Page 1

Date: Nov. 10, 1995

COPIER : SF-2050

1. MEASURES TO IMPROVE THE PERFORMANCE OF THE SEPARATOR PAWL OF THE PAPER EXIT

REVERSING UNIT.

2. IMPROVEMENT OF THE PERFORMANCE OF THE MAIN MOTOR BY INCREASING THE LOAD OF

THE DRIVE LINE.

3. MEASURES TO PREVENT ABNORMAL NOISE FROM THE PAPER DUST REMOVAL ROLLER.

4. MEASURES TO PREVENT JAMS IN THE CURL CORRECTION UNIT.

No. : SP-1954

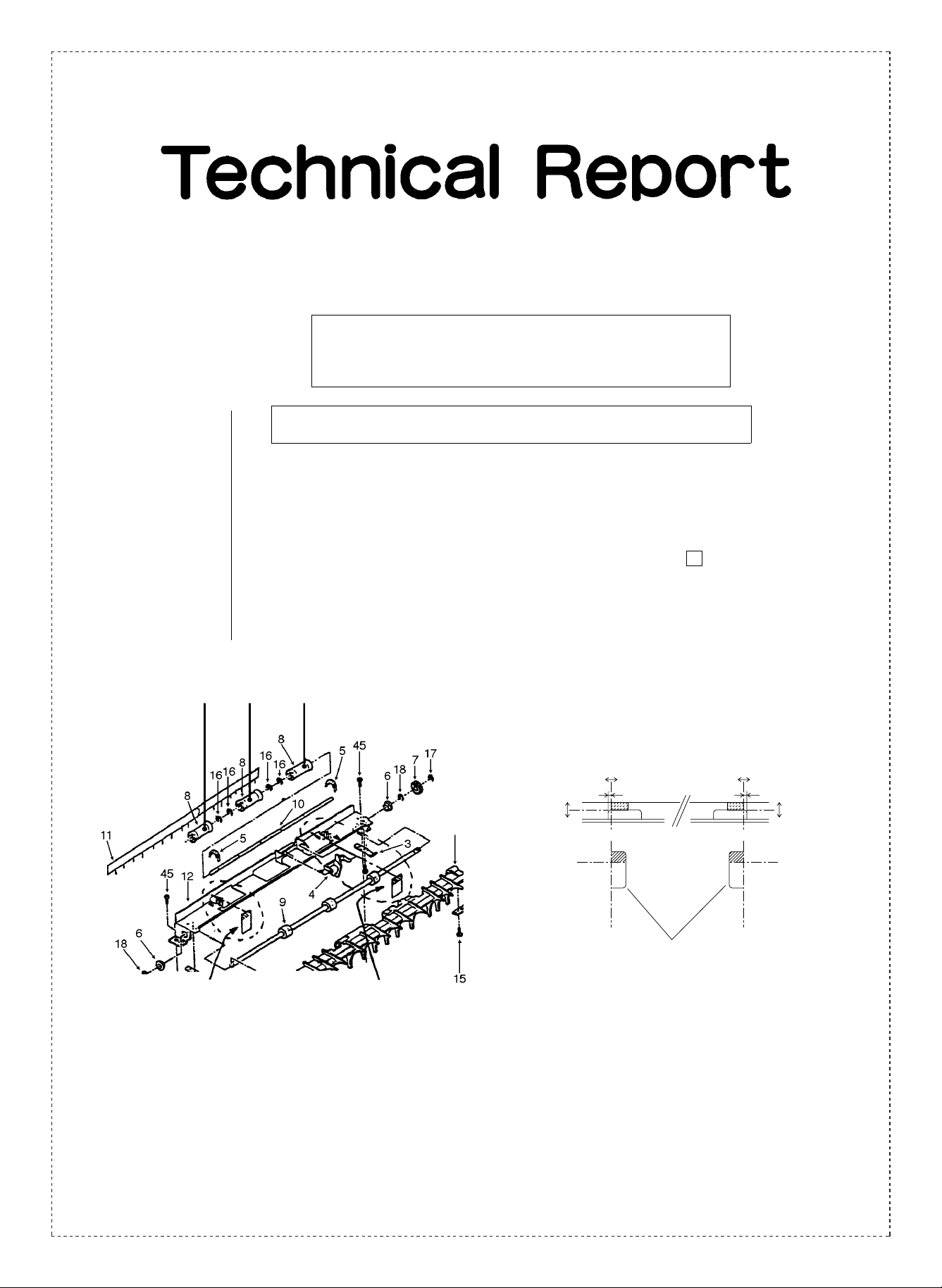

1. Measures to improve the performance of the separator pawl of the paper

exit reversing unit.

