Page 1

Date: Nov. 15, 1995

DUPLICATOR/COPIER :SD-2050/SF-2050

[Service Information]

No. : SP-1970

SERV ICE MANUAL CORRECTIONS.

1.Model name: SD-2050/SF-2050.

2.General: Errors have been found in the service manual and circuit diagrams for the models listed

above, and are hereby reported.

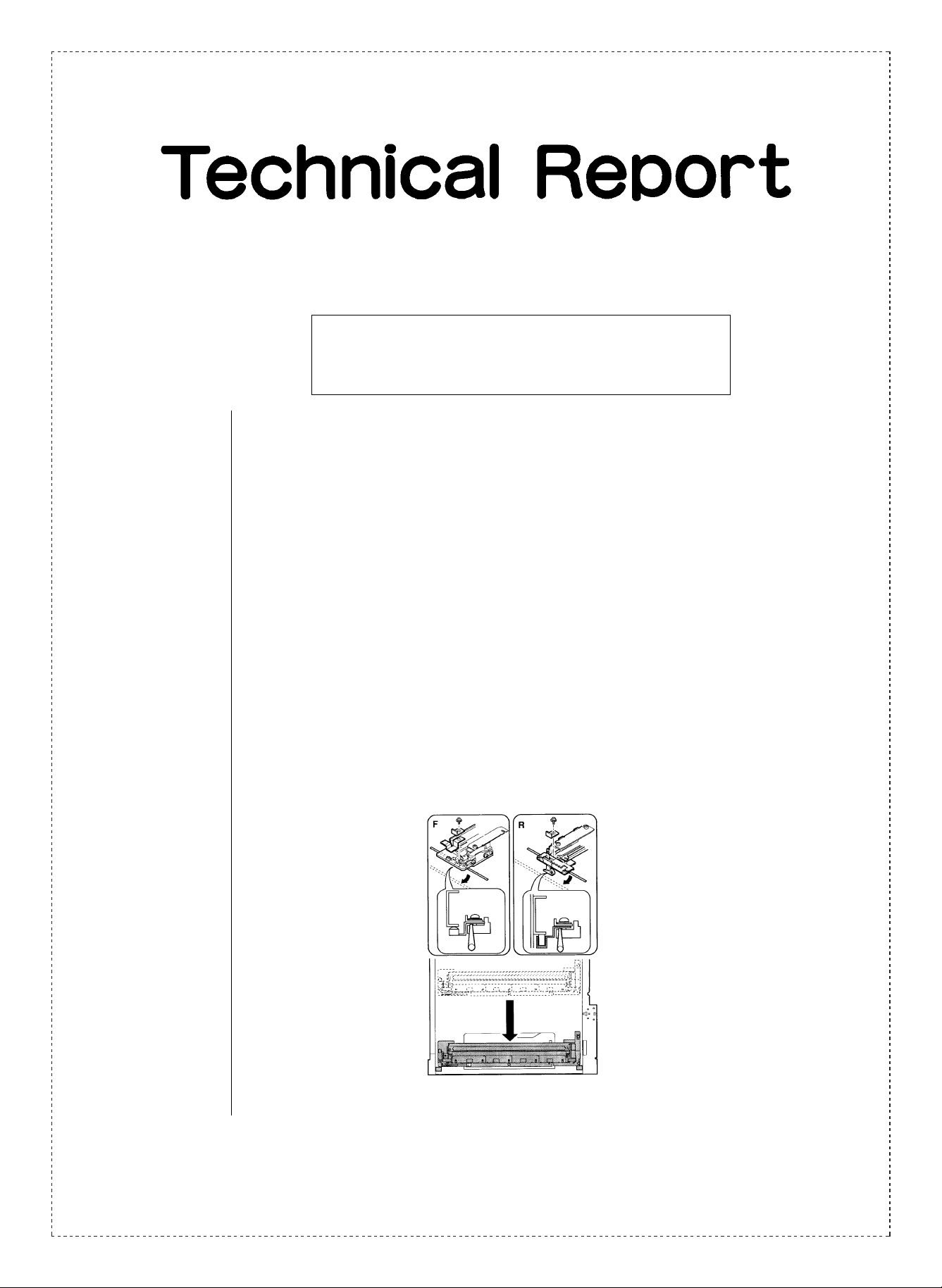

3.Description: 1. There was an error in the content concerning the installating position of the copy lamp

which is listed in Service Manual No. 1 on page 7-13. The error has been corrected as

shown below. (Note: The underlined section(s) are the section(s) that have been

corrected.)

