Page 1

Date: May. 30, 1997

COPIER : SF-2020

No. : SP-2134

1.MEASURE TO ALLEVIATE PROBLEMS OF ELECTRICAL NOISE.

2.CHANGE IN THE SIMULATION LIST.

1. Measure to alleviate problems of electrical noise.

1.Model Name: SF-2020/1020/2120/1 120

2.General: As a measure to reduce electrical noise, the MM interface harness used in the

machines bound for the 200 V series market destinations (the U.K., Germany, Europe)

is now being used for all market destinations.

3.Action: From 1997 April production.

2. Change in the simulation list.

1.Model Name: SF-2020/1020/2120/1 120

2.General: Changes and additions in a portion of the simulation list and trouble list has been

carried out in the models listed above. Please refer to the supplementary page for

details concerning these changes and additions.

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

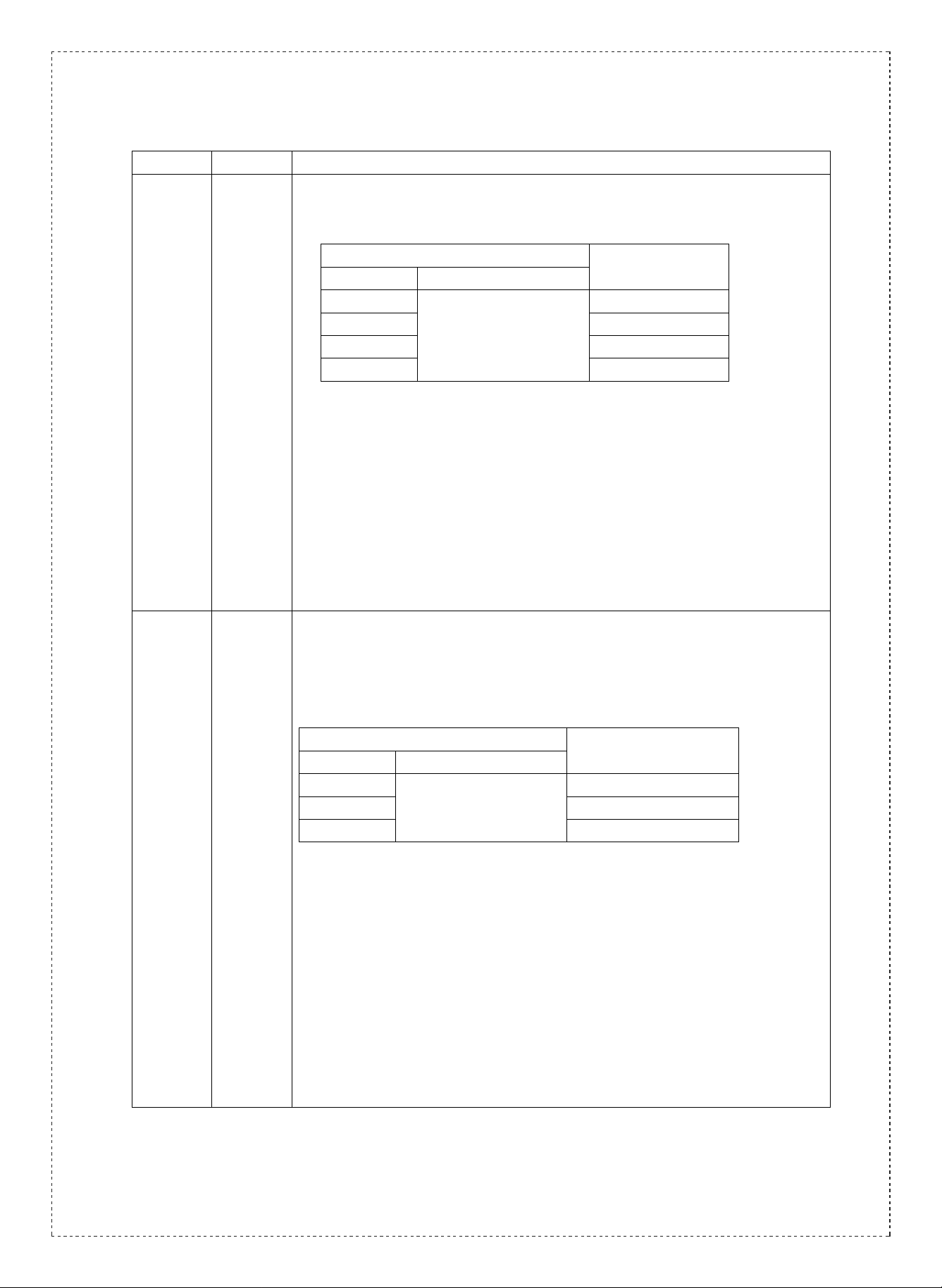

Main code Sub code Content

50 02 Leading edge image position adjustment (measurement value substitution).

Just as with simulation 50-1, the settings for the leading edge image position and leading void position are carried out.

