Page 1

Date: May. 20, 1997

COPIER : SF-2116

1. CHANGE IN THE ELECTRO-MAGNETIC CLUTCH OF THE PAPER FEEDING UNIT CARRIED OUT AS A

MEASURE TO IMPROVE PRODUCTIVITY.

2. MEASURE TO STRENGTHEN THE CLAM SHELL LOCK.

3. MEASURE CARRIED OUT TO IMPROVE PROBLEMS OF NOISE.

4. MEASURE CARRIED OUT TO IMPROVE PROBLEMS OF RISING TEMPERATURES IN THE DC PWB.

5. MEASURE CARRIED OUT TO IMPROVE PROBLEMS OF NOISE.

No. : SP-2117

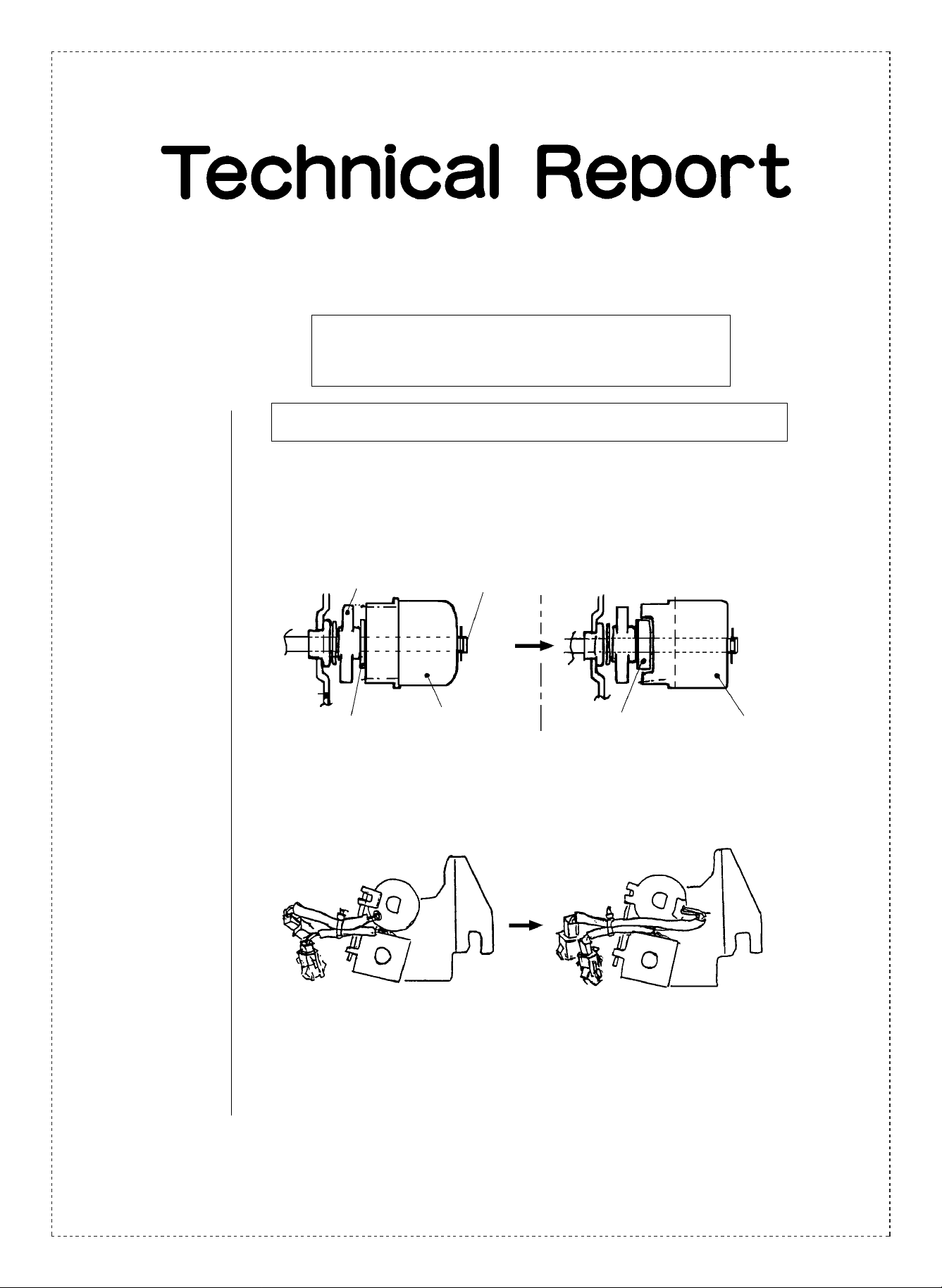

1. Change in the electro-magnetic clutch of the paper feeding unit carried out as a

measure to improve productivity.

1.Model Name: SF-2116/ 1016/21 18/1018/2020/1020/2120/1 120

2.General: A change has been carried out in the electro-magnetic clutch of the paper feeding unit

in the models listed above. This change has been carried out as a measure to improve

productivity.

Collar

PS front roller

Paper feeding

drive frame

(Discontinued) E7

(Discontinued)

22T electro-magnetic clutch:

PCLC-0236FCZZ

(Added)

Clutch bushing:

NBRGC0584FCZZ

(Added)

22T electro-magnetic clutch N:

PCLC-0270FCZZ

Note: As shown in the figure above, the old clutch and E7 are comparable with the new

clutch and the clutch bushing, and therefore an old/new interchangeable

relationship has been established.

Note: As shown in the figure above, line processing direction is different between the old

parts and the new parts.

3.Action: From 1997 February production.

SHARP CORPORATION Reprography Division

1/7

Green

C

Page 2

2. Measure to strengthen the clam shell lock.

1.Model Name: SF-2116/ 1016/21 18/1018/2020/1020/2120/1 120

2.General: When inserting the ADU in the SF-2020, there was a danger of the lock of the machine

becoming loose, causing the possibility of problems of clam shell opening. As a

measure to alleviate this problem, a change has been carried out in the diameter of the

lock lever spring, to improve the load of the spring. The change has also been carried

out in the springs of the other models listed above to establish interchangeability.

3.Action: ∗1 SF-1120/ 2120: From 1996 November production.

Other models: Japanese domestic production:

Running change from 1997 March production.

Chinese (SOCC) production:

Running change from 1997 April production.

French (SMF) production:

Running change from 1997 May production.

