Page 1

Date: May. 8, 1997

COPIER : SF-2120

1. MEASURE TO PREVENT PROBLEMS OF THE BUSHING OF THE REVERSION DRIVE SHAFT BECOMING

DISLOCATED.

2. MEASURE TO PREVENT PROBLEMS OF IMPROPER LOCKING OF THE ADU TRANSPORT GUIDE UNIT.

3. MEASURE TO IMPROVE THE ON/O FF POI NT OF THE POD SENSO R.

4. MEASURE TO ESTABLISH INTERCHANGEABILITY OF THE CLOSING LABEL OF THE MACHINE.

No. : SP-2112

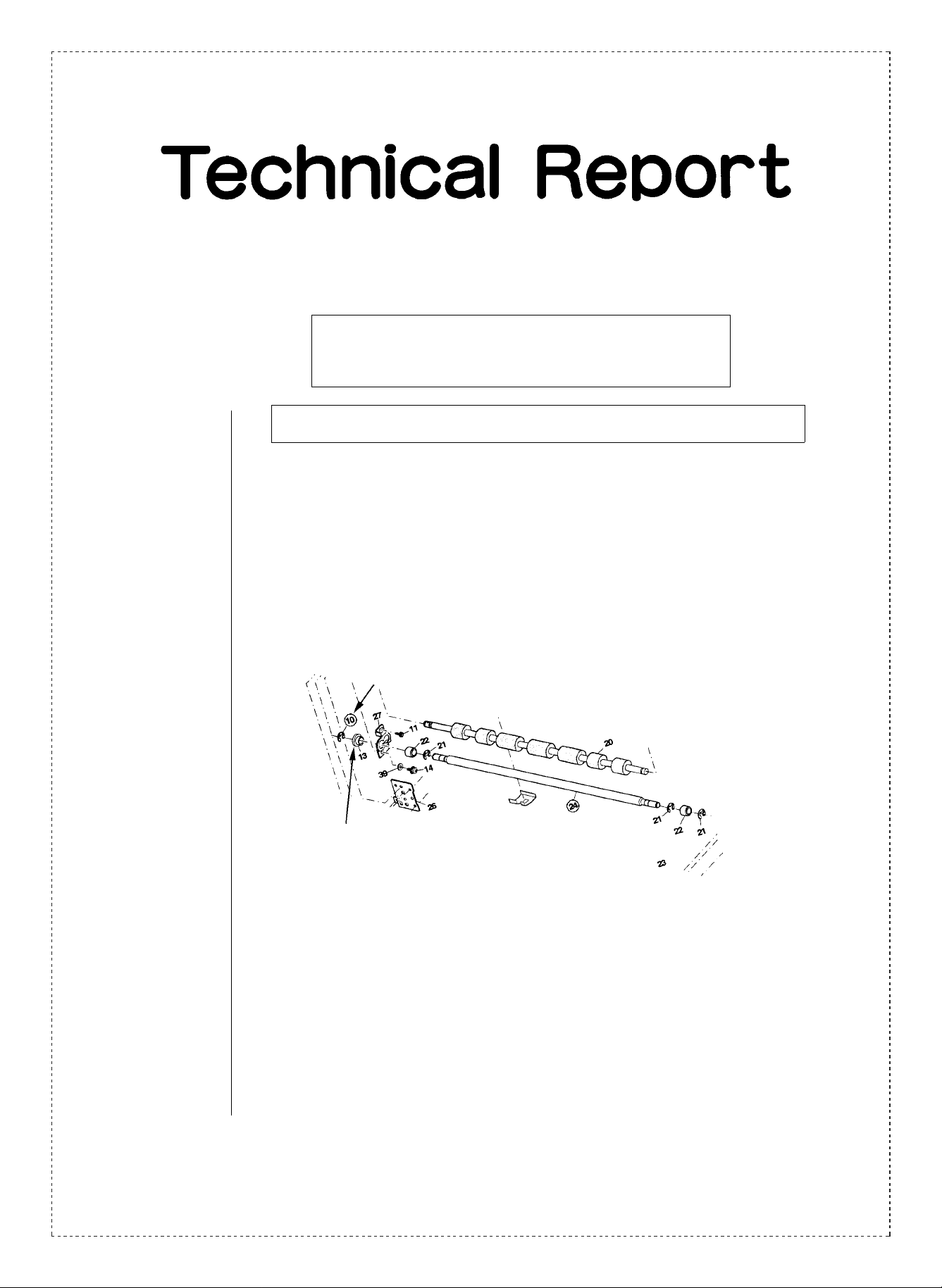

1. Measure to prevent problems of the bushing of the reversion drive shaft becoming

dislocated.

