Page 1

Date: Oct. 21 , 1996

COPIER : SF-2025

(Service information)

No. : SP-2043

REVISION TO SERVICE MANUAL.

1.Model Name: SF-2025

2.General: Due to misprints and omissions in the service manual for the model indicated above,

the following revisions have been made.

Locations marked with an asterisk(∗) indicate content additions, and locations marked

by underlining indicate content corrections.

SHARP CORPORATION Reprography Division

1/13

Green

C

Page 2

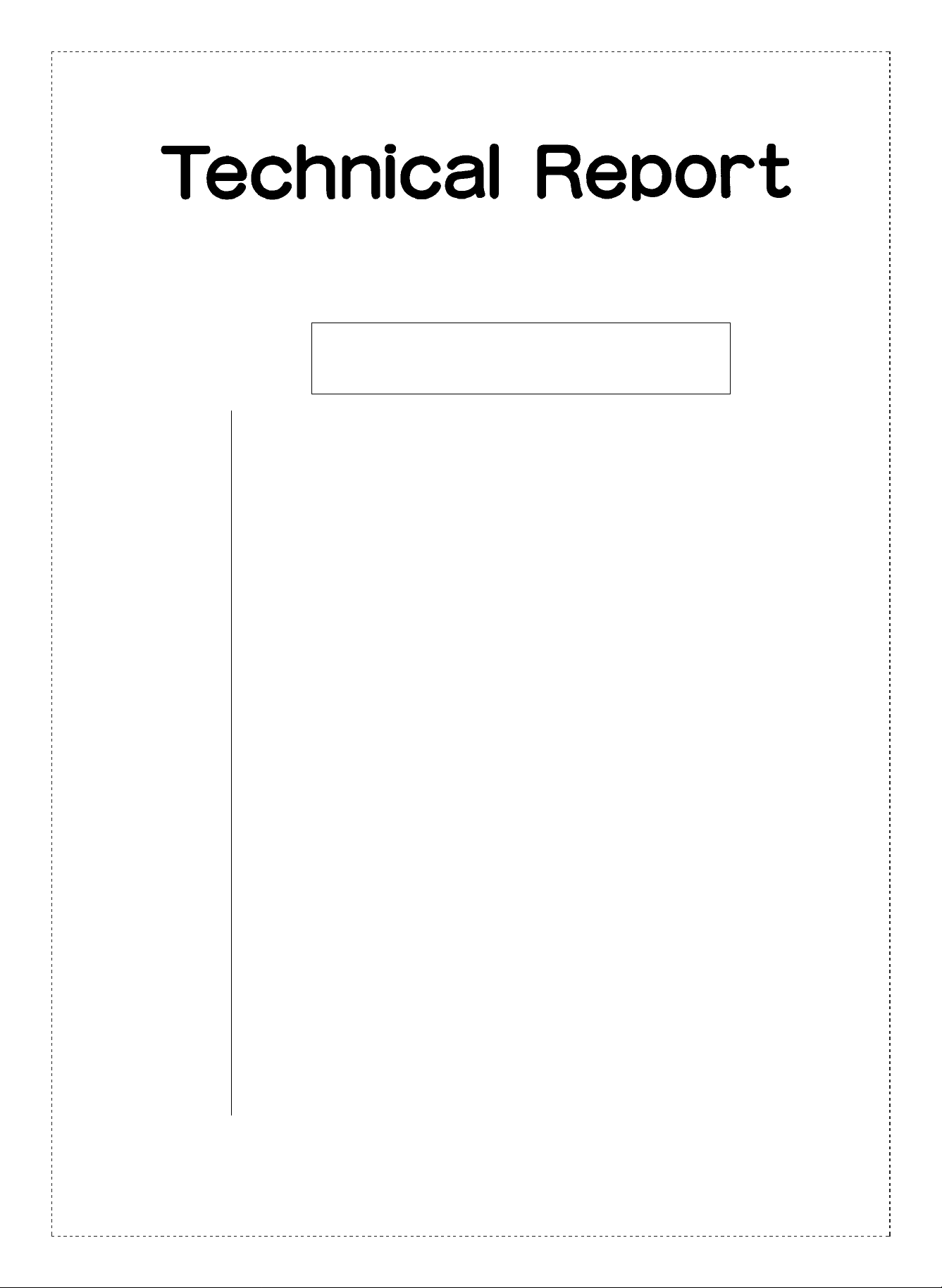

