Page 1

Date: May. 31, 1996

COPIER : SF-2116

No. : SP-2012

NOTIFICA T ION OF CHANGES AND ADDI TI ONS OF PART S.

1.Model name: SF-2116/ 2118/1016/1018

2.General: Additions of parts have been made, and changes have been carried out on some of the

parts in the models listed above, and are hereby reported.

(1) Cases have occurred whereby the manual actuator attached to the lower portion of

the right cabinet was dropped, and a change in the shape of both end portions of the

actuator has been carried out as a measure to prevent this problem from reoccurring.

This change is effective from 1995 mid-October production.

(2) Changes have been carried out in the PID PWB used in the upper frame, and in the

DPPD circuit board of the paper feeding unit. Resistors had been installed on the back

side of the circuit boards in the in order to improve the performance of the paper

sensor, but these resistors have been changed for even more improvement. A change

in the parts codes of the circuit boards has also been carried out in accordance with this

action.

This change is effective from the start of 1996 February production.

SHARP CORPORATION Reprography Division

1/9

Green

C

Page 2

(3) The shape of the fusing roller in the lower frame unit has been changed from a

straight shape to an inverted crown shape to alleviate problems of wrinkling during

black beta and half-tone copy operations.

Note: When using the fusing roller after the change has been carried out it is necessary

to adjust the height of the paper guide in the fusing unit. Paper guide spacers and a

page of explanations have been added to the user’s kit (consumable items).

