Page 1

COPIER : SF-2216

Date

:

Sep. 16, 1998

1. DISCONTINUANCE OF THE PG SEAL CARRIED OUT AS A MEASURE TO IMPROVE

PRODUCTIVITY.

2. MEASURE TO IMPROVE THE ADHESIVE PERFORMANCE OF THE TONER TRANSPORT PIPE.

3. CHANGE IN THE MAKER OF SOME PARTS CARRIED OUT AS A MEASURE TO IMPROVE

PRODUCTIVITY.

4. MEASURE CARRIED OUT TO IMPROVE THE CONTACT POINT OF THE TC UNIT.

No. : SP-2324

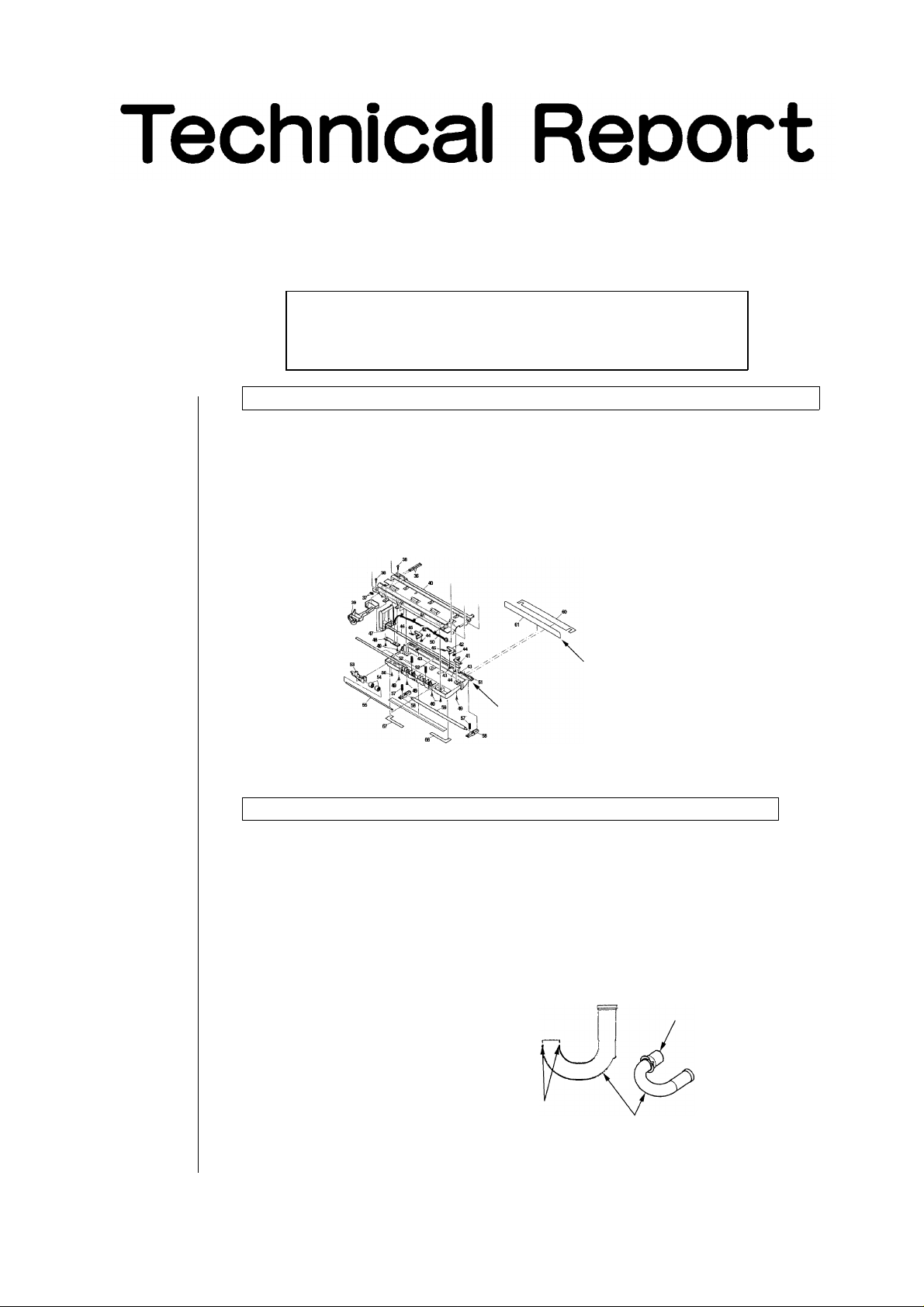

1. Discontinuance of the PG seal carried out as a measure to improve productivity.

1.Model Name: SF-2116/2118/1016/1018/2020/2120/1020/1120

2.General: In accordance with a change that was carried out in the shape of the DV lower paper

