Page 1

COPIER(OPTION) : SF-A17/S54

Date

:

Oct. 1, 1997

No. : SP-2181

1. VARIOUS CHANGES CARRIED OUT AS A MEASURE TO IMPROVE

PRODUCTIVITY.

2. MEASURE CARRIED OUT TO IMPROVE ADJUSTABILITY.

3. ESTABLISHMENT OF PARTS IN ACCORDANCE WITH A REQUEST FROM THE

MARKET.

1. Various changes carried out as a measure to improve productivity.

1.Model Name: SF-A17/A56/A57/A18

2.General: The changes described below have been carried out as a measure to improve

productivity and operationability.

3.Description:

No. Content of change Applicable models

Change carried out in the shape, and change carried out in the color of the

(1)

weight sheet in the copy paper transport section.

Standardization of the front and rear curl sheet in the copy paper transport

(2)

section with those used for the Japanese domestic market.

Change carried out in the material used for the no. 1 separator plate in the copy

(3)

paper transport section.

Change in the protect rubber in the reversion transport section (the same one

(4)

as used in models SF-A57 and A18).

Two flapper rubber units out of four have been discontinued in the reversion

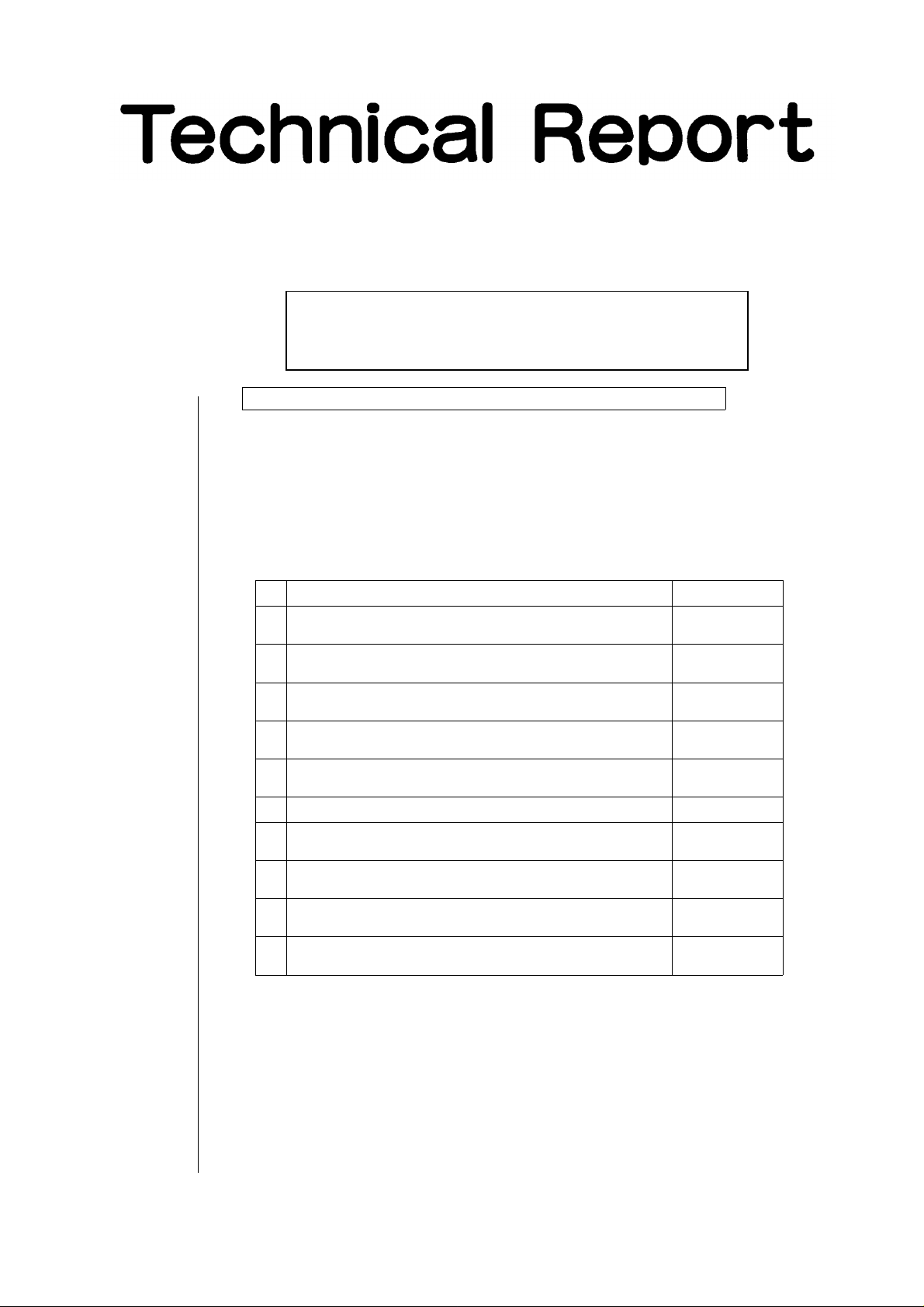

(5)

transport section (please refer to the diagram for details).

(6) Change carried out in the M3 stepped screws 1.4 in the reversion transport section. SF-A17/A56/A57/A18

Change in the display panel of the outer rolling section (the same one as used

(7)

in models SF-A57 and A18).

Change carried out in the thickness of the separator release spring plate in the

(8)

copy paper transport section.

Change in the shape carried out in the ‘‘A’’ tray guide in the copy paper transport

(9)

section.

The third sheet detector in the copy paper tray section has been discontinued

(10)

because it was not being used.

SF-A17/A56/A57/A18

SF-A17/A56/A57/A18

SF-A17/A56

SF-A17/A56

SF-A56/A57

SF-A17/A56

SF-A17/A56/A57/A18

SF-A17/A56/A57/A18

SF-A17/A56/A57/A18

Please refer to the parts list for information concerning part codes, etc.

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

Flapper rubber units

discontinued in two locations.

4.Action: (1) ~ (8) → From 1997 July production.