Page 7-8 (1) Adjusting the Reference Position of Lens

Misprint/Omission

Correction

2/13

Page 3

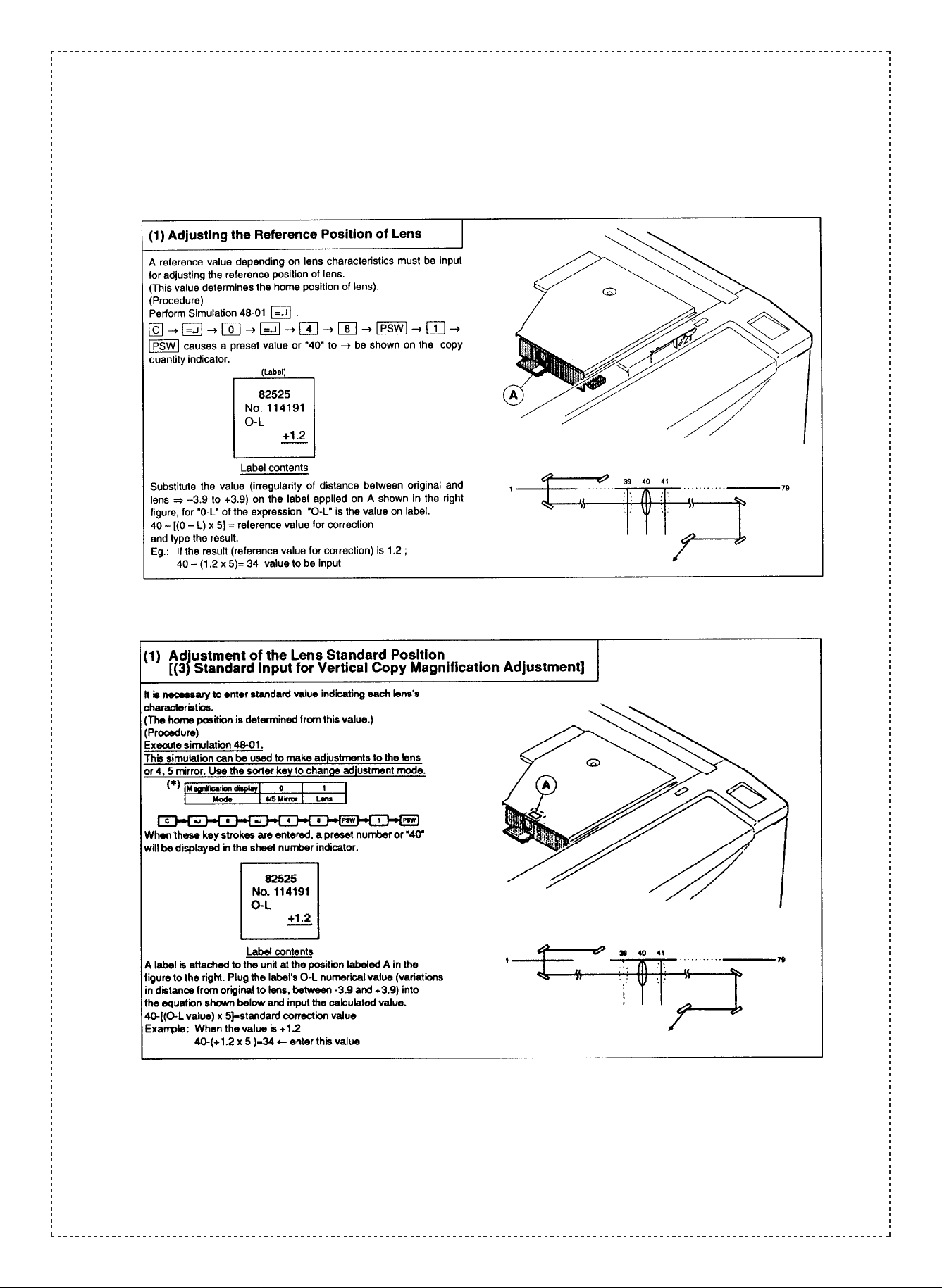

Page 7-8 (2) Adjusting the Reference Position of 4. and 5. Mirror

Misprint/Omission

Correction

3/13

Page 4