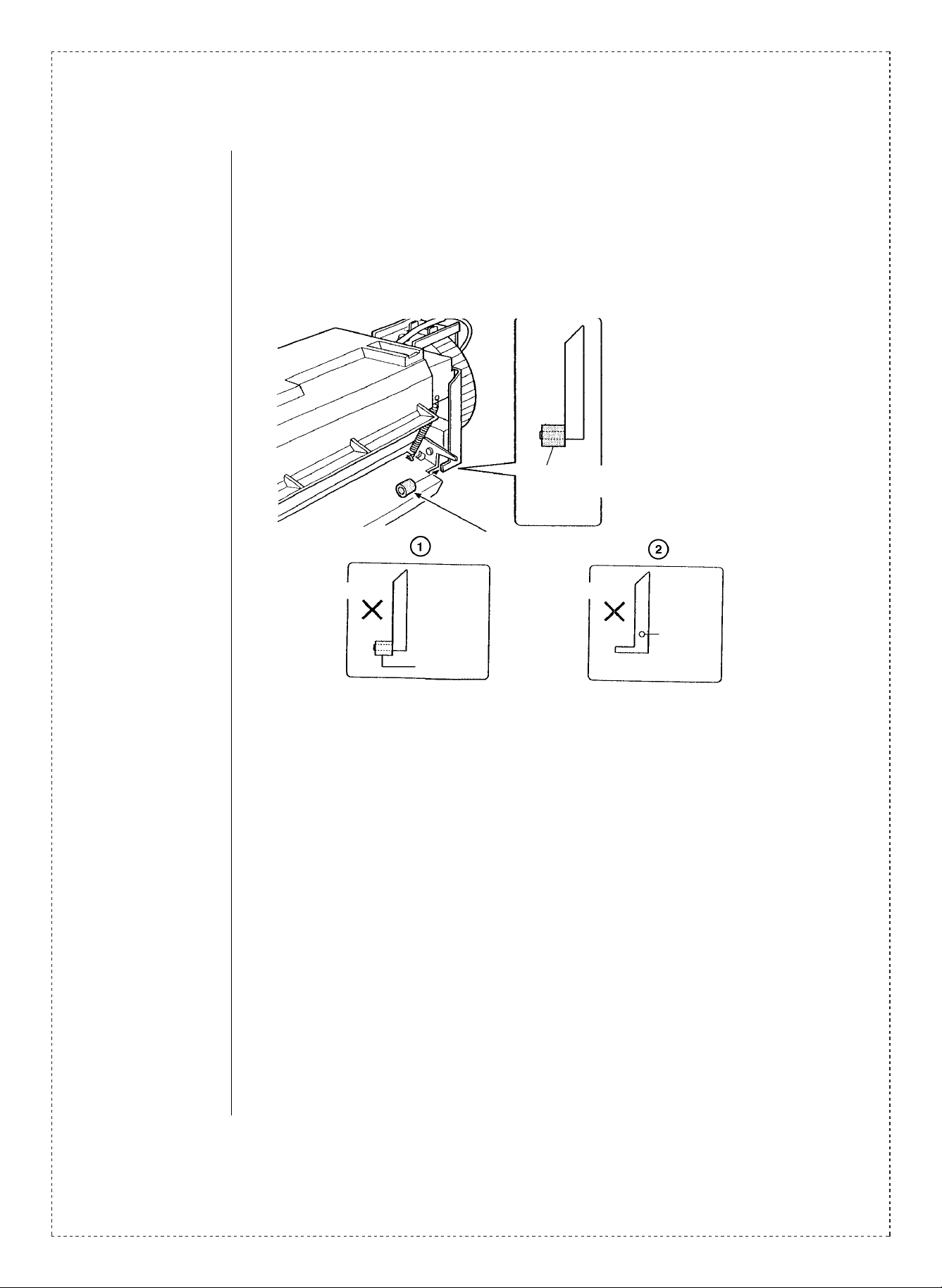

<When Using the Fusion Roller>

When using fusing roller N

(NROLR1058FCZZ) it is necessary to

attach spacers (PSPAG0691FCZZ) to

the P/G. Your cooperation concerning

this matter is requested.

Note: Action has already been carried

out in the fusing UN for ➀ and ➁

below, and the addition of spacers is

therefore not necessary.

➀ Units which have had a spacer

Spacer

(P/G Spacer T)

Spacer (P/G Spacer T)

PSPAG0691FCZZ

added to the edge bushing.

➁ Units which have had changes in

the shape of the metal plate carried

out in accordance with a change in

the metal molds.

Unnecessary

Edge

bushing

Unnecessary

Marking

∗ Japanese production

This change is effective from the start of 1995 August production.

French production (SMF)

This change is effective from 1995 mid-August production.

(4) Additions of parts have been made, and changes in some of the parts have been

carried out in order to alleviate the occurrence of F2 trouble and improve operations

efficiency .

Note: Changes have also been carried out in the printing content of the silk screening in

accordance with the changes described above.

∗ Japanese production

Running change will be effective from the start of 1995 December production.

Chinese production (SOCC)

This change is effective from the start of 1996 February production.

2/9

Page 3

(5) In order to improve production efficiency, the bias circuit of the high voltage unit has

been discontinued and the DC bias voltage has been changed to OV fixed.

∗ Japanese production

This change is effective from 1996 mid-January production.

Chinese production (SOCC)

Running change is effective.

French production (SMF)

Running change is effective.

(6) Abnormal noise sometimes occurs due to the rear cabinet coming in contact with the

base plate when the upper frame is closed. T o alleviate this problem a spacer has been

attached between the lower frame and the base plate to maintain enough space for the

rear cabinet to enter.

(Central portion of the base plate of the rear frame)

Standard A

Base plate

Lower frame R

Base plate

frame spacer

Standard B

The side with

double-sided tape

Rear cabinet

when closed

Base plate frame spacer

Standard B

Base plate

3/9

Page 4

(7) Some scraping occurred between a portion of the cabinets during the vibration test.

To alleviate this problem the measures described below were carried out.

Attached to the hook section in two (2) locations.

Upper cabinet left

Front side of the machine

(Upper cabinet right)

(Hook tape)

(Hook protection)

Protect sheet

b

a

b

a

B

A

B

(Longdimensions)

A

B

11mm

A

2mm

(Short dimesions of the bend section)

B

A

P

Protect sheet

Base plate

4/9

Filament tape

19 x 750 m/m

It is necessary to bend the end portion over.

The action described above has been carried out as an improvement measure for

during shipping operations. No action is necessary after the machine has been installed.

∗ Japanese production

This change is effective from 1996 mid-January production.

Chinese production (SOCC)

This change is effective from the start of mass production.

French production (SMF)

This change is effective from 1996 mid-January production.

