Page 1

Date: Dec. 3, 1996

COPIER : SF-2025

1.CLEANING IN HIGH HUMIDITY AND TEMPERATURE EN V I RONMENTS.

2.PREVENTION OF CONTACT WITH GEAR, SUCTION DUCT UNIT INSTALLATION SCREW.

3.PREVENTING TONER LEAKS FROM TONER HOPPER.

4.PREVENTING AUTO SHUTOFF OF THE DEHUMIDIFIER RESISTOR.

No. : SP-2032

1. Cleaning in high humidity and temperature environments.

1.Model Name: SF-2040

2.General: When successive copies are made in conditions of high humidity and temperature, the

used toner inside the DR cleaner unit may become clogged as a result of rising

temperature in the machine. This may result in poor cleaning. In response to this, we

are executing the following measures.

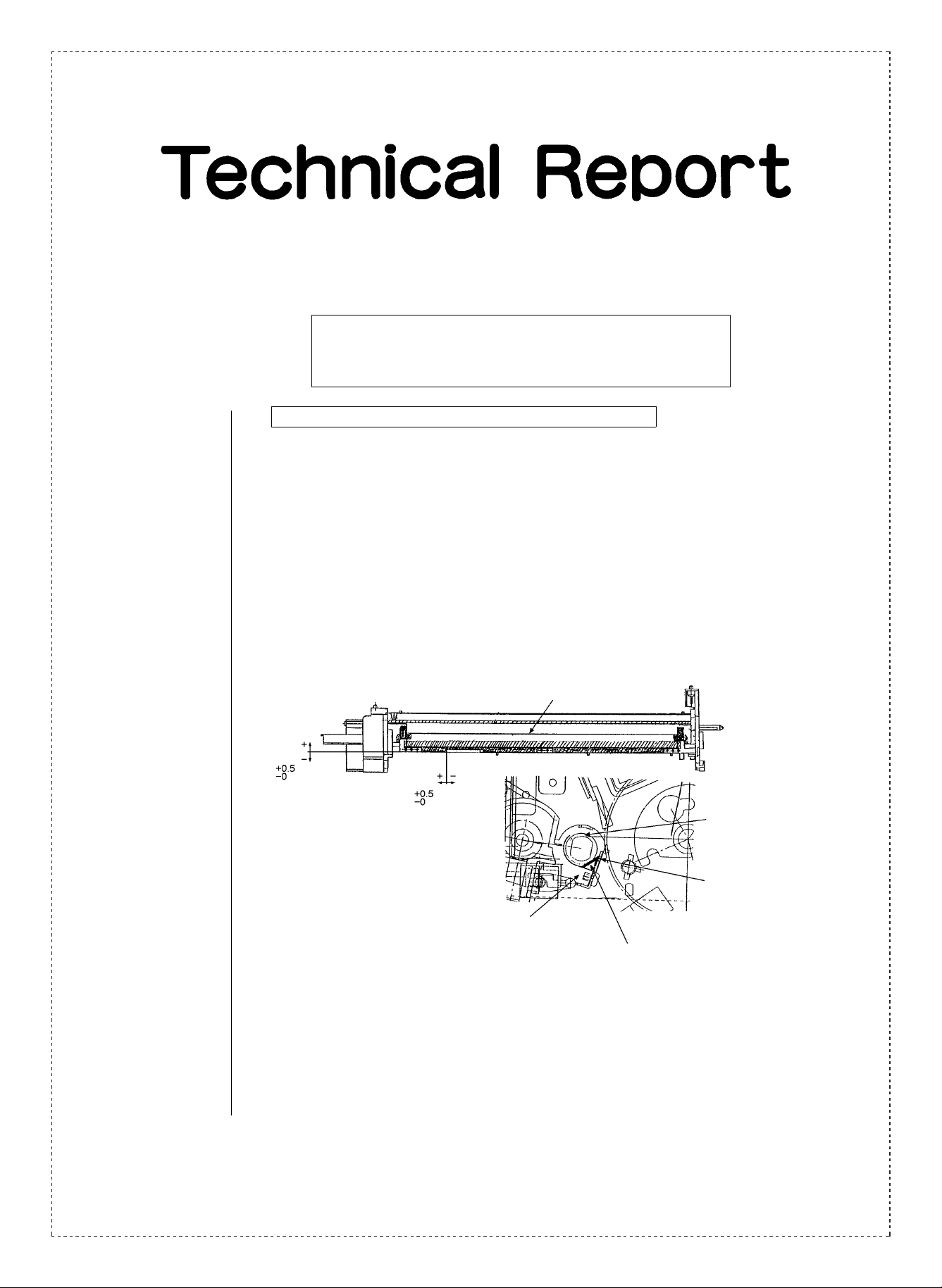

3.Description: We are adding a CL screw sheet below the DR frame to reduce dead space in the DR

cleaner unit.

