Page 1

COPIER : SF-2014

Date

:

Sep. 7, 1995

1. ESTABLISHMENT OF SERVICE PARTS TO TROUBLE SHOOT PAPER DELIVERY SLIP JAMS

AND PREVENT ABNORMAL NOISE.

2. IMPROVEMENT OF INCONSISTENCIES AND MAGNIFICATION ERRORS DURING COPY

ENLARGEMENT OPERATIONS.

3. NOTIFICATION OF CHANGE IN PARTS AND PARTS ADDITIONS.

1. Establishment of service parts to trouble shoot paper delivery slip jams and prevent

abnormal noise.

1.Model name: SF-2014/2114/2214/CM14

Z-800, SN-1420/1430/CM11 (only for machines bound for the USA).

No. : SP-1924

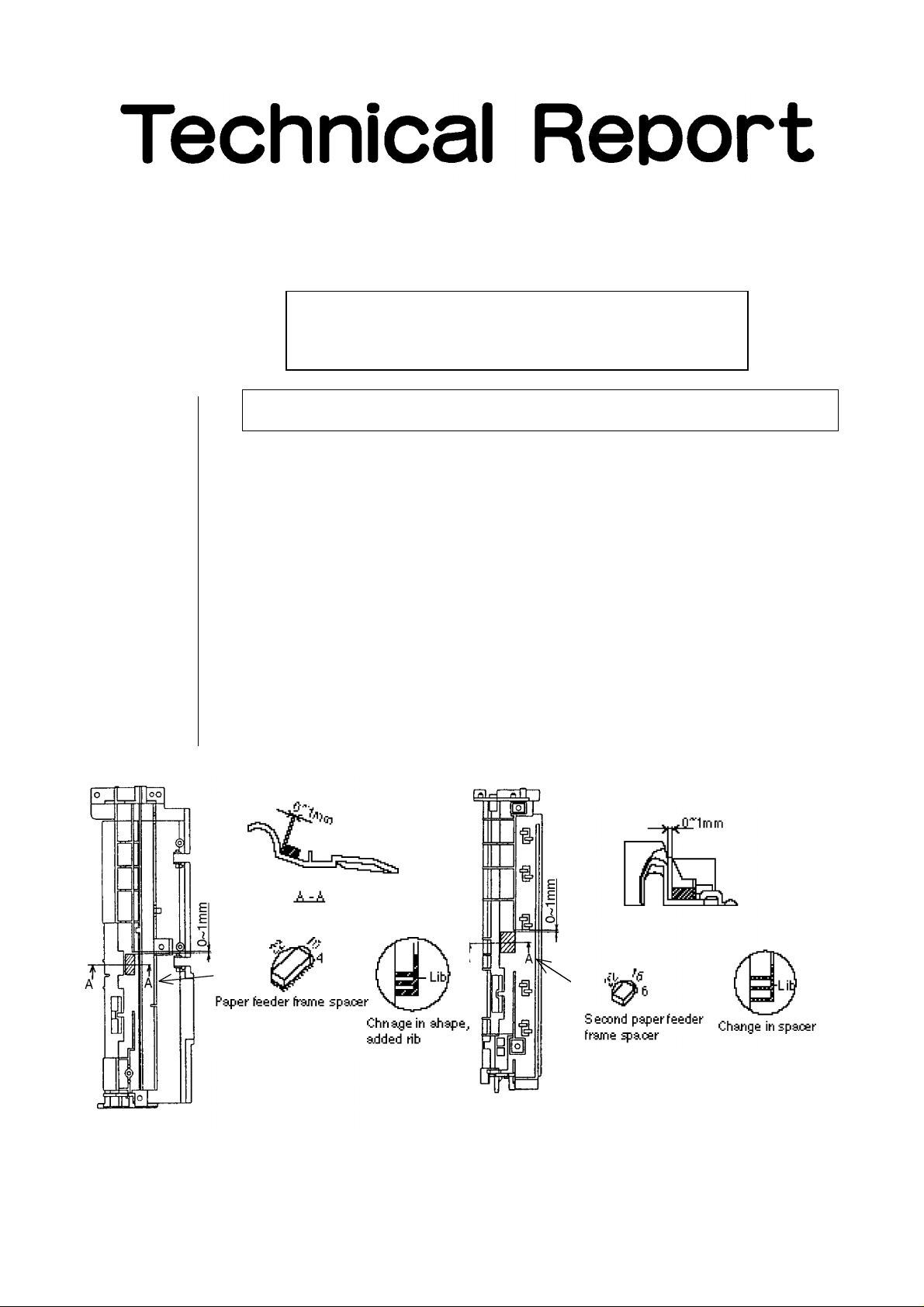

2.General: A change in shape (addition of ribs) in the second paper feeder frame, the 250 cassette

paper feeder frame and the 250 cassette was reported in technical report no. SP-1896

as an improvement measure for paper delivery slip jams and abnormal noise. It is

difficult, however, to exchange units out in the market that were produced before the

changes were introduced with the new units, because it entails exchanging the frame

itself, requiring the exchange of many smaller, related parts. To alleviate this problem,

spacers which can replace the ribs have been established as service parts.