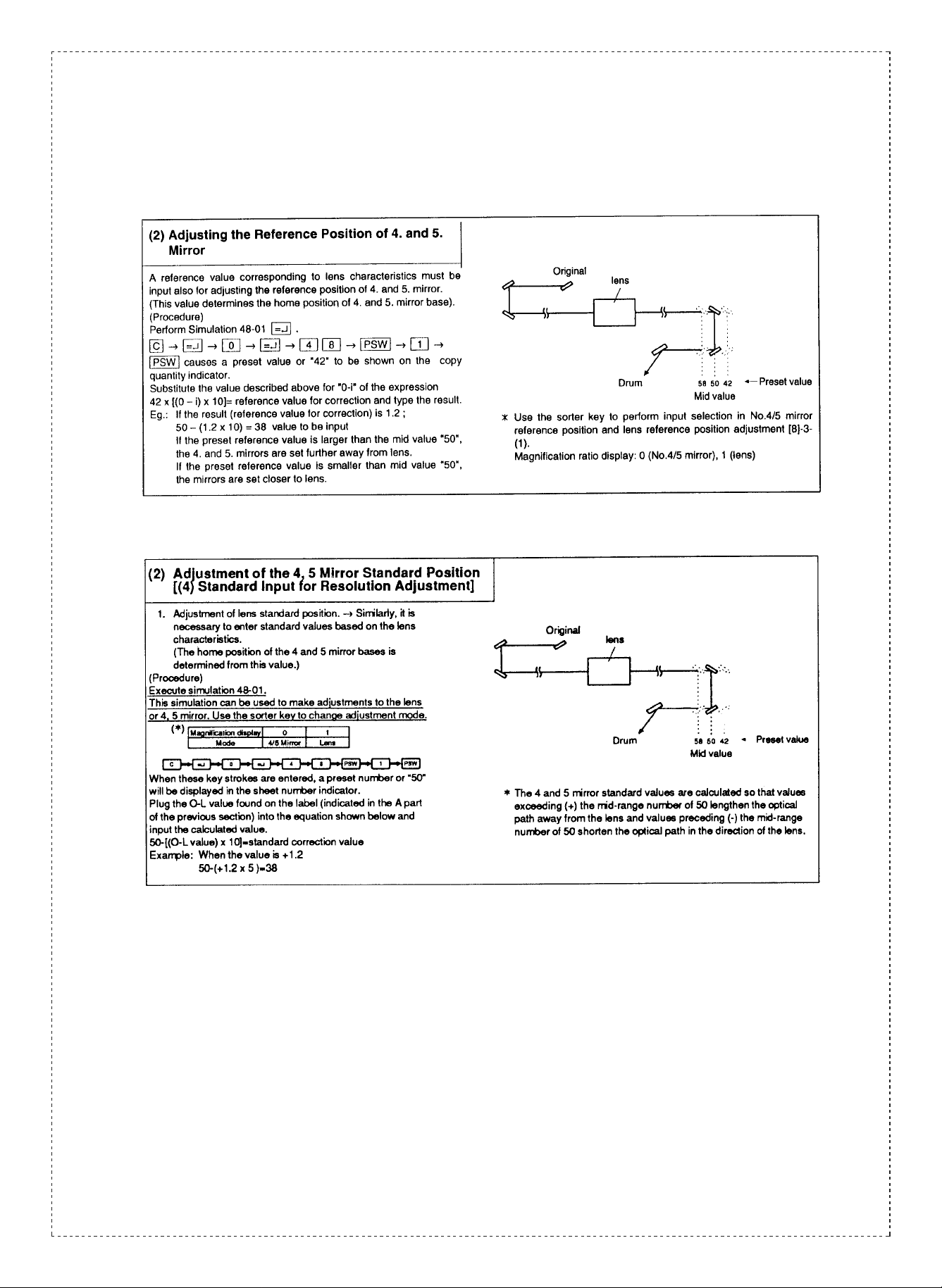

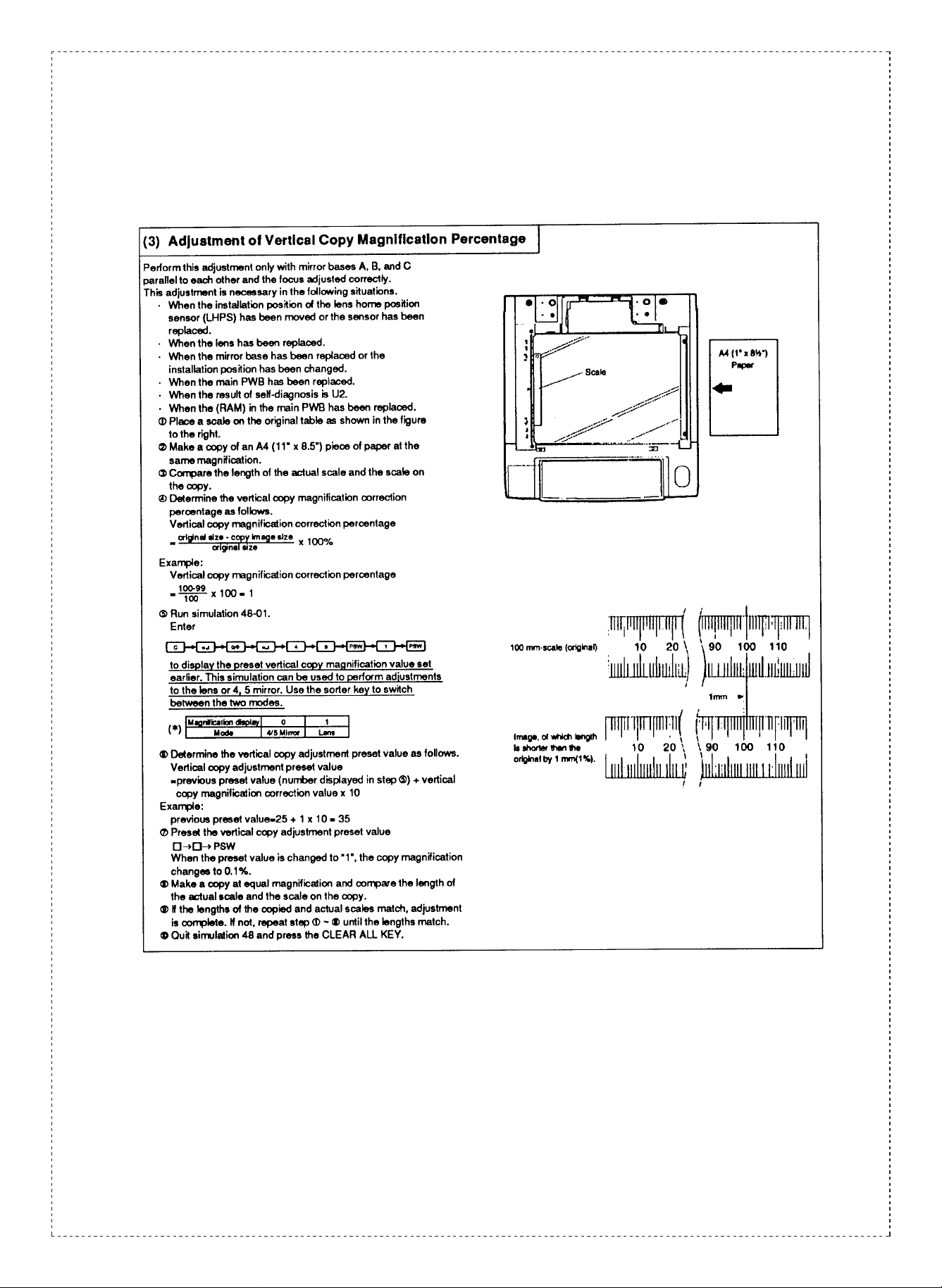

Page 7-8 (3) Adjusting the Longitudinal Magnification

Misprint/Omission

4/13

Page 5

Correction

5/13

Page 6

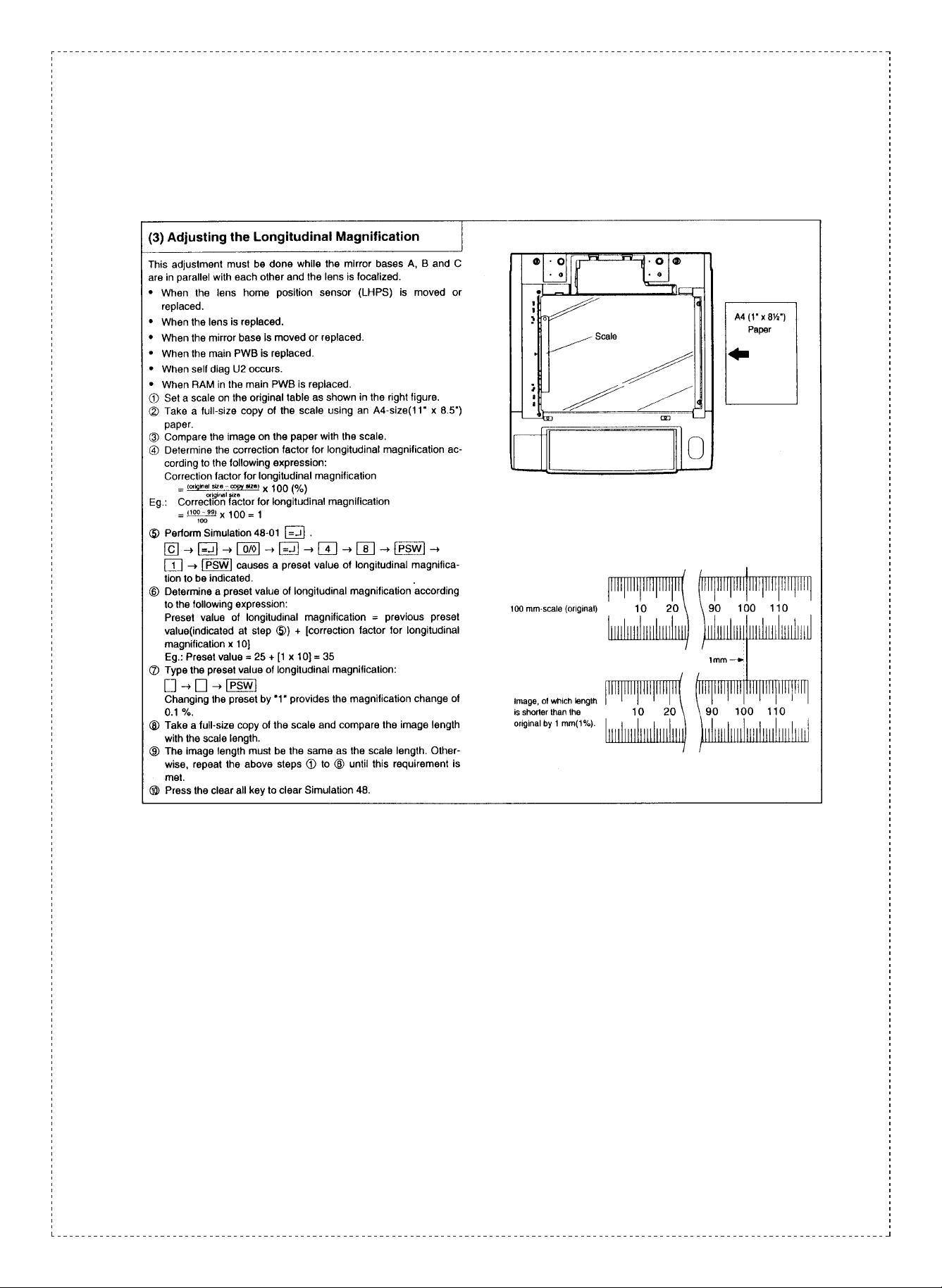

Page 7-9 (4) Adjusting the Resolution

Misprint/Omission

Correction

6/13

Page 7

Page 7-18 A.Developing bias output voltage check

Misprint/Omission

A. Developing bias output voltage check

Check that the output value is -215 ±5V when the exposure in the

manual exposure mode is “1.”

