Page 1

Date: Oct. 9, 1995

COPIER : SF-2014

1. MEASURES TO PREVENT “Z” FOLDING OF THE COPY P APER DUE TO

TRANSPORT CLUTCH SKIPPING MALFUNCTIONS.

2. MEASURES TO PREVENT DEFORMING OF THE 4/5 MIRROR UNIT.

3. ADDITION OF A ADJUSTMENT SPACER IN THE 2/3 MIRROR UNIT.

4. CHANGE IN THE LED USED IN THE OPERATIONS PWB TO IMPROVE

PRODUCTIVITY.

1. Measures to prevent “Z” folding of the copy paper due to transport clutch skipping

malfunctions.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (only for machines bound for the USA).

No. : SP-1936

2.General: Cases where the lead wire of the transport clutch in the main drive unit got pinched by

the rear cabinet in a manner so that the clutch was pulled by the wire, which caused the

clutch to skip and malfunction, resulting in “z” folding of the copy paper. To alleviate this

problem, the following measures were carried out.

Main PWB.

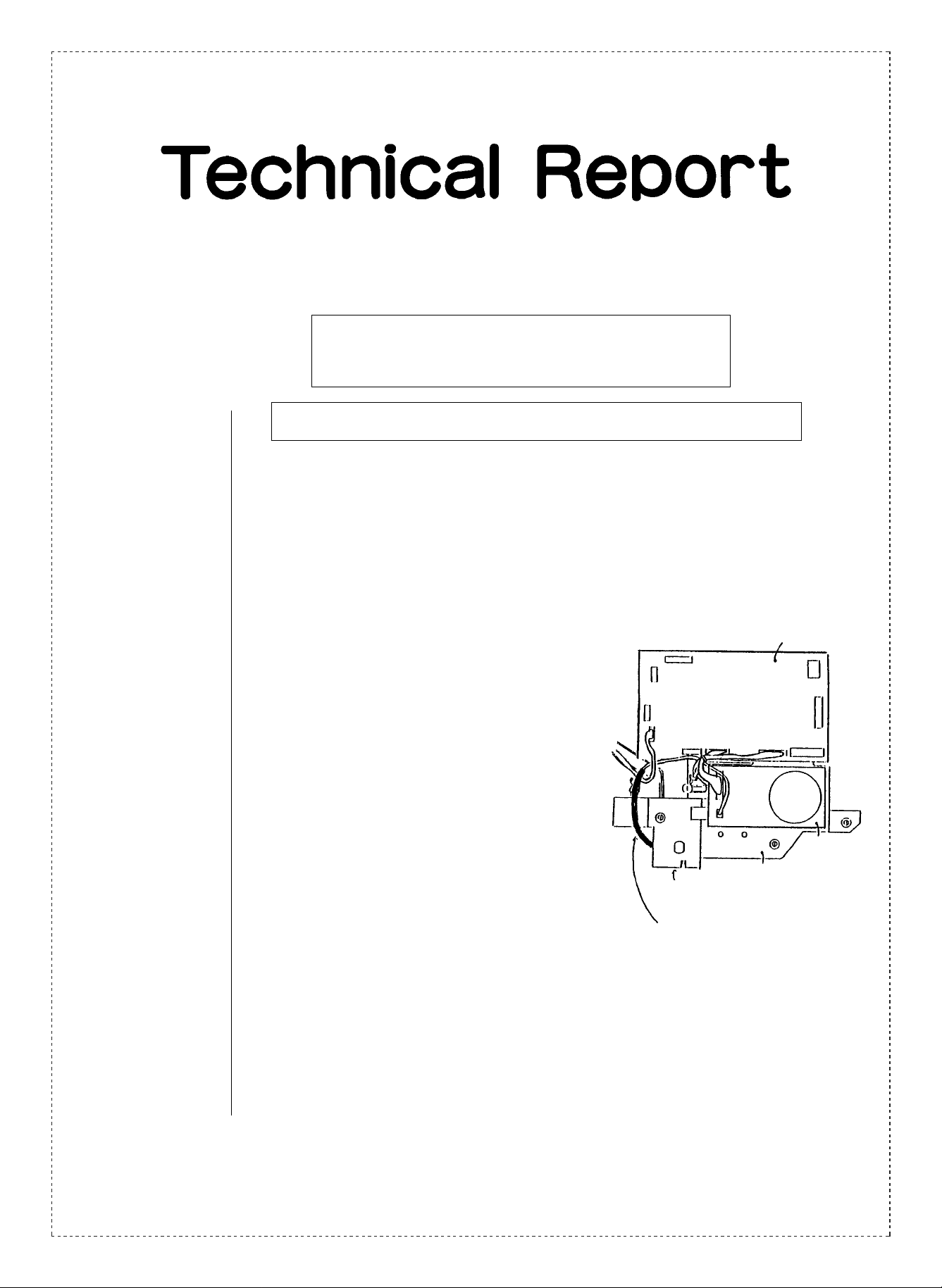

3.Description: The lead wire of the transport clutch was

lengthened, and rerouted to prevent it from

becoming pinched by the rear cabinet, as shown

in the figure shown to the right.

(Note: Until this measure was carried out, caution

had to be exercised after the rear cabinet was

attached so that the lead wire was not pinched.)

Drive unit.

Transport clutch.

(PCLC-0230FCZZ).

The lead wire of the transport

clutch has been lengthened and

rerouted around the outside of

the drive unit.

Main motor.

4.Action: ∗ Japanese production: From the start of 1995 September production.

Chinese (SOCC) production: From the start of 1995 October production.

