Page 1

Date: Nov. 10, 1995

COPIER : SF-2050

1. MEASURES TO PREVENT DOUBLE FEEDING IN THE MANUAL MULTI PAPER FEEDING UNIT.

2. TROUBLE SHOOTING ABNORMAL NOISE FROM THE LENS DRIVE PULLEY IN THE OPTICAL UNIT.

3. MEASURES TO IMPROVE FIXING PERFORMANCE.

4. MEASURES TO IMPROVE THE MEASUREMENT TOLERANCE OF THE PAPER FEEDING ROLLER

SHAFT IN THE ADU UNIT.

No. : SP-1955

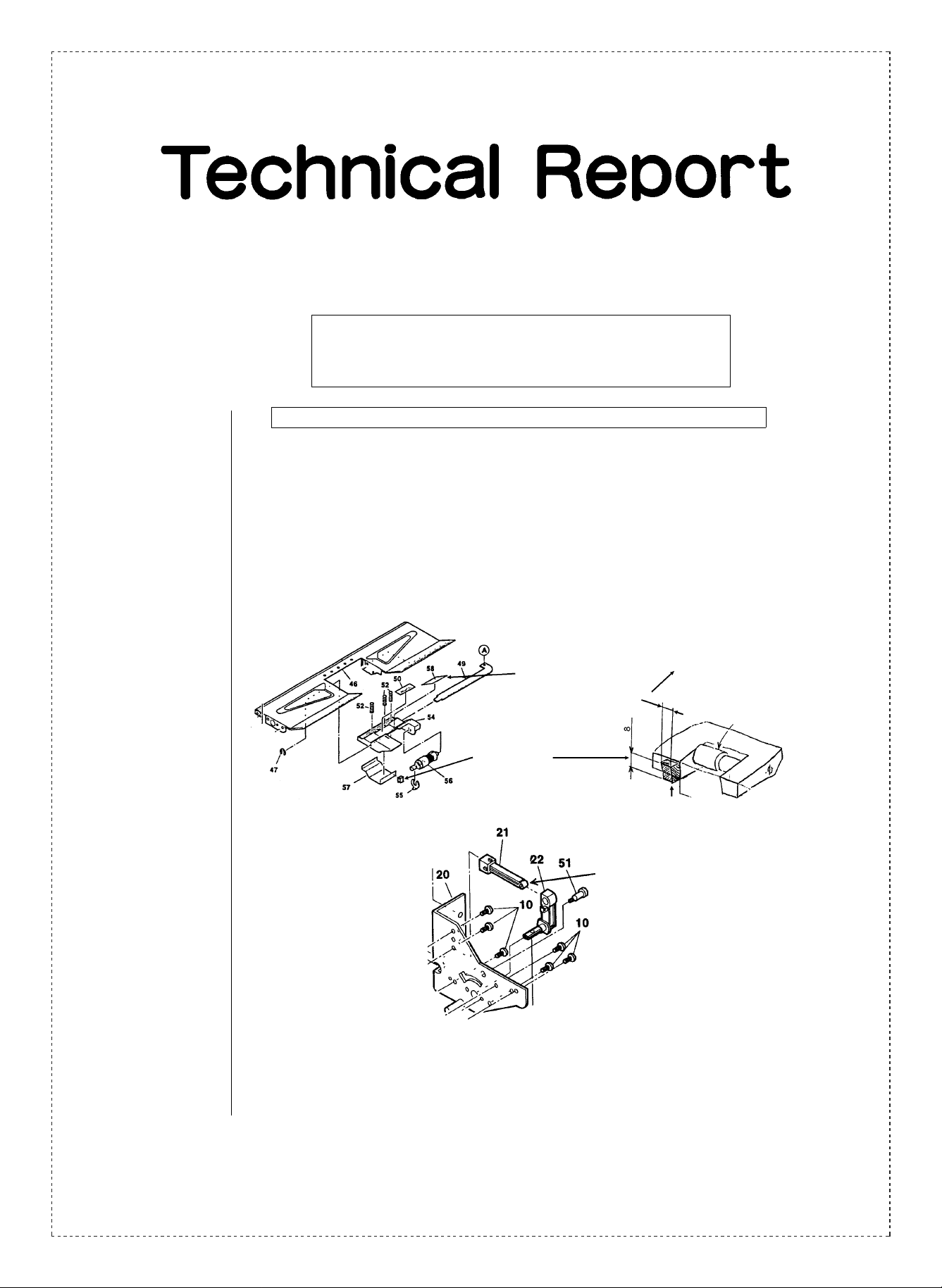

1. Measures to prevent double feeding in the manual multi paper feeding unit.

1.Model name: SF-2050.

2.General: The measures described below have been carried out to prevent problems of double

feeding in the manual multi paper feeding unit.

3.Description: The shape of the cushion material and the mylar of the delivery roller section has been

changed, and white grease has been applied to the pressure release lever.

Manual feed sheet

Sound proof

sheet

White grease has been

applied to the end

section of the pressure

release lever

Original 10 changed to 5

Delivery roller

4.Action: From the start of 1995 August production.

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

2. Trouble shooting abnormal noise from the lens drive pulley in the optical unit.

1.Model name: SF-2050.

2.General: Abnormal noise sometimes occurs when the lens moves to change position. This is

caused by the level difference between the lens drive wire and the lens drive pulley. To

alleviate this problem, the measures described below have been carried out.

3.Description: The maximum position of the lens drive pulley has been changed in order to lessen the

level difference between the lens drive wire and the lens drive pulley.

Note: The color of the lens drive pulley has been changed from black to white in order

to distinguish between the old and new units.

4.Action: From the start of 1995 June production.