1.Model name: SF-2050.

2.General: A mylar and a sheet have been added to improve the paper flow performance in the

paper exit reversing unit.

Furthermore, the distinction of the upper paper delivery roller (P/G -1) which

20

previously had been divided into Japanese domestic use and Overseas use has been

simultaneously changed with the changed described above. The distinction of the upper

paper delivery roller is now divided into the AB line and the Inch line.

AB series

Paper delivery roller B9J (NROLP0937FCZ1)

Color:Black Q’ty: 3

Drop sheet Drop sheet

Standard Standard

1

±0.5

Standard Standard

Drop sheet

±0.5±0.5

1

StandardStandard

±0.5

StandardStandard

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

Inch series

Upper paper delivery roller (NROLP0923FCZZ)

Color:White Q’ty: 3

Drop mylar

3.Action: From the start of 1995 April production.

Standard

±0.5

Standard

±0.5

Standard

Standard

Drop mylar

2. Improvement of the performance of the main motor by increasing the load of

the drive line.

1.Model name: SF-2050.

2.General: There is a possibility of damage occurring to the IC in the main motor, caused by an

increase in the load of the drive line. To alleviate this problem, the prevention measure

described below has been carried out.

3.Description: The shape of the radiant heat plate of the main motor PWB has been changed.

Note: The change described above has been carried out from 1995 mid-September

production, but a temporary measure was carried out from the start of mass production,

which consisted of changing the shape of the radiant heat plate of the main motor PWB

in a later process.

4.Action: From 1995 mid-September production.

2/4

Page 3

3. Measures to prevent abnormal noise from the paper dust removal roller.

1.Model name: SF-2050.

2.General: Abnormal noise sometimes occurs from the paper dust removal roller in the fusing unit.

To alleviate this problem, the prevention measure described below has been carried out.

3.Description: A change in the dust removal roller unit has been carried out by attaching a scraper

tooth spacer between the fusing CL scraper and the roller movable bracket. This

change has been carried out to prevent abnormal noise from occurring.

Scraper spacer

Wide

Narrow

Roller movable bracket

Fusing CL scraper

Screw

4.Action: From the start of 1995 April production.

