Page 1

Date: Oct. 20, 1995

COPIER : SF-2014

1. TROUBLE SHOOTING UNCLEAR COPY IMAGES WHICH OCCUR WHILE USING THE SPF.

2. CHANGE IN IC USED IN THE MAIN PWB TO IMPROVE PRODUCTIVITY.

3. CHANGE IN DV LOWER GUIDE PLATE DUE TO IMPROPER PRESSURE WELDING OF THE

DEVELOPING UNIT.

4. CHANGE IN THE LENGTH OF THE LEAD WIRE OF THE PS CLUTCH IN THE SPF UNIT TO

IMPROVE PRODUCTIVITY.

No. : SP-1931

1. Trouble shooting unclear copy images which occur while using the SPF.

1.Model name: SF-2214

SN-1430 (only for machines bound for the USA)

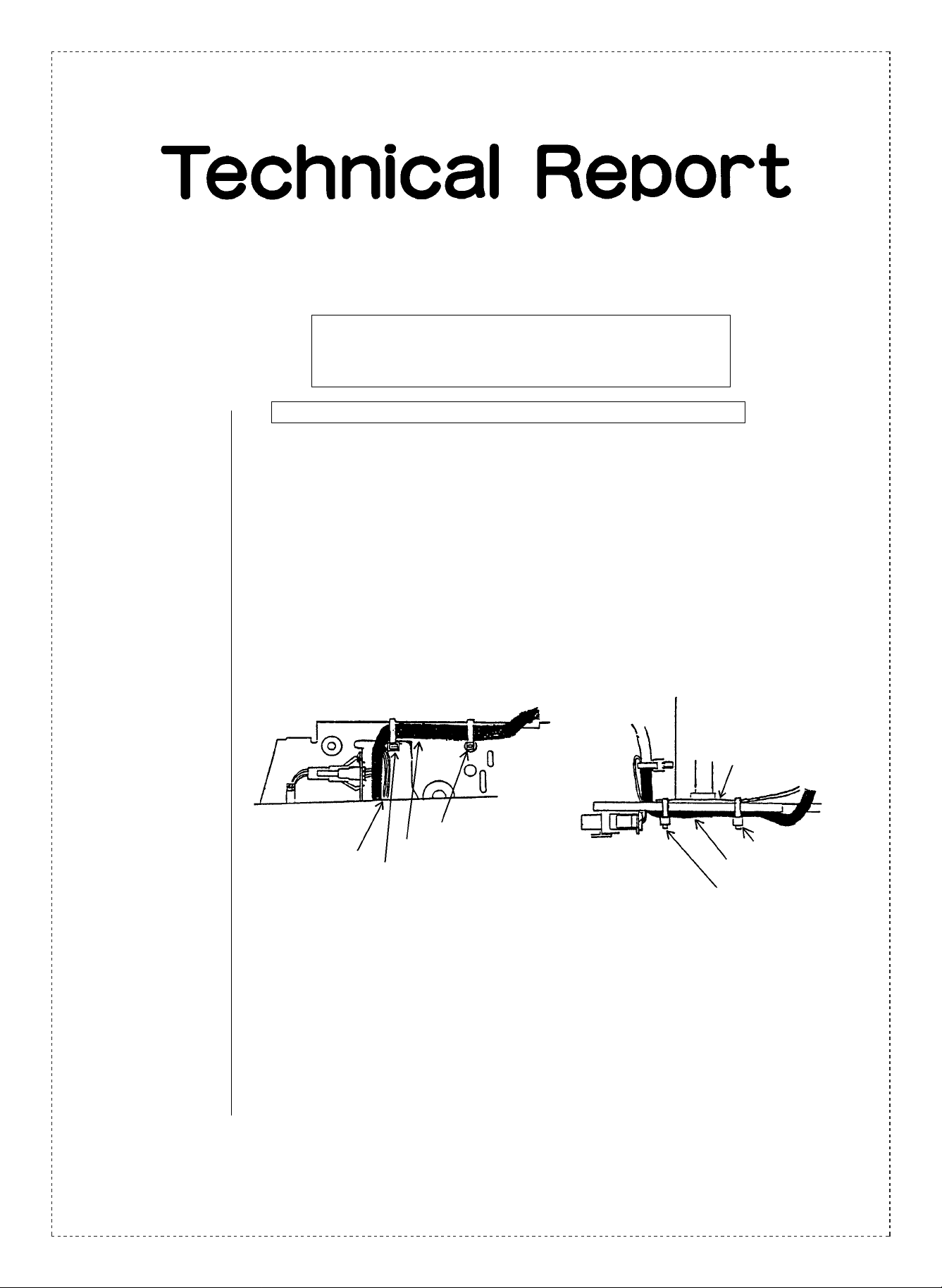

2.General: The copy image is sometimes affected by the revolving load of the transport roller

caused by contact between the roller and the SPF harness in the SPF unit. To alleviate

this problem, the measures described below have been carried out.

3.Description: Previously, the harness was held taught by a wire band, preventing it from coming in

contact with the transport roller. As a better method of separating the harness from the

roller, the length of the harness wires has been changed so that the harness can be

re-routed to avoid contact with the roller, as shown in the figure below.

R Side.

Thermostat.

Convex.

Thermostat.

SPF Harness.

Convex.

Diagram shown from the F side.

F Side.

Diagram shown from above.

Convex.

SPF Harness.

Convex.

4.Action: ∗ Japanese production: Running change after stock is used up.

Chinese (SOCC) production: From 1995 September production.

French (SMF) production: Running change after stock is used up.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

2. Change in IC used in the main PWB to improve productivity.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (only for machines bound for the USA)

2.General: The IC used in the main PWB [IC 107] has been changed to increase productivity. This

change has no affect on the shape or function of the machine or its parts.

3.Action: ∗ Japanese production: From the start of 1995 August production.

Chinese (SOCC) production: From the start of 1995 September production.

French (SMF) production: Running change after stock is used up.

3. Change in DV lower guide plate due to improper pressure welding of the developing

unit.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (only for machines bound for the USA)

