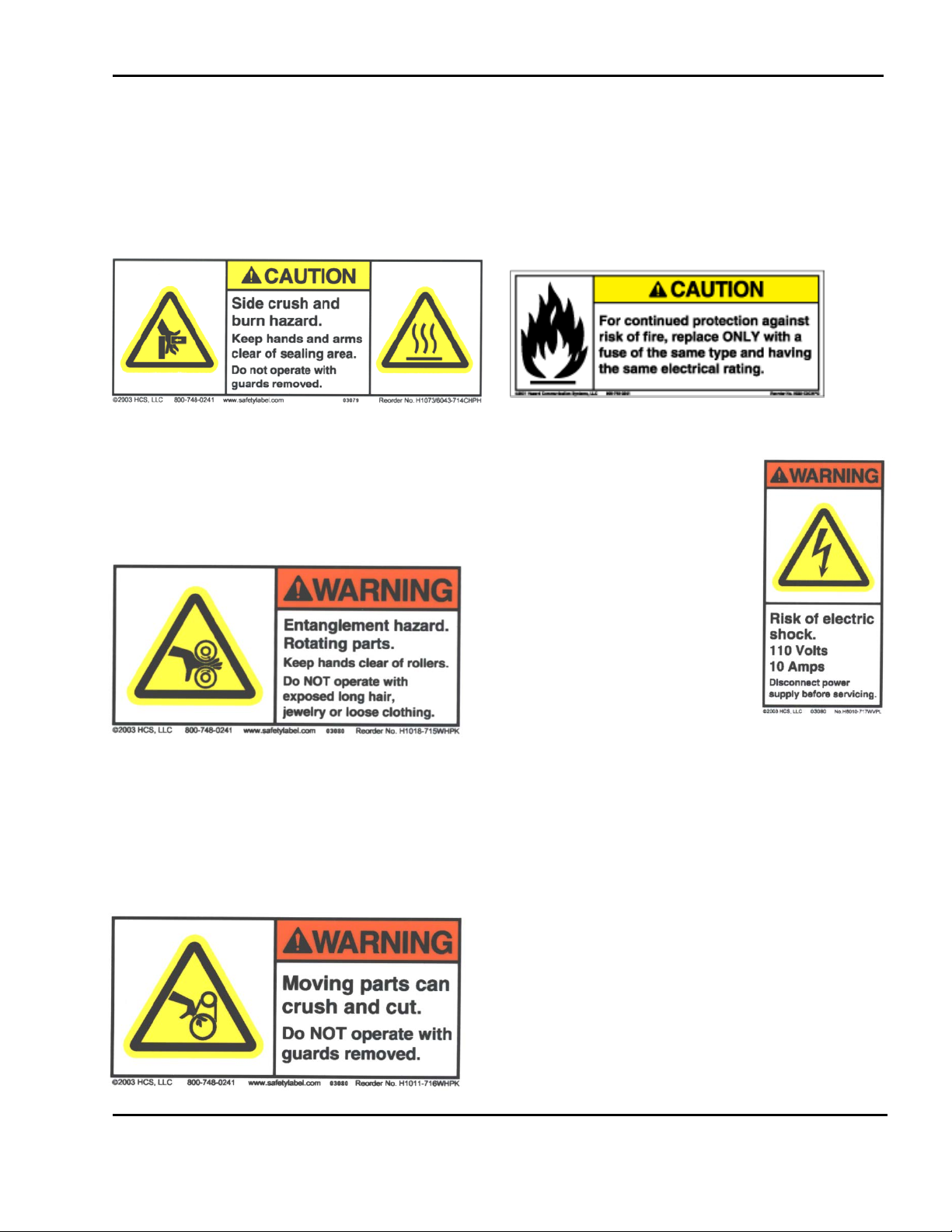

SAF ETY LABELS

The label shown on th e right

or panel guards electrical

to removing any guards

IMPORTANT SAFETY INFORMATION

SX™

The following label is placed on the Sharp SX™

wherever a removable shield or panel guards the

heated sealing area. Always disconnect electrical

power from the machine prior to removing any

guards and/or panels.

The following label is used where there is the

potential of your hands, long hair, jewelry, etc.

becoming entangled between two rotating parts.

Be sure to secure loose item s before approaching

and operating the machine.

The following label on the Sharp SX™ is located

where there is the potential of injury due to pinch

points or moving parts. Make certain electrical

power is disconnec ted befo re rem oving an y guards

and/or panels or servicing the machine.

The following label is locat ed in the proximity of a

fused circuit. Be certain to replace blown fuses

ONLY with fuses with the same electrical rating.

Always disconnect electrical power before

removing an y guards and/o r panels or s ervic ing the

Sharp SX™.

is placed on the Sharp SX™

wherever a removable s hield

components.

Always disconnect electrical

power from the mac hine pri or

and/or panels.

Service and Maintenance Manual 960714-02B © 2007 I2407

Page 4

Section 1- Introduction

TABLE OF CONTENTS

SX™

General Information ................................................ 1-1

About This Manual .............................................. 1-1

Model Variations ................................................. 1-2

Technical Assistance ......................................... 1-2

Theory of Operation ................................................. 1-3

General ............................................................... 1-3

Faults .................................................................. 1-4

EZ-Bags® and Film Materials ............................. 1-5

Thermal Transfer Ribbon .................................... 1-5

Specifications ........................................................... 1-6

Machine Specifications ....................................... 1-6

Packaging Specifications .................................... 1-6

Machine Dimensions ........................................... 1-6

Section 2 – Maintenance & Adjustments

Maintenance Schedule ............................................ 2-1

Daily Maintenance .......................................... 2-1

Annual Maintenance ........................................... 2-1

Cleaning .................................................................... 2-2

General ............................................................... 2-2

Cleaning the Printhead and Film Feed Rollers.... 2-3

Machine Adjustments .............................................. 2-5

Adjusting the Pinch Roller ................................... 2-5

Checking Belt Tension ........................................ 2-6

Checking Belt Tension ........................................ 2-7

Sharp SX™ with Printer ...................................... 2-8

Section 3 – Component Repair

Electrical Assembly ................................................ 3-1

Pressure Jaw and Film Feed Motor Controller s...3-1

Fuses .................................................................. 3-6

24VDC Power Supply ......................................... 3-8

Line Filter .......................................................... 3-16

Main Power Switch (RED)................................. 3-20

Transformers ..................................................... 3-22

Aromat PLC ...................................................... 3-27

Aromat PLC Battery .......................................... 3-28

Color Touch Screen .......................................... 3-30

Cooling Fan ....................................................... 3-33

Solid State Relay .............................................. 3-35

Grey Relay 24V ................................................ 3-39

Red Relay 24V .................................................. 3-41

Printer GPIO Board ........................................... 3-44

Printer Performance Logic Board ...................... 3-45

Printer Power Supply Board .............................. 3-46

24 VDC Fan Assembly...................................... 3-48

Laminated White Ribbon Cable ........................ 3-49

Datamax LCD Module....................................... 3-51

Printhead Stepper Drive .................................... 3-53

Film Feed Assembly .............................................. 3-56

Photoelectric Sensor ......................................... 3-56

Film Feed Motor Drive Belt ............................... 3-60

Film Feed Roller Drive Belt ............................... 3-61

Platen Roller Drive Belt ..................................... 3-63

Film Feed Roller ............................................... 3-67

Platen Roller ..................................................... 3-69

Film Feed Drive Motor ...................................... 3-72

Cradle Lock Cams ............................................ 3-74

Printhead Cradle Assembly .................................. 3-76

Ribbon Rewind Assembly ................................. 3-76

Ribbon Rewind Motor ....................................... 3-76

Primary Ribbon Drive Belt ................................. 3-79

DC Roller Clutch ............................................... 3-81

Secondary Ribbon Drive Belt ............................ 3-83

Adjustable Slip Clutch ....................................... 3-87

Printhead Position Assembly

Printhead Position Motor ................................... 3-89

Printhead Position Drive Belt ............................ 3-92

Printhead Pressure Cams ................................. 3-94

Printhead Position Sensor ............................... 3-100

Thermal Printhead ........................................... 3-102

Ribbon Supply Assembly

Slip Clutch Spring ............................................ 3-103

Ribbon Motion Sensor ..................................... 3-104

Ribbon Clips .................................................... 3-106

Gas Springs ..................................................... 3-107

Cross Flow Fan ................................................ 3-108

................................... 3-89

........................................ 3-103

Service and Maintenance Manual 960714-02B © 2007 I2407

Page 5

Cradle Latch Lever .......................................... 3-110

TABLE OF CONTENTS

SX™

Cradle Latch .................................................... 3-111

Sealer Assembly .................................................. 3-113

Pressure Bar Drive Motor................................ 3-113

Pressure Bar Gearbox .................................... 3-116

Pressure Bar Belt ............................................ 3-118

Linear Bearings ............................................... 3-120

Stripper Plate Assembly .................................. 3-122

Sealpoint Components .................................... 3-129

Seal Wire Tension Springs.............................. 3-132

Stripper Plate Sensors .................................... 3-135

Jaw Position Sensors ...................................... 3-140

Unwind Assembly ................................................ 3-145

Appendix

Replacement Parts Order Form .......................... A-1

Warranty ............................................................. A-2

Protecting Your Printhead ................................... A-3

Printer Menu Structure ........................................ A-6

Wiring Diagram – Located in the back of this

binder or Click Here

Unwind Spring ................................................. 3-145

Section 4 – Troubleshooting

Troubleshooting Chart ........................................ 4-1

Section 5 – Parts Lists

Electrical Assembly ............................................. 5-1

Film Feed Assembly ........................................... 5-3

Frame Assembly ................................................. 5-4

Printhead Cradle Assembly (Model 1108)........... 5-5

Cradle Assembly (Model 1097) ........................... 5-9

Sealer Assembly ............................................... 5-10

Unwind Assembly ............................................. 5-12

Section 6 – Assembly Drawings

Electrical Assembly ............................................. 6-1

Film Feed Assembly ........................................... 6-5

Frame Assembly ................................................. 6-6

Printhead Cradle Assembly (Model 1108)........... 6-9

Cradle Assembly (Model 1097) ......................... 6-14

Sealer Assembly ............................................... 6-17

Unwind Assembly ............................................. 6-20

Service and Maintenance Manual 960714-02B © 2007 I2407

Page 6

SX™

SECTION 1 – INTRODUCTION

GENERAL INFORMATION

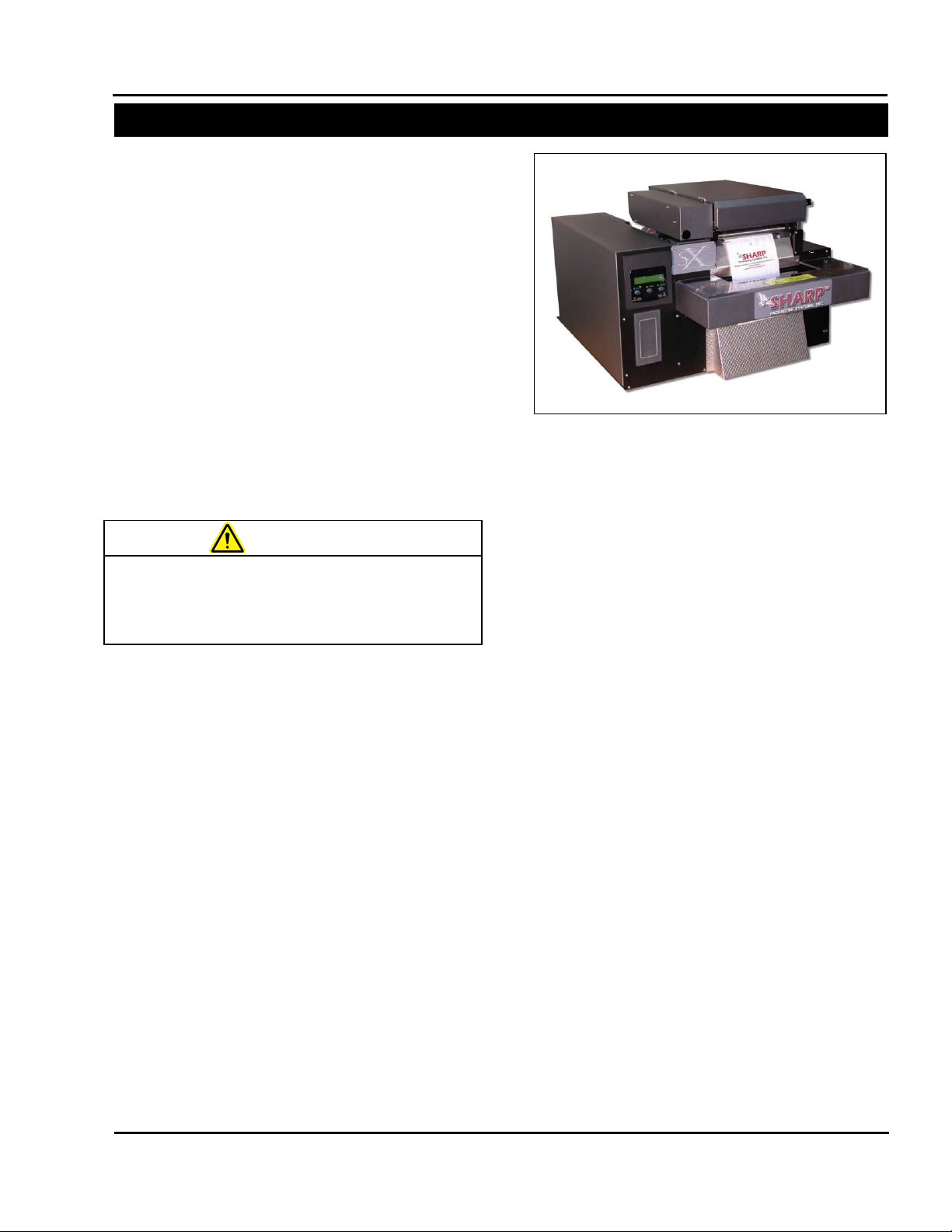

This manual is designed to be used b y Authorized Service Pers onnel only. Sharp

Packaging Systems, Inc. assumes no responsibility for any repairs made on Sharp

Packaging units by anyone other than Authorized Service Technicians.

TESTING

ADJUSTMENT

REPLACEMENT

ABOUT THIS MANUAL

This manual has been prepared for your use in

servicing the Sharp SX™ Packaging Mac hine and

the Sharp SX™ Packaging Machine with Printer.

Included in the procedures are helpful facts on

service, troubleshooting, specifications and parts

information.

All procedures shoul d be performed by a qualified

service technician.

It is important that you f amiliarize yourself with the

product as much as possible before initiating any

maintenance, troubleshooting or repairs.

Make sure you read through the IMPORTANT

SAFETY INFORMATION and INTRODUCTION

sections of this manual before attempting any

service procedures.

As you disassemble your machine to service and replace parts, keep the following points in mind:

• Do not remove or loosen more parts than

needed. Use comm on sense to k eep your work

to a minimum.

