Page 1

Date: Sep. 6, 1995

COPIER : SF-2114

1. TROUBLE SHOOTING DISLOCATION OF THE DARK BOX COVER DURING SHIPPING.

2. TROUBLE SHOOTING WHITE-OUTS DURING HALF-TONE COPY OPERATIONS.

3. TROUBLE SHOOTING SHAFT BUSHING DISLOCATION OF THE PAPER WINDING DRIVE

SHAFT .

4. TROUBLE SHOOTING BLACK STREAKS DURING REDUCTION COPY OPERATIONS.

No. : SP-1923

1. Trouble shooting dislocation of the dark box cover during shipping.

1.Model name: SF-2114/ 2214

SN-1420/1430 (only for machines bound for the USA).

2.General: The cover of the dark box sometimes becomes dislocated from the lens drive shaft in

the optical unit while the machines are being shipped. To alleviate this problem, the

measures described below have been carried out.

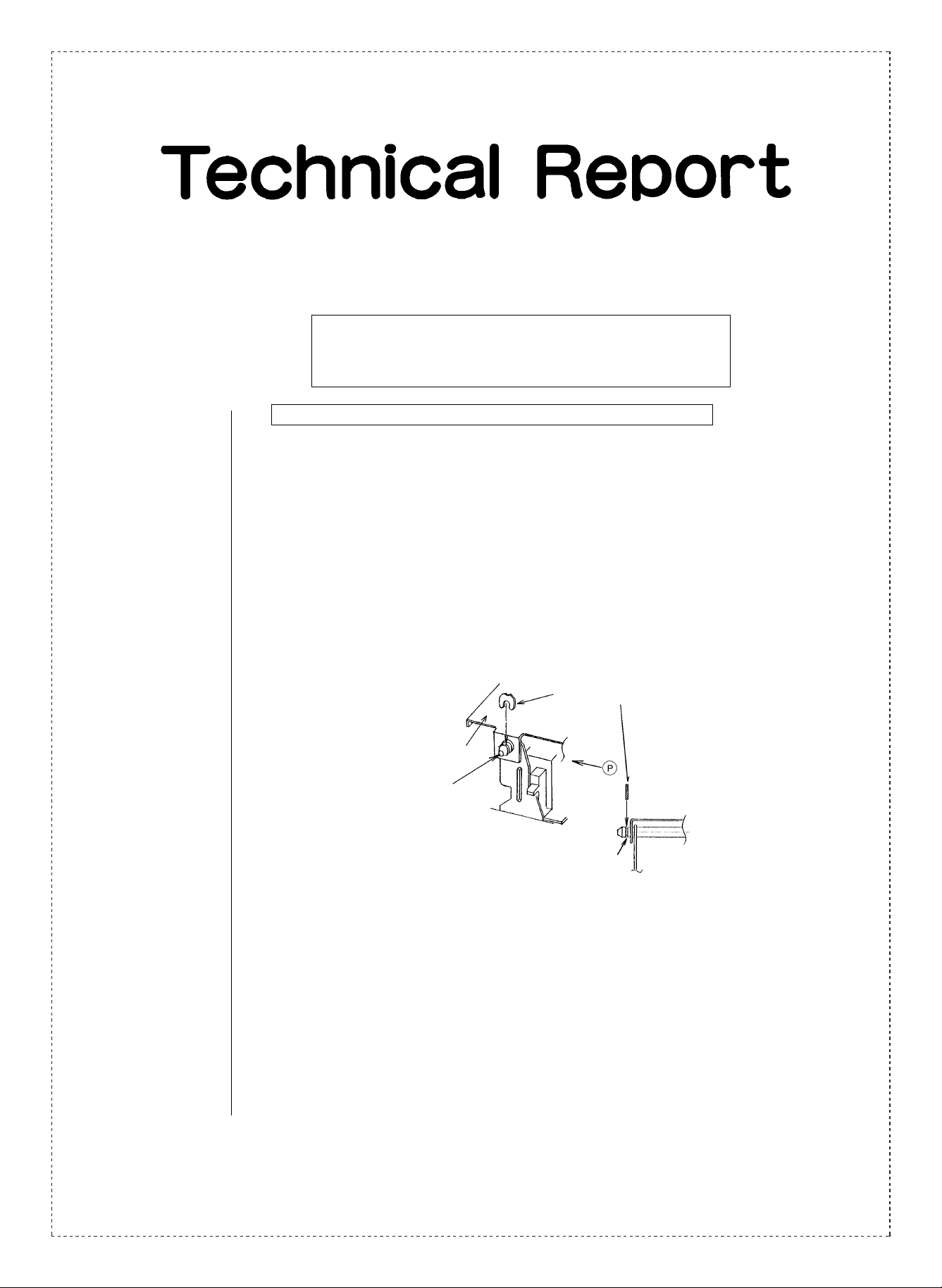

3.Description: A groove has been added to the lens drive shaft, and after inserting the drive shaft

through the dark box cover a plastic E-ring has been attached to prevent the dark box

cover from becoming dislocated.