Mirror base wire stretching

Refer to “[8] ADJUSTMENTS.”

Copy lamp unit installing position

➀ Pass the front/rear mirror base drive wire between the copy lamp unit frame and the

wire fixing plate.

At this time, do not tighten the wire fixing screw.

➁ Press the copy lamp unit onto the positioning plate, and tighten the wire fixing screw .

SHARP CORPORATION Reprography Division

1/7

Green

C

Page 2

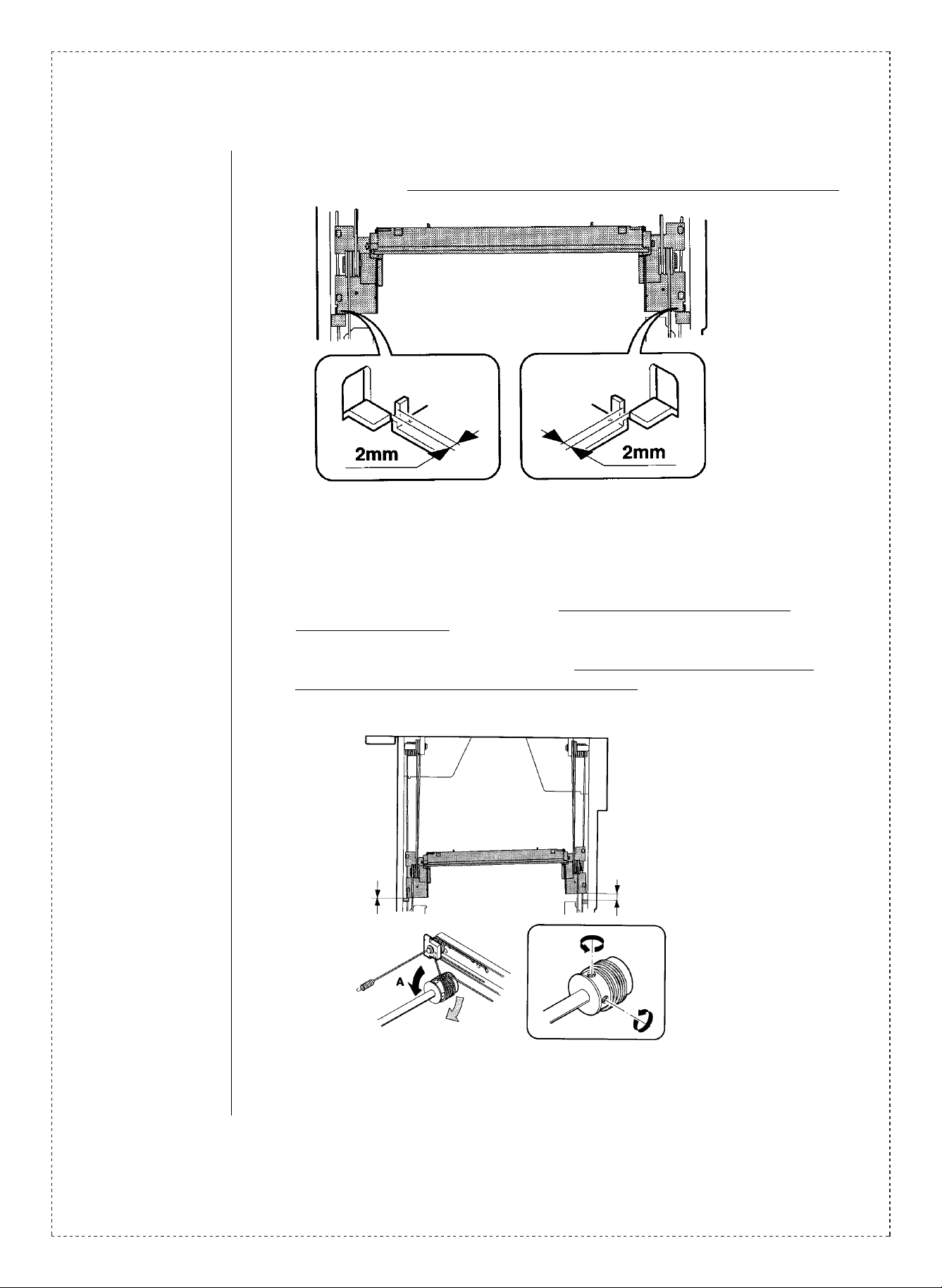

∗ Allow a clearance of 2 mm between the No. 2/3 mirror base unit and the optical

section projection when the copy lamp unit is pressed onto the optical section projection.

No.2/3 mirror base unit installing position

This is to adjust the parallelism of mirror base B and the drum surface and the original

surface.

➀ Manually turn the mirror base drive pulley, and press the copy lamp unit onto the

optical section projection. If the clearance between mirror base B and the rear frame is

2 mm in the front frame side and in the rear frame side, parallelism of mirror base B is

proper and no further adjustment is required. If not, loosen the pulley fixing screw as

shown below, and move the pulley to adjust parallelism.

2/7

Page 3

2. There was an error in the content concerning the entry, “(6) Inputting the scaling

interval move correction value”, which is listed in Service Manual No. 1 on page 8-11.

The error has been corrected as shown below. (Note: The underlined section(s) are the

section(s) that have been corrected.)