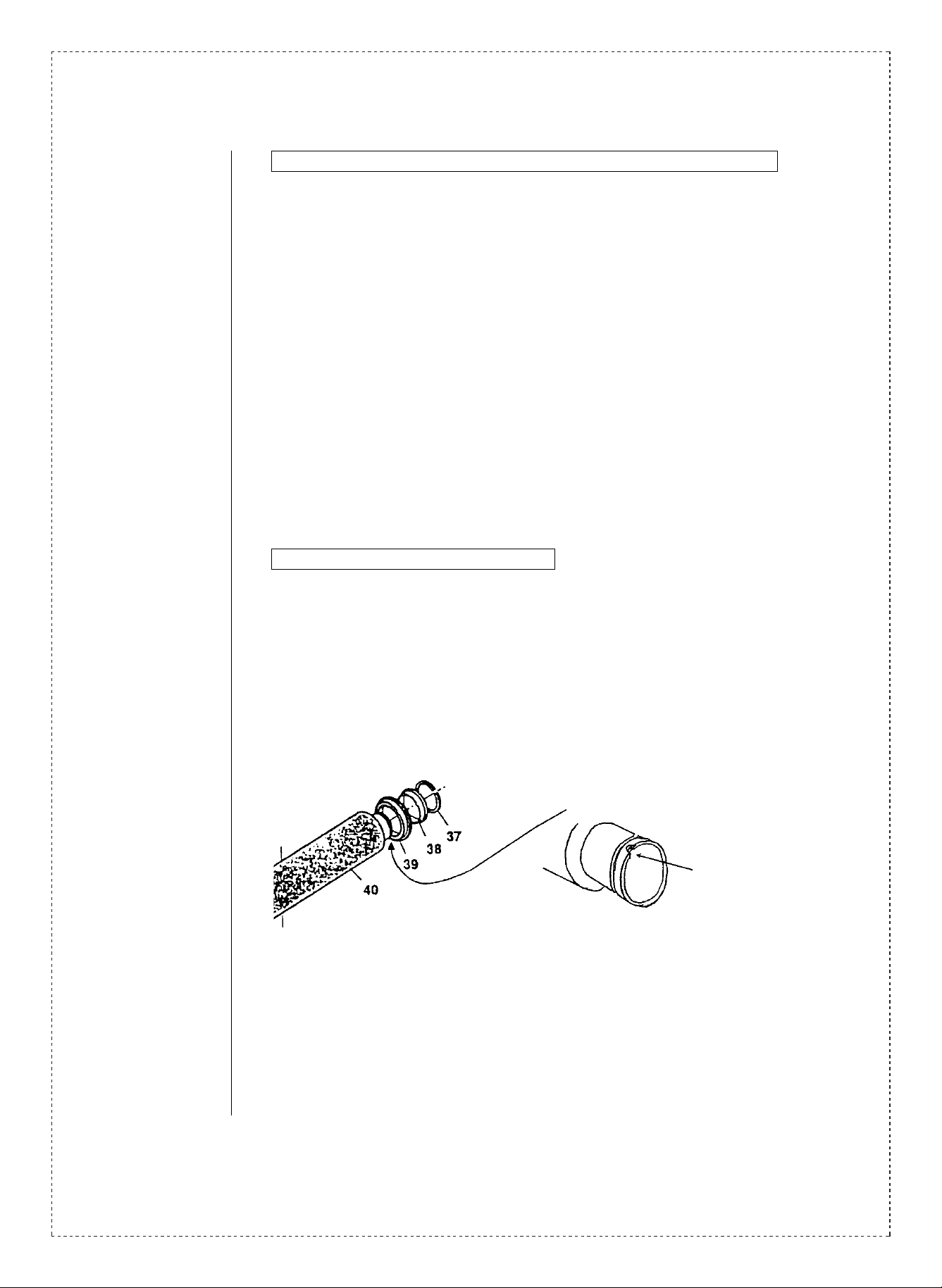

3. Measures to improve fixing performance.

1.Model name: SF-2050.

2.General: The coating thickness and surface roughness of the heat roller has been changed to

improve fixing performance.

The changes in shape described below have been carried out to distinguish the

modified part from old one.

Front side

End face of the heat roller

Added R2.5

Black marking

3.Action: From the start of 1995 August production.