Plastic E-ring. x 1.

Dark box cover.

Lens drive shaft.

Added groove for the E-ring.

4.Action: ∗ Japan production: From the start of 1995 July production.

China (SOCC) production: From the start of 1995 July production.

France (SMF) production: From the start of 1995 October production.

SHARP CORPORATION Reprography Division

1/4

Green

C

Page 2

2. Trouble shooting white-outs during half-tone copy operations.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (only for machines bound for the USA).

2.General: White-outs sometimes occur in the TC case section during half-tone copy operations

when they are carried out during periods of low humidity or other weather conditions

conducive to the occurrence of static electricity. To alleviate this problem, the

improvement measures described below have been carried out (no problems have

occurred during normal text copy operations).

3.Description: To alleviate the problem described above, a change has been carried out in the shape

of the AC guide attached to the TC case.

R2

0

9-0.15

0

8.3-0.15

4.Action: ∗ Japan production: From 1995 mid-July production.

China (SOCC) production: From the start of 1995 August production.

France (SMF) production: From the start of 1995 September production.

3. Trouble shooting shaft bushing dislocation of the paper winding drive shaft.

1.Model name: SF-2014/21 14/2214

Z-800, SN-1420/1430 (only for machines bound for the USA).

2.General: The paper winding drive shaft in the optical unit is supported by a shaft bushing

attached to the frame. The possibility exists that the shaft bushing might become

dislocated during shipping due to the lack of connection allowance for the shaft bushing

when surrounding parts are clustered together. To alleviate this problem, the

improvement measures described below

have been carried out.