3.Description:

250 cassette paper feeder frame: Second cassette paper feeder frame:

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

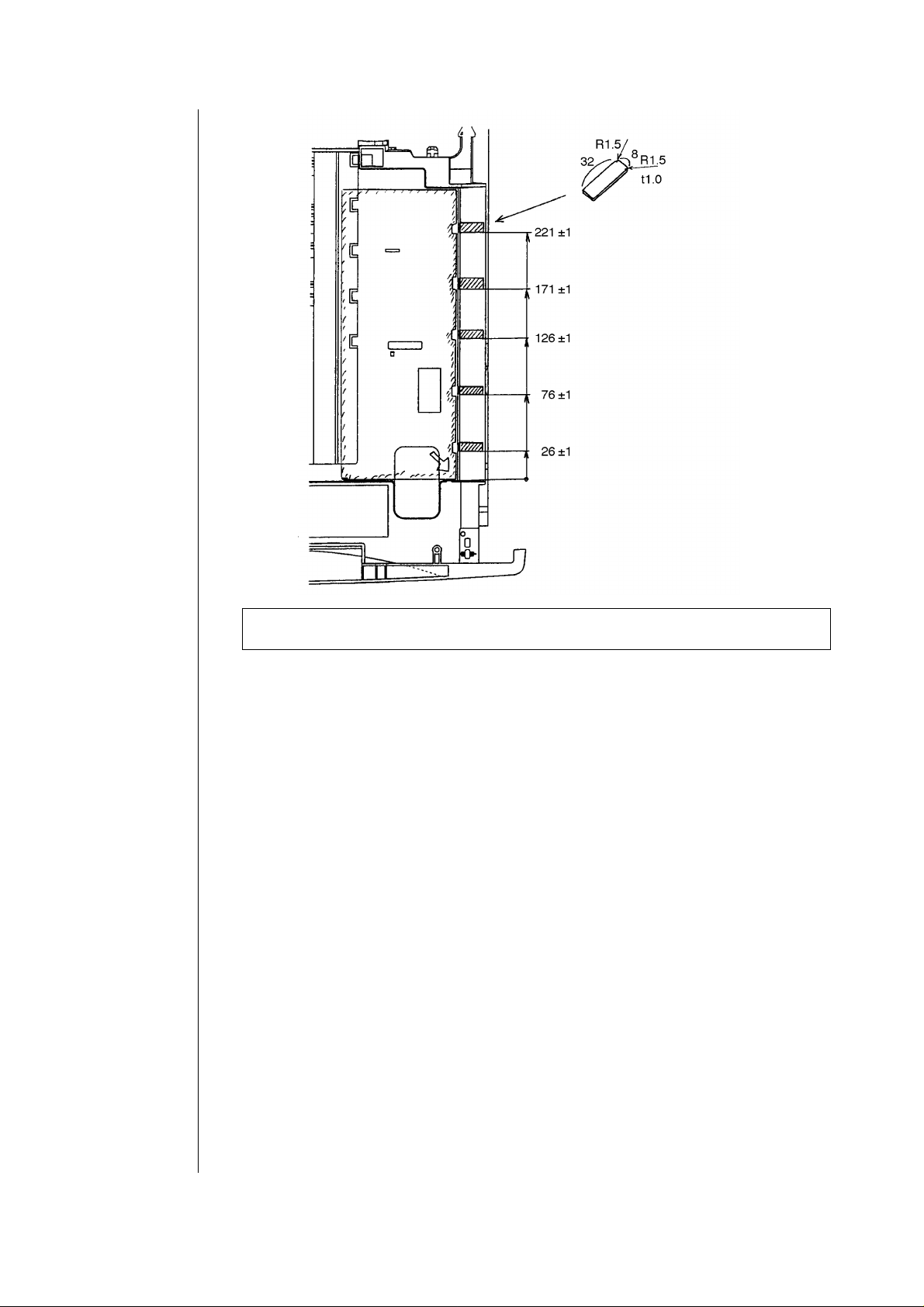

250 cassette:

250 cassette sub-sheet.

( 5 locations )

2. Improvement of inconsistencies and magnification errors during copy enlargement

operations.

1.Model name: SF-2214

SN-1430 (only for machines bound for the USA).