(9) ~ (11) → From 1997 August production.

2. Measure carried out to improve adjustability.

1.Model Name: SF-S54

2.General: The changes described below have been carried out in parts such as the adjustment

rod, transport rollers. These changes have been carried out as a measure to improve

adjustability during low humidity conditions. (These changes are applicable for WLT/A3

sized paper.)

3.Description: • The addition of an adjustment reinforcement plate to the adjustment rod has been

carried out. In accordance with this change the slight diagonal movement toward the

front side during tray removal operations has been corrected to normal.

Also in accordance with the addition of the adjustment reinforcement plate, various

minor cuts have been carried out on the tray.

(1) A change has been carried out in the shape of the lever (S pole).

(2) The addition of a new standard for the lever (S pole sub) has been carried out.

(3) The addition of a new standard for the spring (S pole) has been carried out.

(4) A change has been carried out in the shape of the guide P (tray).

(5) A change has been carried out in the tray assembly in accordance with the

change described in above.

2/5

Page 3

• A change has been carried out in the diameter of the roller due to the discontinuance

of diagonal movement and a change has been carried out in the spring.

(6) The diameter of the roller on the right side has been changed so that it is

the same as the diameter of the roller on the front side.

(7) A change has been carried out in the feed roller assembly in accordance

with the change described in above.

(8) A change has been carried out in the load of the connection bearing spring

of the mechanism section.

105gr (colored gold) → 70gr (colored silver)

(9) A change has been carried out in the press roller assembly in accordance

with the change described in above.

(10) A change has been carried out in the load of the connection bearing

spring of the attachment material section.

75gr (colored silver) → 35gr (colored black)

(11) A change has been carried out in the press roller assembly in

accordance with the change described in above.

4.Action: From the start of 1997 August production.

