Page 1

Date: Nov. 30, 1995

COPIER : SF-2050

1. MEASURE TO PREVENT CONTACT OF THE CAPACITORS USED IN THE OPERATION

CONTROL PWB.

2. MEASURE TO PREVENT DIAGONAL FEEDING DUE TO MALFUNCTIONS IN THE

REGULATION GUIDE PLATE IN THE ADU UNIT .

3. MEASURE TO FIX THE PAPER POSITION WHEN FEEDING COPY PAPER INTO THE FUSING

UNIT.

No. : SP-1975

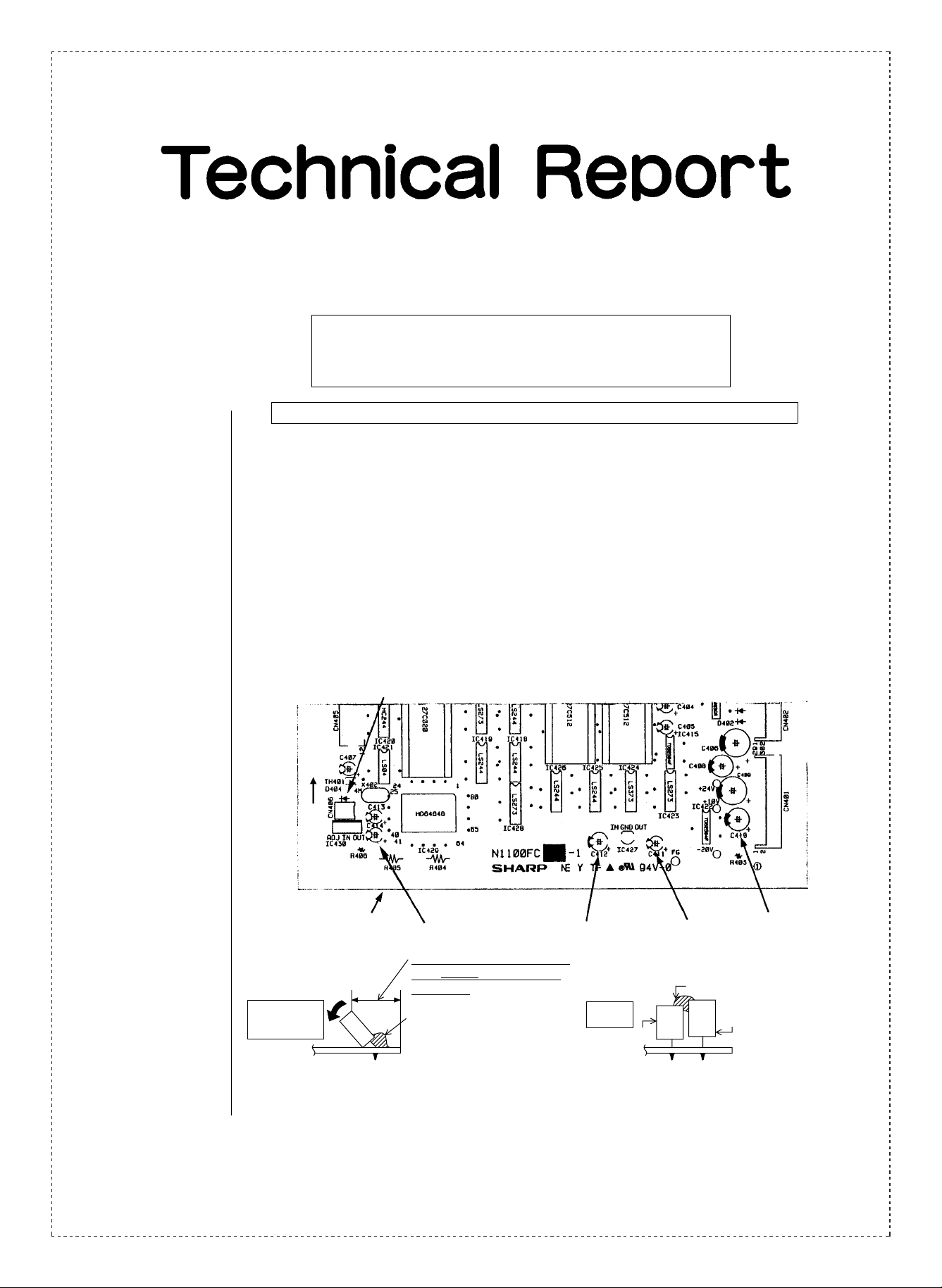

1. Measure to prevent contact of the capacitors used in the operation control PWB.

1.Model name: SF-2050

2.General: There was a danger of some of the capacitors which are used in the operation control

PWB coming in contact with the original document photo sensor PWB or the original

document photo sensor cover. To alleviate this problem, the measure described below

was carried out.

3.Description: As illustrated in the figure shown below, the capacitors have been attached by hot melt,

preventing them from coming in contact with the original document photo sensor PWB

or the original document photo sensor cover.

To prevent D404 from coming in contact with IC 430 or other surrounding

parts, it has been attached to the inside of the PWB.

Toward the

inside face of

the PWB.

Edge face of the PWB.

C414, C412

C411

C414.

The distance is to be greater

than 18 mm from the PWB

edge face.

Attached by hot melt

(To be perpendicular)

C412.

C411.

Attached by hot melt

C410

C409

C410.

