Page 1

COPIER : SF-2116/MF15

Date

:

Jan. 12, 1998

1. MEASURE TO ALLEVIATE PROBLEMS OF FAULTY CONNECTIONS DURING

INSTALLATION OPERATIONS.

2. ADDITION OF A NOISE REDUCTION MOLT CARRIED OUT.

3. MEASURE TO IMPROVE PAPER FLOW PERFORMANCE IN THE U-TURN SECTION.

4. MEASURE TO ALLEVIATE PROBLEMS OF COPY IMAGE MISALIGNMENT.

No. : SP-2226

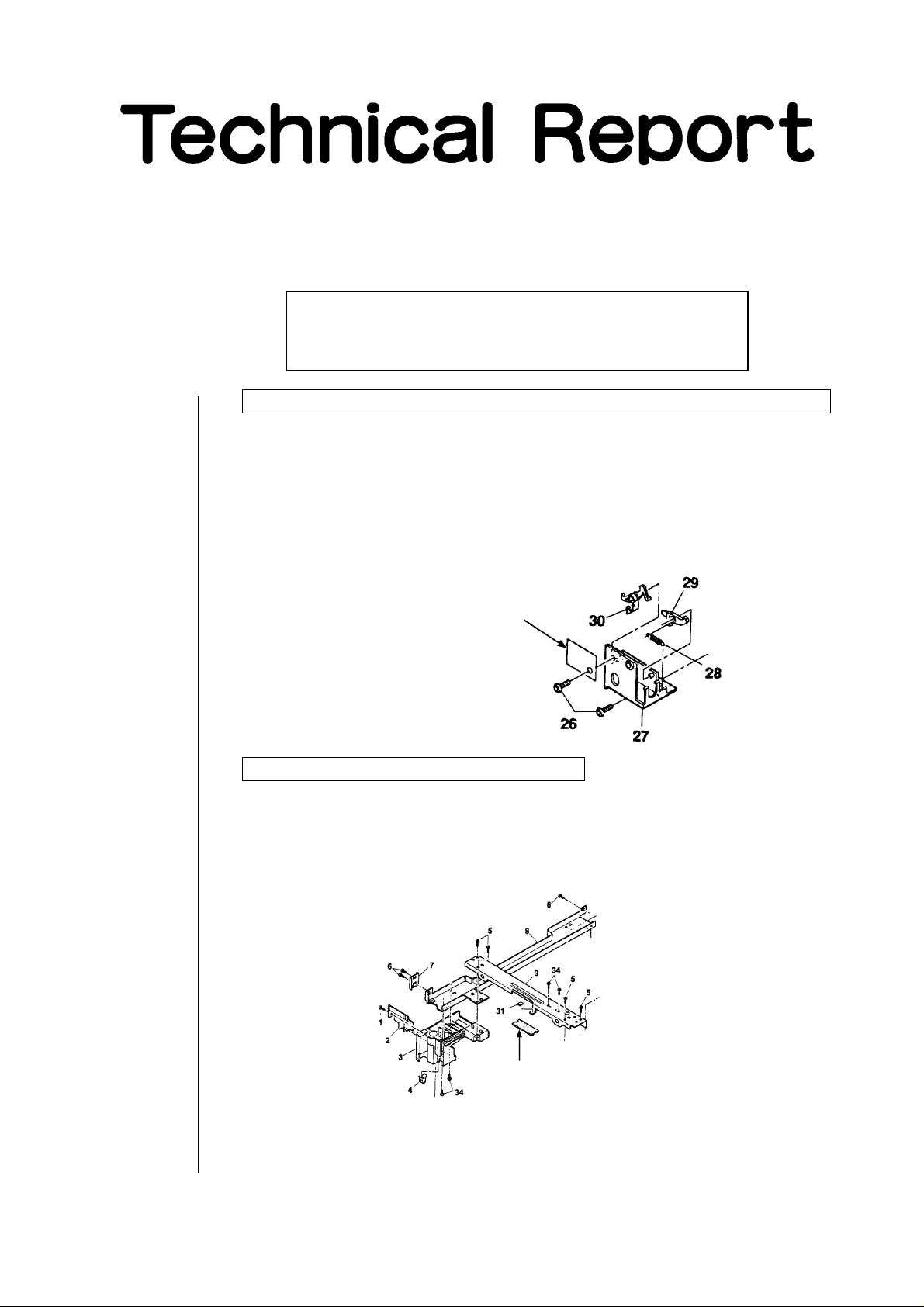

1. Measure to alleviate problems of faulty connections during installation operations.

1.Model Name: SF-MF15

2.General: There were problems in the early stages of mass production, of faulty connections

during installation operations to the machine, caused the manual idle boss A falling over.

As a measure to alleviate this problem, the addition of a manual spacer has been

carried out in the manual solenoid frame section (P/G [35]-27).

Manual spacer

3.Action: From 1995 mid-April production.

2. Addition of a noise reduction molt carried out.

1.Model Name: SF-2118/1018/CM15

2.General: The addition of a noise reduction molt has been carried out to the double base plate

connection plate R (P/G [22]-9, [39]-9).

3.Action: SF-2118: From 1995 mid-May production.

Noise reduction molt

SF-1018: From 1995 mid-May production.

SF-CM15: From the 1st lot of 1995 June production.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

3. Measure to improve paper flow performance in the U-turn section.

1.Model Name: SF-2116/2118/1016/1018

2.General: A change has been carried out in the shape of the release arm of the separating roller in

the lower frame and lower level paper feeding unit. This action has been carried out as a

measure to improve the paper flow performance in the U-turn section.

