Page 1

Date: Oct. 24, 1995

COPIER : SF-2014

No. : SP-1945

MEASURES TO PREVENT THE OCCURRENC E O F

ABNORM AL NOIS E IN THE FA N MOTOR (VFM).

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (only for machines bound for the USA).

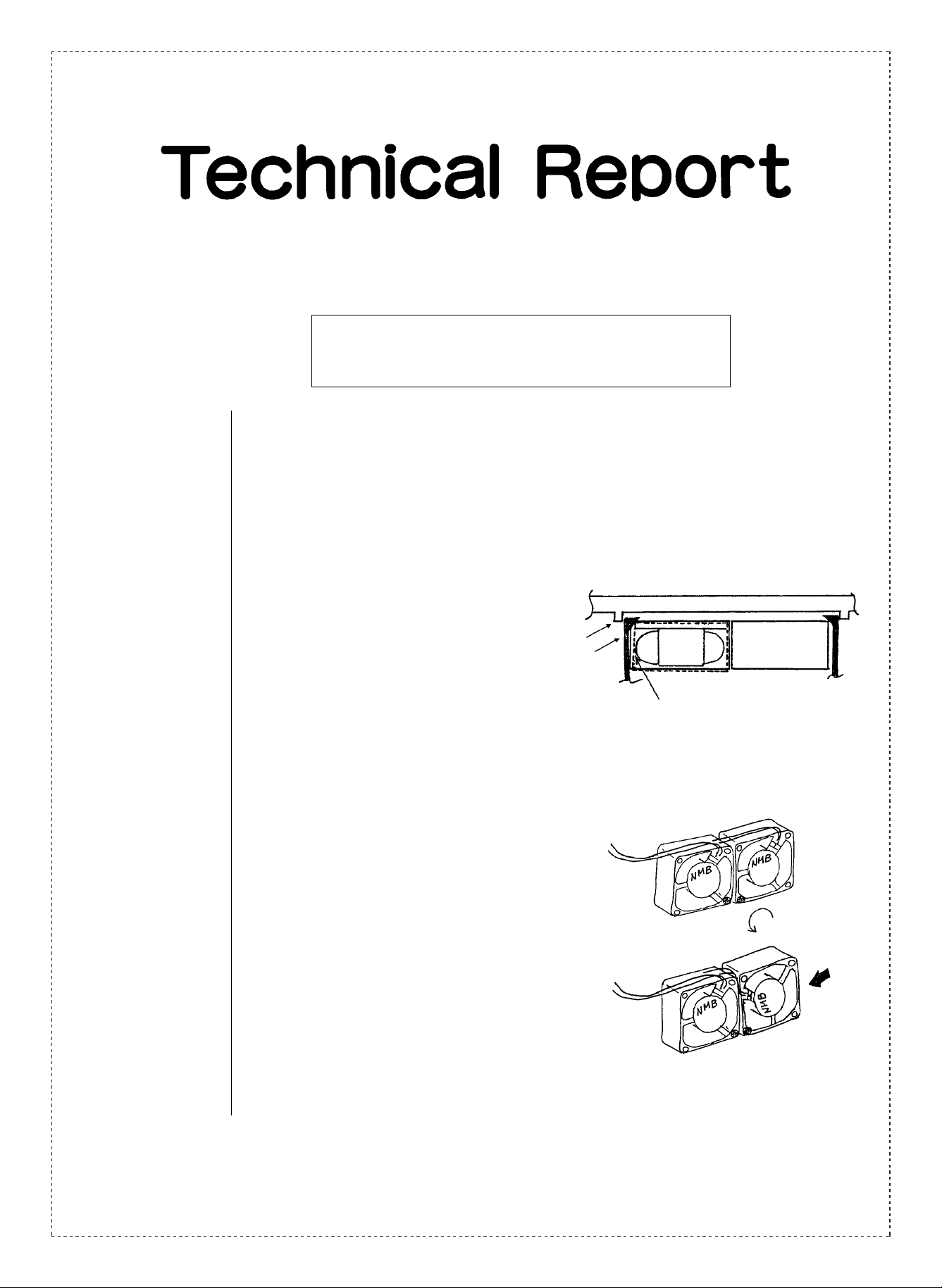

2.General: Cases have occurred where the blades of the exhaust fan motor (VFM) came in contact

with the fan casing, causing abnormal noise when the fan revolved. To alleviate this

problem, the measures described below have been carried out.

<Cause>

To prevent abnormal noise caused by vibrations

from the fan motor, the shape of the teeth which

secured the fan motor in place was changed, but

this change caused problems during the

attachment of the outer case of the machine,

when the teeth created excess pressure on the

casing causing it to become deformed, which

created the danger of the fan casing coming in contact with the blades of the fan motor,

causing abnormal noise.

3.Description: <Market action.>

Should the problem described above occur in a

machine already out on the market, the F side of the

VFM should be rotated 90° and fixed to the R side

when the screws are attached, as shown in the

figure to the right.

(The above measure, when carried out with pressure

applied in the directions indicated by the arrows, will

cause a decrease in the warping (deforming) of the

fan casing.)

Rib.

Pawl.

F Side.

R Side.

Upper left cabinet.

Section where contact

R side.

F Side.

Fan motors produced by a different maker are used

in machines bound for UK-SEEG. The strength of

the parts are greater than that of the machines in

which the problem described above occurred, and

as a result the measures described above are not necessary.

R Side.

SHARP CORPORATION Reprography Division

F Side.