C410

The parts code of the PWB was changed after the measure described above was

carried out.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

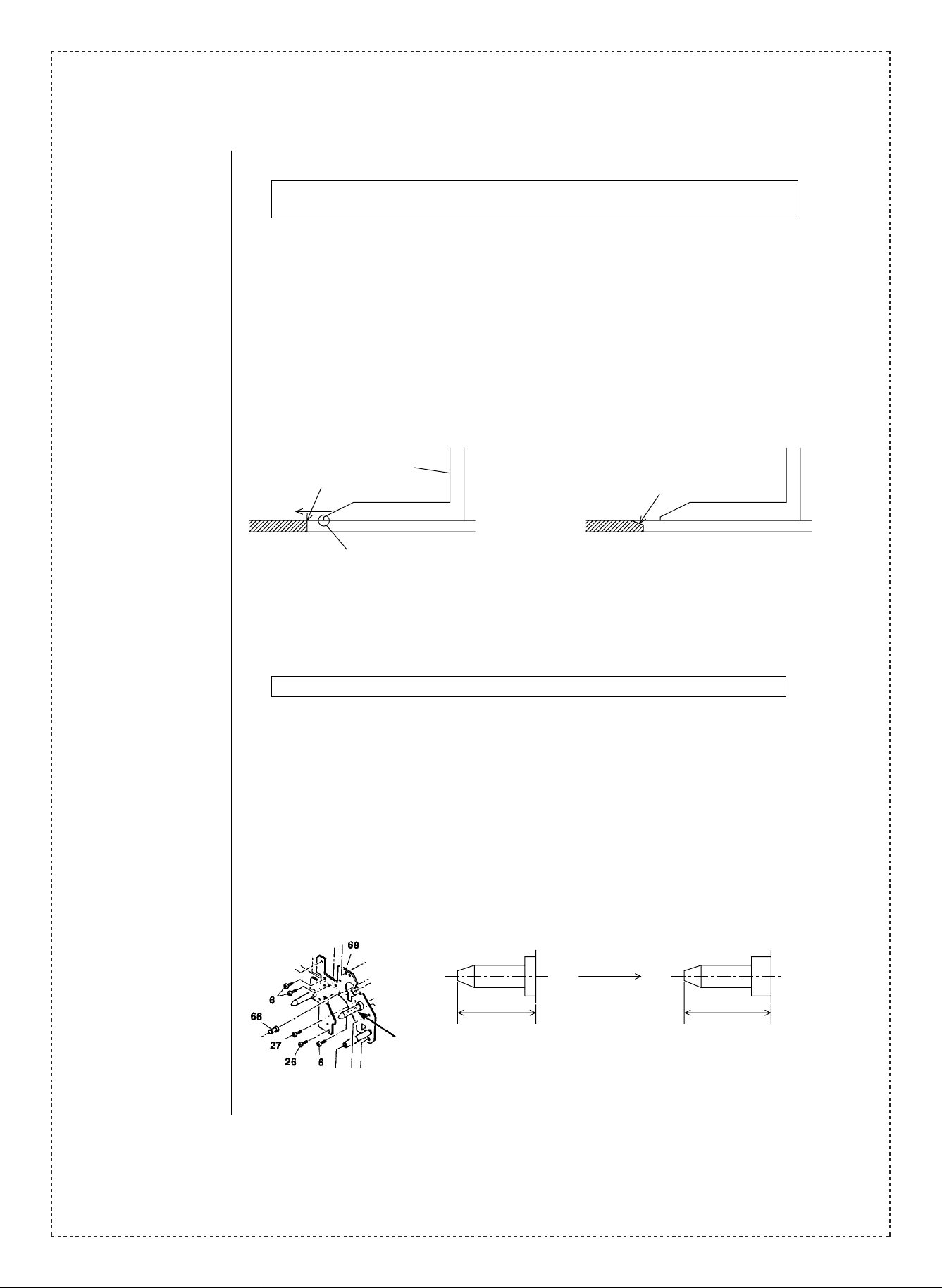

2. Measure to prevent diagonal feeding DUE to malfunctions in the regulation guide

plate in the ADU unit.

1.Model name: SF-2050

2.General: No trouble occurs when the regulation guide plate, which controls the lateral direction of

the copy paper, operates correctly, but the possibility of diagonal feeding arises when

the regulation guide plate is curved, causing it to become caught on the edge of the

square hole of the DUP slide, which prevents it from controlling the copy paper. To

alleviate this problem, the measure described below has been carried out.

3.Description:

Regulation guide plate

Old New

A taper has been added to prevent

Square hole edge

This section interferes with the aquare hole,

causing malfunctioning

the regulation guide plate from

becoming caught

4.Action: From 1995 mid-September production.

3. Measure to fix the paper position when feeding copy paper into the fusing unit.

1.Model name: SF-2050

2.General: When installing the fusing unit into the machine, the boss on the rear side of the fusing

unit sometimes failed to be guided properly into the positioning holes in the rear frame,

causing the boss to hit the face of the frame. To alleviate this problem, the measure

