Page 1

Date: Dec. 13, 1996

COPIER (OPTION) : SF-A15/A54

No. : SP-2079

1.MEASURE T O PREVENT W-FEED IN G OF THE ORIGINAL DOC UM ENT.

2.ESTABLISHMENT OF PARTS AS A MEASURE TO PREVENT

PROBLEMS OF CRIMPING OF THE ORIGINAL DOCUMENT.

1. Measure to prevent W-feeding of the original document.

1.Model Name: SF-A15/A16

2.General: The measure described below has been carried out as a measure to improve problems

of W-feeding of the original document.

3.Description: ➀ Separator plate springs have been stacked double for both F and R as a measure to

maintain the overwrap volume between the separator belt and the feeder roller and

stabilize the paper smoothing performance when a problem of W-feeding occurs.

➁ The cushion mylar sheet has been discontinued and the cushion has thus been left

bare as a measure to increase the friction resistance. This change has been carried

out as a measure to prevent W-feeding of the last two pages of the original document.

(Note : As a market action for machines which were produced before 1996 October ,

it is possible to avoid problems by attaching a cushion on top of the cushion mylar

sheet which is currently installed.)

4

Transport section - 3

Cushion mylar sheet

➁ Only the cushion has been changed.

Separator plate spring

➀ Two separator plate springs have been

stacked one on the other for both F and R.

4.Action: From the start of 1996 October production.

From 1996 mid-October production.

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

2. Establishment of parts as a measure to prevent problems of crimping of the original

document.

1.Model Name: SF-A54/A55

2.General: Crimping of the original document, which sometimes occurs during operations using the

ADF, can affect the copy image. As a measure to alleviate this problem, the following

parts have been established.

3.Description: Added parts

Model type

No. Part name Part code Q’ty

➀ Retainer holder F 0CW2158P054B/ 1

➁ Retainer holder R 0CW2158P055B/ 1

➂ Retainer roller stay N 0CW2158P171E/ 2

➃ Retainer plate plate spring 0CW2176P152A/ 1

➄ Retainer bearing spring 0CW2198P106A/ 2

➅ Retainer bearing 0CW2158P035A/ 2

➆ DF Spacer 0CW2158P034A/ 1

➇ M3 x 6 IT screw 0CW030060FZIT 4

➈ M3 x 6 Tap tight 0CW030060FZTP 2

➉ M3 x 4 IT screw 0CW030040FZIT 2

A54

Series

A55

Series

2/5

Parts marked with a “ ” are effective from the start of mass production.

