Page 1

Date: Nov. 30, 1995

COPIER : SF-2050

1. MEASURE TO PREVENT CRACKING WHEN THE CONNECTOR IS CONNECTED

IN THE DC POWER SUPPLY PWB.

2. ADDITION OF A 4/5 LOCK SHEET.

3. IMPROVEMENT MEASURE TO STRENGTHEN THE UPPER PAWL LEVER OF THE

FUSING UPPER UNIT.

4. MEASURE TO PREVENT DIAGONAL FEEDING IN THE ADU UNIT.

No. : SP-1974

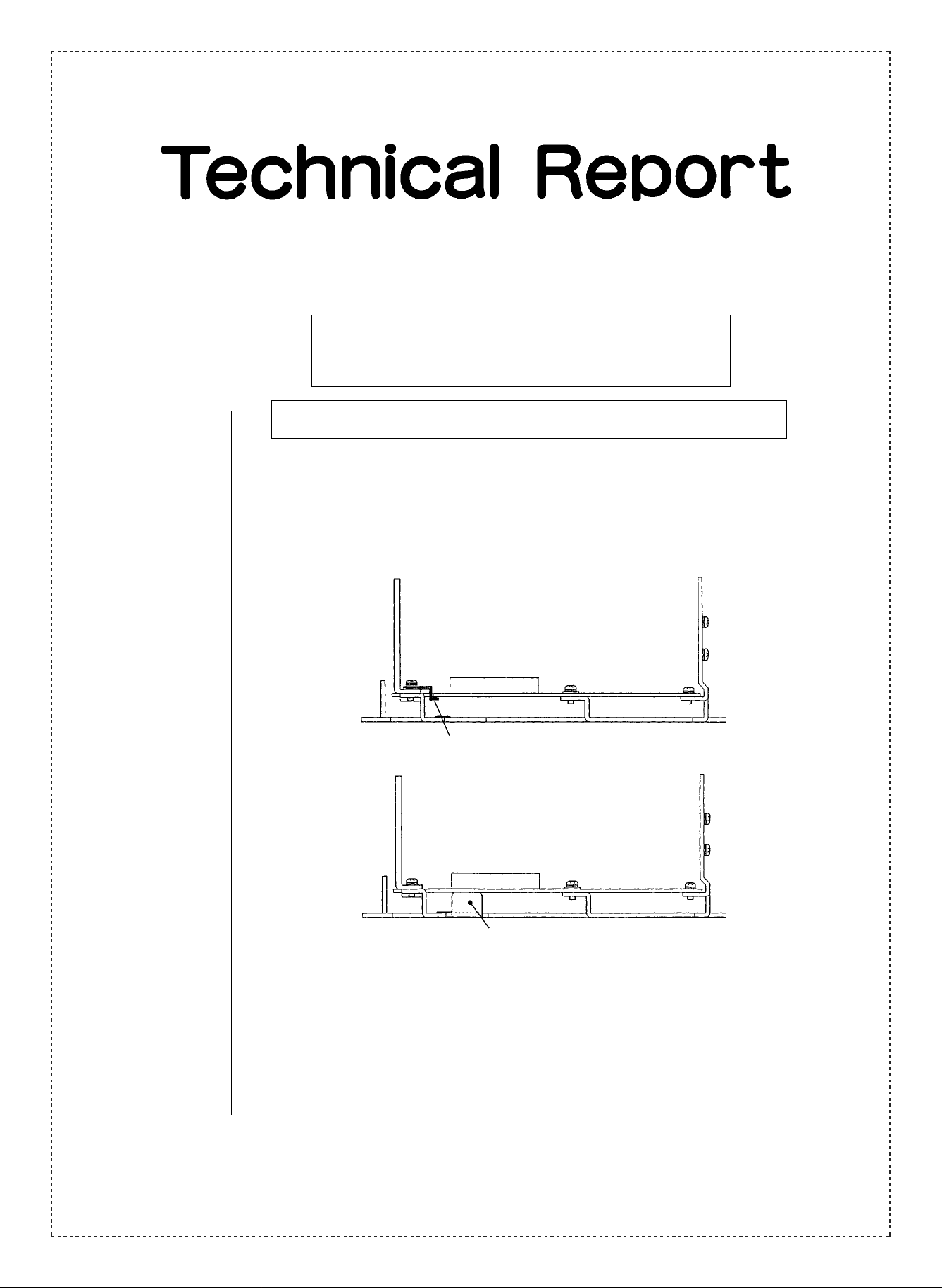

1. Measure to prevent cracking when the connector is connected in the DC power

supply PWB.

1.Model name: SF-2050

2.General: There is a danger of the DC power supply PWB cracking if the connector is inserted

strongly when connecting it. To alleviate this problem, a support has been added to the

lower side of the connector (CN702).

New machine (temporary measure).

Range of part packaging.

Connector CN702.

Added metal support for the PWB.

New machine (permanent measure).

Range of part packaging.

Connector CN702.

The metal pattern for the chassis has been changed, and a bent section has

been added to support the PWB.

3.Action: Temporary measure: From the start of 1995 May production to 1995 September

production.

Permanent measure: 100 V series: From the start of 1995 October production.

200 V series: Running change from 1995 mid-November production.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

2. Addition of a 4/5 lock sheet.

1.Model name: SF-2050

2.General: A 4/5 mirror lock sheet has been added as illustrated in the figure shown below, making

it easier to remove the 4/5 mirror lock screw. This change have been carried out as an

improvement measure to increase operationability during the installation of the machine.

4-5 mirror lock screw

4-5 lock sheet

3.Action: From the start of 1995 May production.