Simulation to check the developing bias: Sim 8-01

Correction

A. Developing bias output voltage check

Check that the output value is -215 ±5V.

Simulation to check the developing bias: Sim 8-01

Page 8-10 SIM.22-03: JAM memory display (JAM map display)

Misprint/Omission

Correction

7/13

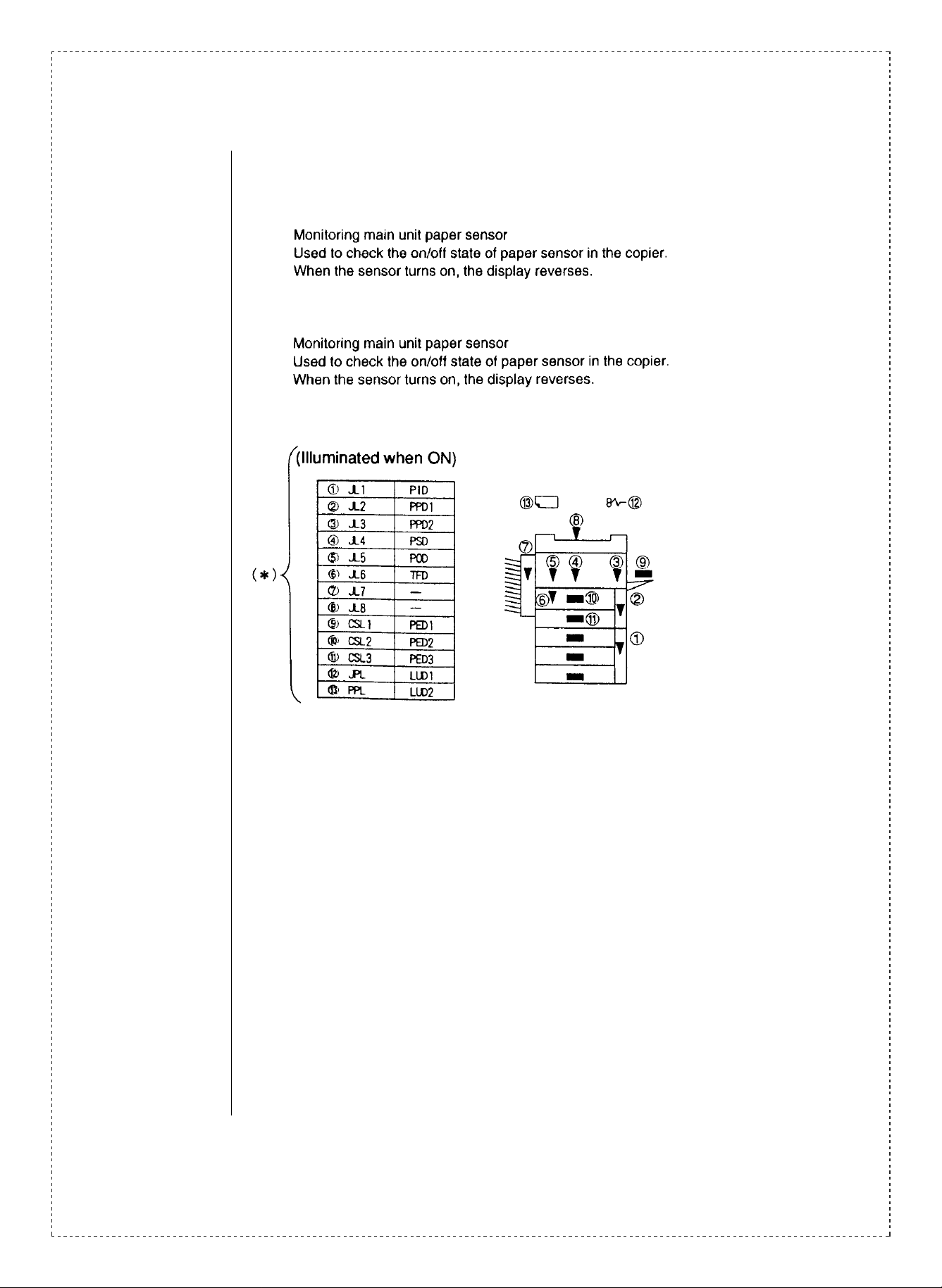

Page 8

Page 8-14 SIM.30-01: Monitoring main unit paper sensor

Misprint/Omission

Correction

8/13

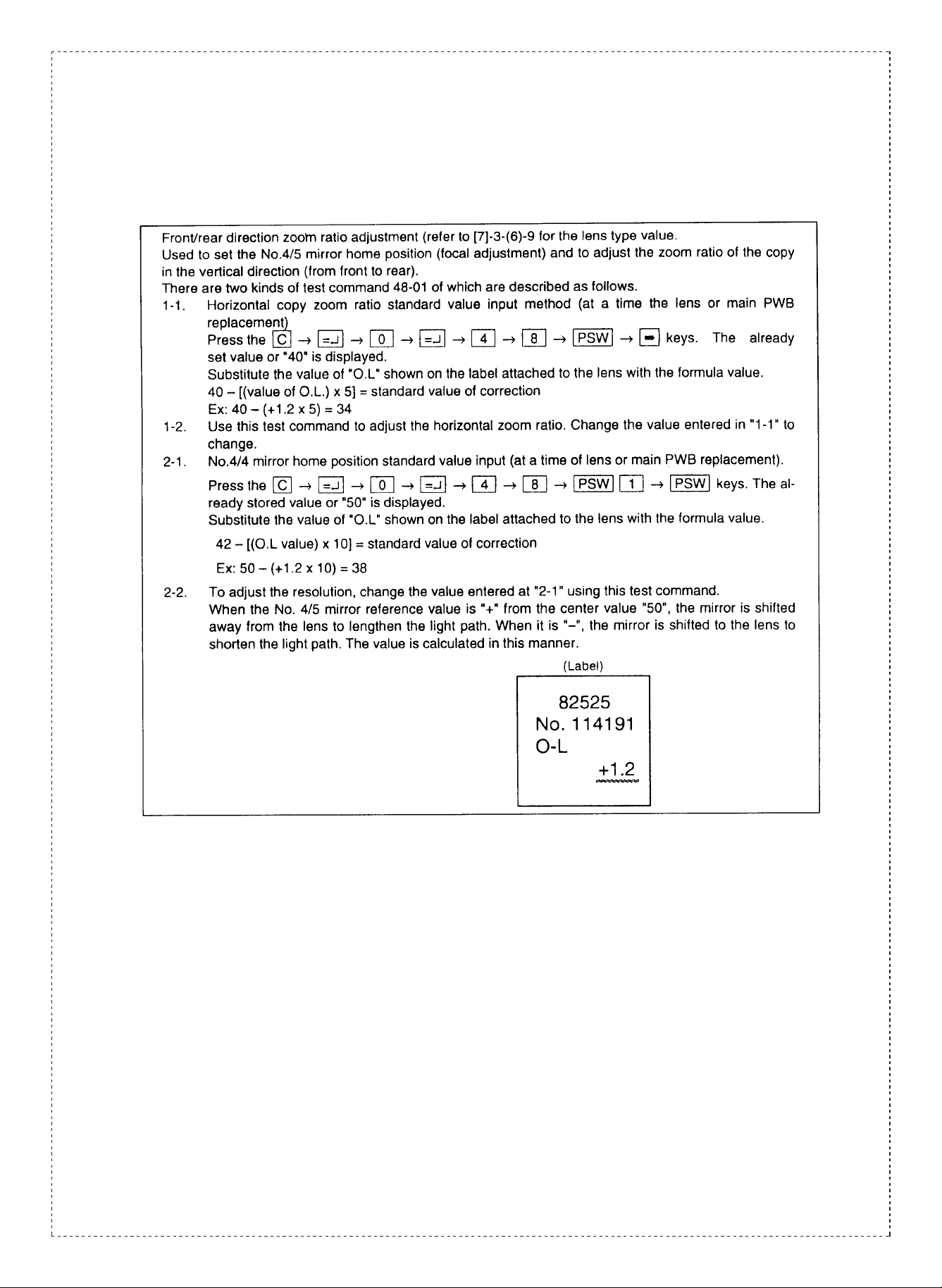

Page 9

Page 8-17 SIM.48-01: Front/rear direction zoom ratio adjustment

Misprint/Omission

9/13

Page 10

Correction

10/13

Page 11

Page 8-20 Trouble status code

Misprint/Omission

11/13

Page 12

Correction

Trouble codes list (SF-2040/2030/2025)

Trouble status code Subordinate code Description

L4 01 Main motor lock detection

00

L5

L8 03 AE sensor output value error detection (only in execution of SIM 47)

H2 00 Fusing thermistor open detection

H3 00 Fusing heat roller high temperature detection

H4 00 Fusing heat roller low temperature detection

U2

U3

U4

U5

U6

U7 00 PC/Modem communication error detection

F1

F2

When F2 trouble occurs, the DV lamp and the copy quantity display blink simultaneously.

When, therefore, simulation 22-15 is performed, the trouble code and the sub code are displayed.

Blink → Execution of Sim 22-15 → Trouble code display → Start key → Sub code display