1.Model Name: SF-2120/1 120

2.General: There have been problems reported in the upper paper delivery cabinet of the models

listed above of the bearings which support the reversion drive shaft and reversion

rollers becoming dislocated due to sagging of the delivery plate. As a measure to

alleviate these problems, the method of inserting the reversion drive shaft bearings has

been reversed, in order to prevent the sagging of the delivery plate, and thus prevent

the bushing from becoming dislocated. In accordance with this change a change in the

shape of the reversion drive shaft has also been carried out.

Discontinued

Tightened from the inside

When carrying out the action described above on machines produced before 1996

December production lots, the new reversion drive shafts which have had the change in

shape carried out should be used.

3.Action: From 1996 December production.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

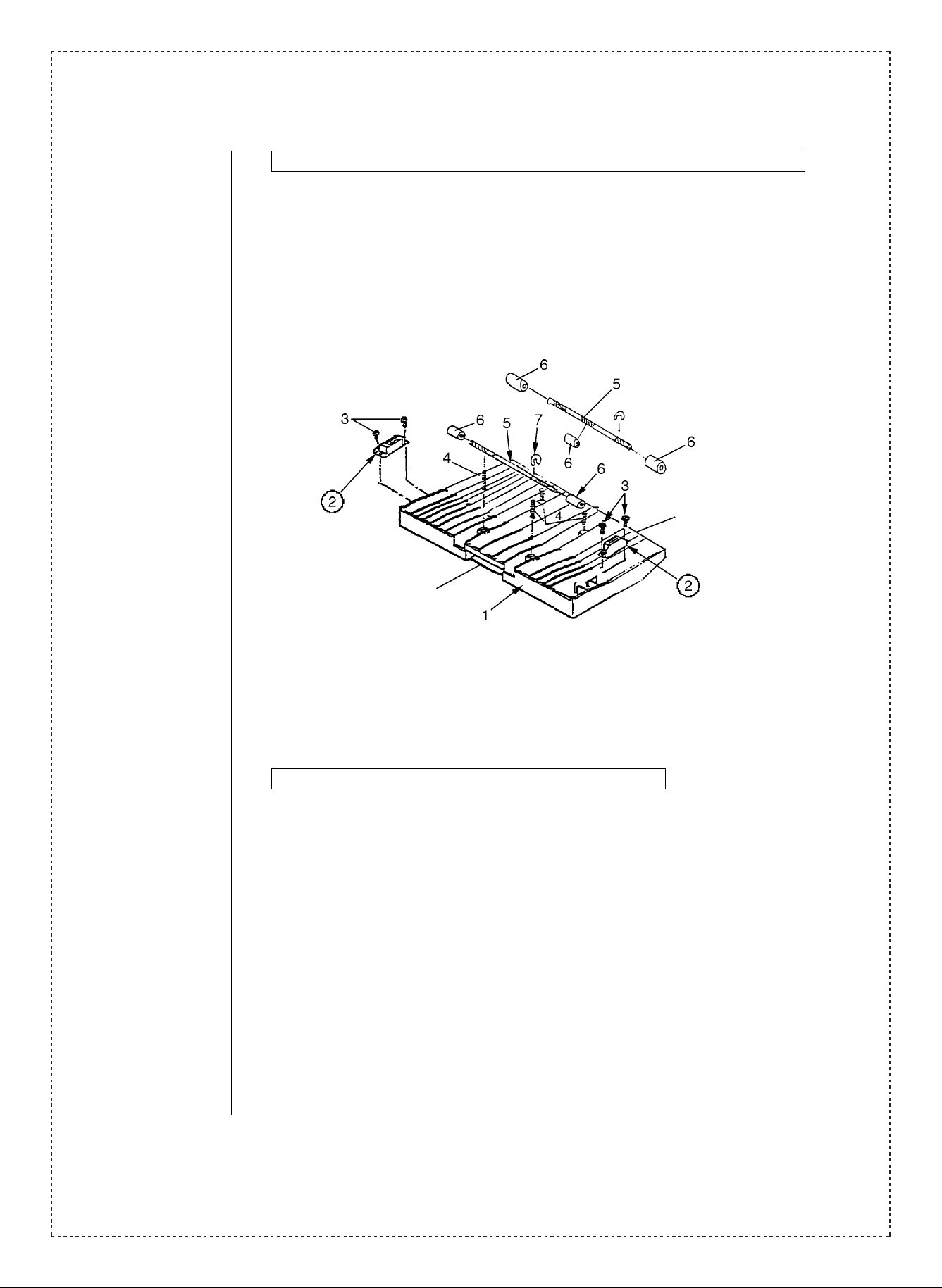

2. Measure to prevent problems of improper locking of the ADU transport guide unit.

1.Model Name: SF-2120/1 120

2.General: There have been problems reported in the ADU transport guide unit in the base plate

unit of the models described above of improper locking caused by deviation in the lock

load. As a measure to alleviate these problems a change in the magnet catch has been

carried out.

