Page 1

Date: Feb. 25, 1997

COPIER : SF-2050

1.MEASURE TO PREVENT PAPER JAMS AT THE UPPER SEPARA T OR PAWL IN

THE FUSING UNIT.

2.MEASURE TO PREVENT PAPER JAMS DUE TO MALFUNCTIONING OF THE

TRANSPORT CLUTCH.

3.IMPROVEMENTS TO THE FUSING UNIT AND UPPER PAWL FIXING PLA T E.

There have been requests from the marketplace to have the previous technical reports

relating to paper jams sent out as a set ,so we send those previous reports along with

this one.

1. Measure to prevent paper jams at the upper separator pawl in the fusing unit.

No. : SP-2105

1.Model Name: SF-2050

2.General: (1) When attempting to remove jammed paper in the direction of the paper delivery after

the copy paper has jammed in an accordion form at the fusing upper separator pawl,

the leading edge of the upper separator pawl sometimes gets caught on the fusing rear

lower paper guide (P/G ). If copy operations are carried out in this condition

17 -22

paper jams will occur.

When jams occur due to the reason described above, there is a danger of damage

occurring to the leading edge of the fusing upper separator pawl, and therefore caution

should be exercised to check for damage if such an occurrence should happen.

(2) When removing jammed paper from the machine, the fusing upper separator pawl

can get caught on the raised section of the fusing rear upper paper guide (P/G )

16 -44

which sometimes causes paper jams to occur.

To alleviate the two problems described above, the following measures have been

carried out.

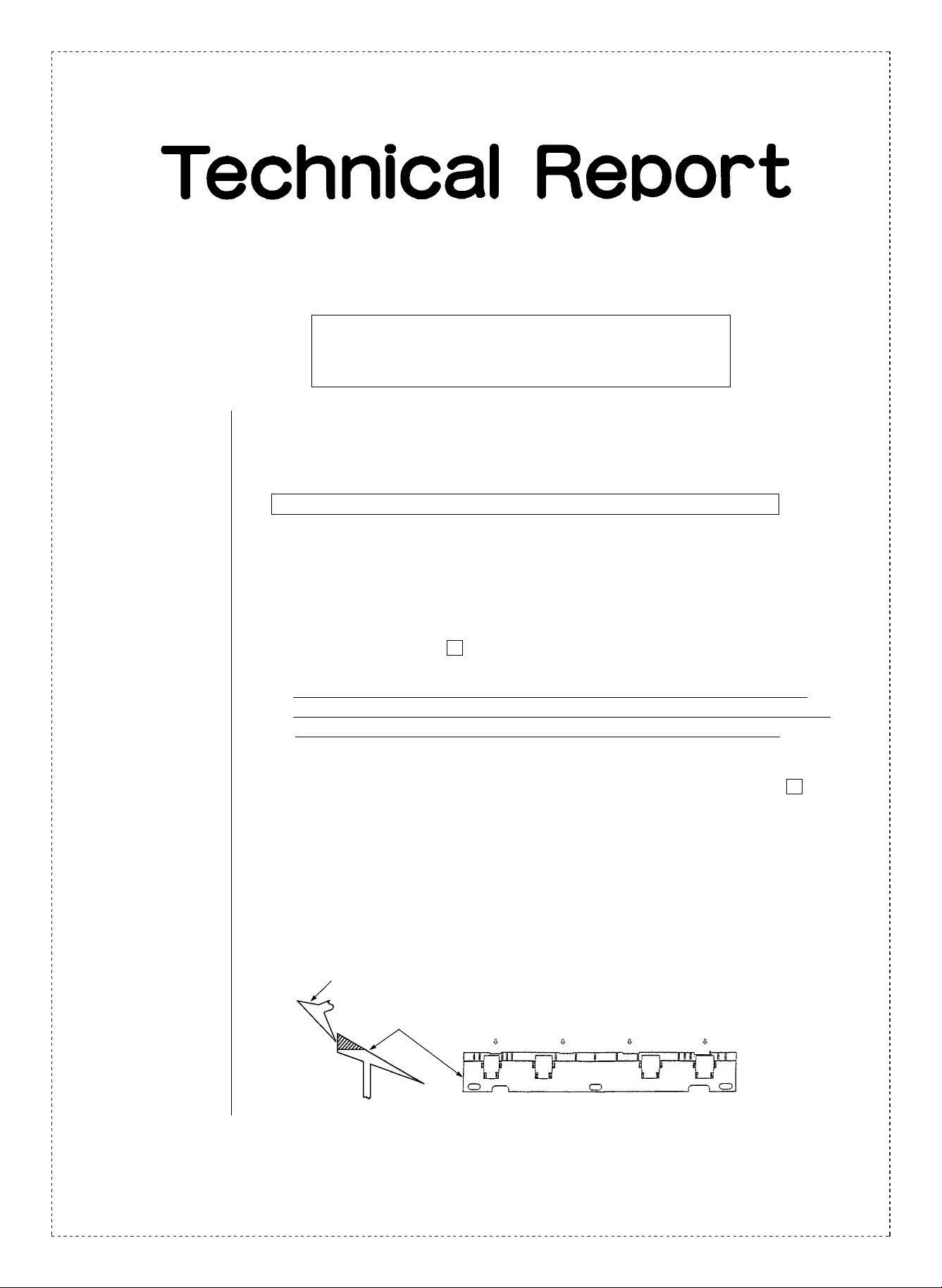

3.Description: (1) As shown in the figure below, four sections of the fusing rear lower paper guide have

