Page 1

COPIER(OPTION) : SF-A55

Date

:

Jul. 9, 1997

1. MEASURE TO ALLEVIATE PROBLEMS OF DTD SENSOR ADJUSTMENT ERRORS (U5-03).

2. MEASURE TO PREVENT PROBLEMS OF DAMAGE TO THE HARNESS.

3. MEASURE TO PREVENT PROBLEMS OF DOUBLE FEEDING.

4. MEASURE TO REDUCE THE NOISE FROM THE FAN MOTOR.

5. ESTABLISHMENT OF THE ORIGINAL DOCUMENT TRAY ASSEMBLY OF THE ADF AND THE

RADF AS SERVICE PARTS.

No. : SP-2149

1. Measure to alleviate problems of DTD sensor adjustment errors (U5-03).

1.Model Name: SF-A55

2.General: A change has been carried out in both the sensor PWB and the control PWB. These

changes have been carried out as a measure to alleviate problems of DTD sensor

adjustment errors (U5-03). This measure has been carried out from 1996 September

production, but the parts had not been established as service parts, and therefore they

have now been established as service parts.

3.Description: 1) Change carried out in the Control PWB.

(Old) (New)

0CW2198J205// → 0CW2198K205T/

Changes carried out in the Control PWBs listed above.

(Old) (New)

[R76]: 0CWE70188J122 → 0CWE70188F272

[R133]: 0CWE70014J151 → 0CWE70014J301

[R94]: 0CWE70188J472 → 0CWE70188F472

[R108]: 0CWE70188J222 → 0CWE70188F222

[R122]: 0CWE70188J332 → 0CWE70188F332

[R116]: 0CWE70188J104 → 0CWE70188F104

2) Change carried out in the DTD sensor.

(Old) (New)

0CWE314000549 → 0CWE314000598

The changes described in and above have been carried out as a measure to improve

the performance of the sensor, by resulting in a decrease in the margin of variance in

the sensitivity of the sensor, as well as improving the actual sensitivity itself.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

3) In accordance with the changes described in and above, a change has been carried

out in the color of the sensor interface harness as a measure to distinguish the old parts

from the new parts.

Sensor interface harness 0CW2198K216// → 0CW2198K216D/

When carrying out replacement operations on the old PWBs, replacement should be

carried out at the same time on both the sensor and the control PWB. The old sensor

interface harness is interchangeable with the new sensor interface harness.

4.Action: From 1996 September production.