CL screw sheet

Tolerance

Tolerance

Screw

.

Attach the CL screw sheet to

the bottom of the DR frame so

that the bend of the mylar fits

below the toner transport

propeller.

.

After attaching the CL screw sheet, fasten the toner receiver onto it with a screw.

(Attach the CL screw sheet after wiping the unit with alcohol. Attach it so that the

double sided tape is smooth.)

Bottom of the DR

frame

CL screw sheet

Toner receiver

4.Action: From the middle of February, 1996 production.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

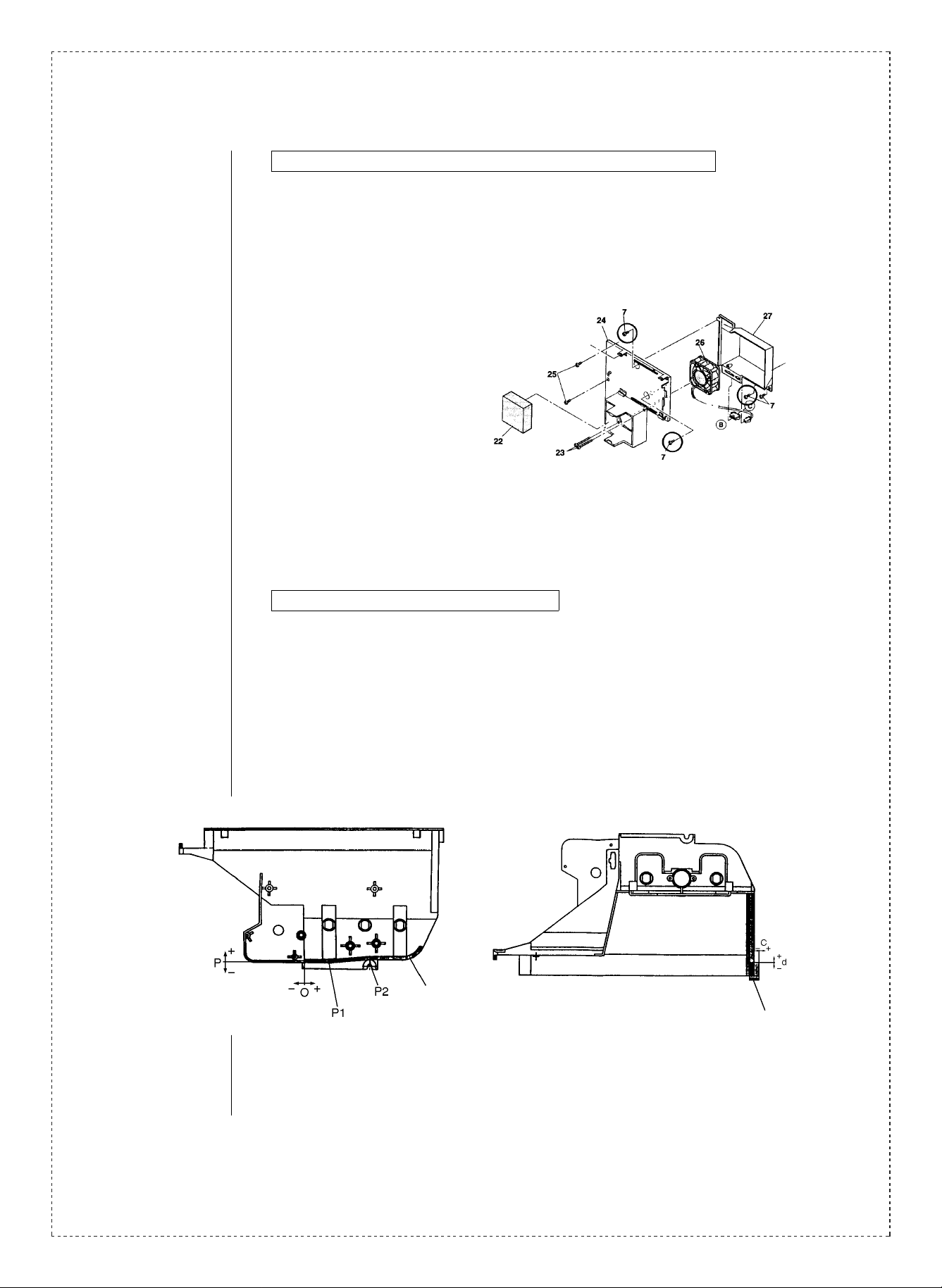

2. Prevention of contact with gear, suction duct unit installation screw .

1.Model Name: SF-2025/2030/2040

2.General: Because the main motor unit gear may come in contact with the tip of the screw

fastening the suction duct unit, we are changing to a shorter screw.