been cut to alleviate the problem of the leading edge of the fusing upper separator pawl

from getting caught.

Fusing upper separator pawl

FU rear lower paper guide

Cut

Cut

SHARP CORPORATION Reprography Division

CutCut

1/5

Green

C

Page 2

(2) The raised section of the fusing rear upper paper guide has been cut (four locations)

to alleviate the problem of the rear edge of the fusing upper separator pawl from getting

caught.

Raised section (four locations)

FU rear upper paper guide

Note: There is a possibility of the same problem occurring if an error is committed in the

sequence each time a change in the position of the upper separator pawl is carried

out (every 100 k), and this has been reported in T/R SP-1987. For this reason your

cooperation in exercising caution to insure that the proper sequence is maintained

is requested.

Furthermore, for machines already out on the market, the raised sections of the

fusing upper paper guide (four locations) should be cut as a measure to alleviate

the problems described above (the raised sections of the fusing upper paper guide

can easily be broken off by using long nose pliers.

4.Action: From 1996 mid-April production.

2. Measure to prevent paper jams due to malfunctioning of the transport clutch.

1.Model Name: SF-2050

2.General: <Problem>

Deviations in the leading edge of copy images and copy paper jams both due to ’z’

folding of the copy paper in the copy paper transport section of the machine sometimes

occur.

<Cause>

If the time required for the clutch changeover is too short when an ’ON’ signal from the

PPD3 sensor is sent from the transport clutch TRC2H to the transport clutch TRC2L,

the worst possible condition may occur, whereby the TRC2H and the TRC2L clutches

both registering as ON, which can sometimes result in damage to the TRC2L clutch.

2/5

Page 3

3.Description: In order to alleviate the problem of the TRC2H clutch and the TRC2L clutch both being

set to ’ON’ at the same time, the ROM software has been changed so that the ON/OFF

status of the TRC2H and the TRC2L clutches is to be monitored every 1 msec.

If both the TRC2H and the TRC2L clutches are determined to be set to ’ON’ at the

same time, the TRC2H clutch is to be changed to ’OFF’ within 1 msec, which is

sufficient to prevent damage from occurring to the TRC2L clutch.(Ver. 4.00 → Ver. 4.01)

We have lengthened the sleeve covering the transport clutch spring to prevent the

spring from coming loose.

Old New

Gear

Sleeve

Gear

Sleeve

4.Action: From 1996 mid-April production.

3. Improvements to the fusing unit and upper pawl fixing plate.

1.Model Name: SF-2050

2.General: During a paper jam, if the paper feedout cabinet is opened and then closed again but

the jammed paper is not removed, the fusing unit’s upper pawl fixing plate may change

shape. To prevent this problem, we have made the following changes.