3.Action: From 1995 mid-March production.

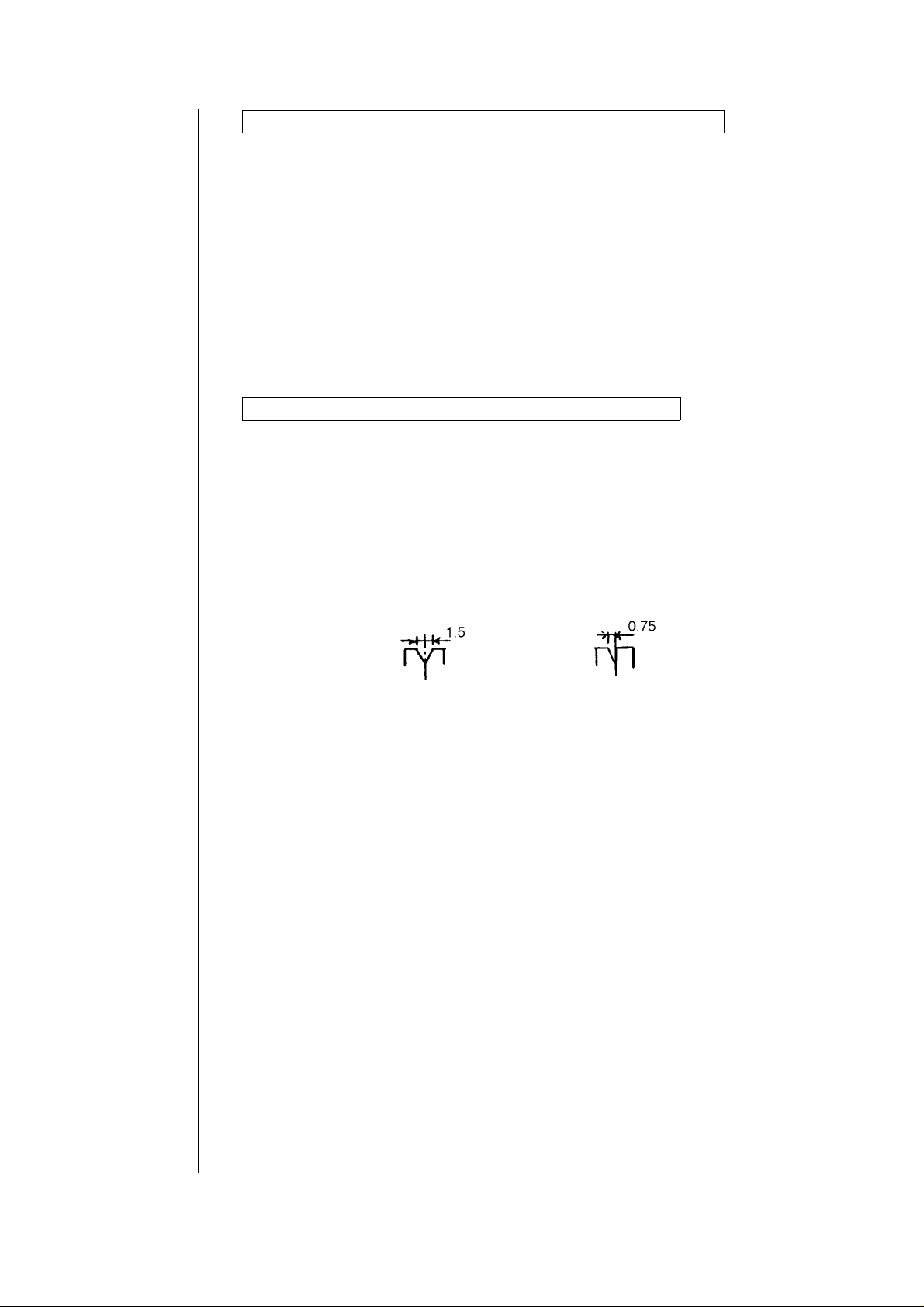

4. Measure to alleviate problems of copy image misalignment.

1.Model Name: SF-2116/2118/1016/1018

2.General: A change has been carried out in the shape of the TC holder and the TC holder cover in

the TC case unit. This action has been carried out as a measure to alleviate problems of

copy image misalignment.

A change has been carried out in the shape of the TC holder.

Old [ZZ]

3.Action: ∗ Japanese domestic production: From the 1st lot of 1995 November production.

New [Z1]

French (SMF) production: From the 1st lot of 1996 January production.

Chinese (SOCC) production: From the 1st lot of 1996 March production.

2/3

Page 3

Ref.

Model

No.

1 SF-MF15

SF-2118

SF-1018

2

SF-CM15 39

SF-2116

SF-2118

3

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

4

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

35

22

19 -42

23 -46

All

26 -10 LHLDZ1230FCZZ LHLDZ1230FCZ1 TC holder F

26 -7 LHLDZ1231FCZZ LHLDZ1231FCZ1 AH TC holder R

26 -9 PCOVP1274FCZZ PCOVP1274FCZ1

26 -6 PCOVP1275FCZZ PCOVP1275FCZ1 TC holder cover R

Current parts New parts

Parts code Parts code

PSPAZ0679FCZZ AC Manual spacer

---PMLT-1031FCZZ AE Damper cushion W3

MARMP0190FCZZ MARMP0190FCZ1

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Price

rank

Separator roller

release arm

AG

TC holder cover F

AC

Parts name

Effec-

tive

time

Mid-

’95/4

Mid-

’95/5

1st lot

’95/6

Mid-

’95/3

Inter-

change-

Note

ability

6

3

∗

3/3

Loading...

Loading...