Change from M4 X 10 to M4 X 6 in the

3 places shown in the figure to the right.

3.Action: ∗ SF-2025 → From the middle of November, 1995 production.

SF-2030/2040 → From the first unit of November, 1995 production.

3. Preventing toner leaks from toner hopper.

1.Model Name: SF-2025/2030/2040

2.General: To prevent toner leaks developing in the corner and bearing, we are changing the molt

and adding parts.

3.Description: The figure shows newly added parts only. Refer to the part guide and part list for part

changes.

Cover molt

PMLT-1090FCZZ

Point of passing

TH molt H

PMLT-1086FCZZ

2/4

Page 3

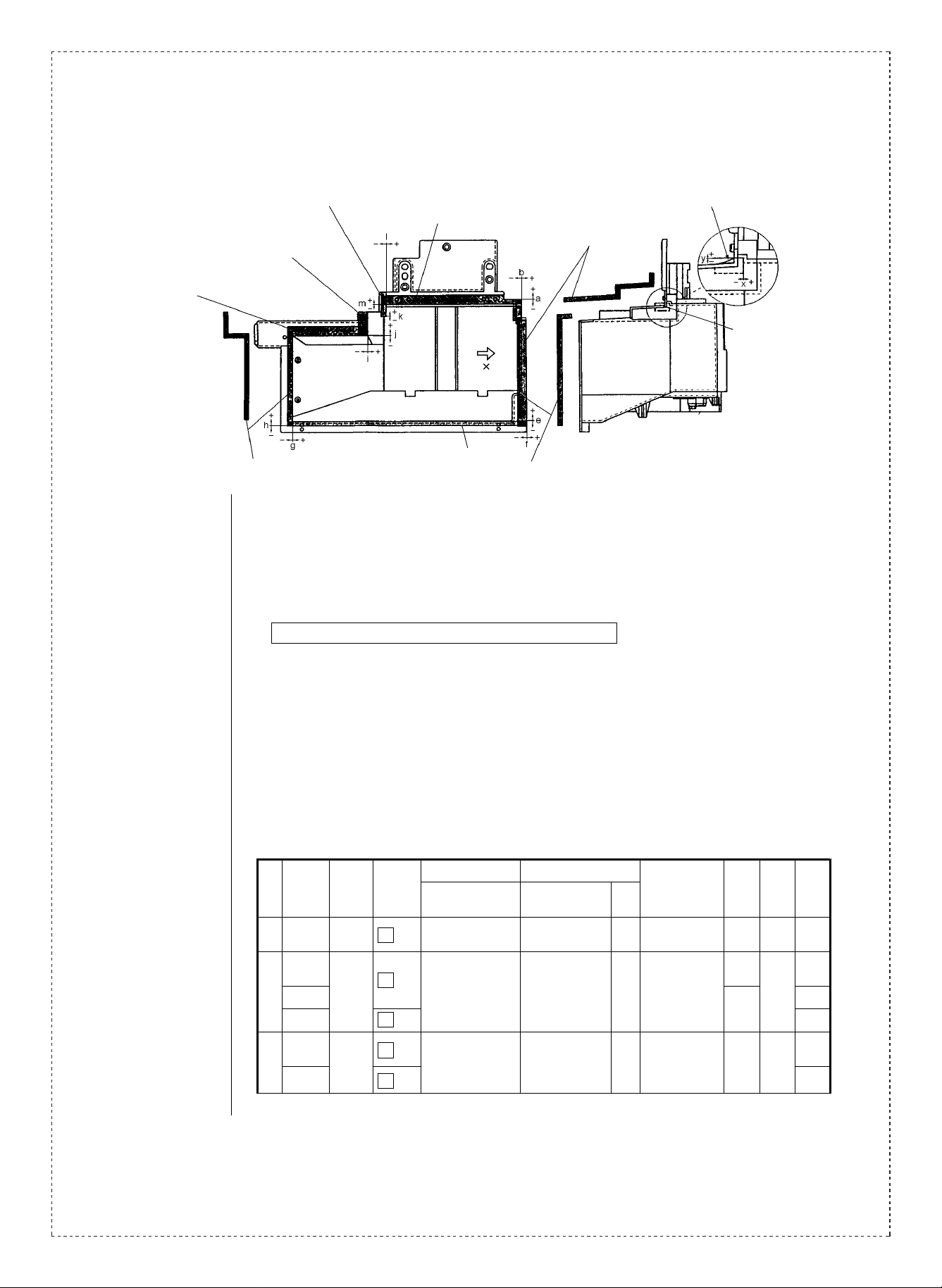

TH molt I

PMLT-1087FCZZ

Cover seal AN 2

PSEL-0711FCZZ

TH molt J

PMLT-1088FCZZ

TH molt F

PMLT-1011FCZ2

Do not push too far into the corner,

so R can adhere properly.

TH molt G

PMLT-1085FCZZ

Corner molt

PMLT-1092FCZZ

TH molt C

PMLT-1008FCZ1

TH molt B

PMLT-1007FCZ1

TH molt H

PMLT-1086FCZZ

4.Action: Domestic (Japan) production → From the first unit of March, 1996 production.

China (SOCC) production. → From the first unit of May, 1996 production.

4. Preventing auto shutoff of the dehumidifier resistor.

1.Model Name: SF-2025/2030/2040

2.General: We are adding a DH relay PWB and changing the harness to enable the dehumidifier

resistor to work even during automatic shutoff mode.

Temporary measures will be taken for 100V versions from the first unit of May, 1996

production, and permanent measures will be taken for 200V versions from the first unit

of June, 1996 production.

Ref.

Model

No.

name

1 SF-2040 All

SF-2025

2

SF-2030

SF-2040

SF-2025

SF-2030

3

SF-2040

Version P/G No.

16 — PSHEP4176FCZZ AG CL screw sheet