Taper side U-turn bearing

(Q’ty: 3 pieces)

Handle side U-turn bearing

(Q’ty: 2 pieces on each side)

Changed

Handle side

Taper side

Changed

3.Action: From 1996 December production.

3. Measure to improve the ON/OFF point of the POD sensor.

1.Model Name: SF-2116/ 1016/21 18/1018/2020/1020/2120/1 120

2.General: The margin of the ON/OFF point of the sensor was too small when installing the POD

actuator in the models listed above, making it difficult to maintain control with the

change in the metal of the attachment plate. As a measure to alleviate this problem an

actuator guide has been added in the fusing unit to improve the movement of the POD.

2/4

Page 3

0 ~+0.5

Standard X

Fusing guide sheet

+1 ~ +3

Standard Y

Standard X

Fusing actuator guide

Fusing upper frame

0 ~ +1

Fusing unit

Standard Y

0 ~ +0.5

Fusing upper frame

Wipe the attachment surfaces clean with alcohol.

3.Action: ∗ SF-2020/1020/2120/1 120: From 1996 mid-November production.

SF-2116/2118/1016/1018: From 1997 January production.

M6716/6718:

4. Measure to establish interchangeability of the closing label of the machine.

1.Model Name: SF-2020/1020/2120/1 120/21 16/1016/21 18/1018

2.General: Clam shell half closing of the machine was carried out as a measure for the SF-2020

series. A “machine closed” indication label was also used for the SF-21 16 series. A new

label has now been made which can be used for both the SF-2020 series and the

SF-2116 series.

3.Action: ∗ SF-2020: Running change.

SF-2116/2118 Japanese domestic production: From 1997 March production.

SF-1016/1018 Chinese (SOCC) production: From 1997 April production.

French (SMF) production: From 1997 May production.

3/4

Page 4

Ref.

Model

No.

name

1

SF-2120

SF-1120

2

SF-2020

SF-1020

SF-2120

SF-1120

SF-2116

SF-1016

SF-2118

SF-1018

3

SF-2020

SF-1020

SF-2120

SF-1120

SF-2116

SF-1016

SF-2118

SF-1018

SF-2020

SF-2120

SF-2020

SF-1020

SF-2120

SF-1120

4

SF-2116

SF-2118

SF-2116

SF-1016

SF-2118

SF-1018

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts m a r ked w it h “ ” i s imp or t an t fo r m ai n ta ini ng t he s a fe ty of the se t. Be sur e t o rep l ace these pa r ts with

sp eci fi e d on es fo r m ain ta in i ng t he s a fe ty an d pe r fo rma nc e o f th e s et .

Version P/G No.

6 -24

6 -10

28 -2 PMAGT0072FCZZ PMAGT0086FCZZ AH Magnet catch

17

Overseas

16

17

16

English

4 languages TLABH1359FCZZ TLABH4084FCZZ AE

1

English

4 languages

!

Current parts New parts

Parts code Parts code

NSFTZ2375FCZZ NSFTZ2375FCZ1 AS Reversion drive shaft

—

—

TLABH1358FCZZ TLABH4083FCZZ AD

—

Q’ty Change

XRESP70-08000

New

PGIDH1765FCZZ

New

PSHEZ4449FCZZ

New

TLABH4083FCZZ

New

TLABH4084FCZZ

Price

rank

AA E Ring 6 Q’ty: 6 → 5

AD Fusing actuator guide

AC Fusing guide sheet

AD

AE

5. Interc ha ng ea ble i f r ep l ace d wi th s a m e typ es of

relate d pa r ts in use.

6. Others.

Parts name

The closing label of the

machine

Effec-

tive

time

1st lot

’96/12

1st lot

’96/12

Mid-

’96/11

1st lot

’97/1

Mid-

’96/11

∗

Inter-

change-

ability

3

3

6

1

6

Note

4/4

Loading...

Loading...