Page 1

Date: Jun. 9, 1997

COPIER : SF-2116

1.MEASURE TO PREVENT DAMAGE TO THE FUSING GEAR.

2.MEASURE TO ALLEVIATE PROBLEMS DUE TO WEAR OF THE PAPER DELIVERY ROLLER

CARRIED OUT AS A MEASURE TO PREVENT PAPER DELIVERY MALFUNCTIONS.

3.CHANGE IN SPECIFICATIONS.

4.ADDITION OF CM 15 AND 16 FIXING PARTS.

No. : SP-2101

1. Measure to prevent damage to the fusing gear.

1.Model Name: SF-2118/ 21 16/1018/1016/2020/2120/1020/1 120

2.General: There have been problems reported of damage occurring to the key portion of the

fusing gear of the SF-2020 series during LTR, A4R, B5R, etc. copy paper lateral

feeding operations. The damage was caused by the temperature of the end of the heat

roller rising above the temperature whereby the material that the fusing gear is made of

becomes soft. As a measure to alleviate this problem the material of the gear has been

changed.

3.Description: (Old) (New)

Fusing gear NGERH0443FCZ1 → NGERH1214FCZZ

4.Action: SF-2020 series: From 1996 September production.

∗1 SF-2118 series: Japanese domestic production: From 1996 October production.

Chinese (SOCC) production: From 1996 mid-October production.

French (SMF) production: From 1996 November production.

2. Measure to alleviate problems due to wear of the paper delivery roller carried out as

a measure to prevent paper delivery malfunctions.

1.Model Name: SF-2118/ 21 16/1018/1016/2020/1020

2.General: There were some problems of the projecting portion of the rubber roller section of the

paper delivery roller N2 in the base plate unit was ground away by friction, which

sometimes caused paper delivery malfunctions to occur. As a measure to alleviate this

problem, a change in the material of the roller has been carried out.

