Page 1

Date: Aug. 1, 1996

COPIER : SF-2116

1. MEASURE TO ALLEVIATE PROBLEMS OF ABNORMAL NOISE IN THE DV DRIVE GEAR.

2. ROM UPGRADE CARRIED OUT IN ACCORDANCE WITH A REQUEST FROM THE MARKET

AND TO ALLEVIATE PROBLEMS OF SOFTWARE BUGS.

3. MEASURE TO ALLEVIATE TROUBLE WITH THE START KEY .

No. : SP-2030

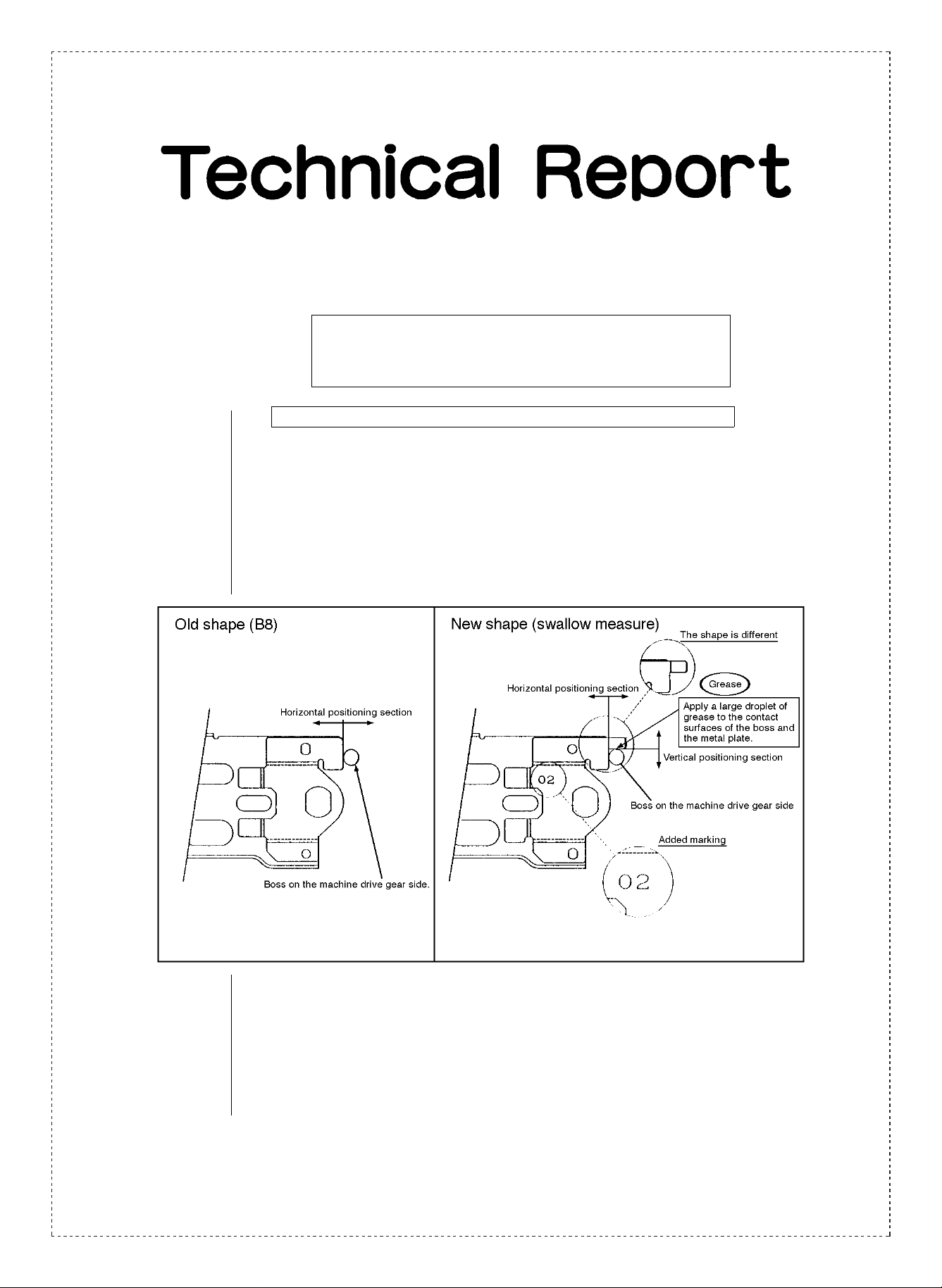

1. Measure to alleviate problems of abnormal noise in the DV drive gear.

1.Model Name: SF-2116/ 21 18/1016/1018

2.General: Abnormal noise sometimes occurs due to a degeneration of the gear fit between the DV

drive unit section and the drive transfer section of the main machine. To alleviate this

problem, a DV drive unit positioning section has been added in the vertical direction to

supplement the one in the original horizontal direction.