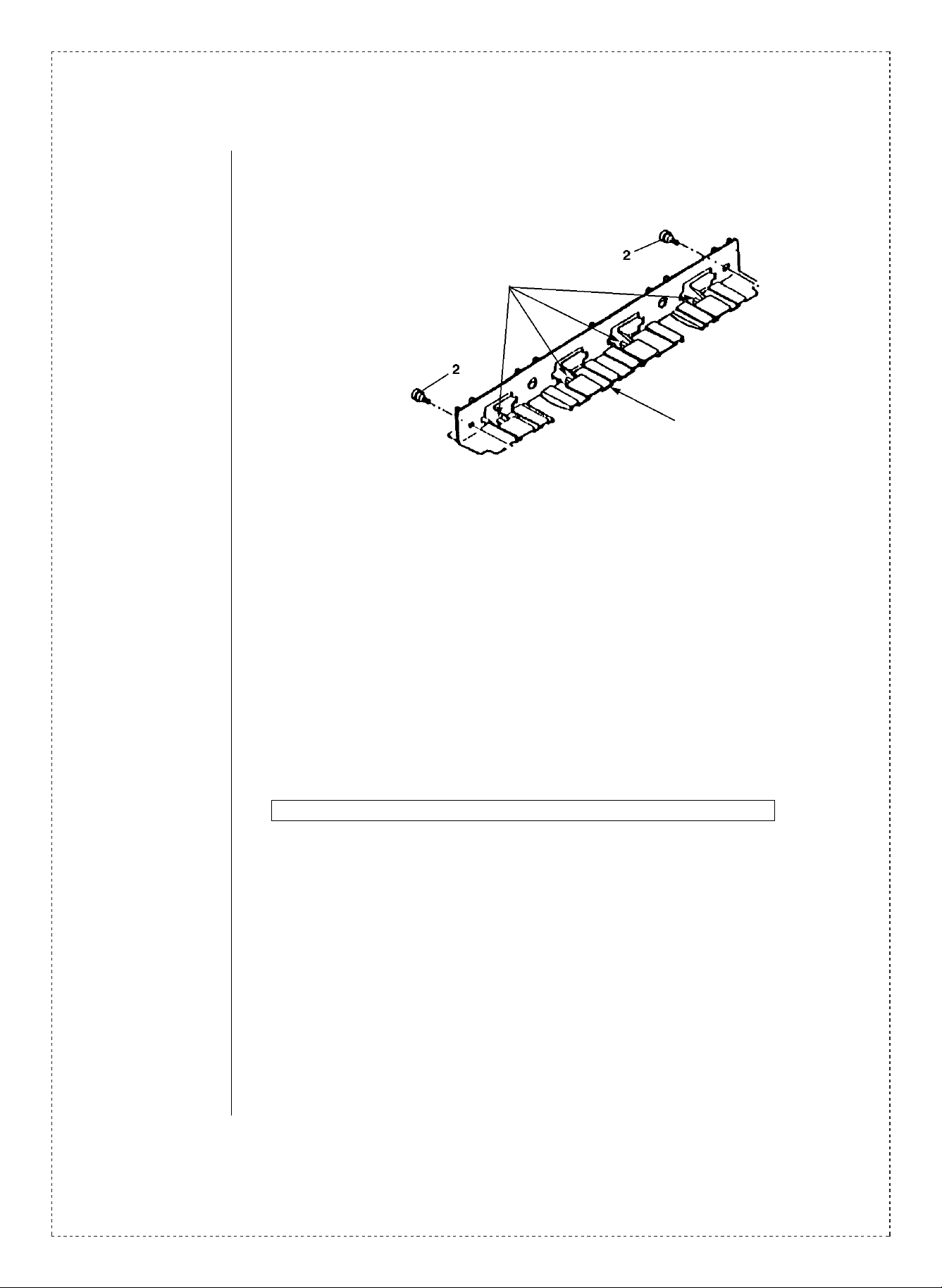

3.Description: • We have added a reinforcem ent sheet and pawl stopper sheet to the upper pawl fixing

plate.

• We have changed the screws for the stopper from M4x16 to M4x6 and changed the

shape of the fusing upper cover , in order to increase the rotation angle of the upper

pawl fixing sheet.

(Added pawl stopper sheet)

Standard A

Notch

Hole

Bend

Upper pawl fixing plate A’SPawl stopper sheet (Q’ty:4)

3/5

Page 4

(Fusing upper cover shape change)

Cut out

(Change to screws for stopper)

M4 × 16

↓

M4 × 6

Cut out

Reinforcement sheet

4.Action: ∗∗ Production in Japan From the middle of November, 1996 production

Production in France (SMF) From the first unit of November, 1996 production

4/5

Page 5

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

1

2

SF-2050 All

3

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i n te r cha ng ea bl e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts m a r ked w it h “ ” i s imp or t an t fo r m ai n ta ini ng t he s a fe ty of the se t. B e s ure t o r ep lac e t he s e pa rts wi th

sp ec i fi e d on es fo r m ai n ta in i ng t he s a fe ty and perfo r ma nc e o f th e s et .

17 -22

16 -44 PGIDM1573FCZZ PGIDM1573FCZ1 AR Fus in g r ea r u p pe r p a per gui d e

33 -10 PCLC-0238FCZ1 PCLC-0238FCZ2 AZ Transport clutch 48TN Q’ty: 2

33 -901

12 -12

49 -59 VHI27C02029FC VHI27C02041FC BB IC

16 -47 LPLTM4862FCZZ CPLTM4862FC01 AV Upper pawl fixing plate AS

16 — PSHEP4403FCZZ AE Pawl stopper sheet 6 Q’ty:4

16 -1 PCOVP1300FCZ1 PCOVP1300FCZ2 AY Fusing upper cover

16 -6 XHBSD40P16000 XHBSE40P06000 AA Screw (M4 × 6)

!

PGIDM1626FCZZ PGIDM1626FCZ1 AQ Fusing rear lower paper guide

CPLTM4827FC51 CPLTM4827FC52 BT Transport drive unit

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Mid-

’96/4

∗∗

3

3

∗

1 location

changed

∗ A change in the drive unit has been carried out in accordance with the change in the

transport clutch.

5/5

Loading...

Loading...