• Mark any wires before disconnecting to make

reassembly easier.

• Use Loctite® Blue or eq uivale nt on al l threaded

fasteners without lock washers.

Within the Component Repair section of this

manual, each repair pr ocedure is broken do wn into

three main categories for each component . These

categories are Testing, Adjustment, and

Replacement and are identified by the following

symbols:

Accompanying this manual, attached to the inside

front cover, is a Compact Disc containing an

electronic color vers ion of this m anual in Ac robat .pdf

format along with other useful digital content. For

more information vie w the README.TXT file located

on the CD.

Adobe Reader is required to view .pdf files and can

be downloaded free of charge from the following

website:

http://www.adobe.com/products/acrobat/alternate.html#50

The digital color version of the manual is also

interactive, allowing the user to simply click onto a

subject within the Table of C ontents to take them to

the specified page.

Service and Maintenance Manual 1-1 960714-02B © 2007 I2407

Page 7

SX™

SECTION 1 – INTRODUCTION

GENERAL INFORMATION

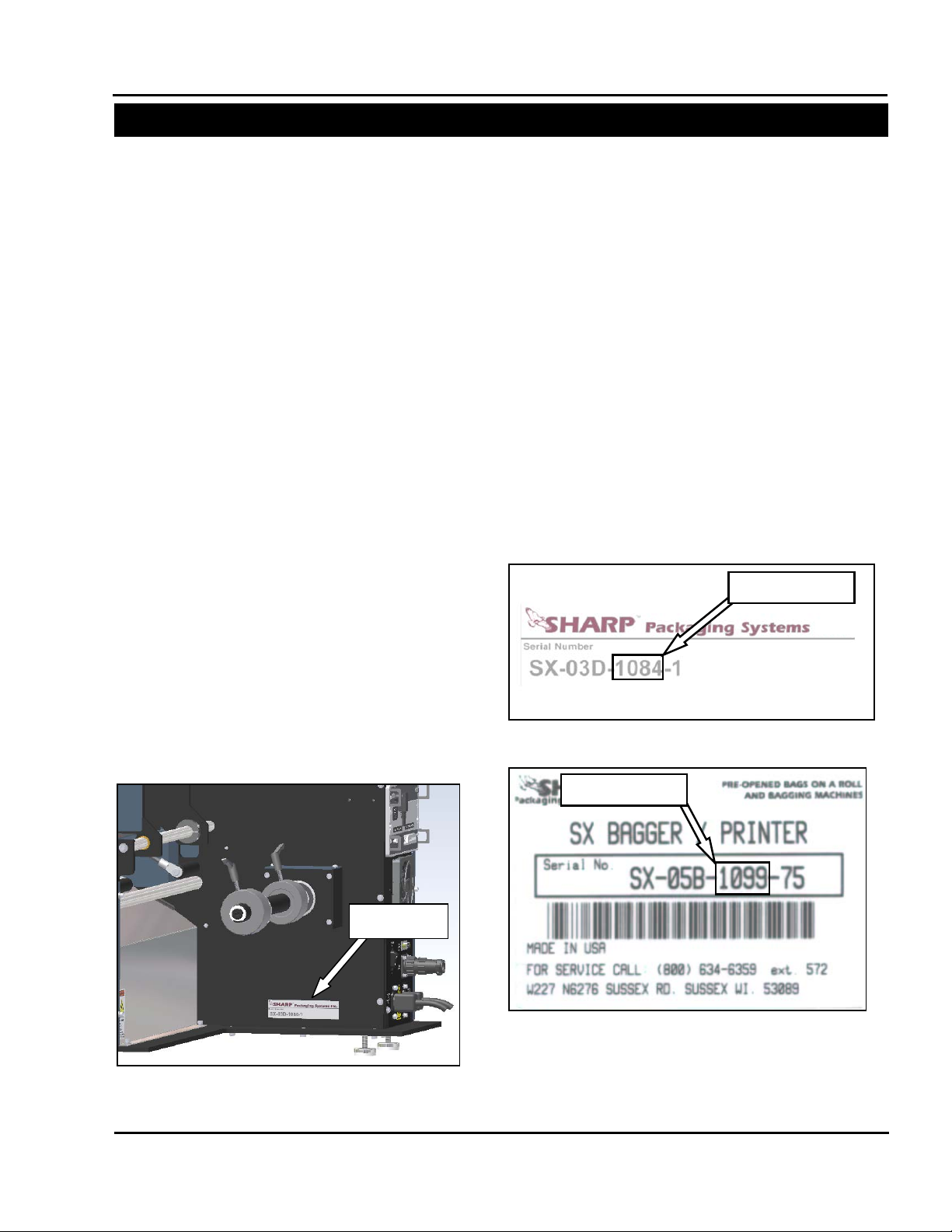

Figure 1-1. Serial Tag Location

Serial Tag

Figure 1-2. Model 1075 and 1084 Serial Tag

Model Number

Figure 1-3. Model 1097, 1099, 1108, and 1109

Model Number

MODEL VARIATION

This manual has been developed to assist in

servicing and maintaining the Sharp SX™ with

Printer model 1108 and the Sharp SX™ model

1109. Although th is manual has been written for

this specific model, the procedures and

techniques for replacing components and

troubleshooting can generally be applied to all

models of the SX™. Major differences in

machine maintenance or component repair will

be noted on a case by case basis. T he parts lists

and assembly drawings located in secti ons 5 and

6 of this manual are specifically for these two

models. If a replacement part is needed for an

older model of machine, please refer to the CD

located in the front of this manual. This CD

contains the parts lists and assembly drawings

for all previous m odels of the Sh ar p SX™ and the

Sharp SX™ with Printer.

The replacement parts lists located on the CD

have been separated by model number for ease

of identifying the parts that are needed. Sim ply

locate the section of the manual that coincides

with the SX™ model you have and proc eed from

there.

TECHINCAL ASSISTANCE

Assistance with the SX™ can be obtained by

notifying Sharp Packaging Systems at:

Sharp Packaging Systems

PO Box 124

Sussex, WI 53089, USA

Service: 800-634-6359 (ext. 572)

service@sharppackaging.com

Parts: 800-634-6359 (ext. 571)

parts@sharppackaging.com

Fax: 262-246-3387

To determine which m odel of t he Shar p SX™ you

have, refer to Figure 1-1. The serial number is

located on a placard or sticker directly below the

roll unwind shaft. The highlighted numbers in

Figures 1-2 and 1-3 coincide with the model of

the machine.

Serial Tag

Service and Maintenance Manual 1-2 960714-02B © 2007 I2407

Page 8

SX™

SECTION 1 – INTRODUCTION

THEORY OF OPERATION

is equipped with a jaw

not designed, nor intended, to be a safety

WARNING

GENERAL

The Sharp SX™ is controlled by a PLC

(Programmable Logic Controller). The PLC

receives input from the operator touchscreen to

control a stepper drive motor and an electric eye

sensor on the bag feeder output end.

The Sharp SX™ is equi pped with a sensor on the

pressure jaw which c a n d et ec t an obs truc ti on. If an

object triggers the sensor , the pressure jaw motor

will reverse, and place the bagger into a fault. A

message appears on the control panel displaying

the jaw fault, allo wing the operator to clear t he seal

area and restart the bagging cycle.

Note: the Sharp SX™ is n ot designed to interface

with automatic infeed units such as counters,

scales, or infeed conveyors.

The Sharp SXTM

obstruction detection sensor. This sensor is

sensor.

• The Sharp SX™ uses pre-opened Sharp EZ-

• A constant stream of air opens (inflates) the

• Product is loaded into the bag.

• Once the bag is loaded , t h e op erator cycles the

• The pressure jaw closes and grips the bag.

• An electric eye is used to sense the trailing

. The bags are dispensed through the

Bags

powered drive rollers.

bag, preparing the bag to be loaded.

machine (either by foot control, optional dual

optical palm buttons, f rom the Touchscreen or

the machine can be set on autom atic cycle) to

seal the bag.

The impulse sealer heats up and seals the bag

while the power drive rollers reverse to

separate the bag at the perforation.

edge of the bag. Hang holes , vent holes, etc.

must be prevented from passing over the

electric eye as this will send a false signal to

Service and Maintenance Manual 1-3 960714-02B © 2007 I2407

the PLC. To prevent this, the e lectric eye has

been designed to be off center of the bag,

however, in som e cases the bags m ay have to

be repositioned when larger hang holes, vent

holes, etc. are present (see Loading Bag Film).

• When the bag is sealed and seal dwell is

complete, the pressure jaw opens.

• The Printhead is lowered and the bag is

indexed forward at prin tin g s peed unt il th e l abe l

is completed. The Printhead is raised and the

balance of the bag length is index ed forward at

full index speed (bagger speed). (Note: This

step occurs only if model is equipped with an

imprinter)

• As the bags are indexed, the Mat erial Unwind

Shaft will spin allowing the bags to be pulled

from the roll. The Material Unwind Shaft is

comprised of a Roll Tensioner with

compression spring, Cor e Chuc k, and a t orsion

spring. When the roll of bags is loaded onto

the machine, pressure is applied to the Roll

Tensioner which in turn applies press ure to the

roll side plate c reat ing a kind of slip clutch. The

pressure that is ap plied t o t he Rol l Tens ioner is

directly proportional to the type and thickness

of the material being used. As this pressure

increases the amount of tension on the web

also increases. The appropriate amount of

pressure that should be applied to the Roll

Tensioner can be found using trial and error.

• The constant stream of air inflates the bag,

preparing the bag to be loaded.

Figure 1-4. Sharp SX™

Page 9

SX™

SECTION 1 – INTRODUCTION

THEORY OF OPERATION

FAULTS

The Sharp SX™ has been designed to alert the

operator, via the Touc hscreen, to a situat ion (fault)

that requires immediate attention. These faults

may indicate a serious condition where, if not

corrected, damage to the unit may occur or the

fault may simply alert the o perator that th e unit has

run out of film. The following is a list of possible

faults that may occur duri ng operation. A detailed

list of faults, causes an d solutions can be found in

the Troubleshooting section of this manual.

• WEB DID NOT BACK UP

The machine reverses the drive rollers to separate

the web of bags at the per f or ation. T he b ag ger has

a photo eye that it uses to detect the trai ling edge

of the bag. When the photo eye does not detect

this trailing edge w ithin the allowed time, this fault

is triggered.

• JAW FAULT

The Obstruction Sensing Jaw has detected an

object in the sealing area during the sealing

operation.

• OBSTRUCTION SENSING JAW TIMER

FAULT

The Obstruction Sensing Jaw did not close within

the preset time, but there was no obstruction

sensed.

• THERE ARE NO BAGS COVERING THE EYE

This fault is triggered when the machine cycle is

initiated and the photo eye is not activated.

• BATCH IS COMPLETE

This message is activated when the bagger has

cycled the specified number of times set by the

operator under Batch Target.

Batch Target – A predetermined num ber of cycles

that will be completed before the machine will

automatically stop.

• WAITING FOR PRINTER SIGNAL*

The bagger has sent a print signal to the printer

and is waiting for a return signal.

*Note: This f ault w il l on ly oc cur if the Shar p SX™ is

equipped with an imprinter.

Service and Maintenance Manual 1-4 960714-02B © 2007 I2407

Page 10

SX™

SECTION 1 – INTRODUCTION

THEORY OF OPERATION

SHARP EZ-BAGS

AND FILM MATERIALS

The Sharp SX™ is design ed to use a wide variety

of bag sizes and materials. Sharp EZ-Bags

recommended for opt imum operating performance,

efficiency and safety. System performance

specifications are based on utilizing consistent,

high quality, pre-ope ned bags . Any bag used mus t

meet Sharp Packaging Systems’ manufacturing

tolerances. The following list shows some of the

Sharp EZ-Bags

films available through Sharp

Packaging Systems, Inc.

• Low Density Polyethylene (LDPE)

• Linear Low Density Polyethylene (LLDPE)

• High Molecular Weight, High Density

Polyethylene (HMWHDPE)

• Laminated Oriented Polypropylene

(Laminate/OPP)

• Polypropylene

• Metallic Films (including conductive films)

• Co-Extruded Films (combination films)

• Other Laminates (any other laminates

laminated with polyethylene)

• Anti-static and Triboelectric films

• VCI corrosion inhibiting films

• Opaque films

Contact Sharp Customer Service (800-634-6359) or

www.customerserviceteam@sharppackaging.com

to order Sharp EZ-Bags

regarding film and bag specifications.

and for information

are

THERMAL TRANSFER RIBBON*

The Sharp SX™ uses thermal transfer ribbon to

print variable information onto the bags as they

pass through the mac hine. The follo wing is a list of

ribbon that is available through Sharp Packaging

Systems, Inc. For ordering inf ormation refer to the

Replacement Parts Order F orm i n the Append ix on

page A-1.

• Standard Direct Wax Ribbon

• Premium Wax Resin Ribbon

*Note: Used only if the Sharp SX™ is equipped

with an imprinter.

SUPPLIES

Thermal Transfer Ribbons

Sharp thermal transfer ribbons are selected

specifically for use with our printer. Use of ribbons

other than those suppli ed by Sharp, m ay result in a

poor quality printing , especiall y bar-codes and th eir

ability to be succes sfully scanned. This may also

void the print head warranty.

Recommended Sharp ribbons are:

• Black ink, scratch and smudge resistant

• 2000’ (609 meters), 3.5 to 4.5 microns thick

• 1” core, no notch required

• Ink side in

• Back coated ribbons only

Special purpose thermal transfer ribbons, sizes

other than those listed above, such as colored

ribbons, or low temperature release ribbons are

available.

Service and Maintenance Manual 1-5 960714-02B © 2007 I2407

Page 11

SX™

SECTION 1 – INTRODUCTION

SPECIFICATIONS

Minimum

Maximum

Bag Width

Bag Length

Film Gauge

2” (5.08 cm)

4” (10.16 cm)

9” (22.86 cm)

32” (81 cm)

.004” (4 mil) 100 microns

.001” (1 mil) 25 microns

Width

Height

Depth

Weight

Power

Rate

Operating

Humidity

** Size of package along with weight and size of product will cause rate to vary.

35.25" [89.54 cm]

26.75" [67.94 cm]

26.00" [66.04 cm]

PACKAGING SPECIFICATIONS

MACHINE SPECIFICATIONS

26.75”

(67.9 cm)

19”

(48.3 cm)

35.25”

(89.5 cm)

DIMENSIONS

200 lbs.

(91 kg)

Req.

115 VAC

50/60 Hz

15 Amps

35**

bags per

minute

Temp

0°-40°C

32°-140°F

Range

10%-90%RH

Non-

Condensing

Service and Maintenance Manual 1-6 960714-02B © 2007 I2407

Page 12

SX™

SECTION 2 – MAINTENANCE AND ADJUSTMENTS

MAINTENANCE SCHEDULE

on the machine.