Page 5

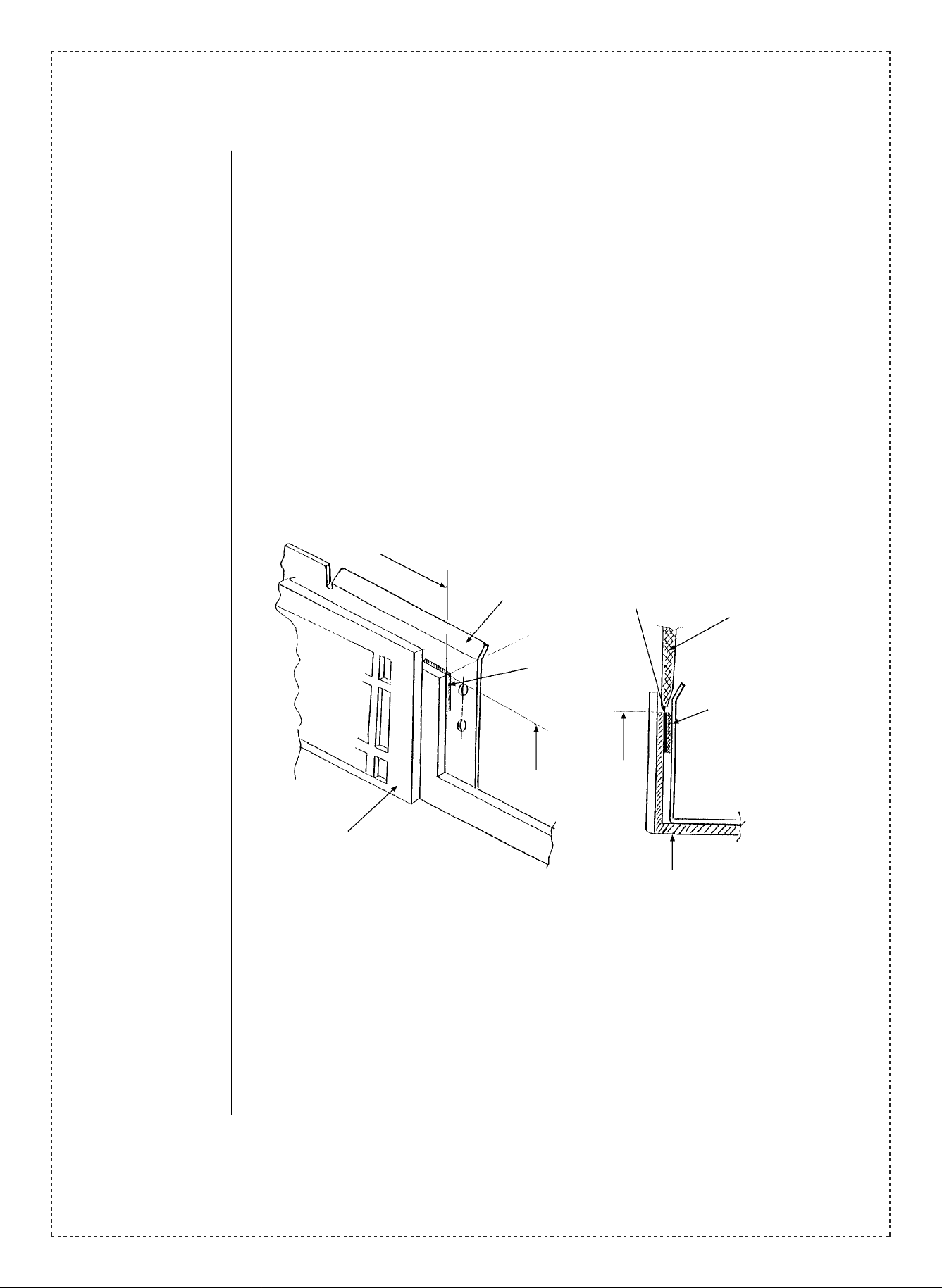

(8) To carry out adjustments on the height of the fusing paper guide, action such as the

addition of height adjustment springs and spacers to the height blocks had been carried out.

Because proper height settings could not be easily established, and because problems

of large deviations in the height occurred, an adjustment plate has been added to

enable successive and simple height adjustments.

The installation procedures for the P/G height adjustment plate are described below.

Please refer to the operations procedures when carrying out the action described above.

1. Action for side F

a. Press the bent portion (standard A) of the adjustment plate to the metal plate section

of the fusing upper frame.

Note: It is essential to make sure that the metal plate is in proper contact with the frame

because the height and direction positions of block F are determined in accordance

with the contact with the frame.

b. The positioning protrusion of elevation block F should be aligned with the holes in

the adjustment plate (standard B) and secured with the upper frame by M3 x 8 screws.

2. Action for side R

a. Secure elevation block R to the top side with M3 x 8 screws. The block should be

secured to the amount of looseness.

3. Adjustment procedures.

a. By loosening the nut and rotating the stopper screw, the length of the extended

portion of the screw can be changed to adjust the height.

b. The height of the P/G is adjusted in accordance with the passing and stopping of the

adjustment tool.

c. Aft er adjustment procedures have been completed, tighten the nut, and take up any

slack with the upper and lower locking screws (2 locations).

Fusing front P/G

Fusing upper frame

Elevation block F

Permanent measure (after 3 months)

P/G Elevation Elevation standard related parts

2.2 Elevation adjustment plate

Clearance gauge

2.1-pass

2.4-stop

(NEW)

P/G elevation adjustment plate

LPLTH5156FCZZ

M3 x 8

XEPSD30P0800

M3 Nut (NEW)

XNGSD30-18000

Drive coupling stopper screw (NEW)

LX-BZ0670FCZZ

Notes

5/9

Page 6

Secured

upper side.

R Side

Standard A

Caution

Press into

contact

Screw lock

Elevation block R

F Side

Standard A

Standard B

Align with fixing

position.

Machines which have undergone the action described above do not require the addition

of the paper guide spacer described in (3) above.

∗ Japanese production

This change is effective from the start of 1996 February production.