1/3

Green

C

Page 2

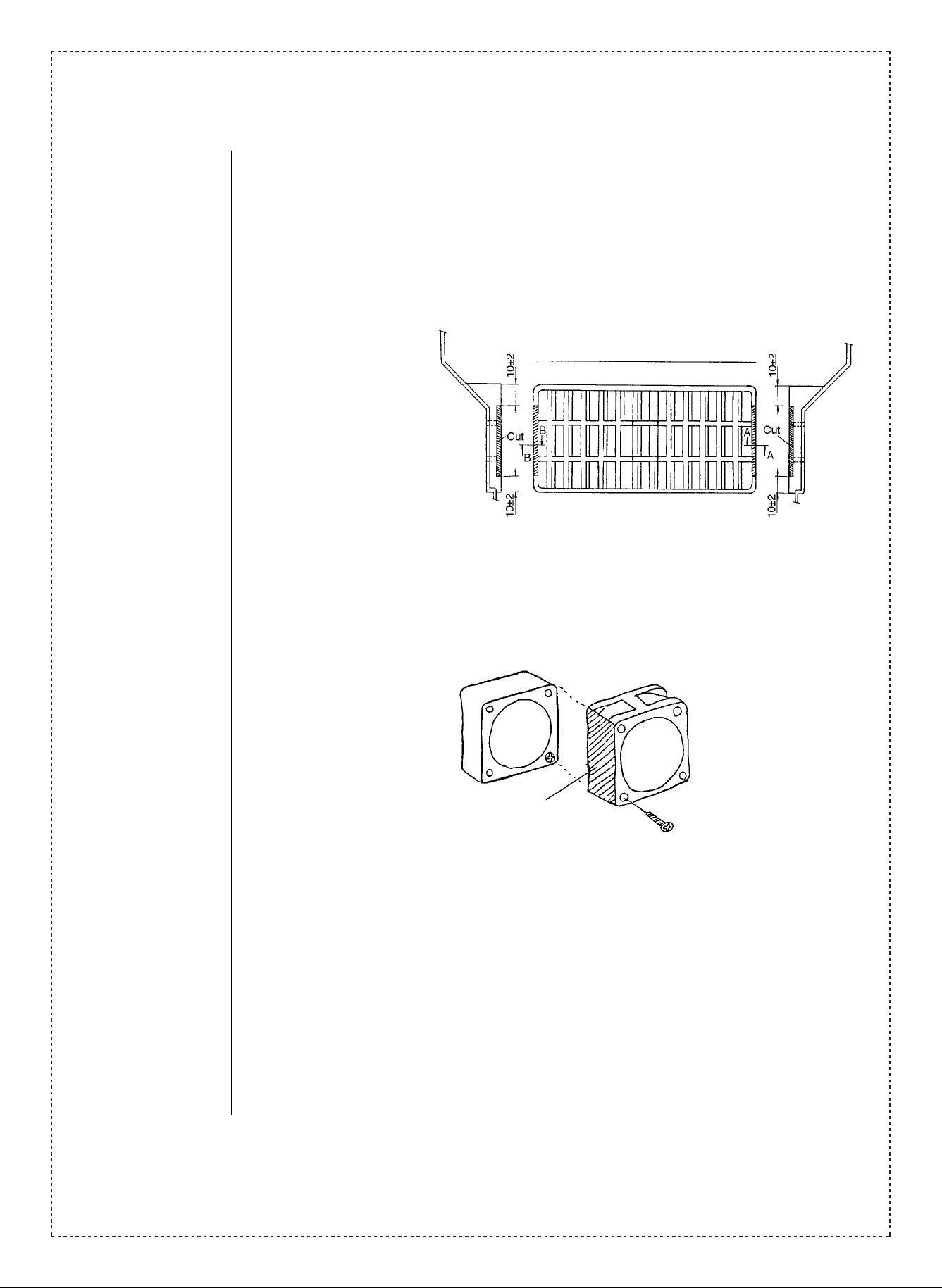

<Temporary and permanent measures.>

(1) The F side of the fan motor (VFM) has been rotated 90° (the same as the market

action described above).

(2) To prevent the fan motor (VFM) from becoming depressed, the rib in the upper left

cabinet has been cut after the production processes have been completed (This has

been accomplished by a change in the metal pattern as a permanent measure).

After the rib cut was

introduced as a

permanent measure (the

change in the metal

pattern), it is no longer

neces s a ry to ro tate the

fan motor (VFM) 90° as

described above, and

this action is no longer

carried out.

The section designated by the

diagonal lines has been cut.

Bottom right side.Bottom left side.

Note: Service parts in stock have had the rib cut already carried out, and therefore no

changes are necessary for the parts codes.

(3) A vibration prevention sheet has been added between the fan motors (VFM)

(to prevent abnormal noised caused by the vibrations).

R side

fan

Added vibration

prevention sheet.

F side

fan

Note: The measures described above were not necessary for machines bound for the

UK-SEEG, but measures <2> and <3> have been carried out anyway as general

improvement measures.

4.Action: ∗ For machines bound for destinations other than UK-SEEG → From 1995

mid-August production.

Only for machines bound for UK-SEEG → Running change.

2/3

Page 3

Ref.

Model

No.

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied on es fo r m ai n ta ini ng t he safe ty an d pe r fo rma nc e o f th e set.

name

Version P/G No.

5

All

only

4

5

!

U.S.A.

Current parts New parts

Parts code Parts code

— PSHEZ4077FCZZ AC

5. Interchangeable if replaced with same types of

6. Others .

Price

relate d parts in use .

Parts name

rank

Vibration

prevention sheet

Effec-

tive

time

∗ —

Inter-

change-

ability

Note

3/3

Loading...

Loading...