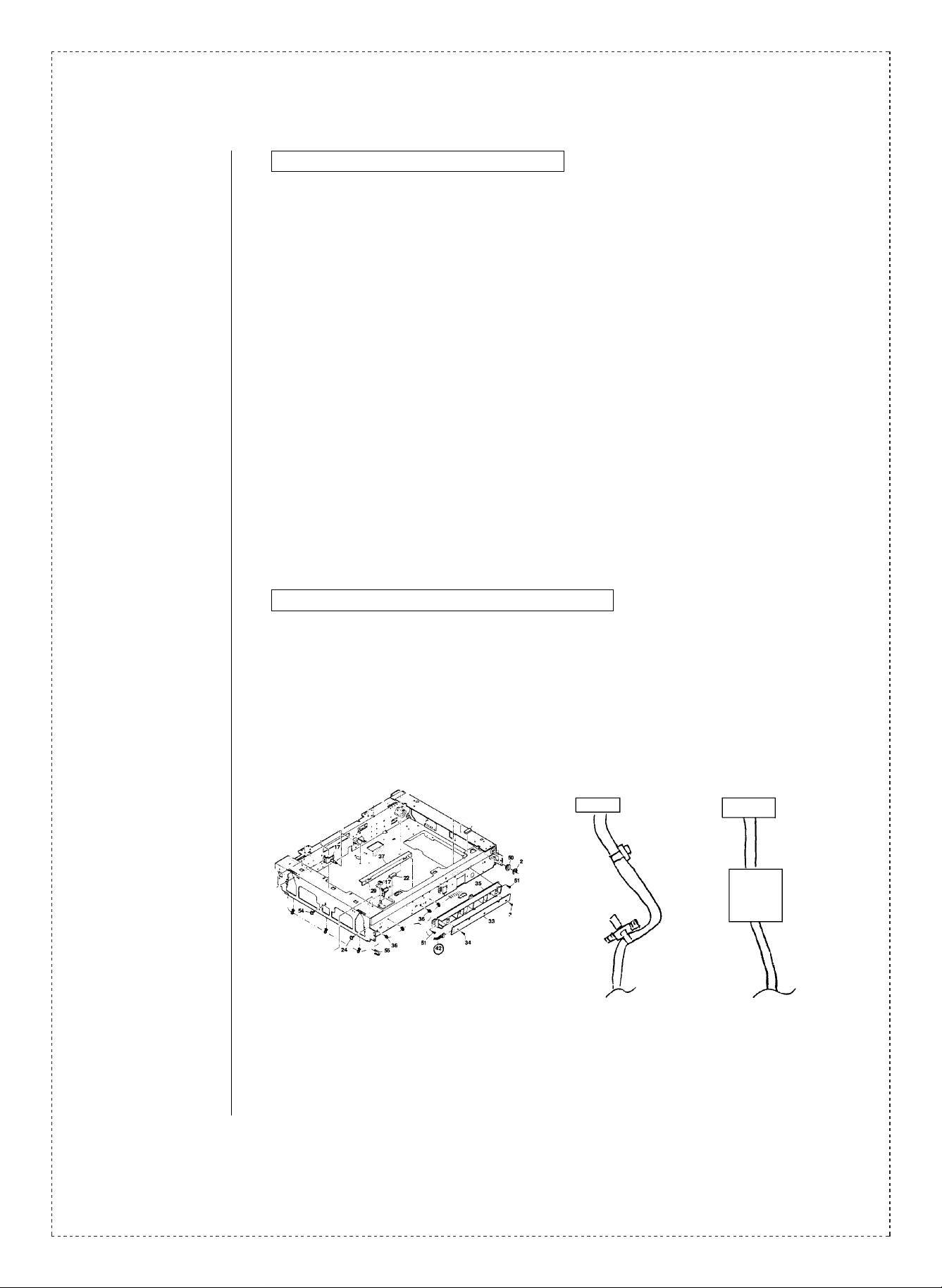

3. Measure carried out to improve problems of noise.

1.Model Name: SF-2020/1020/2120/1 120

2.General: A core, gasket and capacitor has been added to the models listed above. This measure

has been carried out to improve problems of noise.

1) Ferrite core: Germany, Australia,Great Britain.