Green

C

SHARP CORPORATION Reprography Division

1/4

Page 2

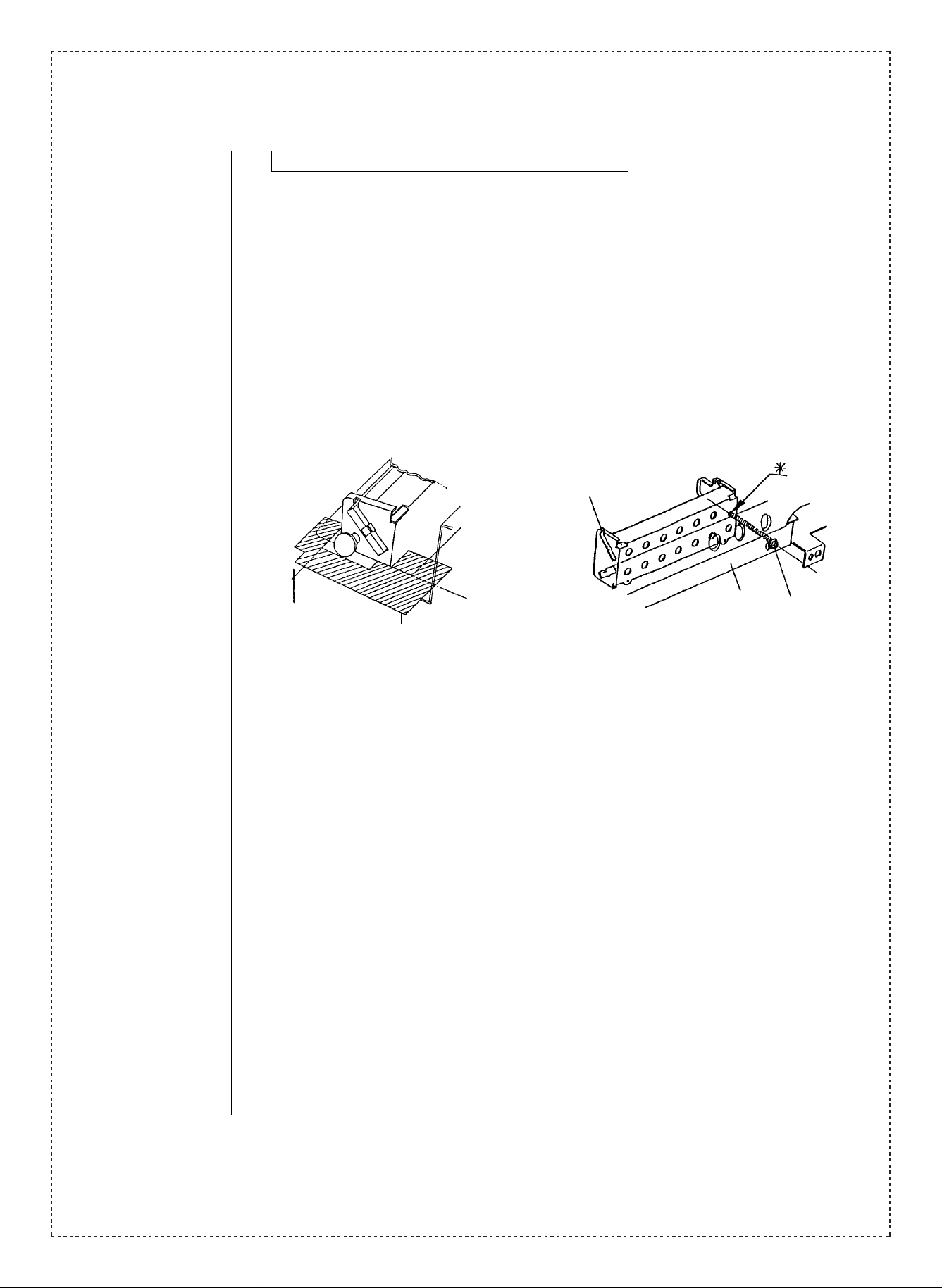

2. Measures to prevent deforming of the 4/5 mirror unit.

1.Model name: SF-2014

Z-800 (only for machines bound for the USA).

2.General: The following measures have been carried out to prevent the loosening of screws and

deforming of the 4/5 mirror unit caused by rough handling during shipping.

3.Description: (1) In order to prevent the 4/5 mirror unit from becoming deformed during shipping, a 4/5

mirror fixing mylar has been added (refer to fig. 1).

(2) In order to prevent the adjustment screws of the 4/5 mirror unit from become loose

the screw lock has been painted (refer to fig. 2).

4/5 Mirror unit.

Optical base plate.

M4 X 40 Sw.w screw.

(Fig. 2).

Attachment standard A.

(Fig. 1)

Attachment standard B.

4/5 Mirror unit fixing mylar

4.Action: ∗ (1) Japanese production: From the start of 1995 August production.

Chinese (SOCC) production: From the start of mass production.

French (SMF) production: From the start of mass production.

(2) Japanese production: From the start of 1995 July production.

Chinese (SOCC) production: From the start of 1995 July production.

French (SMF) production: From the start of 1995 October production.

2/4

Page 3

3. Addition of a adjustment spacer in the 2/3 mirror unit.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (only for machines bound for the USA).

2.General: A spacer has been added in the F side of the 2/3 mirror unit so that the angle can be

adjusted in order to facilitate adjustment of the optical axis.

Second mirror.

2/3 Mirror holder unit

Side F of the machine itself.

Third mirror spacer.