Chinese production (SOCC)

This change is effective from the start of mass production.

French production (SMF)

This change is effective from the start of 1996 March production.

6/9

Page 7

(9) A change has been carried out in the shape of some of the parts in the lower paper

feeding unit in order to improve servicing efficiency and reliability. (This change has

been carried out only on models SF-2118/1018.)

Old New

W base paper feeding frame R LFRM-0866FCZZ LFRM-0866FCZ1

W base paper feeding frame F LFRM-0865FCZZ LFRM-0865FCZ1

W base paper feeding bearing NSFTZ 2182FCZZ NSFTZ 2182FCZ1

W base paper feeding guide sheet (added) PSHEZ4044FCZZ

In accordance with the changes described above, the additions and eliminations of

parts described below have also been carried out. (Please refer to the table below. )

: Necessary

: Unnecessary

how to recognize differences

There is a change in the shape

of the bushing of the double

plate paper feeder roller.

Z1 parts are marked with an "A"

>ABS<

Z1ZZ

A soace is opened

A

Upper double

plate paper

feeding frame

Lower double

plate paper

feeding frame

Double plate

paper feeder

roller bearing

LX-WZ0017FCZZ

washer t0.5 Qty 1

LX-WZ0011FCZZ

washer t0.8 Qty 1

PSHEZ4044FCZZ

Double plate paper feeder guide sheet Qty 1

LX-WZ0144FCZZ

Fusing washer

∗ Attach to the back side of the upper W base

paper feeder frame

LX-WZ0017FCZZ

washer t0.5 Qty 1

Qty

5

This change is effective from the start of 1995 November production.

7/9

Page 8

8/9

Ref.

No.

1

2

3

4

5

6

7

Model

name

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

Version P/G No.

5 -10

10 -48 CPWBF1089FC31 CPWBF1089FC32 AR PID PWB

17 -7

23 -5

19 -25 NROLR1058FCZZ NROLR1058FCZZ BK Pressure roller

19 — PSPAG0691FCZZ AE

All

14

11 -45 RTRNZ0508FCZZ RTRNZ0508FCZ1 BS

19

1

Current parts New parts

Parts code Parts code

MLEVP0673FCZZ MLEVP0673FCZ1 AF

CPWBF1086FC31 CPWBF1086FC32 AP DPPD PWB

VRD-RB2HY202J VRS-RA3AA102J AB Resistor 4

VRNHT2EK1001F VRNHT2EK1501F

Price

Parts name

rank

Manual feed

actuator

Paper guide

spacer

Effec-

tive

time

Mid-

’95/10

1st lot

’96/2

Inter-

change-

ability

3

5

Note

R18

∗

VRNHT2EK5100F VRNHT2EK5100D

— VRNHT2EK1302D R48

VCEAGA1CW476M VCEAJU1CW476M AB Capacitor C1

PSPAZ0695FCZZ

—

LPLTM5164FCZZ

Transistor

AC

High voltage

transformer

Base plate

frame spacer

AC

Hook protection

plate

R19

∗ —

Page 9

Ref.

Model

No.

SF-2116

SF-2118

SF-1016

SF-1018

7

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2116

SF-2118

8

SF-1016

SF-1018

SF-2116

SF-2118

SF-1016

SF-1018

SF-2118

SF-1018

SF-2118

SF-1018

9

SF-2118

SF-1018

SF-2118

SF-1018

<Inter change>

1. Interchangeable. 4. Not interchangeable.

2. C urr e nt t y pe c a n be u s ed i n p la ce of new ty pe .

New ty pe cann ot be us ed i n place of curr ent type .

3. C urre nt ty pe cann ot be used i n place of new ty pe.

New t y pe c a n be u sed in p la ce of c u r ren t ty p e.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

name

Version P/G No.

1

28 PSHEZ4137FCZZ AC

16

All

23 -15 LFRM-0866FCZZ LFRM-0866FCZ1 AN

23 -41 LFRM-0865FCZZ LFRM-0865FCZ1 AY

23 -33 NSFTZ2182FCZZ NSFTZ2182FCZ1 AQ

23 — PSHEZ4044FCZZ AC

!

Current parts New parts

Parts code Parts code

PTPE-0220FCZZ AB Hook tape

—

LPLTM5156FCZZ AE

LX-BZ0670FCZZ AC

XNGSD30-18000 AA Nut (M3)

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Price

rank

Parts name

Cabinet protect

sheet

P/G elevation

adjustment plate

Drive coupling

stopper screw

W base paper

feeding frame R

W base paper

feeding frame F

W base paper

feeding bearing

W base paper

feeding guide

sheet

Effec-

tive

time

∗ —

1st lot

’95/11

Inter-

change-

ability

5

Note

9/9

Loading...

Loading...