Page 1

Date: Nov. 5, 1996

COPIER : SF-2050

1. CHANGE IN PARTS IN ACCORDANCE WITH A HALT IN PRODUCTION.

2. MEASURE TO IMPROVE THE MOVEMENT OF THE REVERSION GATE.

3. CHANGE IN THE MET AL MOLD OF THE PAPER DELIVERY P/G AND

ESTABLISHMENT OF SERVICE PARTS.

1. Change in parts in accordance with a halt in production.

1.Model Name: SF-2050

2.General: A halt in the production of the IC (SRAM used in the operation control PWB and in the

main PWB has occurred, and in accordance the part has been changed to a similar one.

No. : SP-2050

3.Description: Old VHI3664BML-12

↓

New VHILC3564SM10-

4.Action: From 1996 mid-May production.

2. Measure to improve the movement of the reversion gate.

1.Model Name: SF-2050

2.General: Problems have occurred with the reversion gate coming in contact with the fusion upper

P/G, causing an adverse effect on the movement of the reversion gate in the production

process of the models listed above. To alleviate these problems the following measure

has been carried out.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

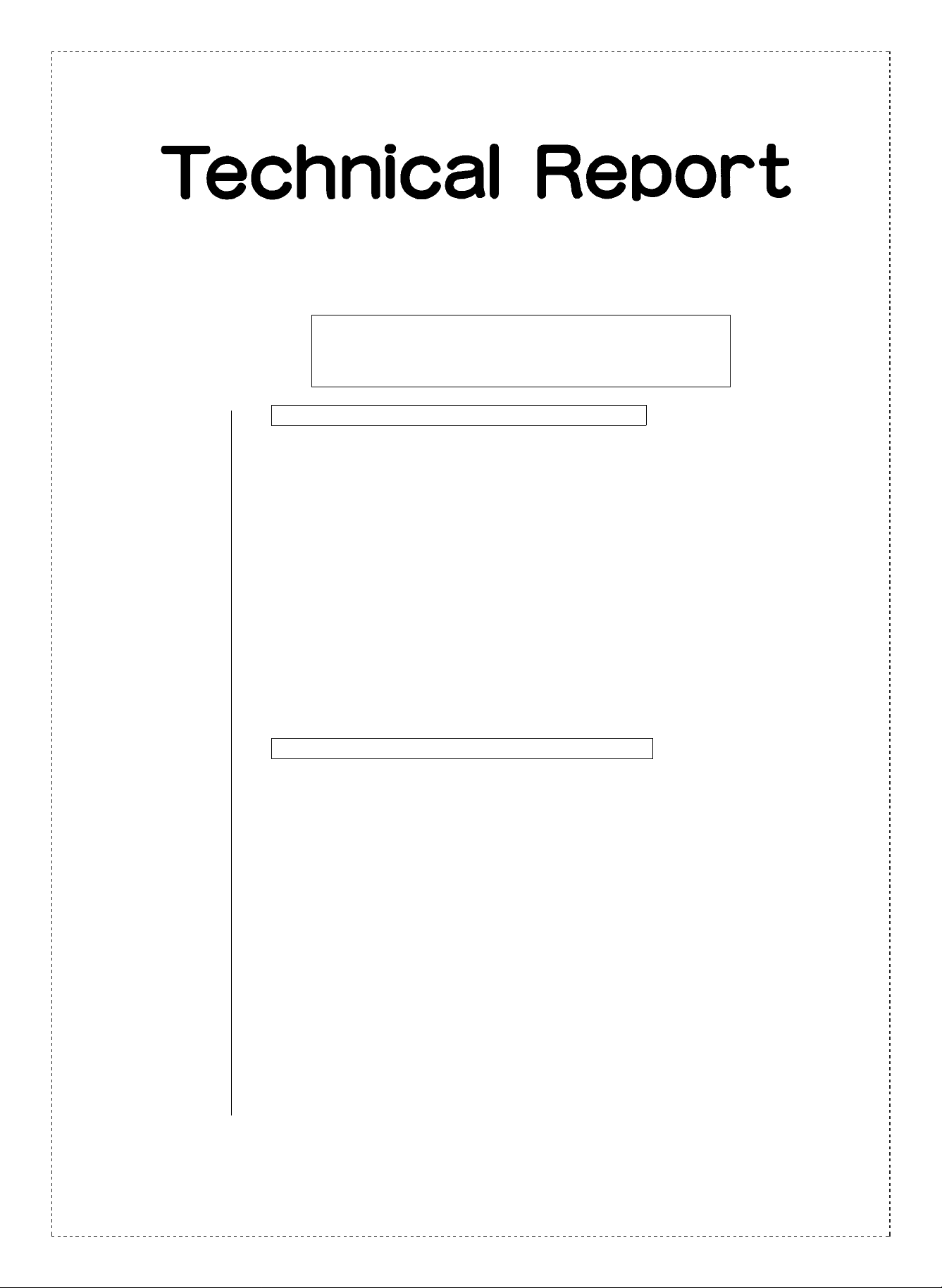

3.Description: A fusing washer has been attached to the upper pawl attachment plate in the fusing unit.