3.Action: ∗1 Japanese domestic production: From the start of 1996 April production.

Chinese (SOCC) production: From the start of 1996 May production.

French (SMF) production: From the start of 1996 June production.

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

2. ROM upgrade carried out in accordance with a request from the market and to

alleviate problems of software bugs.

1.Model Name: SF-2116/ 21 18/1016/1018

2.General: An upgrade of ROM Ver. 2.6 has been carried out, to ROM Ver. 2.7 in accordance with

a request from the market and to alleviate problems of software bugs.

3.Description: (See chart at the end of this report.)

4.Action: ∗2 Japanese domestic production: From 1996 mid-January production.

Chinese (SOCC) production: From the start of 1996 March production.

French (SMF) production: Running change.

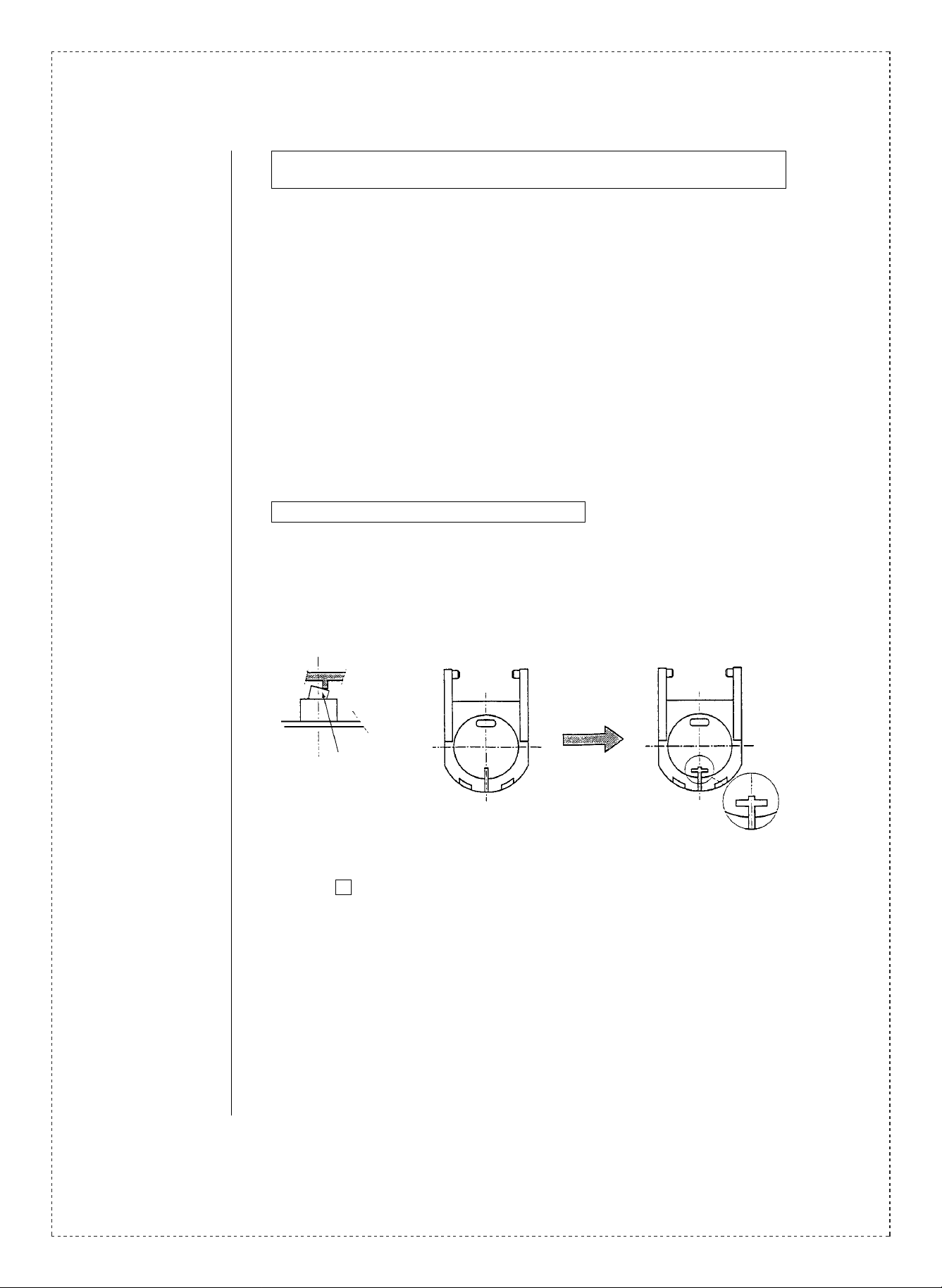

3. Measure to alleviate trouble with the start key.

1.Model Name: SF-2116/ 21 18/1016/1018

2.General: The start switch sometimes does not function properly if the start key is depressed in a

diagonal direction. To alleviate this problem a change in the shape of the back side of

the start key has been carried out.