(ø20.15 → ø20.0)

3. Establishment of parts in accordance with a request from the market.

1.Model Name: SF-A17/A56/A57/A18

2.General: The parts described below have been established as service parts in accordance with a

request from the market.

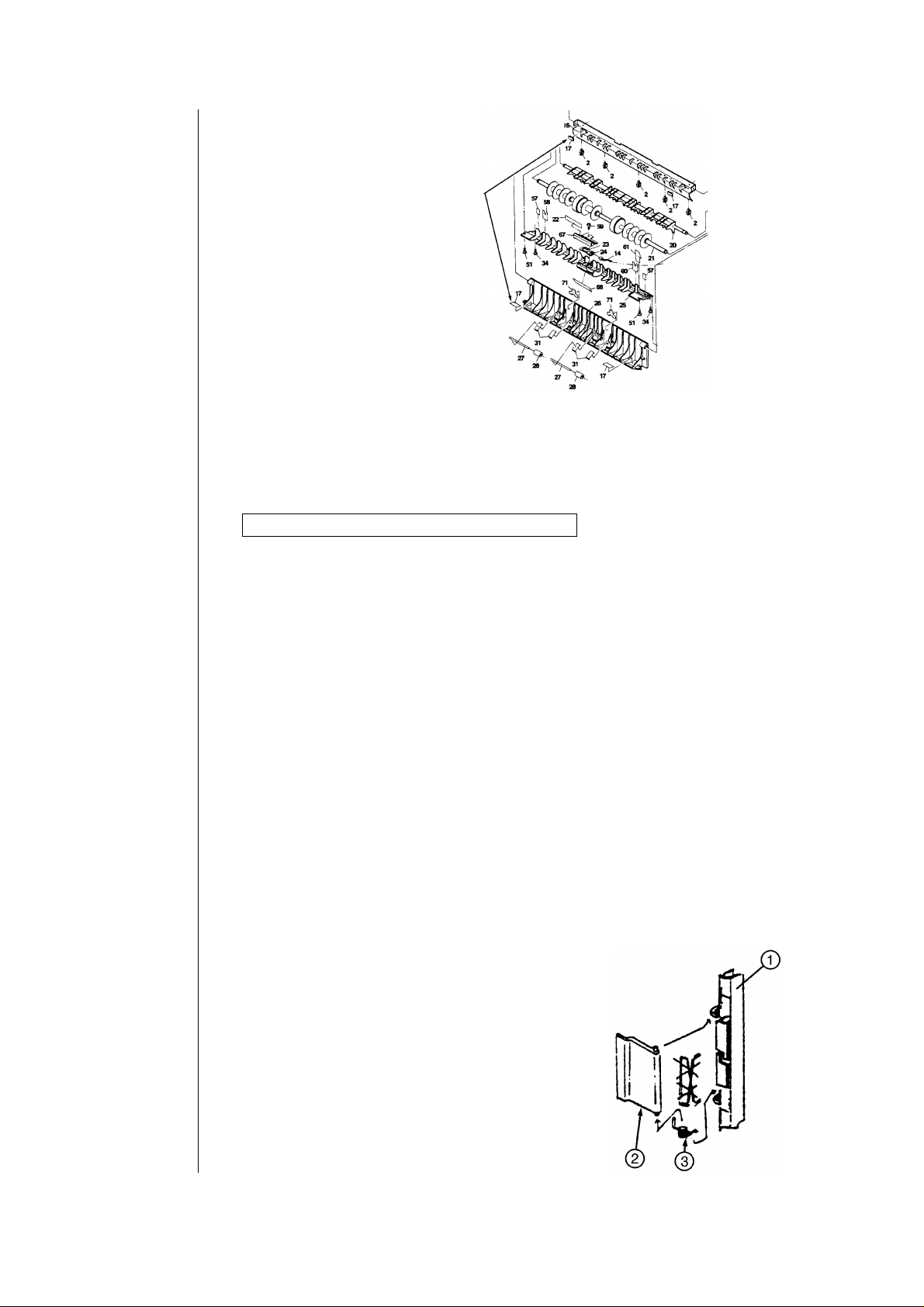

(1) The interface connector (only for models SF-A57 and A18) which connects

the harness with the fan motor ([6]-31) of the reversion transport section.