WARNING

Always remove electrical power from the

prior to performing any maintenance

SX

DAILY MAINTENANCE

• Inspect the electric eye. Clean with a c otton

swab if dirty. Do not use any solvents or

cleaning solutions on the s ensing portions of

the electric eye.

• Clean any excess material from the drive

roller and platen roller on the film feed

assembly. Plastic com pounds tend to buildup on the rollers. Clean regular ly with a soft,

lint-free cloth using a rubber platen roller

conditioner/cleaner or isopropyl alcohol.

• Inspect Teflon tape on the seal wire and

replace if damaged or worn.

• Inspect the anvil rubber on the pressure bar

assembly and replace if damaged or worn.

• Inspect all electrical li nes for any sign of wear

or damage. Replace any lines that appear

worn or unsafe.

• If the Sharp SX is equipped with a printer,

the printhead needs to be cleaned with a

soft, lint-fr ee cloth a nd is oprop yl alcoho l. T his

will be explained further on page 2-3 in the

section entitled “Cleaning the Printhead and

Film Feed Rollers.”

ANNUAL MAINTENANCE

• Check all electrical connections.

• Check entire machine for loose bolts or nuts.

• Inspect all drive belts for excessive wear and

slack.

• Grease the four pressure bar linear guide

bearings using lithium grease (JIS Type 2).*

• Apply a light film of grease to the pressure

bar rack and pinion gearing using lithium

grease (JIS Type 2).*

* Note: The recommended lubrication interval for

the linear guide bearings based on total travel is

approximately 500,000 cycles. Sharp Packaging

Systems suggests greasing the bearings at this

frequency or once a year, whichever comes first.

Both the linear guide be arin gs and th e pr ess ur e bar

gear rack and pinion gear can be lubricated with

the same frequency.

MONTHLY MAINTENANCE

• Clean the foam element located on the

cooling fan on the rear of the machine with

water, wring out, and reinstall.

Service and Maintenance Manual 2-1 960714-02B © 2007 I2407

Page 13

of the machine with any liquid while

components can cause shorts,

WARNING

WARNING

the machine prior to performing any

WARNING

Do not attempt to clean the machine

injury or death.

WARNING

SX™

SECTION 2 – MAINTENANCE AND ADJUSTMENTS

CLEANING

GENERAL

This machine requires regular, periodic

cleaning to ensure reliable service. Shift and

daily cleaning can be performed by the

operator with a minimum of training.

Regular cleaning is important for the proper

operation and performance of the machine.

During operation there wil l be a normal buildup

of dirt, dust, and lubricants on various parts of

the machine. If using the Sharp SX™ with

Printer, ink rubbed off of printed film can also

build up.

The machine and areas directly adjacent to it

should be kept clean of debris as these can

create safety hazar ds for the operator and the

machine.

Disconnect electrical power cords from

maintenance on machine.

Do not spray the electrical components

power is applied. Liquids on electrical

damaging the components and causing

personal injury or death.

Avoid hot surfaces. Do not service the

machine until the heated surfaces have

cooled after disconnecting power.

while it is running. Cleaning the

machine while it is running can damage

the machine and cause severe personal

No cleaning should be performed unless these

safety precautions are thoroughly understood and

are adhered to without exception.

Clean machine surfaces during each pause in

production – NEVER while the machine is running.

Remove contaminants a nd debr is, and use a c lean,

soft lint-free cloth to wipe down the machine.

• Inspect the machine to determine if there has

been an accumulation of dust or other

contamination. Clean if necessary.

• ALWAYS SHUT OFF AND UNPLUG machine

power cord before cleaning or removing any

guards.

• NEVER defeat an y saf et y d evic e or i nterlock on

the machine.

• DO NOT use steel wool on machine surfaces.

Particles of steel wool m ay break off and cause

rusting or contaminate lubricated surfaces.

• DO NOT allow wrenches, fittings or other

metallic objects to lie on machine surfaces

during production.

• DO NOT use chlorine, am monia, alkalis, acids,

or cleaning solutions that will damage m etallic

machine surfaces, cause corrosion or

contaminate containers.

Service and Maintenance Manual 2-2 960714-02B © 2007 I2407

Page 14

on the machine.

WARNING

Do not pour isopropyl alcohol or any

cleaning solution directly onto the

the machine.

CAUTION

Cradle

Cradle Latch

Figure 2-1. Opening the Printhead Cradle

Figure 2-2. Cleaning the Printhead

Thermal

SX™

SECTION 2 – MAINTENANCE AND ADJUSTMENTS

CLEANING

CLEANING THE PRINTHEAD & FILM

FEED ROLLERS

*Note: This section is specifically for t he Model

with Printer . If your model does not have

SX

a printer, only follow st eps 5 and 6 for clean ing

the film feed drive roller.

Always remove electrical power from the

1. With power removed from the machine,

2. Gently slide the ribbon to the side to

3. Moiste n a soft, lint-free cloth with is opropyl

4. Slide the ribbon into its original position.

prior to performing any maintenance

SX

release the cradle latch to grant access to

the printhead and the rubber rollers on the

film feed assembly. Also, open the

printhead cradle cover (Figure 2-1).

expose the printhead.

alcohol and gentl y wipe the surf ace of the

printhead to clean dust and residue from

the surface, as shown in Figure 2-2.

printhead or rollers. Liquids may short

electrical components, causing damage to

Make approximately ten tur ns on t he ribbo n

rewind hub to take up slack and wrinkles,

ensuring it is completel y flat over the rib bon

rollers and printhead.

Service and Maintenance Manual 2-3 960714-02B © 2007 I2407

Cover

Printhead

Page 15

SX™

SECTION 2 – MAINTENANCE AND ADJUSTMENTS

CLEANING

Figure 2-3. Cleaning the Film Feed Drive Roller

Film Feed

Platen

Roller

CLEANING THE PRINTHEAD & FILM

FEED ROLLERS (cont.)

5. Rem oisten the lint-free cloth with isopropyl

alcohol and rub back and forth along film

feed drive roller as shown in Figure 2-3.

Clean roller until residue is removed. Be

careful not to damage rubber coating on

roller, as this will affect machine

performance.

6. Manually rotate film feed drive roller, and

repeat procedure in step 5. Continue

wiping and rotating until the entire surface

of the drive roller is clean.

7. Repe at steps 5 and 6 on the platen roller,

again being careful to not damage the

rubber surface.

Drive Roller

8. When both rollers are clean, thread bag

film through the machine, and close the

printhead cradle cover. Turn the cradle

latch to the locked position.

Service and Maintenance Manual 2-4 960714-02B © 2007 I2407

Page 16

SX™

SECTION 2 – MAINTENANCE AND ADJUSTMENTS

MACHINE ADJUSTMENTS

SX™

SECTION 2 – MAINTENANCE AND ADJUSTMENTS

MACHINE ADJUSTMENTS

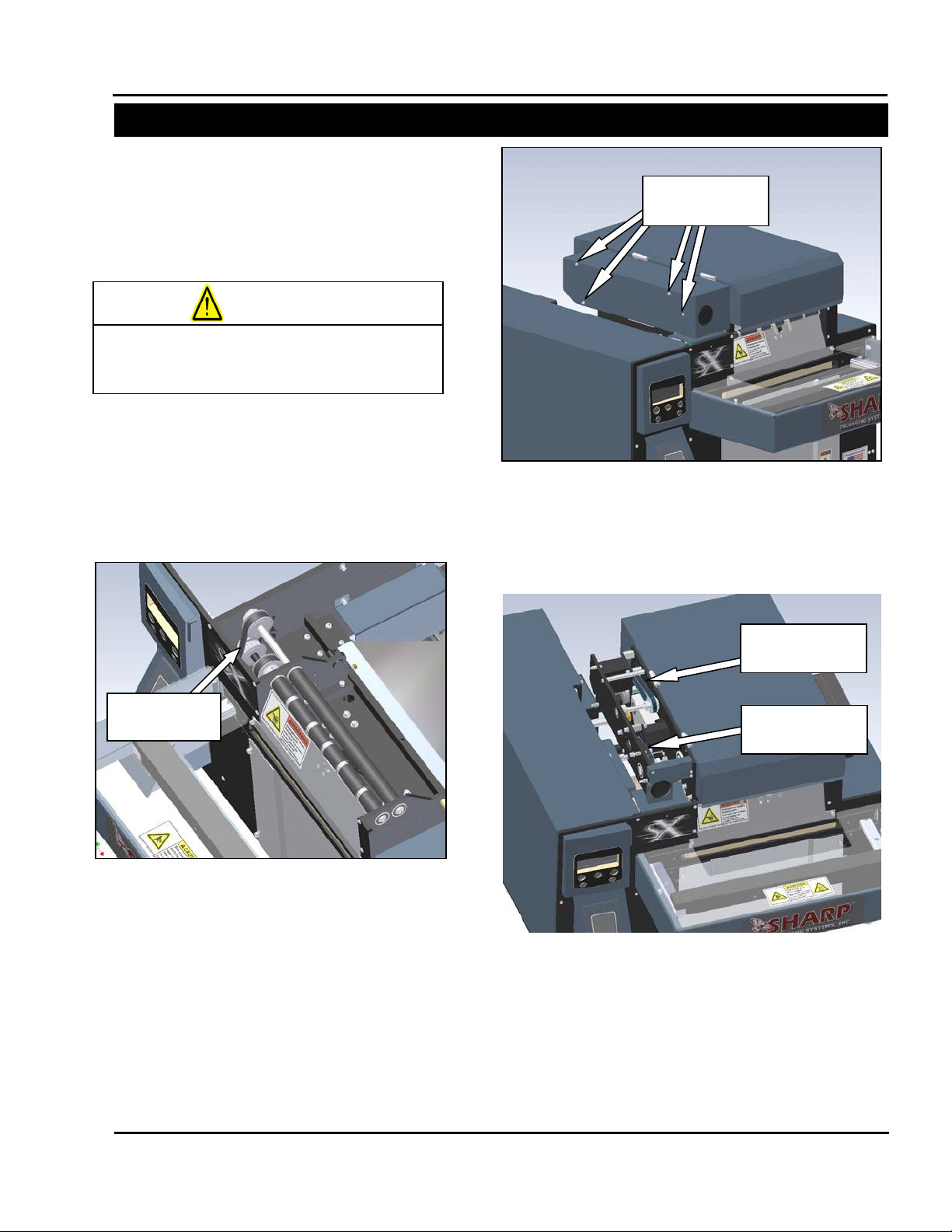

Figure 2-4. Pinch Roller Adjustment Screws

Pinch Roller

Adjustment Set Screws

Figure 2-5. Jam Nut and Set Screw

Set Screw and Jam Nut

Flush for Initial Adjustment

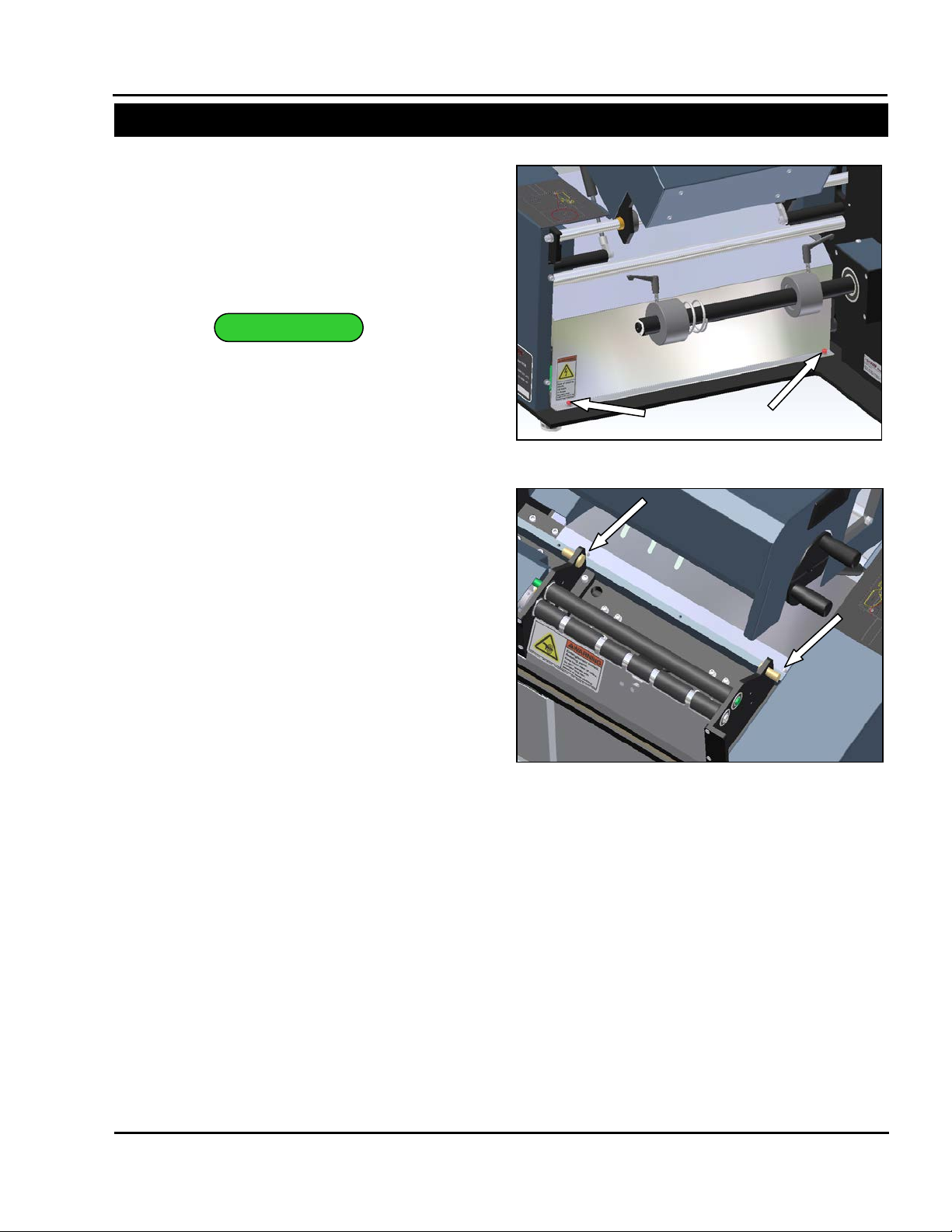

ADJUSTING THE PINCH ROLLER

The pinch roller adjustment is used to control

excess “traveling” of the film to either side of the

pinch roller. This traveling is due to uneven

pressure distributed by the pinch roller onto the

drive roller. This pressure is created by slidespring mechanisms on each end of the pinch ro ller.

Under normal usage, the pinch roller should not

come out of adjustment. Before changing the

factory settings on the pinch roller, be sure to check

the unwind for proper web tension and alignment.

If changing the roll setting does not prevent

traveling, follow these steps to adjust the pinch

roller tension.

1. O pen the printhead cradle cover to expose the

printhead components and pinch roller.