No.10 pin white

To the operation panel

→

Ferrite core

2/7

Page 3

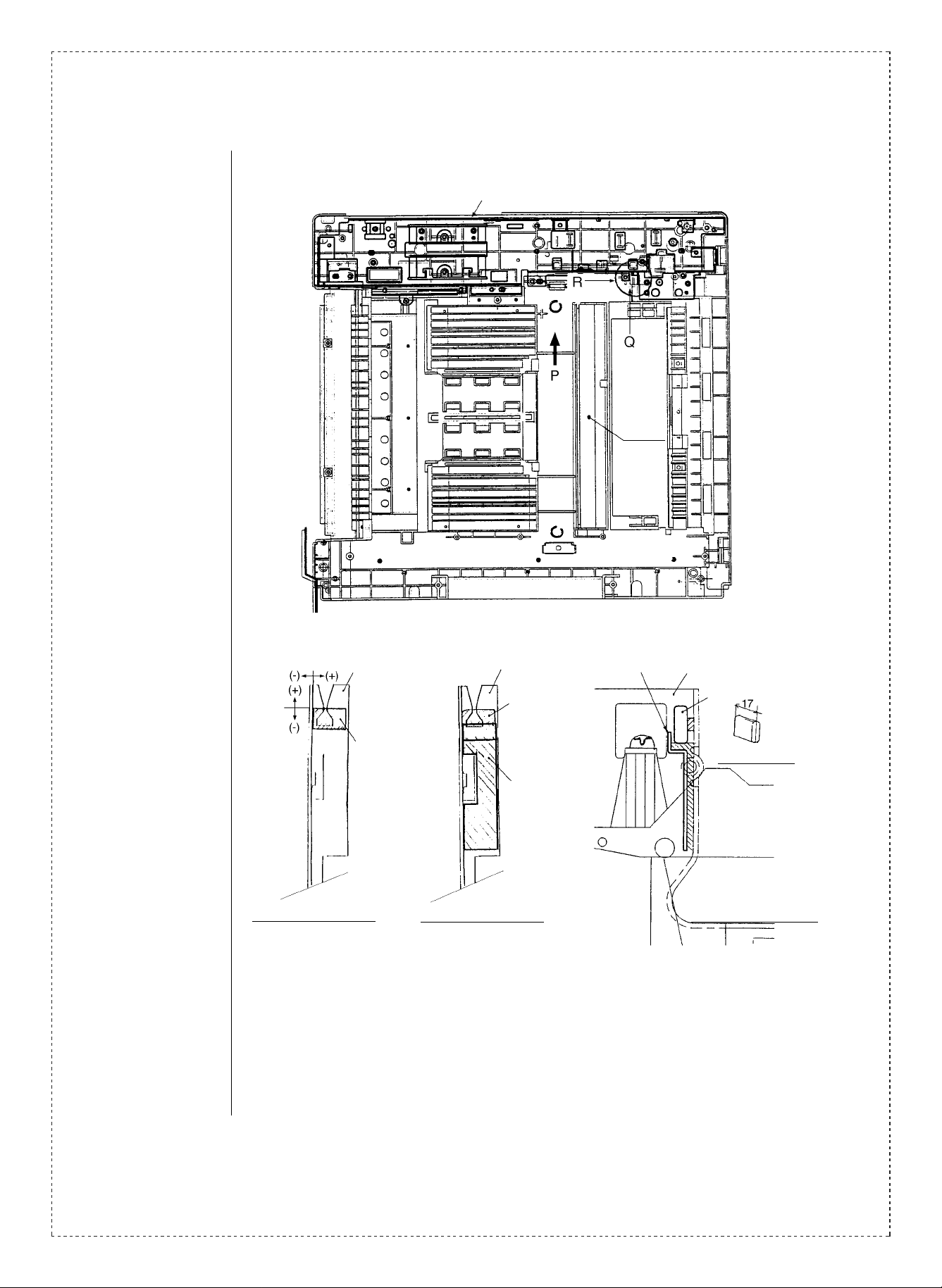

2)Gasket A, Gasket attachment sheet:Germany, Australia, Great Britain.

Lower frame R AS

Machine

base plate

Gasket

attachment sheet

Lower frame R As

Gasket A

Gasket length

Y Standard

X Standard

Lower frame R AS

Gasket

Lower frame R AS

Gasket

Gasket

attachment sheet

R Arrow-view diagram (1/2)

R Arrow-view diagram (2/2)

Q Arrow-view diagram

〈 Attachment procedure 〉

[1] Attach the gasket.

[2] Bring the bent portion of the gasket attachment sheet in contact with the gasket and

attach.

3/7

Page 4

3) Gasket B: Germany

Australia

Great Britain

SF-2010/1020

Lower frame

Machine rear direction

SF-2120/1 120

Lower frame R

Attachment standard:

Y direction

Leave space

open

Attachment standard:

Y direction

+0

-0.5

Lower frame R

+0

-0.5

Main harness

Gasket B

W base plate

Rear frame

Machine rear direction

Main harness

Gasket B

Attachment should be carried out

more than 10 mm on the plate metal

of the 2nd base plate.

4/7

Page 5

4) Seracon 0.01µ : all market destinations.

After installing, bend sidewise so

Install on the back side of D 37

that it does not come in contact with

the attachment plate metal.

3.Action: From 1996 mid-November production.