(2) The sensor harness inside the copy paper feeding tray section.

3/5

Page 4

Ref.

Model name Version P/G No.

No.

1

(1)

SF-A17/A56

SF-A57/A18

1

(2)

1

(3)

SF-A17/A56

1

(4)

1

SF-A56/A57

(5)

1

(6)

1

(7)

1

(8)

1

(9)

1

(10)

SF-A17/A56

SF-A57/A18

SF-A17/A56

SF-A17/A56

SF-A57/A18

All

3 -87

3 -88

3 -76

4 -68

5 -56

5 -17

5 -38

1 -49

4 -60

4 -55

4 -5

7 -24

7 -9

7 -7

Current parts New parts

Parts code Parts code

0CW2214P375// 0CW2214P524// AG Weight sheet

0CW2214P346// 0CW2214P492//

0CW2214P345// 0CW2214P491// Curl sheet F

0CW2214P156// 0CW2214P102// AE Separator plate 1

0CW2171P539// 0CW2221P336// AU Protect rubber

0CW2214P347//

0CW2078P023B/ 0CW2078P086B/ AB Screw (M3)

0CW2214P355// 0CW2223P319// AN Display panel

0CW2214P154// 0CW2214P154D/ AH Spring

0CW2214P475// Discontinued ---- Shutter F sheet 6

0CW2214P006// 0CW2214P006E/ AY A tray guide 4

0CW2214P045//

0CWE31400336 Photo interrupter

0CW2214K202// 0CW2214K202E/ AS ASM-tray harness 1

Q’ty Change

4 → 2

Discontinued ----

Price

rank

AH

AD Flapper rubber 6

Parts name

Curl sheet R

Tray sensor lever 3

Effec-

tive

time

1st lot

’97/7

1st lot

’97/8

change-

Inter-

Note

ability

1

1

6

4/5

Page 5

Ref.

Model name Version P/G No.

No.

2

(1)

2

(2)

2

(3)

2

(4)

2

(5)

2

SF-S54

(6)

2

(7)

2

(8)

2

(9)

2

(10)

2

(11)

2

3

SF-A57/A18

(1)

3

SF-A17/A56

(2)

SF-A57/A18

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

All

AB series

Inch series 0CW2198K210// AL ASM-tray sensor B

1 -25

1

1 -3

1 - 502

2 -61

2 -510

2 -56

2 -511

3 -15

3 -502

1

6

7

Current parts New parts

Parts code Parts code

0CW4059P301// 0CW4059P375// AN Lever (S-pole)

0CW4059P374//

---0CW4059P095// Spring (S-pole)

0CW4074P315// 0CW4074P376// AZ Guide P (Tray)

0CW4074K102// 0CW4074K146// BA Tray ass’y

0CW4059P002// 0CW4059P005// AZ Roller (Feed-H)

0CW4059K007// 0CW4059K200// BB Feed roller ass’y

0CW4064P025// 0CW4054P138C/ AD Joint collar spring

0CW4074K106// 0CW4059K201// AH Press roller H ass’y

0CW4054P138C/ 0CW4074P079// AF Joint collar spring

0CW4074K119// 0CW4066K065// AN Press roller K ass’y

0CW4059K060// AS S-pole-ass’y ∗

----

0CWE74382WE03 AL CT-interface connector

0CW2198K209// AP ASM-tray sensor A

Price

rank

AF

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Parts name

Lever (S-pole-sub)

Effec-

tive

time

1st lot

’97/8

---- 6

Inter-

change-

ability

4

Note

∗ The assembly units of (2) and (3) .

5/5

Loading...

Loading...