2. Confirm the preset adjustment of the pinch

roller. The top of the set s crew should be flush

with the top of the hex jam nut. If either side is

not flush, turn the j am nut counter-clockwise to

unlock the set scr ew. Adjust the set screw to

the proper height, an d retighten the jam nut to

lock into place. Clos e cradle cover, and cycle

machine to check for traveling issues.

3. If the pinch roller adjustment springs are set

correctly and the film still travels, release the

jam nut and turn the set screw opposite the

side the media is pulling towards down in 1/4

turn increments. Loc k the jam nut, and check

for traveling. Continue this process until the

bag film feeds out ev enly and does n ot walk to

either side.

Service and Maintenance Manual 2-5 960714-02B © 2007 I2407

Service and Maintenance Manual 2-5 960714-02B © 2007 I2407

Page 17

SX™

SECTION 2 – MAINTENANCE AND ADJUSTMENTS

MACHINE ADJUSTMENTS

on the machine.

WARNING

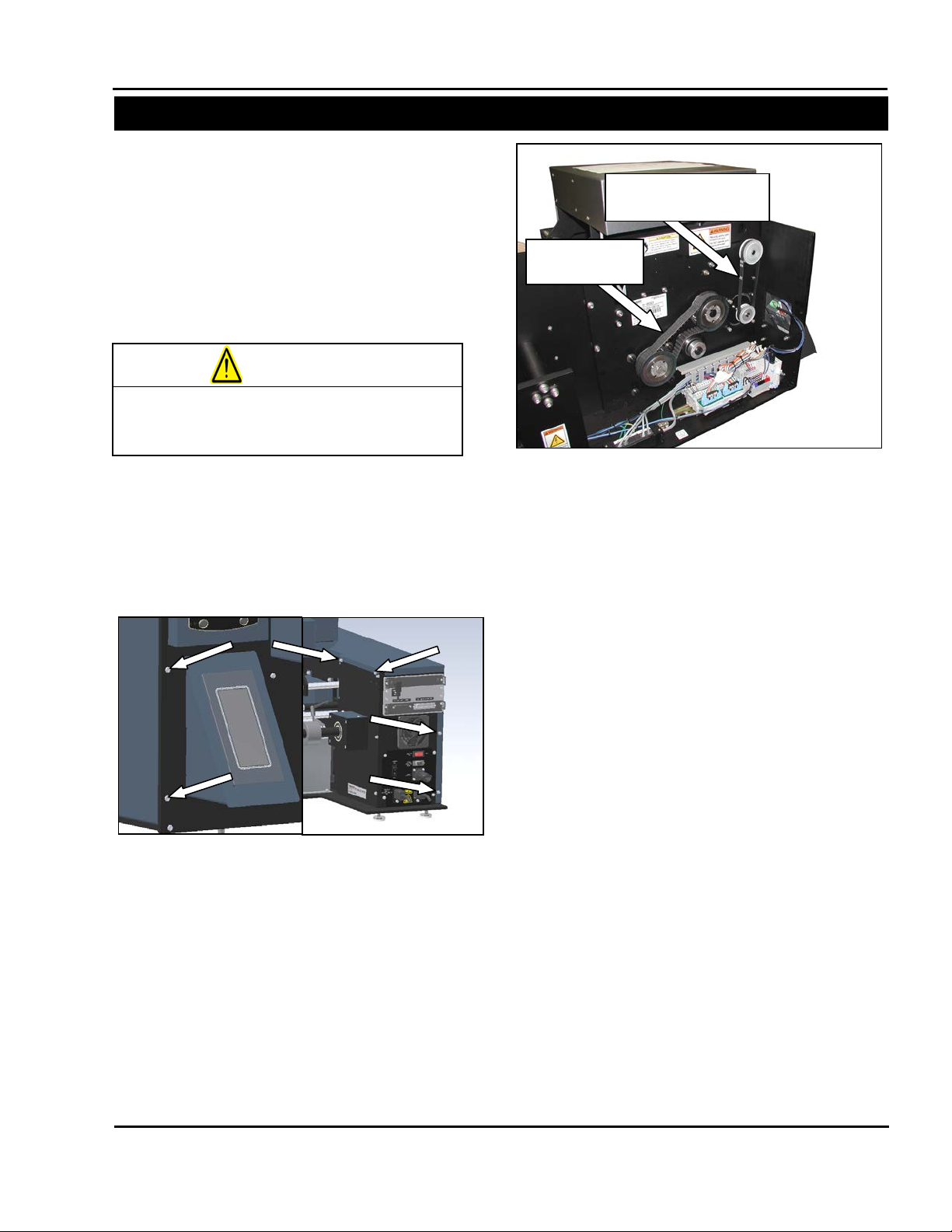

Figure 2-7. Pressure Bar and Film Feed Belts

Pressure Jaw

Drive Belt

Film Feed Motor

Drive Belt

Figure 2-6. Frame Cover Screws

CHECKING BELT TENSION

Sharp SX

The Sharp SX has three belts, one whic h drives

the pressure jaw and two that drive the film feed

drive roller. To ensure proper operation of the

machine, these belts ne ed t o be c hecked for proper

tension to avoid slip.

Always remove electrical power from the

1. With machine power disconnected, remove

2. Locate the pressure jaw drive belt (Figure 2-

prior to performing any maintenance

SX

the left side frame guard. Remove the two

screws on the rear face plate, the t wo screws

on the front face plate, and the two s crews on

the middle unwind plate (Figure 2-6).

7). Depress the center of the belt to

determine if the tension is appropriate. The

belt should deflect approximately 1/8” when

depressed with one finger at the center of the

longest belt span.*

3. If the belt deflects more than 1/8 loosen the

four motor mounting screws and apply

downward pressure to the pressure bar drive

motor. When m otor is in desired position for

proper belt tension, tighten four screws and

verify the belt deflects the recommended

amount. Repeat until belt is correctly

tensioned.

4. Locate the film feed motor drive belt (Figur e 2-

7). Repeat the process in step two to check

for correct tension. This belt should deflect

approximately 3/32” at proper tension. If too

tight or too loose, repea t step thr ee o n the f ilm

feed drive motor.

*Note: Belt tension shou ld be just e nough to ensure

a positive interference between belt and sprocket

teeth without allowing th em to jum p. If too t ight , t he

load may cause undue stress on the shafts and

shorten belt life. If too loose, the belt will not

engage the sprocket pr operly and the drive w ill slip

under normal loads. For a mor e de tai led method of

determining proper belt tension, contact Sharp

Packaging Systems customer service or consult

the belt manufacturer.

Service and Maintenance Manual 2-6 960714-02B © 2007 I2407

Page 18

SX™

SECTION 2 – MAINTENANCE AND ADJUSTMENTS

MACHINE ADJUSTMENTS

Film Feed Roller

Drive Belt

Figure 2-8 Pulley Guard Screws

Note: Cradle Removed for Clarity

Sharp SX (con’t)

5. Rele ase the cradle latch and open the c radle.

Remove the pulley cover to expose the drive

roller belt.

6. Chec k the film feed drive roller belt for tension

(Figure 2-9). This belt should deflect

approximately 1/16” using one finger to push

on the center of the belt span. If adjustment is

needed, loosen the idler screw and slide to

increase tension. Retighten screw and check

tension.

7. Reinstall frame guard and pulley guard that

were removed earlier. Clos e cradle and lock

into position.

Service and Maintenance Manual 2-7 960714-02B © 2007 I2407

Page 19

SX™

SECTION 2 – MAINTENANCE AND ADJUSTMENTS

MACHINE ADJUSTMENTS

on the machine.

WARNING

Figure 2-12. Ribbon Rewind Motor Belt and

Ribbon Rewind

Motor Belt

Printhead Lift

Drive Belt

Figure 2-10 Platen Roller Drive Belt

Note: Cradle Removed for Clarity

Platen Roller

Drive Belt

Outside Cradle

Screws

Figure 2-11. Removing the Outside Cr ad le Cov er

Sharp SX with Printer

The Sharp SX with Printer utilizes seven drive

belts during operation: one to drive the pressure

jaw, two to drive film feed roller s, one for the plat en

roller, one for the printhead lift cams, and two to

drive the printer ribbon rewind hub.

Always remove electrical power from the

prior to performing any maintenance

SX

1. Foll ow steps 1 through 6 o n pages 2-6 and 2-7

to check for proper tensio n of the pressure bar

drive belt and the two film feed drive belts.

2. Check the platen roller drive belt for tension

(Figure 2-10). This belt should deflect

approximately 1/16” using one finger to push

on the center of the belt span.

3. If belt tension is incorrect, loosen the idler

screw and slide idler t o add or rem ove tension.

Tighten screw and check belt. Repeat as

necessary.

4. Repl ac e t he pu lley guard by reinstall ing th e t wo

mounting screws.

5. Rem ove the four screws that hold the outside

cradle cover (Figure 2-11). Slide the cover off

to expose the ribbon r ewind hub drive and the

printhead lift drive.

6. Chec k the tension on the ribbon rewind motor

drive belt (Figure 2-12) using the same

procedure for the film feed drive belt. This belt

should deflect about 1/16”.

Printhead Lift Drive Belt

7. If belt does not have proper tension, loosen

four motor mounting screws and apply

pressure to motor towards the rear of the

machine. Retighten motor screws and check

for tension. Repeat as necessary.

Service and Maintenance Manual 2-8 960714-02B © 2007 I2407

Page 20

SX™

SECTION 3 – COMPONENT REPAIR

MACHINE ADJUSTMENTS

Ribbon Rewind

Slip Clutch Belt

Figure 2-13. Ribbon Rewind Slip Clutch Belt

Sharp SX with Printer (con’t)

8. Check the tension on the printhead lift drive

belt (Figure 2-12). This belt should deflect

1/16”. If incorrect, fol low method in step seven

to achieve proper tension.

9. Repl ace outsid e cradle c over, and reinstal l four

screws removed in step 5.

10. Close the printhead cradle and turn the latch

counter-clockwise to lock into position.

11. Open the top cradle cover by lifting on the

recessed plastic handle.

12. Locate the slip clutch belt between the left

printhead plate and the outer plate on the

hinged side of the cradle (Figure 2-13). At

proper tension, this belt should deflect about

1/16”.

13. To add or remove tension to this belt, loosen

the two screws on the idler plate and slide it

forward or backward to ad d or remove tension.

Tighten the screws, and rec heck belt. Repeat

as necessary.

14. Once all belt tensio ns have been check ed and

properly set, replace the side frame guard.

Service and Maintenance Manual 2-9 960714-02B © 2007 I2407

Page 21

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

TESTING

Figure 3-3. Fuse Probe Locations

Figure 3-1. Load Plate Screws

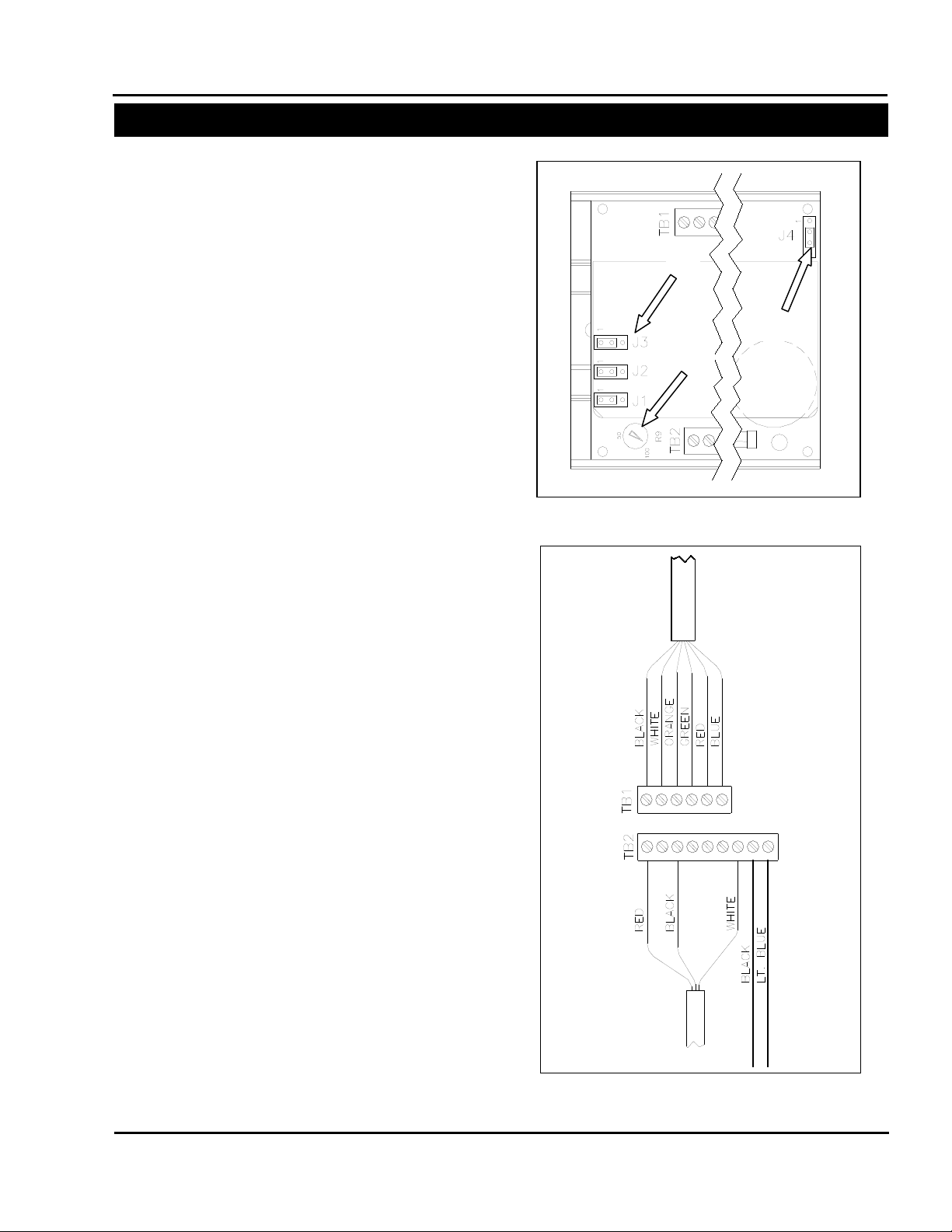

Figure 3-2. TM4500 Drive locations

Pressure

Jaw

Film

Feed

on the machine.

