Page 1

Date: Sep. 10, 1996

COPIER : SF-2014

1. MEASURE TO PREVENT FOGGING OF THE TABLE GLASS CAUSED BY SILICON OIL.

2. MEASURE TO PREVENT THE LEADING EDGE OF THE COPY IMAGE FROM BECOMING OUT OF POSITION.

3. CHANGE IN THE METHOD OF PACKAGING.

4. MEASURE FOR PREVENTING PROBLEMS OF DOUBLE FEEDING DURING MANUAL MULTI-FEED OPERATIONS.

5. MEASURE FOR PREV ENTING DAMAG E TO THE HAR NESS DUE TO OPENI NG AND CLOSING OF THE UPPER AND

LOWER FR AME.

6. MEASURE TO PREV ENT CASSETTE FE EDI N G J AMS DUE TO DAMP COPY PAPER.

No. : SP-2027

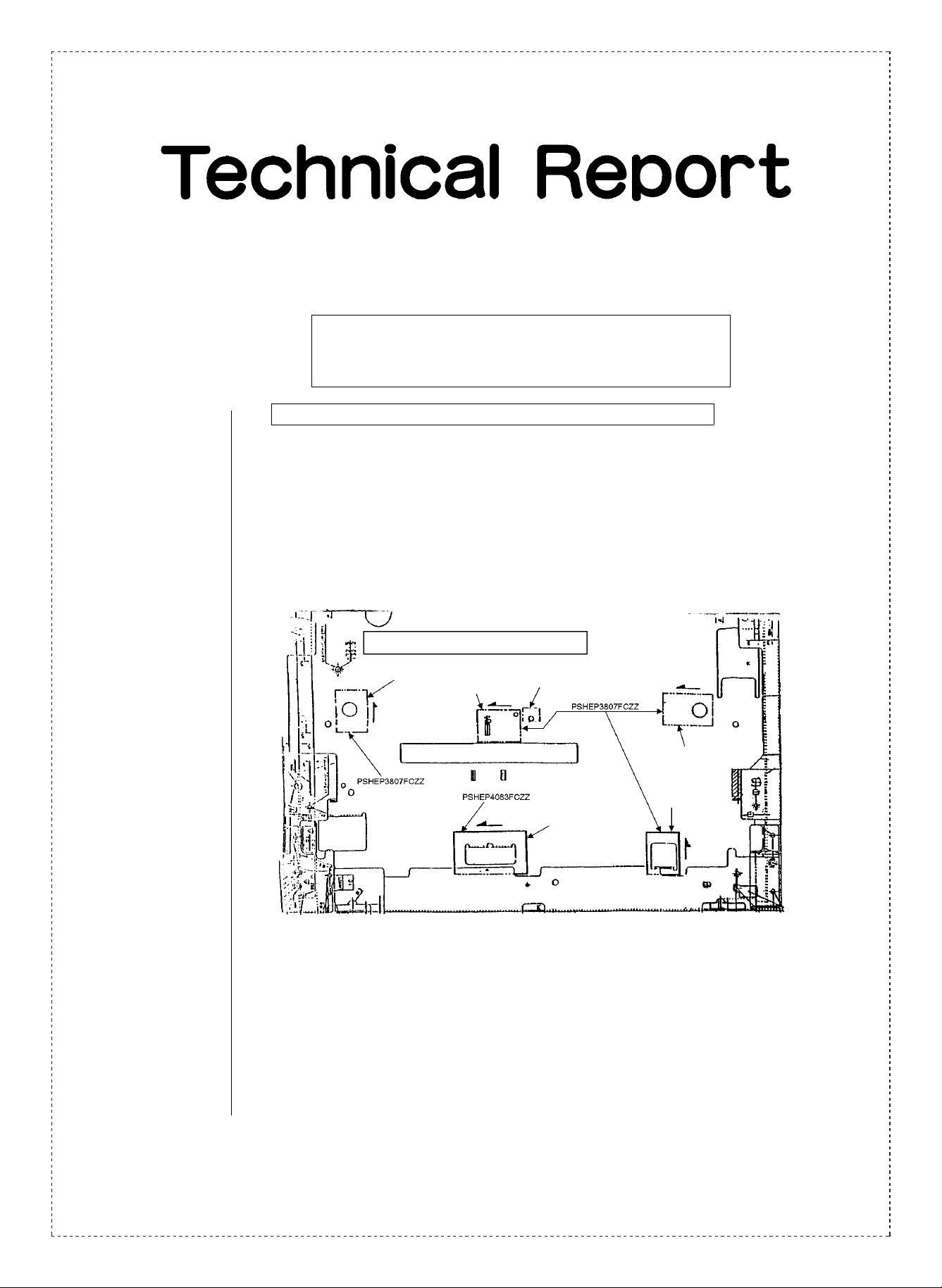

1. Measure to prevent fogging of the table glass caused by silicon oil.

1.Model Name: SF-2014/21 14/2214 Z-800

SN-1420/1430 (only for models bound for the USA)

2.General: The silicon oil of the fusing roller sometimes vaporizes and seeps into the optical unit

through holes in the unit, causing the inner surface of the table glass to become fogged.

To alleviate this problem the holes of the optical unit have been covered with sheets to

prevent the silicon oil from seeping in.

Attachment locations for the sheets

Hole ➀

Sheet ➀

Sheet ➁

Hole

Wire saddle

Hole

➂

(F side)

➁

Ozone filter insertion opening

Sheet ➂

Sheet ➃

Sheet ➄

Hole ➄

Hole ➃

(Paper discharge side)

3.Action: Japanese domestic production: From the start of 1996 April production.