2.General: Inconsistencies and magnification errors sometimes occurred during the copy check

carried out during the production process. The problem occurred during enlargement

copy operations (129%) when using the SPF, and was caused by the following reason.

<Reason> The problem was caused by a combination of two factors: the increase in

the drive load of the SPF and the lack of margin on the enlargement side of

the SPF motor control circuit.

3.Description: Changes and additions have been carried out on a portion of the resistors in the SPF

control PWB to improve performance.

á The resistor in location R322 has been changed from 15kΩ to 10kΩ.

í A 22 kΩ resistor has been attached to the rear side between pin-1 and pin-8 of IC 301.

4.Action: Japan production: From the start of 1995 August production.

China (SOCC) production: From 1995 mid-July production.

2/4

Page 3

3. Notification of change in parts and parts additions.

1.Model name: SF-2214

SN-1430 (only for models bound for the USA).

2.General: Changes in parts and parts additions were reported in technical report no. SP-1856 for

the SPF unit drive section, but due to insufficient explanations and printing omissions,

the changes and additions are once again being reported. (As all of the changes

described below have been carried out as of the start of mass production, only

corrections and additions to the parts guide are necessary.)

3.Description: á Added encoder gear (‘‘a’’ in the figure).

í Added washer (‘‘b’’ in the figure).

ó Added E-ring (‘‘c’’ in the figure).

ú Change in the horizontal pin to an SP pin

(‘‘22" in the figure).

ñ Changed screws (‘‘5" in the figure).

Ñ Added RE PWB (‘‘99" in the figure).

ª Added screw (‘‘98" in the figure).

º Added screw (‘‘100" in the figure).

¿ Added PS support plate (‘‘103" in the figure).

‘‘ Added CS ring (‘‘104" in the figure).

11

Added F6 bearing (‘‘105" in the figure).

4.Action: From the start of mass production.

Ref.

Model

name

Version P/G No.

18

All

19

16

17

U.S.A.

only

18

No.

SF-2014

SF-2114

SF-2214

SF-CM14 52 PSPAZ0669FCZZ

SF-2014

SF-2114

SF-2214

1

Z-800

SN-1420

SN-1430

SN-CM11 52 PSPAZ0669FCZZ

Z-800 17

SN-1420

SN-1430

Current parts New parts

Parts code Parts code

----

PSPAZ0670FCZZ

PSHEZ3873FCZZ

(Q’ty: 5)

PSPAZ0670FCZZ

PSHEZ3873FCZZ

(Q’ty: 5)

Price

rank

AG

AD

AG

AD

Parts name

Paper feeder

frame spacer

Second paper

feeder frame

spacer

250 Cassette

sub-sheet

Paper feeder

frame spacer

Second paper

feeder frame

spacer

250 Cassette

sub-sheet

Effec-

tive

time

---- 6

Inter-

change-

ability

Note

3/4

Page 4

Ref.

No.

Model

name

Version P/G No.

Current parts New parts

Parts code Parts code

Price

rank

Parts name

Effec-

tive

time

Inter-

change-

ability

Note

SF-2214 All 24 -53

SN-1430

2

SF-2214 All

SN-1430

SF-2214 All

3

á

SN-1430

SF-2214 All

3

í

SN-1430

SF-2214 All

3

ó

SN-1430

SF-2214 All

3

ú

SN-1430

SF-2214 All

3

ñ

SN-1430

SF-2214 All

3

Ñ

SN-1430

SF-2214 All

3

ª

SN-1430

SF-2214 All

3

º

SN-1430

SF-2214 All

3

¿

SN-1430

SF-2214 All

3

‘‘

SN-1430

SF-2214 All

3

11

SN-1430

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with ‘‘ ’’ is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

U.S.A.

only

23 -53

24

23

3

3 -22

3 -5

3

VRD-HT2EY153J VRD-HT2EY103J

VRD-HT2EY223J Resistor 22kΩ

PTNPT0016FCZZ AC Encoder gear

----

XWHSD30-05060

(Q’ty: 2)

XRESP20-04000 E-ring

LPINS0155FCZZ LPINS1021HCZZ SP pin

XEBSD30P06000

(Q’ty: 2)

----

XBPSD30P04000

(Q’ty: 2)

CPWBF1076FC51 AQ RE PWB

XHPSD30P06000

XHBSD30P06000

LPLTM4752FCZZ AC PS hold plate

LX-RZ1017HCZZ AA CS-ring

NBRGC0190FCZ1 AD F6 bearing

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Resistor 10kΩ

[R322]

AA

Washer

AA

Screw (M3X4)

AA Screw (M3X6)

∗

1st lot

3

6

3

6

4/4

Loading...

Loading...