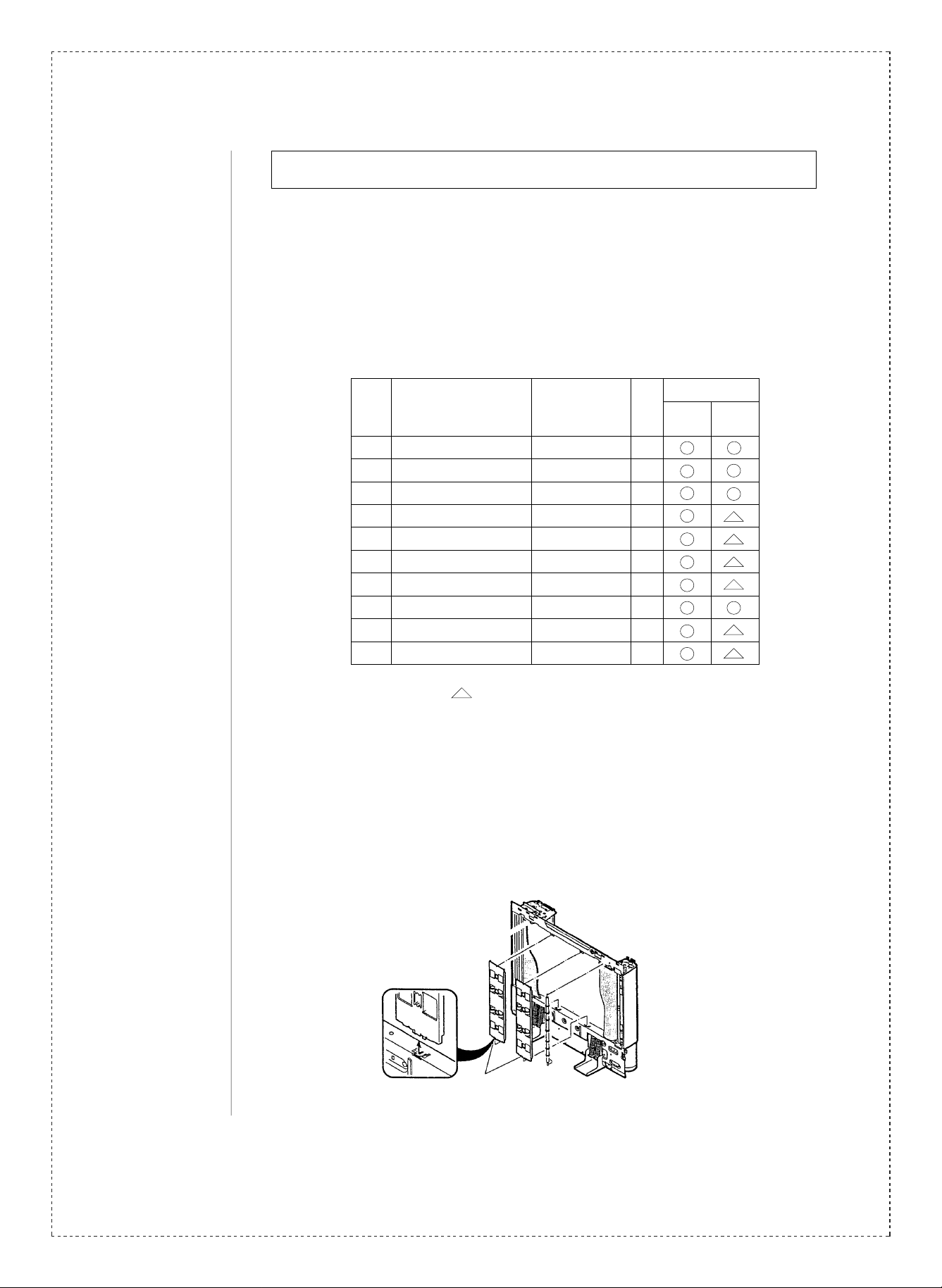

[Sequence for installing original document retainer parts]

1. Detach and remove old parts.

1) Turn the power supply of the copy machine OFF.

2) Open the ADF. Detach the retainer roller stay assembly by removing the two screws

attaching it (two locations, one on each of the left and right sides). Remove the belt

retainer roller holder (F side) and belt roller holder (R side) ∗2 which secure the front

and rear sides of the D belt retainer roller ∗3, and remove the D belt retainer roller.

(Note: The screws which were removed will be used later, and should therefore not

be lost.

(∗2, and ∗3 are for model SF-A54 only.)

(Figure - 1)

Page 3

2. Attach newly established parts.

1) Assemble and attach the retainer roller stay N (0CW2158P171E), which is to function

in place of the retainer bearing spring 36, retainer holder 37, retainer holder-2 38,

and retainer bearing 39 from the retainer roller stay assembly which was detached

in 1-2) above.

2) Attach the retainer plate plate spring ➃ (0CW2176P152A) to the retainer roller

stay N with two S2 screws (M3 x 6 IT tap tight 0CW030060FZTP).

3) Attach one retainer bearing ➅ (0CW2158P035A) to each of the two retainer bearing

springs ➄ (0CW2198P106A), and attach the retainer plate plate spring ➃ with one

S3 screw (M3 x 4 IT screw, 0CW03004FZIT).

(Figure - 2)

3. Assemble and attach.

1) Using the removed screw (∗1) , attach the DF spacer ➆ (0CW2158P034A) to the

location where the belt roller holder (∗2) which was removed in 1-2) above was

attached.

2) Using the screws 75 which secured the retainer roller stay from 1-1) above, attach

the retainer roller stay N (two assembled units) which were assembled in 2-1)

above to the ADF . When attaching the retainer roller stay N to the ADF, the roller

stay N on the right side in 2-3) above (with the plate spring and bearing assembled)

should always be attached to the paper delivery side (the right side).

Note: Care should be exercised to insure that the bearing attached to the retainer

roller stay N does not become detached. Caution should also be exercised

to prevent the delivery belt from tearing.

3) Attach the retainer holder F ➀ (0CW2158P054B) and the retainer holder R ➁

(0CW2158P055B) with two S1 screws (M3 x 6 IT screws, 0CW030060FXIT).

3/5

Page 4

4.Action: From the start of 1996 August production.

(Figure - 3)

4/5

Page 5

Ref.

Model

No.

SF-A15

1

SF-A16

SF-A54

2

➀

SF-A55

SF-A54

2

➁

SF-A55

SF-A54

2

➂

SF-A55

SF-A54

2

➃

SF-A55

SF-A54

2

➄

SF-A55

SF-A54

2

➅

SF-A55

SF-A54

2

➆

SF-A55

SF-A54

2

➇

SF-A55

SF-A54

2

➈

SF-A55

SF-A54

2

➉

SF-A55

SF-A54

2

SF-A55

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p lac e of c u r ren t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

4 -15

4 -57

2

4

2

4

2

4

2

4

All

2

4

2

4

2

4

2

4

2

4

2

4

2

4

!

Current parts New parts

Parts code Parts code

0CW2199P121// Q’ty: 2 → 4 AZ Separator plate spring

0CW2199P387A/ 0CW2166P296// AG Cushion

0CW2158P054B/

0CW2158P055B/ Retainer holder R

0CW2158P171E/ AR Retainer roller stay N Q’ty: 2

0CW2176P152A/ AH Ret a i n e r p la t e p la t e s pring

0CW2198P106// AG Retainer bearing spring

—

0CW2158P035A/ AD Retainer bearing

0CW2158P034A/ AC DF spacer

0CW030060FZIT

0CW030060FZTP Q’ty: 2

0CW030040FZIT Screw (M3 x 4)

0CW2158K193// BN Retainer kit

Price

rank

AS

AA

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

Retainer holder F

Screw (M3 x 6)

Effec-

tive

time

1st lot

’96/10

Mid-

’96/10

1st lot

’96/8

Inter-

change-

ability

6

3

6

Note

Q’ty: 2

Q’ty: 4

Kit

➀ - ➉

5/5

Loading...

Loading...