Chinese (SOCC) production: From the start of 1996 May production.

French (SMF) production: From the start of 1996 June production.

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

2. Measure to prevent the leading edge of the copy image from becoming out of position.

1.Model Name: SF-2014/21 14/2214 Z-800

SN-1420/1430 (only for models bound for the USA)

2.General: The leading edge of the copy image sometimes becomes out of position due to

looseness of the winding drive shaft gear in the optical unit due to temperature and

humidity conditions. To alleviate this problem the diameter of the winding drive shaft

pressure section has been increased and the pin has been changed.

3.Action: Japanese domestic production: From the start of 1996 April production.

Chinese (SOCC) production: From the start of 1996 May production.

French (SMF) production: From the start of 1996 June production.

3. Change in the method of packaging.

1.Model Name: SF-2014/21 14/2214 Z-800

SN-1420/1430 (only for models bound for the USA)

2.General: 4 cushions have been added between the top pad and the bottom pad in the shipping

cartons as a packaging improvement measure to help prevent shipping damage.

3.Action: Japanese domestic production: From the start of 1996 April production.

Chinese (SOCC) production: From the start of 1996 May production.

French (SMF) production: From 1996 mid-April production.

4. M easur e for preve nting problem s of double f eeding dur ing manu al multi-feed op era tions.

1.Model Name: SF-2014/21 14/2214 Z-800

SN-1420/1430 (only for models bound for the USA)

2.General: Problems of double feeding sometimes occur during manual multi-feeding operations

due to deviations in the pressure spring load caused by looseness in the assembly of

various parts. To alleviate this problem the pressure spring has been changed to one

which is more resistant to spring load deviations.

3.Action: Japanese domestic production: From the start of 1996 January production.

Chinese (SOCC) production: From the start of 1996 January production.

French (SMF) production: From the start of 1996 February production.

2/5

Page 3

5. Measure for preventing damage to the harness due to opening and closing of the

upper and lower frame.

1.Model Name: SF-2014/21 14/2214 Z-800

SN-1420/1430 (only for models bound for the USA)

2.General: There was a possibility of damage occurring to the main harness due to the harness

coming in contact with the rear frame when the upper and lower frames are open and

closed, caused by wrapping of the tip of the harness making it thicker . To alleviate this

danger a sheet has been added to the inner surface of the power supply PWB holder.

3.Action: Running change from 1996 mid-March production.

Note: The change described above has already been carried out on Chinese (SOCC)

production and French (SMF) production. (Refer to SP-1964)

The change described above in this report refers only to existing stock used in

Japanese domestic production.

6.Measure to prevent cassette feeding jams due to damp copy paper.

1.Model Name: SF-2014/21 14/2214/CM14 Z-800

SN-1420/1430 (only for models bound for the USA)

2.General: The copy paper absorbs moisture during periods of high humidity, causing the paper

size to increase slightly which can sometimes lead to cassette feeding jams during B4

size copy operations. To alleviate this problem the shape of the paper cassette has

been changed as shown in the figure below to prevent cassette feeding jams.

➀ A change has been carried out in the dimensions

of the section indicated by the shaded area.

➁ A change has been carried out in the shape of the

side plate stopper.

➁ A change has been carried out in the dimensions of the

side plate stopper.

Old

Side plate stopper.

New

3.Action: Japanese domestic production: From the start of 1996 June production.

Chinese (SOCC) production: From the start of 1996 May production.

3/5

Page 4

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

1

2

3

4

5

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

All

U.S.A.

SEEG

only

U.S.A.

only

All

U.S.A.

SEEG

only

U.S.A.

only

All

U.S.A.

SEEG

only

U.S.A.

only

All

U.S.A.

SEEG

only

U.S.A.

only

All

U.S.A.

SEEG

only

U.S.A.

only

All

U.S.A.

SEEG

only

U.S.A.

only

All

U.S.A.

SEEG

only

U.S.A.

only

6

7

8

6

7

8

6 -49

7 -49

8 -49

6

7

8

25

22

24

17 -25

51 -25

53 -25

13

13

14

PSHEP3807FCZZ

(Q’ty: 5)

— PSHEP4083FCZZ AC Optical hole sheet

NSFTZ2056FCZ1 NSFTZ2056FCZ2 AP Winding drive shaft

LPINS0288FCZZ LPINS1021HCZZ AA Pin

— SPAKA5504FCZZ AH Cushion ∗26

MSPRC2219FCZ1 MSPRC2502FCZZ AB Pressure spring

— PSHEP3959FCZZ AE AC PWB inner sheet

Q’ty: 5 → 9 AB Cabinet hook sheet

∗16

∗13

∗33

See

6

text

4/5

Page 5

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

6

SF-2014

SF-2114

SF-2214

SN-1420

SN-1430

Z-800

U.S.A.

U.S.A.

SEEG

All

only

only

19 -9

18 -9

17 -9

GCASP0164FCZ1 GCASP0164FCZ2 AZ Cassette 250 ∗ 3

∗1 Japanese domestic production: From the start of 1996 April production.

Chinese (SOCC) production: From the start of 1996 May production.

French (SMF) production: From the start of 1996 June production.

∗2 Japanese domestic production: From the start of 1996 April production.

Chinese (SOCC) production: From the start of 1996 May production.

French (SMF) production: From 1996 mid April production.

∗3 Japanese domestic production: From the start of 1996 January production.

Chinese (SOCC) production: From the start of 1996 January production.

French (SMF) production: From the start of 1996 February production.

5/5

Loading...

Loading...