This section has become diagonal.

NewOld

In the shape of a cross.

In consideration of serviceability, the new start key has been established with the LED

filter (P/G ) as an assembled part.

2-6

3.Action: ∗3 Japanese domestic production: From 1996 mid-April production.

Chinese (SOCC) production: From 1996 mid-March production.

2/5

Page 3

Ref.

Model

No.

SF-2116

SF-2118

1

SF-1016

SF-1018

SF-2116

SF-2118

2

SF-1016

SF-1018

SF-2116

SF-2118

3

SF-1016

SF1018

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new t y pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la c e of c u rr en t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

11 -30 CFRM-0687FC01 CFRM-0687FC02 AL DV drive frame ∗13

All

29 -54 VHI27C01061FC VHI27C01066FC AY IC ∗23

All

2-5

All

!

Current parts New parts

Parts code Parts code

CBTN-0197FC01 CBTN-0197FC32 AL Start key

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

rank

Effec-

tive

time

∗33

Inter-

change-

ability

Note

3/5

Page 4

List of content for ROM version upgrade of V2.6 → V2.7.

No. Problem content Cause and Description

Simulation 46-2 (exposure adjustment) has been added. The exposure adjustment settings have been set to each

1

When copy operations are carried out after placing A4R

copy paper in the ADF and the ADF tray sensor has

registered A4, the original document is scanned as A4R

2

but the image area is A4. (This problem occurs only

when the shadow compensation mode is in effect.

When simulation 41-1 is carried out the operation LED

corresponding to the original document does not

3

illuminate.

When multi-manual feed operations are changed to

multi-copy oprations during DPCM reduction copy

4

operations, residual images of page one appear from the

second copy onward. (This problem occurs for copy

paper sizes of A4 or greater.)

Even though the rear edge void has been set during

simulation 26-20, when multi-manual feedoperations are

5

carried out for DPCM the rear edge void operations

cannot be carried out for the second page.

The interrupt key is not acknowledged after the

preliminary paper feeding operation has been completed

6

during single manual feed operations.

When single manual feed copy operations are carried out

after the interrupt key has been depressed and the

machine has been put in the interrupt mode, and if the

7

interrupt key is then depressed once again during these

copy operations the settings from before the interrupt

mode was set are not reset.

The counter values remain in the single count mode even

though A3 copy operations are carried out after the

8

cassette detection setting has been set to “extra”.

There is no rear edge void for page two original

9

document copies when multi-manual feed copy

operations are carried out using the ADF.

The original document remaining lamp continues to flash

when copy operations are halted (due to copy paper

running out or jams, etc.) while the machine is in OC

10

mode, even though the original document has been

removed from on top of the platen and placed in the

ADF. (This problem includes the DPCM mode.)

If OC mode or DPCM copy operations are carried out

during interrupt mode and a copy operation halt occurs,

the original document remaining lamp does not flash

11

when the interrupt mode is terminated by depressing the

interrupt key.

When an original document is set in the ADF and the

interrupt key is depressed after ADF copy operations

12

have finished, interrupt reserve mode is set.

When the copy count setting is carried out after the clear

key is depressed and the copy operations are halted

13

during DPCM page two copy operations, and the copy

operations are then resumed, the copy operations start

up from page two.

maximum velue (exposure level 1.0).

This trouble occurs when the original document size

changes during copy operations but the copy paper tray

does not change accordingly.

→ A change has been carried out so that when the

original document size changes during AMS or manual

copy operations, the illumination timing of the blank lamp

is reset from the new size of the original document.

This problem occurs when simulation 41-1 is carried out

once the original document size is detected after placing

it on the platen. A correction has been carried out so that

the original document size data is cleared when the

execution of simulation 41-1 is started.

Problem of copies with residual images are alleviated by

correcting the ON timing for the grid bias and the blank

lamp illumination timing for the second copy onward of

page one.

This problem has been alleviated by correcting the

illumination timing of the blank lamp so that the rear edge

void operations can be carried out on the second page.

This problem has been alleviated by carrying out a

correction on the program so that the interrupt key will be

acknowledged during single manual feed operations.

(The machine status will be interrupt reserved.)

This problem has been alleviated by carrying out a

correction on the program so that the settings before the

interrupt mode is set and the settings after the interrupt

key is depressed during single manual feed copy

operations are all returned to their original settings.

This problem has been alleviated by changing the

program so that normal copy paper size run detection is

carried out even though the copy paper cassette size has

been set to “extra”, and a double count is registered for

A3 and WLT sizes.