The settings for the leading edge image position are carried out by this simulation through the direct input of the measured

leading edge misalignment L1 and L2.

51 02

No. of copies display section

Decimal place no. 3 Decimal place 2 and decimal place 1

A

bL2

C Leading edge void adjustment

d Rear edge void adjustment

(Example)

For a case whereby L1 = 24.5 mm, [2], [4], and [5] are input. After input has been carried out, the display of the no. of

copies display section will be A45.

Points of caution to be observed when the input of L1 and L2 is carried out.

•The effective no. of decimal places for L1 and L2 is 3.

(the display, however, is only the lower 2 decimal places, and the top decimal place (decimal place 3) is pushed

out and now displayed.)

•L1 and L2 should be input to the first decimal point (when the first decimal point is “0,” the last input should be “0.”

•When the input of numerical value of L1 and L2 is carried out, and more than 4 decimal places are input, the newest 3

decimal places are considered to be in effect.

On the other hand if only 2 decimal places are input, the lowest decimal place (decimal place 1) from the last input

becomes the top decimal place (decimal place 3).

(Example)

When the last input value was 245, and the next input is 24, the value which is stored in memory is 524.

•After L1 and L2 has been input, calculations and renewal (memory) of the register adjustment A and B of simulation 50-1

are carried out only after the print button is set to ON. Register adjustment A and B values are not renewed when the

magnification display, or the CA keys are ON.

Register volume adjustment.

The settings for the copy paper sagging volume in the register section are carried out. Warm-up for the simulation run is

started, and the current set tray register volume is displayed in the no. of copies display.

The READY lamp is illuminated once the warm-up is finished, and copy operations are commenced when the print button

is ON.

There are several items to be displayed, and therefore data classification is carried out by the 3rd decimal place of the no.

of copies display, and the data is displayed by the lower decimal places.

Display changes are carried out by the magnification display key.

1~99

Display data

L1

2/5

No. of copies display section

Decimal place no. 3 Decimal place 2 and decimal place 1

A

b Manual register volume

C ADU paper feeding register volume

* Details concerning adjustments are as described below. Adjustments are carried out for the amount of time (register

volume) between when the paper transport sensor (PPD) is set to ON to when the paper feeding operations are set to

OFF during paper feeding operations. Adjustment range is from 1 to 99.

The register volume is calculated as (set value) x 1 msec + 70 msec.

Settings:

A-manual (initial value: 50)

B-Cassette

C-ADU register volume

HOUND A (B-Cassette initial setting: 40)

In accordance with software internal processing for WLT, A3, LG, B4, full skap, LTR, and A4R, +15 is added to the

simulation setting.

(Example)

When the simulation setting is 40, +15 is added in accordance with the software internal processing, and the actual value

becomes 55.

HOUND B (B-Cassette initial setting: 40)

In accordance with software internal processing for WLT, A3, LG, and B4, +20 is added to the simulation setting.

(Example)

When the simulation setting is 40, +20 is added in accordance with the software internal processing, and the actual value

becomes 60.

ADU (C-ADU register volume initial setting: 45)

1~99

Tray register volume

Display data

← Initial setting:40

← Initial setting:50

← Initial setting:45

(Hound B only)

Page 3

Main code Sub code Content

01 ADU interface plate home position setting (hound B only).

02

52

Adjustments are carried out from the input of the interface plate home position values.

When the simulation is run the current adjustment value is displayed on the no. of copies display.

The setting range is from 1 to 8 to 30. The smaller the setting value, the wider the position of the interface plate.

∗ (initial setting: 13)

ADU rear edge plate home position setting (hound B only).

Adjustments are carried out from the input of the rear edge plate home position values.

When the simulation is run the current adjustment value is displayed on the no. of copies display. The setting range is

from 1 to 8 to 30.

The smaller the setting value, the wider the position of the rear edge plate.

∗ (initial setting: 30).

ADU transport motor speed adjustment.

Adjustments are carried out from the input of the ADU transport motor speed adjustment values.

When the simulation is run the current adjustment value is displayed on the no. of copies display.

∗ 05

The target speed changes with the size of the copy paper to be transported.

Halt position setting for the (R) ADF (during single side copy operations).

The settings are carried out for the halt position of the original document transported during ADF (single side) copy

01

53

02

04

operations.

When the simulation is run the current set halt position data is displayed on the no. of copies display. After the numerical

value is input, the values are stored in memory when the print button is ON.

∗ The setting range is from 0 to 15 (initial setting: 8).

Halt position setting for the (R) ADF (during double side copy operations).

The settings are carried out for the halt position of the original document transported during ADF (double side) copy

operations.

When the simulation is run the current set halt position data is displayed on the no. of copies display.

After the numerical value is input, the values are stored in memory when the print button is ON.

∗ The setting range is from 0 to 15 (initial setting: 8).

ADF register sensor adjustments.