WARNING

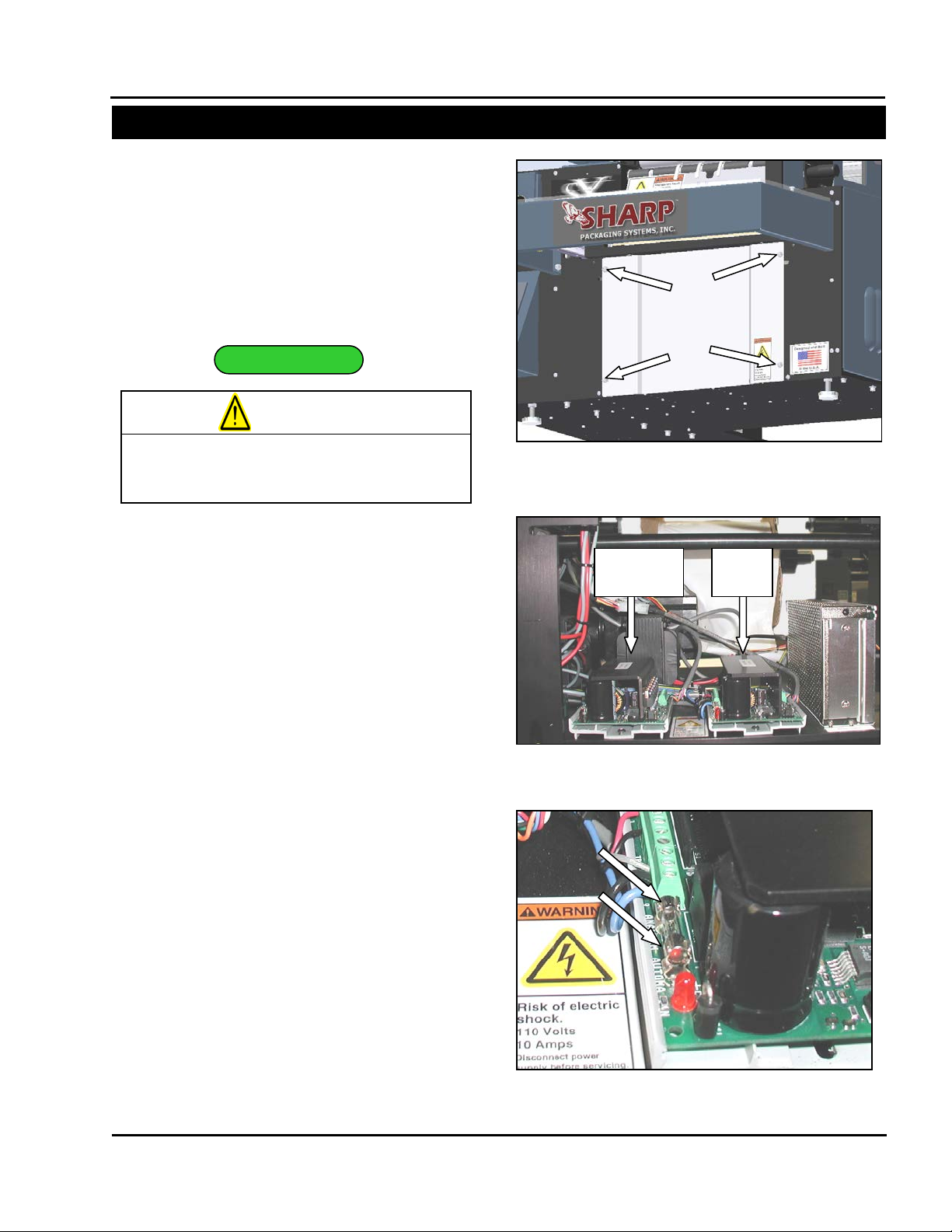

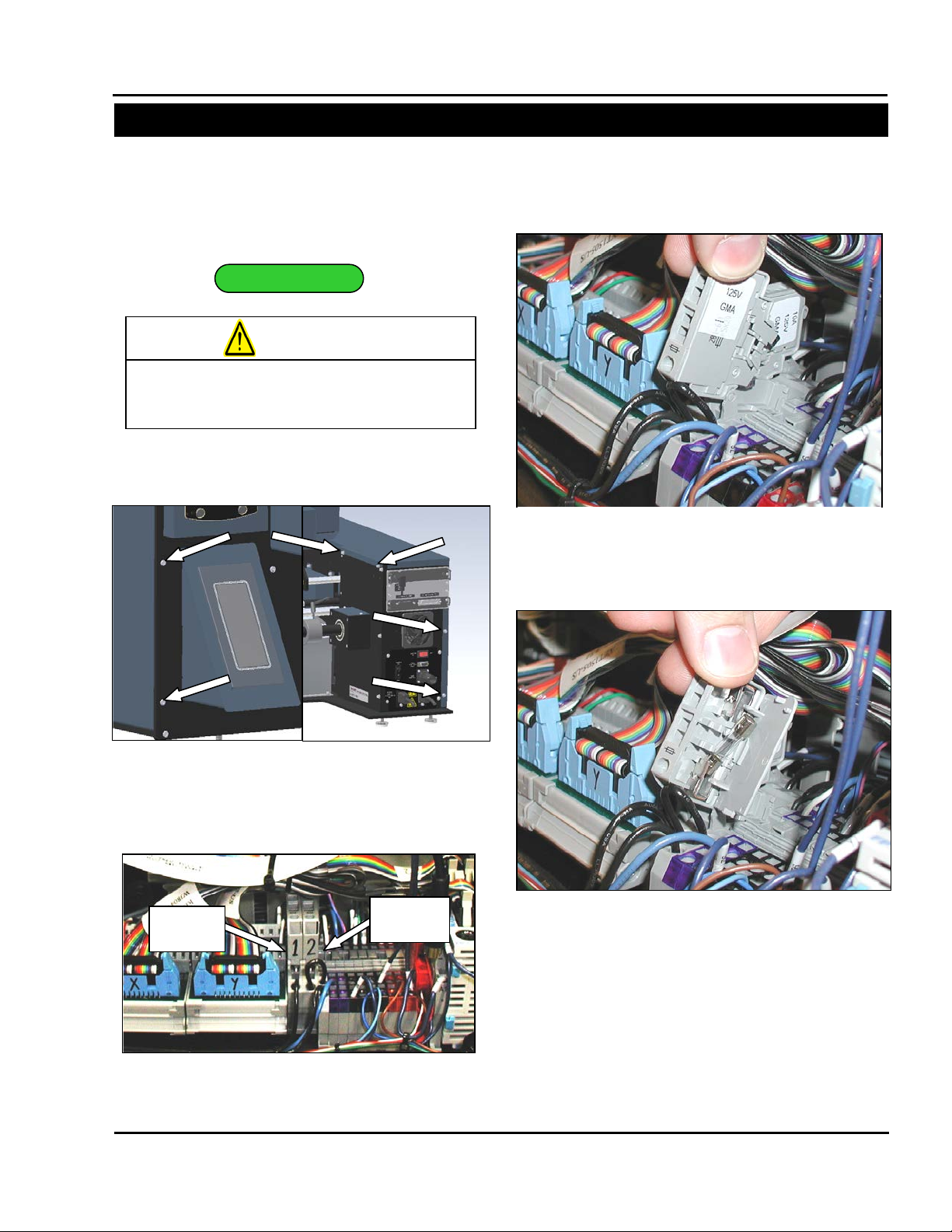

PRESSURE JAW AND FILM FEED MOTOR CONTROLLERS

The Sharp SX

technology to precisely control the movement of

various mechanical systems. This section will

describe how to service the two TM4500 stepper

drive units. These units control the Pressure Jaw

and Film Feed motors.

Always remove electrical power from the

prior to performing any maintenance

SX

1. Remove the four screws holding the Load

Plate, set screws and Load Plate aside (Figure

3-1).

2. Locate the two identical stepper drives inside

the Sharp SX

drive is on the left and the Film F eed drive is on

the right (Figure 3-2).

3. Loc ate the fuse on th e defective u nit (Figure 3-

3).

4. Set your Digital Volt/Ohm Meter (DVOM) to test

for continuity.

5. With the red probe, make contact with the

metal on one side of the fuse and with the

black probe make c ontact with the ot her side of

the fuse (Figure 3-3).

6. If your DVOM indicates that there is no

continuity, replace the fuse.

Note: A blown fuse can be an indication of a

larger problem. If you continue to blow fuses,

test the stepper motors and power

connections.

TM

bagger uses stepper drive

TM

Bagger. The Pressure Jaw

Service and Maintenance Manual 3-1 960714-02B © 2007 I2407

Page 22

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

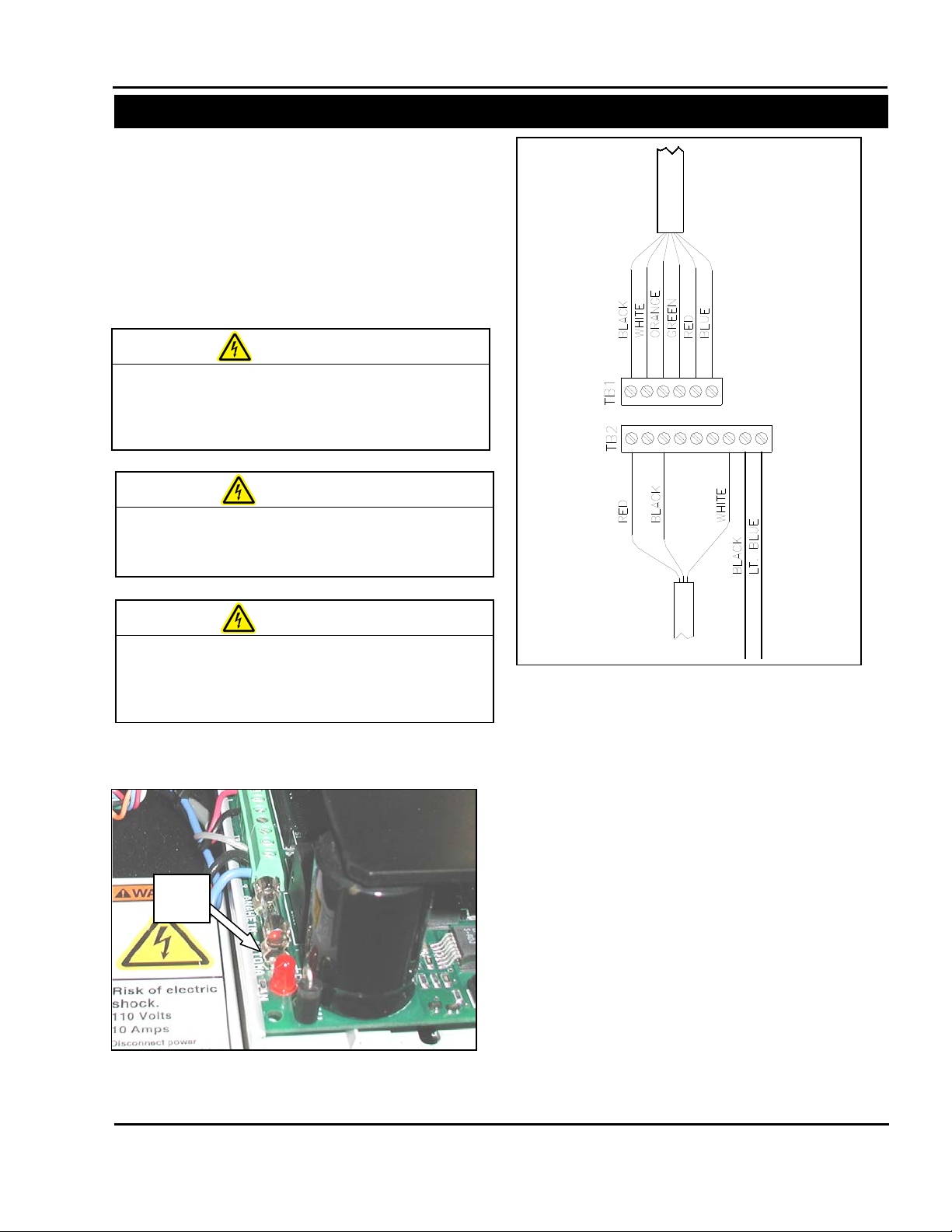

Figure 3-5. TM4500 Wiring Configuration

Figure 3-4. Status LED Location

Red

LED

MACHINE WHILE POWER IS APPLIED.

UNEXPECTED MACHINE STARTUP CAN

CAUSE SERIOUS INJURY.

WARNING

AND ARMS CLEAR OF MOVING PARTS.

WARNING

USE PROPER TROUBLESHOOTING

TECHNIQUES TO AVOID ELECTRICAL SHOCK.

WARNING

PRESSURE JAW AND FILM FEED

MOTOR CONTROLLERS (con’t)

7. If the fuse is OK, check the wiring of TB1 and

TB2. Reconnect any loose wires. (Figure 3-5).

8. Connect power cords to the Sharp SX

and turn the bagger on.

USE EXTREM E CAUTION WHILE SERVICING A

DO NOT ATTEMPT TO SERVICE THE MACHINE

DURING NORMAL OPERATION. KEEP HANDS

WHEN TESTING ELECTRICAL COMPONENTS

WHILE POWER IS APPLIED TO T HE MACHINE,

9. Loc ate Red LED on the de fective drive (Figure

3-4).

Service and Maintenance Manual 3-2 960714-02B © 2007 I2407

TM

Bagger

10. If the LED is blinking, use the following

information to diagnose the problem.

• Is the LED blinking once?

This error code indicates t hat there is an open

or sporadic connection in one of the motor

wires. Check the wiring and ensure that the

connector screws are tight.

• Is the LED blinking twice?

This error code indica tes th at ther e is a s hort in

one of the motor lines . This can either occur in

the windings of the motor or be caused by

loose wiring.

1. Disconnect the motor from the drive at the

white 2x3 pin plug.