2/3

Page 3

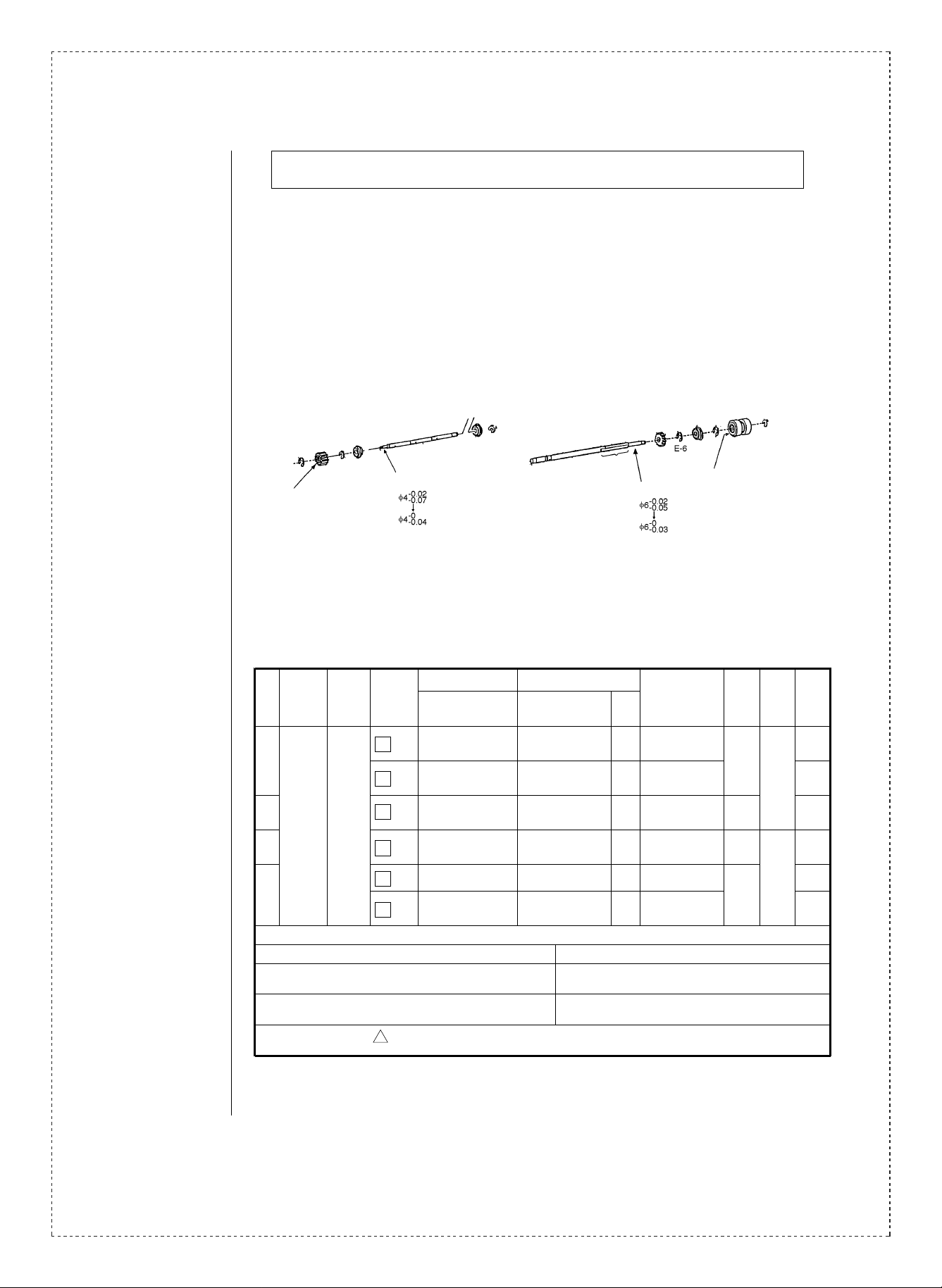

4.Measures to improve the measurement tolerance of the paper feeding roller shaft

in the ADU unit.

1.Model name: SF-2050.

2.General: Gear-16T and the ADU paper feeding roller are inserted in the roller shaft and paper

feeding roller shaft in the ADU unit, but the margin of clearance disappears when the

measurement tolerance conditions of either of them deteriorates. To alleviate this

problem, the measurement tolerance has been changed.

3.Description:

Bearing side.

Roller shaft

One-way clutch insertion section

One-way clutch insertion section

(One-way clutch)

4.Action: From the start of 1995 October production.

Ref.

Model

No.

1

2

SF-2050 All

3

4

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

s p eci fi e d on es fo r m ain ta in i ng t he s a fe ty an d pe rf o rma nc e o f th e s et .

name

Version P/G No.

45 -58 PSHEP3496FCZZ PSHEP4060FCZZ AC

45 PSHEZ3947FCZZ PSHEZ3947FCZ1 AA

7 -55

16 -40 NROLT1074FCZZ NROLT1074FCZ1 BQ Upper heat roller

38 -26 NSFTZ2189FCZZ NSFTZ2189FCZ1 AP Roller shaft

38 -30 NSFTZ2191FCZZ SNFTZ2191FCZ1 AU

!

Current parts New parts

Parts code Parts code

NPLYZ0262FCZZ NPLYZ0262FCZ1 AH Lens drive pulley

Paper feeding roller shaft

D cut section

Side printed with “NTN lock”

( one-woy clutch )

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

rank

Manual feed

sheet

Sound proof

sheet M

Paper feeding

roller shaft

Effec-

tive

time

1st lot

’95/8

1st lot

’95/6

1st lot

’95/8

1st lot

’95/10

Inter-

change-

ability

3

1

Note

3/3

Loading...

Loading...