Page 1

COPIER : SF-2050

Date

:

Nov. 5, 1997

No. : SP-2193

1.PREVENTING PAPER JAMS IN THE ADU.

2.PREVENTING DOUBLE FEEDING AT THE ADU.

3.PREVENTING STATIC ELECTRIC DISCHARGE IN THE ADU.

1. Preventing paper jams in the ADU.

1.Model Name: SF-2050

2.General: In order to prevent paper jams during ADU paper supply, we have changed the materials

used in the paper supply and reverse rollers. We have also added Mylar to the ADU

transport paper guide.

<Old> <New>

ADU paper feeding roller NROLR1088FCZZ → NROLR1238FCZZ

(Rubber: gray) (Rubber: yellow)

ADU reverse roller NROLR0964FCZZ → NROLR1239FCZZ

(Rubber: gray) (Rubber: yellow)

ADU transport PG sheet F (PSHEP4550FCZZ)

ADU transport PG sheet R (PSHEP4551FCZZ)

Standard X: (Bottom of beat) 0 to +1

Standard Y: (Plate opening terminal surface and

both sheet pasting terminal surfaces) ±1

Note 1: Wipe the attachment surface off with alcohol

before performing the procedure.

2: The sheet should not ride up on the beat.

3: The sheet should not float up over the bend

in the sheet metal.

Attachment position

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

ADU transport PG sheet R

Standard X

Standard Y

Standard X

ADU transport PG sheet F

Beat

Beat

ADU transport PG

PGIDH1589FCZZ

3.Action: From the first unit of September, 1997 production on.

2. Preventing double feeding at the ADU.

1.Model Name: SF-2050

2.General: In order to prevent double feeding during ADU paper supply, we have changed the

pressure of the fulcrum spring, thereby changing the contact pressure of the reverse

roller from 475 to 325 g.

<Old> < New>

Fulcrum spring MSPRC2327FCZ1 MSPRC2693FCZZ

(Color: Plain plating) (Color: Plating coated with black)

3.Action: From the first unit of September, 1997 production on.

2/4

Page 3

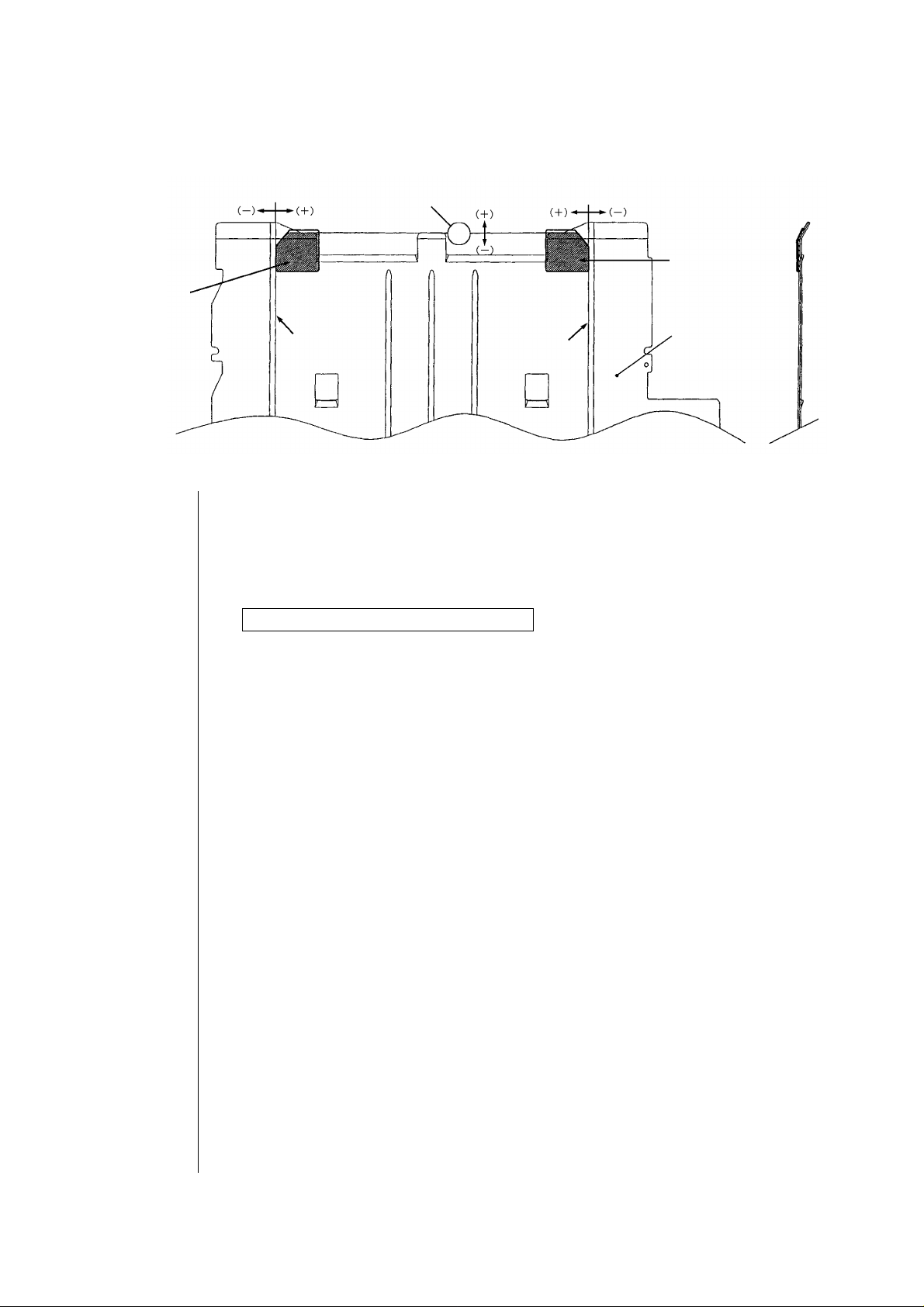

3. Preventing static electric discharge in the ADU.

1.Model Name: SF-2050

2.General: In order to prevent problems with static electric discharge, we have added a ground

harness and a washer to the above model.

Ground harness attachment position

∗ Connect the ground harness between A and B, shown above.

3/4

Page 4

Washer attachment position

Added LX-WZ0010FCZZ (Q’ty: 1)

3.Action: From the first unit of September, 1997 production on.

Ref.

Model

No.

1

SF-2050 All

2 38 -4 MSPRC2327FCZ1 MSPRC2693FCZZ Fulcrum spring 3

3

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

3. Current type cannot be used in place of new type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Version P/G No.

name

38 -34 NROLR1088FCZZ NROLR1238FCZZ AU ADU paper feeding roller

38 -6

39

38

39

39 LX-WZ0010FCZZ AA Washer

New type cannot be used in place of current type.

New type can be used in place of current type.

Current parts New parts

Parts code Parts code

NROLR0964FCZZ NROLR1239FCZZ AP ADU reverse roller

----

----

PSHEP4550FCZZ

PSHEP4551FCZZ ADU transport PG sheet R

DHAI-2899FCZZ HP ADU ground harness

Price

rank

AD

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Parts name

ADU transport PG sheet F

Effec-

tive

time

1st lot

’97/9

Inter-

change-

ability

3

6

6

Note

4/4

Loading...

Loading...