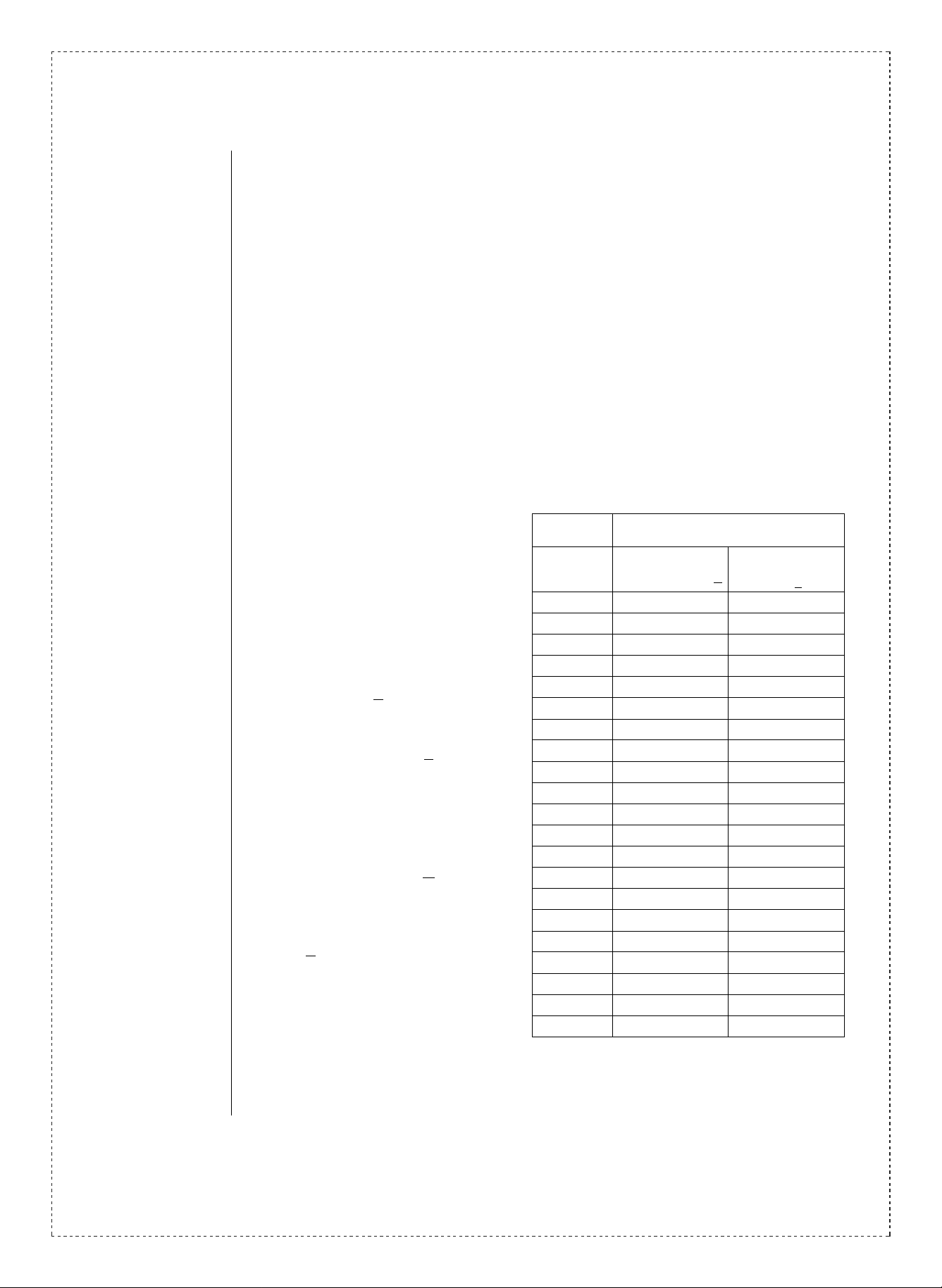

(6)Zoom shift correction value input

(Lens characteristics input)

Each lens has a variation in the focal distance, and the lens shift distance at zoom copy

must correspond to the lens focal distance.

If the lens shift distance at each zoom copy is fixed to a value regardless of the lens

focal distance, the coy magnification ratio will vary in proportion to the radiation in the

lens focal distance.

To prevent against the above trouble, the lens focal distance ranks (in the left table) are

stored in the memory by the simulation. When zoom copying, the lens shift distance is

calculated accordingly to the lens focal distance based on the data to obtain the proper

zoom ratio.

Comparison between the lens value and the

simulation input value

(When focusing or the

magnification ratio is not proper

in zoom copy)

1. When focusing or the

magnification ratio is not proper

in zoom copy, adjust as follows:

.

When focusing or the

magnification ratio of 50%

reduction is not proper, change

simulation 48-01B setting.

.