10

All

9

16 -7

All

15 -7

Current parts New parts

Parts code Parts code

XHBSD40P10000 XHBSE40P06000 AA Screw (M4 X 6)

PMLT-1006FCZ1 PMLT-1085FCZZ AC TH cushion G

Price

Parts name

rank

Effec-

tive

time

Mid-

’96/2

Mid-

’95/11

1st lot

’95/11

∗ 4

Inter-

change-

ability

6

3

Note

3/4

Page 4

Ref.

No.

Model

name

SF-2025

SF-2030

SF-2040

Version P/G No.

16 -11

15 -11

Current parts New parts

Parts code Parts code

PMLT-1009FCZ1 PMLT-1087FCZZ

Price

rank

Parts name

TH cushion I

Effec-

tive

time

Inter-

change-

ability

Note

SF-2025

SF-2030

SF-2040 15 -10

SF-2025

SF-2030

SF-2040 15 -9

SF-2025

SF-2030

3

SF-2040 15

SF-2025

SF-2030

SF-2040 15

SF-2025

SF-2030

SF-2040 15

SF-2025

SF-2030

SF-2040 15

SF-2025

SF-2030

SF-2040 15

All

16 -10

16 -9

16

16

16

16

16

PMLT-1010FCZ1 PMLT-1089FCZZ TH cushion L

AC

PMLT-1011FCZ1 PMLT-1011FCZ2 TH cushion F

PMLT-1086FCZZ TH cushion H

PMLT-1088FCZZ AB TH cushion J

—

PMLT-1090FCZZ AC Cover molt

PMLT-1092FCZZ AB Corner molt

PSEL-0711FCZZ AE Cover seal

4

∗

6

4/4

SF-2025

SF-2030

SF-2040

SF-2025

SF-2030

SF-2040

4

SF-2025

SF-2030 200V

SF-2040 23 DHAI-2542FCZZ DHAI-2542FC11 BD

SF-2025

SF-2030

SF-2040

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la ce of curr en t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

10 -3

All

9-3

24 DHAI-2537FCZZ DHAI-2537FC11 BF

100V

series

23

24 DHAI-2538FC11 DHAI-2538FC12 BF

series

10

All

9

!

DHAI-2514FC11 DHAI-2514FC12 BR

DHAI-2541FCZZ DHAI-2541FC11 BD

— CPWBF1208FC51 AQ DH relay PWB 6

Lower unit main

harness

AC harness

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

1st lot

’96/6

4

Loading...

Loading...