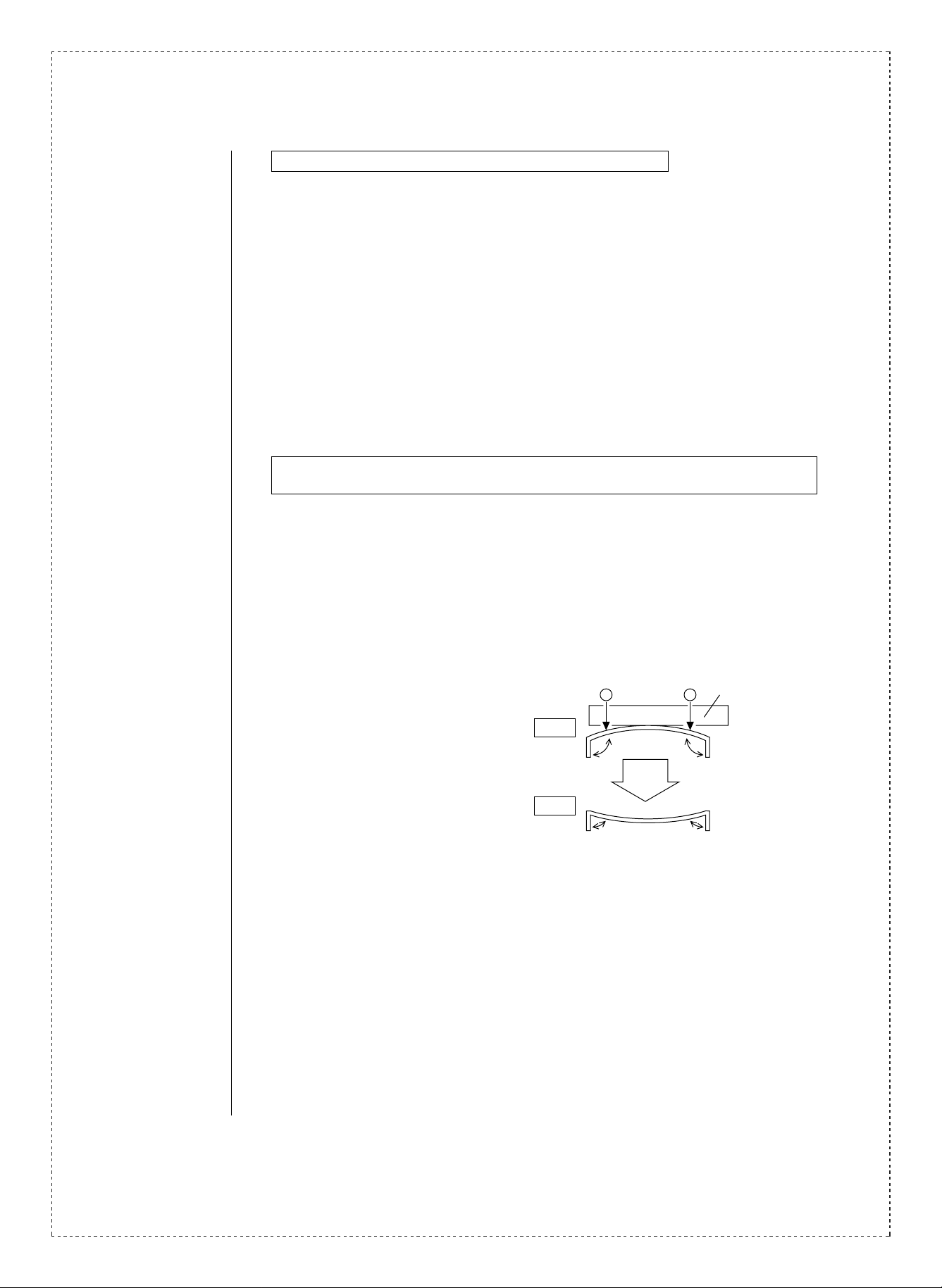

2.General: There is a possibility of improper pressure welding of the developing unit being caused

by the DV guide plate bending upwards, which pushes up the developing unit, resulting

in improper pressure welding.

3.Description: As shown in the figure to the right, the

angle of the DV guide plate where it is

attached by the attachment screws has

been changed to prevent the plate from

bending upwards.

Note: Pertinent, related material was

reported in T/R STE-003. Please refer

B A

Old

90° 90°

Changed

New

88.5°±0.5°

Developing unit

Upward curve

Flat tending toward

a downward curve

88.5°±0.5°

to this technical report for information

concerning the attachment and the

modification of the current parts.

4.Action: ∗ Japanese production: From 1995 mid-August production.

Chinese (SOCC) production: From the start of 1995 August production.

French (SMF) production: From the start of 1995 October production.

2/4

Page 3

4. Change in the length of the lead wire of the PS clutch in the SPF unit to improve

productivity.

1.Model name: SF-2214

SN-1430 (only for machines bound for the USA)

2.General: The lead wire of the PS clutch used in the SPF unit is longer than that used in other