3.Action: From the start of mass production.

4. Change in the LED used in the operations PWB to improve productivity.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (only for machines bound for the USA).

2.General: The diode used in the operations PWB has been changed to one with a standard

diameter that is narrower than the one used previously. This change has been carried

out to improve operation efficiency.

Third mirror.Arrow diagram P.

3.Action: Japanese production: From the start of 1995 October production.

Chinese (SOCC) production: From the start of 1995 November production.

French (SMF) production: From the start of 1995 December production.

3/4

Page 4

Ref.

Model

No.

SF-2014

SF-2114

SF-2214

1

Z-800

SN-1420

SN-1430

SF-2014 All

2

Z-800

SF-2014

SF-2114

SF-2214

3

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

4

SF-2014

SF-2114

SF-2214

Z-800

SN-1420

SN-1430

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

sp eci fi e d on es fo r m ai n ta in i ng t he s a fe ty an d pe rf o rma nc e o f th e s et .

name

Version P/G No.

12 -11

All

only

only

All

only

All

only

All

only

11 -11

12 -11

7

5

7

5

6

21 -13

19 -13

20 -13

21 -14

19 -14

20 -14

!

U.S.A.

U.S.A.

U.S.A.

U.S.A.

U.S.A.

Current parts New parts

Parts code Parts code

PCLC-0230FCZZ PCLC-0230FCZ1 AZ Transport clutch

PSHEP3870FCZZ AE

—

PSHEZ4049FCZZ

VHPSLR-320MCA VHPSLR322MC3F

VHPSLR-320VCA VHPSLR322VC3F

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

rank

4/5 unit fixing

mylar

Third mirror

spacer

AC

LED

Effec-

tive

time

∗

1st lot

∗ 1

Inter-

change-

ability

1

6

Note

4/4

Page 5

Loading...

Loading...