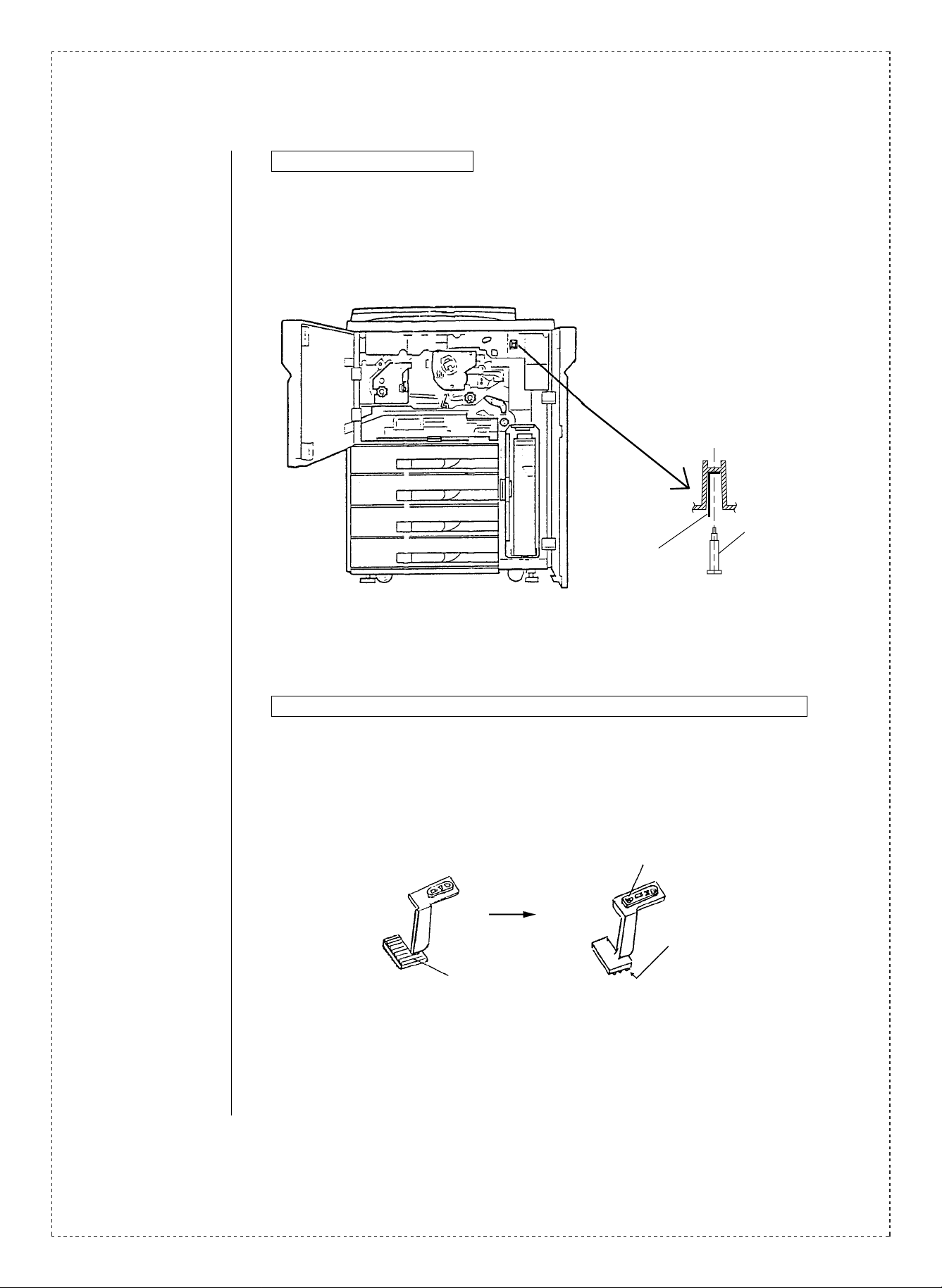

3. Improvement measure to strengthen the upper pawl lever of the fusing upper unit.

1.Model name: SF-2050

2.General: The marginal strength which was allotted the upper pawl lever of the fusing upper unit

was insufficient, and to alleviate this problem and strengthen the upper pawl lever a

change was carried out in the shape of the lever as illustrated in the figure shown below.

Strengthened section.

Three (3) ribs.

Old

Knurling.

New

3.Action: From the start of 1995 August production.