2. Check the motor and wiring for shorts.

Page 23

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

Figure 3-8. TM4500 Configuration

A

B C ADJUSTMENT

Figure 3-6. Load Plate Screws

Figure 3-7. TM4500 Drive locations

Pressure

Jaw

Film

Feed

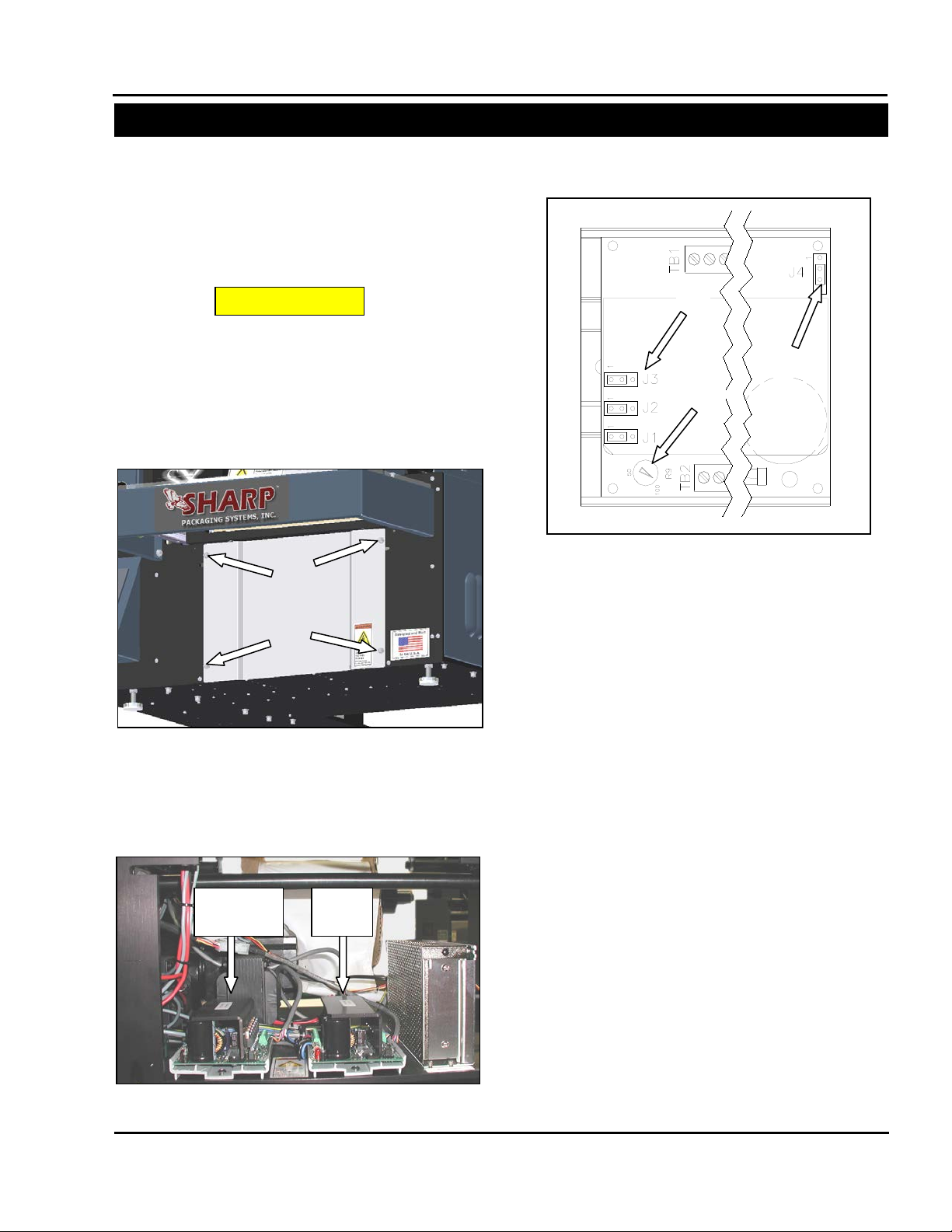

PRESSURE JAW AND FILM FEED

MOTOR CONTROLLERS (con’t)

11. Refer to section on testing transformers to test

incoming voltage.

The TM4500 Stepper Drives are controlled by the

Aromat PLC and should be left at the factory

default settings. T he following steps will guide you

through resetting the drives to factory defaults.

1. Remove the four screws from the Load Plate

and set aside (Figure 3-6).

2. There are two identical TM4500 drives, the

Pressure Jaw motor controller is on t he lef t and

the Film Feed motor controller is on the right

(Figure 3-7).

3. Set Jumpers JP1, JP2 and JP3 so that the

jumpers covers pins 1 and 2 (Figure 3-8 A)

4. Adjust Kick Current POT (potentiometer) so

that arrow points to 100 (Figure 3-8 B).

5. Set jumper JP4 so that the jumper covers pins

2 and 3 (Figure 3-8 C).

6. Reattach Load Plate to front of machine with

screws and locking washers.

Service and Maintenance Manual 3-3 960714-02B © 2007 I2407

Page 24

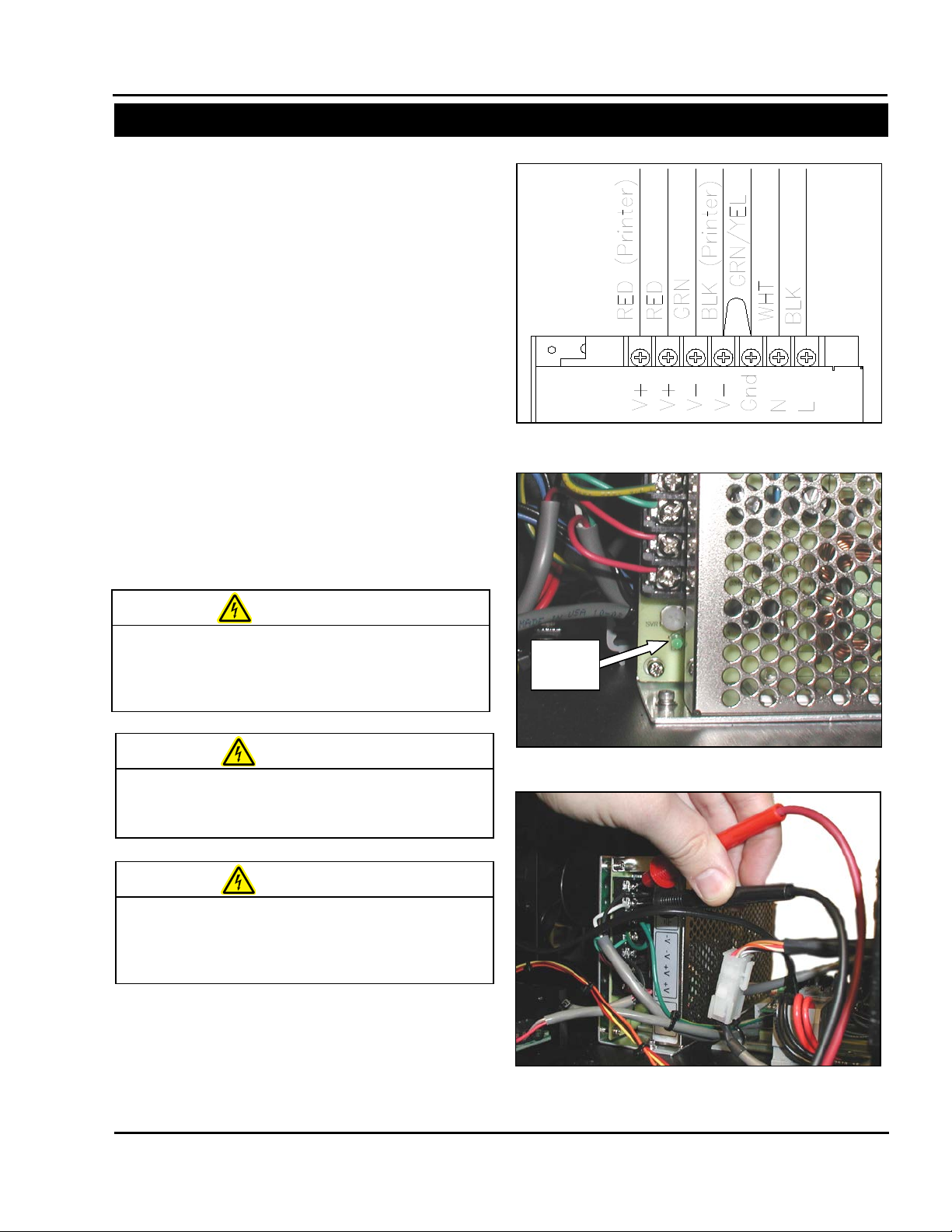

Figure 3-11 Green Connector Block

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

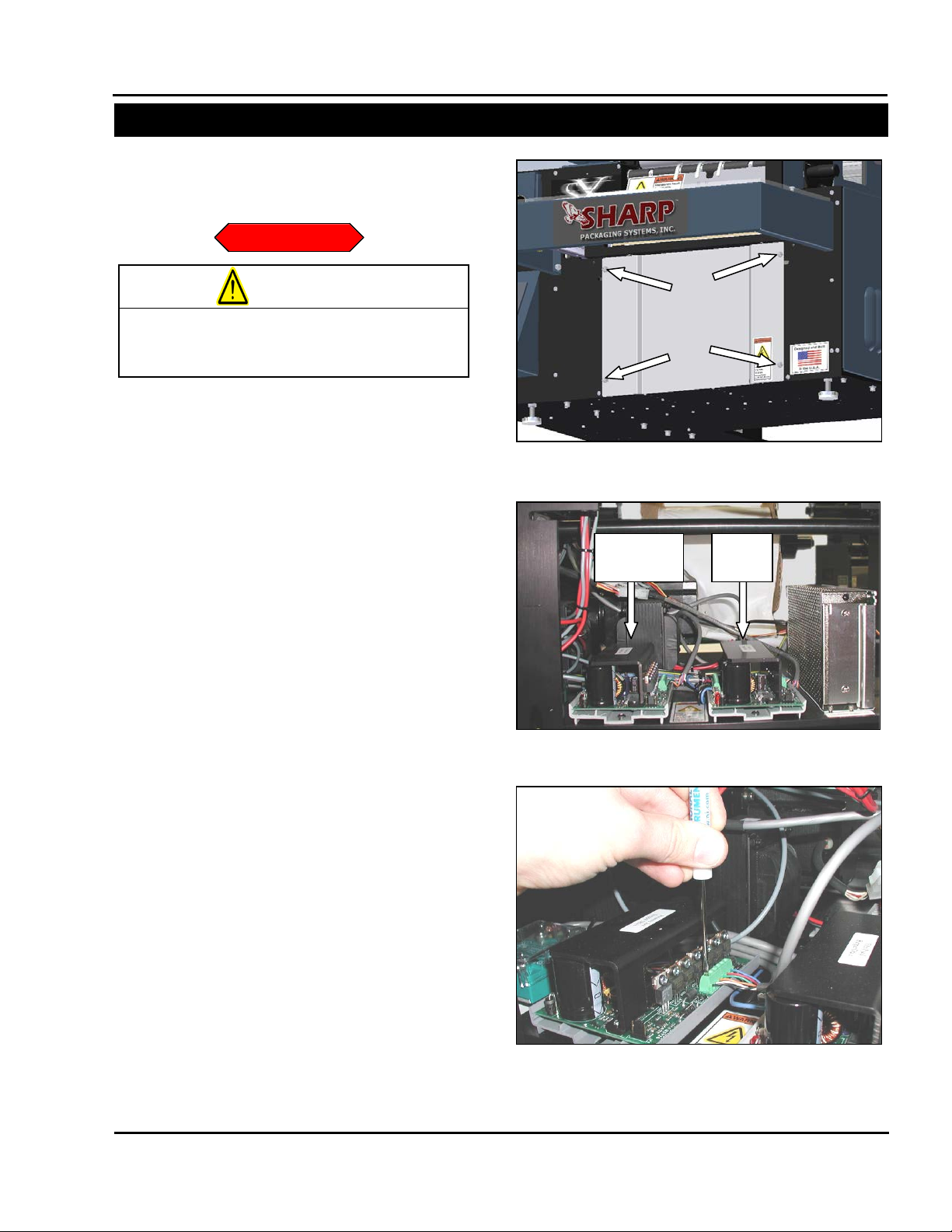

REPLACEMENT

Figure 3-10. TM4500 Drive locations

Pressure

Jaw

Film

Feed

Figure 3-9. Load Plate Screws

on the machine.

WARNING

PRESSURE JAW AND FILM FEED

MOTOR CONTROLLERS (con’t)

Always remove electrical power from the

1. Remove the four screws holding the Load

2. Loc ate the TM45 00 Steppe r Drive tha t requires

3. Unscrew all connections from the green

4. Slide drive out of grey DIN rail holder. The

5. Remove new drive from static bag.

prior to performing any maintenance

SX

Plate, set screws and Load Plate aside (Figure

3-9).

replacement. The Pressure Jaw motor

controller is on the lef t and the Fi lm Feed motor

controller is on the right (Figure 3-10).

connection blocks TB1 and TB2 (Figure 3-11).

drive is held in the DIN rail holder by friction

and requires considerable force to remove.

Brace the machine with one hand while firm ly

pulling the drive toward you with the other

hand.

Service and Maintenance Manual 3-4 960714-02B © 2007 I2407

Page 25

Figure 3-13. TM4500 Wiring Configuration

Figure 3-12. TM4500 Configuration

A

B

C

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

PRESSURE JAW AND FILM FEED

MOTOR CONTROLLERS (con’t)

6. Set jumpers JP1, JP2 and JP3 so that the

jumper covers pins 1 and 2 (Figure 3-12 A).

7. Set the POT so that the arrow points to 100

(Figure 3-12 B).

8. Set jumper JP4 so that the jumper c overs pins

2 and 3 (Figure 3-12 C).

9. O rientate drive so T B2 is on your left and slide

new drive into DIN rail holder. This will take

considerable force. Brace the machine with

one hand wile firml y pushing the new drive into

the DIN rail holder.

10. Reconnect all wires as they were con nected to

the previous drive (Figure 3-13).

11. Reattach Load Plate t o front of machine using

screws and locking washers.

Service and Maintenance Manual 3-5 960714-02B © 2007 I2407

Page 26

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

TESTING

Figure 3-14. Frame Cover Screws

Figure 3-16. Pivot Fuse Holder

Figure 3-17. Fuse Access Door

Figure 3-15. Fuse Locations

System

Fuse

Stepper

Fuse

on the machine.

WARNING

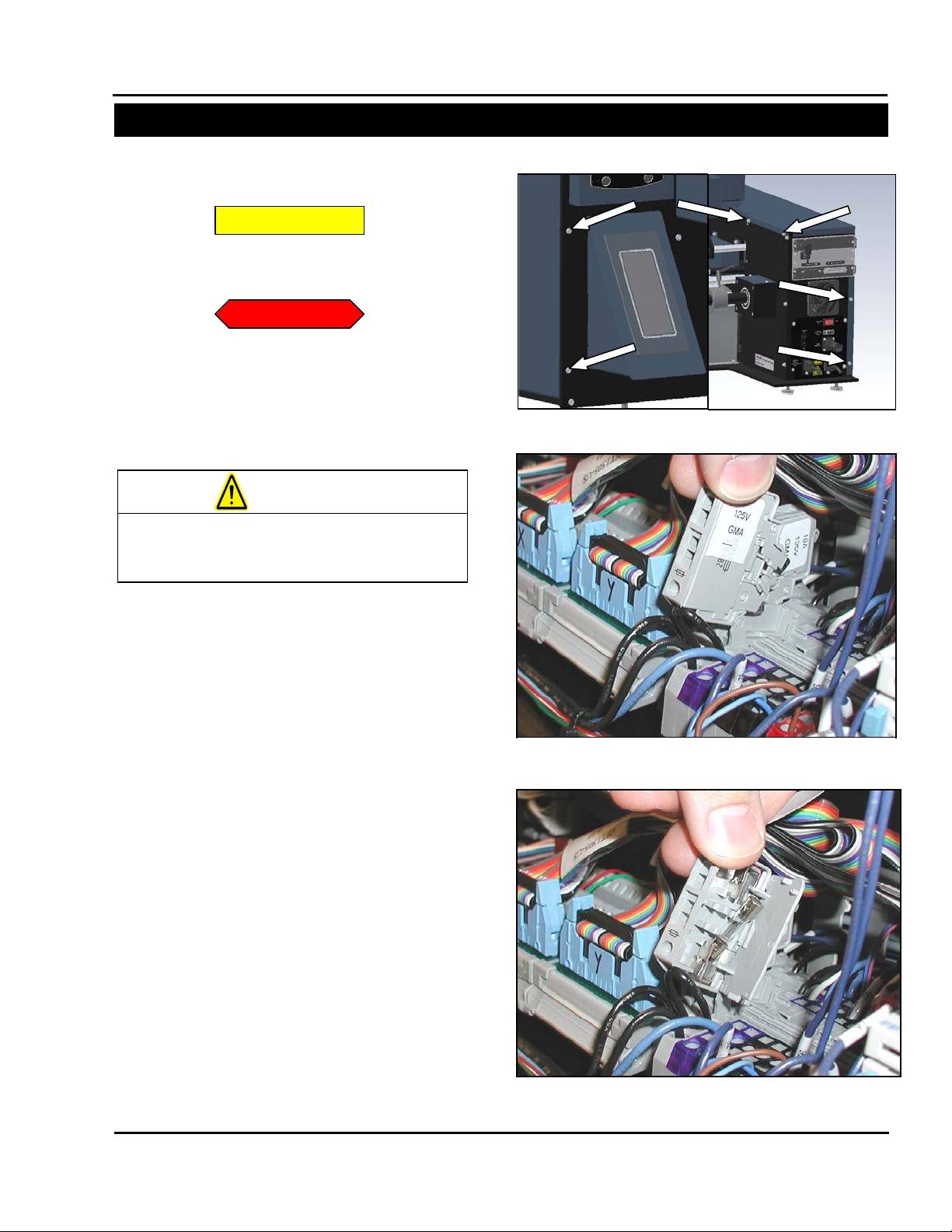

FUSES

The Sharp SX

protect the machinery from overloads. Fuses are

NOT intended to prot ect against electrocution and

are not considered a safety device.