This problem has been alleviated by changing the

program so that rear edge voids are possible for page

two and after during original document copy operations.

ADF copy operations are permitted if an original

document is set in the ADF after the ADF cover has been

opened and closed one time when the OC copy

operations have been halted. (The program has been

corrected so that the original document remaining lamp

does not flash.)

This problem occurs when the copy status before the

interrupt mode was set was such that the copy paper ran

out or a problem such as a jam occurred while the copy

operations were in progress. This problem has been

alleviated by changing the program so that the original

document remaining lamp flashes when the interrupt

mode is terminated.

This problem has been alleviated by changing the

program so that the machine is put into the interrupt

mode when the interrupt key is depressed after copy

operations have been completed.

This problem has been alleviated by changing the

program so that the copy operations start up from page

one after DPCM copy operations have been halted.

4/5

Page 5

Multi copy page count settings cannot be carried out

when the ADF mode is changed to OC mode after copy

14

operations are halted during an ADF copy multi-0 page

count.

The main motor continues to run after the ADF cover is

opened once the last page has been delivered during

15

ADF copy operations with original document stream

mode settings.

When the copy button is depressed and the 1 set 2 copy

lamp is off after copy operations have been terminated

16

by depressing the ca key during DPCM copy operations,

the DPCM copy operations are resumed.

When an original document is set in the ADF after DPCM

copy operations have been halted, the original document

17

remaining lamp flashes.

The original document size indication remains on after

copy size settings are carried out by overseas original

document size input operations, even if the interrupt

18

mode is set. Furthermore, after the interrupt mode is

terminated the original document size indication does not

return to its original status before the interrupt mode was

set.

When the clear key is depressed while the ADF final

original document copy operations are in progress and

19

an original document is set in the original document tray

while the machine is operating, the ADF mode cannot be

set even if copy operations have finished.

Simulation 46-2 (easy exposure adjustments) has been

changed to 70-12.

20

Toner scattering measures are not carried out until 5K

copies have passed after developer replacement

operations have been carried out.

21

The copy reduction/enlargement percentage does not

return to 100% when the interrupt key is depressed and

22

the machine is set to interrupt mode during OC mode

AMS ON reduction/enlargement copy operations for

Swallow-B domestic bound machines.

OC original document detection does not take place after

the machine is halted due to the copy paper running out

23

(P display) during multi-manual paper feed copy

operations. (The original document size display does not

change.)

When the interrupt mode is set during APS copy

operations with the AMS set to OFF, and the cassette

selection key is depressed, the copy paper cassette tray

changes. After the interrupt mode is terminated,

24

however the copy paper cassette tray setting is different

than before the interrupt mode was set. Before, when the

APS is OFF before the interrupt mode was set, the

cassette selection setting was not returned to its original

status once the interrupt mode was terminated.

This problem has been alleviated by changing the

program so that the multi page count input is allowed

when the copy operations have been halted.

This problem has been alleviated by changing the

program so that the stream mode is terminated and copy

operations are finished when the ADF cover is opened

after the last page has been delivered.

This problem has been alleviated by changing the

program so that the DPCM is cleared when the CA key is

depressed and copy operations are halted.

This problem has been alleviated by changing the

program so that the original document remaining lamp

does not flash when an original document is set in the

ADF after DPCM copy operations have been halted.

This problem has been alleviated by changing the

program so that the original document size indication is

extinguished when the interrupt mode is set. The original

document size from before the interrupt mode was set is

remembered, and once the interrupt mode is terminated

the original document size indication from before the

interrupt mode was set is once again displayed.

This problem has been alleviated by changing the

program so that the ADF mode is set.

Because this simulation is only used during production

operations, it has been set to the 70 series. (Simulation

setting changes take place only when the % key, the

EXP key or the CA key are depressed. When the copy

button is depressed the EXP 5.0 value calculation is

carried out in addition to the setting value registration.)

As a measure for toner scattering, toner concentration

correction value is lowered to a maximum of 10 when the

power supply is turned ON and the fusing temperature is

O

C, or when the main motor is turned OFF for

below 80

more than 5 hours. However, problem arise when the

power supply is turned OFF except during copy

operations, the appropriate toner concentration is already

lowered, preventing the proper toner concentration.

Before the APS commenced without the

reduction/enlargement percentage being returned to

100%. This problem has been alleviated by changing the

program so that the APS settings are carried out after the

reduction/enlargement percentage is returned to 100%.

This problem has been alleviated by correcting the

program so that the original document detection is once

again carried out when the multi-manual paper feed copy

operations are halted due to the copy paper running out.

This problem has been alleviated by changing the

program so that when the APS is ON before the interrupt

mode was set, the cassette selection setting is carried

out automatically. When the APS is OFF before the

interrupt mode is set, the cassette selection setting is

returned to its original.

5/5

Loading...

Loading...