F3

E2 00 Backup memory error detection

C2 00 Transfer charger overcurrent

CC — Document size sensor level error detection

03

04

05

06

00

01

20

21

02

03

00

01

02

03

04

05

06

00

01

02

03

08

09

10

00

01

02

03

04

05

06

08

14

02

31

32

35

12

22

Lens initial error detection

No. 4/5 mirror motor error detection

No. 4/5 mirror home position (MBHPS) detection error

Lens motor error detection

Lens home position (LHPS) detection error

Memory SUM check error detection

Counter SUM check error detection

Mirror home lock detection

Mirror home position (MHPS) detection error

ADU alignment plate operation error detection

ADU rear edge plate operation error detection

ADF communication error detection

A motor operation error detection

B motor operation error detection

Resist sensor detection error

Eject sensor detection error

Timing sensor error detection

Empty sensor error detection

Desk communication error detection

Desk-1 cassette lift up error detection

Desk-2 cassette lift up error detection

Desk-3 cassette lift up error detection

Desk DC24V power error detection

Desk LCC lift up motor overcurrent detection

Desk transport motor error detection

Sorter communication error detection

Sorter jogger motor error detection (S52 only)

Sorter transport motor error detection

Sorter guide bar oscillation motor abnormality detection (S53 only)

Sorter indexer upper limit detection error (S15 only)

Sorter BIN upper /lower limit error detection (S18 only)

Sorter indexer lower limit detection error (S15 only)

Sorter home sensor error detection (S18 only)

Sorter BIN shift motor error detection

Sorter staple shift motor error detection (S53 only)

Sorter take-up sensor error detection (S18 only)

Toner hopper motor error detection

ID sensor level error detection

DM sensor level error detection

Half toner correction adjustment error detection

Main unit upper cassette liftup motor trouble detection

Main unit lower cassette liftup motor trouble detection

12/13

Page 13

Trouble status code Subordinate code Description

EE

OP 00 Communication trouble between operation PWB and main PWB

EL

EU

Upper limit of toner density detected in auto developer adjustment

Lower limit of toner density detected in auto developer adjustment

List of display codes other than trouble codes

Trouble status code Subordinate code Description

CH — Cover open (lighting) / developing unit not installed (blinking)

PC — Personal counter not installed / waiting for input of auditor code

PF — Copy inhibition command is received from host in a machine with PC/modem

13/13

Loading...

Loading...