machines, and was previously shortened by binding it with a wire band, so that it could

be used in the same way as with the other machines. To improve productivity, however,

the PS clutch has been changed.

3.Description:

4.Action: ∗ Japanese production: From 1995 mid-October production.

Chinese (SOCC) production: From 1995 mid-November production.

French (SMF) production: From 1995 mid-December production.

3/4

Page 4

Ref.

Model

No.

SF-2214 All

1

SN-1430

SF-2014

SF-2114

SF-2214

2

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

3

Z-800

SN-1420

SN-1430

SF-2214 All

4

SN-1430

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied ones fo r m ai n ta in i ng t he s a fe ty an d pe rformance o f the s et .

name

Version P/G No.

only

All

only

All

only

only

3 -61

20 -44

18 -44

19 -44

5 -27

4 -27

5 -27

3 -85

!

U.S.A.

U.S.A.

U.S.A.

U.S.A.

Current parts New parts

Parts code Parts code

DHAI-2301FCZZ DHAI-2301FC11 AT SPF Harness

VHISLA7024M-P VHISLA7024MT/ AS IC[IC 107]

LPLTM4543FCZZ LPLTM4543FCZ1 AP

PCLC-0156FCZZ PCLC-0256FCZZ AX

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others.

Parts name

rank

DV Lower guide

plate

Electromagnetic

clutch 22

Effec-

tive

time

∗

Inter-

change-

ability

1

3

1

Note

4/4

Loading...

Loading...