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

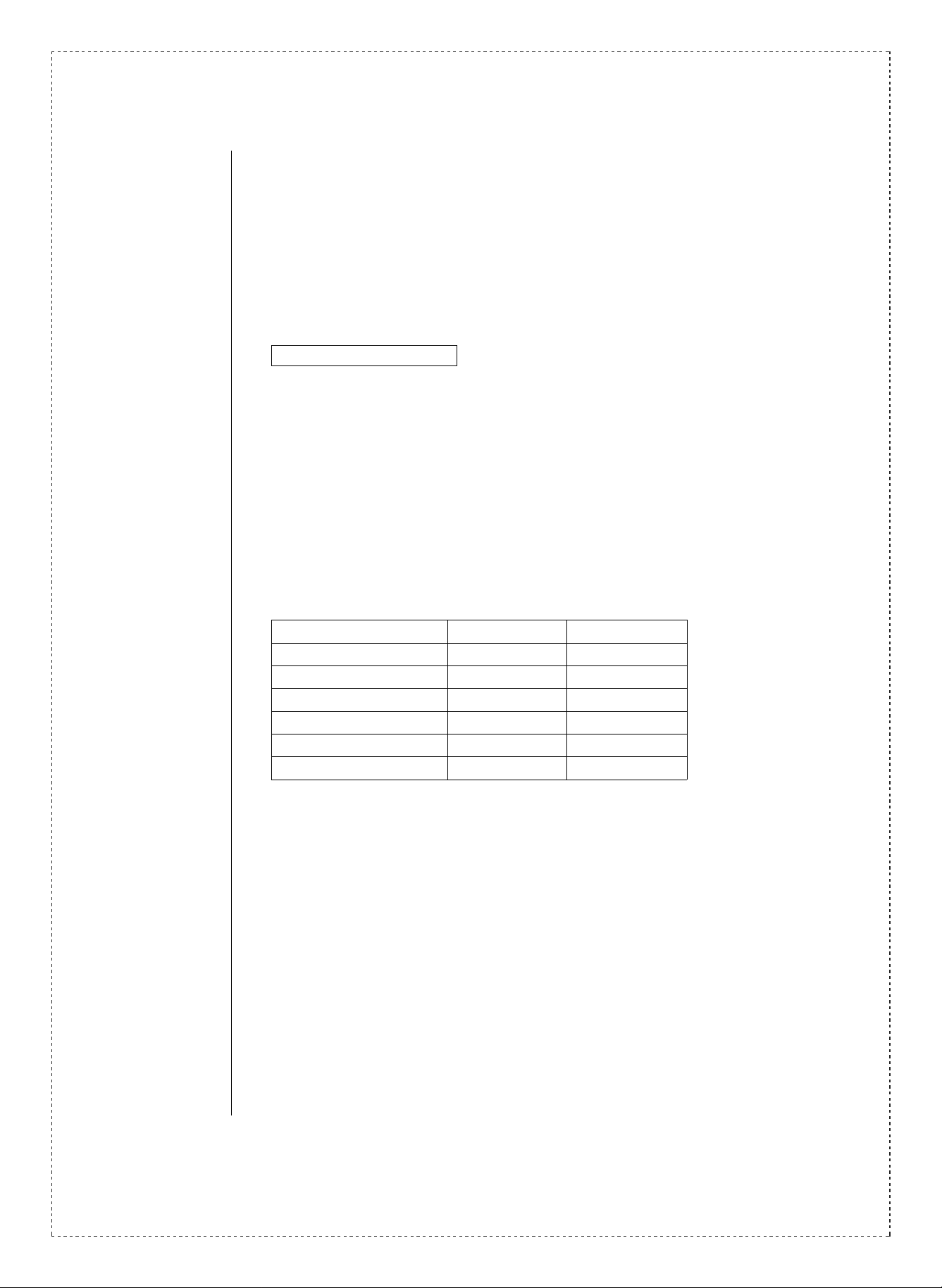

3.Description: Paper delivery roller N2 NROLR1056FCZ2

↓↓

Paper delivery roller N3 NROLR1056FCZ3

4.Action: SF-2116/ 2118/1016/1018: Running change.

SF-2020/1020: From the start of 1996 October production.

3. Change in specifications.

1.Model Name: SF-2116/ 21 18/1016/1018/21 16N,ND/21 18N,ND

2.General: A change has been carried out in the specifications of the models listed above in

accordance with a return of patents held by other companies. In accordance with this

change a version upgrade of the content of the program in the ROM unit in the main

PWB unit has been carried out. (Please refer to the accompanying supplementary

pages for information concerning the content of the change in specifications.)

(SF-2116/2118/1016/1018: V 2.7 → V 2.9)

(SF-2118N,ND: V 2.8 → V 2.9)

3.Description:

Old New

Main PWB UN (100 V) Main A CPWBN1079FC51 CPWBN1079FC61

Main PWB UN (200 V) Main A CPWBN1079FC52 CPWBN1079FC62

Main PWB UN (100 V) Main B CPWBN1079FC53 CPWBN1079FC63

Main PWB UN (200 V) Main B CPWBN1079FC54 CPWBN1079FC64

Main PWB UN (SEEG) Main B CPWBN1079FC59 CPWBN1079GH68

ROM Unit (SF-2116/2118/1016/1018) VHI27C01066FC VHI27C01095FC

4.Action: ∗2 Japanese domestic production: From 1996 November production.

Chinese (SOCC) production: From 1997 January production.

French (SMF) production: From 1997 January production.

2/5

Page 3

Swallow V2.8→V 2.9 List of change contents

No. Problem Movement after change was carried out.

A change has been carried out in the control of the

magnification display and lens movement control when

the zoom key is set to the ON position. (Patent recovery)

When the zoom key is depressed, the magnification

display is sequencially changed while the zoon key

remains in the depressed position. The lens movement

commences when the zoom key is set to the OFF

1

position, or when the 50% magnification position or the

200% magnification position is reached. Therefore, when

the zoom up key is depressed the magnification can be

changed until the key is released, or until 200%

magnification is reached., and when the zoom down key

is depressed the magnification can be changed until the

key is released, or until 50% magnifiction is reached.

A change has been carried out in the movement which

occurs when the interrupt key is depressed during copy

operations carried out in the ADF mode. (Patent recovery)

When the interrupt key is depressed during ADF mode

2

copy operations, the copy operations of the original

document which had already been fed are continued until

they are completed, after which the machine switces

over to OC mode even if there are still original document

pages left in the ADF to be copied.

When the machine changes over to the interrupt

reservation mode during ADF mode copy operations and

3

an empty paper tray is detected on the last copy page of

the final fed original document page, the main motor will

continue to run.

When the copy paper tray detection is set to LT and LTR

copy paper is detected, a jam does not occur and instead

the copy paper is fed into the machine at a speed of 18

4

pages per minute, which causes the temperature of both

ends of the fusing roller to rise, which can cause the

fusing gear to crack.

When the zoom key is depressed, the magnification will

automatically increase or decrease, but while the

magnification is changing (increasing or decreasing)

when the initial fixed magnification value (100% or 4R +

4E) is reached the magnification will stop changing

(increasing or decreasing). When the fixed magnification

value has been reached and the zoom key is released

and then depressed once again, the magnification will

increase (or decrease) until the next fixed magnification

value, where it will once again stop.

