Page 1

Date: Feb. 27, 1997

COPIER : SF-2050

1.MEASURE TO IMPROVE THE EFFICIENCY OF THE DISCHARGE BRUSH IN

THE CURL CORRECTION UNIT.

2.MEASURE TO ALLEVIATE PROBLEMS OF STREAKING CAUSED BY THE

ROLLER OF THE PAPER DISCHARGE SECTION.

1. Measure to improve the efficiency of the discharge brush in the curl correction unit.

1.Model Name: SF-2050

2.General: In order to improve the static electricity removal of the curl correction un’s of the above

models during paper transmission, we have changed from non-conductive double-sided

tape for the static removal brush to conductive double-sided tape.

No. : SP-2104

3.Action: ∗1 Japanese production From 1996 mid-November production.

SMF production From 1996 November production.

2. Measure to alleviate problems of streaking caused by the roller of the paper

discharge section.

1.Model Name: SF-2050

2.General: Lines may be transferred to the paper from the roller in the paper discharge section of

the above models. To prevent this, we have made the following changes to the paper

discharge reverse section.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

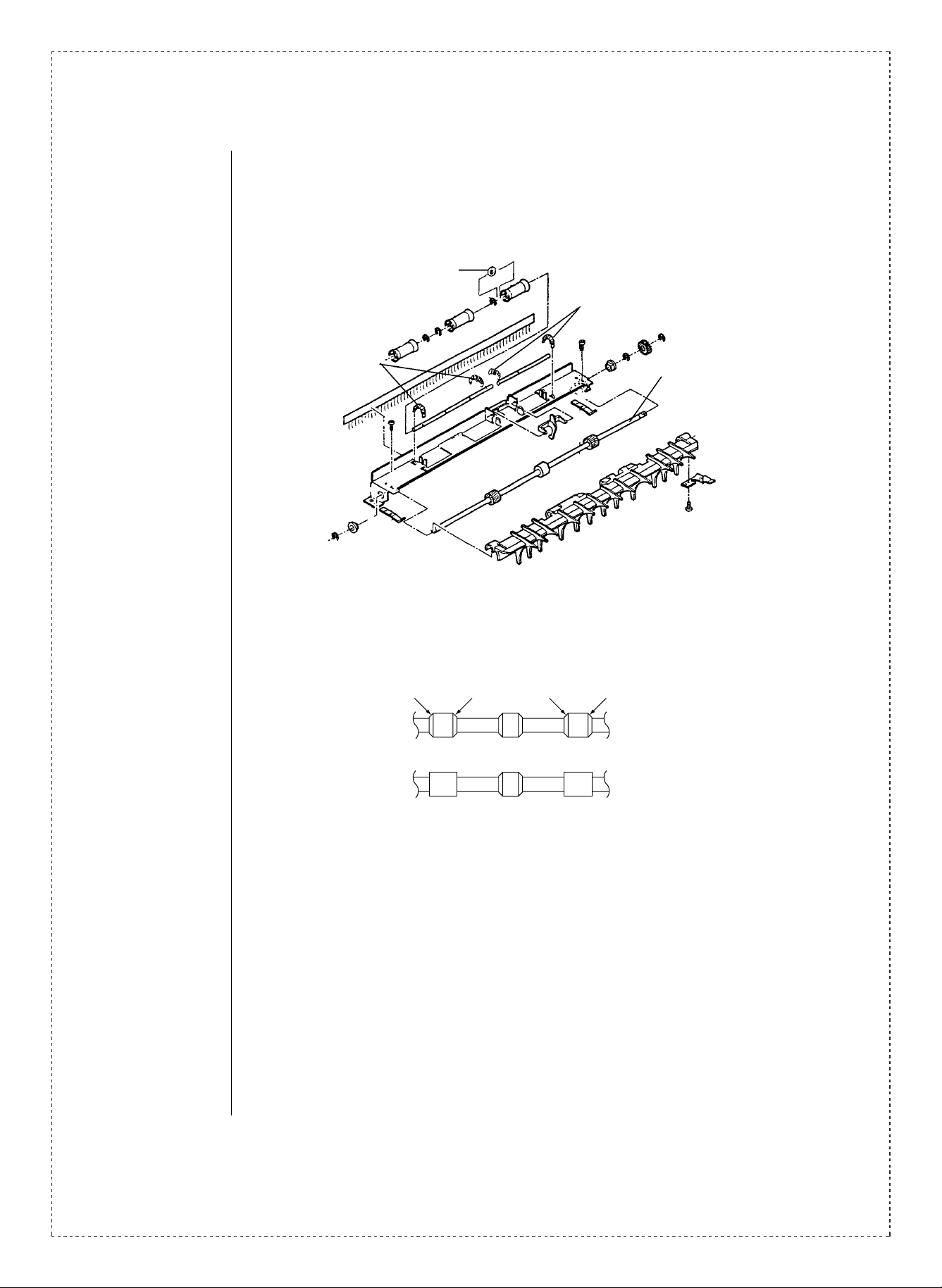

3.Description: (1) Addition of a C-roller chamfer to the corner of the paper delivery roller.

(2) Change in the spring pressure of the drive roller.

(3) Addition of a washer to control the position of the drive roller.

Added washer LX-WZ0139FCZZ

Changed drive roller

SP-A (black)

MSPRT2586FCZZ

New Drive roller SP-A (black) — free length 16 mm ← use the longer shaft

{

Drive roller SP-B (r ed) — free l engt h 18 mm ← use the short er shaf t

(Old) Drive roller SP (silver) — free lengt h 15 m m

Roller change content

Changed drive roller SP-B (red)

MSPRT2587FCZZ

Changed paper delivery roller HA

New

Old

With the exception of the center section, roller chamfers

have been added to the edges of both sides of the roller.

4.Action: ∗2 Japanese production From 1996 mid-October production.

French production From 1996 October production.

2/3

Page 3

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

1

SF-2050 All

2

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t y pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la c e of c u rr en t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

27 -20

20 -15 NROLR1070FCZ1 NROLR1070FCZ2 AR Paper delivery roller

20 -3 MSPRT2075FCZZ Discontinued — Drive roller SP 6 Q’ty: 4

20

!

PBRSR0148FCZZ PBRSR0148FCZ1 AL Discharge brush ∗1

— MSPRT2586FCZZ

— MSPRT2587FCZZ Drive roller SP B

— LX-WZ0139FCZZ AA Washer 6

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Drive roller SP A

AC

∗2

3

3 Q’ty: 2

3/3

Loading...

Loading...