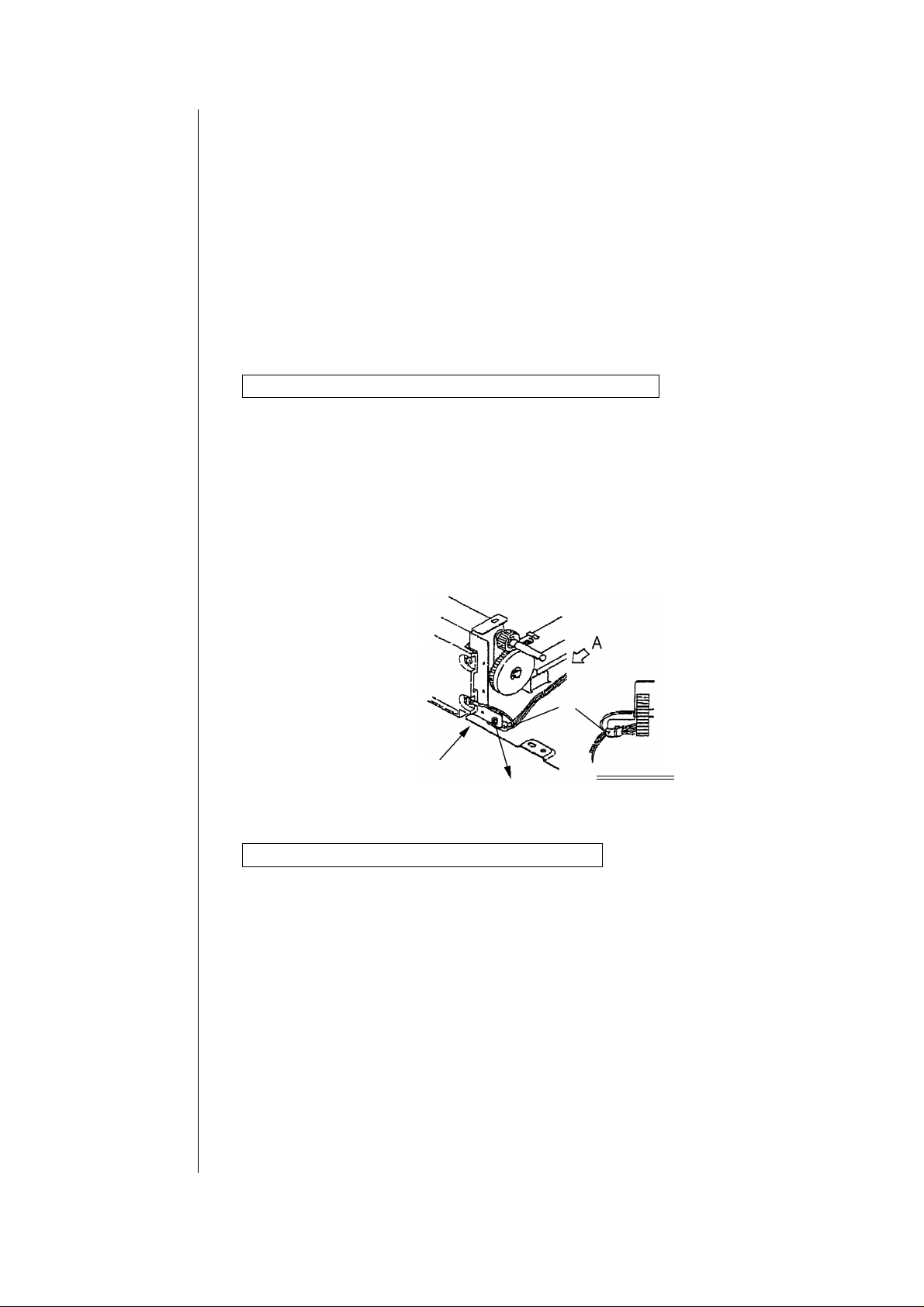

2. Measure to prevent problems of damage to the harness.

1.Model Name: SF-A17/A18

2.General: The harness is fixed to the round hole section of the paper delivery side plate in the

reversion transport section, but there were problems of the harness biting into the round

hole section, which can result in damage to the harness. As a measure to alleviate this

problem, a change has been carried out in the harness. The new harness is encased in

a tube for protection.

Tube, added in one location

Tube

Paper delivery unit

Hole

3.Action: From 1997 June production.

Arrow view A

3. Measure to prevent problems of double feeding.

1.Model Name: SF-A14/A15

2.General: There have been problems of double feeding during paper feeding operations of the

original documents. As a measure to alleviate this problem, a change has been carried

out in the material of the separator belt of the transport section.

3.Description: Material Polyurethane rubber → EPDM

Color Black → Gray

4.Action: From 1997 July production.

2/4

Page 3

4. Measure to reduce the noise from the fan motor.

1.Model Name: SF-A18/A57

2.General: A noise sheet has been attached to the inside of the DF cover of the ADF. This change has

been carried out as a measure to reduce the noise from the fan motor.

Noise sheet A

3.Action: From 1997 May production.

5. Establishment of the original document tray assembly of the ADF and the RADF as

service parts.

1.Model Name: SF-A17/A55/A57

2.General: The original document tray assembly of the models listed above has been established

as a service part. This change has been carried out in accordance with a request from

the market.

Part code Part name Model name

1) 0CW2198K049// Tray assembly (AB) SF-A55

2) 0CW2198K050// Tray assembly (AB) SF-A55

3) 0CW2198K051// Tray assembly (Inch) SF-A55

4) 0CW2198K141// Tray assembly (AB) BE SF-A55

5) 0CW2214K089//

6) 0CW2214K126//

7) 0CW2214K090//

8) 0CW2214K049//

Original document tray

assembly (Inch)

Original document tray

assembly (BE)

Original document tray

assembly (AB)

Original document tray

assembly

SF-A17/SF-A57

1)8) → For the Japanese domestic market.

2)7) → For the SEEG, U.K., and Australian markets.

4)6) → For all AB series destination markets except those listed above.

3)5) → For all inch series destination markets.

3/4

Page 4

Ref.

Model

No.

name

1

1)

SF-A55

1

2)

1

3)

SF-A17

2

SF-A18

SF-A14

3

SF-A15

SF-A18

4

SF-A57

SF-A55

5

SF-A17

SF-A57

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

Version P/G No.

4 -9

7 -901

7 -54

7 -73

7 -51

7 -52

7 -55

All

SEEG

UK

Australia

AB series

ex. the above

Inch series 0CW2198K051//

SEEG

UK

Australia

AB series

ex. the above

Inch series 0CW2214K089// BT

7 -59

3 -32

3 -85

6 -6

6 -3

2 -80

4 -20

1

2

7

Current parts New parts

Parts code Parts code

0CW2198J205// 0CW2198K205T/ CC Control board assembly

0CWE70188J122 0CWE70188F272

0CWE70014J151 0CWE70014J301 Resistor [R133]

0CWE70188J472 0CWE70188F472 Resistor [R94]

0CWE70188J222 0CWE70188F222 Resistor [R108]

0CWE70188J332 0CWE70188F332 Resistor [R112]

0CWE70188J104 0CWE70188F104 Resistor [R116]

0CWE314000549 0CWE314000598 AP PBA-Sensor 2 PWB

0CW2198K216// 0CW2198K216D/ BB

0CW2215K211// 0CW2215K211B/ AH ASM-RU Harness

0CW2224K210// 0CW2224K210B/ AM ASM-Earth wire 15

0CW2166P290C/ 0CW2199P421// AN Separator belt ’97/7 3

0CW2215P328// AP Noise sheet ’97/5

0CW2198K050//

0CW2198K141//

----

0CW2214K090//

0CW2214K126//

Price

rank

AA

BR Tray assembly

BS

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Parts name

Resistor [R76]

ASM-R Sensor interface

harness

Original document tray

assembly

Effec-

tive

time

’96/9

’97/6

----

Inter-

change-

ability

3

1

6

Note

Q’ty’ 2

Q’ty’ 3

4/4

Loading...

Loading...