Original document detection level adjustments are carried out for the ADF register sensor.

When the simulation is run the adjustments for the register sensor original document detection levels are carried out, and

the original document detection level after adjustments are completed is displayed on the no. of copies display.

The display range is from 0 to FFh.

Setting Transport motor speed

45

50

60

(Target speed): - (5 mm/sec)

(Target speed)

(Target speed): + (10 mm/sec)

When the setting is “-1" the speed

decreases by -1 mm/S.

When the setting is ”+1" the speed

increases by +1 mm/S.

(Initial setting: 58)

3/5

Page 4

Trouble code Sub code Content Conditions

•During initialization, the MHPS does not change to OFF within 1.5

seconds after the feed operations of the mirror commence.

L1 00 Mirror feed trouble

L3 00 Mirror return trouble

L4 01 Main motor trouble

L5 02 Lens trouble

0-1 Zero cross pulse (FW) trouble •The zero cross pulse width is off by more than 10%.

L8

H2 00 Fusing thermostat open detection •When the thermostat (TH) input value is greater than 4.07 v.

H3 00 Fusing high temperature trouble

H4 00 Fusing low temperature trouble

U2

U4

U5

03 AE sensor trouble

01 Back-up memory errors

04 Back-up IC (EEPROM) access error

00 ADU communication error •When a communication error occurs within the ADU.

02 Interface plate motor trouble

03 Rear edge plate motor trouble

12 ADU transport motor trouble

00 ADF communication error •When a communication error occurs within the ADF.

01 Register sensor adjustment trouble

02 Delivery reversion sensor adjustment trouble

05 Timing sensor adjustment trouble

11 Paper feeding motor trouble

16 ADF fan motor trouble

•During copy operations, the MHPS does not change to OFF within 0.5

seconds after the feed operations of the mirror commence.

•The mirror is not in the home position when MIRROR START occurs

during copy operations (MHPS is OFF).

•During initialization, the MHPS does not change to ON within 2.5 seconds

after the return operations of the mirror commence.

•During copy operations, the MHPS does not change to ON within 2

seconds after the return operations of the mirror commence.

•The MMRE (encoder) pulse is not detected for a time period of greater

than 0.05 sec while the main motor is in operation.

•The lens movement does not end within 10 seconds after the lens

movement commences.

•LHPS is not detected while the lens is moving to the home position, even

if the lens is moving in fixed intervals.

•When the AE sensor input does not change after the special

measurements of the AE sensor (simulation 47) are carried out.

•When a fusing temperature of greater than 240 (the thermostat input

value is less than 0.38 v) is detected.

•When the ready temperature is not reached within 90 seconds during

warm-up operations.

•When a fusing temperature (set temperature) of less than -40 is detected

after warm-up operations have been completed during temperature control.

•When the counter total and the check sum value are compared and do

not match.

•When data reading and writing operations can not be carried out to the

back-up IC (EEPROM).

•When the interface plate initialization operations (the interface plate

returns to the home position) are not completed within 5 seconds.

•When the rear edge plate initialization operations (the rear edge plate

returns to the home position) are not completed within 5 seconds.

•The DMRE (encoder) pulse is not detected for a time period of greater

than 0.05 sec while the ADU transport motor is in operation.

•When the encoder input is less than the fixed value even after 500 ms

have passed with the transport motor PWM at the maximum value.

•When the encoder input is greater than the fixed value even after 500 ms

have passed with the transport motor PWM at the minimum value.

•When the register sensor adjustments (simulation 53-4) have been

carried out and the adjustment value is outside the adjustment range.

•When the delivery reversion sensor adjustments (simulation 53-5) have

been carried out and the adjustment value is outside the adjustment range.

•When the timing sensor adjustments (simulation 53-6) have been carried

out and the adjustment value is outside the adjustment range.

•The revolution pulse is not detected for a time period of greater than 0.1

sec while the paper feeding motor is in operation.

•When the ADF fan motor lock detection signal is detected as continuing

for 2 seconds.

*

4/5

Page 5

Ref.

Model

No.

name

SF-2020

SF-1020

1

SF-2120

SF-1120

<Int er chang e>

1. Interc hang eable . 4. Not inter chang eabl e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts ma r ked w i th “ ” is imp or t an t fo r m a in ta i ning t he s a fe ty of the s e t. B e s u re to re pl ac e t he se pa r ts with

specified on es fo r m a inta i ni ng t he sa fe ty an d pe r fo rm an c e of t he s e t.

Version P/G No.

Overseas

12 -53 —

!

Current parts New parts

Parts code Parts code

Added

DHAI-2568FCZZ

5. Interc ha ng ea bl e i f rep la c ed w i th s a me t y pe s o f

related parts in use.

6. Others.

Price

rank

AP MM interface harness

Parts name

Effec-

tive

time

1st lot

’97/4

Inter-

change-

ability

6

Note

5/5

Loading...

Loading...