Always remove electrical power from the

prior to performing any maintenance

SX

1. Remove Frame Cover Screws. There are six

screws to remove (Figure 3-14).

2. Remove Frame Cover and set aside.

3. Locate the two Fuses. (Figure 3-15)

TM

Bagger uses a series of fuses to

4. Pivot fuse holder to gain access to the Fuse

Access Door on the defective fuse.

5. Open Fuse Access Door and remove fuse

(Figure 3-17)

6. With a DVOM set to test for continuit y, touch the

black probe to one side of the fuse and the red

probe to the other side of the fuse. If the DVOM

does not indicate continuity, replace fuse.

Service and Maintenance Manual 3-6 960714-02B © 2007 I2407

Page 27

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

ADJUSTMENT

REPLACEMENT

Figure 3-18. Frame Cover Screws

Figure 3-19. Pivot Fuse Holder

Figure 3-20. Fuse Access Door

on the machine.

WARNING

FUSES (con’t)

There are no adjustments necessary on fuses.

A blown fuse can be an indic ation of a larger issue

with the electronics in t he Sharp SX

NOT REPLACE A BLOWN FUSE WITH A

LARGER AMPERAGE FUSE. If you continue to

blow fuses, troubleshoot other components to

discover problem.

Always remove electrical power from the

prior to performing any maintenance

SX

1. Remove Frame Cover Screws; there are six

screws to remove (Figure 3-18).

2. Loc ate the defective fus e. The 10 Amp system

fuse is on the left and the 5 amp stepper driv e

fuse is on the right.

3. Pivot fuse holder to gain access to the Fuse

Access Door (Figure 3-19).

4. Open Fuse Access Door and remove fuse

(Figure 3-20).

5. Replace with a 5x20mm fuse of the same

amperage.

6. Close ac cess door and pivot fuse holder back

into its home position.

7. Repl ace Frame Cover with sc rews and locking

washers.

TM

Bagger. DO

Service and Maintenance Manual 3-7 960714-02B © 2007 I2407

Page 28

TESTING

Figure 3-22. Motor Cover Front Screws

Figure 3-21. Motor Cover Rear Screws

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

24 VDC POWER SUPPLY

The Sharp SX

power supply for all sensors, relays and control

components. This section will explain how to

troubleshoot and if necessary, replace the power

supply.

The symptoms of a non-functioning Power Supply

are easy to spot. The “Bag Open Cage Fan” and

“Cabinet Cooling Fan” are not powered by the 24

VDC power supply. If when powering up a

machine, the fans can be heard running, but the

rest of the system is unresponsive, The Power

Supply is most likely defective. If a machine is

completely unresponsive, refer to the section on

checking and replacing fuses.

1. Plug machine in but do not turn on.

2. Remove any bags in the machine web path

and remove bag roll.

3. Rem ove the two rear screws a nd the two front

screws from the Motor Cov er (Figure 3-21 and

Figure 3-22).

4. Remove Motor Cover and set aside.

5. Loc ate the 24 VDC Po wer Sup ply.

Note: The Power Supply location changes

depending on your version of the Sharp SX

Bagger. The wiring however is exactly the

same.

TM

bagger uses a single 24 VDC

TM

Service and Maintenance Manual 3-8 960714-02B © 2007 I2407

Page 29

Figure 3-23. 24 VDC Power Suppl y

Figure 3-24. Power Supply Status LED

Status

LED

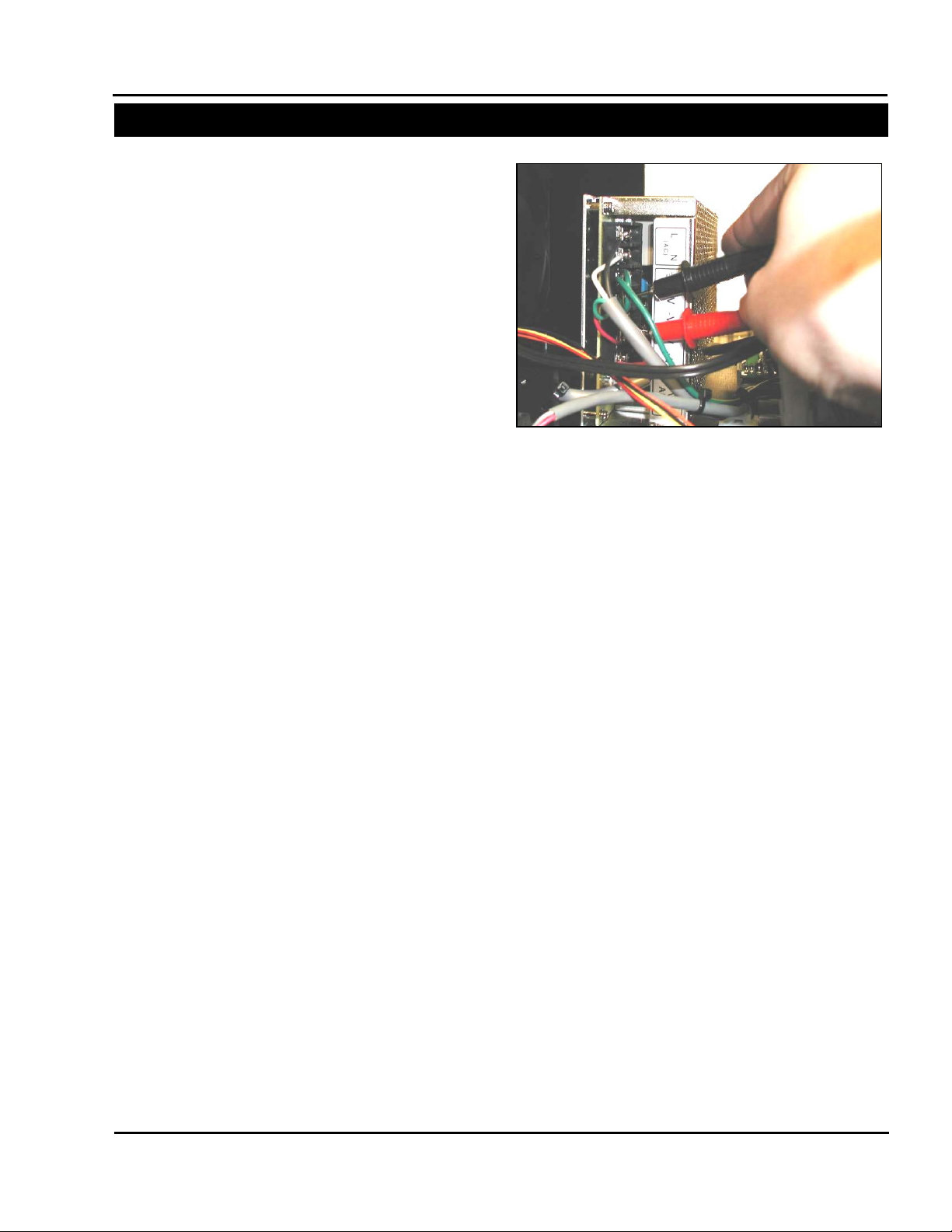

Figure 3-25. Probing 120 VAC on Power Supply

MACHINE WHILE POWER IS APPLIED.

CAUSE SERIOUS INJURY.

WARNING

AND ARMS CLEAR OF MOVING PARTS.

WARNING

USE PROPER TROUBLESHOOTING

TECHNIQUES TO AVOID ELECTRICAL SHOCK.

WARNING

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

24 VDC POWER SUPPLY (con’t)

6. Visua lly check wir ing on Power S upply. (Figure

3-23)

Note: The “V-“connection on the Power Supp ly

is connected to “Earth Ground ” by a short wire.

Also, lines labeled with “Printer” are only

present on baggers with a printer.

7. If there is a noticeable problem with the wiring

of the Power Supp ly, refer to the re placement

section for directions to rewire power supply.

8. T urn ON device using the power switch in the

back of the machine.

9. Check that the Green Status LED is

illuminated. (Figure 3-24) If it is, you may

proceed to step 13.

10. Set your DVOM to a range capable of testing

120 Volts AC.

USE EXTREM E CAUTION WHILE SERVICING A

UNEXPECTED MACHINE STARTUP CAN

DO NOT ATTEMPT TO SERVICE THE MACHINE

DURING NORMAL OPERATION. KEEP HANDS

WHEN TESTING ELECTRICAL COMPONENTS

WHILE POWER IS APPLIED TO T HE MACHINE,

11. Probe the L and N contacts on the Power

Supply with a DVOM; it should display

approximately 120 VAC (Figure 3-25).

Service and Maintenance Manual 3-9 960714-02B © 2007 I2407

Page 30

Figure 3-26. Probing “V-“ and “V+”

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

24 VDC POWER SUPPLY (con’t)

12. If 0 VAC is displayed, there is no power

reaching the Power S upply. Check the 10 amp

system fuse and ensure there are no loose

wires.

13. Set your DVOM to a range capable of

measuring 24 VDC. Prob e bet ween th e “ V-“and

“V+” contacts on the Power Supply (Figur e 3-

26).

14. If 0 Volts DC is displayed, then the Power

Supply is defective. Ref er to the Replacement

section.

Service and Maintenance Manual 3-10 960714-02B © 2007 I2407

Page 31

ADJUSTMENT

Figure 3-29. Voltage Selector Switch

Figure 3-27. Motor Cover Rear Screws

Figure 3-28. Motor Cover Front Screws

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

24 VDC POWER SUPPLY (con’t)

The Sharp SX

user adjustable setti ngs. These settings are set at

the factory and do not require regular adjustment.

The following steps will guide you through setting

the Power Supply to the factory defaults.

1. Rem ove the two rear screws a nd the two front

screws from the Motor Cov er (Figure 3-27 and

Figure 3-28).

TM

Bagger’s Power Supply has two

2. Loc ate the 24 VDC Po wer Sup ply.

Note: The power supply location changes

depending on your version of the Sharp SX

TM

Bagger. The wiring however is exactly the

same

.

3. Loc ate the red Switch on t he side of the Power

Supply. (Figure 3-29).

4. Set the Voltage Selector Switch to 115V.

Note: If your region uses 230 VAC as the

standard voltage, a step-down transformer is

required. This will lower the voltage entering

the machine to 115 VAC. Set the Voltage

Selector Switch to 115V regardless of your

region.

Service and Maintenance Manual 3-11 960714-02B © 2007 I2407

Page 32

Figure 3-30. Adjusting Power Supply Voltage

Figure 3-31. Testing 24 VDC on Power Supply

E WHILE POWER IS APPLIED.

UNEXPECTED MACHINE STARTUP CAN

CAUSE SERIOUS INJURY.

WARNING

AND ARMS CLEAR OF MOVING PARTS.

WARNING

USE PROPER TROUBLESHOOTING

TECHNIQUES TO AVOID ELECTRICAL SHOCK.

WARNING

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

24 VDC POWER SUPPLY (con’t)

5. Plug the Sharp SX

machine on.

USE EXTREM E CAUTION WHILE SERVICING A

MACHIN

DO NOT ATTEMPT TO SERVICE THE MACHINE

DURING NORMAL OPERATION. KEEP HANDS

WHEN TESTING ELECTRICAL COMPONENTS

WHILE POWER IS APPLI ED TO THE M ACHINE,

6. Set your DVOM to a range capable of

measuring 24 VDC.

7. W ith one hand, position a small screwdriver on

the voltage adjustment POT (Figure 3-30).

8. Place the black probe on the “V-“contact and

the red probe on the “V+” contact (Figure 3-31).

9. Adjust the POT until your DVOM reads 24.0

VDC +/- .5.

Note: Depending on your v ersion of the Sharp

TM

Bagger, the Power Supply POT may be

SX

difficult to reach. If this is the case, measure

the voltage, then set the probes aside and

adjust the voltage with a small screwdriver.

Repeat until DVOM indicates 24.0 VDC.

10. Replace Motor Cover us ing s crews and loc king

washers.

TM

Bagger in and turn the

Service and Maintenance Manual 3-12 960714-02B © 2007 I2407

Page 33

REPLACEMENT

Figure 3-32. Motor Cover Rear Screws

Figure 3-33. Motor Cover Front Screws

Figure 3-34. Power Supply screw locations

Figure 3-35. Voltage Selector Switch

on the machine.

WARNING

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

24 VDC POWER SUPPLY (con’t)

1. T urn off the Shar p SX

all power cords.

Always remove electrical power from the

prior to performing any maintenance

SX

2. Rem ove the two rear screws a nd the two front

screws from the Motor Cov er (Figure 3-32 and

Figure 3-33).

TM

Bagger and disconnec t

3. Disconnect all wires from the Power Supply.

4. Remove the three screws holding the Power

Supply to the frame. (Figure 3-34).

5. Remove the defective Power Supply and set

aside.

6. W ith new power supp ly, check that the Voltage

Selector Switch is set to 115 VAC (Figure 3-

35).

Note: If your region uses 230 VAC as the

standard voltage, a step-down transformer is

required. This will lower the voltage entering

the machine to 115 VAC. Set the Voltage

Selector Switch to 115V regardless of your

region.