2/4

Page 3

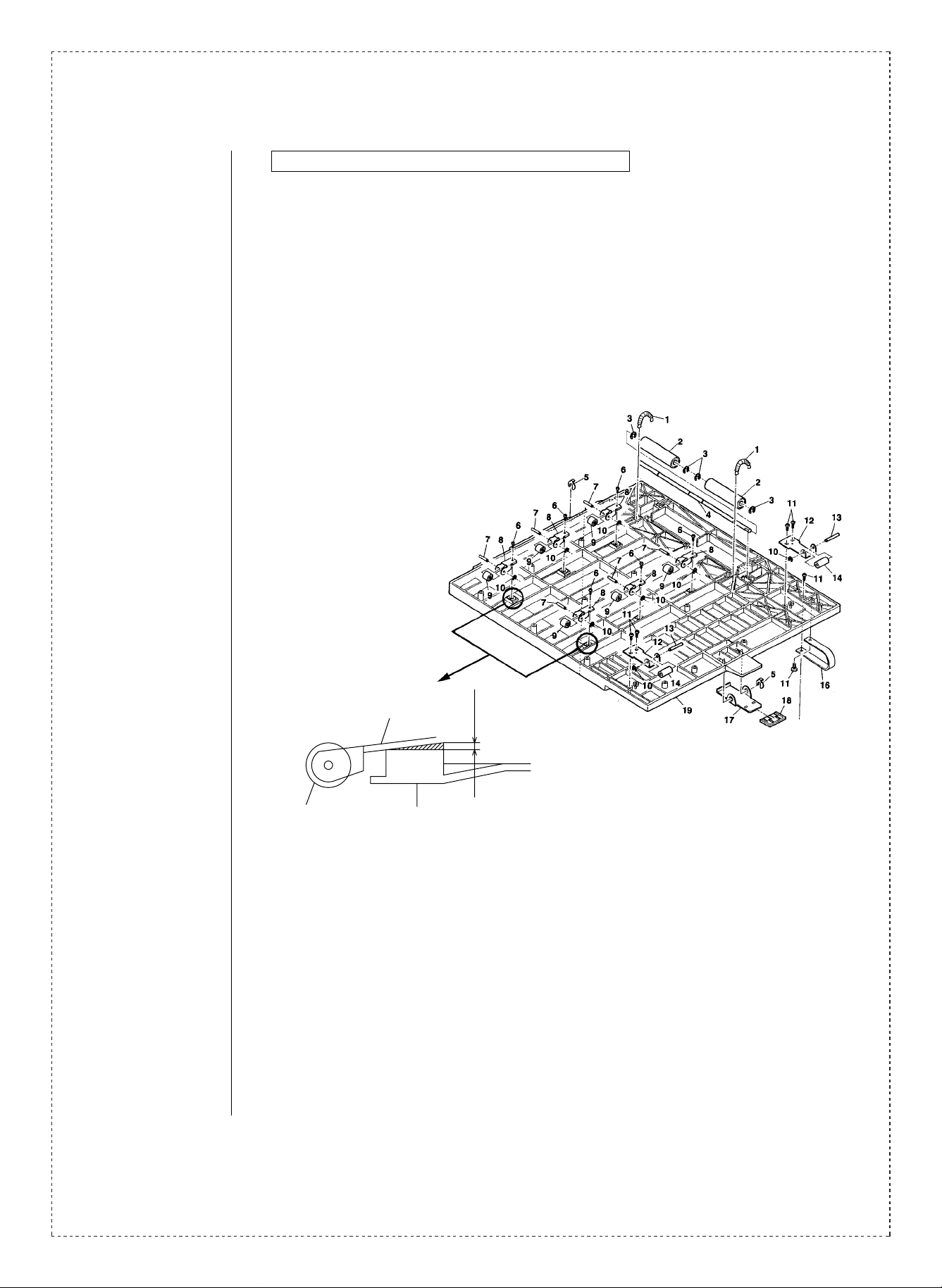

4. Measure to prevent diagonal feeding in the ADU unit.

1.Model name: SF-2050

2.General: There was a possibility of diagonal feeding of B5, A4, and other sizes of copy paper

with short lengths in the ADU unit, due to weak pressure of the drive roller in the ADU

unit transport section. To alleviate this problem, the measure described below were

carried out.

3.Description: As illustrated in the figure shown below, a change was carried out in the shape of the

transport paper guide to increase the pressure of the drive roller, thereby eliminating the

cause of the diagonal feeding.

Plate spring

0.7±0.1

Drive roller

A taper has been added to the installment section of the

drive roller to increase the drive roller pressure.

Transport paper guide

4.Action: From the start of 1995 November production.

3/4

Page 4

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

13 -23

100V

series

1

SF-2050

2

3

4

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

sp eci fi e d on es fo r m ai n ta in i ng t he s a fe ty an d pe rf o rma nc e o f th e s et .

56 -901

13 -23

200V

series

56 -901

48 — PSHEP4051FCZZ AC 4/5 Lock sheet

All

16 -48 MLEVP0684FCZZ MLEVP0684FCZ1 AE Upper pawl lever

39 -19 PGIDM1590FCZZ PGIDM1590FCZ1 BC

!

CPWBN1124FC31 CPWBN1124FC32 CD

DC power

supply PWB

CPWBN1125FC31 CPWBN1125FC32 CE

Transport paper

guide

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

1st lot

’95/10

See

text

1st lot

’95/5

1st lot

’95/8

1st lot

’95/11

1

—

3

4/4

Loading...

Loading...