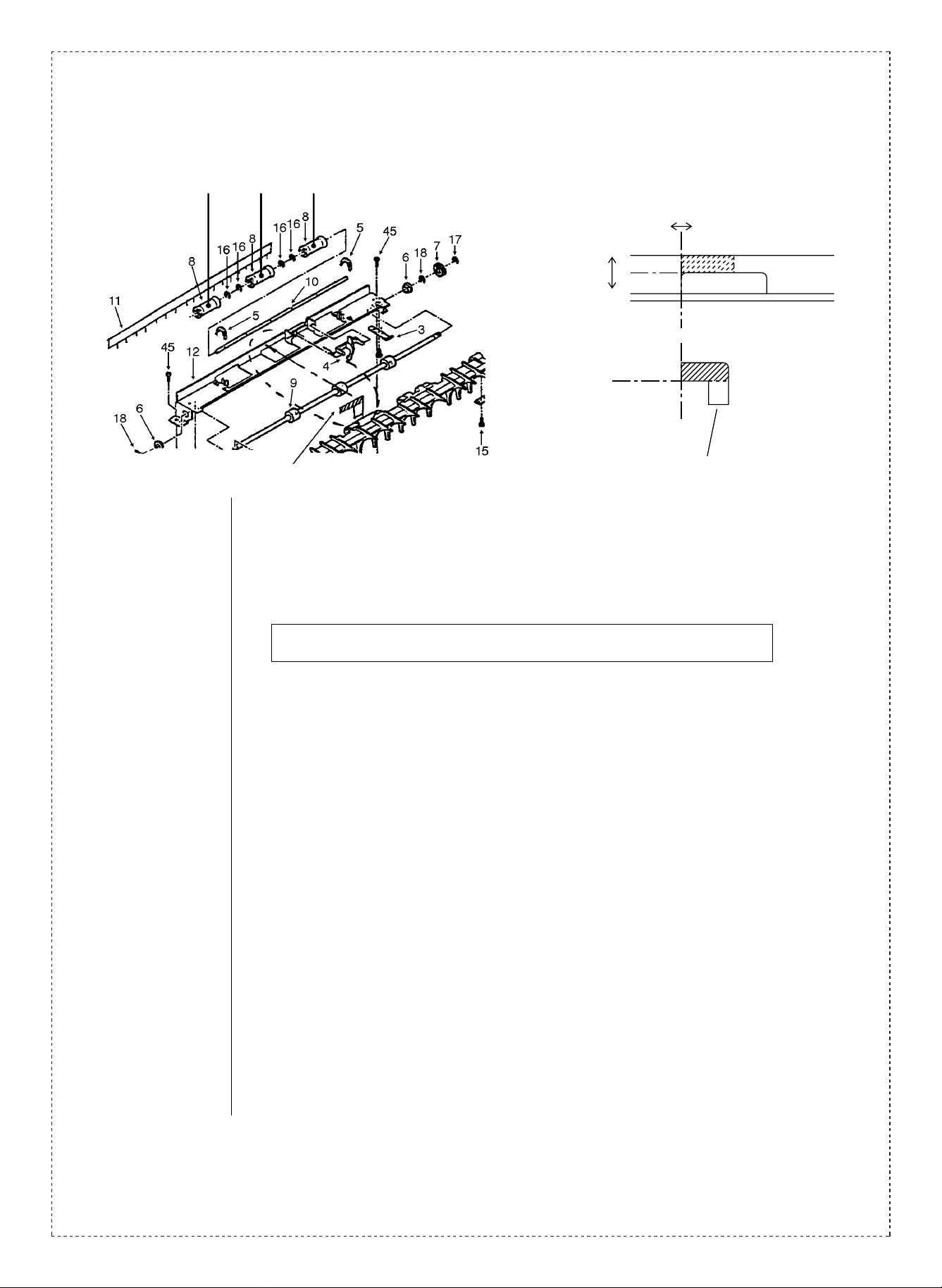

4. Measures to prevent jams in the curl correction unit.

1.Model name: SF-2050.

2.General: Jams sometimes occur in the curl correction unit at the location marked with an “x” in

the figure shown below. To alleviate this problem, the prevention measures described

below have been carried out.

3.Description: Temporary measures:

Temporary parts (curl plate spacers) have been attached to increase the distance

marked with an “A” in the figure shown below, to prevent jams from occurring.

Permanent measures:

To prevent jams from occurring, the distance marked with an “A” in the figure shown

below has been increased by changing the angle of the section in the upper reversing

PG marked with an “x” in the figure shown below. (In accordance with this change, the

temporary parts described above are no longer necessary.)

3/4

Page 4

Gate

Direction of

copy paper flow

×

Attached

temporary parts

Upper reverse PG

4.Action: Temporary measures → From 1995 mid-June production.

Permanent measures → From the start of 1995 September production.

Ref.

Model

No.

1

SF-2050

2

3

4

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

specifie d on es fo r m ain taining t he s a fe ty an d pe r fo rma nc e o f th e s et .

name

Version P/G No.

AB

series

20 —

Inch

series

AB

series

20 -1

Inch

series

13 -20 PMOTP0769FCZZ PMOTP0769FCZ1

17 CROLP1107FC31 CROLP1107FC32

All

27

!

Current parts New parts

Parts code Parts code

PSHEP3874FCZZ AB Drop sheet

PSHEP3928FCZZ

NROLP0937FCZ1

( For Japan)

NROLP0923FCZZ

(For overseas )

— PSPAZ0686FCZZ AG

PGIDH1618FCZZ PGIDH1618FCZ1 AR

NROLP0937FCZ1

(AB series )

NROLP0923FCZZ

(Inch series )

Price

rank

AC

BR

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

Drop mylar

Delivery roller

upper

Main motor N

Paper dust

removal roller

unit

Curl plate

spacers

Upper reverse

paper guide

Effec-

tive

time

1st lot

’95/4

1st lot

’95/9

1st lot

’95/4

Mid

’95/6

1st lot

’95/9

Inter-

change-

ability

6

3 Q’ty: 3

1

6 Qty: 2

3

Note

Q’ty: 2

4/4

Loading...

Loading...