Service and Maintenance Manual 3-13 960714-02B © 2007 I2407

Page 34

Figure 3-36. 24 VDC Power Suppl y

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

24 VDC POWER SUPPLY (con’t)

7. Reconnect all wires to the Power Supply

(Figure 3-36).

8. Place new Power Supply in the Sharp SX

Bagger in the sam e location and or ientation as

the old power supply.

9. Us e screws from old Power Suppl y and secure

new Power Supply to the frame.

10. Reconnect power cord to the Sharp SX

Bagger and turn machine on.

11. Set your DVOM to a range capable of

measuring 24 VDC.

TM

TM

Service and Maintenance Manual 3-14 960714-02B © 2007 I2407

Page 35

Figure 3-38. Testing 24 VDC on Power Supply

Figure 3-37. Adjusting Power Supply Voltage

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

24 VDC POWER SUPPLY (con’t)

12. With one hand, position a sm all screwdriver on

the voltage adjustment POT (Figure 3-37).

13. Place the black probe on the “V-“contact and

the red probe on the “V+” contact (Figure 3-38).

14. Adjust the POT until your DVOM reads 24.0

VDC.

Note: Depending on your v ersion of the Sharp

TM

Bagger, the Power Supply POT may be

SX

difficult to reach. If this is the case, measure

the voltage, then set the probes aside and

adjust the voltage with a small screwdriver.

Repeat until DVOM indicates 24.0 VDC.

15. Replace Motor Cover.

Service and Maintenance Manual 3-15 960714-02B © 2007 I2407

Page 36

TESTING

Figure 3-39. Frame Cover Screws

Figure 3-42. Remove three spade connectors

Figure 3-XX Mandrel Support screws

Figure 3-41. Mandrel Support Plate Bottom

Screws

Plate

screws

Mandrel

screws

Figure 3-40. Mandrel Support Screws

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

LINE FILTER

This procedure requires working with exposed

high voltages. Only qualifie d personnel familiar

with electrical safety should perform this

procedure.

1. Remove all power to the machine.

2. Remove the six screws holding the Frame

Cover. Set screws and Frame Cover aside

(Figure 3-39).

3. Remove any bags on a roll from machine.

4. Rem ove the seven scr ews holding th e Mandrel

Support Plate, set screws and plate aside

(Figure 3-40 & Figure 3-41).

Note: There are seven screws holding the

Mandrel Support Plate. Use care when

removing bottom scr ews and never work on an

unstable platform.

5. Detach the three spade connectors from the

Line Filter (Figure 3-42).

Support

Service and Maintenance Manual 3-16 960714-02B © 2007 I2407

Page 37

GRN-Earth

BLK-L

BLU-N

Figure 3-43. Wire colors and locations

Figure 3-44. Mandrel Support Plate alignment

Recessed

Circle

MACHINE WHILE POWER IS APPLIED.

STARTUP CAN

CAUSE SERIOUS INJURY.

WARNING

AND ARMS CLEAR OF MOVING PARTS.

WARNING

TECHNIQUES TO AVOID ELECTRICAL SHOCK.

WARNING

on the machine.

WARNING

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

LINE FILTER (con’t)

6. Reconnect the power cord to the machine.

Note: There will be exposed 120 VAC. Use

extreme caution when working with expos e d wires .

USE EXTREM E CAUTION WHILE SERVICING A

UNEXPECTED MACHINE

DO NOT ATTEMPT TO SERVICE THE MACHINE

DURING NORMAL OPERATION. KEEP HANDS

WHEN TESTING ELECTRICAL COMPONENTS

WHILE POWER IS APPLIED TO T HE MACHINE,

USE PROPER TROUBLESHOOTING

7. With a DVOM configured to m easure 120 V AC,

contact the red probe to the L pin and th e Blac k

probe to the N pin. If 120 VAC is not indicated,

the Line Filter is defective or no power is

reaching the machine.

8. Unplug machine from any power sources.

Always remove electrical power from the

9. Rec onnect spade connectors to th e Line Filter

10. Replace the seven screws for the Mandrel

prior to performing any maintenance

SX

(Figure 3-43).

Support Plate but do not tighten down.

11. Hand tighten the four top s crews, ens uring that

the end of the Material Roll Mandrel is sitting

inside the recessed circle of the Mandrel

Support Plate (Figure 3-44).

12. Tighten all screws with an Allen Wrenc h.

Service and Maintenance Manual 3-17 960714-02B © 2007 I2407

Page 38

ADJUSTMENT

REPLACEMENT

Figure 3-45. Frame Cover Screws

Figure 3-48. Remove three spade connectors

Mandrel

screws

Figure 3-46. Mandrel Support screws

Figure 3-47. Mandrel Support Plate Bottom

Screws

Plate

screws

on the machine.

WARNING

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

LINE FILTER (con’t)

There are no adjustments necessary on the Line

Filter.

Always remove electrical power from the

1. Remove the six screws holding the Frame

2. Rem ove the seven scr ews holding th e Mandrel

3. Remove the three spade connectors from the

prior to performing any maintenance

SX

Cover, set screws and Frame Cover aside

(Figure 3-45).

Support Plate, set screws and plate aside

(Figure 3-46 & 3-47).

Note: There are seven screws holding the

Mandrel Support Plate. Use care when

removing bottom scr ews and never work on an

unstable platform.

Line Filter (Figure 3-48).

Support

Service and Maintenance Manual 3-18 960714-02B © 2007 I2407

Page 39

Module

Screws

Figure 3-49. Line Filter Screws

GRN-Earth

BLK-L

BLU-N

Figure 3-50. Wire colors and locations

Figure 3-51. Mandrel Support Plate alignment

Recessed

Circle

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

LINE FILTER (con’t)

4. Rem ove the two screws h olding the Line Filter

to the Rear Face Plate (Figure 3-49).

5. Remove Line Filter.

6. Orientate new module so the two spade

connectors are towards the top.

7. Refasten new module to frame with screws

from defective module.

8. Reattach the three connector wires, Earth

(Green) on the left, Neutral (Blue) on the top

right, and Live (Black ) on the bottom (Figure 3-

50).

9. Replace the seven screws for the Mandrel

Support Plate but do not tighten down.

10. Hand-tighten the four top s crews, ensur ing that

the end of the Material Roll Mandrel is sitting

inside the recessed circle of the Mandrel

Support Plate (Figure 3-50).

11. Tighten all screws with an Allen wrench.

12. Replace Frame Cover with screws and lock

washers.

Service and Maintenance Manual 3-19 960714-02B © 2007 I2407

Page 40

TESTING

ADJUSTMENT

Figure 3-52. Frame Cover Screws

Figure 3-53. Main Red Switch location

Main

Switch

5A Fuse

10A Fuse

Figure 3-54. Fuse Locations

on the machine.

WARNING

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

MAIN POWER SWITCH (RED)

Always remove electrical power from the

1. Remove the six screws holding the Frame

2. T urn the switch to the OFF posit ion (Figure 3-

3. Configure your DVOM to test for continuity,

4. Turn the switch to the ON position.

5. Configure your DVOM to test for continuity,

6. If the Main Power Switch is not found to be

There are no adjustments necessary on the Main

Power Switch.

prior to performing any maintenance

SX

Cover, set screws and Frame Cover aside

(Figure 3-52).

53).

contact one probe to th e 5 A F use a nd the other

probe to the 10A Fuse (F igure 3-54) It should

NOT read continuity.

contact one probe to th e 5 A F use and the other

probe to the 10A Fuse ( Figure 3-54). It should

read continuity. If it does not, ensure there are

no loose wires. If the wiring is not defective,

replace the Main Power Switch.

defective, troubleshoot the Line Filter and fuses

if you haven’t already done so.

power

Service and Maintenance Manual 3-20 960714-02B © 2007 I2407

Page 41

REPLACEMENT

Figure 3-55. Frame Cover Screws

Figure 3-56. Plastic divider locat ion

Plastic divider

Figure 3-57. Back of Main Power Switch

Retaining

Clips

on the machine.

WARNING

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

MAIN POWER SWITCH (RED) (con’t)

Always remove electrical power from the

1. Remove the six screws holding the Frame

2. Rem ove the seven scr ews holding th e Mandrel

3. Remove the three spade connectors from the

4. The switch is held in place by four retaining

5. O rientate switch so t he plastic divi der is on the

6. Reconnect the three spade connectors. The

prior to performing any maintenance

SX

Cover. Set screws and Frame Cover aside

(Figure 3-55).

Support Plate, set screws and plate aside.

back of the Main Power Switch (Figure 3-56).

clips, squeeze clips on eith er side of the switch

while firmly pushing switch out of Rear Face

Plate (Figure 3-57).

left side as you are look ing at the back of the

switch as you snap it into the Rear F ace Plate.

Snap replacement switch into Rear Face Plate.

Light Blue wire is attached to the contact

furthest from you; the two Black wires are

attached to the remaining contacts.

Service and Maintenance Manual 3-21 960714-02B © 2007 I2407

Page 42

TESTING

Figure 3-59. Motor Cover Rear Screws

Figure 3-58. Motor Cover Front Screws

Figure 3-60. Load Plate Screws

on the machine.

WARNING

Figure 3-61. Transformer locations for the SX

Stepper Drive

Seal Wire

Solid State Relay

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

TRANSFORMERS

The Sharp SX

transformers. One is used for the Seal Wire and the

other is used for the two TM4500 stepper drives.

They are each 0.365 KVA transformers with a

120(P):28(S) voltage rat io. Only replace with equal

or greater KVA rating and same voltage ratio.

Always remove electrical power from the

prior to performing any maintenance

SX

1. Rem ove the two rear screws a nd the two front

screws holding the Motor Cover. (Figure 3-58

and Figure 3-59)

TM

Bagger uses two “Step-Down”

2. Remove Motor Cover and set aside.

3. Remove the four screws holding the Load

Plate, set screws and Load Plate aside (Figure

3-60.)

4. Locate the transformer you wish to

troubleshoot and proceed to that section

(Figure 3-61).

Note: Transformer locations will change

depending on your version of the SX. The

Stepper Drive transformer’s wires terminate in

a terminal block. T he Seal Wire transformer is

connected to the Solid State Relay and Seal

Wire.

1108 and 1109

Service and Maintenance Manual 3-22 960714-02B © 2007 I2407

Page 43

Figure 3-63. Left side Seal Bar connection

Figure 3-64. Probing right side of Seal Wire

Figure 3-62. Testing pin 2 of Solid State Relay

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

TRANSFORMERS (con’t)

Seal Wire Transformer

1. Rem ove clear plastic covering over Solid State

Relay.

2. Set your DVOM to test for continu ity. With the

Black probe, contact the B lue terminal block in

the electrical area, with the Red prob e, contact

pin 2 of the Solid State Relay. (Figure 3-62)

Your DVOM should indicate continuity. If it

does not, check the transformer wiring. If the

wiring is correct, the transformer is defective

and will require replacement.

3. Rem ove the Left scr ew holding the Red wire to

the Seal Wire. Pull wire away from contact

(Figure 3-63).

4. W ith a DVOM set to t est for continuit y, contact

one probe to the loose Red wire you just

disconnected, and contact the other probe to

the right screw holding the other Red wire to

the Seal Wire (Figure 3-64).

5. T he DVOM will indica te co ntinuit y, if it does not

the Seal Wire Transformer is defective and

must be replaced.

6. If the transformer is not defective, troublesho ot

the Solid State Relay and the Seal Wire.

Service and Maintenance Manual 3-23 960714-02B © 2007 I2407

Page 44

ADJUSTMENT

Figure 3-66 Testing two front terminal blocks

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

Figure 3-65 Print Head Stepper Drive

Stepper

Terminal

MACHINE WHILE POWER IS APPLIED.

UNEXPECTED MACHINE STARTUP CAN

CAUSE SERIOUS INJURY.

WARNING

AND ARMS CLEAR OF MOVING PARTS.

WARNING

USE PROPER TROUBLESHOOTING

TECHNIQUES TO AVOID ELECTRICAL SHOCK.

WARNING

TRANSFORMERS (con’t)

Stepper Drive Transformer

1. Locate the two terminal blocks with the Red

wires connected to the transformer (Figure 3-

65).

Note: Location and orientation will vary

depending on model.

2. W ith a DVOM set to test for continuity, probe

the two front terminal blocks and the two rear

terminal blocks . Both s hould in dic at e c ont inu ity.

(Figure 3-66).

3. Rec onnec t machine to po w er and turn m ac hine

on.

USE EXTREM E CAUTION WHILE SERVICING A

DO NOT ATTEMPT TO SERVICE THE MACHINE

DURING NORMAL OPERATION. KEEP HANDS

WHEN TESTING ELECTRICAL COMPONENTS

WHILE POWER IS APPLIED TO T HE MACHINE,

4. Set your DVOM measure 120 VAC. Probe the

two terminal blocks connected to the Black

wires from the transform er. The DVOM should

indicate 120 VAC. If it does not, troubleshoot

the wiring from the main DIN Rail (located

under the frame guard behind the display,

where terminals, PLC, and fuse blocks are

snapped onto).

There are no adjustments necessary on

transformers.

Transformer

Note: Electrical assembly isolated for clarity

Service and Maintenance Manual 3-24 960714-02B © 2007 I2407

Page 45

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

REPLACEMENT

Figure 3-67. Motor Cover Rear Screws

Figure 3-68. Motor Cover Front Screws

Figure 3-69. Transformer locations on an 1108 or

Stepper Drive

Seal Wire

Figure 3-70. Frame Cover Screws

on the machine.

WARNING

TRANSFORMERS (con’t)

Always remove electrical power from the

1. Remove the two rear and two front screws

prior to performing any maintenance

SX

holding the Motor Cover on. Set screws and

Motor Cover aside (Figures 3-67 & 3-68)...

2. Locate transformer that requires replacement

(Figure 3-70).

1109

3. If you are replacing the Seal W ire Transformer

Remove the six screws holding the Frame

Cover, set screws and Frame Cover aside

(Figure 3-70).

Service and Maintenance Manual 3-25 960714-02B © 2007 I2407

Page 46

SX™

SECTION 3 – COMPONENT REPAIR

ELECTRICAL COMPONENTS

Figure 3-71. Load Plate Screws

Figure 3-72 Transformer Bolt Locations

TRANSFORMERS (con’t)

4. If you are replacing the Stepper Drive

Transformer, remove the four screws holding

the Load Plate, set screws and Load Plate

aside (Figure 3-71).

5. Foll ow each of the four wir es coming out of the

Transformer and note the ir locations and color.

You may want to write this information down.

Note: The wiring diagram i n this ma nual can b e

used to determine transformer connections;

however it is easier to write this information

down.

6. Disconnect the ends of each wire and feed

them back through any Wire Troughs or Wire

Ties. You will prob ably have to cut a few W ire

Ties to do this.

7. Remove the four screws holding the

Transformer to the Base Plate (Figure 3-72).

8. Note the orientation of the Red and Black