When the magnification ratio of

50% reduction is not proper,

change simulation 48-01E

setting.

2. When focusing or the

magnification ratio of 200%

enlargement is not proper:

.

When focusing is not proper,

change simulation 48-01C

setting.

.

When the magnification ratio is

not proper, change simulation

48-01F setting.

Lens display

value

O-L

-4.0 ~ -3.8 66 ~ 65 89 ~ 87

-3.8 ~ -3.4 65 ~ 63 87 ~ 83

-3.4 ~ -3.0 63 ~ 61 83 ~ 79

-3.0 ~ -2.6 61 ~ 59 79 ~ 75

-2.6 ~ -2.2 59 ~ 57 75 ~ 71

-2.2 ~ -1.8 57 ~ 55 71 ~ 67

-1.8 ~ -1.4 55 ~ 53 67 ~ 63

-1.4 ~ -1.0 53 ~ 51 63 ~ 59

-1.0 ~ -0.6 51 ~ 49 59 ~ 55

-0.6 ~ -0.2 49 ~ 47 55 ~ 51

-0.2 ~ +0.2 47 ~ 45 51 ~ 47

+0.2 ~ +0.6 45 ~ 43 47 ~ 43

+0.6 ~ +1.0 43 ~ 41 43 ~ 39

+1.0 ~ +1.4 41 ~ 39 39 ~ 35

+1.4 ~ +1.8 39 ~ 37 35 ~ 31

+1.8 ~ +2.2 37 ~ 35 31 ~ 27

+2.2 ~ +2.6 35 ~ 33 27 ~ 23

+2.6 ~ +3.0 33 ~ 31 23 ~ 19

+3.0 ~ +3.4 31 ~ 29 19 ~ 15

+3.4 ~ +3.8 29 ~ 27 15 ~ 11

+3.8 ~ +4.0 27 ~ 26 11 ~ 7

adjustment Sim. 48-01D

Cprrection reference value

No.4/5 mirror focus

Vertical magnification

ratio adjustment Sim.