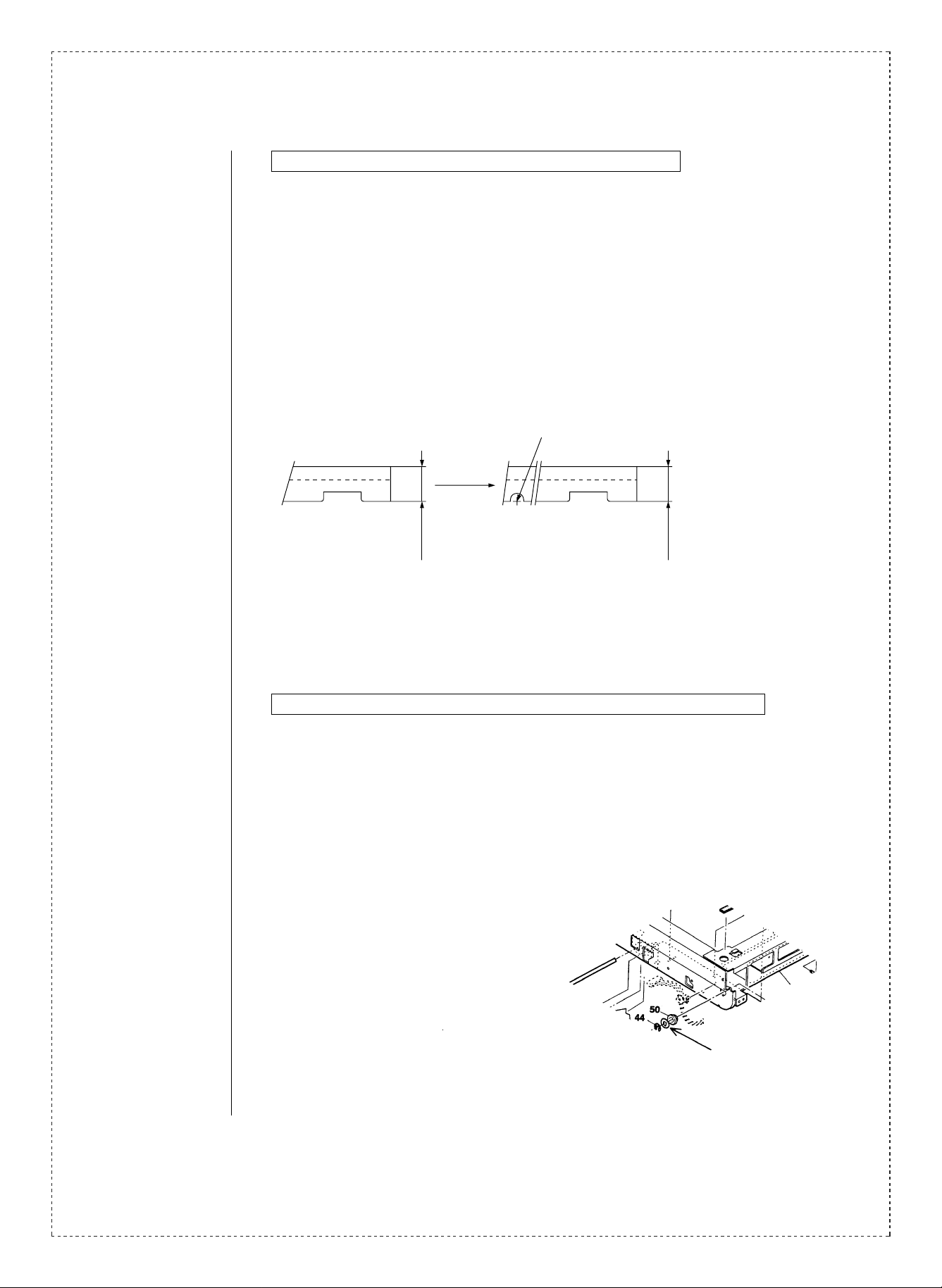

3.Description: <Temporary measure>

As shown in the figure to the right, a washer

has been added between the E-ring and the

shaft bushing to prevent the shaft bushing

from becoming dislocated.

2/4

Washer

(LX-WZ0042FCZZ).

Parts establishment has

been carried out.

Page 3

For China (SOCC) production only: This change was carried out during the period from

1995 mid-June production to 1995 July production.

<Permanent measure>

In order to increase the shaft bushing allowance with the optical bed plate, the shaft

bushing has been changed to a longer one.

(Old) (New)

When the new, longer shaft

bushing is used, the washer

used in the temporary

measure described above

become unnecessary.

NBRGC0504FCZZ NBRGC0133FCZ1

57

4.Action: ∗ Japan production: From the start of 1995 August production.

China (SOCC) production: From the start of 1995 August production.

France (SMF) production: From the start of 1995 October production.

4. Trouble shooting black streaks during reduction copy operations.

1.Model name: SF-2214

SN-1430 (only for machines bound for the USA).

2.General: A white mylar sheet has been attached to the upper paper guide of the SPF slit (slit

upper paper guide mylar) as a counter measure for black streaks which occur during

reduction copy operations carried out using the SPF.

3.Description:

7

Slit upper paper guide mylar.

(PSHEP4016FCZZ).

SPF Slit upper paper guide.

A section.

(PGIDH1501FCZ1).

Slit upper paper guide mylar.

Diagram indicated by arrow “P”.

4.Action: ∗ Japan production: From the start of 1994 October production.

China (SOCC) production: From the start of mass production.

France (SMF) production: From the start of mass production.

SPF Slit upper paper guide.

3/4

Page 4

Ref.

Model

No.

SF-2114

SF-2214

SN-1420

SN-1430

1

SF-2114

SF-2214

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

2

Z-800

SN-1420

SN-1430

SF-2014

SF-2114

SF-2214

3

Z-800

SN-1420

SN-1430

SF-2214 All

4

SN-1430

<Interchange>

1. Interc ha ng ea bl e. 4. N ot i nt er ch an ge ab l e.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with “ ” is important for maintaining the safety of the set. Be sure to replace these parts with

speci fied on es fo r m ai n ta ini ng t he safe ty an d pe r fo rma nc e o f th e set.

name

Version P/G No.

6 -90

All

U.S.A.

U.S.A.

U.S.A.

U.S.A.

U.S.A.

only

All

only

All

only

All

only

only

8 -90

6

8

15

14

15

6 -50

7 -50

8 -50

3

!

Current parts New parts

Parts code Parts code

NSFTZ2055FCZZ NSFTZ2055FCZ1 AK

— PRNGP0081FCZZ AA Plastic E-ring 6

CGIDM1493FC51 CGIDM1493FC52 AK AC guide unit 1

NBRGC0504FCZZ NBRGC0133FCZ1 AC Bea ring

— PSHEP4016FCZZ AB

Price

5. Interchangeable if replaced with same types of

relate d parts in use .

6. Others .

Parts name

rank

Lens drive shaft

A

Slit upper paper

guide mylar

Effec-

tive

time

∗

Inter-

change-

ability

3

Note

4/4

Loading...

Loading...