When attaching the fusing washer, care should be exercised to avoid blocking the hole

in the upper pawl attachment plate.

4.Action: From the start of 1996 June production.

3. Change in the metal mold of the paper delivery P/G and establishment of service

parts.

1.Model Name: SF-2050

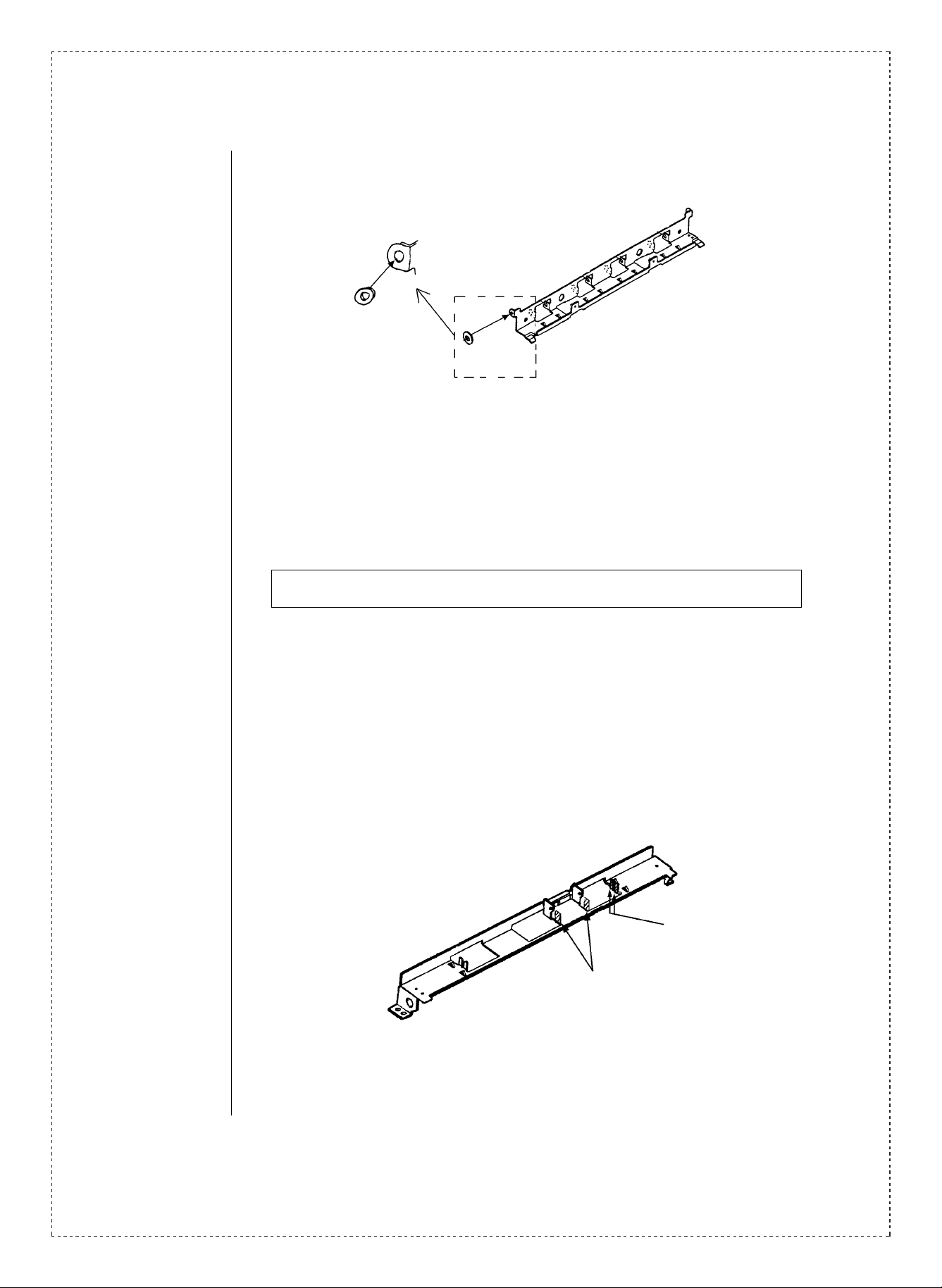

2.General: Problems occurred with the shape of the paper delivery P/G. As a measure to alleviate

these problems, a change in the metal mold was carried out.

Furthermore, the Paper delivery P/G unit has been established as a service part.

3.Description: As shown in the figure below, the position for one of the bends has been moved, and

additional bends have been added in two new locations.

The position for one of the

bends has been moved.

Additional bends

4.Action: From 1996 mid-June production.

2/3

Page 3

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

1

2 16

SF-2050 All

3

<Inter change>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la ce of curr en t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

49 -60

53 -56

20 -11

!

VHI3664BML-12 VHILC3564SM10- AS IC (3664BML-12)

LX-WZ0144FCZZ AA Fusing washer

BC

Paper delivery

P/G unit

AB series

Paper delivery

P/G unit

Inch series

—

CGIDH1562FC53

CGIDH1562FC54

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Mid-

’96/5

1st lot

’96/6

Mid-

’96/6

1

6

3/3

Loading...

Loading...