Page 1

Date: Nov. 30, 1995

COPIER : SF-2116

1. MEASURE TO PREVENT U2 TROUBLE.

2. MEASURE TO PREVENT THE CLUTCH IN THE MANUAL MULTI PAPER FEEDING UNIT

FROM SLIPPING.

3. MEASURE TO PREVENT THE CORNERS OF THE LEADING EDGE OF THE COPY PAPER

FROM FOLDING.

4. MEASURE TO PREVENT PRINTING MIS-COPIES (WASHED-OUT COPIES) DUE TO

MOISTUR E ABS O RBANCE OF TH E CO PY PAPER.

No. : SP-1972

1. Measure to prevent U2 trouble.

1.Model name: SF-2116/ 2118/1016/1018

2.General: The IC (ROM) in the main PWB was changed to version 2.5 from the start of 1995 July

production, but there was a possibility of U2 trouble occurring due to the extremely rare

conditions described below. To alleviate this problem, a change was carried out on the

software, and version 2.5 was changed to version 2.6.

There was a possibility of U2 trouble occurring when the power supply of the machine

was turned off immediately after delivery of the last copy during multi copy operations,

and then turned back on again. This problem occurred as a result of a particular timing

between the delivery of the last copy and the turning off of the power supply of the

machine, and as a result, there is basically no problem during normal operations.

The ROM label shown below has been used with a portion of the August production lot

of model SF-2118, but the ROM version is the same, version 2.6.

SWALLOW

Main V2.5

Green

3.Action: From the start of 1995 August production.

2. Measure to prevent the clutch in the manual multi paper feeding unit from slipping.

1.Model name: SF-MF15

2.General: Slipping sometimes occurred in the one-way clutch in the manual multi paper feeding

unit. This problem was considered to be a result of the diameter of the manual paper

feeding bearing being a little too small. To alleviate this problem, a change was carried

out on the tolerance of the diameter of the bearing.

Old New

φ5 → φ5

-002

-007

0

-003

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

3.Action: From the start of 1995 October production.

3. Measure to prevent the corners of the leading edge of the copy paper from folding.

1.Model name: SD-21 16/21 18/ 1016/1018

2.General: There is a possibility of the corners of the leading edge of the copy paper folding when

thin copy paper for use in the Japanese domestic market is used in machines with a

sorter installed. To alleviate this problem, the measure described below has been

carried out.

3.Description: A change has been carried out in the material used in the discharge brush of the fusing

unit, and the pressure of the brush has been lessened (softened).

4.Action: Running change from 1995 mid-September production.

4. Measure to prevent printing mis-copies(washed-out copies)due to moisture

absorbance of the copy paper.

1.Model name: SF-2116/ 2118/1016/1018

2.General: The resistance of the rubber of the PS lower roller is low and the electrical charge

during printing operations is transferred through the PS roller from the copy paper to

GND. When copy paper that has absorbed moisture is used, printing mis-copies

occurs (washed out copies). To alleviate this problem, the measure described below

has been carried out.

3.Description: The rubber of the PS roller has been changed to one with a higher resistance.

In accordance with the change described above, the parts code for the PS lower roller

has also been changed, and the old and new parts can be distinguished apart by the

method described below.

Method of distinguishing between the old and new parts:

Temporary: Black marking on the end of the bearings.

Permanent: A center hole has been added to the end of the bearings

(toward the front of the machine).

2/3

Center hole

Page 3

4.Action: ∗ UK → From 1995 mid-September production.

For machines bound for agencies → From 1995 mid-October production.

For machines bound for destinations other than those listed above → Running

change in accordance with consumption of stock.