described below has been carried out.

3.Description: As illustrated in the figure, the shape of the boss has been changed to a step-type, to

improve the performance of the boss by making it easier for it to be guided into the

positioning hole.

Old New

AB

Change in shape.

The length of 'B' is 12 mm longer than

the length of 'A'.

4.Action: From the start of 1995 November production.

2/3

Page 3

Ref.

No.

1

Model

name

SF-2050

Version P/G No.

English

100V

series

Spanish

French

German

English

200V

series

5 -37

53 -907

5 -37

53 -907

5 -37

53 -907

5 -37

53 -907

5 -37

53 -907

Current parts New parts

Parts code Parts code

CPWBN1100FC52 CPWBN1100FC57

CPWBN1100FC54 CPWBN1100FC58

CPWBN1100FC55 CPWBN1100FC59

CPWBN1144FC52 CPWBN1144FC54

CPWBN1144FC51 CPWBN1144FC55

Price

rank

CA

Parts name

Operation

control PWB

Effec-

tive

time

1st lot

’95/10

Inter-

change-

ability

3

Note

2

3

<Interchange>

1. Interc ha ng ea bl e. 4. Not interchange able.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied ones fo r m ain taining t he s a fe ty and perfo r ma nce o f the set .

39 -26 LDAIU0519FCZZ LDAIU0519FCZ1 BH

All

16 -69

!

CFRM-0860FC01 CFRM-0860FC02 AU

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Duplex base

plate

Fusing frame R

upper

Mid-

’95/9

1st lot

’95/11

3/3

Loading...

Loading...