48-01A

For Sim. 48-01B/C/E, use the P. No. attached to

the lens as the reference of the input value.

3/7

Page 4

3. There was an error in the content listed in Service Manual No. 1 on page 8-27. The

simulation number used for the position adjustments in the ADU unit, for the rear end

plate and the interface board was incorrect, and has been corrected as shown below.

(1) Position adjustment for the rear end plate:

simulation No. : SIM.52-01 (incorrect) → SIM.52-02 (corrected).

(2) Position adjustment for the interface board:

Simulation No. : SIM.52-02 (incorrect) → SIM.52-01 (corrected).

4. A change has been carried out in the content concerning the entry “9. Curl Correction

Unit Adjustments”, which is listed in Service Manual No. 1 on page 8-29. The curl

correction unit itself has been changed as of the first lot of production, and in

accordance with this change the adjustment procedures have also been changed, and

the content on page 8-29 of Service Manual No. 2 has been changed as shown below .

➀ Remove the curl correction unit from the main body.

➁ Loosen the fixing screw of the roller support plate.

➂ Insert the nip quantity adjustment jig(UKOG-0237FCZZ)between the curl roller and

the reverse roller, slide the roller support plate to adjust so that the nip quantity

becomes as shown below.(Adjust both on the front and rear sides.)

AB series in Japan and The lead tip of 5.6(AB) of the

outside Japan: nip quantity adjustment jig.

Inch series outside Japan: The lead tip of 5.8(IN)of the nip

quantity adjustment jig.

Roller support plate

Jig insertion point

Nip quantity adjustment jig

Parts code:UKOG-0237FCZZ

Price rank:BA

Reverse roller

Curl roller

Jig insertion point

4/7

Page 5

➃ When a curl is generated to cause folding, wrinkles, and a jam, adjust as follows:

∗1. In the case of upward curl on the ADU tray, reduce the interval between the curl

roller and the reverse roller by 0.2mm.

∗2. In the case of downward curl on the ADU tray, increase the interval between the curl

roller and the reverse roller by 0.2mm.

Destination ∗1 Normal ∗2

AB series in Japan and outside

Japan

Inch series outside Japan 5.6 5.8 6.0

5. The explanation chart for the JAM data corresponding to each LCD display of the

JAM counter display in Simulation 22-02.

Display Explanation

LCC LCC Feed Jam.

CAS1 Tray 1 Feed Jam.

CAS2 Tray 2 Feed Jam.

CAS3 Tray 3 Feed Jam.

CAS4 Tray 4 Feed Jam.

BYPASS Manual Tray Feed Jam.

ADU ADU Feed Jam.

PFD1 PFD1 Residual Jam.

PFD2 PFD2 Residual Jam.

PFD3 PFD3 Residual Jam.

PFD4 PFD4 Residual Jam.

DPFD DPFD Residual Jam.

PPD1 PPD1 Residual Jam.

PPD2 PPD2 Residual Jam.

PPD3 PPD3 Residual Jam.

PSD PSD Residual Jam.

POD POD Residual Jam.

DPID1 DPID1 Residual Jam.

DPID2 DPID2 Residual Jam.

PFDL2 PFDL2 Residual Jam.

DPPD1 DPPD1 Residual Jam.

DPPD2 DPPD2 Residual Jam.

DPPD3 DPPD3 Residual Jam.

SPID Sorter Paper Entry Jam.

SPOD Sorter Paper Discharge Jam.

OG_FD RADF Reserve Coppy Paper Jam.

OG_ST RADF Supply Jam.

EXT RADF Discharge Jam.

REV RADF Reverse Roller Jam.

5.4 5.6 5.8

5/7

Page 6

6. A part of the circuit diagram for the operations control PWB was not included in the

collection of circuit diagrams, and has been added.

6/7

Page 7

7/7

Loading...

Loading...