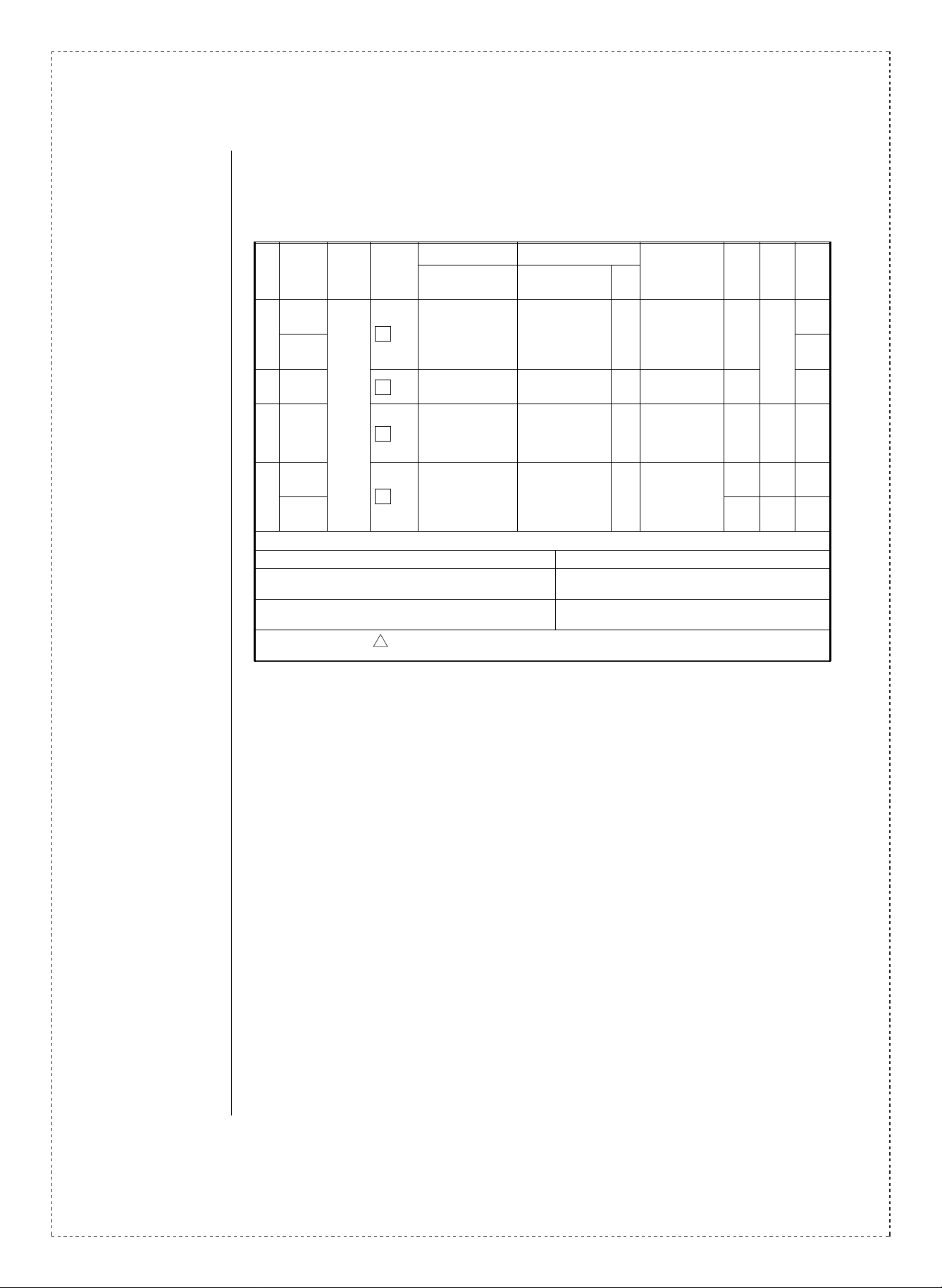

Ref.

Model

No.

SF-2116

SF-2118

1

SF-1016

SF-1018

2 SF-MF15

SF-2116

SF-2118

3

SF-1016

SF-1018

SF-2116

SF-2118

4

SF-1016

SF-1018

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied ones fo r m ain taining t he s a fe ty and performa nc e o f the set .

name

Version P/G No.

29 -54 VHI27C01060FC VHI27C01061FC AY IC [IC7]

35 -11 NSFTZ2183FCZZ NSFTZ2183FCZ1 AM

All

16 -14 PBRSR0140FCZZ PBRSR0140FCZ1 AH Discharge brush

19 -10 NROLR1055FCZZ NROLR1055FCZ1 AY PS roller lower

!

Current parts New parts

Parts code Parts code

5. Interchangeable if replaced with same types of

6. Others .

Price

relate d parts in use .

Parts name

rank

Manual paper

feeding shaft

Effec-

tive

time

Mid-

’95/8

1st lot

’95/10

See

text

∗

Mid-

’95/10

Inter-

change-

ability

3

1 Q’ty: 2

Note

3/3

Loading...

Loading...