guide, the PG seal has been discontinued. This action has been carried out as a

measure to improve productivity

PG seal 2

DV lower paper guide

3.Action: From the 1st lot of 1998 August production.

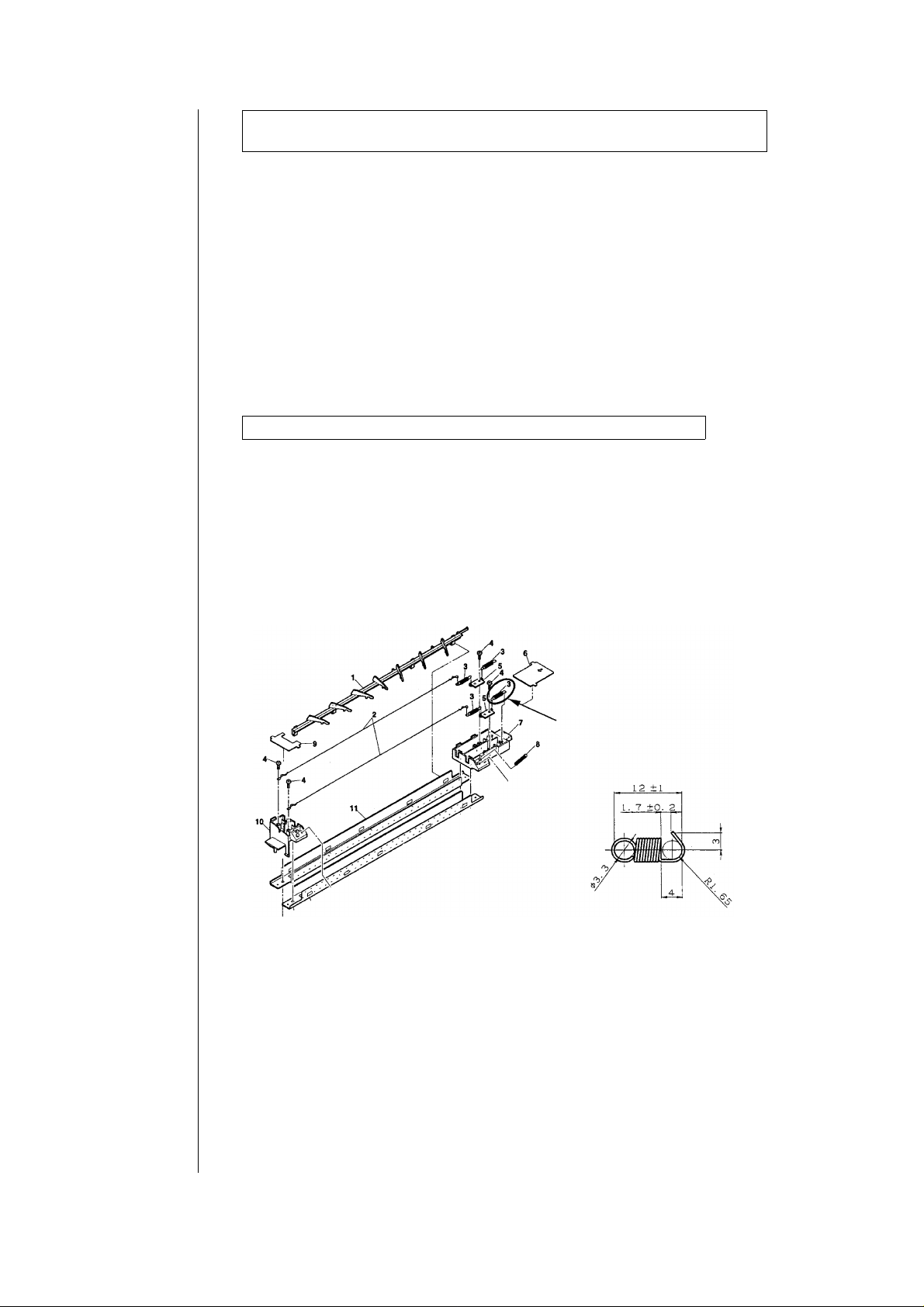

2. Measure to improve the adhesive performance of the toner transport pipe.

1.Model Name: SF-2116/2118/1016/1018/2216/2020/2120/1020/1120

2.General: A change has been carried out in the shape of the waste toner transport pipe. This

action has been carried out as a measure to improve the adhesive performance

between the waste toner transport pipe and the waste toner cap. Furthermore, in

accordance with the change described above, the color of the waste toner transport

pipe has been changed from black to transparent.

Waste toner cap

Holes of φ 3 have been opened in the waste toner transport

pipe in 2 locations to improve the adhesive performance.

Waste toner pipe

3.Action: From the 1st lot of 1998 August production.

1/4

SHARP CORPORATION Reprography Division

Green

C

Page 2

3. Change in the maker of some parts carried out as a measure to improve

productivity.

1.Model Name: SF-2116/2118/1016/1018/2216/2020/2120/1020/1120

2.General: A change has been carried out in the maker of the DPPD1 PWB and the paper feeding

interface PWB used in the paper feeding unit. This action has been carried out as a

measure to improve productivity.

3.Action: From the 1st lot of 1998 August production.

4. Measure carried out to improve the contact point of the TC unit.

1.Model Name: SF-2116/2118/1016/1018/2216/2020/2120/1020/1120

2.General: A change has been carried out in the shape of the contact spring of the TC unit. The

change has been carried out in 1 location as illustrated in the diagram shown below.

This action has been carried out as a measure to improve the contact of the TC unit.