When the interrupt key is depressed and the machine is

changed over to the interrupt mode during ADF mode

copy operations, and there are still original document

pages left on the ADF tray, the ADF mode is maintained.

However, if there are not original document pages left on

the ADF tray the machine will be changed over to the OC

mode.

Furthermore, after the machine has been changed over

to the interrupt mode, if no original document is set on

the ADF and the OC cover is opened and closed, the

machine will automatically change over to the OC mode.

When the machine changes from the interrupt

reservation mode to the interrupt mode and an empty

paper tray is detected, the main motor no longer

continues to run in the interrupt reservation mode.

When the tray detection is smaller than the LT size and

the paper size being fed into the machine is larger than

B5, when the copy paper is finished being delivered a

jam shall be registered.

However, each counter will register one count for each

sheet of copy paper being delivered.

4. Addition of CM 15 and 16 fixing parts.

1.Model Name: SF-CM15/16

2.General: Additions of the following fixing parts have been carried out as a measure to prevent

the models described above from falling.

3.Description: 1) Toothed washer: XWVSD40-05000 (figure 1)

2) Binding band: LBNDJ1001HCZZ

3) Filament tape: ZTAPEF199000C (figure 2)

4) Power supply PWB protector spacer: PSP AP1394FCZZ (figure 3)

3/5

Page 4

Paper feeding power supply unit

CPWBF1083FC51-56

2) Binding band (290 mm)

LBNDJ1001RCZZ

W Base plate rear frame

(LFRM-0867FCZZ)

Filament tape

Width19×Length150 mm

Filament tape

Width9×Length150 mm

Fold back the

leading edge

Filament tape

1) M4 toothed washers (Q’ty: 2)

XWVSD40-05000 (Q’ty: 2)

PFU “trans” reinforcement plate

LPLTP5022FCZZ

Fixing material: Attach to the standard in the center of the

cushion. Caution should be exercised to insure that the

fixing material does not come in contact with the cushion.

Cushion

Tape attachment standard: Caution

should be exercised to insure that the

tape is not attached to portion “A”.

It is necessary to fold back the leading edge

of the filament tape.

Regulation plate

Figure 1

P-arrow diagram

Cassette

The shaded portion

is the double-sided

tape section.

Figure 2

Power supply PWB

protector spacer.

Power supply PWB

protector spacer.

W Base plate rear frame

4.Action: SF-CM 16: From 1996 October production.

SF-CM 15: From 1996 November production.

4/5

P-arrow diagram

Figure 3

Page 5

Ref.

Model

No.

SF-2118

SF-2116

SF-1016

SF-1018

1

SF-2020

SF-2120

SF-1020

SF-1120

SF-2116

SF-2118

SF-1016

2

SF-1018

SF-2020

SF-1020

SF-2116

SF-1016

SF-2116

SF-1016

SF-2118

3

SF-1018

SF-2118

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-CM16

4

SF-CM15

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i n te r cha ng ea bl e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts m a r ked w it h “ ” i s imp or t an t fo r m ai n ta ini ng t he s a fe ty of the s e t. B e sur e t o rep l ac e t he se pa r ts with

speci fied ones fo r m ai n ta ini ng t he s a fe ty an d pe r fo rmance o f th e s et .

name

Version P/G No.

16 -26

All

17 -26

19 -17

All

20 -17

100V

200V CPWBN1079FC52 CPWBN1079FC62 BX Main PWB UN (200v)

29 -901

100V CPWBN1079FC53 CPWBN1079FC63 BW Main PWB UN (100v)

200V CPWBN1079FC54 CPWBN1079FC64 BX Main PWB UN (200v)

29 -54 VHI27C01066FC VHI27C01095FC BA ROM UN

All

49

All

40

!

Current parts New parts

Parts code Parts code

NGERH0433FCZ1 NGERH1214FCZZ AP Fusing GEAR

NROLR1059FCZ2 NROLR1056FCZ3 AY Paper delivery roller

CPWBN1079FC51 CPWBN1079FC61 BW Main PWB UN (100v)

XWVSD40-05000 AA Toothed washer

LBNDJ1001HCZZ AE Binding band

New

PSPAP1394FCZZ AC

Price

rank

5. Interchangeable if replaced with same types of

related parts in use.

6. Others .

Parts name

Power supply PWB

protector spacer

Effec-

tive time

1st lot

’96/9

Running

change

1st lot

’96/10

1st lot

’96/10

1st lot

’96/11

Inter-

change-

ability

∗1

3

1

3

∗23

6

Note

[IC7]

5/5

Loading...

Loading...