4. Measure carried out to improve problems of rising temperatures in the DC PWB.

1.Model Name: SF-2020/1020/2120/1 120

2.General: A change has been carried out in the models listed above as a measure to prevent the

temperatures in the DC PWB from rising. The straightening bridge diode has been

change to a shot key type which has a small electrical power consumption (low

temperature).

3.Action: From 1996 October production.

5. Measure carried out to improve problems of noise.

1.Model Name: SF-2020/2120

2.General: A reactor has been added to the models listed above. This action has been carried out

as a measure to improve problems of noise.

5/7

Page 6

Harness

Fan

Rear frame

UN ASSY

M3 birling concave

M3 x 12 bind

M3 x 4 bind

(Qty: 2)

Reactor attachment plate B

(LPLTM5347FCZZ)

Using screws

M3 birling concave

ø 7 hole

Pawl A

M3 x 4 bind

M3 x 12 bind(XBBSD30P12000)(Q’ty: 1)

M3 x 2 bind(XBBSD30P04000)(Q’ty: 6)

ø 3.5 hole

M3 birling concave

Reactor attachment figure

3.Action: ∗2 SF-2020: From 1996 December production.

SF-2120: From 1997 January production.

M3 birling convex

ø 7 hole

ø 3.5 hole

M3 x 4 bind

M3 birling concave

Reactor

Transistor UN

Reactor attachment plate A

(LPLTM5346FCZZ)Pawl A insertion

6/7

Page 7

Ref.

Model name Version P/G No.

No.

SF-2116/2118 All

SF-1016/1018 Overseas

SF-2020/2120 All

SF-1020/1120 Overseas

SF-2116/2118 All

1

SF-1016/1018 Overseas

SF-2020/2120 All

SF-1020/1120 Overseas

SF-2116/2118 All

SF-1016/1018 Overseas

SF-2020/2120 All

SF-1020/1120 Overseas

SF-2116/2118 All

SF-1016/1018 Overseas

2

SF-2020/2120 All

SF-1020/1120 Overseas

17 -11

18 -11

17

18

17

18

10 -31

11 -31

2

7

Current parts New parts

Parts code Parts code

PCLC-0236FCZZ PCLC-0270FCZZ AW Electro-magnetic clutch

NEW

NBRGC0584FCZZ

—

Q’ty Change

XRESP70-08000

MSPRC2275FCZZ MSPRC2591FCZZ AC Lock lever spring ∗13

NEW

RCORF0026FCZZ

Price

rank

AD Clutch bushing

AA E ring

AL Ferrite core

Parts name

Effec-

tive

time

1st lot

’97/2

Inter-

change-

ability

4

6

Note

SF-2020/1020

SF-2120/1120

3

SF-2020/2120 All

SF-1020/1120 Overseas

4

SF-2020/2120

5

<Interchange>

1. Interchang eabl e. 4. Not intercha ngeabl e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts m a r ked w it h “ ” i s imp or t an t fo r m ai n ta ini ng t he s a fe ty of the s e t. B e sur e t o rep l ace t he s e pa r ts wi th

speci fi e d on es fo r m ai n ta in i ng t he s a fe ty and pe r fo rmance o f th e s et .

Germany

Australia

U.K.

All

Germany

U.K.

!

20

12

39

40 -21

21 —

VHDD3SBA60/-1 VHDD4SBS6//-1 AN Bridge diode

—

NEW

PGSK-0012FCZZ

NEW

PSHEP4456FCZZ

NEW

PGSK-0013FCZZ

NEW

VCKYPA1HB103K

NEW

LPLTM5346FCZZ

NEW

LPLTM5347FCZZ

NEW

XBBSD30P12000

NEW

XBBSD30P04000

5. Interchang ea bl e i f r ep lac ed w i th s a me t y pe s o f

related parts in use.

6. Others.

AG Gasket A

AD Gasket attachment sheet

AS Gasket B

AA Seracon

AG Reactor attachment plate A

AL Reactor attachment plate B

M3×12 bind

AA

M3×4 bind

Mid-

’96/11

1st lot

’96/10

6

4 [BD303]

∗26

7/7

Loading...

Loading...