3.Action: From 1998 mid-July production.

2/4

Location of the change

Changed spring

Page 3

Ref.

No.

1

2

Model

name

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2020

SF-2120

SF-1020

SF-1120

SF-2020

SF-2120

SF-1020

SF-1120

SF-2116

SF-2216

SF-1016

SF-1018

SF-2216

SF-2020

SF-2120

SF-1020

SF-1120

SF-2116

SF-2118

Version P/G No.

10 -51 PGIDM1543FCZZ PGIDM1543FCZ1 AQ

10 PSEL-0669FCZZ Discontinued ---- PG seal 2

11 -51 PGIDM1543FCZZ PGIDM1543FCZ1 AQ

11 -61 PSEL-0669FCZZ Discontinued ---- PG seal 2

14 -51

All

15 -51 CPIPP0182FC04 CPIPP0182FC05

17 -7

Current parts New parts

Parts code Parts code

CPIPP0182FC04 CPIPP0182FC05

Price

rank

AM

Parts name

DV lower paper

guide

DV lower paper

guide

Toner transport

pipe

Effec-

tive

time

1st lot

'98/8

Inter-

change-

ability

5

1

Note

SF-1016

SF-1018

SF-2216 17 -7

SF-2020

SF-2120

SF-1020

3

SF-1120

SF-2116

SF-2118

SF-1016

SF-1018

SF-2216

SF-2020

SF-2120

SF-1020

SF-1120

23 -5

18 -7

33 -5

17 -8

18 -8

47 -901

CPWBF1086FC32 CPWBF1086FC34

CPWBF1088FC31 CPWBF1088FC34

AL

DPPD1 PWB

1

Paper feeding

interface PWB

3/4

Page 4

Ref.

Model

No.

SF-2116

SF-2118

SF-1016

SF-1018

4

SF-2216

SF-2020

SF-2120

SF-1020

SF-1120

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

3. Current type cannot be used in place of new type.

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Version P/G No.

name

26 -3

All

36 -3

New type cannot be used in place of current type.

New type can be used in place of current type.

Current parts New parts

Parts code Parts code

MSPRT1395FCZZ MSPRT2795FCZZ AB Spring M

Price

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Parts name

rank

Effec-

tive

time

Mid-

'98/7

* Only 1 location changed.

Inter-

change-

ability

3 *

Note

4/4

Loading...

Loading...